Externally-added self-lubricating gear device

A gear device, self-lubricating technology, applied in transmission parts, gear lubrication/cooling, belt/chain/gear, etc., can solve the problems of low safety, limited gear working environment, etc., and achieve the effect of reliable lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The structure of the external self-lubricating gear device of the present invention is set as:

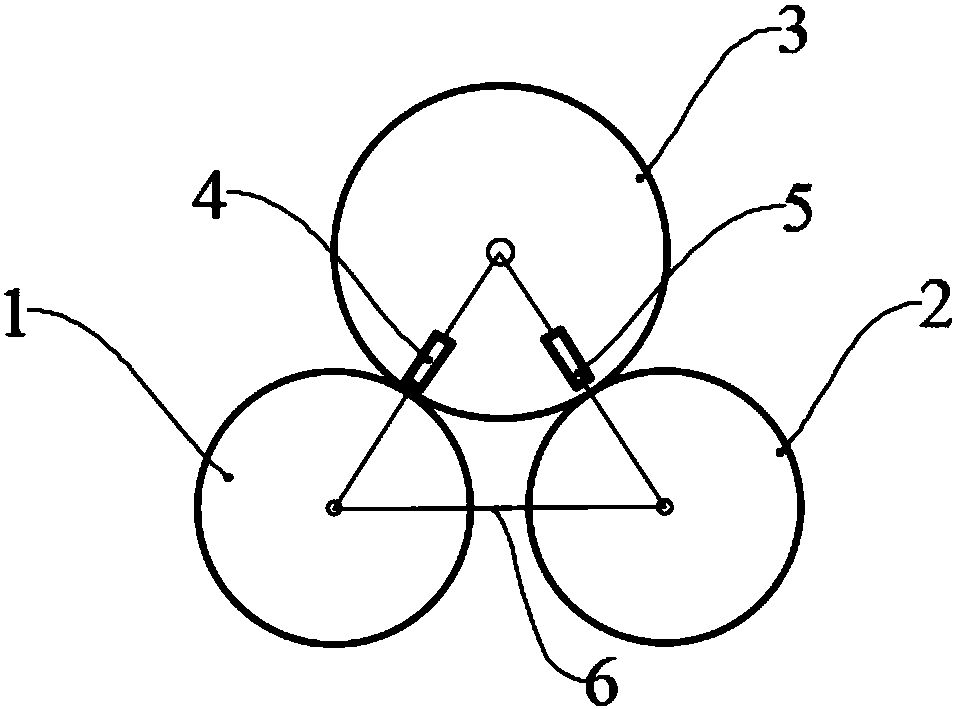

[0020] see figure 1 , the big roller 1 is connected with the small roller 2 through the connecting rod 6; the lubricating wheel 3 is connected with the big roller 1 through the left pressing mechanism 4; the lubricating wheel 3 is connected through the right The pressing mechanism 5 is connected with the small roller 2 .

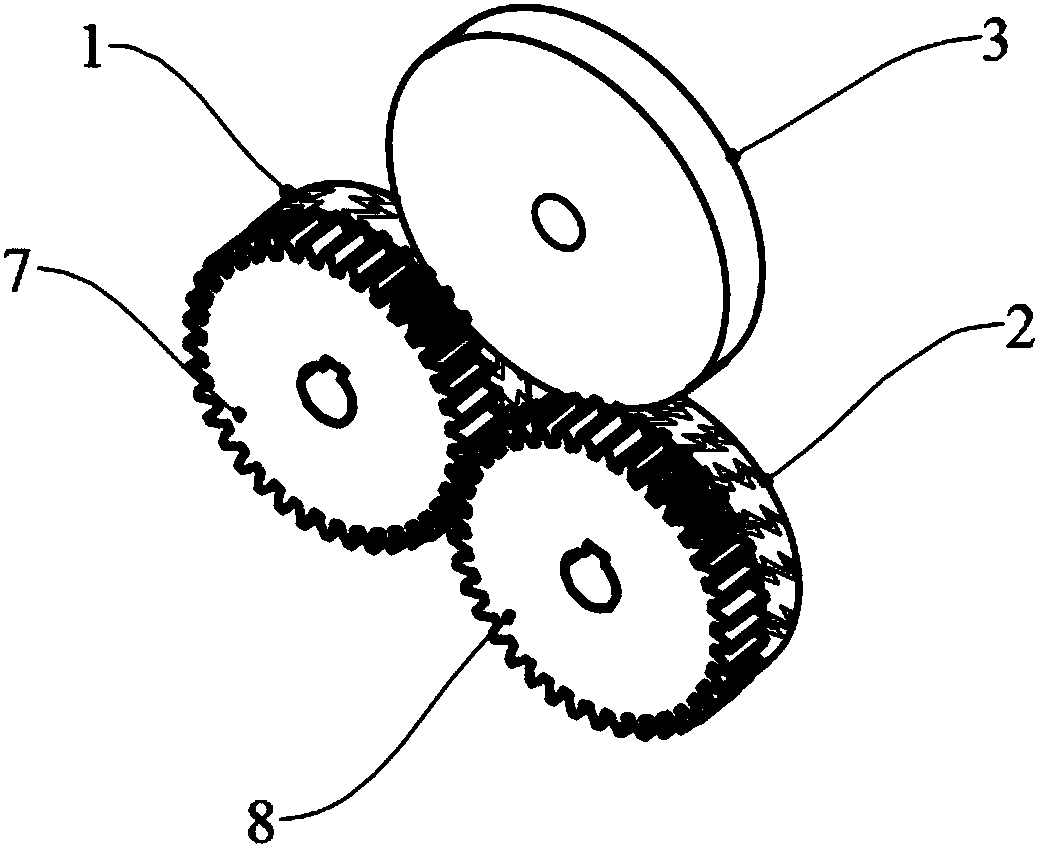

[0021] see figure 2 , is a three-dimensional structural diagram of the present invention, wherein the large roller 1 is fixedly connected with the driving gear 7, and the small roller 2 is connected firmly with the driven gear 8; the driving gear 7 is connected with the driven gear The gears 8 mesh with each other, and are the working parts that need to be lubricated. The lubricating wheel 3 is in contact with the large roller 1 and the small roller 2 respectively, and the friction generated during movement will scrape off the self-lubricating material,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com