Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Reduce the degree of coking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-shrinkage high-strength polyester industrial yarn and preparation method thereof

ActiveCN108385189AIncrease the cross-sectional areaReduce the temperatureSpinnerette packsFibre typesYarnThermal insulation

The invention relates to a low-shrinkage high-strength polyester industrial yarn and a preparation method thereof. The preparation method comprises: carrying out solid phase condensation polymerization tackifying on a modified polyester, melting, metering, extruding, cooling, oiling, drawing, carrying out heat setting, and winding, wherein the unchanged longitudinal height is maintained during thecooling, the cross section area of the slow cooling chamber is increased while the plate surface temperature of the spinning plate is maintained by using the thermal insulation method, and the oil agent for oiling contains 67.30-85.58 wt% of crown ether. According to the present invention, the preparation method is simple; the material of the prepared low-shrinkage high-strength polyester industrial yarn is the modified polyester with the molecular chain including a terephthalic acid chain segment, an ethylene glycol chain segment and a diol chain segment having the branched chain, the fracture strength is more than or equal to 7.3 cN / dtex, and the dry heat shrinkage rates at the conditions comprising 177 DEG C, 10 min and 0.05 cN / dtex and the conditions comprising 190 DEG C, 15 min and 0.01 cN / dtex respectively are 1.8+ / -0.5% and 3.5+ / -0.5%.

Owner:JIANGSU HENGLI CHEM FIBER

Low-wear fluidized bed catalyst for preparing aromatics from methanol and preparation method of low-wear fluidized bed catalyst for preparing aromatics from methanol

ActiveCN104437594AHigh selectivityHigh solid contentMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveMethanol

The invention relates to a low-wear fluidized bed catalyst for preparing aromatics from methanol, and a preparation method for the low-wear fluidized bed catalyst for preparing the aromatics from the methanol, and mainly solves the technical problem that an existing catalyst is large in wear. According to the technical scheme adopted, the fluidized bed catalyst comprises the following components in percentage by weight: (1) 20.0-55.0% of kaolin, (2) 10.0-25.0% of a binder, (3) 0.2-15.0% of phosphorus oxide; (4) 0.1-10.0% of metal element oxide, and (5) 25.0-60.0% of a ZSM-5 molecular sieve, wherein the phosphorus oxide is added during preparation of slurry for spray-drying a catalyst, and the problem is well solved, and the low-wear fluidized bed catalyst and the preparation method thereof can be used for industrial production of preparing the aromatics from the methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Binderless nano ZSM-5/beta symbiotic zeolite molecular sieve catalyst

InactiveCN104437611ASimple preparation processRaw materials are easy to obtainMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveChemistry

The invention relates to a binderless nano ZSM-5 / beta symbiotic zeolite molecular sieve catalyst. The binderless nano ZSM-5 / beta symbiotic zeolite molecular sieve catalyst is mainly used for solving the problems in the prior art that the activity is relatively low when the prepared ZSM-5 / beta symbiotic zeolite molecular sieves contain binders and the strength is relatively poor when the prepared ZSM-5 / beta symbiotic zeolite molecular sieves do not contain the binders. According to the binderless nano ZSM-5 / beta symbiotic zeolite molecular sieve catalyst, through adopting the technical scheme of firstly carrying out mixed shaping on silicon and aluminum raw materials, then, converting the silicon and aluminum raw materials into nano ZSM-5 and beta zeolite molecular sieves by using a mixed aqueous solution of organic amine and organic quaternary ammonium base, and carrying out modification, thereby forming the binderless nano ZSM-5 / beta symbiotic zeolite molecular sieves; the problems are better solved, and the prepared binderless nano ZSM-5 / beta symbiotic molecular sieve catalyst can be applied to the industrial production of preparing propene from methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

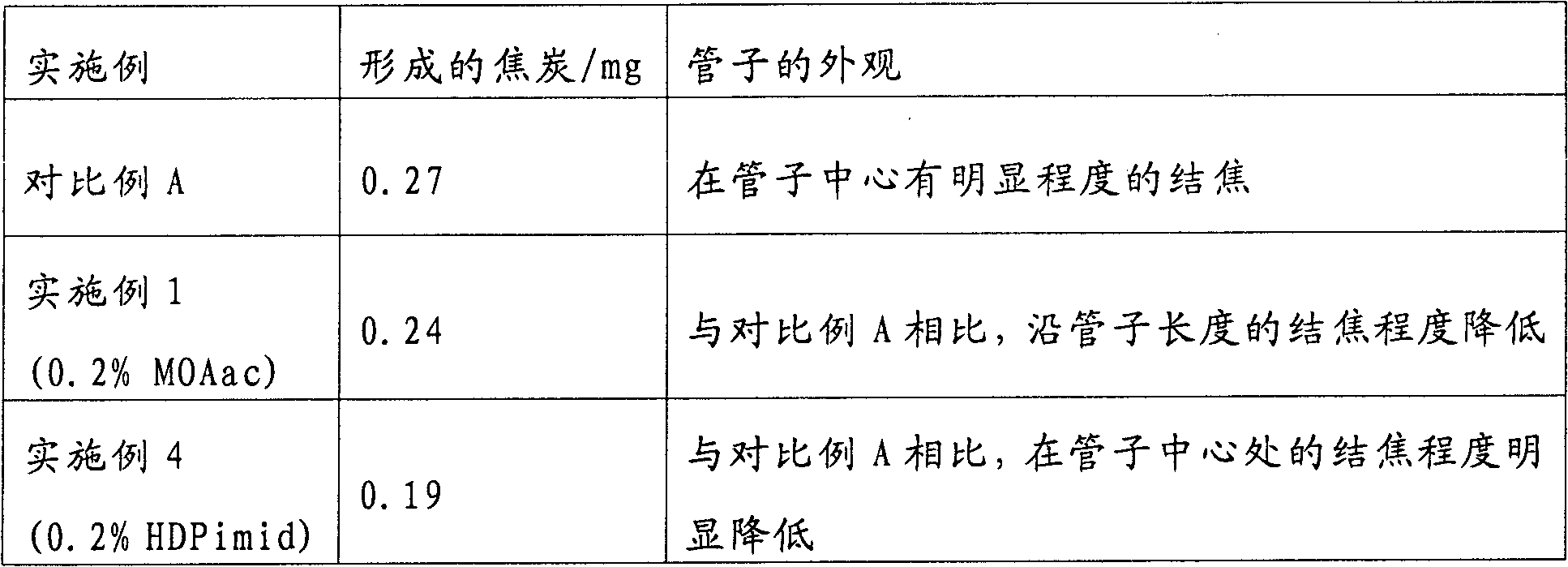

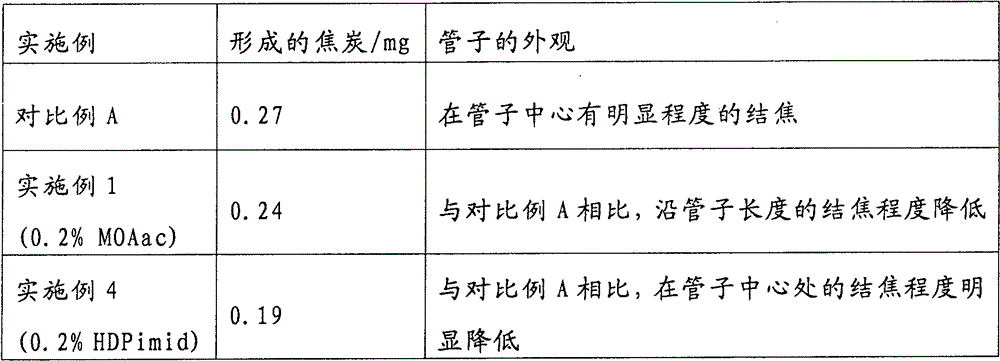

Lubricating compositions

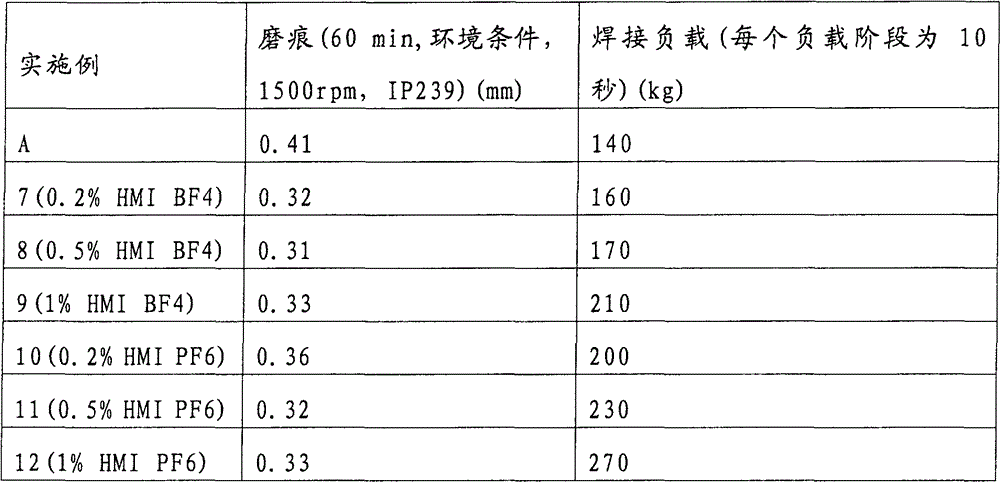

ActiveCN102625827AReduced silt accumulationReduce the degree of cokingLubricant compositionSludgeBase oil

A lubricating composition comprising: (i) from 50% to 99% by weight of base oil; (ii) from 0.01% to 5% by weight of ionic liquid; and (iii) from 0.01% to 10% by weight of additive; wherein the lubricating composition has a pour point of at most -54 DEG C, a flashpoint of at least 246 DEG C and a kinematic viscosity at 100 DEG C in the range of from 4.9 to 5.4 mm2 / s. The lubricating compositions according to the present invention are suitable for use in turbine engine oils and are useful for reducing the build up of sludge and for reducing coking in the lubricating composition.

Owner:SHELL INT RES MAATSCHAPPIJ BV

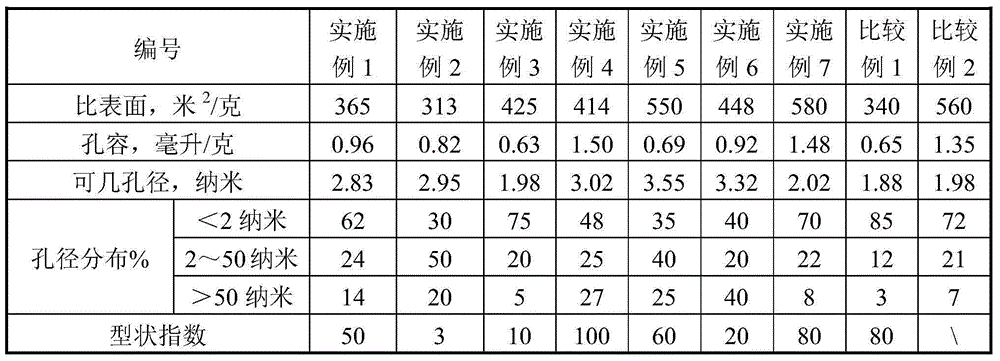

Binderless ZSM-5/beta symbiotic molecular sieve catalyst and preparation method thereof

InactiveCN104437613AHigh strengthImprove stabilityMolecular sieve catalystsBulk chemical productionMolecular sievePtru catalyst

The invention relates to a binderless ZSM-5 / beta symbiotic molecular sieve catalyst and a preparation method thereof. The binderless ZSM-5 / beta symbiotic molecular sieve catalyst is mainly used for solving the problems in the prior art that the activity is relatively low when the prepared ZSM-5 / beta symbiotic zeolite molecular sieves contain binders and the strength is relatively poor when the prepared ZSM-5 / beta symbiotic zeolite molecular sieves do not contain the binders. According to the binderless ZSM-5 / beta symbiotic molecular sieve catalyst and the preparation method thereof, through adopting the technical scheme of firstly carrying out mixed shaping on silicon and aluminum raw materials, then, converting the silicon and aluminum raw materials into ZSM-5 and beta zeolite molecular sieves with the shape index of 3-100 by using a mixed aqueous solution of organic amine and organic quaternary ammonium base, and carrying out modification, thereby forming the binderless ZSM-5 / beta symbiotic zeolite molecular sieve catalyst; the problems are better solved, and the prepared binderless ZSM-5 / beta symbiotic molecular sieve catalyst with the shape index of 3-100 can be applied to the industrial production of preparing propene through cracking alkenes.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing propylene by catalytic cracking of C4 olefin

InactiveCN106608789AOvercoming activityOvercoming selectivityMolecular sieve catalystsBulk chemical productionMolecular sieveComposite channel

The invention relates to a method for producing propylene by catalytic cracking of C4 olefin. The method mainly solves the problem that the existing catalyst has poor stability and low propylene selectivity. The method comprises forming ZSM-5 molecular sieve raw powder with a shape index of 3-100 from raffinate C4, carrying out alkali treatment to obtain a molecular sieve catalyst having a composite channel structure, and carrying out a reaction process under conditions of a reaction temperature of 400 to 600 DEG C, reaction pressure of 0 to 0.3MPa and a weight airspeed of 1 to 50h<-1>. The method well solves the problem and can be used for industrial production of propylene by catalytic cracking of C4 olefin.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-modulus low-shrinkage stiff cord and preparation method thereof

ActiveCN108385418AIncrease the cross-sectional areaReduce the temperatureFibre typesFilament/thread formingYarnSlow cooling

The invention relates to a high-modulus low-shrinkage stiff cord and a preparation method thereof. The preparation method comprises the following steps: performing solid-phase polycondensation-viscosity enhancement, melting, metering, extrusion, cooling, oiling, stretching, heat setting and winding to obtain high-modulus and low-shrinkage polyester industrial yarns; twisting to obtain a cord; making the cord into a high-modulus low-shrinkage stiff cord by a two-bath impregnation method, wherein during cooling, the longitudinal height is kept constant and the cross-sectional area of a slow cooling chamber is increased; meanwhile, the surface temperature of a spinneret plate is kept in a heat preserving way in the slow cooling chamber; an oiling agent contains 67.30 to 85.58 percent by weight of crown ether; during use of the oiling agent, 14 to 18 percent by weight emulsion is prepared with water. The preparation method disclosed by the invention is simple; the prepared high-modulus low-shrinkage stiff cord is made from modified polyester of which the molecular chain includes a terephthalic acid chain segment, an ethylene glycol chain segment and a dihydric alcohol chain segment with a branched chain, is greater than or equal to 80N in breaking strength, and is greater than or equal to 37KN / m in cord bonding strength.

Owner:JIANGSU HENGLI CHEM FIBER

Binder-free ZSM-5 molecular sieve catalyst, and preparation method and use thereof

InactiveCN104107707AOvercome stabilityOvercome propyleneMolecular sieve catalystsHydrocarbon from oxygen organic compoundsRare-earth elementLow activity

The invention relates to a binder-free ZSM-5 molecular sieve catalyst, and a preparation method and a use thereof. The problems of low activity of a binder-containing ZSM-5 molecular sieve in the prior art and low intensity of a binder-free ZSM-5 molecular sieve in the prior art are mainly solved. The catalyst comprises 90-100wt% of a ZSM-5 molecular sieve with the shape index of 3-100 (the shape index is defined as a length ratio of a longest edge to a shortest edge of a molecular sieve crystal in a three dimensional direction), 0-5wt% of phosphorus or oxide thereof, and 0-5wt% of at least one of rare earth elements or oxides thereof. The preparation method well solves the problems, and the binder-free ZSM-5 molecular sieve catalyst prepared in the invention can be used in the industrial production for preparing propylene and aromatic hydrocarbons by using methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

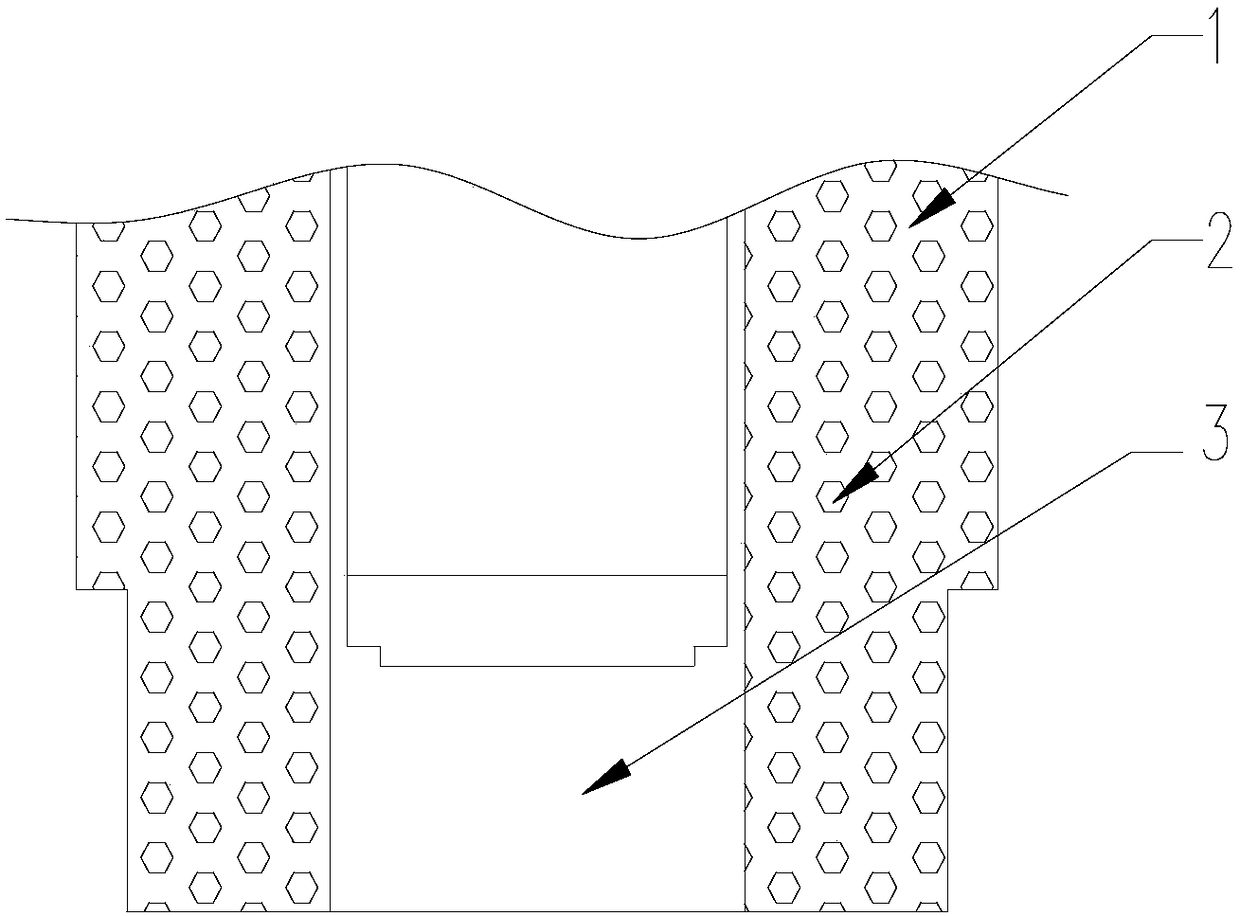

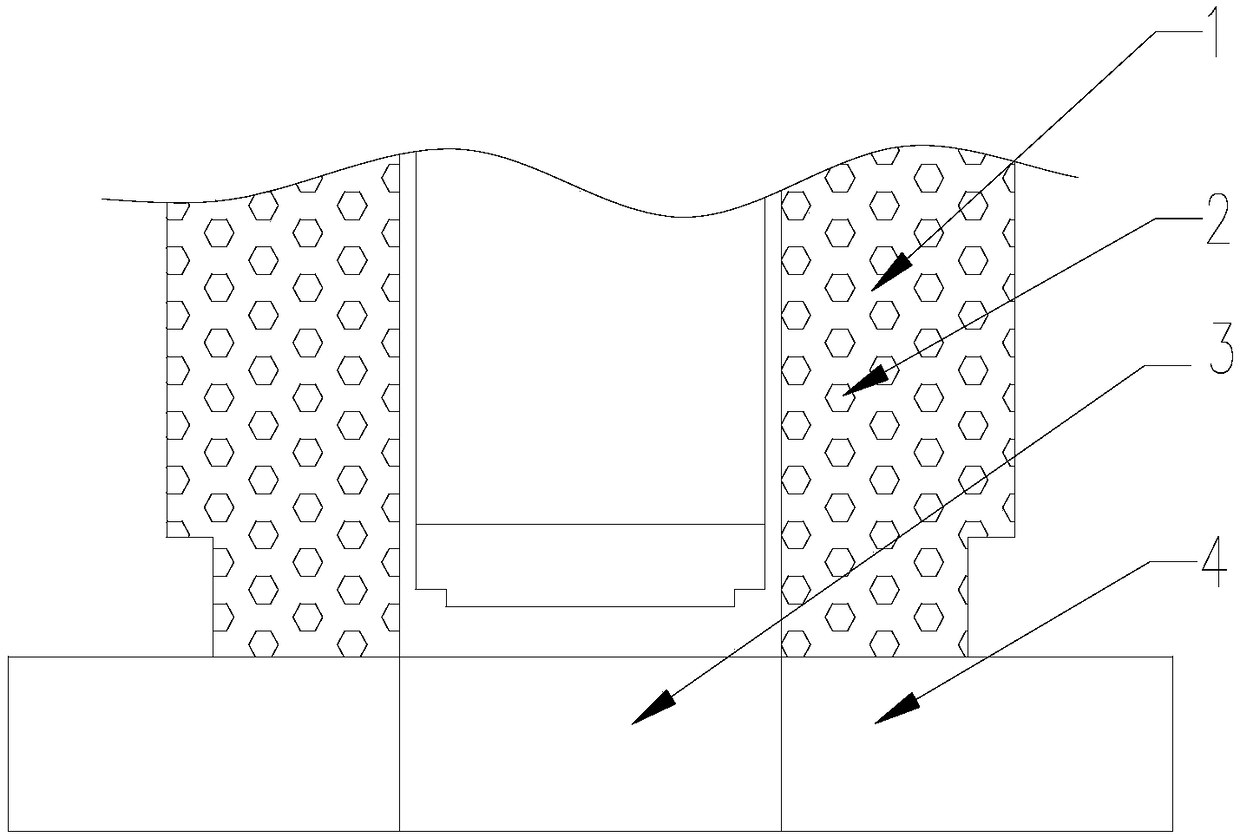

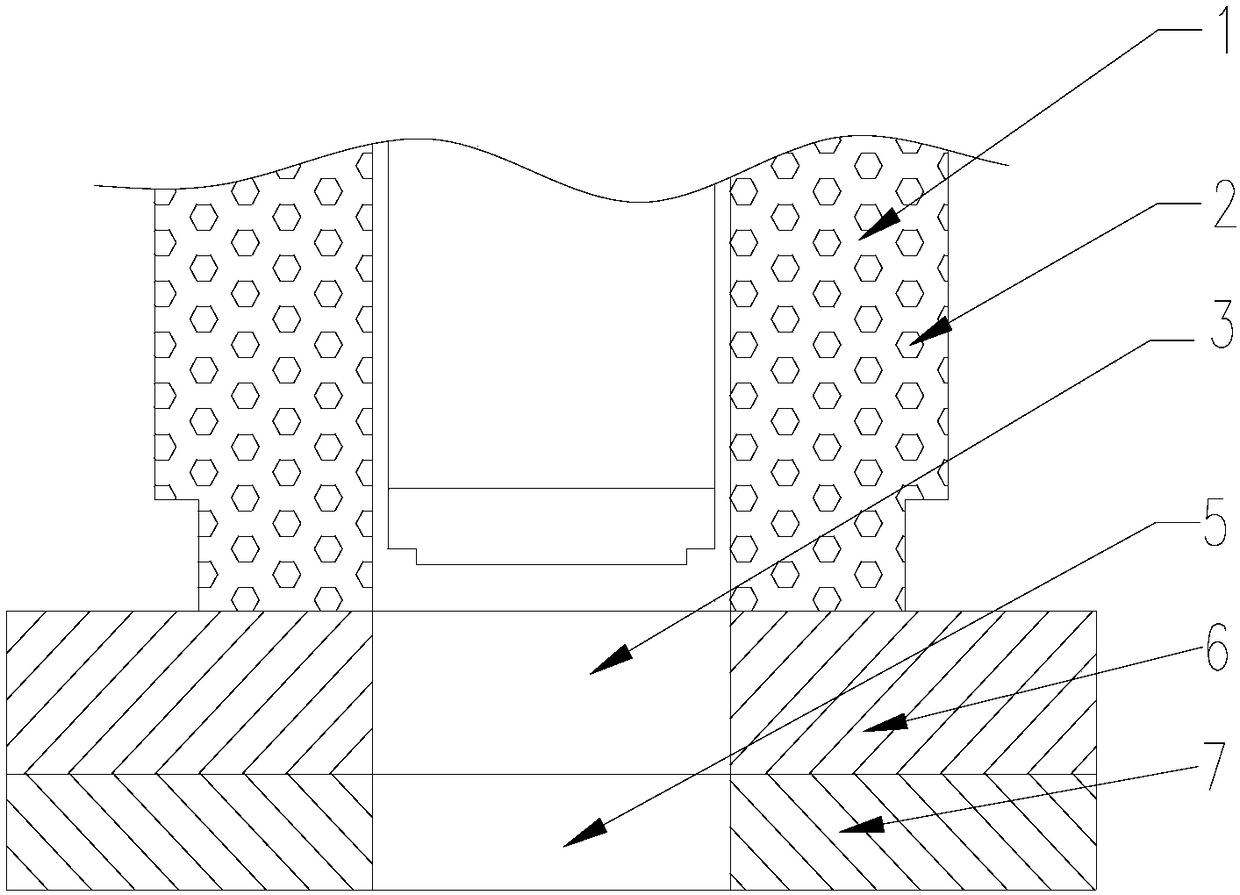

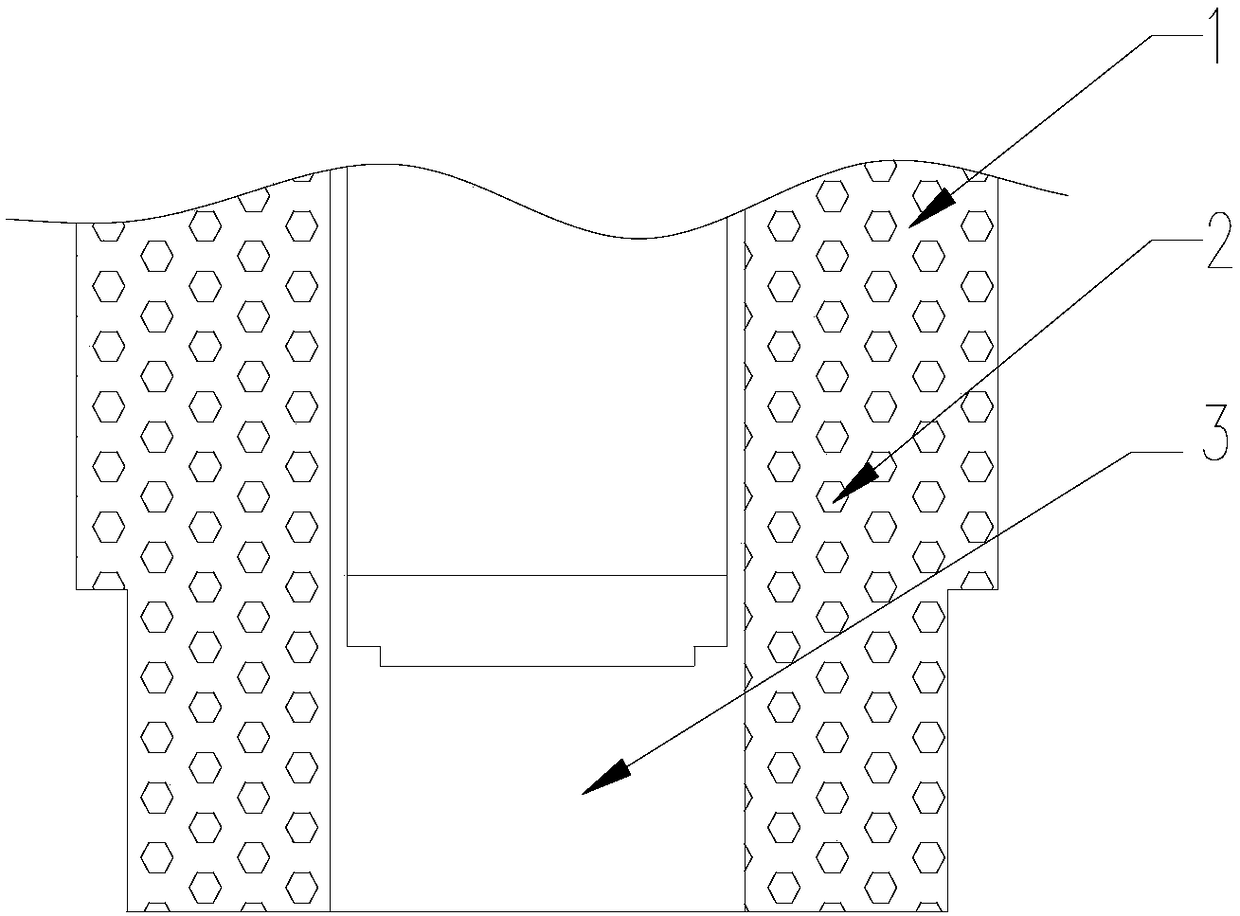

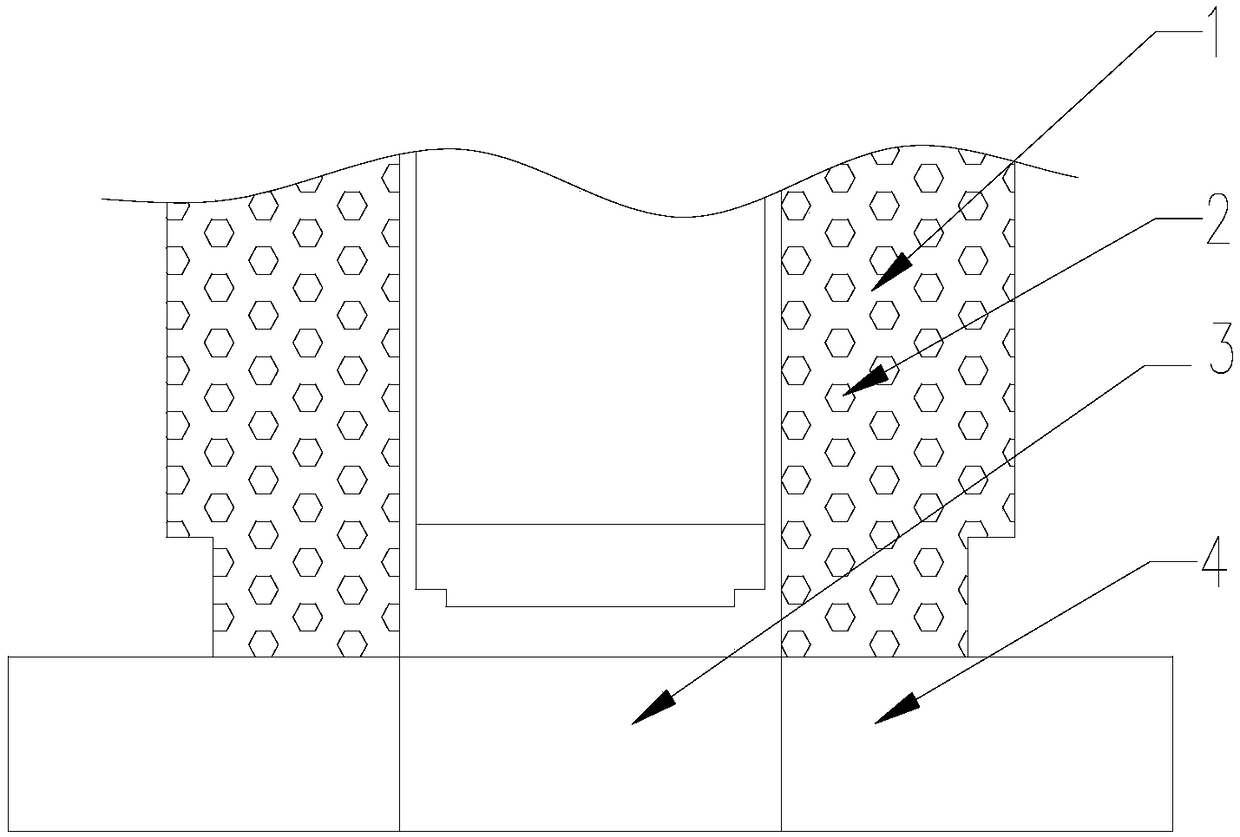

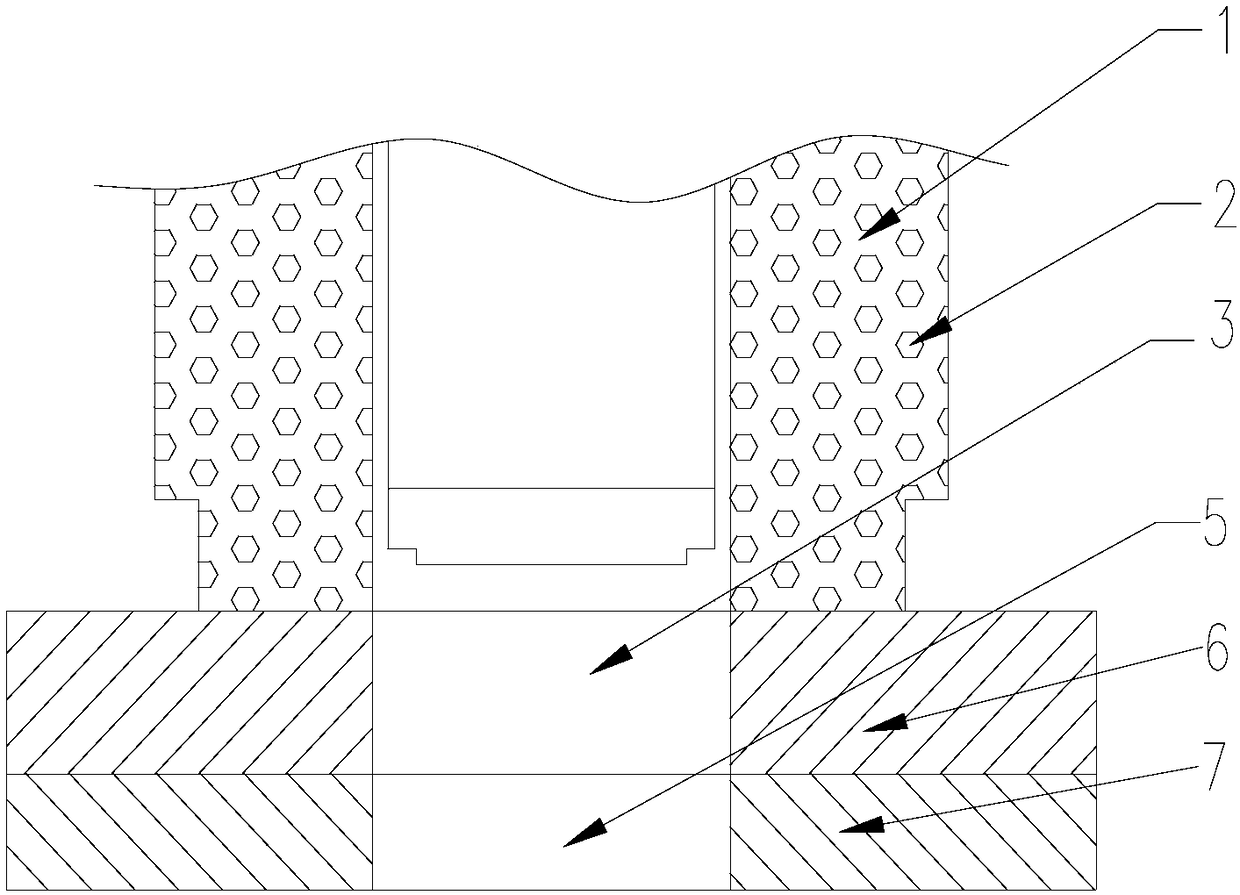

Flame detector cooling device and method

PendingCN106838976AImprove cooling effectHigh temperature resistanceDomestic cooling apparatusChamber safety arrangementFlame detectionCooling pipe

The invention discloses a flame detector cooling device which comprises a flame detector probe (1), a cooling air blow-off nozzle (2) of the flame detector probe, an outer cooling tube (3), an optical fiber (4) and an inner cooling tube (5). The flame detector cooling device is characterized in that the flame detector probe (1) is arranged in the outer cooling tube (3); the inner cooling tube (5) is sleeved in the outer cooling tube (3); and the optical fiber (4) is arranged in the inner cooling tube (5), one end of the optical fiber (4) is connected to the flame detector probe (1) while the other end of the optical fiber is connected to an external system, and a flame detecting optical fiber protecting pipe is changed from a single-layered cooling air duct into a double-layered cooling air duct, so that problems that the optical fiber is easy to damage, the flame detecting probe is easy to clog and the like are solved.

Owner:ELECTRIC POWER SCI RES INST OF GUIZHOU POWER GRID CO LTD

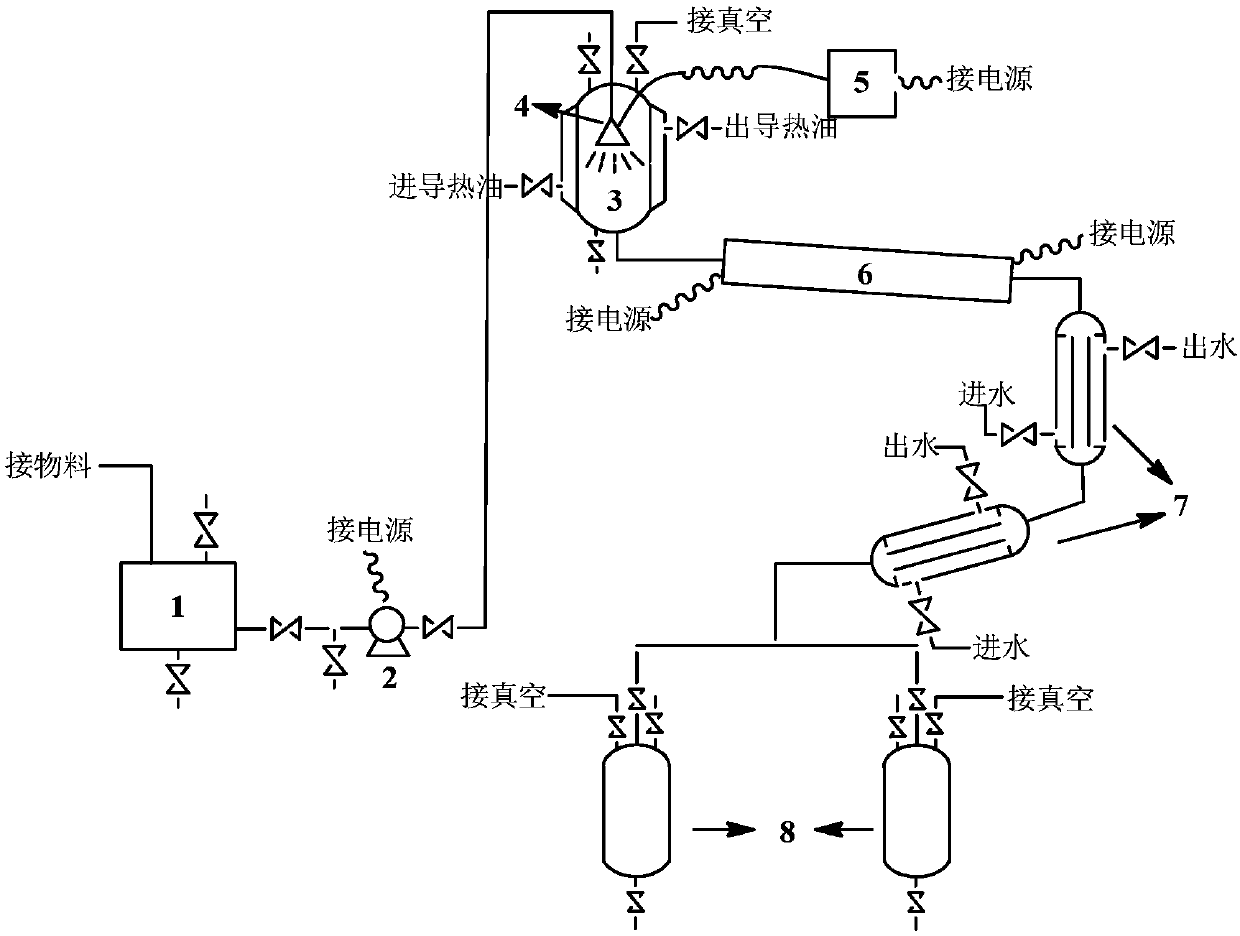

Process and device for producing myrcene by thermal cracking of beta-pinene

PendingCN107602322ALower gasification temperatureNot easy to cokeHydrocarbon by isomerisationSmall dropletEngineering

The invention discloses a process and device for producing myrcene by thermal cracking of beta-pinene. According to the flowing direction of material, the device is mainly composed of a raw material storage tank, a metering and feeding pump, an ultrasonic atomization gasification device, an inductive coupling thermal cracking tube, a condenser and a product collector which are sequentially connected in series, wherein an ultrasonic atomization nozzle is arranged at the top of the ultrasonic atomization gasification device; and the ultrasonic atomization nozzle is connected with an ultrasonic atomizer controller. At ordinary pressure or low pressure, beta-pinene is subjected to ultrasonic atomization treatment and becomes uniformly dispersed micron-scale small droplets, complete atomizationgasification is realized at relatively low temperature, and a gasified material rapidly enters the inductive coupling thermal cracking tube and carries out rapid thermal cracking reaction, thus generating myrcene.

Owner:广东松林香料有限公司

Binder-free ZSM-5 molecular sieve catalyst, and preparation method and use thereof

InactiveCN104107710AImprove stabilityReduced activityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsLow activityShape index

The invention relates to a binder-free ZSM-5 molecular sieve catalyst, and a preparation method and a use thereof. The problems of low activity of a binder-containing ZSM-5 molecular sieve in the prior art and low intensity of a binder-free ZSM-5 molecular sieve in the prior art are mainly solved. The binder-free ZSM-5 molecular sieve catalyst comprises 90-100wt% of a ZSM-5 molecular sieve with the shape index of 3-100 (the shape index is defined as a length ratio of a longest edge to a shortest edge of a molecular sieve crystal in a three dimensional direction), 0-5wt% of a P element or oxide thereof, and 0-5wt% of at least one of V, Cr, Mn, Fe, Co and Ni, or oxide thereof. The preparation method well solves the problems, and the binder-free ZSM-5 molecular sieve catalyst prepared in the invention can be used in the industrial production for preparing propylene by using methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for propylene preparation through methanol conversion, and preparation method thereof

ActiveCN103418425AImprove stabilityHigh selectivityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sievePtru catalyst

The present invention relates to a catalyst for propylene preparation through methanol conversion, and a preparation method thereof, wherein problems of poor catalyst stability and not high propylene selectivity in the existing propylene preparation reaction through methanol conversion in the prior art are mainly solved with the present invention. The technical scheme comprises that the catalyst comprises the following components, by weight, a) 30-80% of ZSM-5 having a shape index of 3-100, wherein the shape index is defined as a ratio of the longest edge length to the shortest edge length of the molecular sieve crystal in the three-dimensional direction, and b) 20-70% of a binder. With the technical scheme, the problems in the prior art are well solved, and the method can be used for industrial production of propylene preparation through methanol conversion.

Owner:CHINA PETROLEUM & CHEM CORP +1

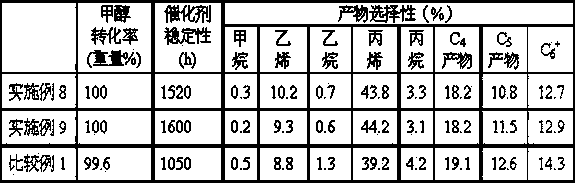

Catalyst for preparing propylene and aromatic hydrocarbons by converting methanol, and preparation method and use thereof

ActiveCN104107708AImprove stabilityHigh yieldMolecular sieve catalystsHydrocarbon from oxygen organic compoundsShape indexAromatic hydrocarbon

The invention relates to a catalyst for preparing propylene and aromatic hydrocarbons by converting methanol, and a preparation method thereof. The problems of fast inactivation and low yield of propylene and aromatic hydrocarbons of present catalysts in the process for preparing propylene by converting methanol are mainly solved. The catalyst comprises 20-90% of ZSM-5 molecular sieve with the shape index of 3-100 (the shape index is defined as a length ratio of a longest edge to a shortest edge of a molecular sieve crystal in a three dimensional direction), 0.05-3% of a transition metal oxide and 18-69% of a binder. The catalyst provided by the invention well solves the problems, and can be used in the industrial production for preparing propylene and aromatic hydrocarbons by using methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Binderless nano ZSM-5/beta symbiotic molecular sieve catalyst

InactiveCN104437610AOvercome stabilityOvercome propyleneMolecular sieve catalystsHydrocarbon from oxygen organic compoundsChemistryAqueous solution

The invention relates to a binderless nano ZSM-5 / beta symbiotic zeolite molecular sieve catalyst. The binderless nano ZSM-5 / beta symbiotic zeolite molecular sieve catalyst is mainly used for solving the problems in the prior art that the activity is relatively low when the prepared ZSM-5 / beta symbiotic zeolite molecular sieves contain binders and the strength is relatively poor when the prepared ZSM-5 / beta symbiotic zeolite molecular sieves do not contain the binders. According to the binderless nano ZSM-5 / beta symbiotic zeolite molecular sieve catalyst, through adopting the technical scheme of firstly carrying out mixed shaping on silicon and aluminum raw materials, then, converting the silicon and aluminum raw materials into nano ZSM-5 and beta zeolite molecular sieves by using a mixed aqueous solution of organic amine and organic quaternary ammonium base, and carrying out modification, thereby forming the binderless nano ZSM-5 / beta symbiotic zeolite molecular sieves; the problems are better solved, and the prepared binderless nano ZSM-5 / beta symbiotic molecular sieve catalyst can be applied to the industrial production of preparing propene and arene from methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for refining 4-amino diphenylamine

InactiveCN1470499AHigh yieldIncrease contentAmino compound purification/separationDistillationAniline

The present invention relates to a method for refining 4-aminodiphenylamine by adopting three-column continuous rectification and intermittent distillation. The crude product of 4-aminodiphenylamine can be obtained by rectification in the column No.1, and the substances of phenylamine, phenazine and azobenzene can be obtained at the top of column, said crude product can be purified in column No.2, in the column No.3 the phenylamine is separated, and the intermittent column can be used for making batch distillation of 4-aminophenylamine made up by using column bottoms of column No.2 and returning it into column No.2 for refining it. The yield rate of its whole process can be raised to 99% from 94%, and the content of 4-aminodiphenylamine in the finished product is greater than 99 wt%, at the same time the phenylamine can be recovered, and can be used.

Owner:JIANGSU SINORGCHEM TECH CO LTD

Additive for improving slagging feature of high-iron Zhundong coal and application method thereof

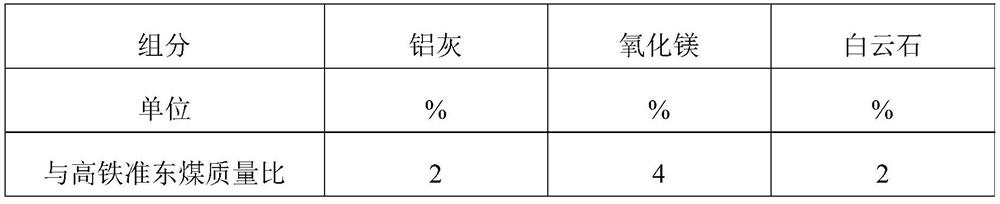

ActiveCN110360587AImprove slagging characteristicsSimple ingredientsSolid fuel pretreatmentSolid fuelsIndustrial wasteMagnesium

The invention discloses an additive for improving the slagging feature of high-iron Zhundong coal and an application method of the additive. The additive is composed of, by mass, 15%-65% of aluminum ash, 25%-50% of magnesium oxide and the balance dolomite. According to the application method of the additive, mixed coal is prepared according to the mass ratio of (3-8):100 between the additive and the high-iron Zhundong coal, wherein the aluminum ash accounts for 1%-6% of the mass of the high-iron Zhundong coal, the magnesium oxide accounts for 1%-5% of the mass of the high-iron Zhundong coal, and the dolomite accounts for 1%-5% of the mass of the high-iron Zhundong coal. The application method comprises the implementation steps that firstly, according to the mass of the high-iron Zhundong coal, the mass of each ingredient of the additive is determined; the additive and the high-iron Zhundong coal are crushed and mixed in a coal mill or undergo flowing mixing in a primary air pipeline, and finally the mixture is fed into a hearth to be combusted. The additive is composed of natural minerals and industrial waste, the ingredients are simple, the cost of the additive is low, and the additive has the effects of fixing sodium, improving an ash fusion point and fixing sulphur, can significantly improve the features of ash deposition, coking and slagging of the high-iron Zhundong coal and improve the blending combustion ratio of the high-iron Zhundong coal.

Owner:XI AN JIAOTONG UNIV

Mode for laying boiler furnace burning guarding belt

InactiveCN101230978AIncrease investmentIncrease inputBoiler flue tubes/fire tubesBoiler furnaceRefractory

The invention relates to a laying method of a refractory belt in a boiler furnace. The refractory belt is arranged on water screens of the four sides of the boiler furnace. The laid refractory belt is of rectangular and is divided into four small parts. The space among the four parts is cross-shaped. The horizontal space and the vertical space between every two of the four small parts are both 1meter. The upper rectangular refractory belt keeps a 1meter space with the lower rectangular refractory belt. All four small rectangles are 0.5-1meter long and wide. The big rectangular refractory belt is 6-7 meters long and 4.5-5.5meters wide. The laying method of the refractory belt in the boiler furnace can be put into operation during the boiler outage period. The practice of a company where the boiler works for continuous half a year after changing the laying method of the refractory belt proves that, compared with the state before changing the laying method of the refractory belt, the input amount of desuperheated water increases obviously, the main steam temperature is easy to be adjusted by hand and the overranging rate of the main steam temperature decreases obviously, the coking degree in the boiler furnace is obviously lessened, thus guaranteeing the safe and economical operation of the boiler and achieving the anticipated effects.

Owner:HENAN ZHONGFU IND

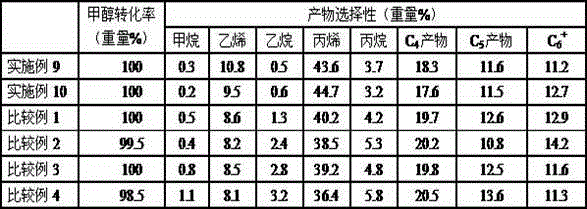

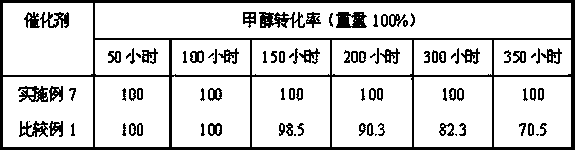

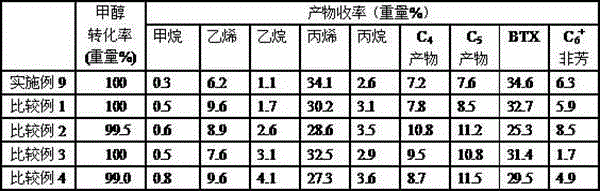

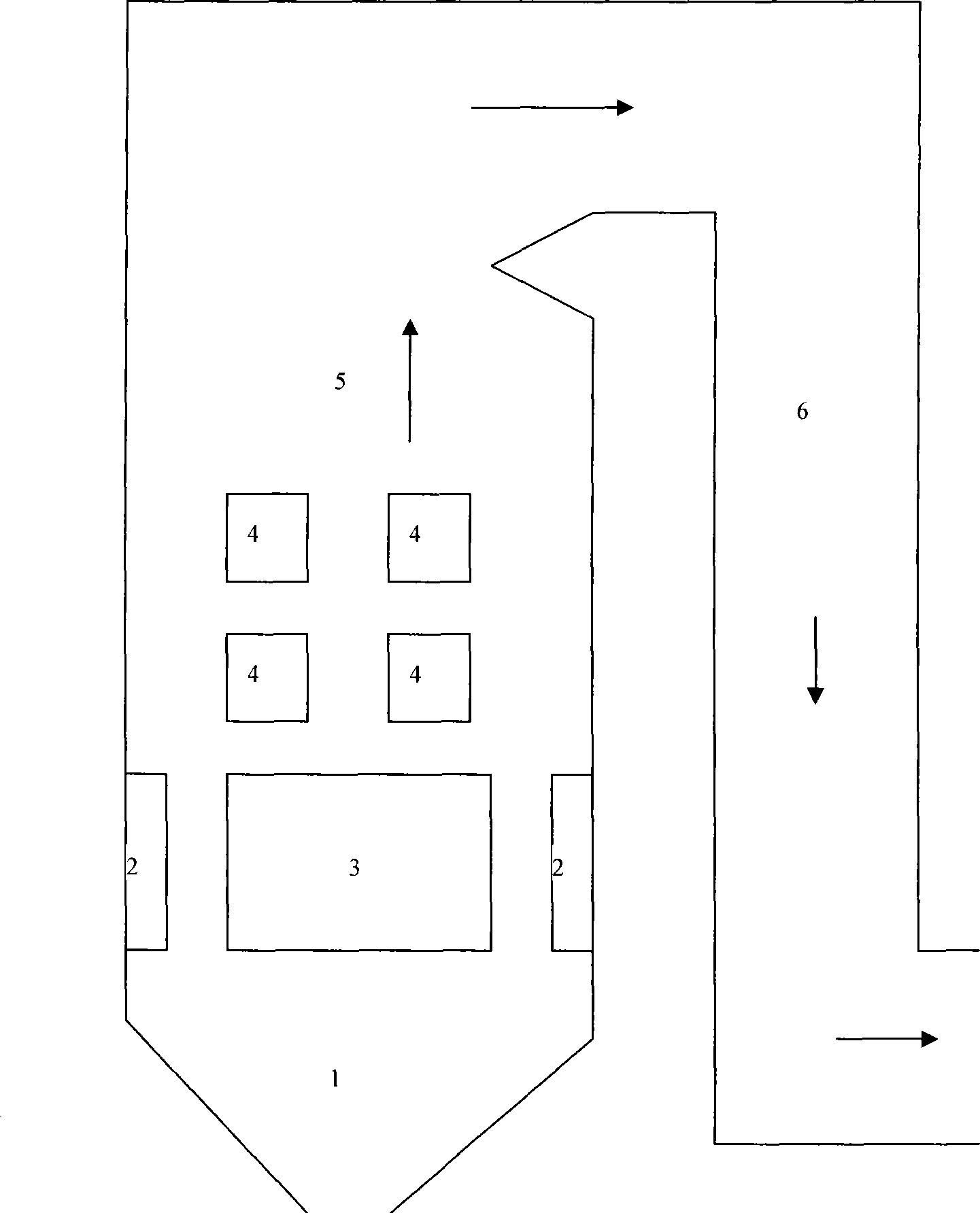

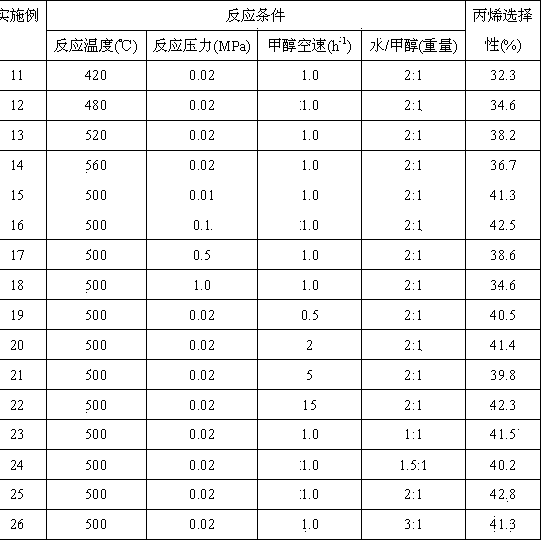

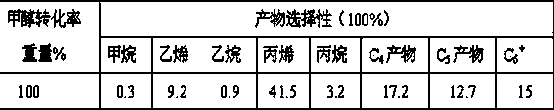

Method for propylene preparation through methanol conversion

InactiveCN103420754AReduced degree of cokingHigh catalyst stabilityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveAqueous solution

The present invention relates to a method for propylene preparation through methanol conversion, wherein problems of poor catalyst stability and not high propylene selectivity in the prior art are mainly solved with the present invention. The technical scheme comprises that: a methanol aqueous solution is adopted as a raw material, a ZSM-5 molecular sieve with a shape index of 3-100 is adopted as a catalyst at a reaction temperature of 400-600 DEG C under reaction pressure of 0.01-5 MPa at a methanol weight space velocity of 0.5-15 h<-1> according to a mass ratio of water to methanol of 0.2-5:1. With the technical scheme, the problems in the prior art are well solved, and the method can be used for industrial production of propylene preparation through methanol conversion.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for preparing propylene through methanol conversion and preparation method and application thereof

ActiveCN112206811AImprove catalytic stabilityHigh selectivityMolecular sieve catalystsMolecular sieve catalystMolecular sievePtru catalyst

The invention provides a catalyst for preparing propylene through methanol conversion as well as a preparation method and application thereof. The preparation method of the catalyst for preparing propylene through methanol conversion comprises the following steps: mixing a tetrapropylammonium bromide aqueous solution, a water glass aqueous solution and a sodium metaaluminate aqueous solution to obtain a mixed solution; carrying out crystallization treatment on the mixed solution at 150-210 DEG C for at least 6 hours, and washing, drying and roasting a crystallization product to obtain a Na-type ZSM5 molecular sieve; and carrying out ion exchange on the Na-type ZSM5 molecular sieve and an ion exchange solution, washing, drying and roasting to obtain the H-type ZSM5 molecular sieve. The preparation method provided by the invention is simple in technological process, good in repeatability and suitable for industrial production; the catalyst for preparing propylene by converting methanol obtained by the preparation method has the characteristics of high propylene selectivity and good catalytic stability.

Owner:PETROCHINA CO LTD

A kind of anti-wicking polyester industrial filament spinning oil and preparation method thereof

The invention belongs to the technical field of polymer fiber production, and particularly relates to spinning oil for an anti-wicking industrial polyester filament and a preparation method of the spinning oil. According to the spinning oil for the anti-wicking industrial polyester filament provided by the invention, an anti-wicking agent is reasonably mixed with the spinning oil; and the mixed oil contains refined mineral oil and an antistatic agent, and simultaneously contains a water repellent agent in a fluorocarbon structure, so that the spinning oil provided by the invention has good heat resistance, bundling property and smoothness, and also has excellent hydrophobic property; the oil provided by the invention can reach the effects of low smoke amount, low coking degree and few broken filaments in the spinning process; and the prepared industrial polyester filament has excellent anti-wicking property.

Owner:ZHEJIANG HAILIDE NEW MATERIAL

Mode for laying boiler furnace burning guarding belt

InactiveCN100582572CIncrease investmentIncrease inputBoiler flue tubes/fire tubesBoiler furnaceRefractory

The invention relates to a laying method of a refractory belt in a boiler furnace. The refractory belt is arranged on water screens of the four sides of the boiler furnace. The laid refractory belt is of rectangular and is divided into four small parts. The space among the four parts is cross-shaped. The horizontal space and the vertical space between every two of the four small parts are both 1meter. The upper rectangular refractory belt keeps a 1meter space with the lower rectangular refractory belt. All four small rectangles are 0.5-1meter long and wide. The big rectangular refractory belt is 6-7 meters long and 4.5-5.5meters wide. The laying method of the refractory belt in the boiler furnace can be put into operation during the boiler outage period. The practice of a company where the boiler works for continuous half a year after changing the laying method of the refractory belt proves that, compared with the state before changing the laying method of the refractory belt, the input amount of desuperheated water increases obviously, the main steam temperature is easy to be adjusted by hand and the overranging rate of the main steam temperature decreases obviously, the coking degree in the boiler furnace is obviously lessened, thus guaranteeing the safe and economical operation of the boiler and achieving the anticipated effects.

Owner:HENAN ZHONGFU IND

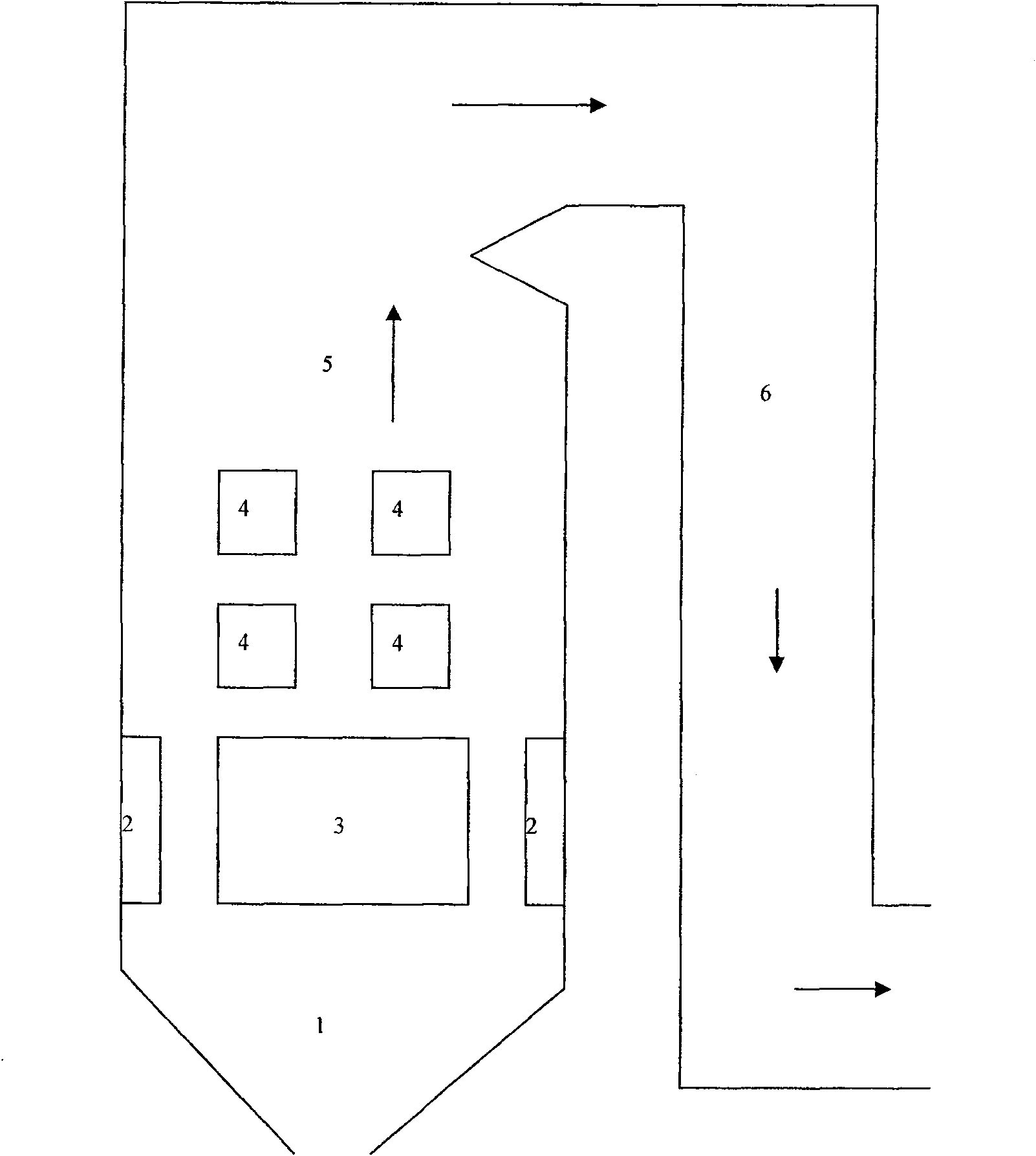

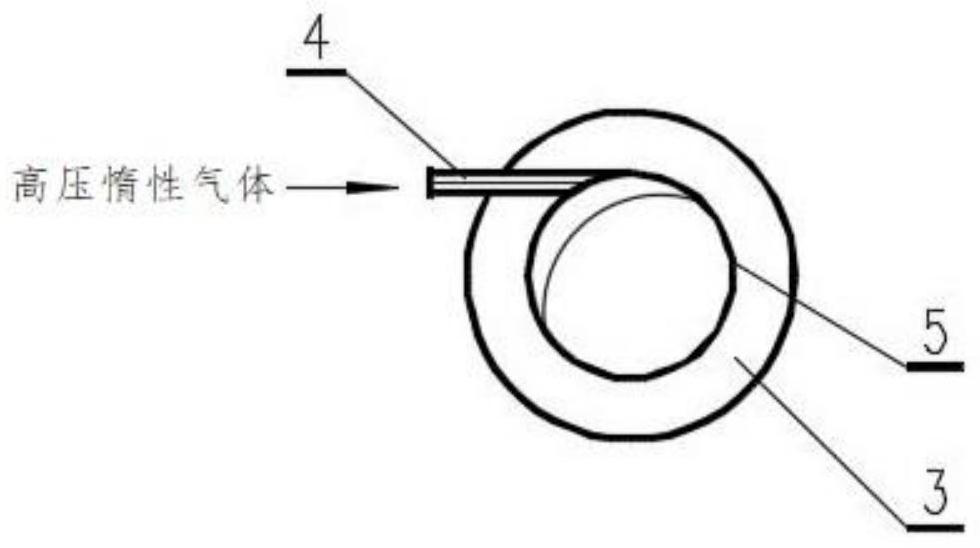

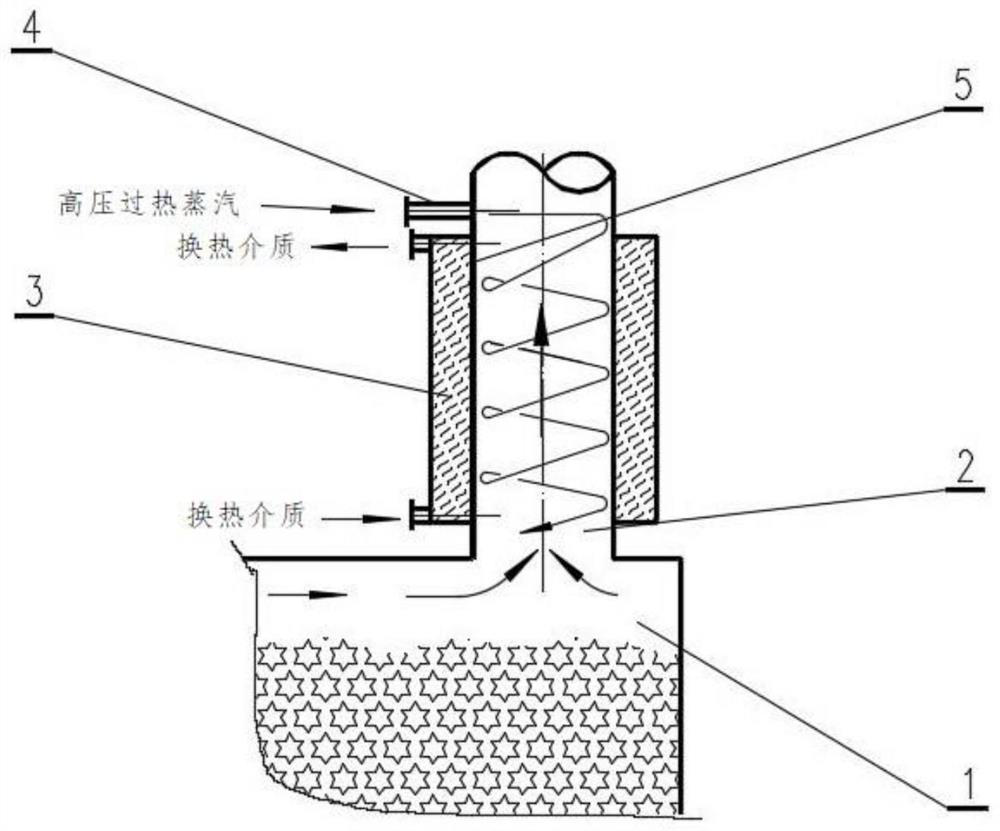

Method for preventing or reducing coking of inner wall of ascension pipe of coke oven

PendingCN113429989AReduced degree of cokingEnsure heat exchange efficiencyCoke oven safety devicesOven incrustations prevention/removalTarThermal efficiency

The invention relates to a method for preventing or reducing coking on the inner wall of an ascending pipe of a coke oven. High-pressure inert gas is supplied into the ascending pipe from the upper end of the ascending pipe along the tangential direction of the inner wall of the ascending pipe; tar deposited on the inner wall of the ascension pipe is scoured by high-pressure airflow to prevent newly precipitated tar from being deposited on the inner wall of the ascension pipe; and the high-pressure airflow carries the washed tar and other substances to enter the carbonization chamber. The coking degree of the inner wall of the ascension pipe can be reduced, the raw gas heat exchange efficiency is guaranteed, and the production and maintenance cost is reduced; meanwhile, maximum utilization of resources in the coking production process is achieved, and carbon emission is reduced.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Silicon-zinc-modified catalyst carrier and preparation method and application thereof

ActiveCN107961778AEasy to operateHigh activityCatalyst carriersCatalyst activation/preparationEpoxyPolymer modified

The invention relates to the field of catalysts and discloses a silicon-zinc-modified catalyst carrier and a preparation method and application thereof. The method comprises contacting modified silicone oil and a water-soluble zinc compound with an alumina carrier, wherein the modified silicone oil comprises one or more of alkyl-modified silicone oil, polyether-modified silicone oil, epoxy-modified silicone oil, amino-modified silicone oil, polymer-modified silicone oil and hydroxyl-modified silicone oil. The preparation method improves the surface acid amount and the acid strength of the carrier so that the carrier can be used for preparation of a highly active hydrotreatment catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

System and method for continuously producing mesophase pitch

InactiveCN111944552AImprove uniformitySimple processWorking-up pitch/asphalt/bitumen by meltingWorking-up pitch/asphalt/bitumen by solidifying/disintegratingReaction temperatureMechanical engineering

The invention relates to the field of production of mesophase pitch, in particular to a system and a method for continuously producing mesophase pitch. The system comprises a feeding device and a reaction device which are connected in sequence, wherein the feeding device is used for melting raw materials and heating the raw materials to a reaction temperature, and the reaction device is used for converting the materials from the feeding device into mesophase pitch in a free downward flowing mode under a non-stirring condition; the reaction device is a cylindrical container with a height-diameter ratio of greater than 3; the reaction device comprises a liquid material inlet located in the upper part of the reaction device, and a liquid material outlet is located in the bottom of the reaction device; and a stirring part and a filler are not arranged in the reaction device. The system and the method provided by the invention can further improve the uniformity of an obtained mesophase pitch product and the content of the mesophase pitch on the premise of ensuring good comprehensive performance of the obtained mesophase pitch product.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Building construction method for expansion device of household garbage incineration boiler

PendingCN113108287AGuaranteed stability and securitySolve deformation damageCasings/liningsIncinerator apparatusFiberAluminum silicate

The invention discloses a building construction method for an expansion device of a household garbage incineration boiler. The building construction method comprises the following steps of construction preparation and inspection, welding of furnace wall metal pieces, construction of pouring materials on the inner side of the upper portion of the expansion device, construction of pouring materials on the lower portion of the expansion device, laying of Z-shaped expansion joint aluminum silicate fiber cotton, installation of phi 120 aluminum silicate fiber ropes and construction of pouring materials on the outer side of the upper portion of the expansion device. When the construction method is used for building the expansion device of the household garbage incineration boiler, the problems of deformation and damage of the expansion device of the household garbage incineration boiler and a building layer in the area range of the expansion device can be effectively solved; the phenomena of throttling, blocking, coke hanging and the like caused by burning loss, damage, cracking and falling of the building layer are effectively avoided; normal and stable operation of a unit is guaranteed; the overhaul and maintenance period is shortened; the combustion efficiency of the boiler is stabilized; environmental pollution is reduced; the technology is advanced; and practicability is high.

Owner:POWER CHINA HENAN ENG CO LTD

Lubricating compositions

ActiveCN102625827BReduced silt accumulationReduce the degree of cokingLubricant compositionSludgeBase oil

A lubricating composition comprising: (i) from 50% to 99% by weight of base oil; (ii) from 0.01% to 5% by weight of ionic liquid; and (iii) from 0.01% to 10% by weight of additive; wherein the lubricating composition has a pour point of at most −54° C., a flashpoint of at least 246° C. and a kinematic viscosity at 100° C. in the range of from 4.9 to 5.4 mm2 / s. The lubricating compositions according to the present invention are suitable for use in turbine engine oils and are useful for reducing the build up of sludge and for reducing coking in the lubricating composition.

Owner:SHELL INT RES MAATSCHAPPIJ BV

An additive for improving high-speed railway Zhundong coal slagging characteristics and its application method

ActiveCN110360587BImprove slagging characteristicsRelieve contaminationSolid fuel pretreatmentSolid fuelsPhysical chemistryEngineering

Owner:XI AN JIAOTONG UNIV

Method for preparing high purification myrcene by thermal cracking beta firpene

ActiveCN100556870CFast heatingReduce menstrual timeHydrocarbonsHydrocarbon preparationResidence timePinene

Owner:SOUTH CHINA AGRI UNIV

Method for refining 4-amino diphenylamine

InactiveCN1189445CHigh yieldIncrease contentAmino compound purification/separationDistillationAniline

Owner:JIANGSU SINORGCHEM TECH CO LTD

Binder-free zsm-5/β co-crystallized molecular sieve catalyst and its preparation method and use

ActiveCN104437614BHigh strengthSimple preparation processMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sievePtru catalyst

The invention relates to a binder-free ZSM-5 / β co-crystallized zeolite molecular sieve catalyst and its preparation method and application, which mainly solves the problem that the ZSM-5 / β-co-crystallized zeolite molecular sieve prepared by the prior art has relatively low activity when a binder is contained. The problem of poor strength when low and no binder. In the present invention, the catalyst comprises the following components in terms of weight percentage: a) 87-99.25% ZSM-5 / β co-crystallized molecular sieve with a shape index of 3-100; b) 0.5-5% Mg, Ca, Sr , Ba at least one element; c) 0.2~5% of at least one element in V, Cr, Mn, Fe, Co, Ni; d) 0.05~3% of La, Ce, Pr, Nd at least The technical scheme of an element solves the problem well, and the prepared catalyst can be used in the industrial production of methanol to propylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com