Mode for laying boiler furnace burning guarding belt

A laying method and boiler furnace technology, applied in the direction of boiler smoke tube/fire tube, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

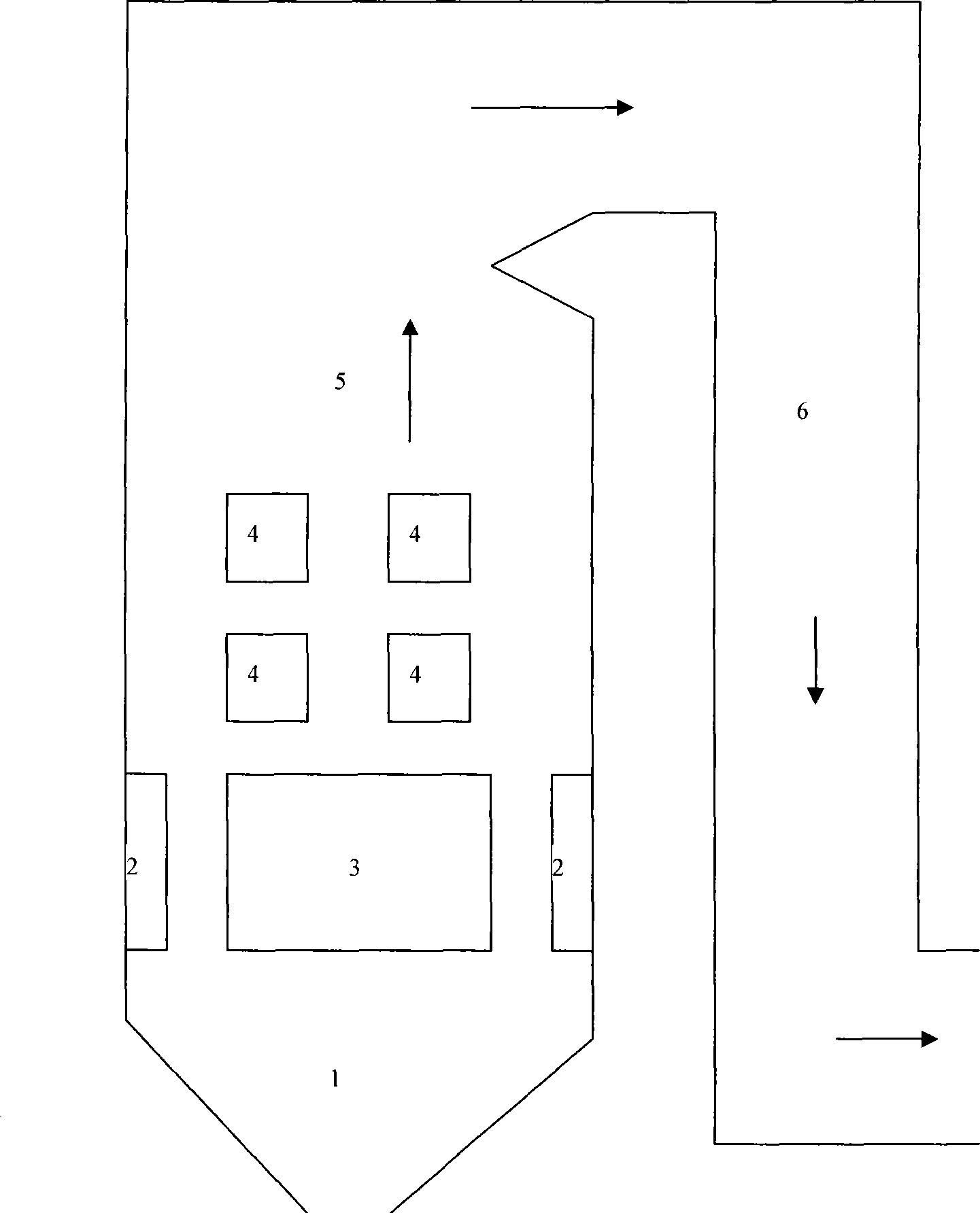

[0010] The location and tools for implementation are marked in the diagram, and the specific instructions are as follows: 1. Cold ash hopper; 2. Burner; 3. Large rectangular combustion belt; ; 6. Tail flue.

[0011] The way of laying the guard combustion belt in the boiler furnace is to lay the guard combustion belt 4 on the water-cooled walls 5 on all four sides of the furnace. The shape of the guard combustion belt 4 is rectangular and divided into four small pieces. "Ten" shape, the horizontal and vertical spacing between each block is 1 meter, and the distance from the lower rectangular guard burning belt 3 is also 1 meter, the length and width of the four small rectangles are all 1 meter, and the large rectangular guard The burning belt is 6.5 meters long and 5 meters wide.

[0012] The two sides of the rectangular guard combustion belt 3 on the four sides water wall 5 of the original boiler furnace are equally reduced in length, and the reduced guard combustion band are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com