Method for preparing compound Ti-based lubricating grease based on polymethylphenyl silicone

A technology of polymethylphenylsiloxane and composite titanium, which is applied in the field of lubricating grease, can solve the problems of unrelated to the performance of composite titanium-based grease, low dropping point of grease, low dropping point, etc., and achieve good industrialization prospects, The effect of high dropping point and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

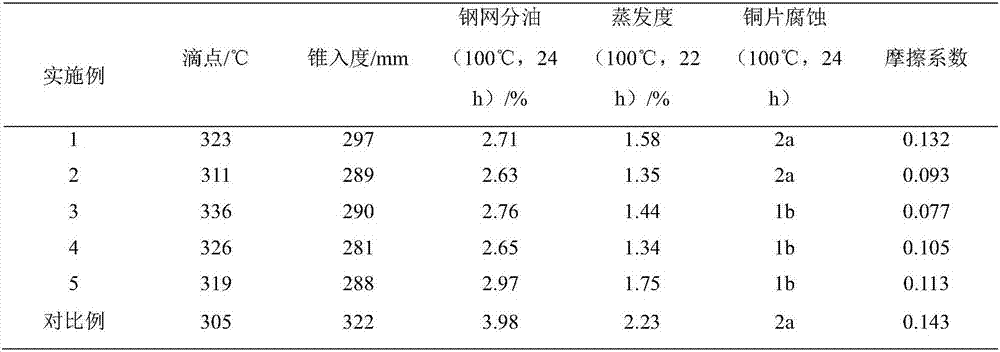

Examples

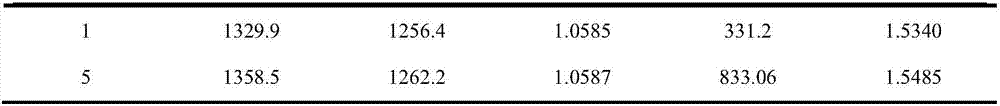

Embodiment 1

[0037] Mix 80mL xylene, 50mL acetone, 0.157mol dimethyldichlorosilane, 0.043mol diphenyldichlorosilane and 0.1mol methylphenyldichlorosilane, keep warm at 30°C, mix 57.6ml water and 100ml acetone Add the mixed solution dropwise to the mixed solution and react at 30°C for 12 hours; after the reaction, wash the product with distilled water until neutral, then add 0.00375mol of hexamethyldisiloxane and 0.077g of tetramethylammonium hydroxide solution , reacted at 100°C for 10h, and washed the product with distilled water for 3-5 times after the reaction; put the washed product into a distillation device and heated it to 135°C, and removed the solvent under reduced pressure until no liquid distilled out. The liquid is polymethylphenylsiloxane.

[0038] Mix and heat 118.75g KN4010, 6.25g polymethylphenylsiloxane, 75.72g 12-hydroxystearic acid, and 30.77g benzoic acid to 95°C, keep stirring for 20min; heat up to 120°C, add 0.25mol isopropyl titanate Esters, heat preservation and st...

Embodiment 2

[0040] The preparation of polymethylphenylsiloxane was the same as in Example 1.

[0041] Mix and heat 112.5g KN4010, 12.5g polymethylphenylsiloxane, 75.72g 12-hydroxystearic acid, and 30.77g benzoic acid to 95°C, keep stirring for 20min; heat up to 120°C, add 0.25mol n-butyl titanate Esters, heat preservation and stirring, during which the by-product alcohols were blown out by nitrogen gas and condensed and collected. After 5 hours, 112.5g KN4010 and 12.5g polymethylphenylsiloxane were added to the system; the temperature was slowly raised to 220°C for high-temperature refining. After raising the temperature to the desired temperature, keep it for 3 minutes, then pour it into a stainless steel container, and after cooling down to room temperature naturally, add 4ml of water and repeatedly stir and shear, grind and homogenize to obtain the composite titanium-based grease.

Embodiment 3

[0043] The preparation of polymethylphenylsiloxane was the same as in Example 1.

[0044] Mix and heat 100g KN4010, 25g polymethylphenylsiloxane, 75.72g 12-hydroxystearic acid, and 30.77g benzoic acid to 95°C, keep stirring for 20min; heat up to 120°C, add 0.25mol isopropyl titanate, Insulate and stir, during which the by-product alcohols are blown out with nitrogen gas and condensed and collected. After 5 hours, 100g KN4010 and 25g polymethylphenylsiloxane are added to the system; the temperature is slowly raised to 220°C for high-temperature refining. Keep it at the required temperature for 3 minutes, then pour it into a stainless steel container, cool it down to room temperature naturally, add 4ml of water, stir and shear repeatedly, grind and homogenize to get the composite titanium-based grease.

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com