Simplified process method of lost wax casting

A technology that simplifies the process and lost wax casting. It is used in manufacturing tools, casting equipment, casting molds, etc. It can solve the problems of large quality fluctuations, unfavorable processing, errors, etc., to simplify process methods, save costs, and change product styles. flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Describe in detail below in conjunction with accompanying drawing.

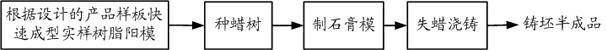

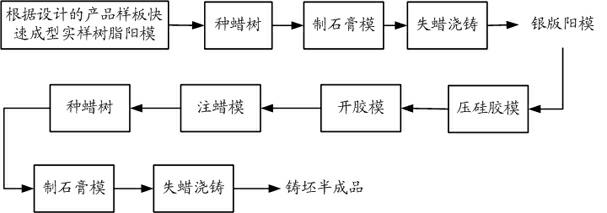

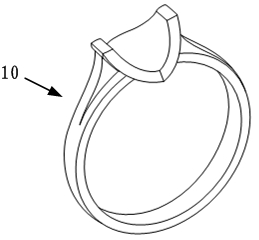

[0024] Take the preparation of ring products as an example, see image 3 , shows the method of the prior art—a resin material ring male mold 10 formed by a rapid prototyping machine, whose shape, structure, and size are consistent with the actual ring to be prepared. exist figure 1 The lost-wax casting process shown in method one is used to replace the wax model and plant wax trees to fill plaster molds.

[0025] Also take the preparation of ring products as an example, see Figure 4 , Figure 5 , Figure 6 , shows a resin material ring female mold 20 for making a wax pattern in the lost wax casting process, including an upper mold 20a and a lower mold 20b, and the upper mold 20a includes an upper template 21a, a positioning protrusion 22a, an upper mold cavity 23a and The upper mold runner 24a connected to the upper mold cavity 23a; the lower mold 20b includes a lower template 21b, a positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com