Aeroengine turbine guide vane polishing protection wax and polishing method

A technology for turbine guide vanes and aero-engines, which is used in grinding/polishing equipment, chemical instruments and methods, and grinding machines. , good plasticity and adhesion, suitable physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

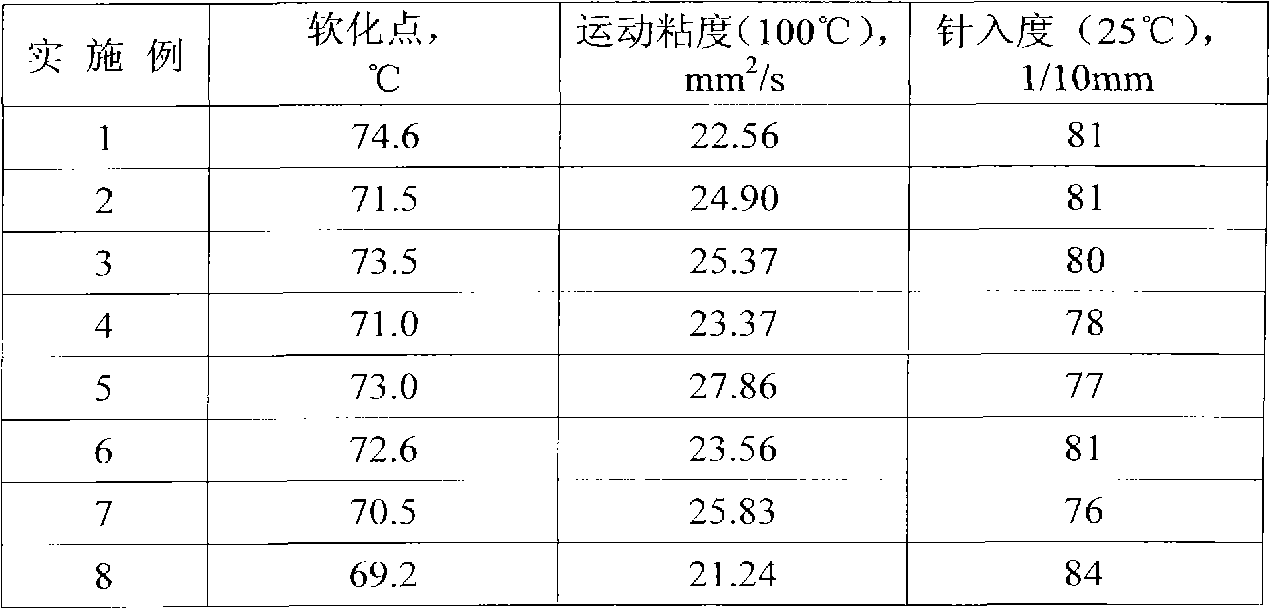

Examples

Embodiment

[0031] Embodiment: (below all represent by weight percentage)

[0032] experiment method

[0033] The following test methods are the usual methods for testing petroleum products used in the examples.

[0034] Softening point GB / T4507

[0035] Penetration GB / T 4985

[0036] Kinematic viscosity GB / T265

Embodiment 1

[0039] 75 # Microcrystalline wax, drop melting point 76.2°C, penetration 201 / 10mm (Nanchong Oil Refinery) 45%

[0040] Refined hydrogenated rosin, softening point ≥ 78.0°C (Zhuzhou Matsumoto Forestry Co., Ltd.) 20%

[0041] Polyisobutylene, average molecular weight 1233 (Jinzhou Jinglian Lubricating Oil Additive Co., Ltd.) 10%

[0042] Soft microcrystalline wax, dropping point 59.0°C, penetration 851 / 10mm (Hebei Feitian Petrochemical Co., Ltd.) 25%

Embodiment 2

[0044] 80 # Microcrystalline wax, drop melting point 81.6°C, penetration 131 / 10mm (Jingmen Oil Refinery) 5%

[0045] 75 # Microcrystalline wax, drop melting point 76.2°C, penetration 201 / 10mm (Nanchong Oil Refinery) 38%

[0046] Refined hydrogenated rosin, softening point ≥ 78.0°C (Zhuzhou Matsumoto Forestry Co., Ltd.) 19%

[0047] Polyisobutylene, average molecular weight 1233 (Jinzhou Jinglian Lubricating Oil Additive Co., Ltd.) 13%

[0048] Soft microcrystalline wax, dropping point 59.0°C, penetration 851 / 10mm (Hebei Feitian Petrochemical Co., Ltd.) 25%

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com