Preparation method of bitumen balls

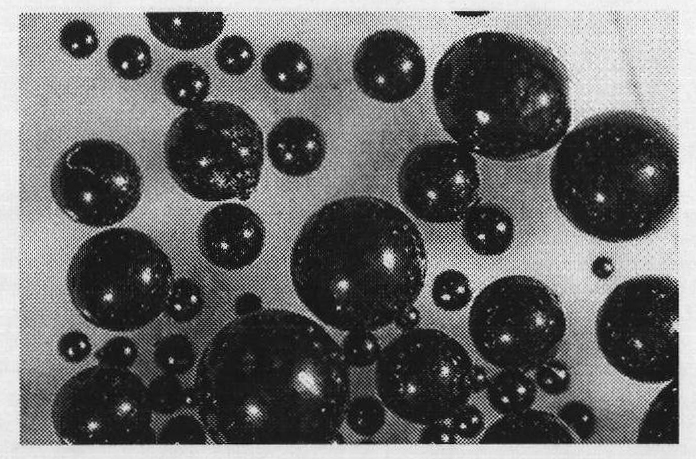

A technology of asphalt balls and asphalt, which is applied in the direction of solidification/crushing and processing tar asphalt/petroleum asphalt/natural asphalt, etc. It can solve the problems of mutual collision and adhesion of asphalt balls, rough surface of asphalt balls, complex process, etc., and achieve uniform ball diameter and surface The effect of smooth and simplified preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1, prepare asphalt ball

[0023] 1) Naphthalene (viscosity reducer) is placed in the reactor, heated to melt it, and under the condition of stirring, add petroleum asphalt with a softening point of 180° C. with a mass ratio of 70:30 to naphthalene in the reactor. After installing the reaction kettle, raise the temperature of the reaction kettle to 180°C at a stirring rate of 70r / min, keep the temperature constant for 1 hour, and cool down naturally to prepare modulated asphalt.

[0024] 2) Prepare 300 ml of an aqueous solution of polyvinyl alcohol (polymerization degree: 500) with a mass concentration of 5% as a suspension medium, and heat it to 80° C. at a stirring speed of 720 r / min.

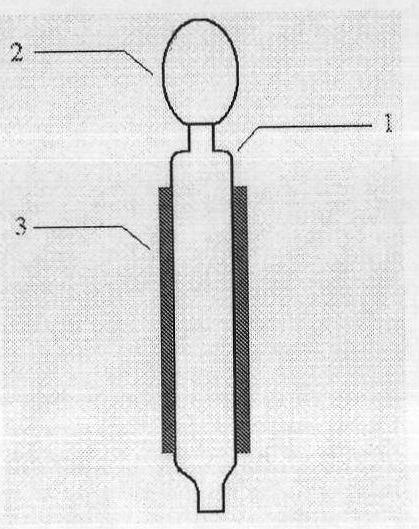

[0025] 3) Heat the modulated asphalt prepared in step 1) to 110°C to make it have a certain fluidity, and use figure 1 The adding device shown absorbs 15g of prepared asphalt, and adds the prepared asphalt at a constant speed of 10ml / min below the surface of the suspension m...

Embodiment 2

[0026] Embodiment 2, prepare asphalt ball

[0027] 1) Put dimethylnaphthalene (viscosity reducer) in the reaction kettle, heat it to melt, and add the viscosity reducer to the reaction kettle with a mass ratio of 57:43 and a softening point of 280 ℃ coal tar pitch. After installing the reactor, raise the temperature of the reactor to 280°C at a stirring rate of 70r / min, keep the temperature constant for 2 hours, and cool down naturally to prepare modulated asphalt.

[0028] 2) Prepare 300 ml of 5% polyvinyl alcohol (polymerization degree 1000) aqueous solution as the suspension medium, and heat it to 85° C. at a stirring speed of 720 r / min.

[0029] 3) Heating the modulated asphalt prepared in step 1) to 180°C to make it have a certain fluidity, use figure 1 The adding device shown draws 10g of modulated asphalt, and adds the modulated asphalt at a constant speed of 6ml / min below the surface of the suspension medium; keep the temperature at 86°C for 10min, and then cool down...

Embodiment 3

[0030] Embodiment 3, prepare asphalt ball

[0031] 1) Put methylnaphthalene (viscosity reducer) in the reactor, heat it to melt it, and under the condition of stirring, add to the reactor the high Softening point asphalt, the asphalt is obtained by heat condensation at 400°C for 3 hours. After installing the reactor, raise the temperature of the reactor to 280°C at a stirring rate of 70r / min, keep the temperature constant for 1.5h, and cool down naturally to prepare modulated asphalt.

[0032] 2) Prepare 300 ml of 5% polyvinyl alcohol (polymerization degree: 2000) aqueous solution as a suspension medium, and heat it to 86° C. at a stirring speed of 720 r / min.

[0033] 3) Heating the modulated asphalt prepared in step 1) to 180°C to make it have a certain fluidity, use figure 1 The adding device shown draws 15g of modulated asphalt, and adds the modulated asphalt at a constant speed of 3ml / min below the liquid surface of the suspension medium; keep the temperature at 86°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com