Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

154results about "Working-up pitch/asphalt/bitumen by solidifying/disintegrating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

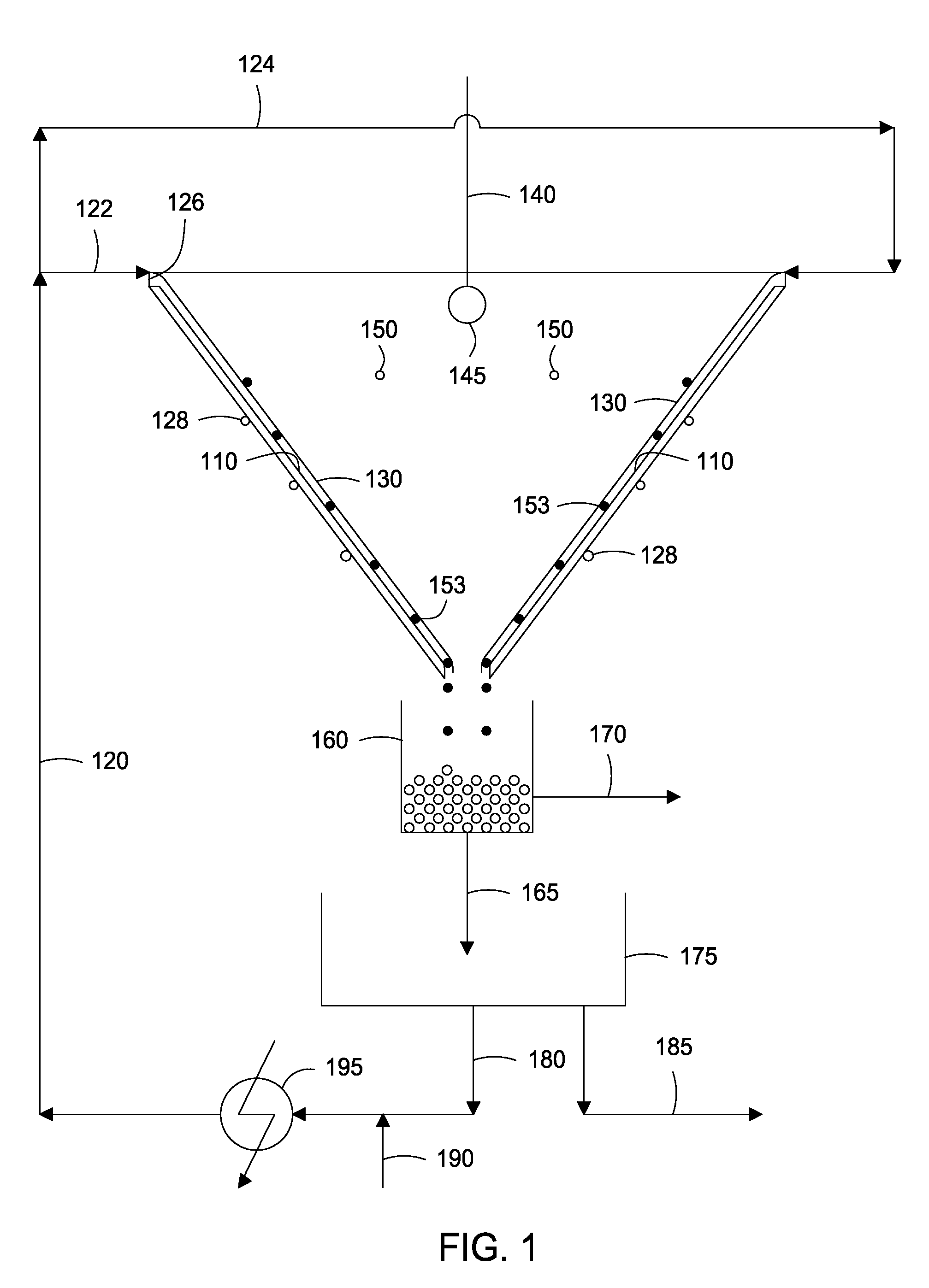

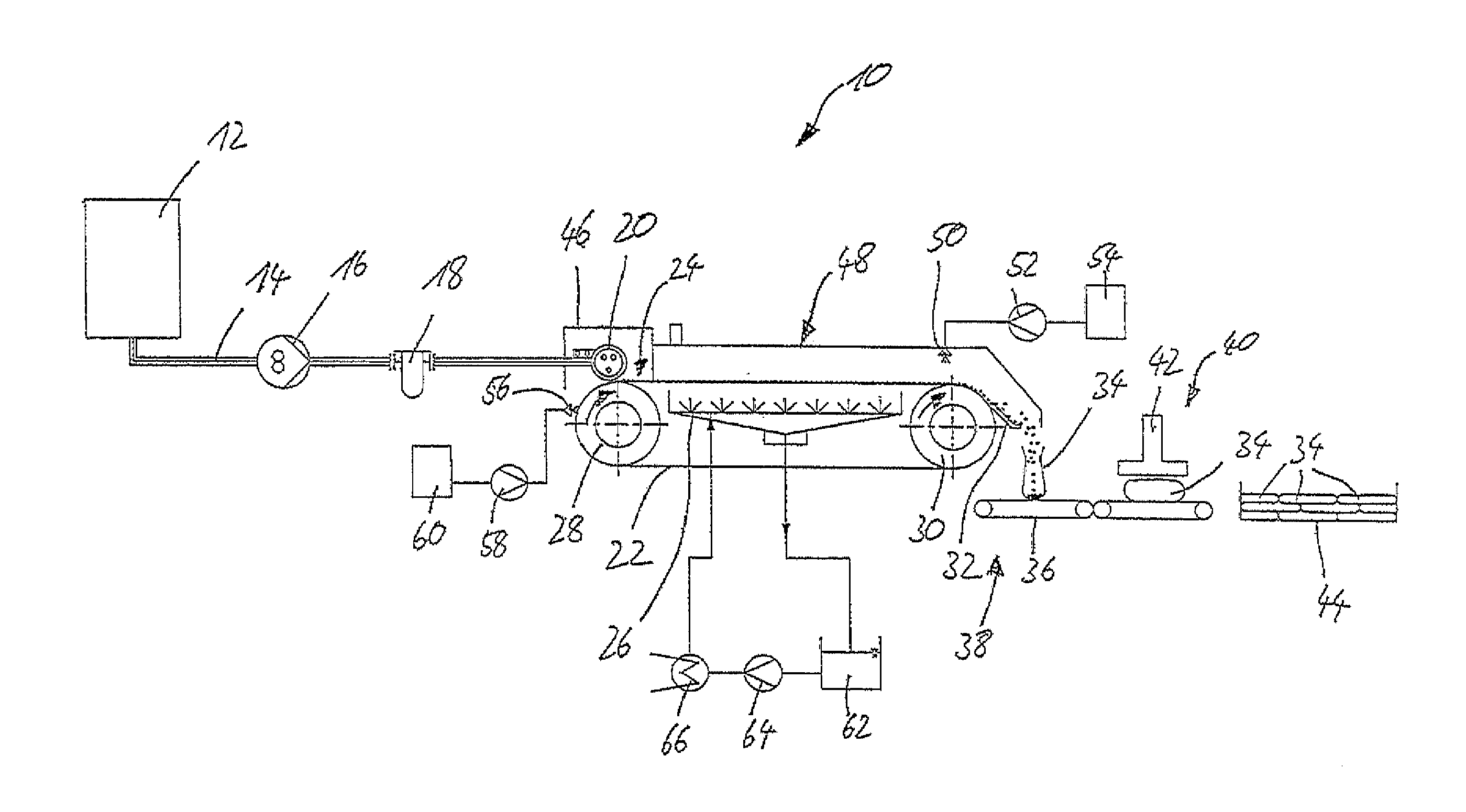

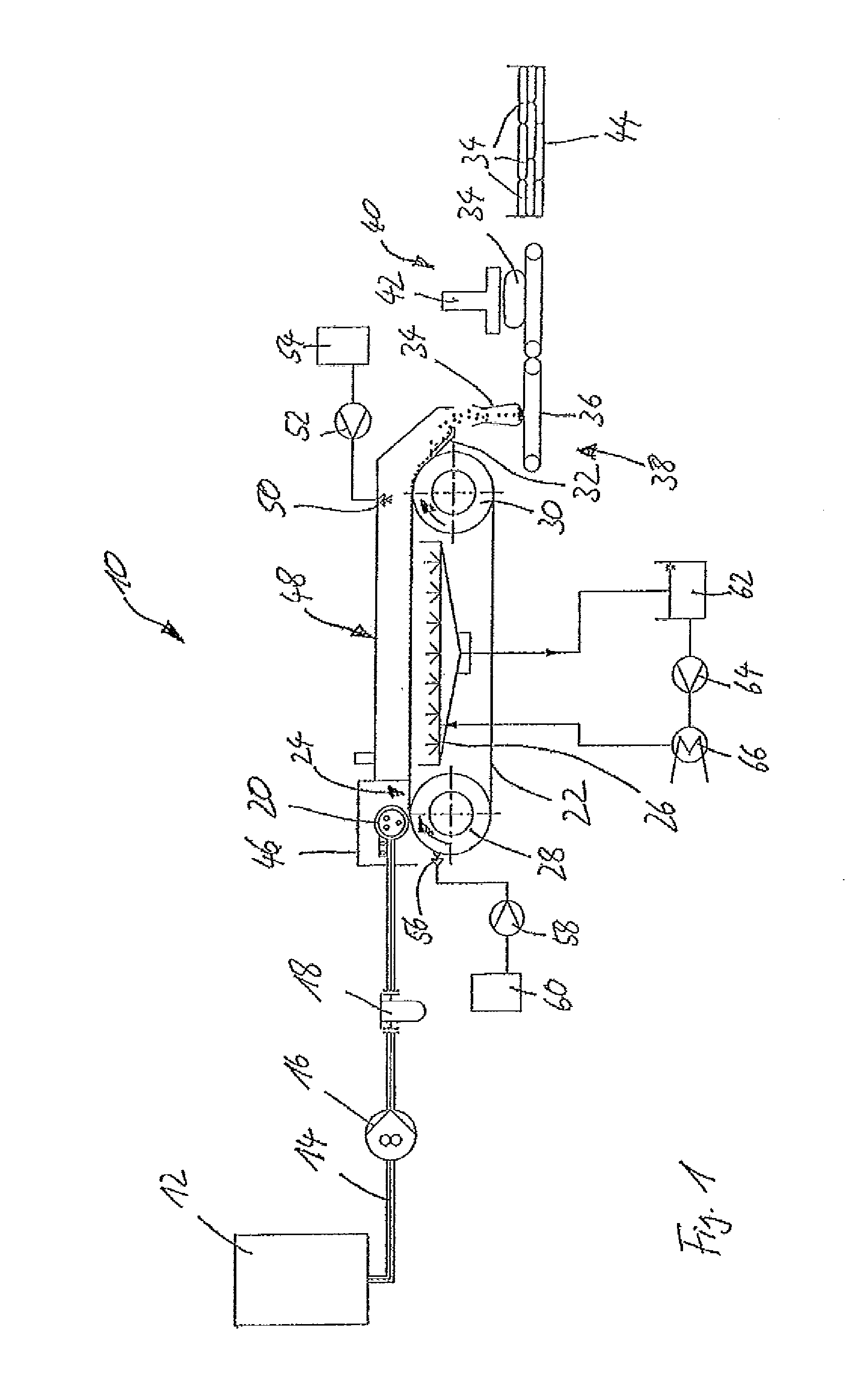

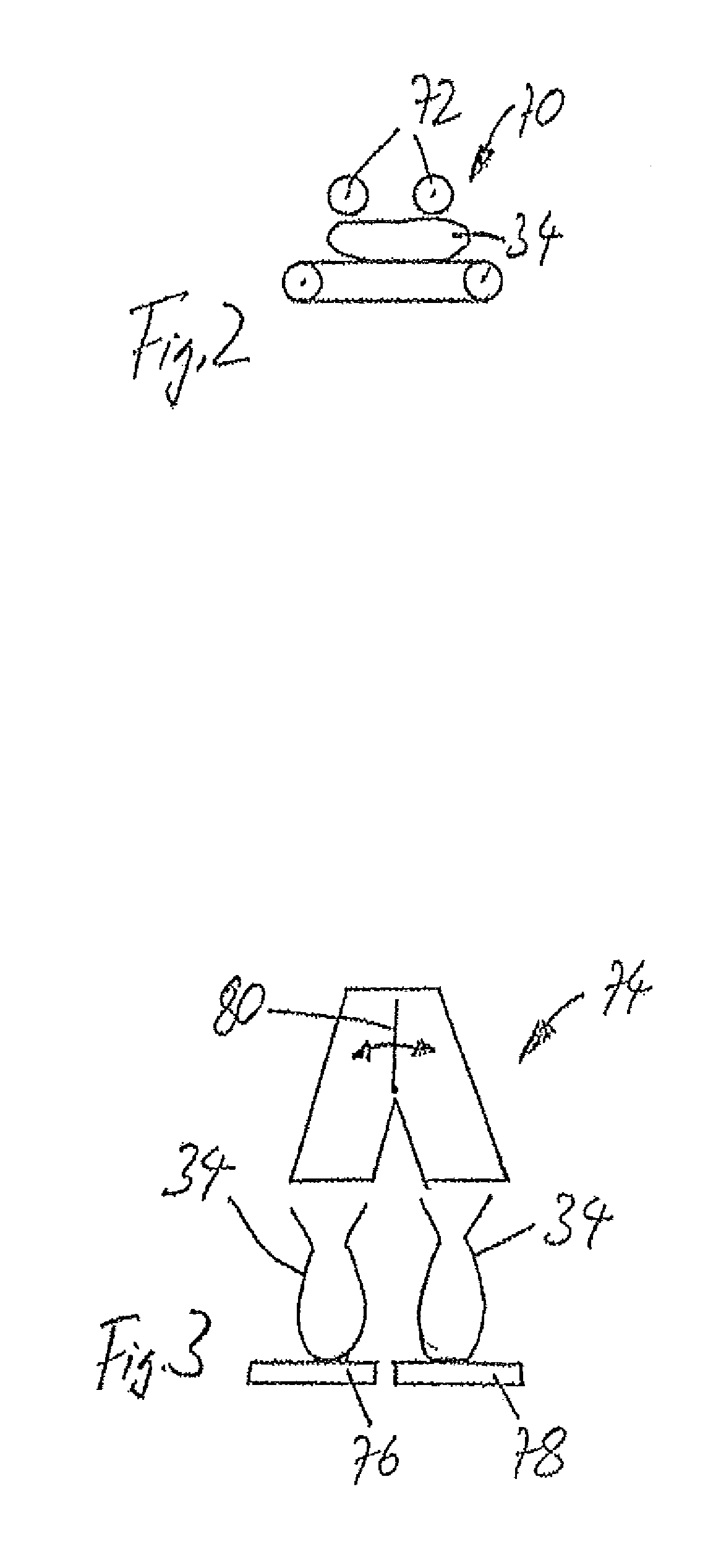

Hot asphalt cooling and pelletization process

ActiveUS7968020B2Granulation by liquid drop formationAuxillary shaping apparatusProcess systemsAsphalt

Owner:KELLOGG BROWN & ROOT LLC

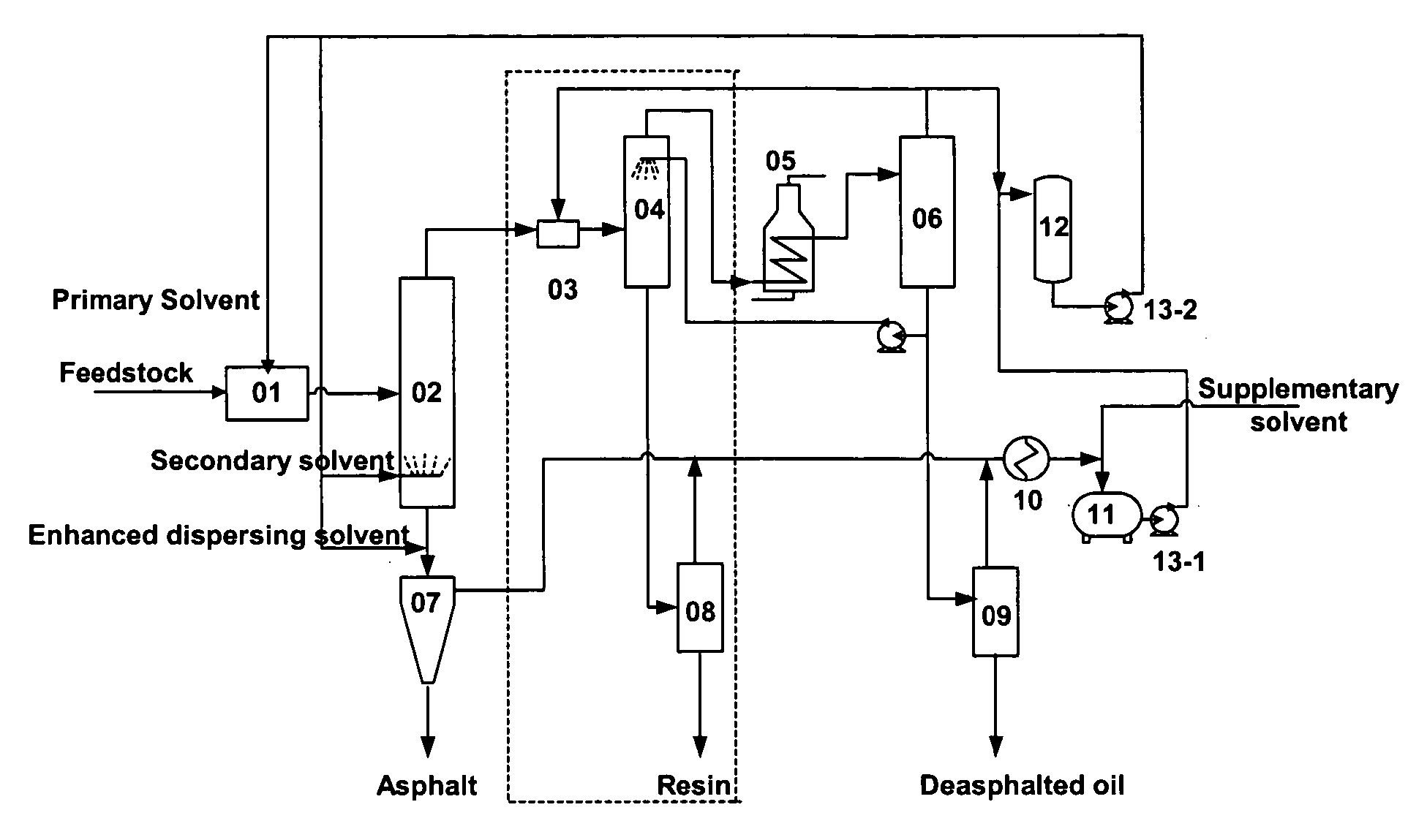

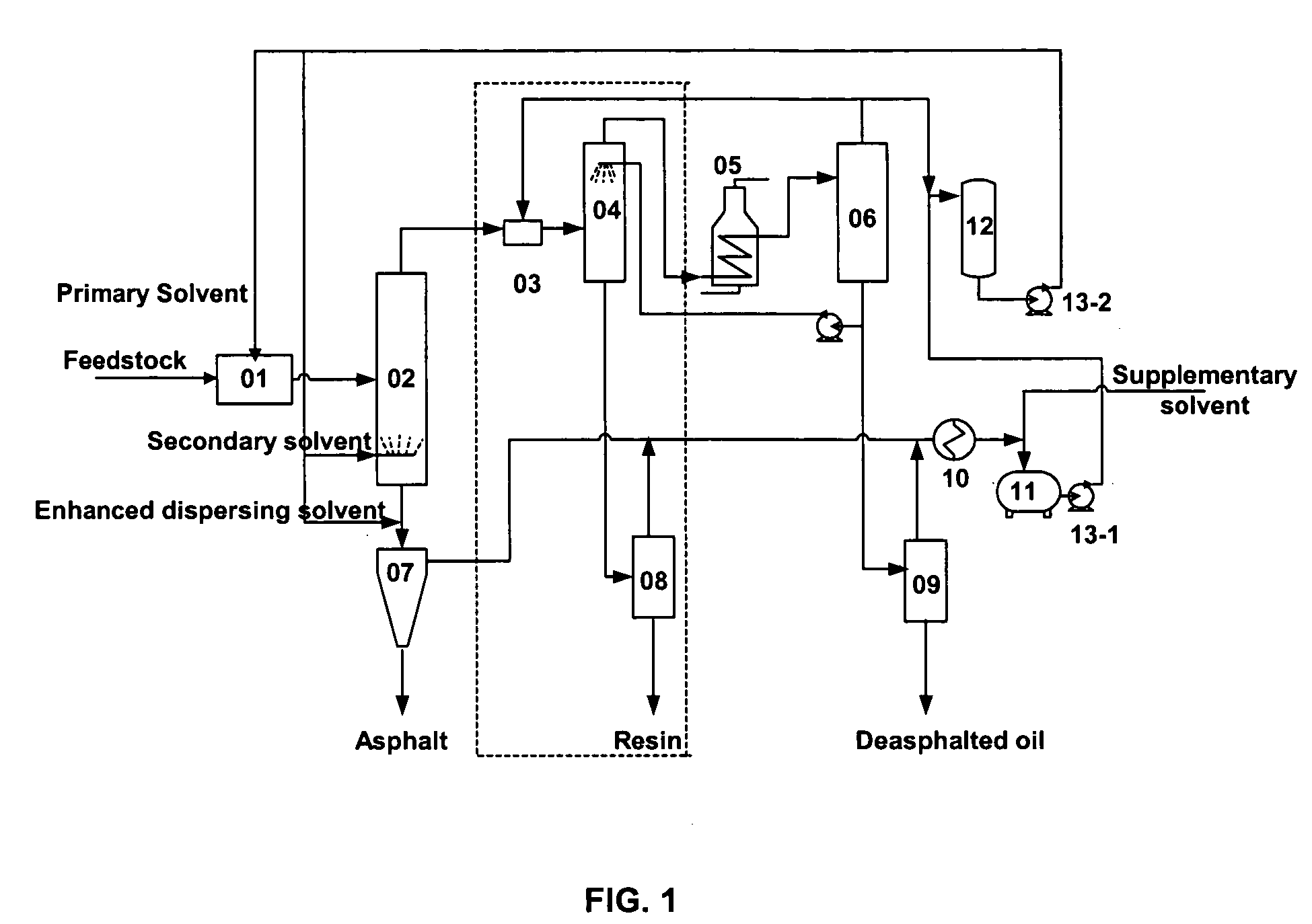

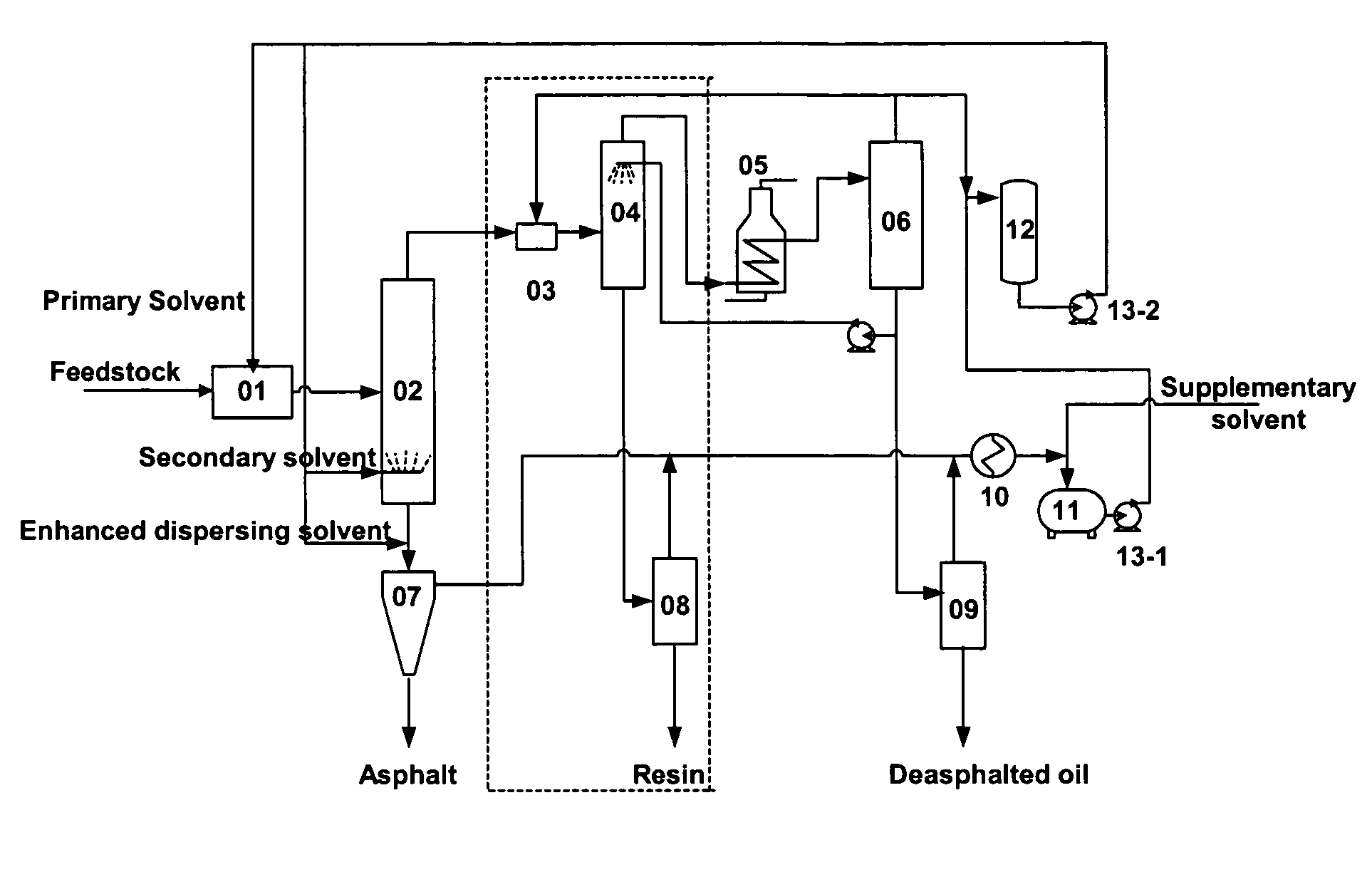

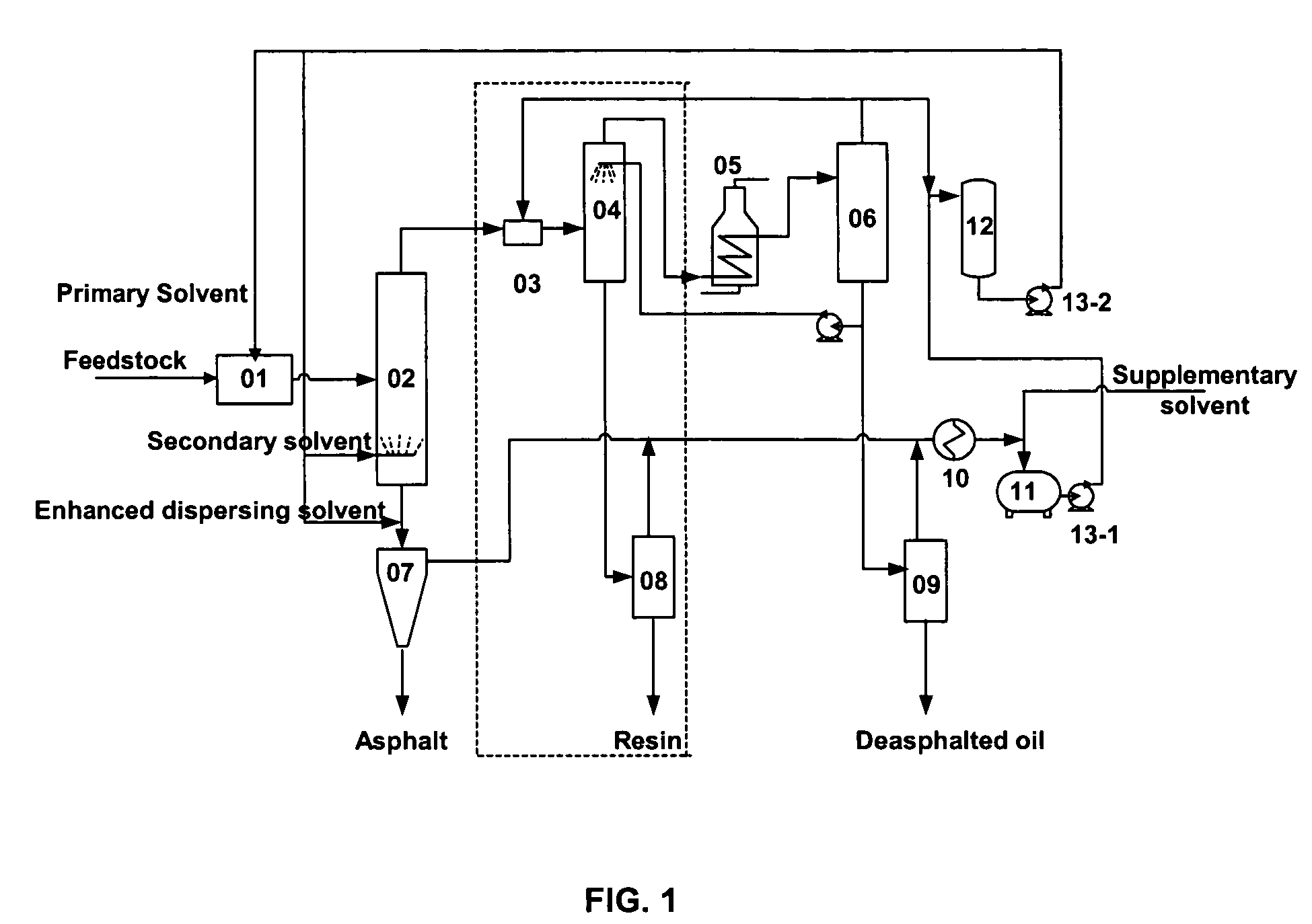

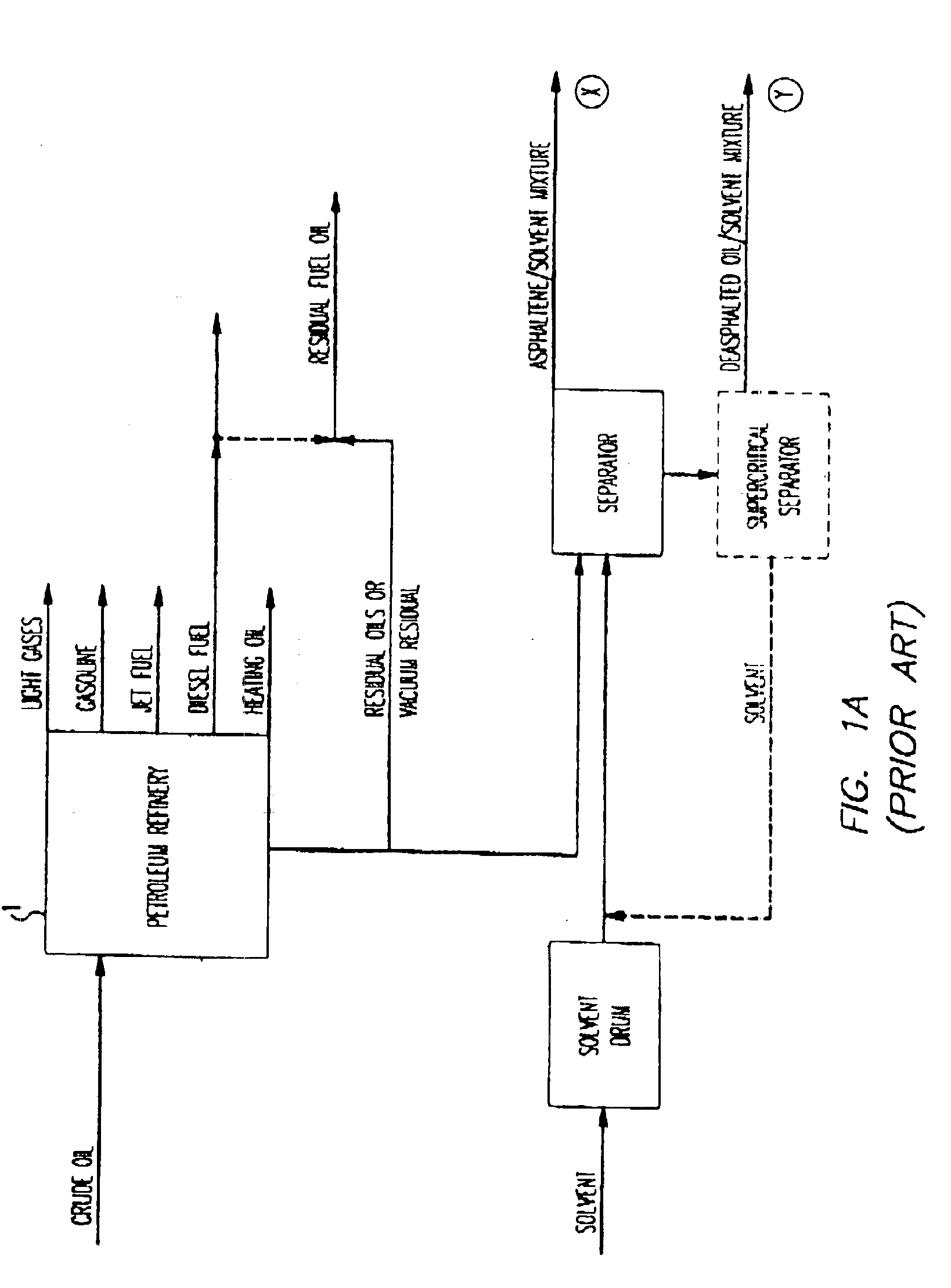

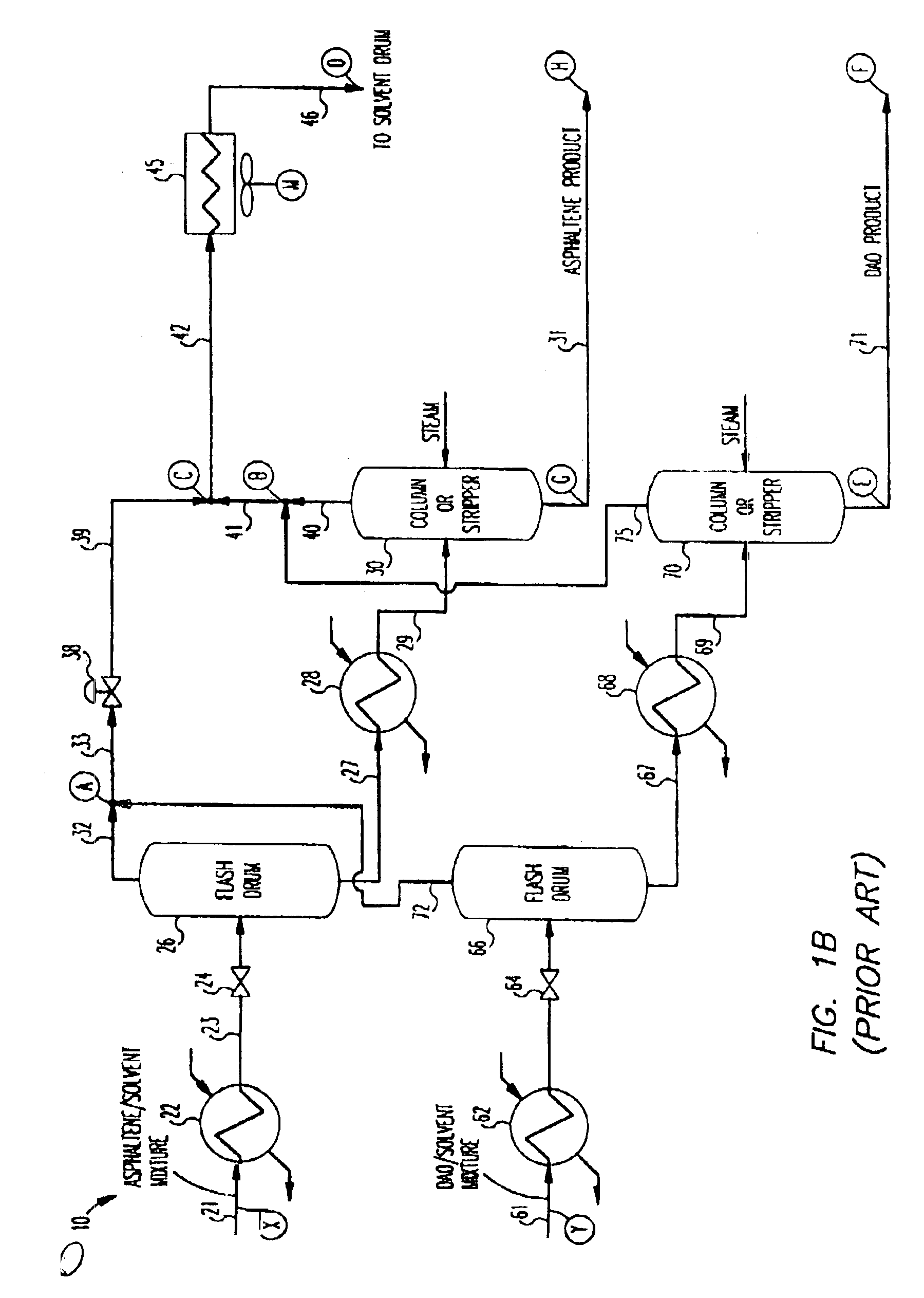

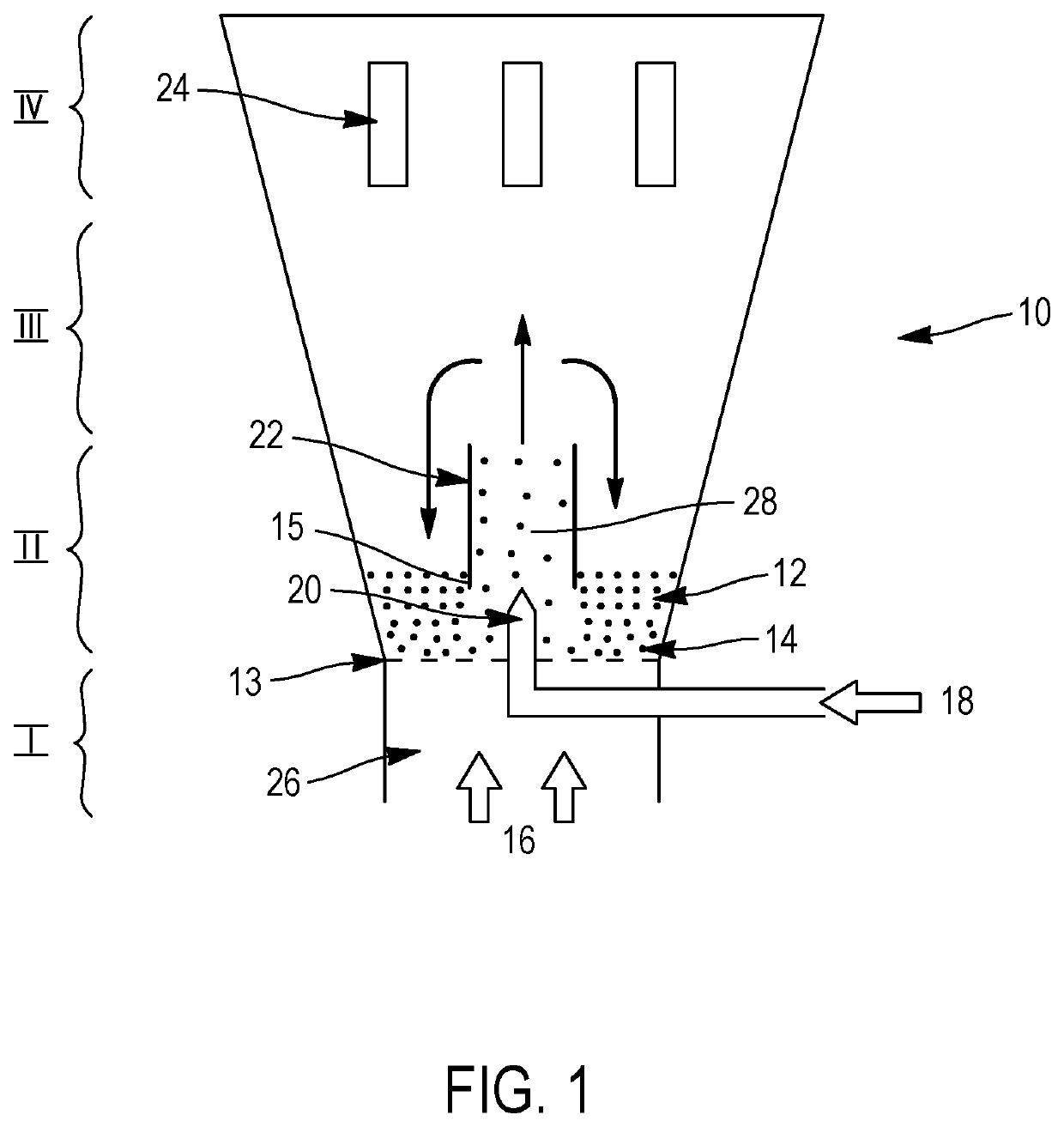

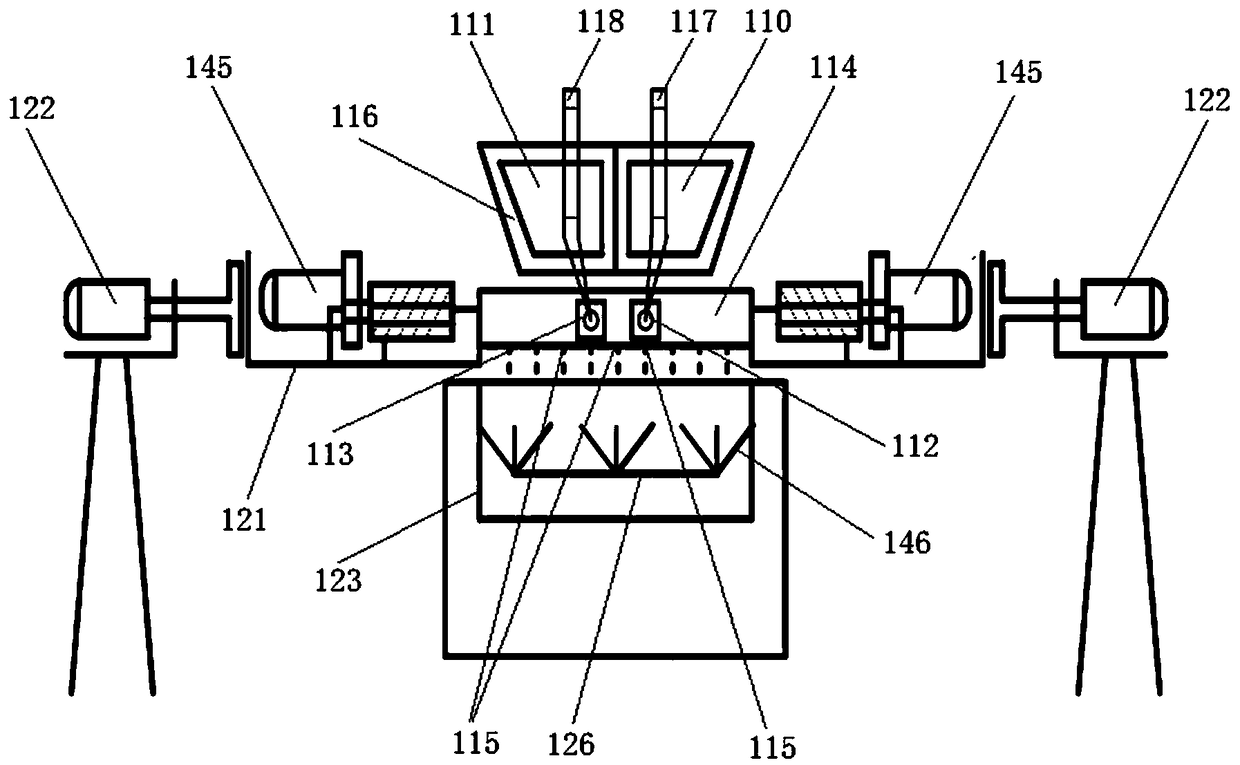

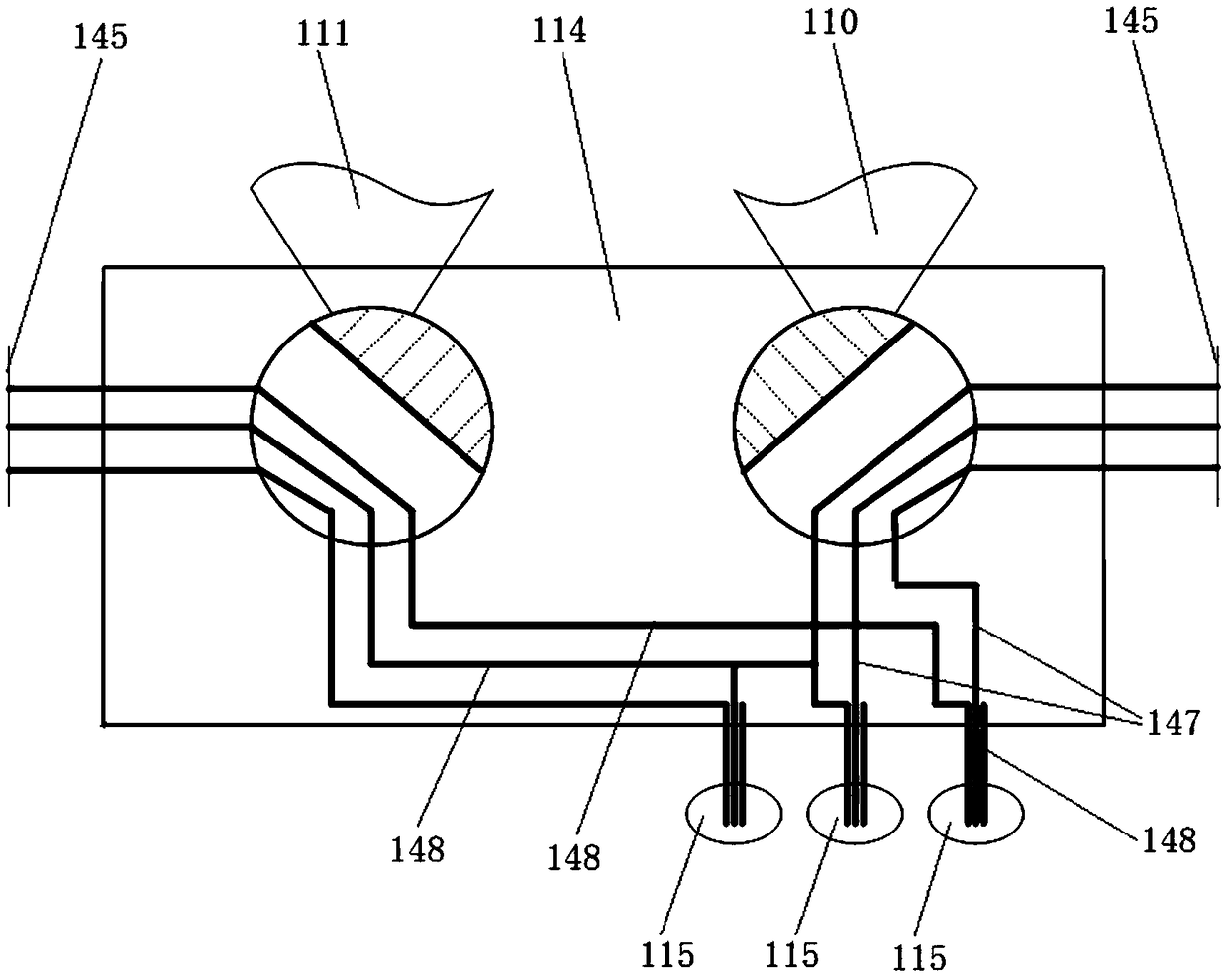

Deep separation method and processing system for the separation of heavy oil through granulation of coupled post-extraction asphalt residue

ActiveUS20070007168A1High yieldSimple processWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by solidifying/disintegratingSolid particleOil phase

The present invention is a separation method and system in which granulation of coupled post-extraction asphalt residue is used to achieve deep separation of heavy oil. A dispersion solvent is introduced into the asphalt phase after separation by solvent extraction and the asphalt phase undergoes rapid phase change in a gas-solid separator and is dispersed into solid particles while the solvent vaporizes, resulting in low temperature separation of asphalt and solvent with adjustable size of the asphalt particles. The separation method of this invention also includes a three-stage separation of heavy oil feedstock, in which the deasphalted oil phase separated from heavy oil is treated with supercritical solvent and results in the further separation of the resin portion of the deasphalted oil, maximizing the yield and quality of the deasphalted oil. The processes and systems in this invention use atmospheric pressure and a low temperature gas-solid separator instead of a high temperature and high pressure furnace and do not require the feed pre-heating or heat exchange equipment at the inlet of resin separator column, resulting in a simplified process flow and reduced investment.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

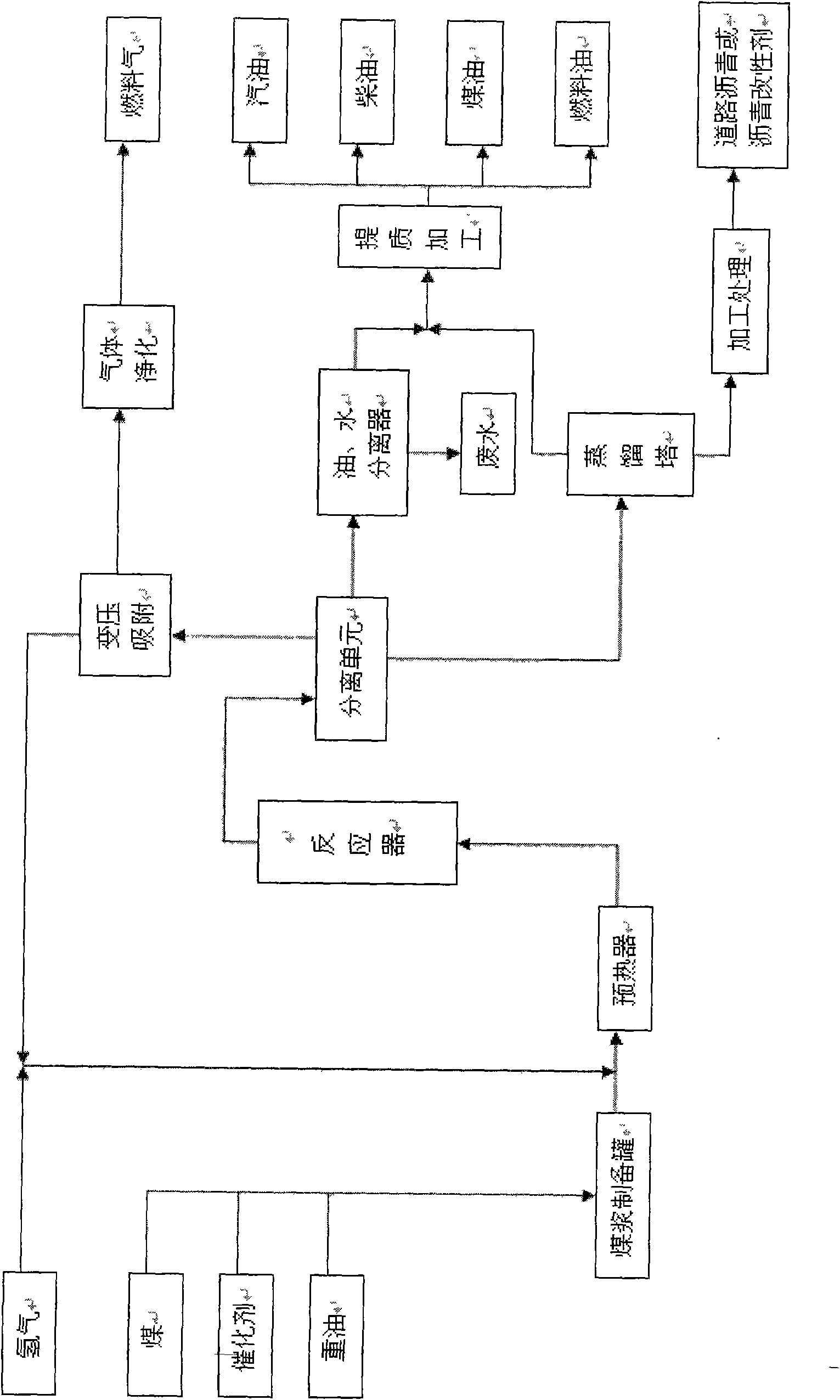

Method for simultaneously producing liquid fuel and asphalt paving materials by coprocessing coal and heavy oil

InactiveCN101649220AReduce investmentLow costHydrocarbon distillationGaseous fuelsKeroseneDistillation

The invention relates to a method for simultaneously producing liquid fuel and asphalt paving materials by coprocessing coal and heavy oil. The method comprises the following steps: mixing coal dust, catalyst and heavy oil to prepare pulp; preheating and entering a reactor to carry out reaction; separating reaction products to separate gaseous substance, light oil, water and heavy mixture; extracting hydrogen from the separated gaseous substance through pressure swing adsorption; returning the purified hydrogen to the reactor to be used circularly, and using the remaining gas as fuel after purification; carrying out oil-water separation on the separated light oil and water to obtain the light oil and the water; leading the heavy mixture into a distilling tower to obtain coarse oil and tower bottom product through distillation separation; mixing the coarse oil and the light oil to obtain liquid fuels of gasoline, kerosene, diesel fuel, fuel oil, and the like through upgrading process; and processing the tower bottom product to get the asphalt paving materials. The invention has the advantage that under the moderate process condition, the liquid fuel and asphalt paving materials canbe produced simultaneously.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

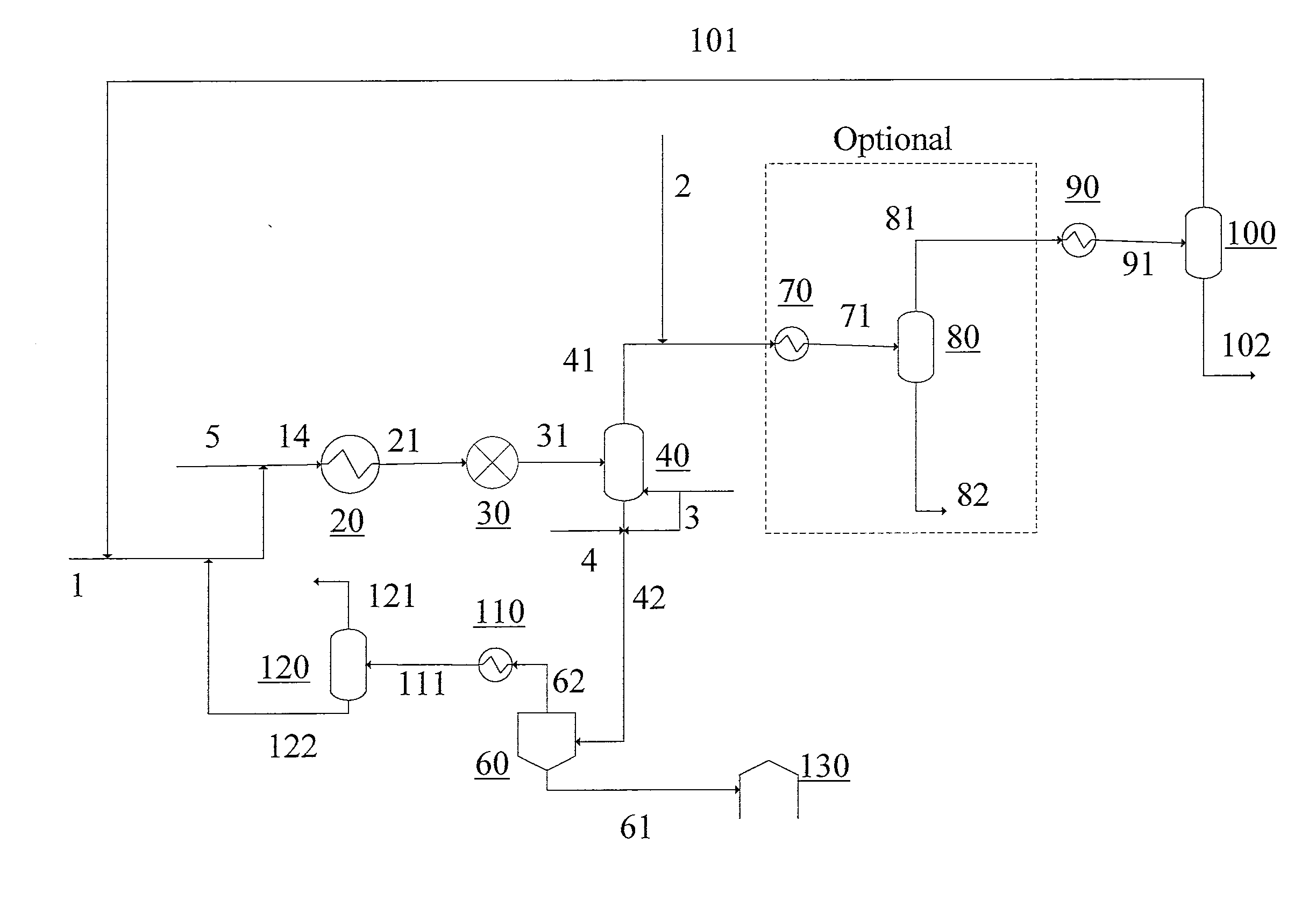

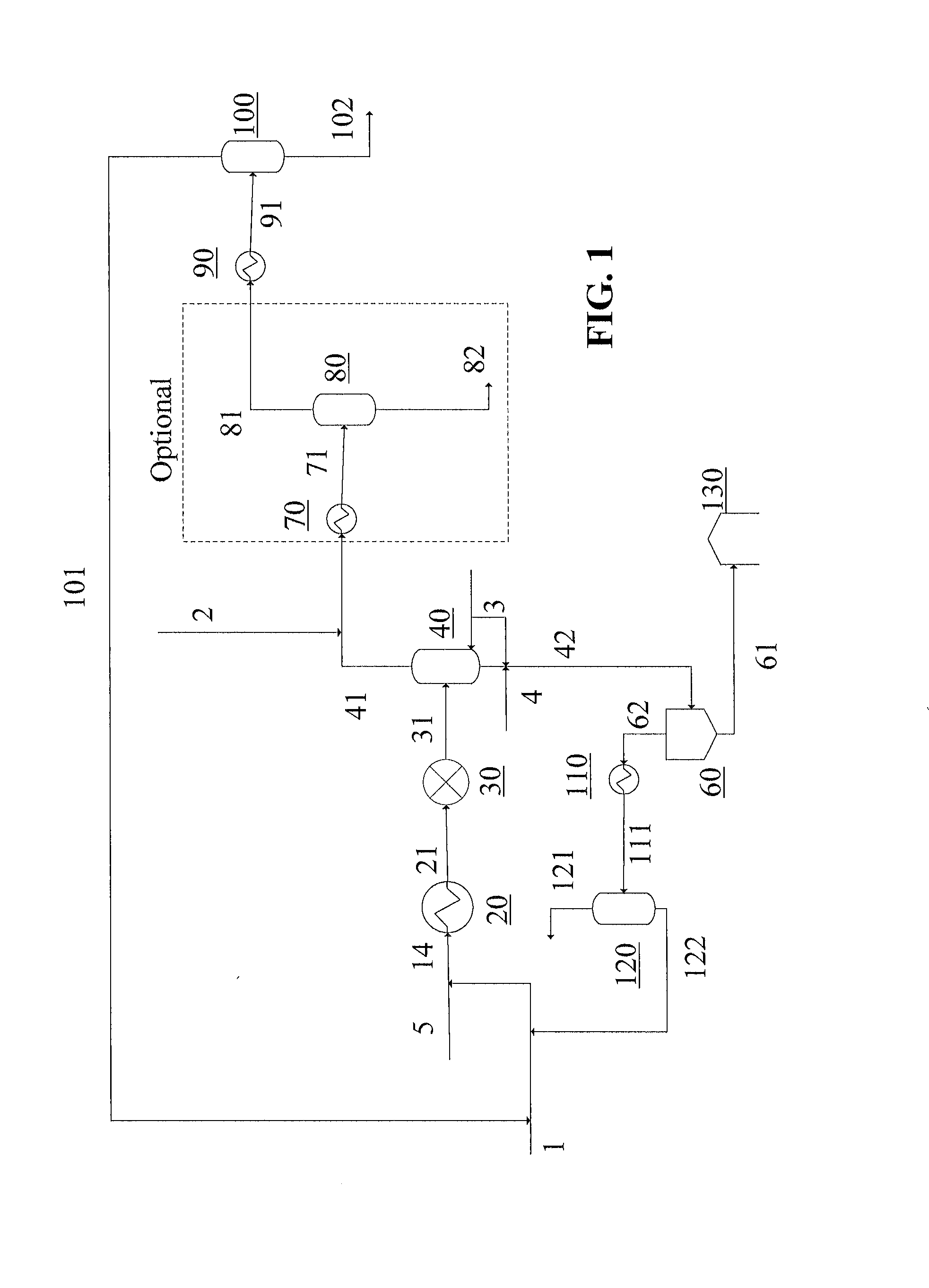

Deep separation method and processing system for the separation of heavy oil through granulation of coupled post-extraction asphalt residue

ActiveUS7597794B2High yieldSimple processWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by solidifying/disintegratingSolid particleOil phase

The present invention is a separation method and system in which granulation of coupled post-extraction asphalt residue is used to achieve deep separation of heavy oil. A dispersion solvent is introduced into the asphalt phase after separation by solvent extraction and the asphalt phase undergoes rapid phase change in a gas-solid separator and is dispersed into solid particles while the solvent vaporizes, resulting in low temperature separation of asphalt and solvent with adjustable size of the asphalt particles. The separation method of this invention also includes a three-stage separation of heavy oil feedstock, in which the deasphalted oil phase separated from heavy oil is treated with supercritical solvent and results in the further separation of the resin portion of the deasphalted oil, maximizing the yield and quality of the deasphalted oil. The processes and systems in this invention use atmospheric pressure and a low temperature gas-solid separator instead of a high temperature and high pressure furnace and do not require the feed pre-heating or heat exchange equipment at the inlet of resin separator column, resulting in a simplified process flow and reduced investment.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Hard asphalt granulation method and device thereof

InactiveCN102876345AImprove adaptabilityAdaptableWorking-up pitch/asphalt/bitumen by solidifying/disintegratingEngineeringAsphalt

The invention relates to a hard asphalt granulation method and a device thereof. The method comprises the following steps: heating hard asphalt to a molten state, delivering the hard asphalt in the molten state to a distributing device capable of adjusting fluid falling speed, evenly distributing the hard asphalt onto a rotary steel belt in a dropwise state, and carrying out forced cooling on the steel belt with a cooling water spraying system arranged below the rotary steel belt, so that cured asphalt granules are separated and fall off from the steel belt at the rotary end of the rotary steel belt. The method has the advantages of simple technical process, low pressure grade, low operating cost, high production efficiency and small pollution, can conveniently adjust the size of the hard asphalt granules, and has strong adaptability to hard asphalts with different softening points (viscosities). The produced asphalt granules have the advantages of uniform size and beautiful appearance, do not directly contact the cooling medium, and can obviously reduce the smoke dust and water pollution in the production process.

Owner:CHINA PETROLEUM & CHEM CORP

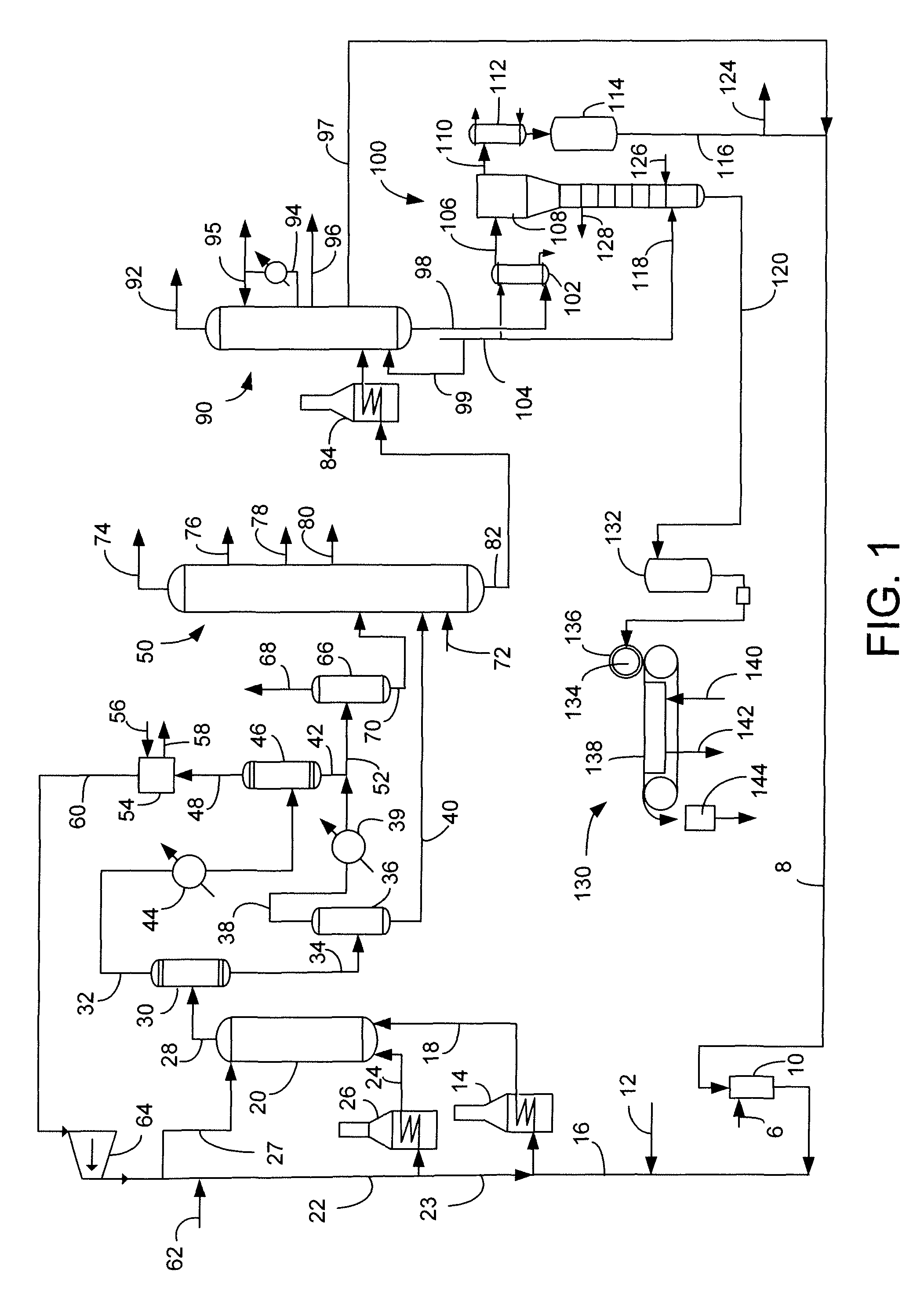

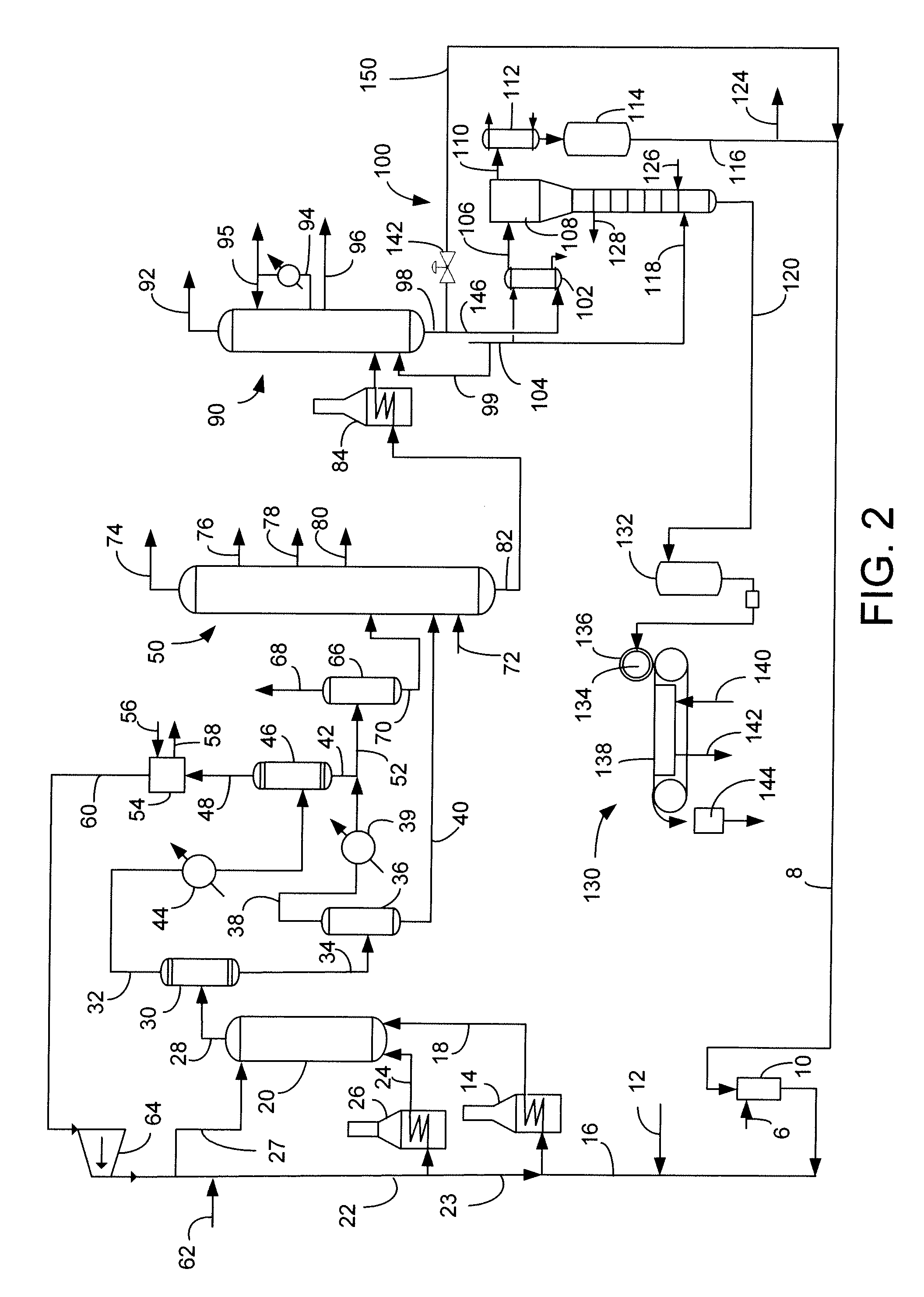

Process for separating pitch from slurry hydrocracked vacuum gas oil

InactiveUS8540870B2Easy to manageLess stickyWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by solidifying/disintegratingParticulatesSlurry

A process is disclosed for converting heavy hydrocarbon feed into lighter hydrocarbon products. The heavy hydrocarbon feed is slurried with a particulate solid material to form a heavy hydrocarbon slurry and hydrocracked in a slurry hydrocracking unit to produce vacuum gas oil (VGO) and pitch. A first vacuum column separates VGO from pitch, and a second vacuum column further separates VGO from pitch. As much as 15 wt-% of VGO can be recovered by the second vacuum column and recycled to the slurry hydrocracking unit. A pitch composition is obtained which can be made into particles and transported without sticking together.

Owner:UOP LLC

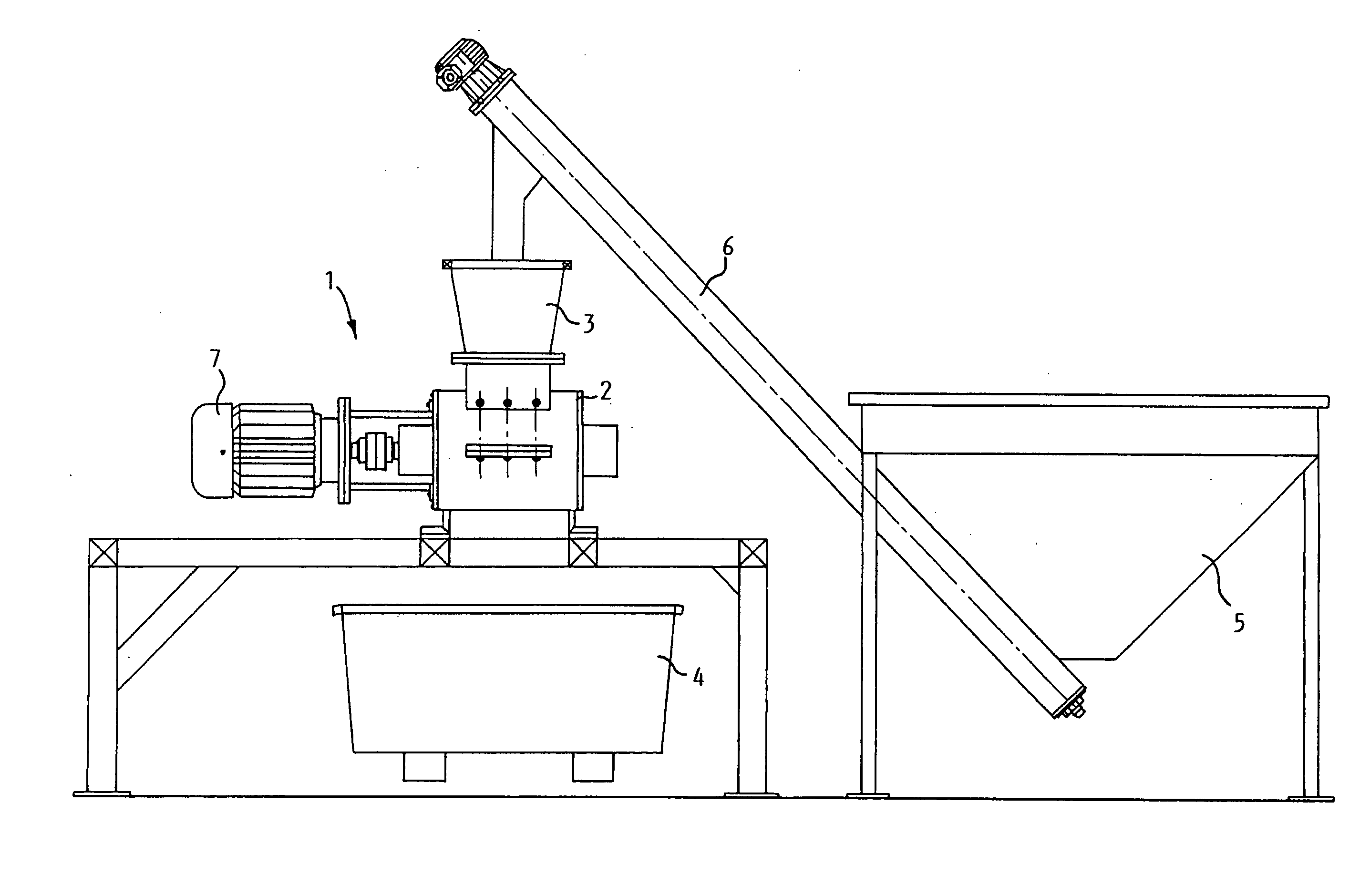

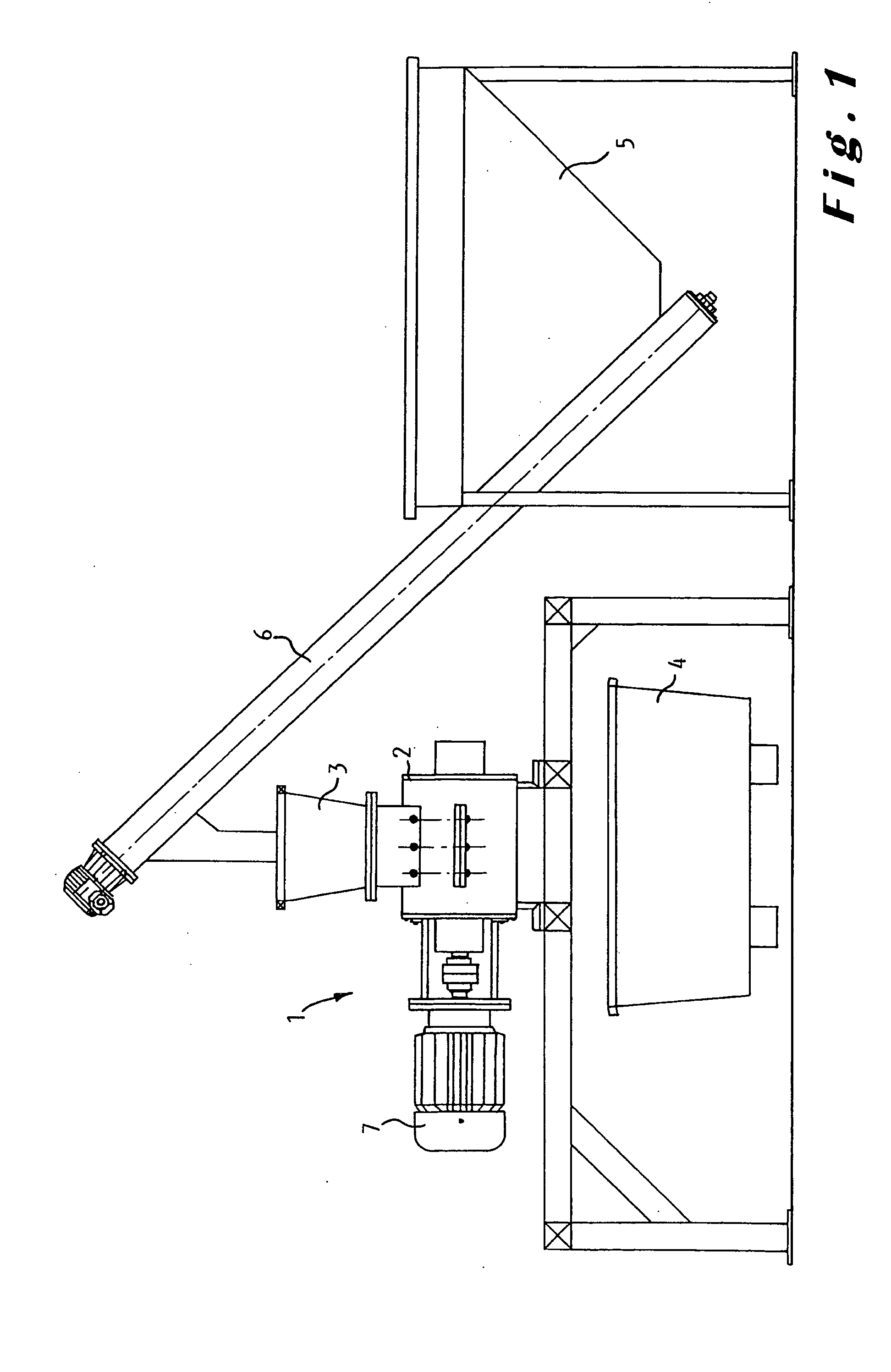

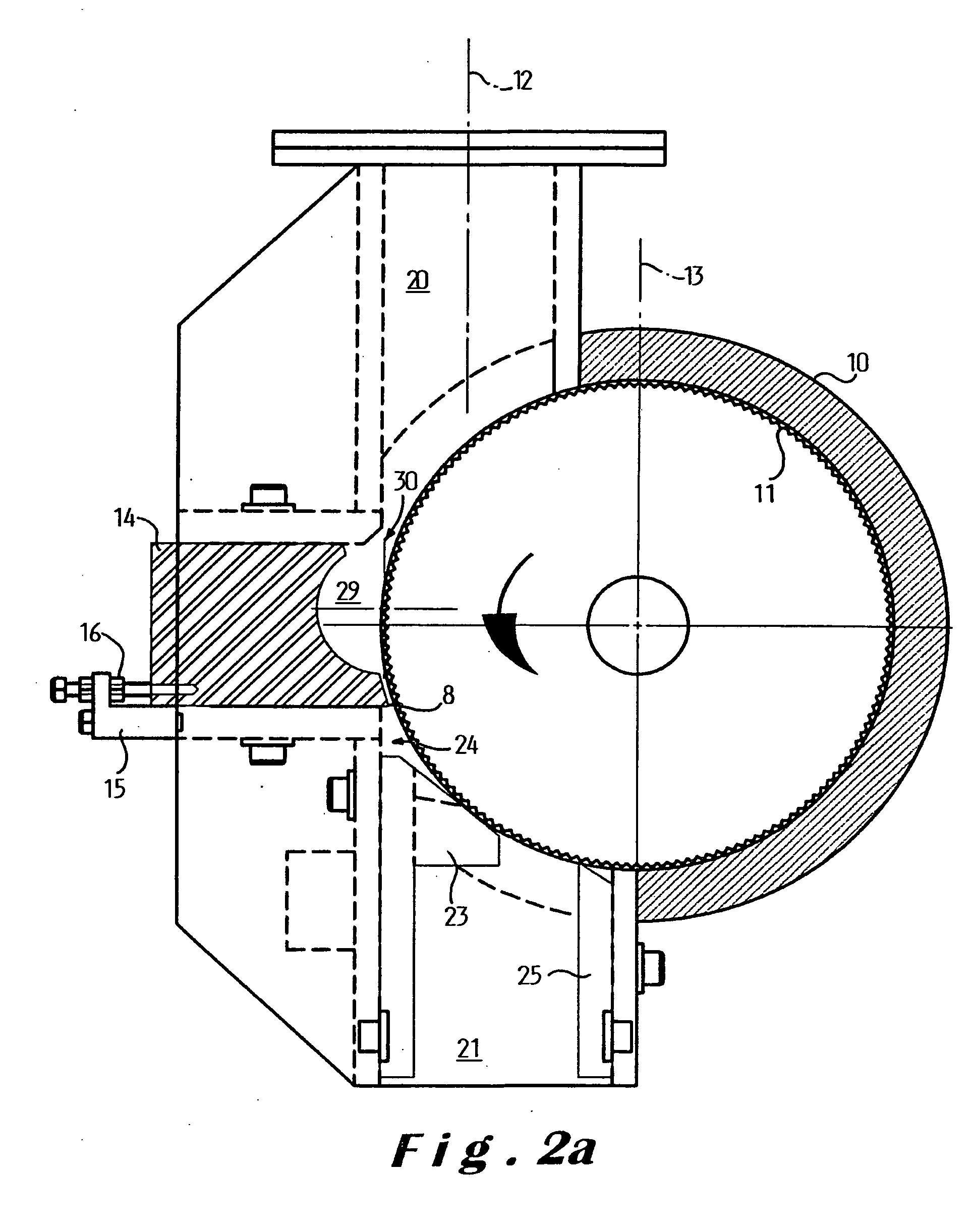

Unit and method for recycling a bituminous membrane

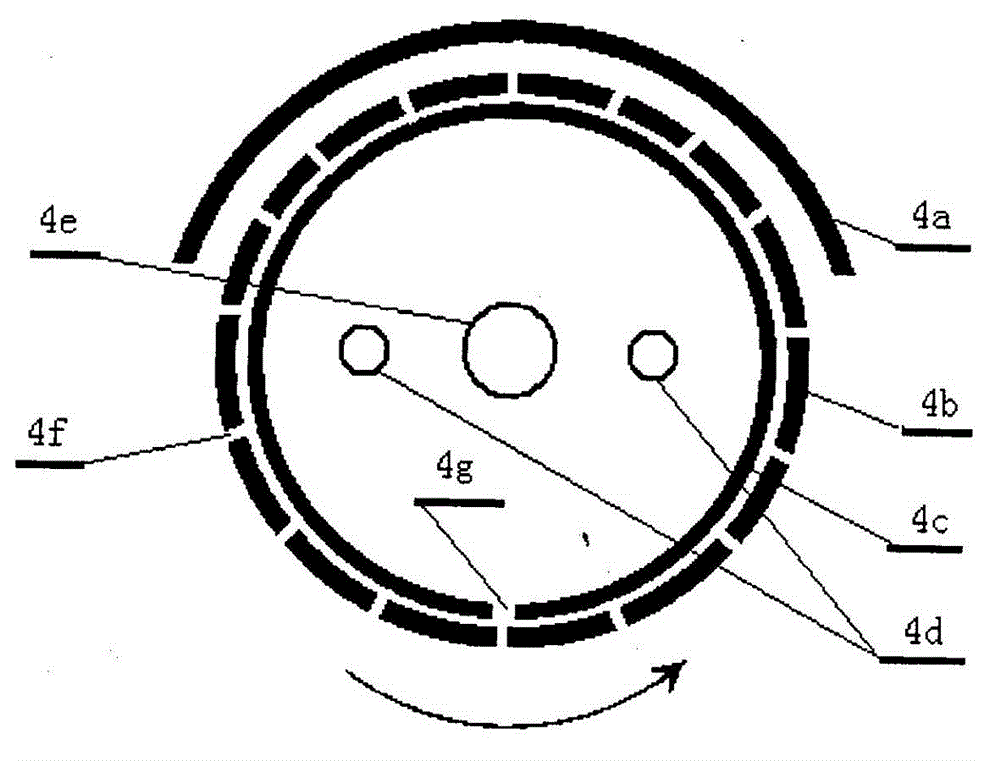

ActiveUS20050263625A1Simpler and less-expensive constructionEasy to usePlastic recyclingWorking-up pitch/asphalt/bitumen by solidifying/disintegratingMembrane methodTrituration

Method and unit for recycling a bituminous membrane provided with at least one reinforcement, which membrane is reduced to pieces which are introduced into a recycling unit, provided with a first rotor, housed in a first stator, and where they are heated and ground, said pieces being conveyed into a chamber, delimited by an external wall of the first rotor and a recess arranged in a counter-element mounted on the stator, where they are subjected to a trituration, the pieces thus triturated then being discharged from the chamber by flowing along said external wall of the rotor.

Owner:IMPERBEL

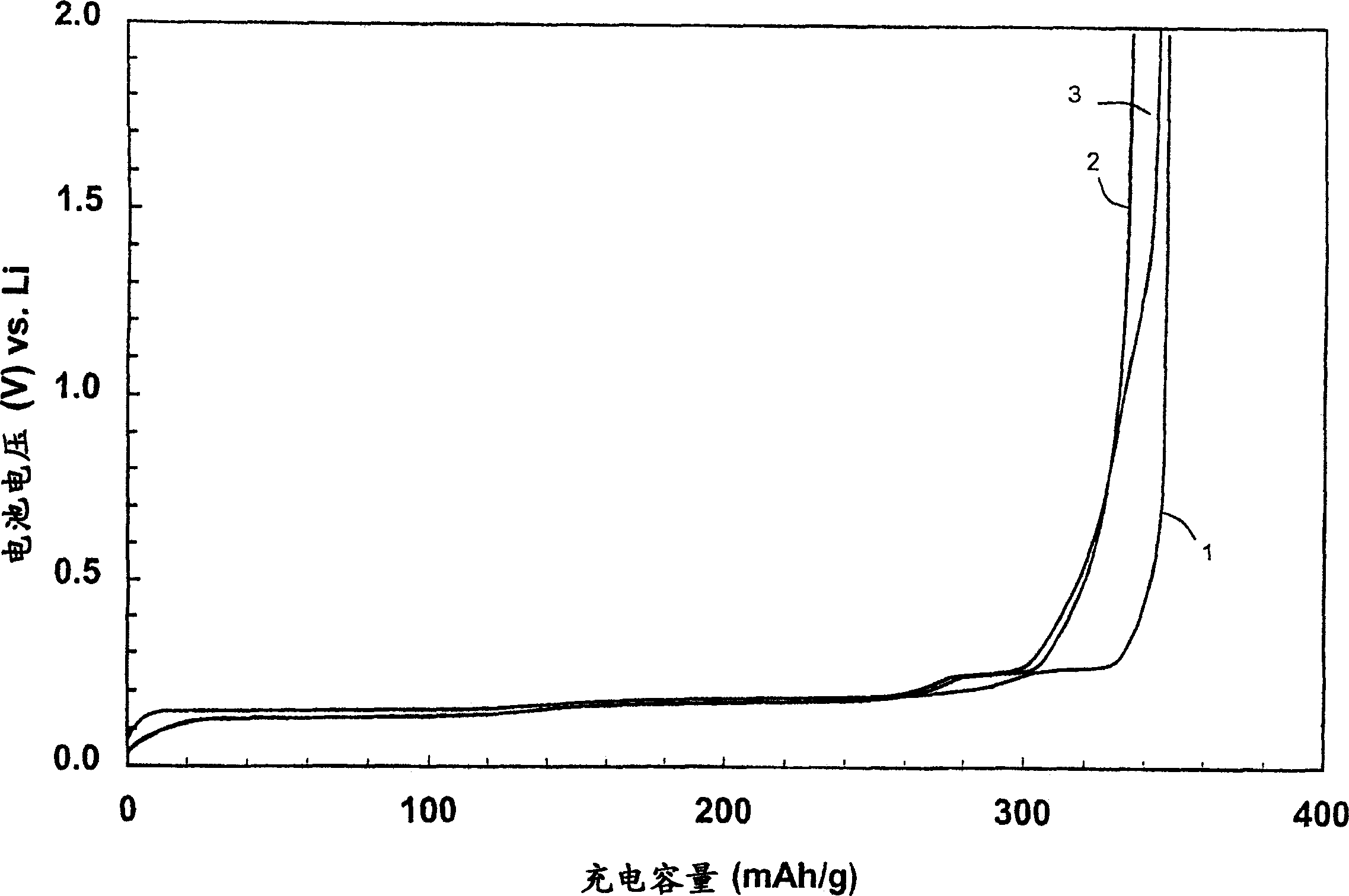

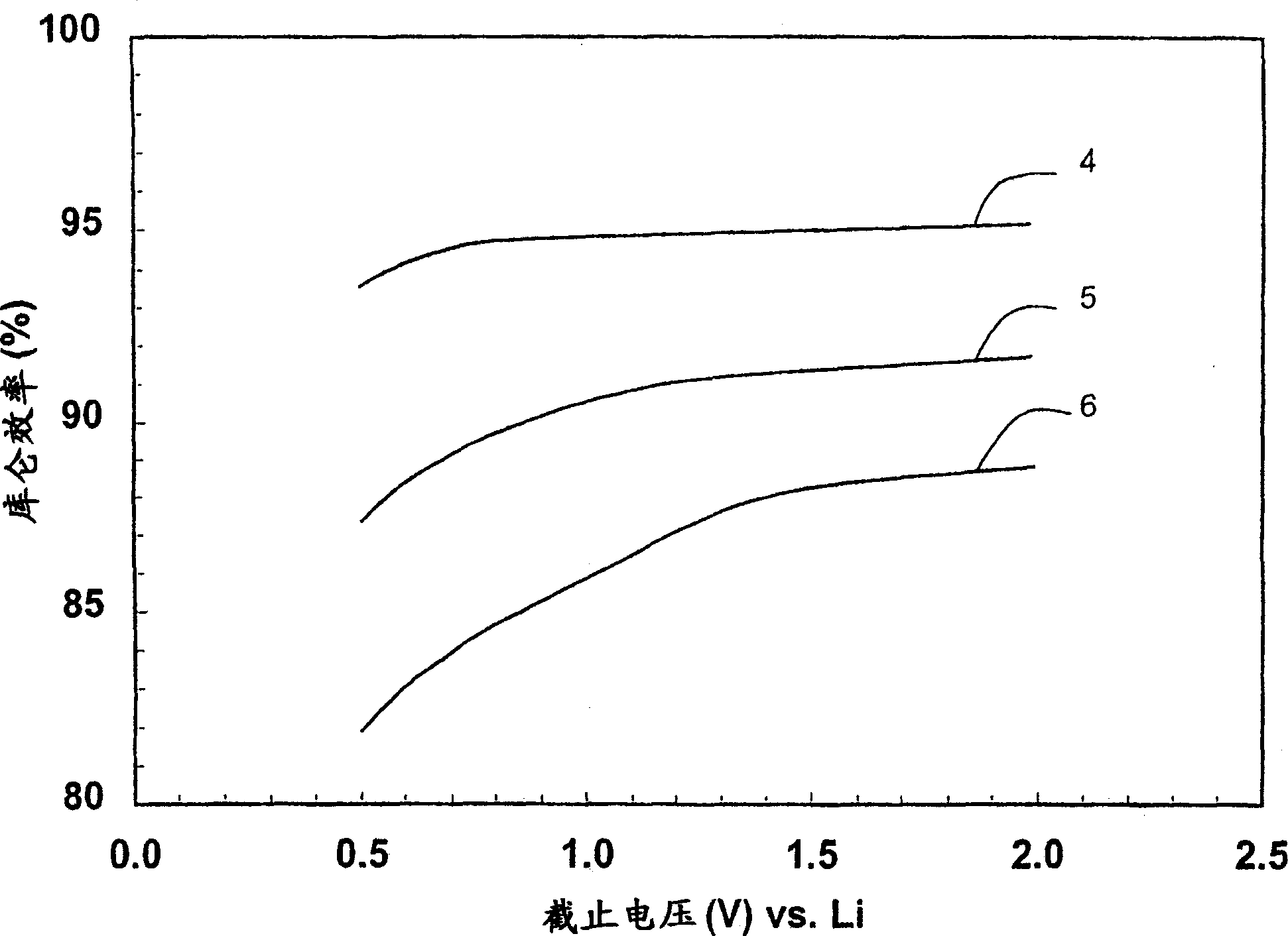

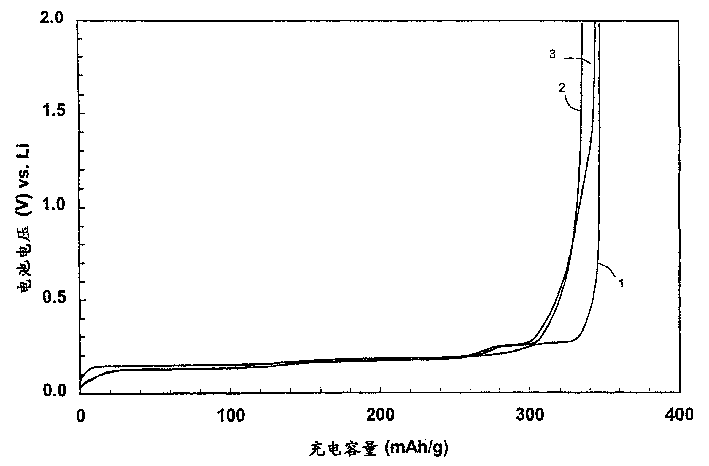

Processes for producing coke, artificial graphite and carbon material for negative electrode of non-aqueous solvent type secondary battery and pitch composition used therefor

InactiveUS7008526B2Improve productivityHigh degree of graphitizationCell electrodesDirect heating destructive distillationHigh densityGraphite

When a pitch composition prepared by mixing 100 parts by weight of mesophase pitch with 10 to 1,000 parts by weight of coal tar pitch, is heat-treated at a temperature of 500° C. or higher, it is possible to produce a high-density coke at a high yield while avoiding the foaming of the mesophase pitch. In addition, when the coke is graphitized at a temperature of 2,000° C. or higher, it is possible to obtain an artificial graphite having a high graphitization degree. Further, when the coke is first pulverized and then graphitized at a temperature of 2,000° C. or higher, it is possible to obtain a high-crystallinity graphite powder which can be suitably used as a carbon material for a negative electrode of non-aqueous solvent type secondary battery having a high discharge capacity and a high charge-discharge efficiency.

Owner:MITSUBISHI GAS CHEM CO INC

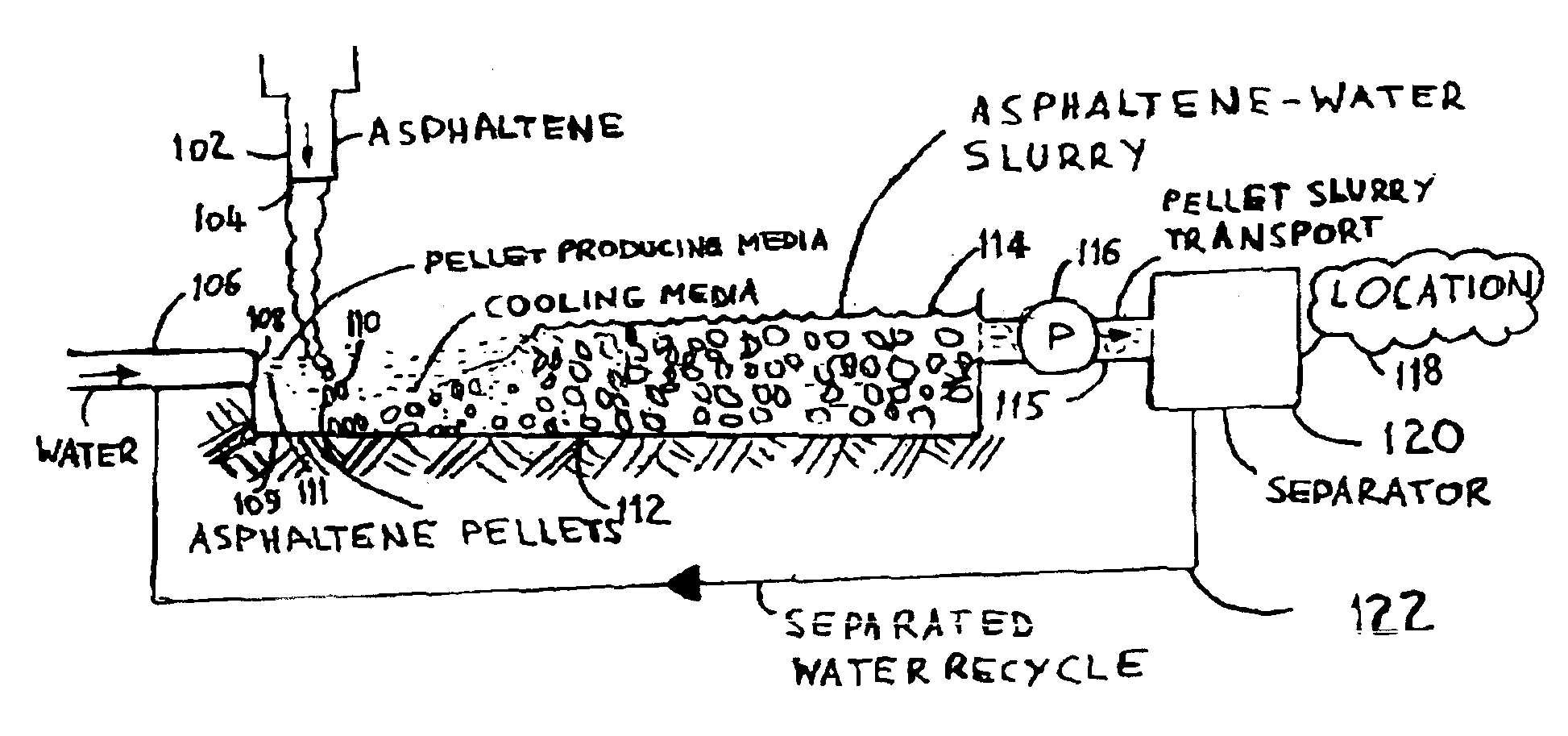

Method of and apparatus for producing pellets from heavy hydrocarbon liquid

InactiveUS7101499B1Granulation by liquid drop formationAuxillary shaping apparatusLiquid stateLiquid water

Apparatus for producing pellets from hot heavy hydrocarbon or asphaltene, in accordance with the present invention, includes flow means that supplies the hot heavy hydrocarbon or asphaltene through a conduit to its outlet; and pellet producing medium or means that breaks up the liquid stream of the hot asphaltene flowing out of the outlet of the conduit and produces pellets of asphaltene. Furthermore, the apparatus includes a reservoir or container that collects the pellets of heavy hydrocarbon or asphaltene together with some fluid producing a slurry; and transporting means that transports the slurry to the required location. Preferably, the fluid is liquid water. In addition, the pellet producing medium preferably is liquid water.

Owner:ORMAT IND LTD

High-softening-point asphalt as well as preparation method and application thereof

ActiveCN104946289AReduce manufacturing costNarrow family composition distributionWorking-up pitch/asphalt/bitumen by chemical meansWorking-up pitch/asphalt/bitumen by solidifying/disintegratingFiberCarbon fibers

The invention discloses a high-softening-point asphalt as well as a preparation method and an application thereof. Medium-temperature asphalt is adopted as a raw material to prepare high-softening-point asphalt by adopting an air oxidation method; then partial light components in the high-softening-point asphalt are removed by adopting a vacuumizing method, and finally the high-softening-point asphalt suitable for preparing foam carbon or spinning asphalt can be produced. The softening point of the high-softening-point asphalt is 200 to 280 DEG C, the content of an n-heptane soluble substance (HS) is less than 10 percent, the content of a methylbenzene soluble substance (TS) is less than 20 percent, the content of methylbenzene insoluble-pyridine soluble sustancce (TI-PS) is 9 to 20 percent, the content of pyridine insoluble-quinoline soluble (PI-QS) is 5 to 15 percent, and the content of quinoline insoluble substance (QI) I 50 to 70 percent. The high-softening-point asphalt is not only rich in raw materials and low in cost, but also narrow in group composition distribution and suitable for being used as a raw material for high-performance foam carbon and carbon fibers.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD +1

Coated carbonaceous particles particularly useful as electrode materials in electrical storage cells, and methods of making the same

InactiveCN1625593AGood fluidity of powderIncrease capacityFinal product manufactureConductive materialStorage cellMaterials science

A method of making coated carbonaceous particles comprising: providing a carbon residue forming material; providing particles of the carbonaceous material; mixing the carbon residue forming material with the particles of the carbonaceous material at an elevated temperature; depositing a coating of carbon residue forming material thereon; and stabilizing the coated particles by subjecting the coated particles to an oxidation reaction. These coated carbon-containing particles are particularly suitable for the production of electrodes in accumulators, especially rechargeable accumulators.

Owner:PYROTECK INC

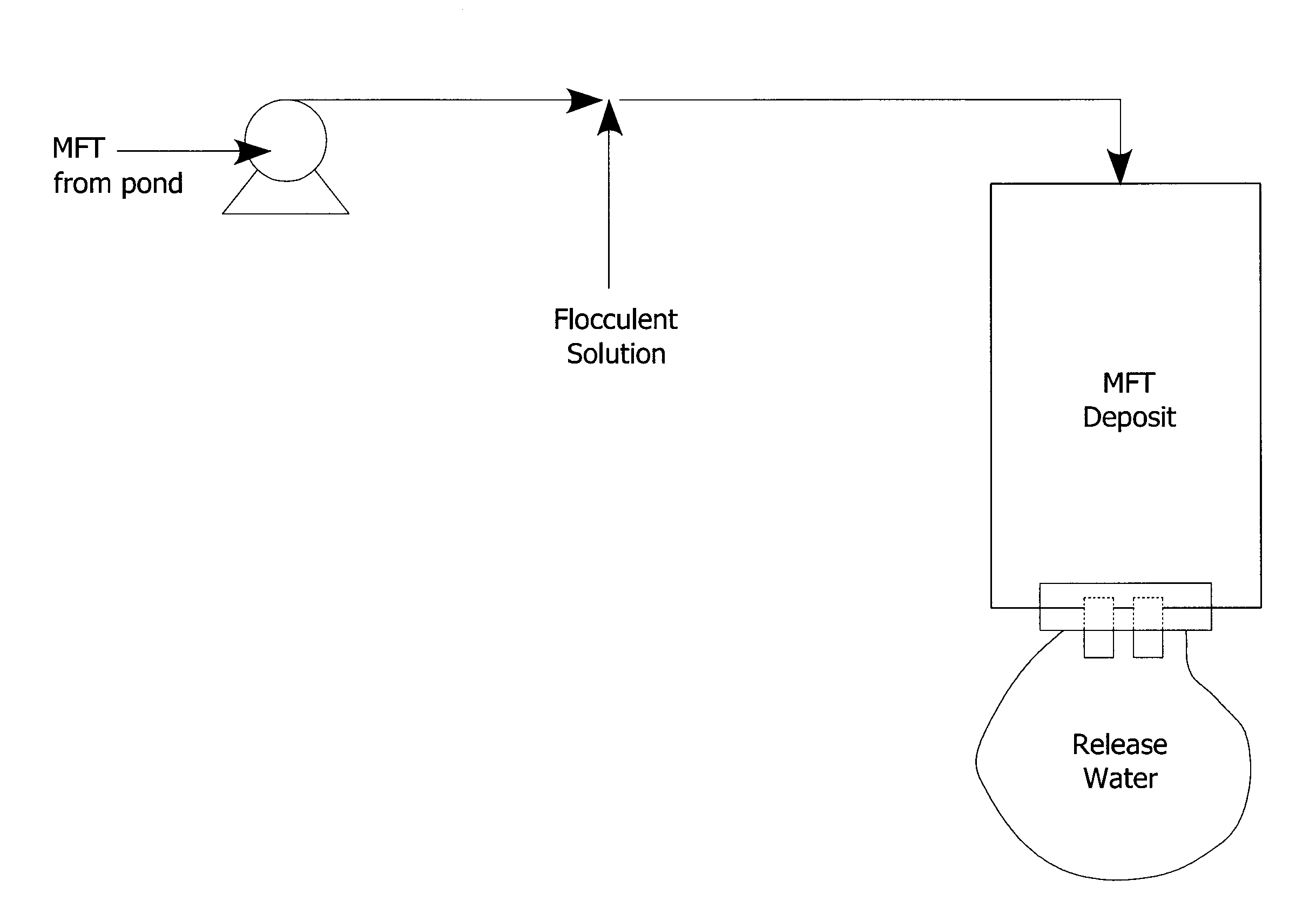

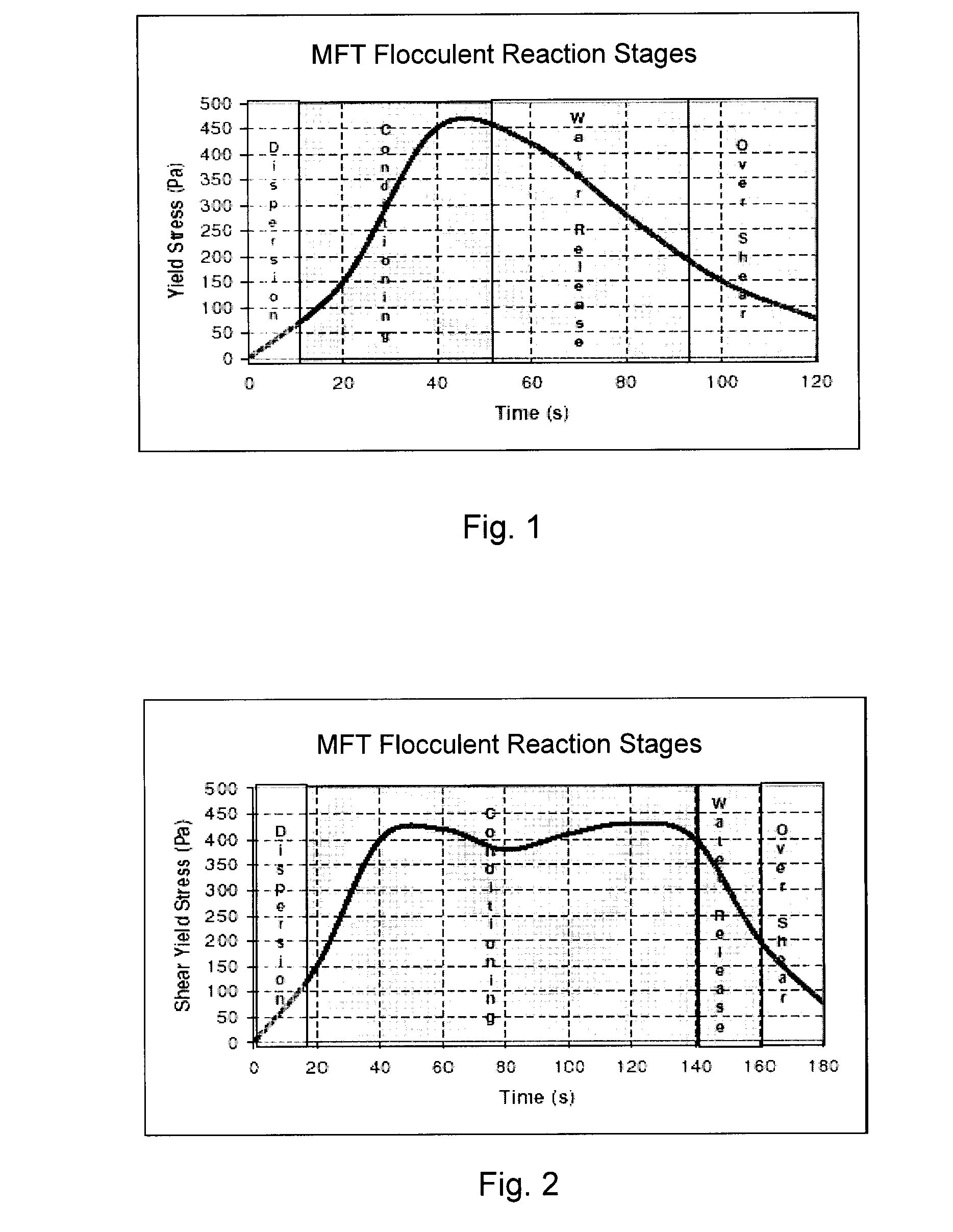

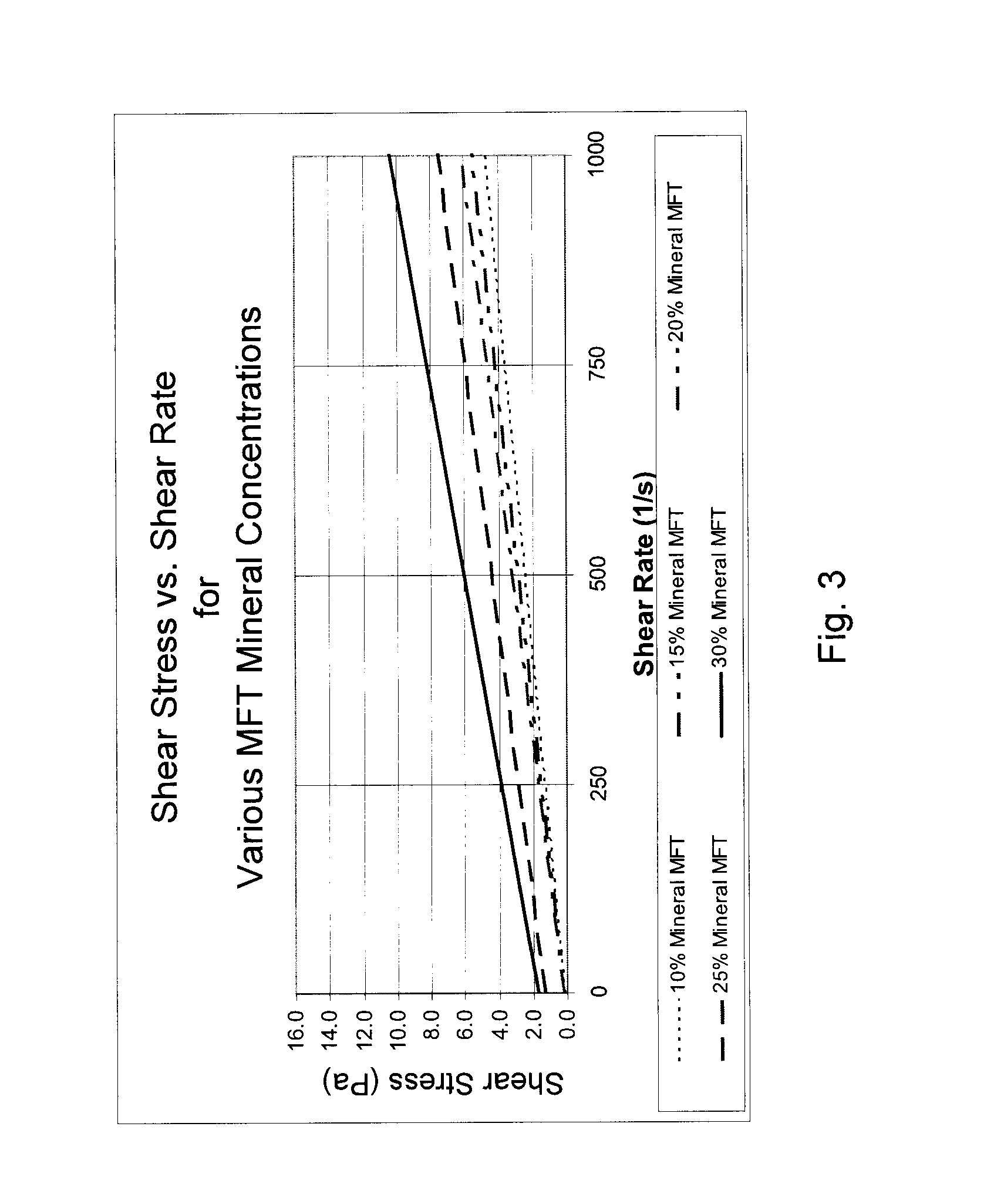

Process for Drying Oil Sand Mature Fine Tailings

ActiveUS20130043165A1Efficient actionSufficient energyDewatering/demulsification with chemical meansSludge treatment by de-watering/drying/thickeningFlocculationReactor system

A process for drying fine tailings is provided. The process, which may use a pipeline reactor system, comprises providing an in-line flow of the fine tailings; continuously introducing a flocculent solution to cause dispersion and commence flocculation of the fine tailings and may comprise rapid turbulent mixing; subjecting the fine tailings to flocculation and water release conditioning in-line to cause formation and rearrangement of floes and increasing the yield shear stress to form flocculated fine tailings while avoiding over-shearing of the flocs; and depositing the fine tailings to allow the release of water, formation of a non-flowing fine tailings deposit and drying of the non-flowing fine tailings deposit. The process enables effective in-line dispersion, flocculation and water release, resulting in reliable deposition and drying of the fine tailings deposit.

Owner:SUNCOR ENERGY INC

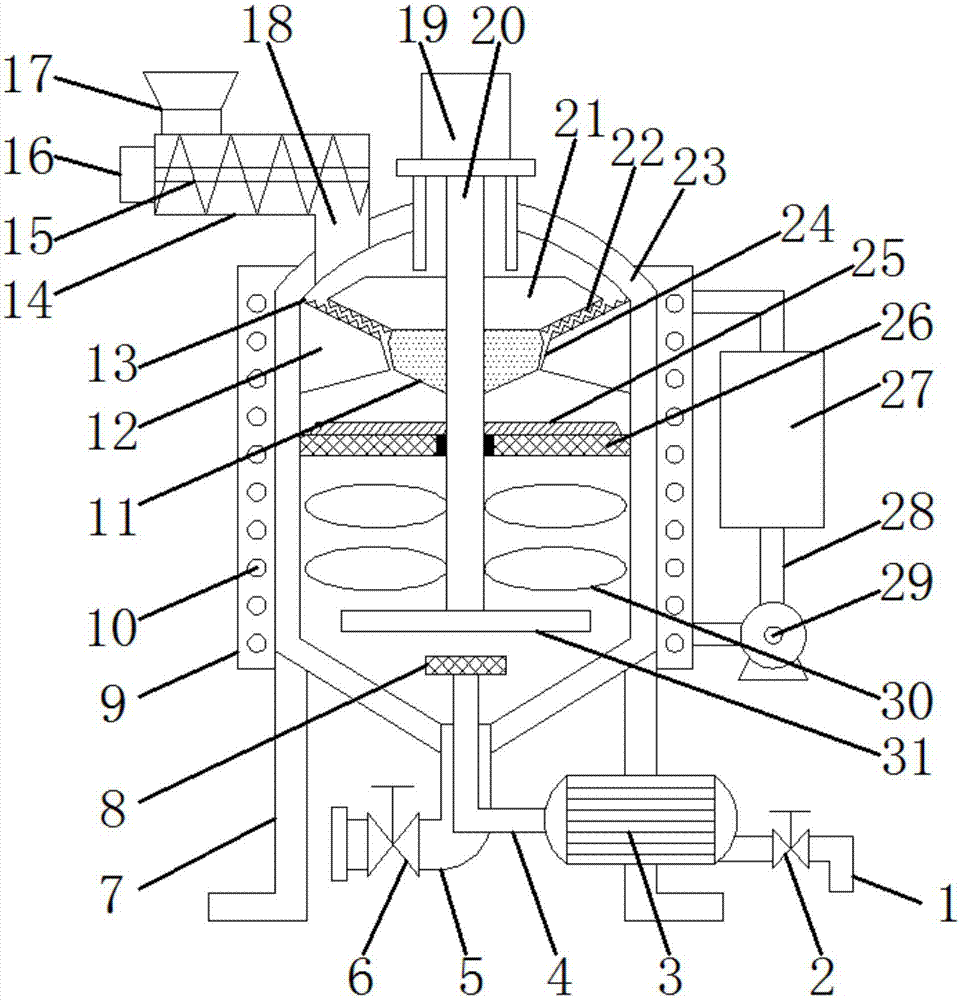

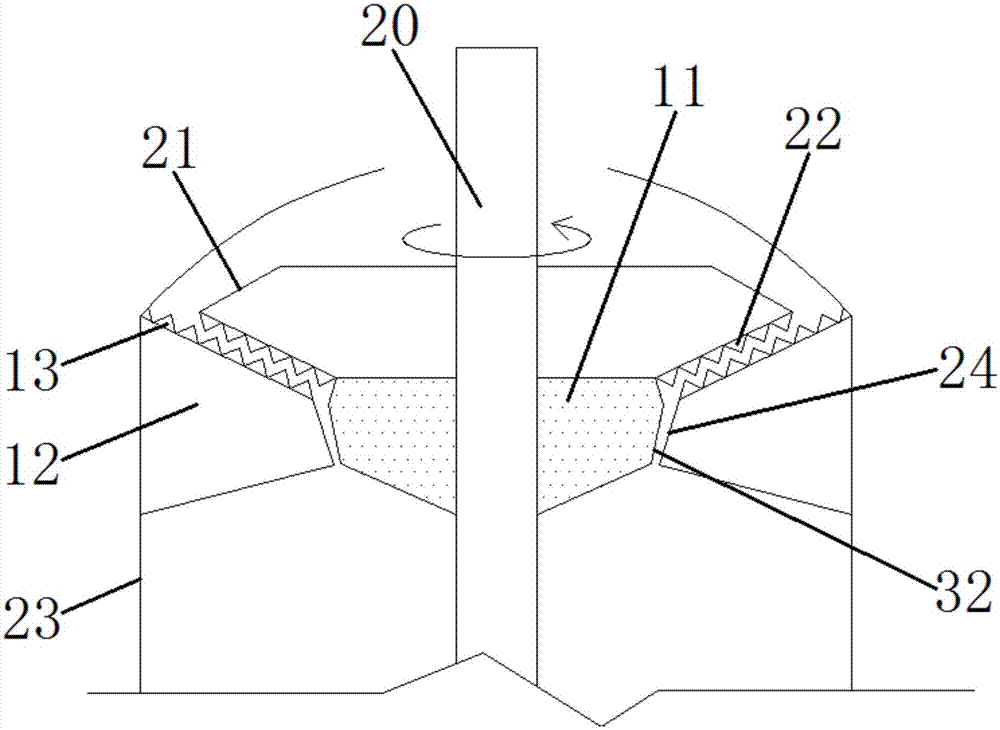

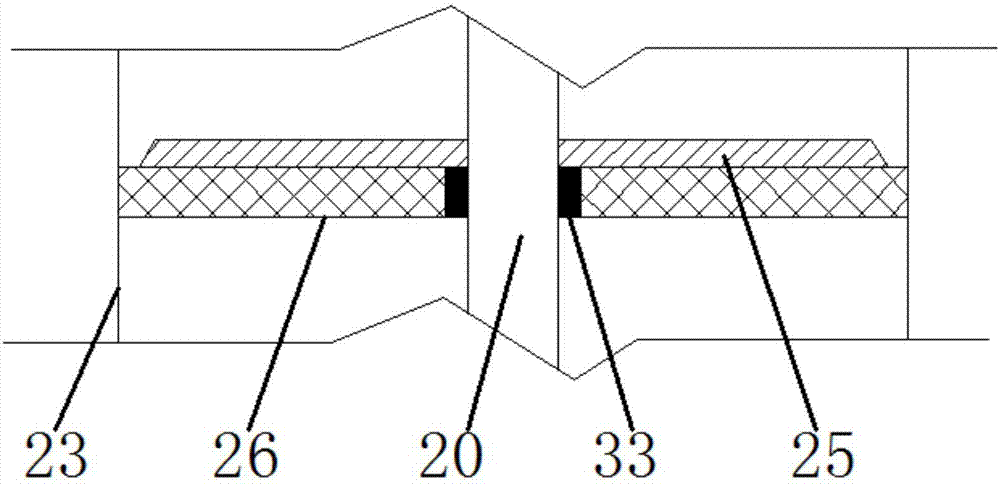

Asphalt crushing and melting equipment for municipal construction

InactiveCN107365596AEasy to crushCrushing and meltingWorking-up pitch/asphalt/bitumen by meltingWorking-up pitch/asphalt/bitumen by solidifying/disintegratingMelting tankCoupling

The invention discloses an asphalt crushing and melting equipment for municipal construction, which comprises a non-melting slag discharge pipe, a heating sleeve, a grinding roller, a fixed breaking hammer and an asphalt melting tank. A support frame is installed at the bottom of the asphalt melting tank. The upper end of the melting tank is connected to the asphalt input pipe; the top of the asphalt melting tank is equipped with a stirring motor, the rotating shaft of the stirring motor is connected to the rotating shaft through a coupling, and the rotating shaft is installed vertically inside the asphalt melting tank, and the top of the rotating shaft is welded Breaker, the bottom side of the rotary breaker is equipped with a number of rotating breaker teeth, and the bottom side of the rotary breaker is equipped with a fixed breaker; it realizes the convenient addition of asphalt blocks and avoids clogging; it realizes grinding treatment and further crushing, which is convenient for asphalt Block melting operation; realize the separate discharge of non-melting slag and asphalt melt, improve the effect and quality of asphalt melting; it is beneficial to the melting of asphalt, the heat transfer oil circulates, and the heating effect is good.

Owner:CHANGSHA KEYUE ENTERPRISE MANAGEMENT CONSULTING CO LTD

Preparation method of bitumen balls

InactiveCN101792678AIncrease useWide variety of sourcesWorking-up pitch/asphalt/bitumen by solidifying/disintegratingAlcoholPolyvinyl alcohol

The invention discloses a preparation method of bitumen balls, which comprises the following steps: 1) putting viscosity depressants into a reaction kettle, heating and melting; under the condition of stirring, adding bitumen with high softening point; under the condition of stirring, heating the reaction kettle to a temperature not lower than the softening point of the bitumen with the high softening point and keeping the temperature for 1-3 hours; and cooling to obtain the prepared bitumen, wherein the softening point of the bitumen with high softening point is 180-300 DEG C; and 2) heating the prepared bitumen to 90-180DEG C, and enabling the bitumen has mobility, in the state of heat preservation, adding the prepared bitumen below the suspending medium liquid level of which the temperature is 80-90 DEG C, keeping for 1-10min at the temperature of 80-90 DEG C, and cooling to obtain the bitumen balls, wherein the suspending medium is polyving alcohol aqueous solution. The method of the invention has the characteristics of full utilization of raw materials of bitumen, reduced waste of raw materials, simple preparation process, and low production cost; and the bitumen ball prepared by the method is more uniform, and has smoother surface, thus avoiding the crash and adhesion of bitumen balls.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Enhanced methods for solvent deasphalting of hydrocarbons

InactiveUS20130098735A1Enhanced mass transferImprove reliabilityThermal non-catalytic crackingWorking-up pitch/asphalt/bitumen by selective extractionOperational costsCombined use

Improvements to open-art Solvent Deasphalting (SDA) processes have been developed to reduce capital and operating costs for processing hydrocarbon streams are provided whereby open art SDA scheme is modified to include appropriately placed mixing-enabled precipitators (MEP's) to reduce solvent use requirements in an asphaltene separation step and to increase overall reliability for SDA processes, particularly suitable for Canadian Bitumen. When integrated with a mild thermal cracker, the improved SDA configuration further improves crude yield to be pipeline-ready without additional diluent and for use to debottleneck existing facilities such as residue hydrocrackers and coking units.

Owner:MEG ENERGY CORP

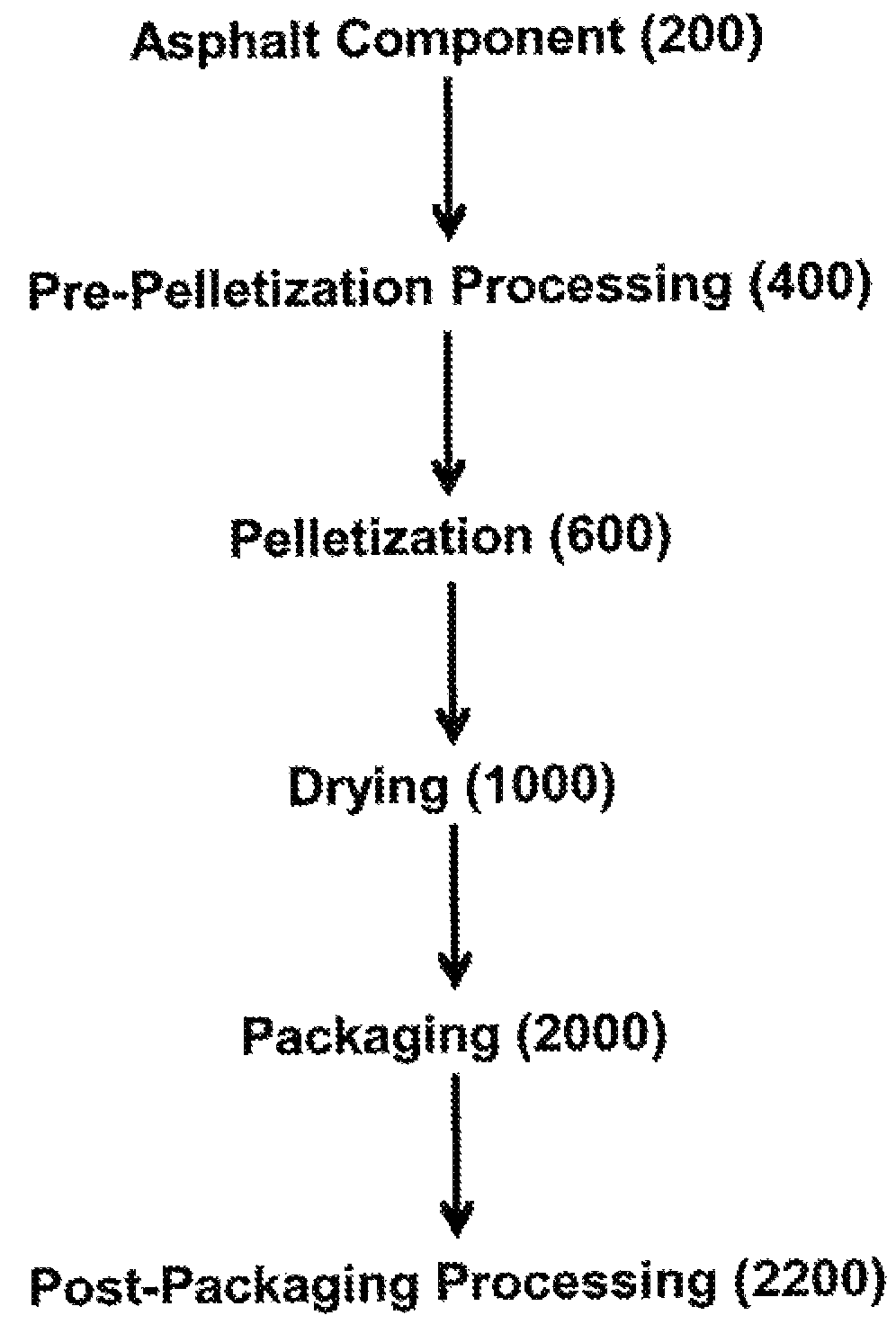

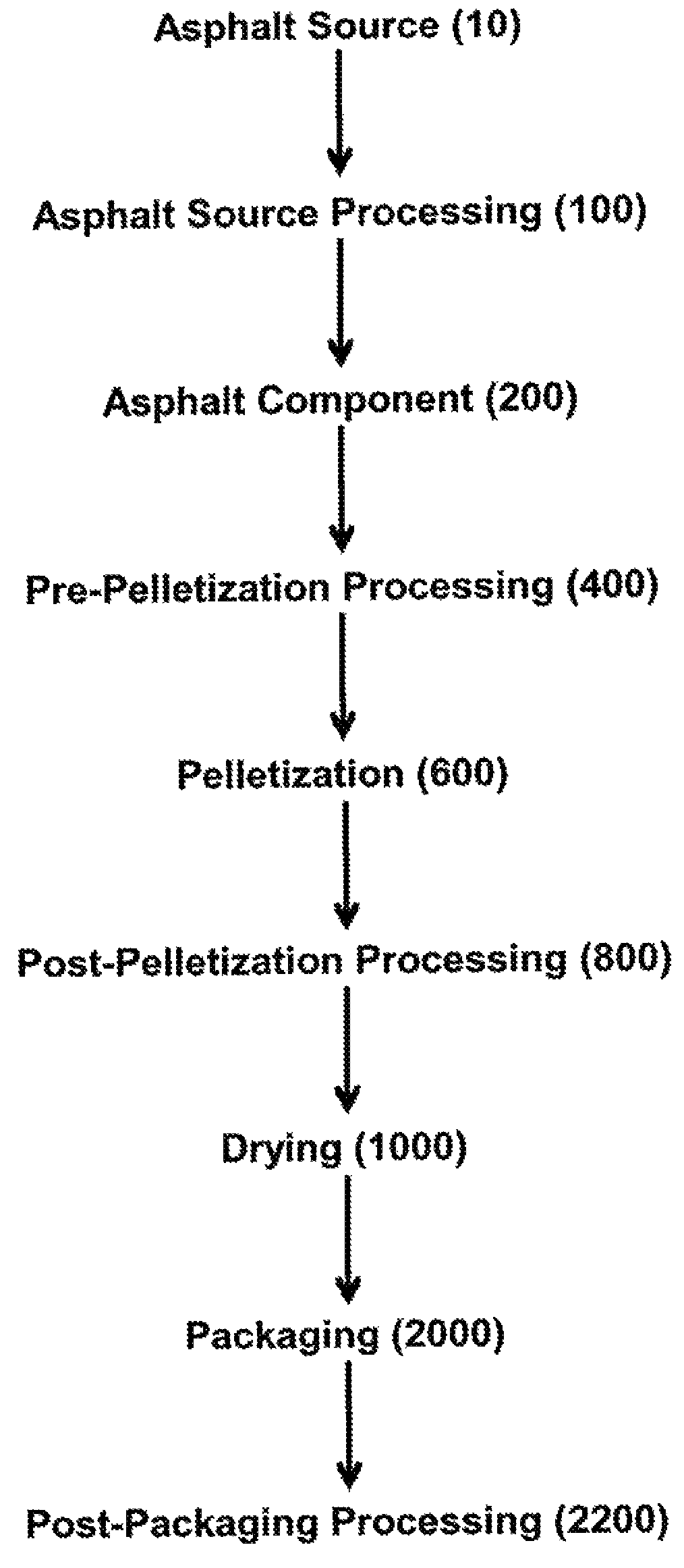

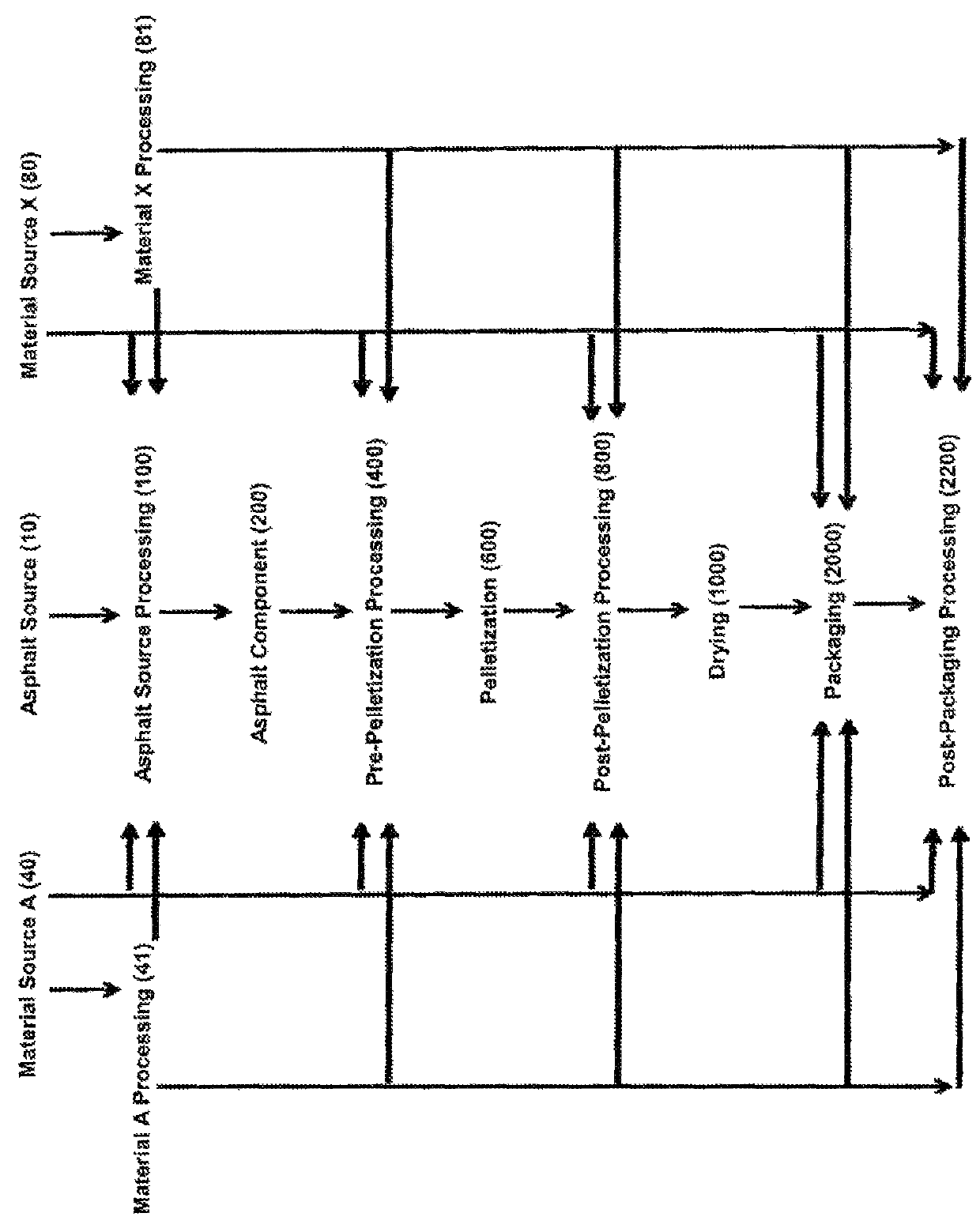

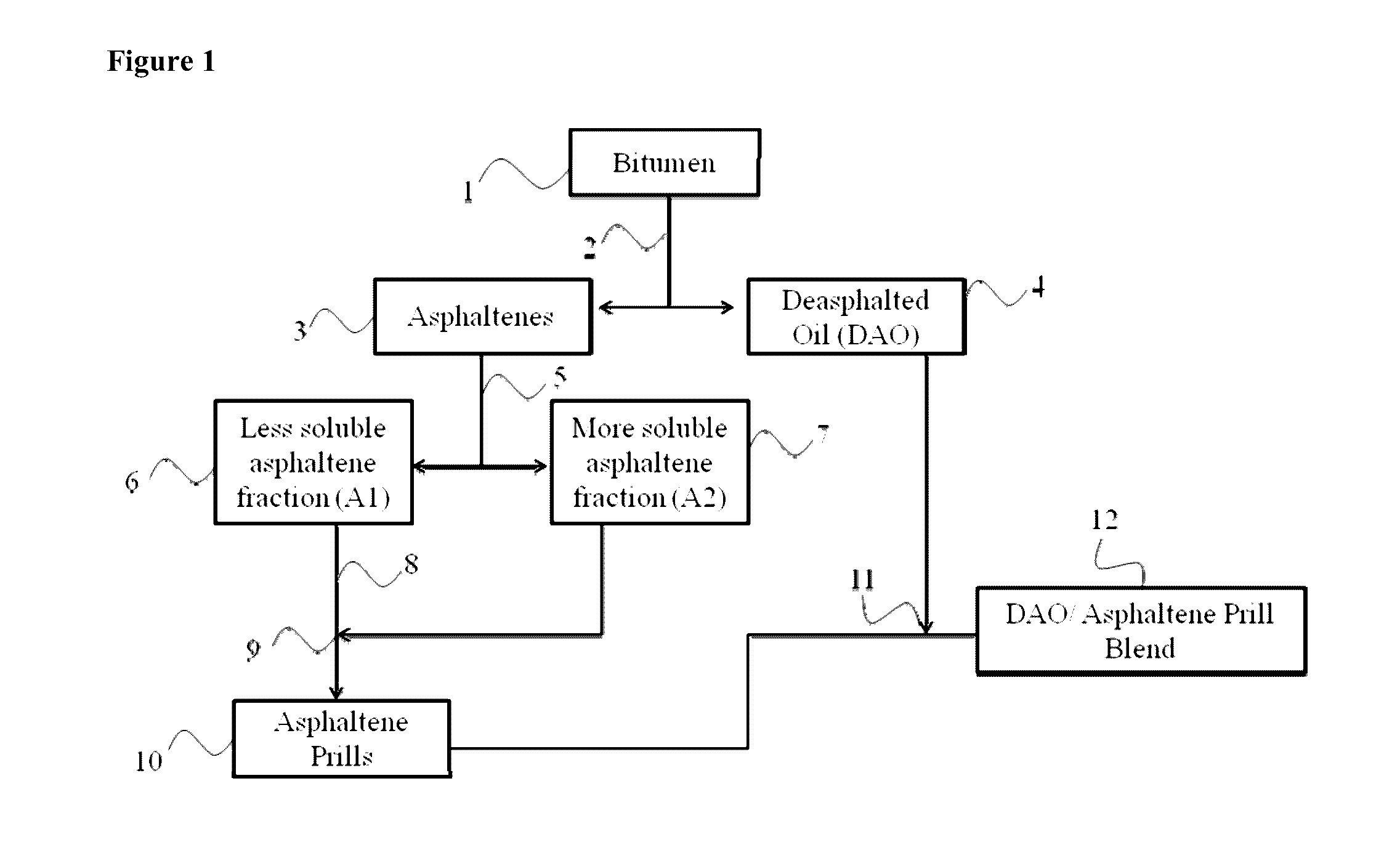

Continuous process for fractioning, combination, and recombination of asphalt components for pelletization and packaging of asphalt and asphalt-containing products

A continuous process for fractioning, combination, and recombination of asphalt sources into asphalt components for pelletization of asphalt and asphalt-containing products such that the pellets formed are generally uniform in dimension, freely flowing, free from agglomeration, and the pelletized asphalt is packaged, and preferably compatibly packaged, for additional processing and applications.

Owner:GALA INDUSTRIES INC

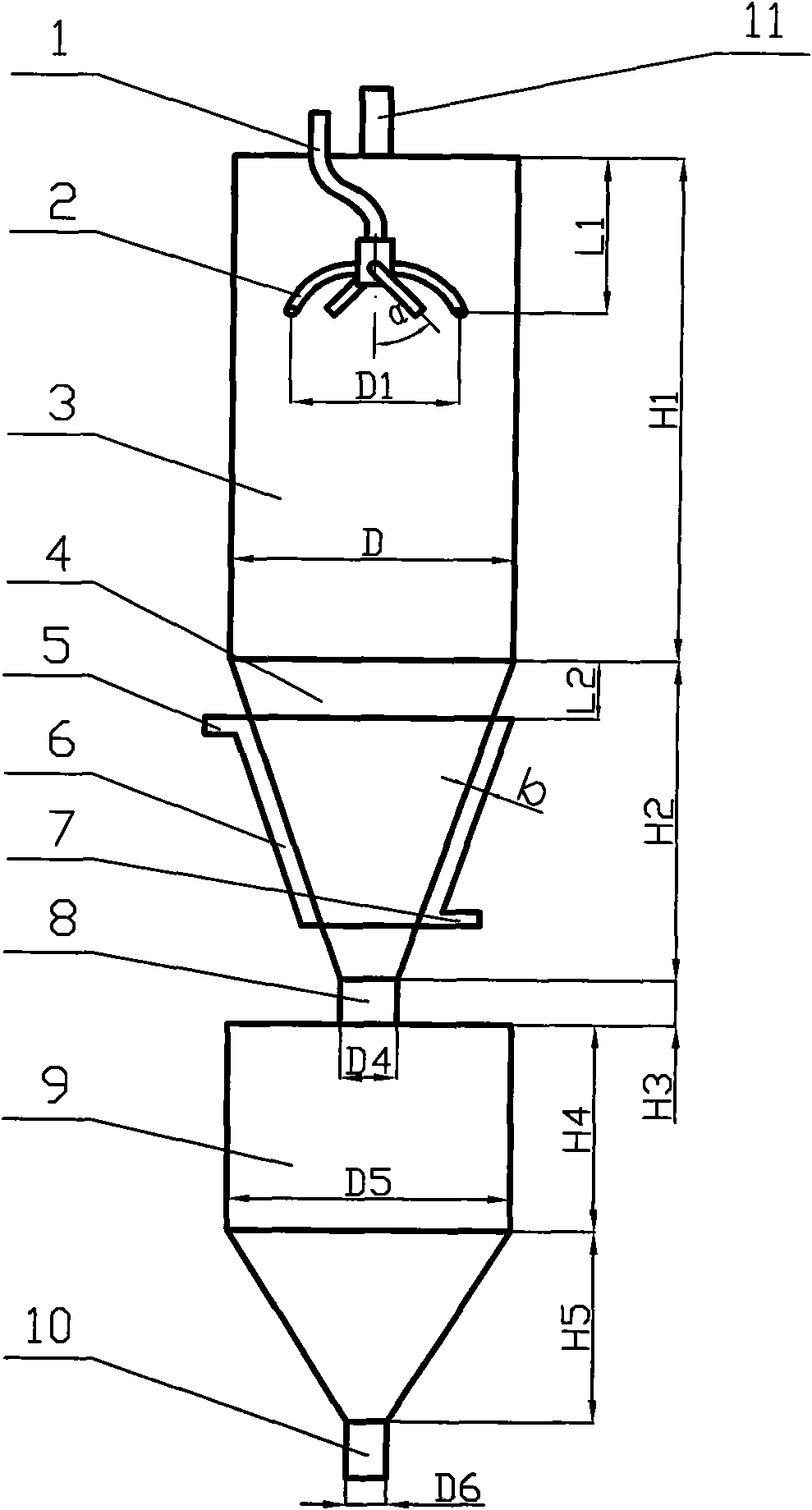

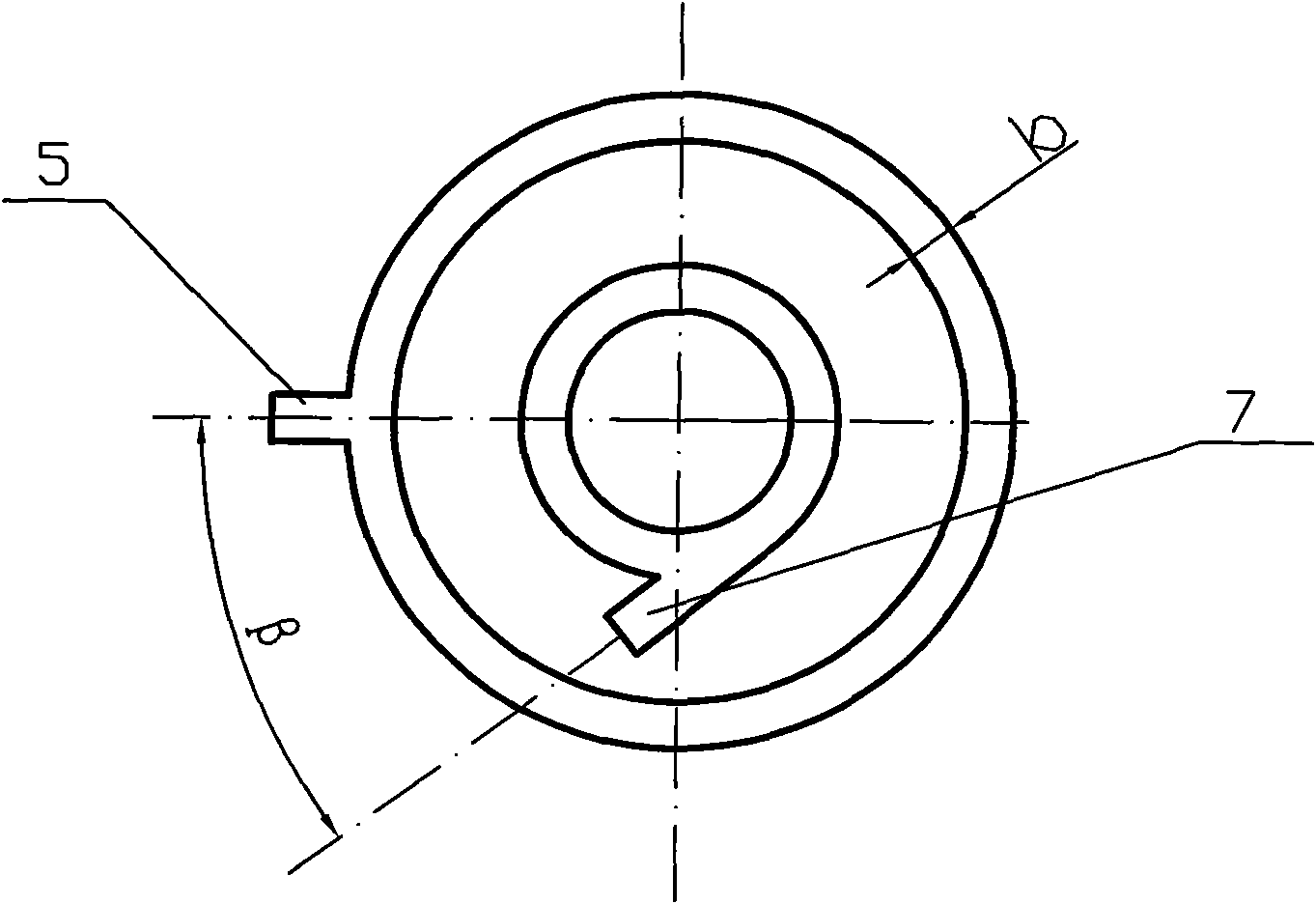

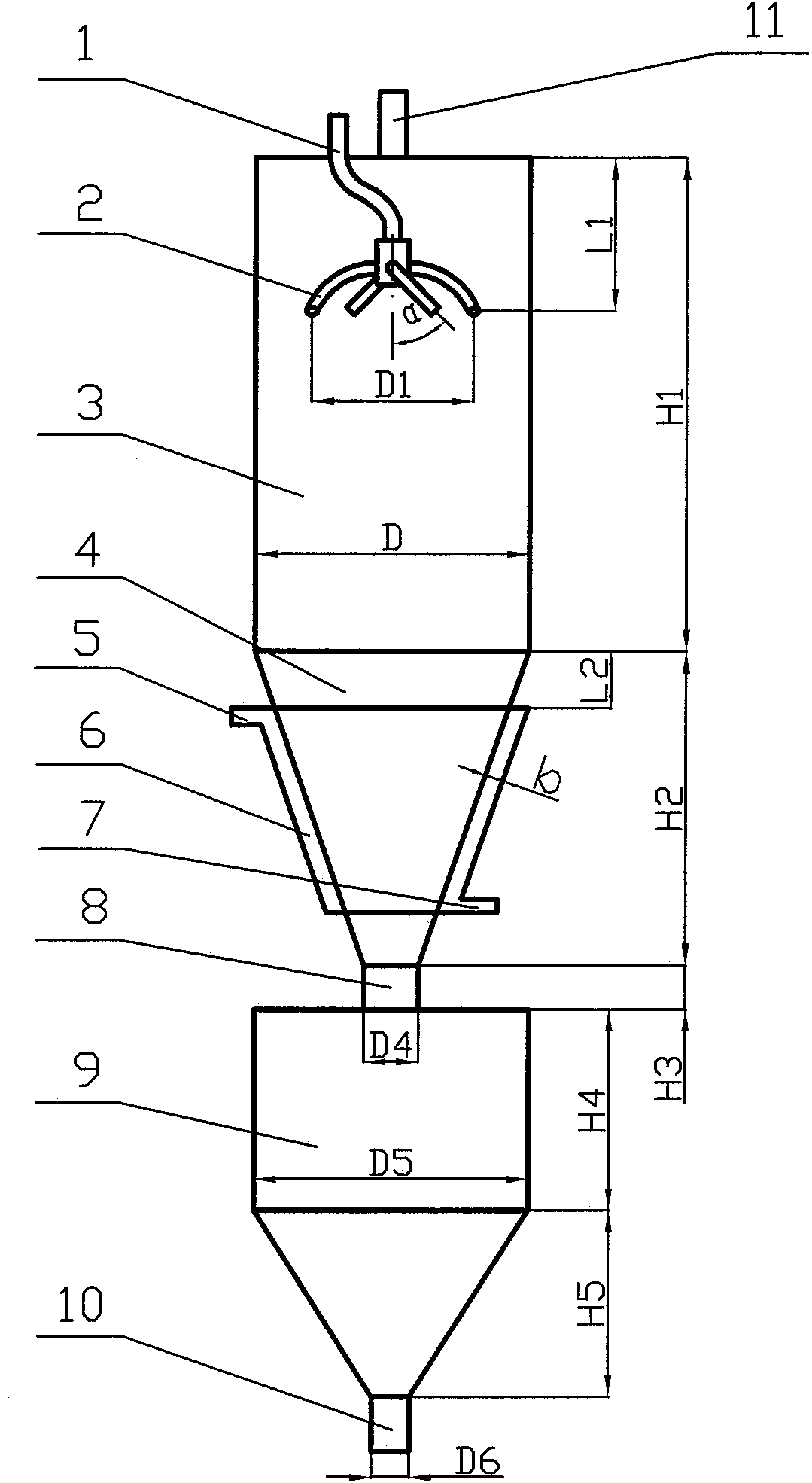

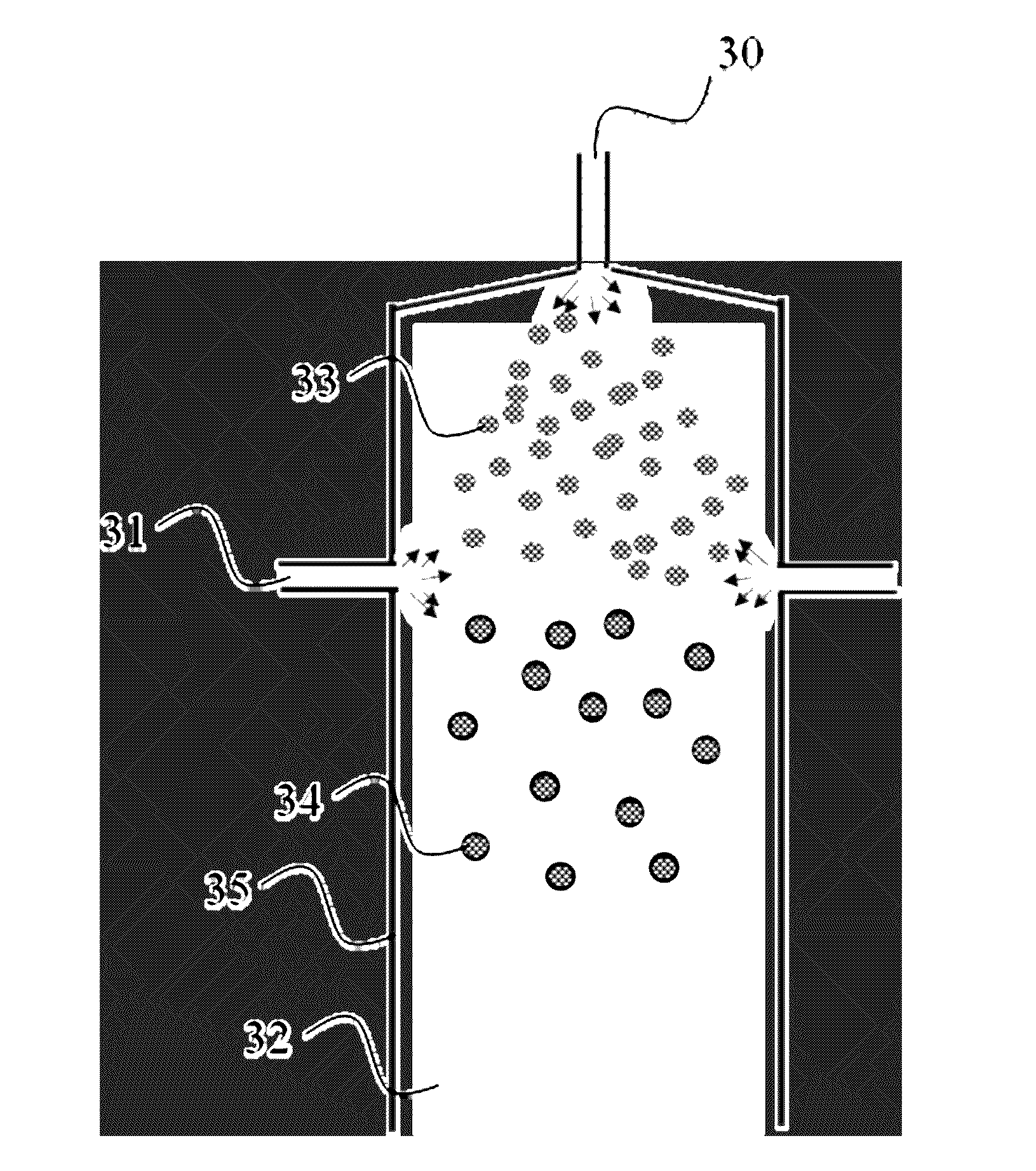

Spraying and granulating separation column with jacket cooling system on taper section

InactiveCN101987286AAchieve coolingNo internal components addedGranulation by liquid drop formationWorking-up pitch/asphalt/bitumen by solidifying/disintegratingSpray nozzleEngineering

The invention relates to a spraying and granulating separation column with a jacket cooling system on a taper section. The main structure of the separation column mainly comprises a granulating column body, a spraying and granulating nozzle system and a lower discharge pot from top to bottom, wherein the granulating column body can be formed by a separation and precipitation section, a taper section and a jacket cooling system; the spraying and granulating nozzle system can be formed by a distributor master pipe and a plurality of distributor branch pipes; the distributor branch pipes are symmetrically distributed, and the jet direction of the outlets of the distributor branch pipes form a certain angle with the vertical direction, which can form a rotating flow field with tangential velocity; the jacket cooling system comprises a tangential cooling water outlet, a radial cooling water inlet and a jacket main body; and cooling water rotates and upwards flows in a jacket, separated particles rotate and downwards flow in the spraying and granulating separation column, and the rotating and flowing directions of the cooling water and the separated particles are opposite to form contranatant heat exchange. In the invention, rotating flow fields of different degrees can be formed in the granulating column through adjusting the angles of the charge distributor and the number of the distributor branch pipes to realize different particle distribution states and improve the gas-solid separation efficiency; and different heat exchange efficiencies can be realized through adjusting the temperature, the pressure and the flow rate of a cooling water inlet and the structural size of a cooling water jack, and then the particle temperature can be reduced to control the temperature of the granulating column.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for solving polluted environment form coal tar smoke by molding, granulating coal tar under water

InactiveCN101050371ABenzopyrene reductionLess smokeWorking-up pitch/asphalt/bitumen by solidifying/disintegratingWater cyclingProcess engineering

This invention relates to a method for molding and granulating coal tar pitch under water, which can solve the environmental pollution problem caused by coal tar pitch fume. The method comprises: (1) pre-cooling coal tar pitch to 220-250 deg.C with a hot fluid carrier; (2) further cooling coal tar pitch to 130-150 deg.C with a coal tar pitch cooler; (3) pumping cooled coal tar pitch into a granulator by a flow pump, and granulating by the granulator under water; (4) molding and granulating, and circulating the cooling water. The method can avoid coal tar pitch fume in the storage tank or produced by coal tar pitch discharge, thus improve the operation conditions. The method is suitable for treating coal tar pitch fume during coal tar processing.

Owner:SHANDONG IRON & STEEL CO LTD

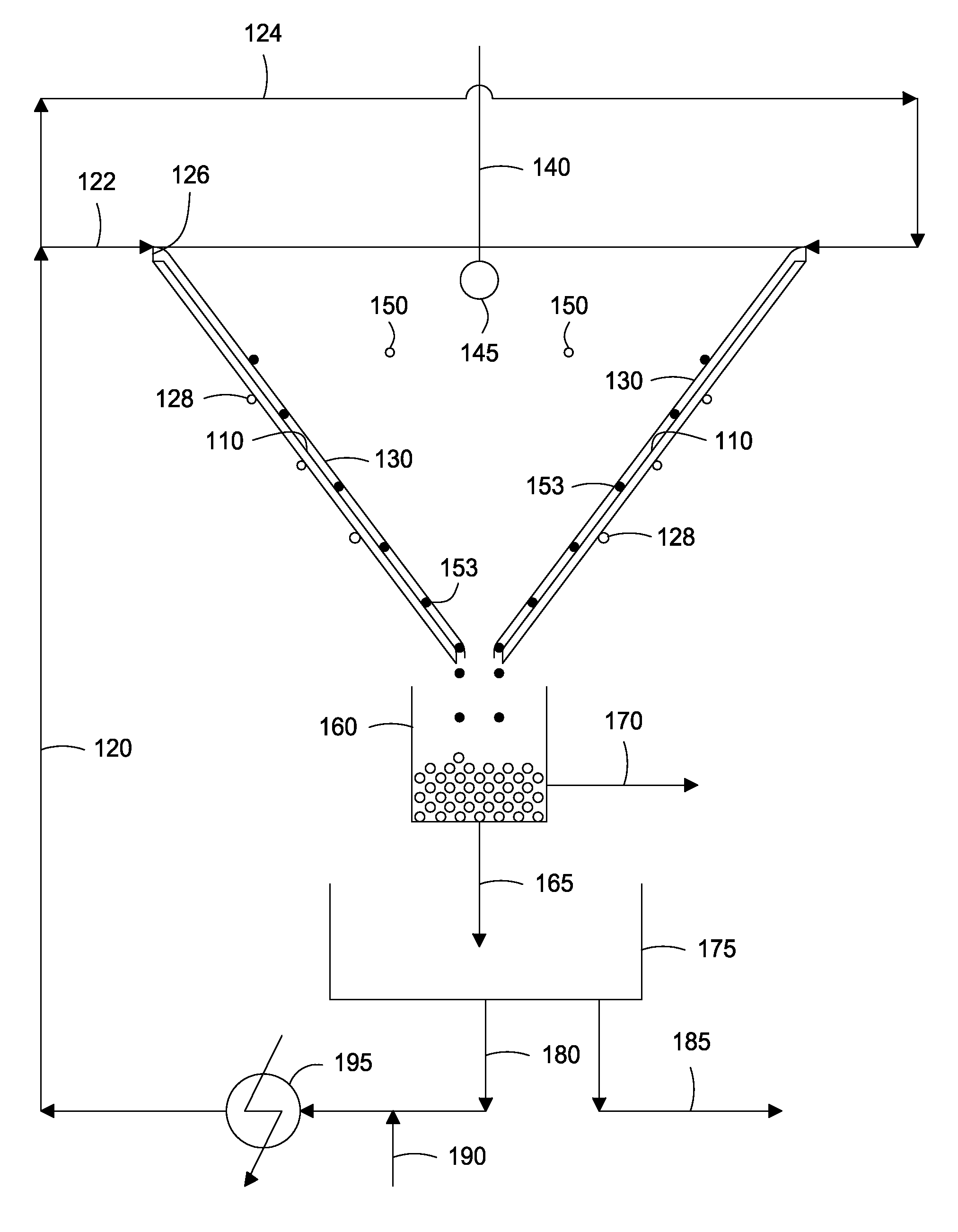

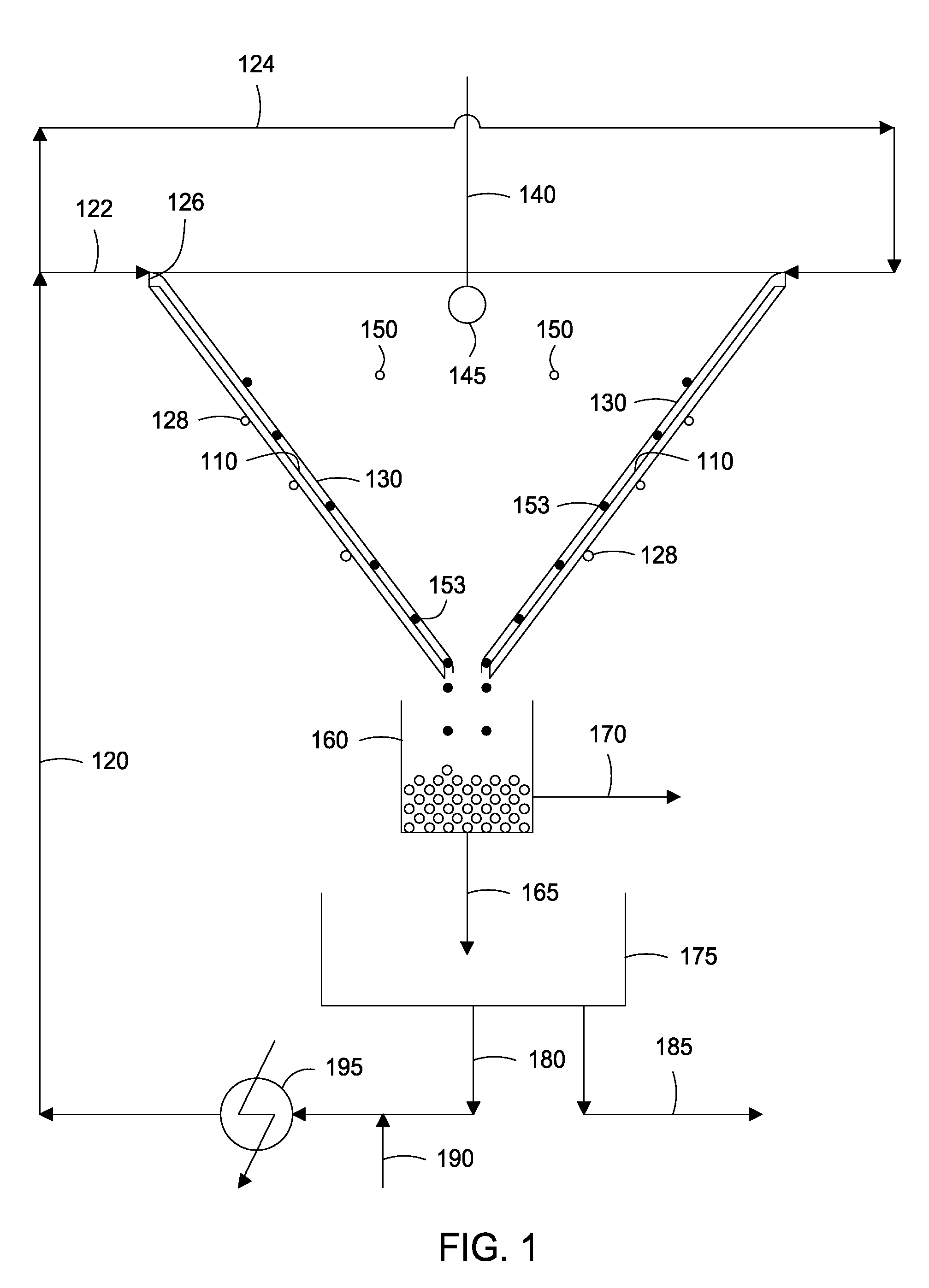

Hot Asphalt Cooling and Pelletization Process

ActiveUS20090272676A1Granulation by liquid drop formationAuxillary shaping apparatusProcess systemsAsphalt

Systems and methods for pelletizing hot asphaltenes are provided. Asphaltenic hydrocarbons can be dispersed to provide two or more asphaltenic particles. The asphaltenic hydrocarbons can be at a temperature of from about 175° C. to about 430° C. The asphaltenic particles can be contacted with a film of cooling medium. The film can have a thickness of from about 1 mm to about 500 mm. At least a portion of the asphaltenic particles can be solidified by transferring heat from the asphaltenic particles to the cooling medium to provide solid asphaltenic particles. The solid asphaltenic particles can be separated from at least a portion of the cooling medium.

Owner:KELLOGG BROWN & ROOT LLC

Bitumen solid at ambient temperature

ActiveUS20200165458A1Conserving formIn situ pavingsWorking-up pitch/asphalt/bitumen by meltingCelluloseAnticaking agent

Granules of material usable as a road binder or as a sealing binder including a core and a coating layer, wherein: the core consists of a first composition including at least one material selected from: a bitumen base, a pitch, a clear binder, and the coating layer consists of a second composition which includes: at least one viscosifying compound selected from cellulose ethers, and at least one anticaking agent. Also, a method for producing granules of material that can be used as a road binder or as a sealing binder, and the use thereof as a road binder, in particular for the production of coated materials. Also, a method for producing coatings from granules of material that can be used as a road binder or as a sealing binder and to a method for transporting and / or storing and / or handling granules.

Owner:TOTAL MARKETING SERVICES SA

Method and apparatus for the production of bitumen blocks

InactiveUS20150166897A1Highly accurate adherenceEnough timeLaminationWorking-up pitch/asphalt/bitumen by meltingEngineeringMechanical engineering

A method and an apparatus for the production of bitumen blocks, with a drop former for generating bitumen drops from molten bitumen, with a belt cooler having a rotating belt for cooling and solidifying the bitumen drops deposited on the rotating belt into tablets, and with a decanting device for decanting the tablets into bags, the tablets being at least partially combined, inside the bags filled with tablets, into a compact bitumen mass.

Owner:IPCO GERMANY GMBH

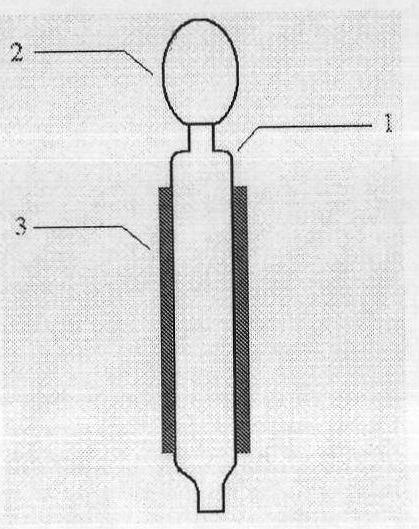

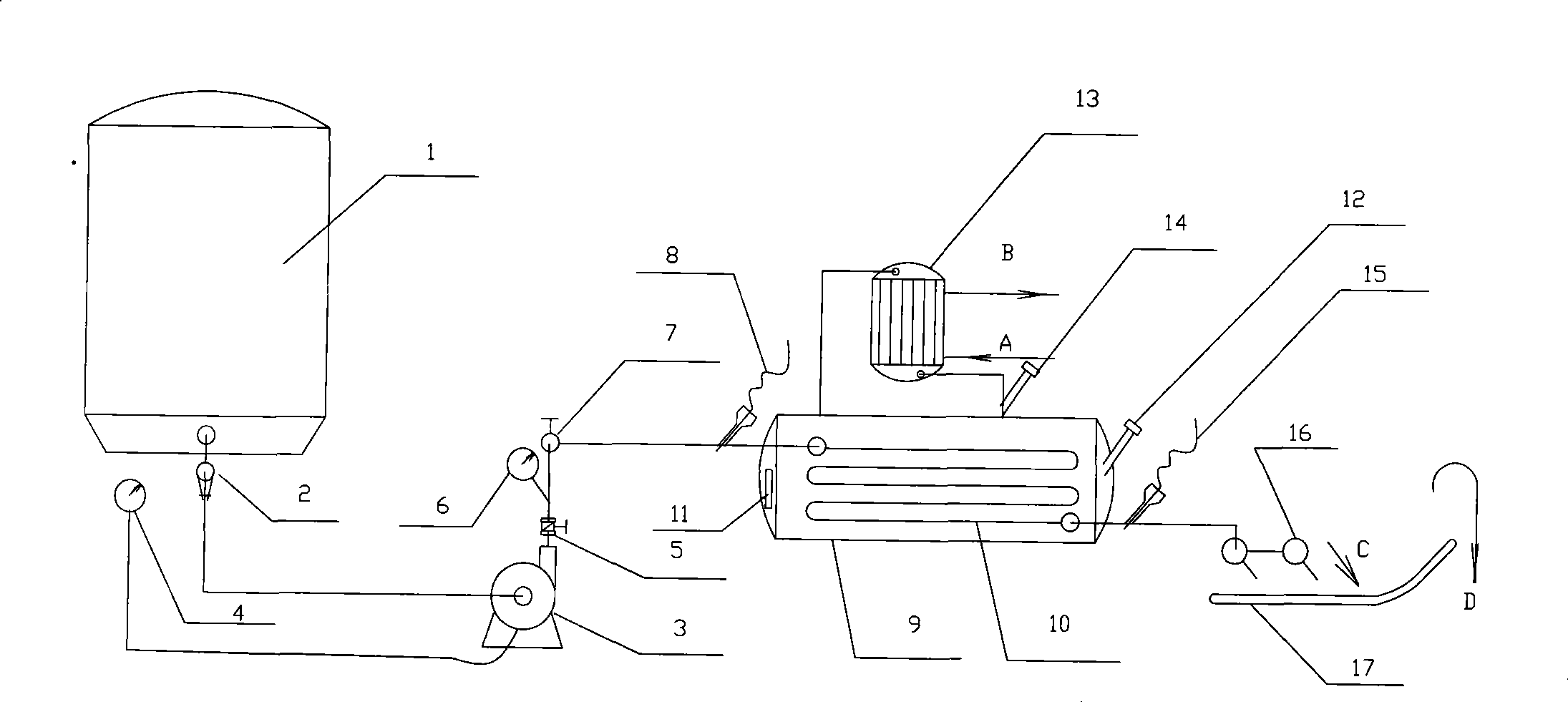

Asphalt moulding method and system apparatus thereof

InactiveCN101463260AUniform thicknessLess hollowWorking-up pitch/asphalt/bitumen by solidifying/disintegratingCooling coilEngineering

The invention discloses an asphalt forming method, comprising the steps of pressurizing and cooling liquid asphalt and then jetting the asphalt via a nozzle-type former for cooling formation. The invention also provides a system device for implementing the method. The device is mainly composed of a forming pump (3), a gasification cooler (9), a cooling coil (10), a steam condenser (13), the nozzle-type former (16) and a link plate conveyor (17), the cooling coil (10) is disposed in the gasification cooler (9), the steam condenser (13) is connected with the gasification cooler (9), the nozzle-type former (16) is connected with the end of the cooling coil (10) and is disposed above the link plate conveyer (17). The device is simple in process and convenient in operation, and pressurizes andcools the asphalt in a sealed system for formation so that the asphalt has quite small contact area with the air, thus can solve the problems such as inferior appearance, high moisture and serious pollution, etc. The cured asphalt is columnar in shape, uniform in thickness and almost solid and has water content not more than 5%, which accords with the national standards.

Owner:BAOSHAN IRON & STEEL CO LTD

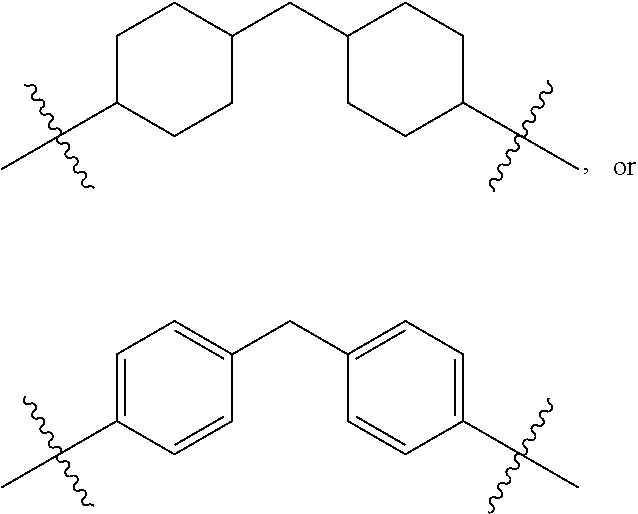

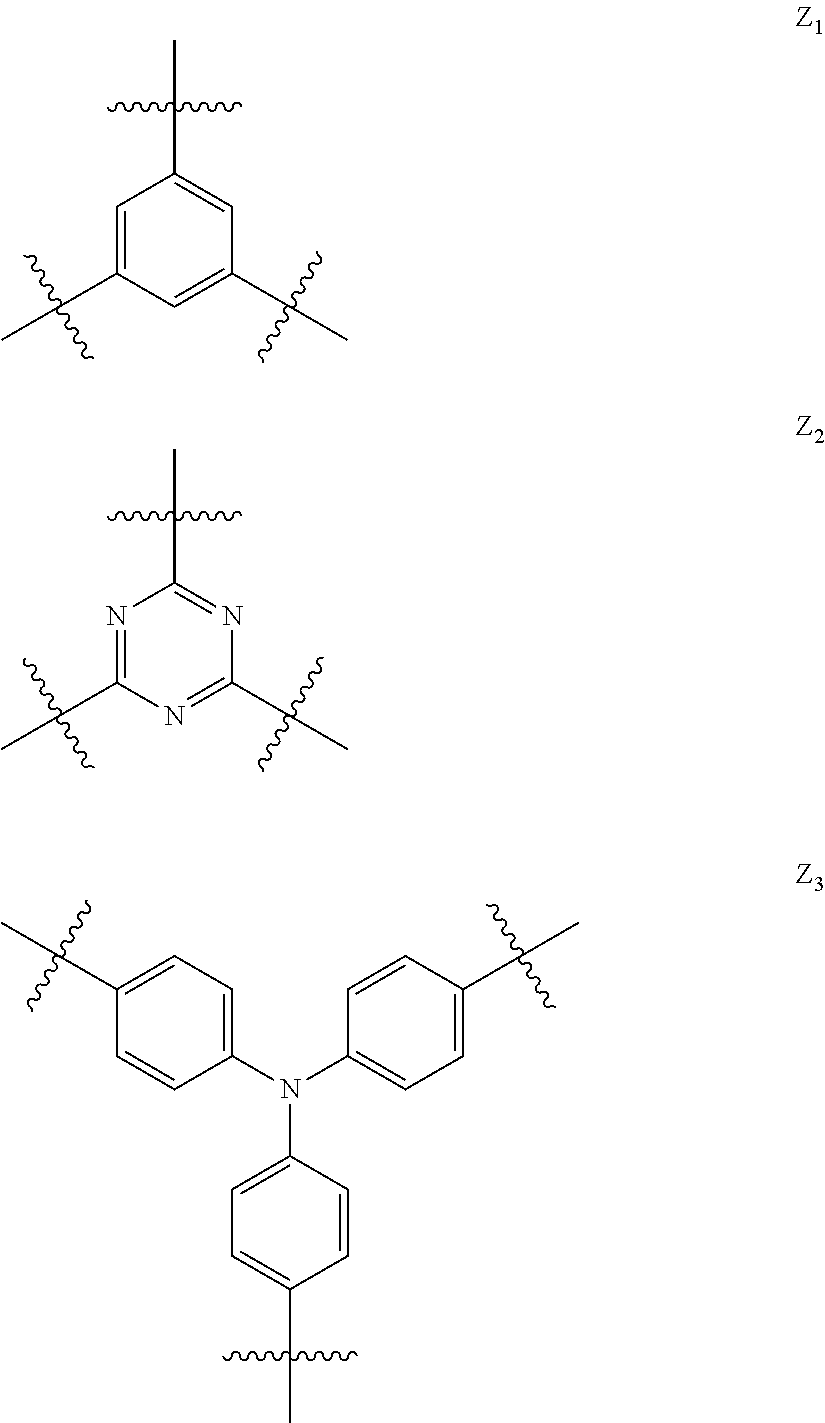

Granules Comprising Bitumen and a Thermoplastic Polyurethane Elastomer, Method for its Preparation and its Uses

ActiveUS20150291798A1Good dispersionReduce preparation timeWorking-up pitch/asphalt/bitumen by solidifying/disintegratingTextiles and paperFiberThermoplastic polyurethane

Disclosed are granules comprising an elastomeric polyurethane and bitumen, processes for preparing the granules in an extruder and to their use for preparing a bituminous binder, which may especially be used for producing prefabricated sealing membranes by depositing said bituminous binder onto a fibrous support.

Owner:SOPREMA SA

Pouring steel belt type asphalt granulation production unit

PendingCN109456784AImprove consistencyAvoid bondingWorking-up pitch/asphalt/bitumen by solidifying/disintegratingSolid particleAsphalt

Owner:北京紫瑞天成科技有限公司

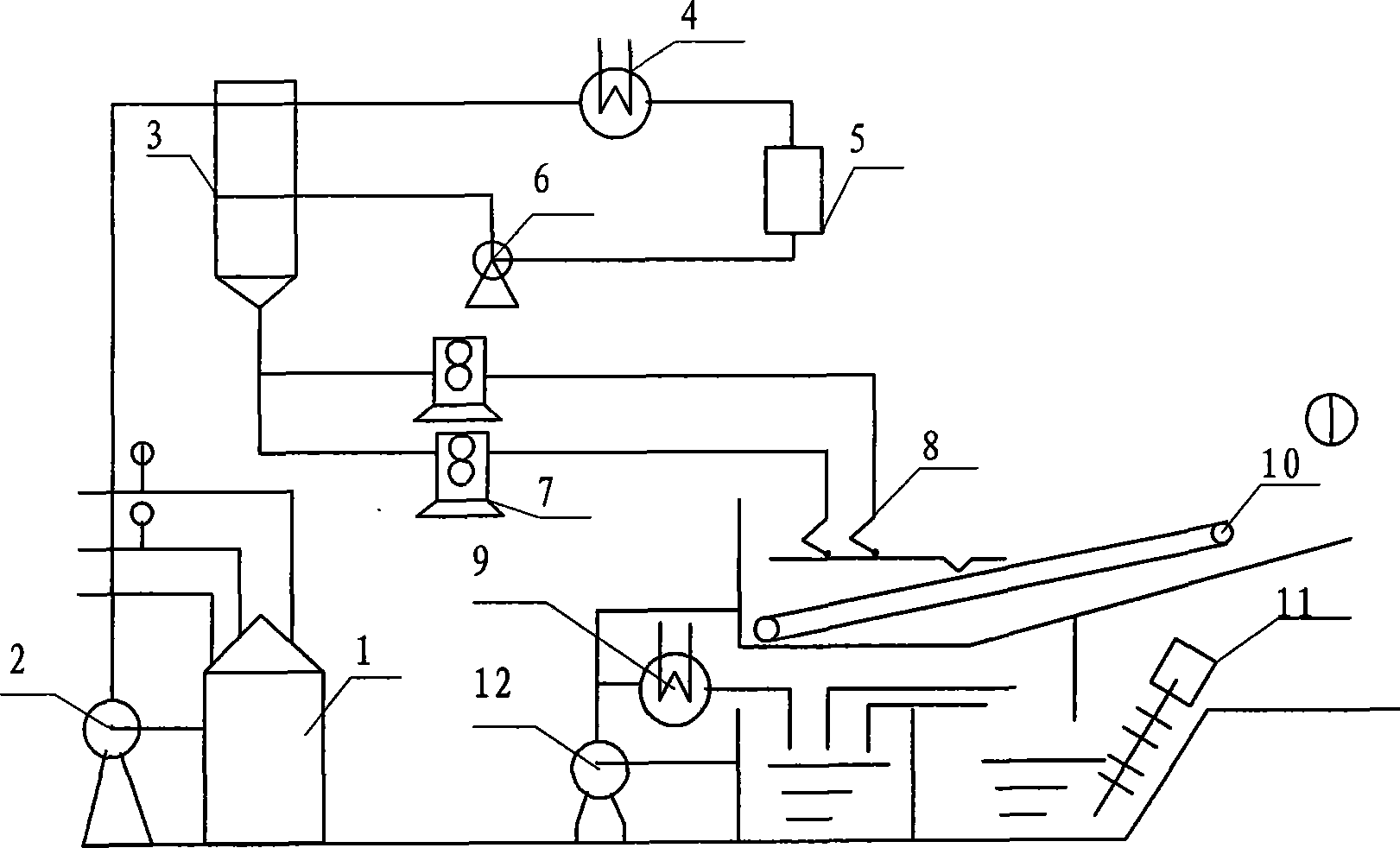

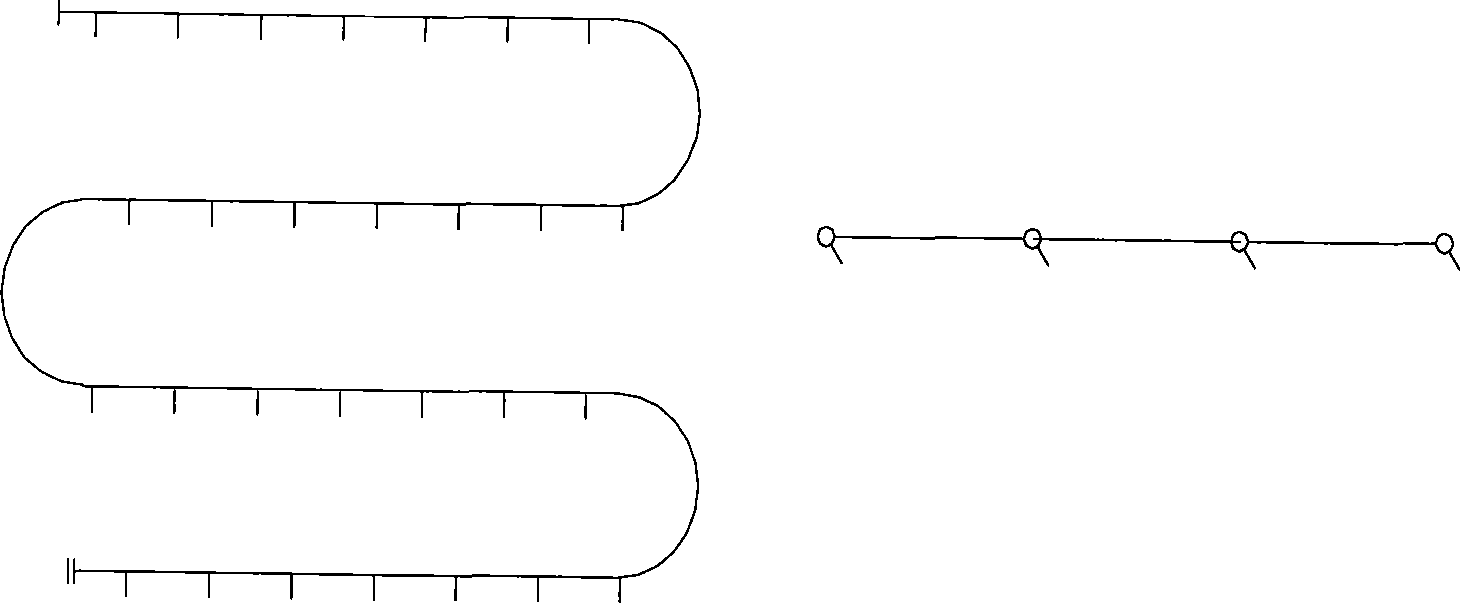

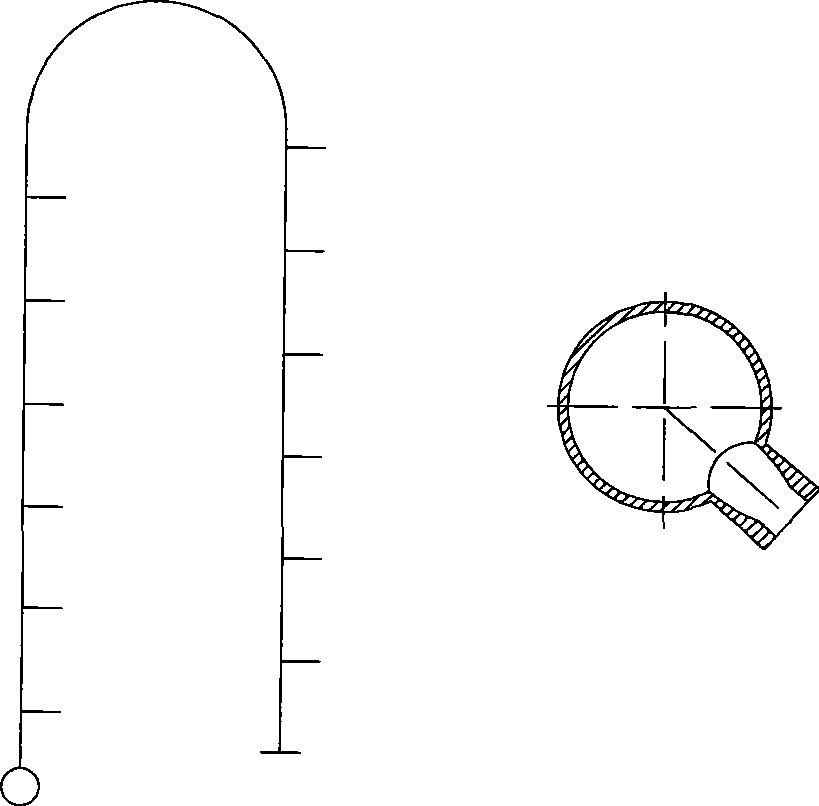

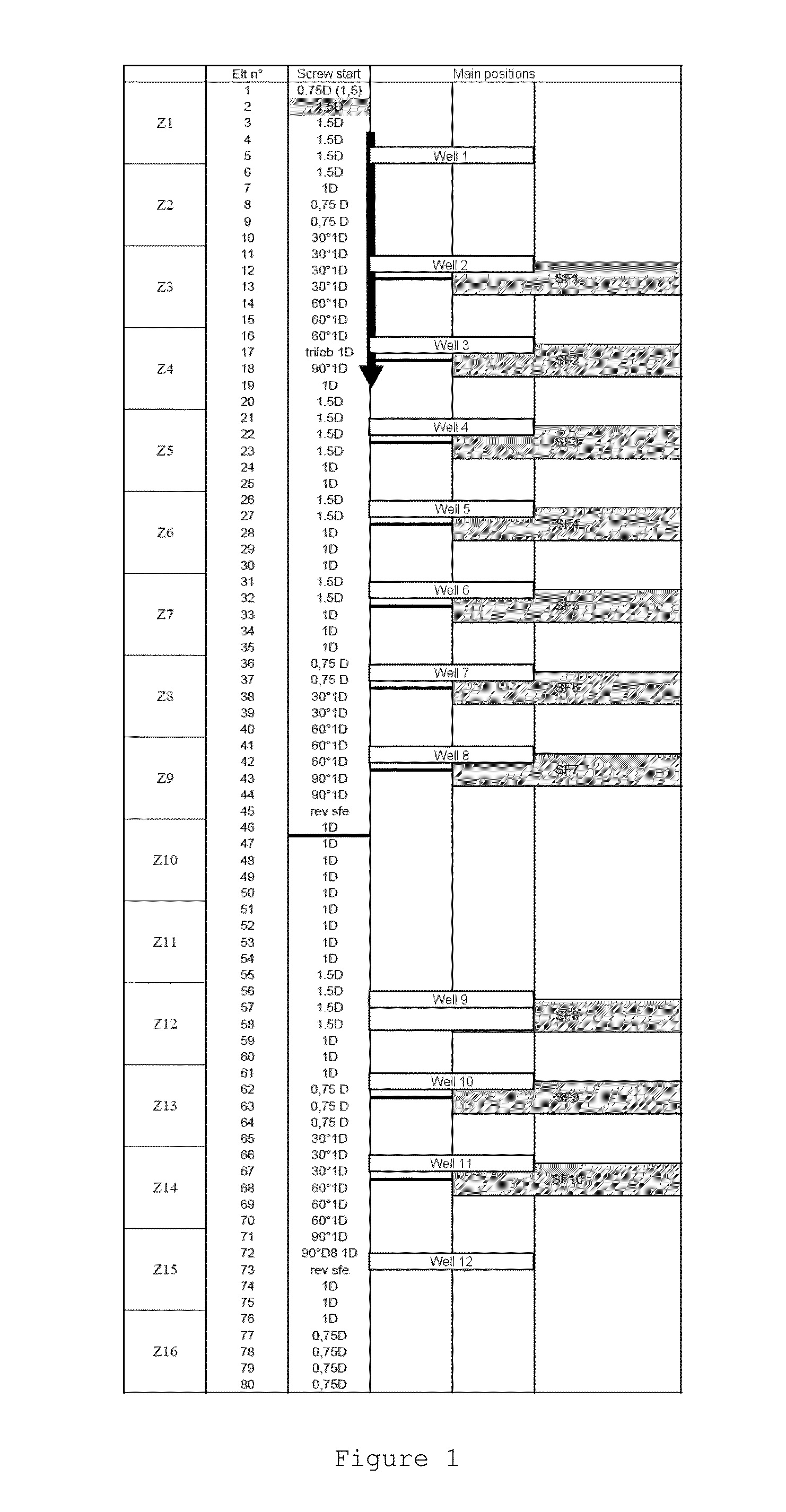

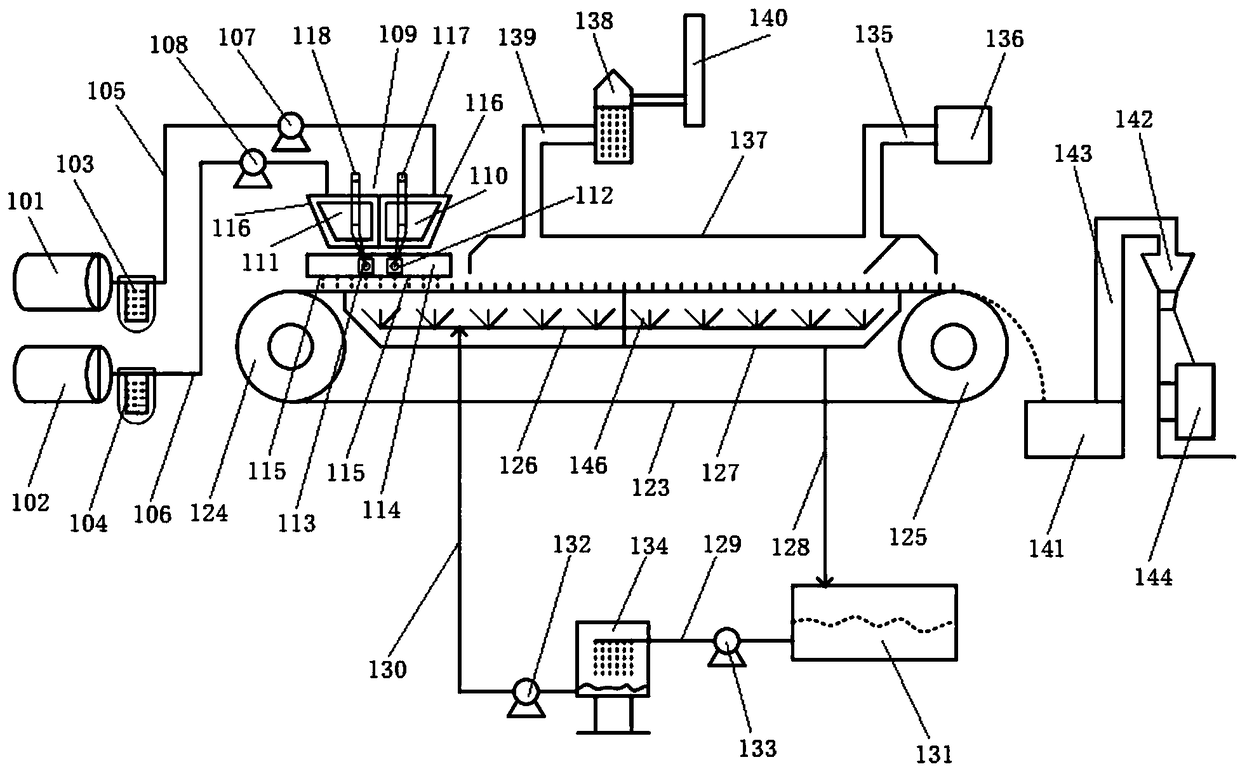

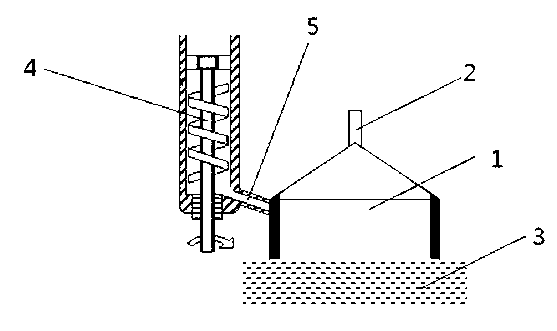

Apparatus and method for recovering solvent in granulation of de-oiled asphalt with high softening point

InactiveCN103102894AEasy to operateLess investmentWorking-up pitch/asphalt/bitumen by solidifying/disintegratingHigh energySolid particle

The invention relates to an apparatus and a method for recovering a solvent in granulation of de-oiled asphalt with a high softening point. Specifically speaking, the de-oiled asphalt with a high softening point discharged from the bottom of a solvent deasphalting tower is granulated through a screw extrusion system, and obtained granular de-oiled asphalt is directly introduced into a de-oiled asphalt solvent enrichment chamber; and the top of the solvent enrichment chamber is provided with a solvent gas recovery pipeline communicated with a solvent recovery system, and facilities like a de-oiled asphalt solid particle water entering slideway are arranged in the chamber so as to prevent the de-oiled asphalt from directly falling into cooling water and prolonging time for releasing of the solvent by the granular de-oiled asphalt. Compared to the prior art, the method for recovering the solvent in granulation of the de-oiled asphalt with a high softening point has the following advantages: the whole process is simple and easily practicable, equipment like a heating furnace and a stripping tower in a conventional de-oiled asphalt solvent separation unit are omitted, and the phenomena of high energy consumption, long flow process and instable operation in recovery of the solvent used for the de-oiled asphalt with a high softening point are avoided.

Owner:CHINA PETROLEUM & CHEM CORP +1

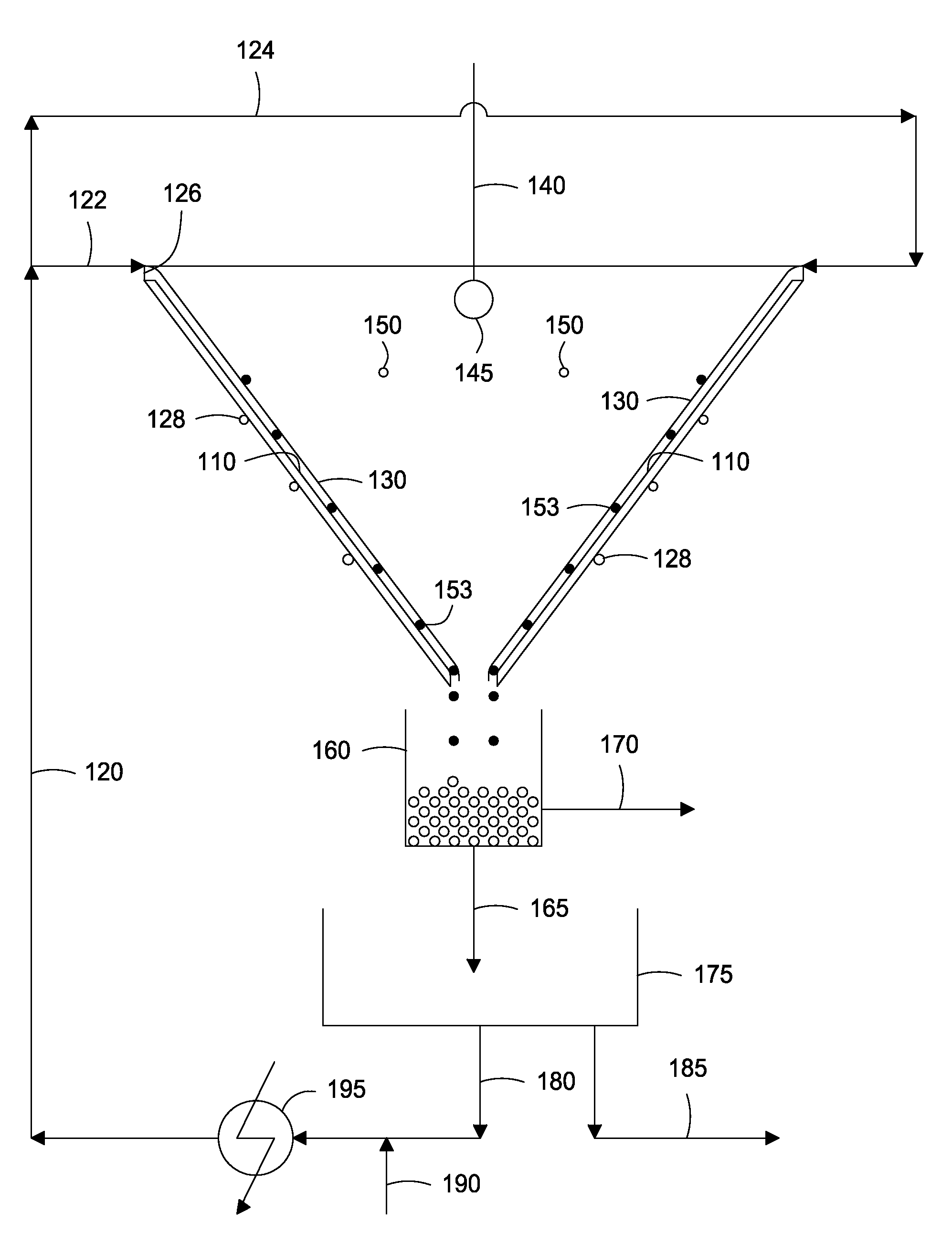

Bitumen processing and transport

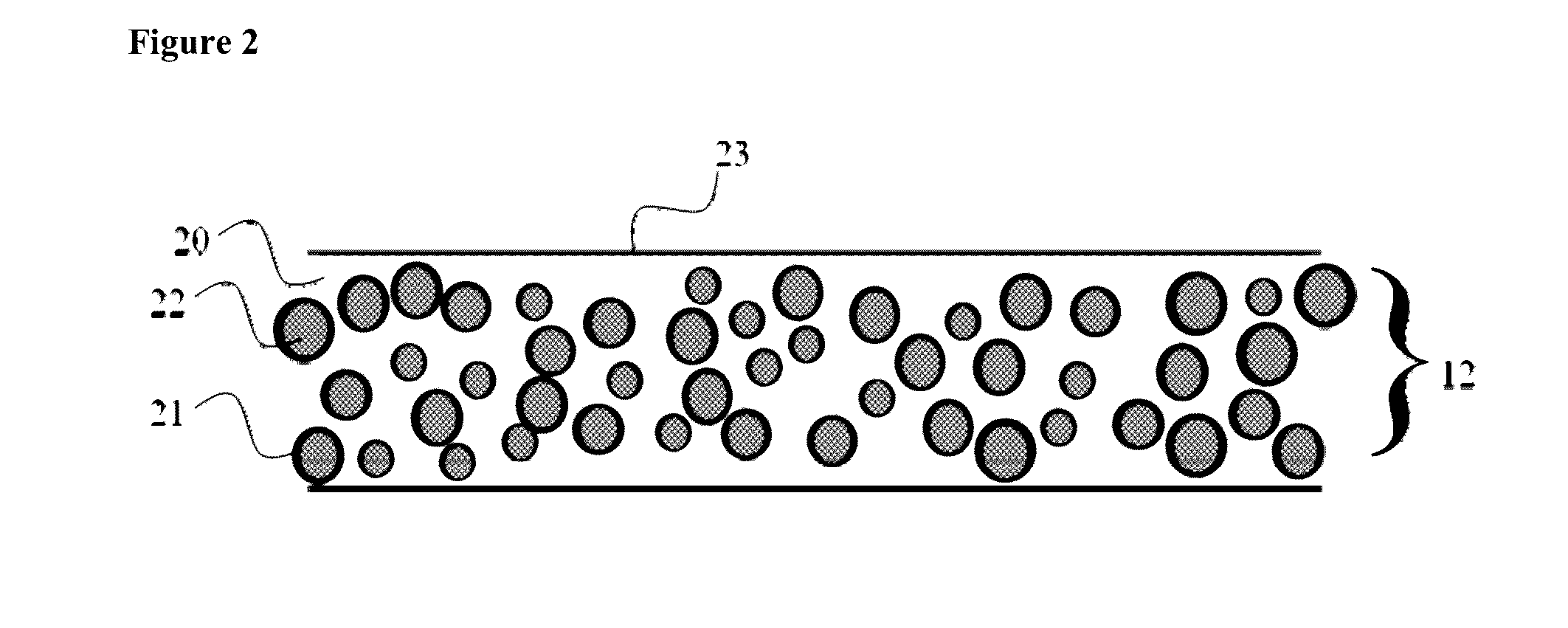

ActiveUS20170002275A1Low viscosityImprove liquidityTreatment with plural serial stages onlyWorking-up pitch/asphalt/bitumen by solidifying/disintegratingSolubilityAsphaltene

Methods for preparing, converting, and / or transporting bitumen are provided. Asphaltene prills, prilling processes, and converted bitumen suitable for transport are disclosed. One method for preparing bitumen for transport comprises: separating asphaltene from the bitumen to generate a deasphalted oil and asphaltene; separating the asphaltene into a first asphaltene fraction and a second asphaltene fraction, the first asphaltene fraction being less soluble in deasphalted oil and the second asphaltene fraction being more soluble in deasphalted oil; and forming an asphaltene prill comprising an inner core comprising the second asphaltene fraction and an outer layer comprising the first asphaltene fraction. Asphaltene prills disclosed herein may comprise an inner core comprising an asphaltene fraction having more solubility in deasphalted oil, and an outer layer comprising an asphaltene fraction having less solubility in deasphalted oil. Methods for the transport of bitumen via a pipeline are disclosed.

Owner:CENOVUS ENERGY

Low energy one-step method for preparing asphalt balls

ActiveCN103695019ALow costImprove securityWorking-up pitch/asphalt/bitumen by solidifying/disintegratingEngineeringCooling down

The invention relates to a low energy one-step method for preparing asphalt balls. The method comprises steps of directly adding high softening point asphalt, naphthaline, dispersing agent and water into a normal pressure reaction kettle according to weight ratio of 1:(0.35-0.5):(0.01-0.3):(20-40), rising temperature up to 75-95DEG C at stirring rate of 200-500rpm, keeping warm for 1-5 hours at the temperature, then separating solid and liquid directly without cooling down so as to obtain the asphalt balls. The one-step method has the advantages of directly preparing the asphalt balls by one step, having low equipment cost due to the use of normal pressure reaction kettle, and having high safety and low energy consumption.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Coal pitch refining method used for synthesizing mesophase pitch

ActiveCN108102679AMolecular weight controllableMeet the requirements of high value-added productsWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by solidifying/disintegratingDistillationSolvent

The invention relates to a coal pitch refining method used for synthesizing mesophase pitch. The coal pitch refining method used for synthesizing mesophase pitch comprises following steps: coal pitchis smashed and sieved, a mixed solvent A is added into coal pitch, an obtained mixture is stirred, is allowed to stand, and is subjected to layering so as to obtain an upper layer which is a mixed solution A of the mixed solvent A and coal pitch, and a lower layer which is an impurity mixture containing coal powder coke particles; the upper layer mixed solution A is subjected to filtering and distillation for recovery of the mixed solvent A so as to obtain crude coal pitch; a mixed solvent B is added into the crude coal pitch, and stirring, standing, and layering are carried out so as to obtain an upper layer which is a mixed solution B of the mixed solvent B and refined coal pitch, and a lower layer which is a heavy asphalt impurity mixture; the upper layer mixed solution B is subjected to filtering and distillation for recovery of the mixed solvent B so as to obtain refined coal pitch can be used for synthesizing mesophase pitch. The coal pitch refining method is capable of realizingseparation of coal pitch effective components with impurities such as coal powder coke particles under normal pressure conditions, the obtained refined coal pitch can be taken as a high grade carbonmaterial raw material, and the requirements of subsequent high added value product production are satisfied.

Owner:SHANDONG RUICHENG AEROSPACE CARBON MATERIAL CO LTD

Purification method for coal pitch with high softening point

InactiveCN104232135AReduce energy consumptionEffective prolapseWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by solidifying/disintegratingPurification methodsMetal impurities

The invention discloses a purification method for coal pitch with a high softening point and belongs to the technical field of tar deep processing. The purification method comprises the following steps: mixing pitch with small-molecule aromatic hydrocarbons and obtaining pitch particles by using a granulator and a cutting-off machine; extracting the pitch particles with a solvent to obtain porous pitch particles; extracting the porous tar particles with alkali solution and acid solution to obtain the content of silicon and the content of metal and performing solid-liquid separation; washing the extracted particles with deionized water and performing solid-liquid separation; drying the substances in an inert atmosphere or vacuum environment to obtain purified pitch. The purification method disclosed by the invention has the benefits that the porous pitch particles are extracted by using low-temperature alkali and acid of 30-80DEG C, so that silicon and other metal impurities in the coal pitch are effectively removed; the total ash content of the obtained purified pitch is less than 0.005 percent, the content of the silicon is less than 0.001 percent and the content of the metal impurities is less than 0.002 percent; higher use requirement can be met; besides, the purification method is simple in process step and lower in energy consumption.

Owner:SICHUAN CHUANGYUE CARBON MATERIAL

Method for preparing millimeter-sized asphalt balls from naphthalene-containing asphalt micropowder

ActiveCN106318425AOxidation does not melt fasterIncrease production capacityWorking-up pitch/asphalt/bitumen by solidifying/disintegratingActivated carbonCarbonization

A method for preparing millimeter-sized asphalt balls from naphthalene-containing asphalt micropowder comprises steps as follows: HNO3 is added to the naphthalene-containing asphalt micropowder, and the asphalt micropowder is left to stand at the room temperature, subjected to solid-liquid separation, washed with deionized water to be neutral and dried; and the millimeter-sized asphalt-based activated carbon balls are prepared after micropowder balling, oxidation without melting, carbonization and activation treatment. The method has the advantages of being low in cost and free of waste.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Popular searches

Liquid hydrocarbon mixture production Working-up tar Refining with acid-containing liquids Distillation separation Chemical/physical/physico-chemical processes Liquid-gas reaction processes Tar working-up by solvent extraction Tar working-up by distillation Building insulations Hydrocarbon oil cracking

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com