Asphalt moulding method and system apparatus thereof

A molding method and system device technology, applied in curing/crushing processing of tar pitch/petroleum pitch/natural pitch, etc., can solve the problems of uncontrollable molding temperature, unadjustable temperature and pressure, brittleness, etc. The effect of reducing churn, improving user satisfaction, and reducing irregularities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

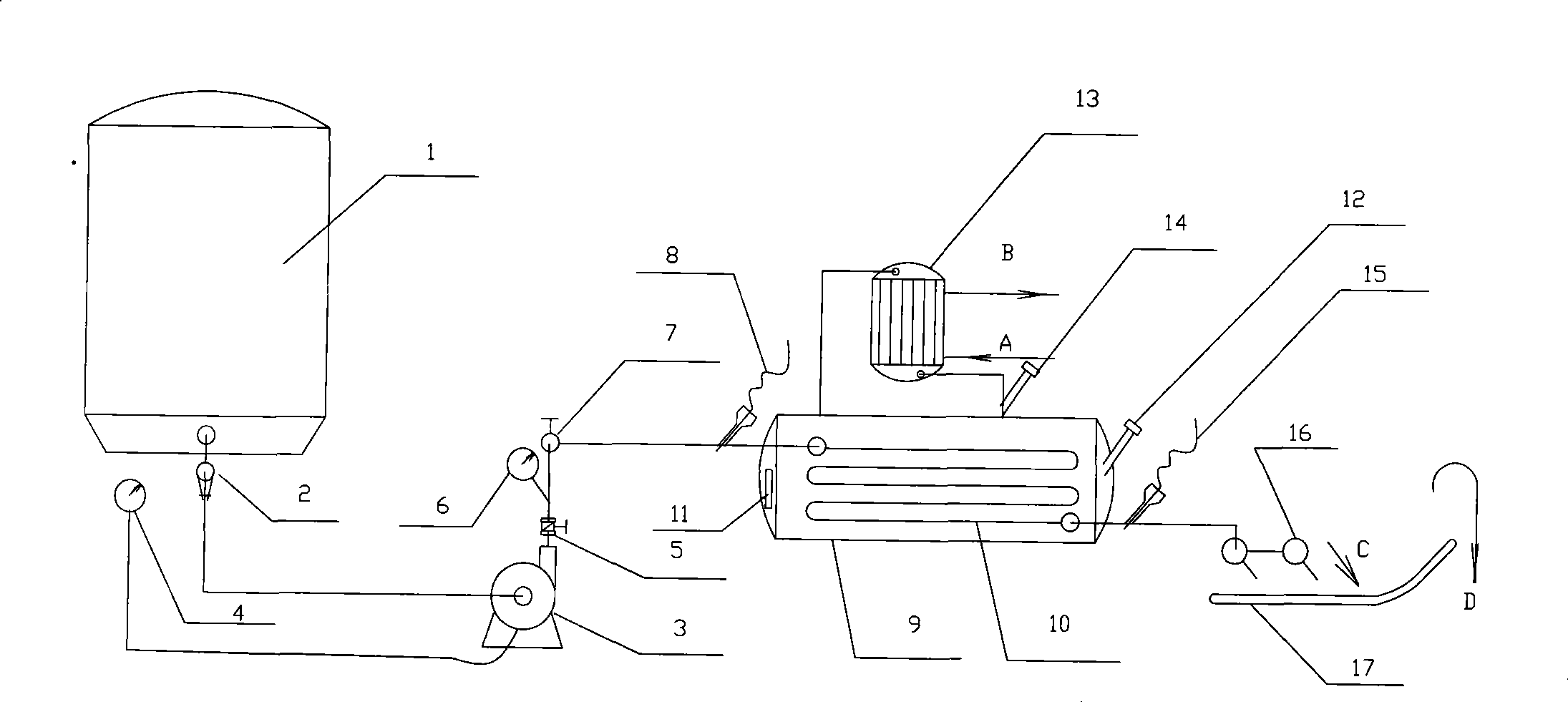

[0031] Embodiment 1 (medium temperature asphalt forming):

[0032] The medium-temperature asphalt coming out of the high tank 1 has a temperature of 170°C to 180°C, and the flow rate is adjusted by the centrifugal forming pump 3 through the butterfly valve 5, and the mass flow rate is 11t / h. Asphalt is pumped into vaporization cooler 9 (horizontal type, with an area of about 35m 2 ), where the bitumen is indirectly cooled by hot water. After the hot water absorbs the heat of the asphalt, it is vaporized and rises to the steam condenser 13 (vertical, with an area of 30m2) through the steam riser. 2 ), where the steam is condensed and cooled by cold water and returned to the evaporative cooler 9, the temperature of the return water is 80°C to 90°C, and the condensed water is recycled in a closed circuit to reduce scaling. The cooling water adopts the circulating water of the asphalt cooling pool, and a filter is installed at the inlet of the circulating pump. The water te...

Embodiment 2

[0034] Embodiment 2 (medium temperature asphalt forming):

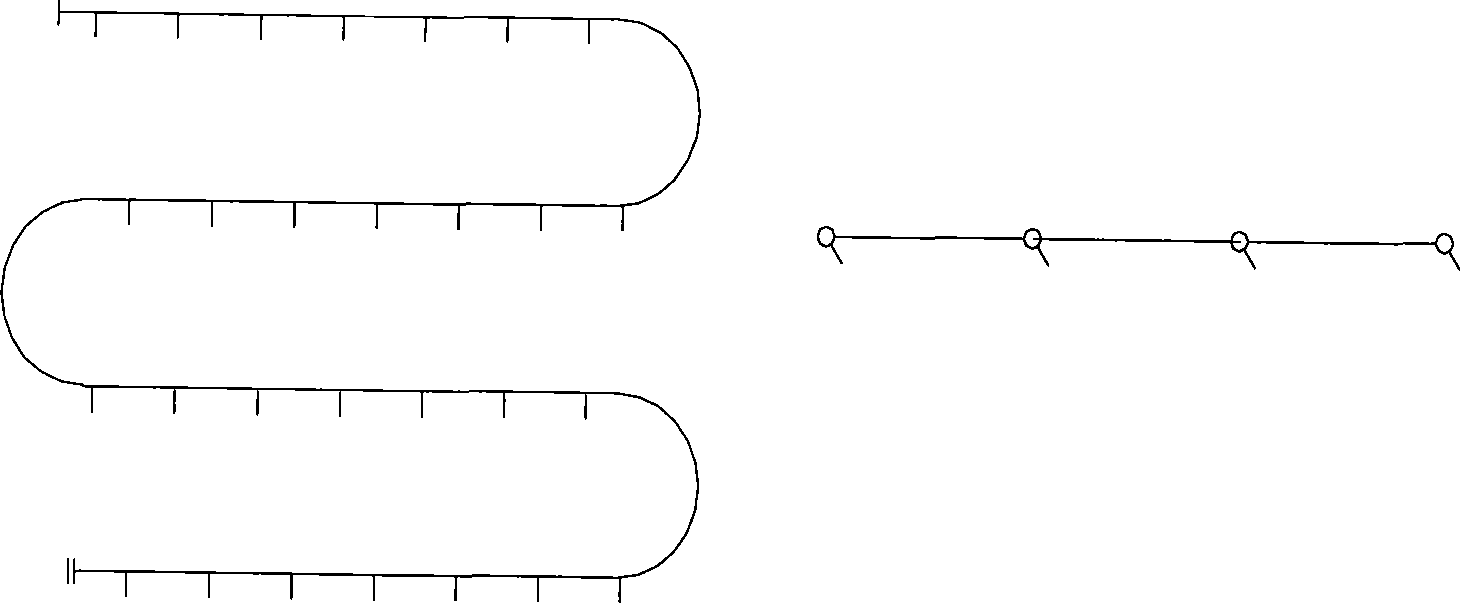

[0035]The temperature of the medium-temperature asphalt coming out of the high tank 1 is 180° C. to 190° C., and the cooling control part of the asphalt is the same as in the first embodiment. The temperature of the medium-temperature asphalt coming out of the evaporative cooler is 145° C. to 155° C., and enters the nozzle shaper 16 . The nozzle is attached to the U-shaped main pipe of DN80 (see image 3 ), the front and rear rows of nozzles are staggered. The inner diameter of the nozzle outlet is 12mm, the length is 60mm, and the number is 14, forming an angle of 15° with the vertical downward direction. The front and rear adjacent rows of nozzles are arranged in a staggered manner, and the distance between the nozzles is evenly arranged according to the width of the chain plate.

Embodiment 3

[0036] Embodiment three (medium temperature asphalt forming):

[0037] The medium-temperature asphalt coming out of the high tank 1 has a temperature of 180°C to 200°C, and the flow rate is adjusted by the centrifugal forming pump 3 through the butterfly valve 5, and the mass flow rate is 10t / h. Asphalt is pumped into vaporization cooler 9 (horizontal type, with an area of about 35m 2 ), where the bitumen is indirectly cooled by hot water. After the hot water absorbs the heat of the asphalt, it is vaporized and rises to the steam condenser 13 (vertical, with an area of 30m2) through the steam riser. 2 ), where the steam is condensed and cooled by cold water and returned to the evaporative cooler 9, the temperature of the return water is 80°C to 92°C, and the condensed water is recycled in a closed circuit to reduce scaling. The cooling water adopts the circulating water of the asphalt cooling pool, and a filter is installed at the inlet of the circulating pump. The wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com