Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2622results about How to "Easy to crush" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

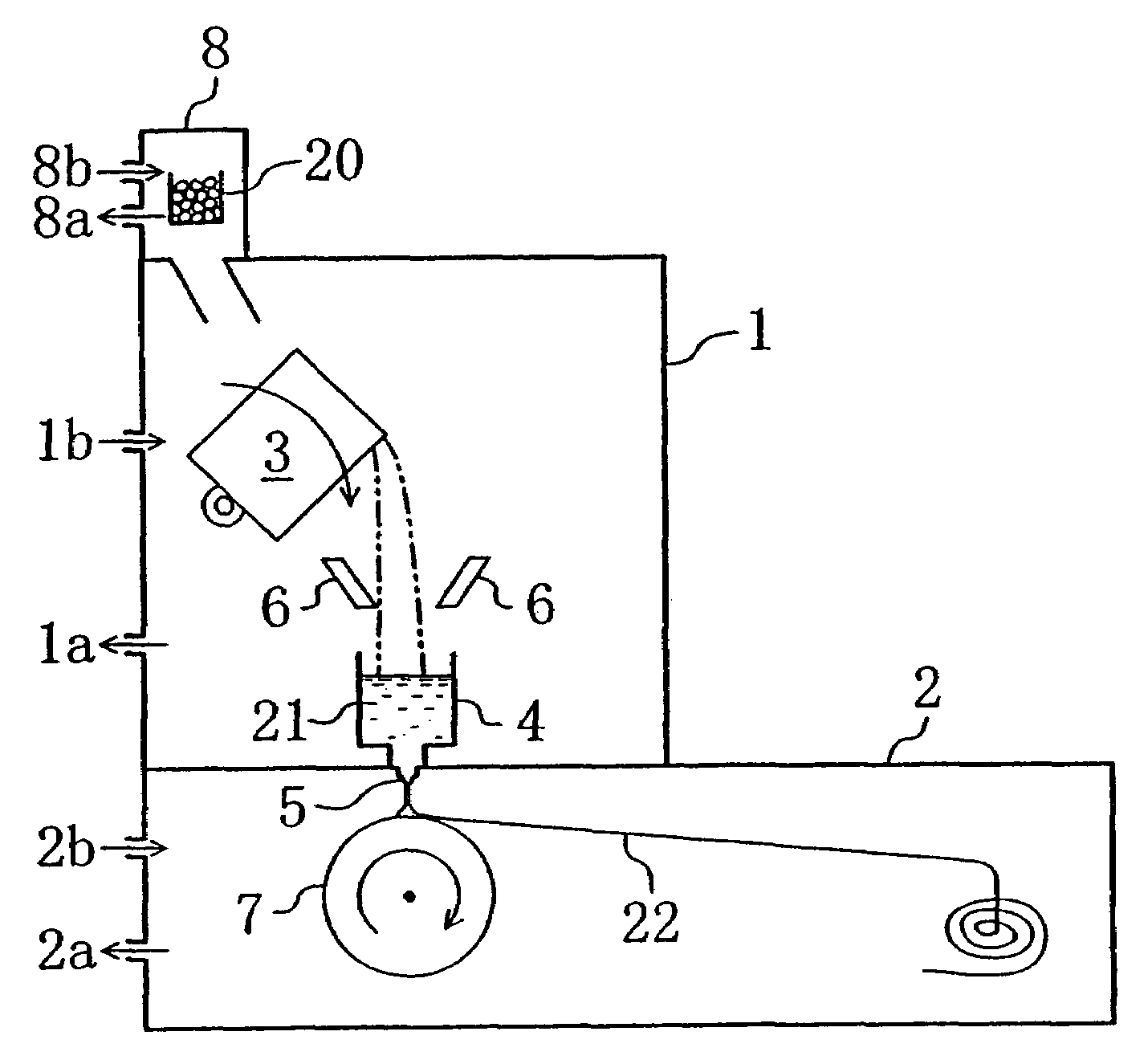

Process for producing a plant extract containing plant powder

InactiveUS20040161524A1Increase contentEasy to crushSolid waste disposalAnimal feeding stuffHas active ingredientAdditive ingredient

The present invention relates to a method for producing a liquid plant extract containing plant powder, which comprises concentrating a liquid extract containing an active ingredient in the presence of the plant powder, the liquid extract being obtained from a plant containing the active ingredient; a process for producing a plant extract containing plant powder, which is characterized by comprises concentrating and drying a liquid extract containing an active ingredient in the presence of the plant powder, the liquid extract being obtained from a plant containing the active ingredient; a liquid plant extract or plant extract containing plant powder which comprises a liquid extract or plant extract containing the active ingredient obtained from a plant containing the active ingredient and comprises plant powder, and in which the content of the active ingredient in the liquid extract or plant extract is higher than that in the plant; and a food and drink or feed to which the liquid plant extract or plant extract containing plant powder is added.

Owner:KYOWA HAKKO BIO CO LTD

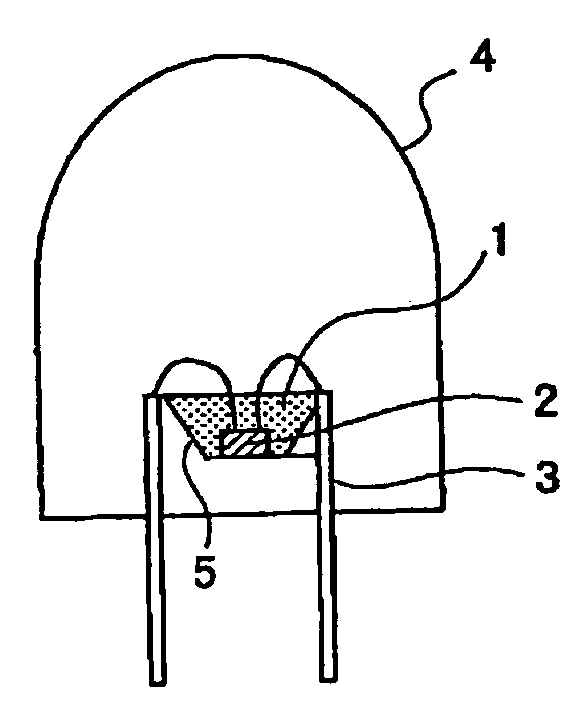

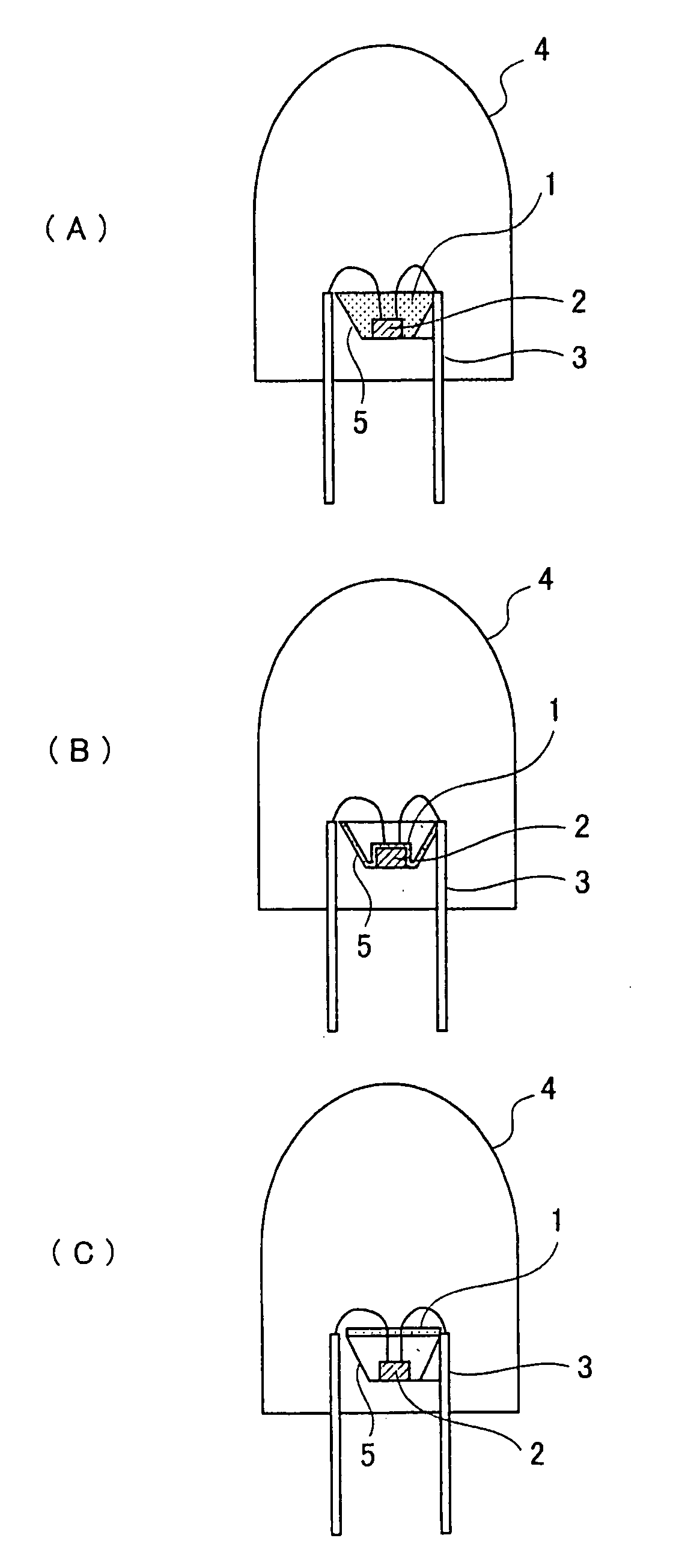

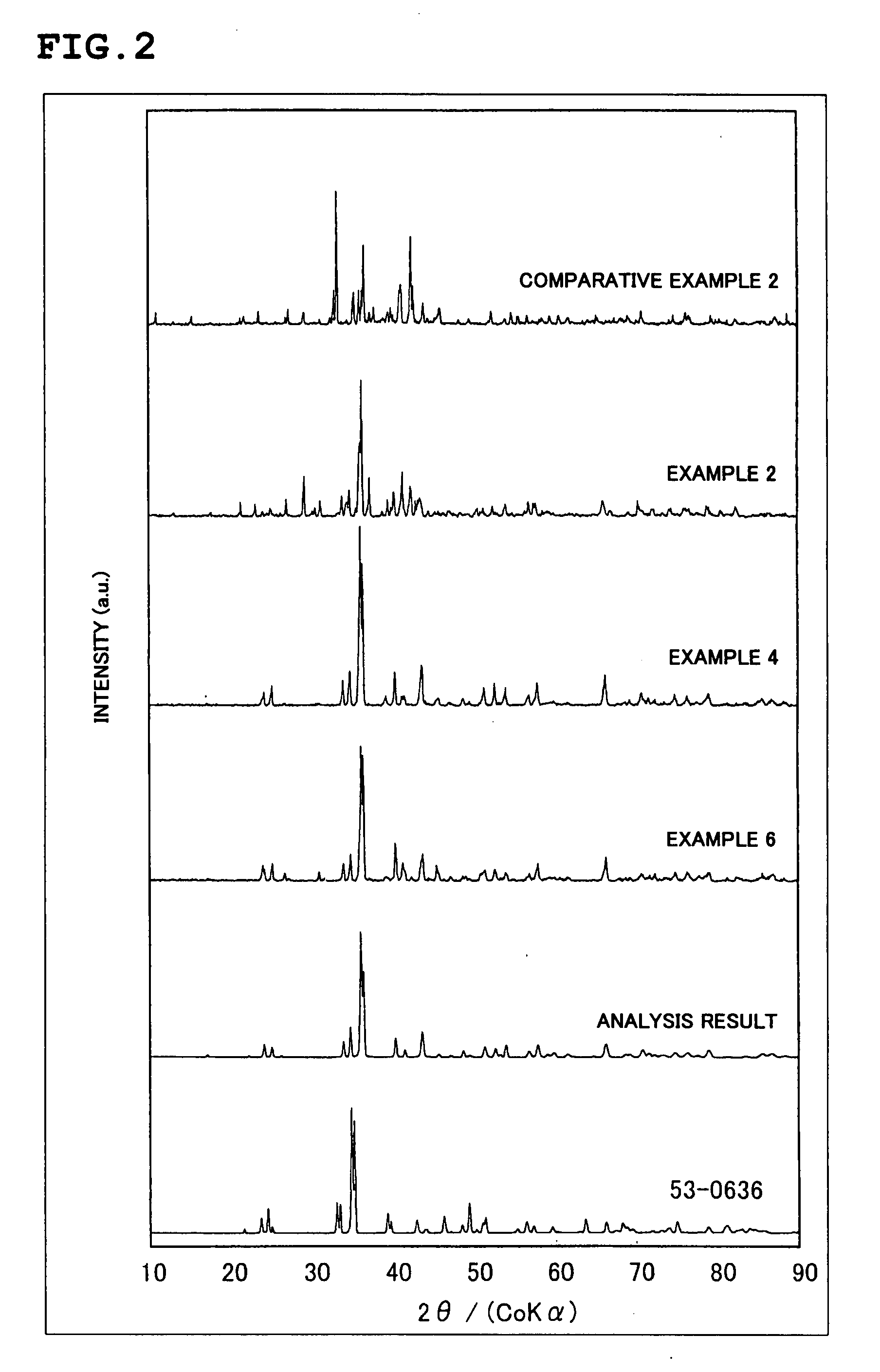

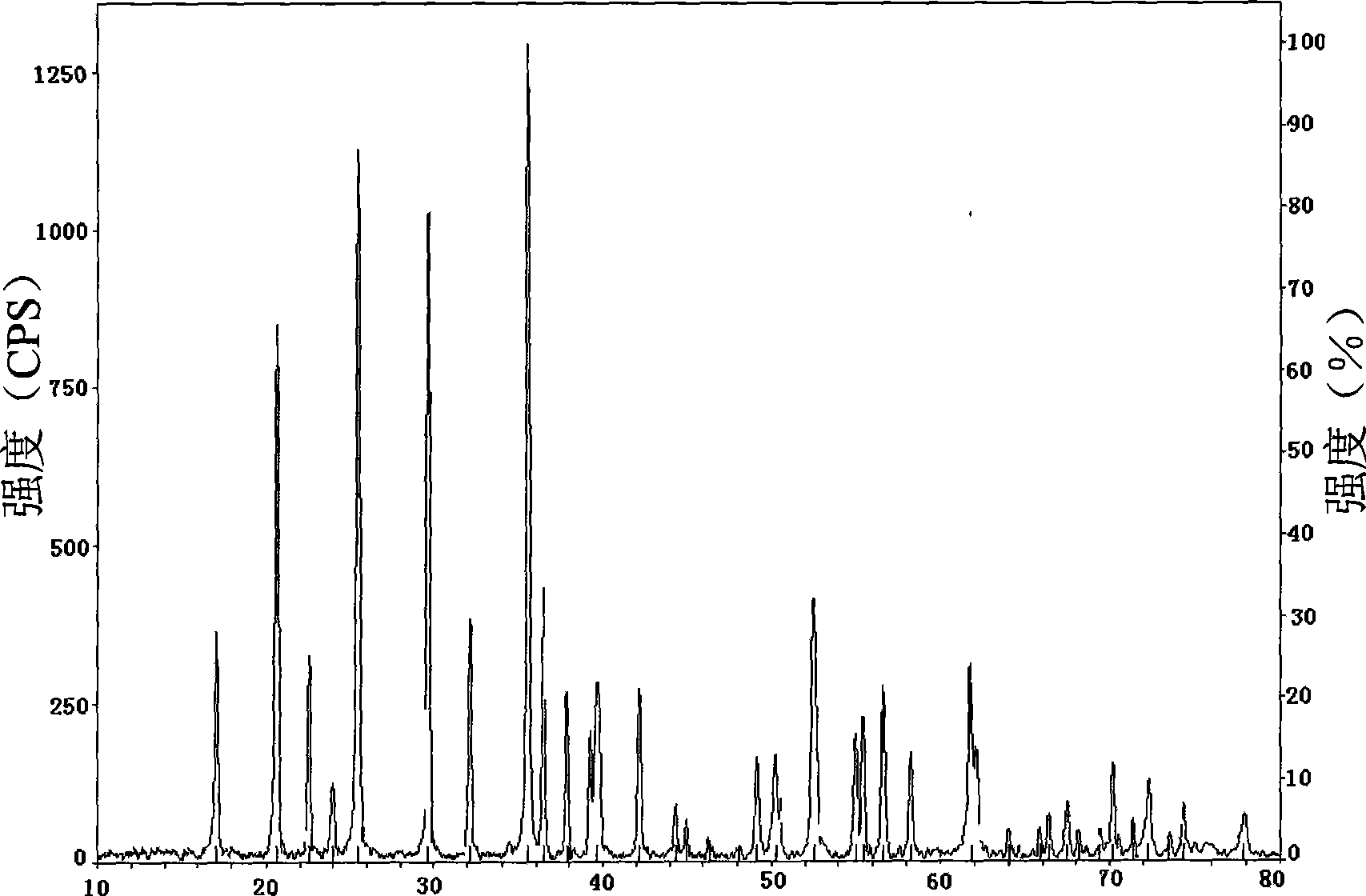

Phosphor and manufacturing method of the same, and light emitting device using the phosphor

InactiveUS20060220047A1Improve efficiencyIncrease intensityDischarge tube luminescnet screensLamp detailsUltravioletPeak value

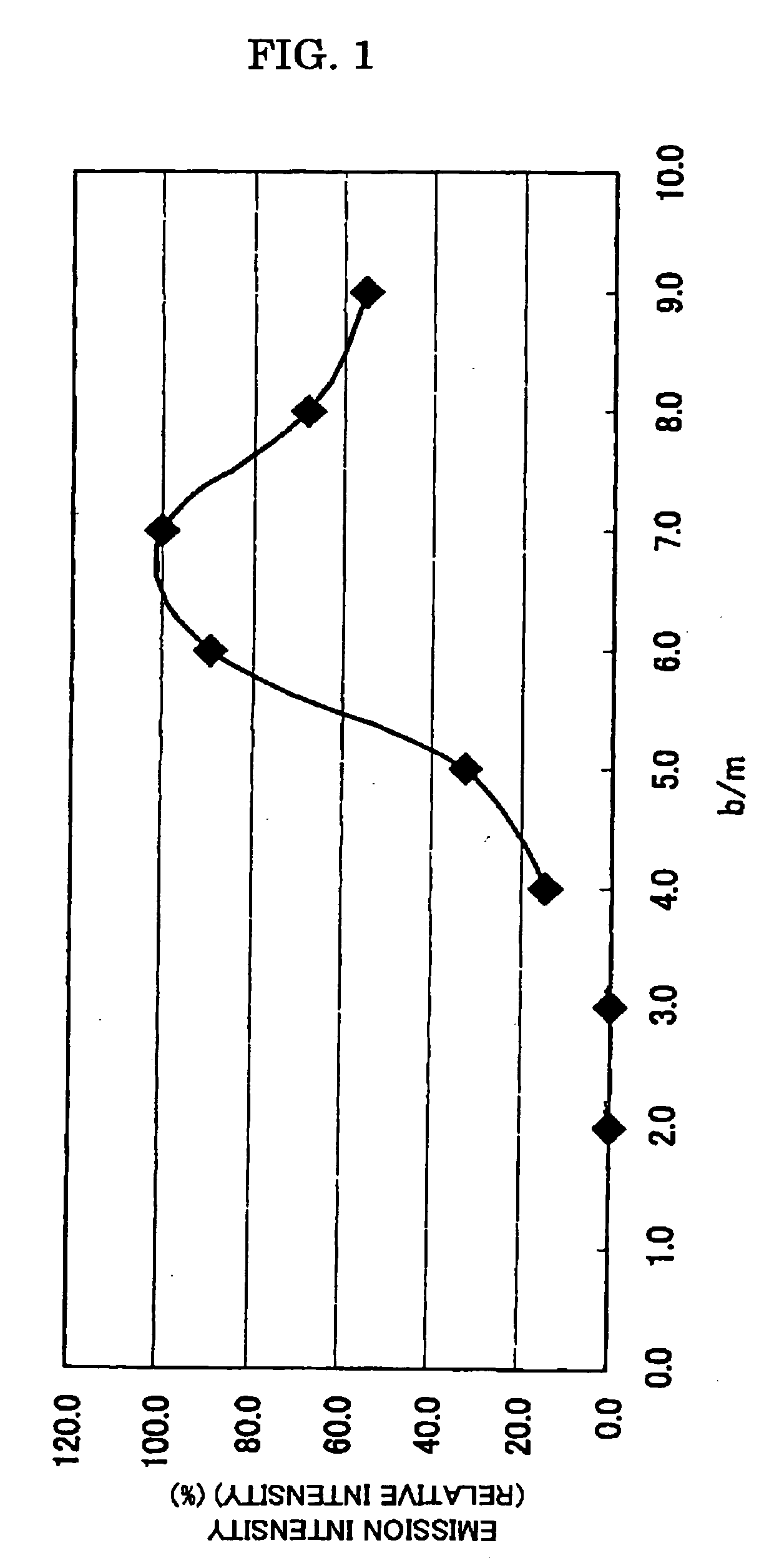

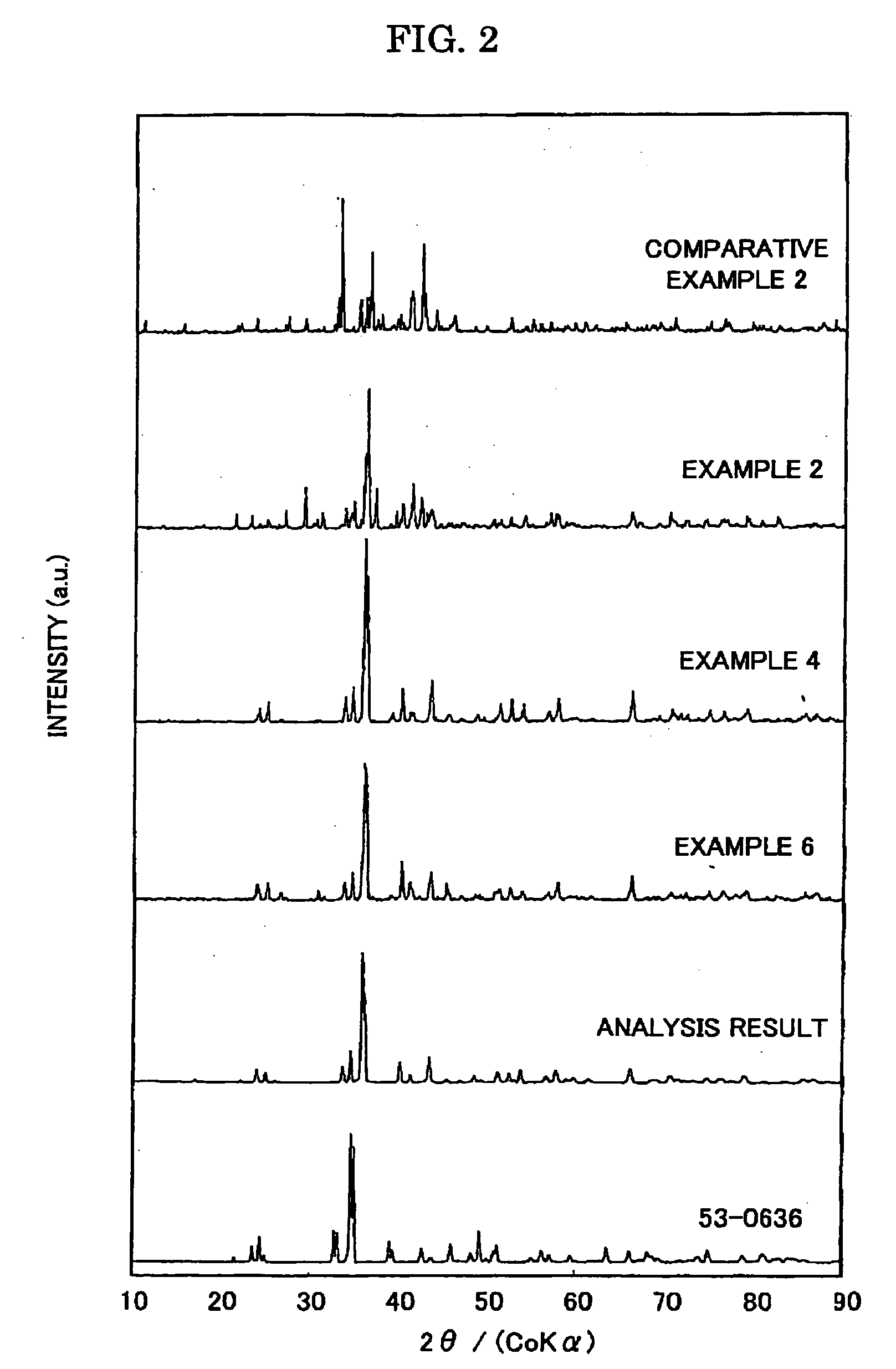

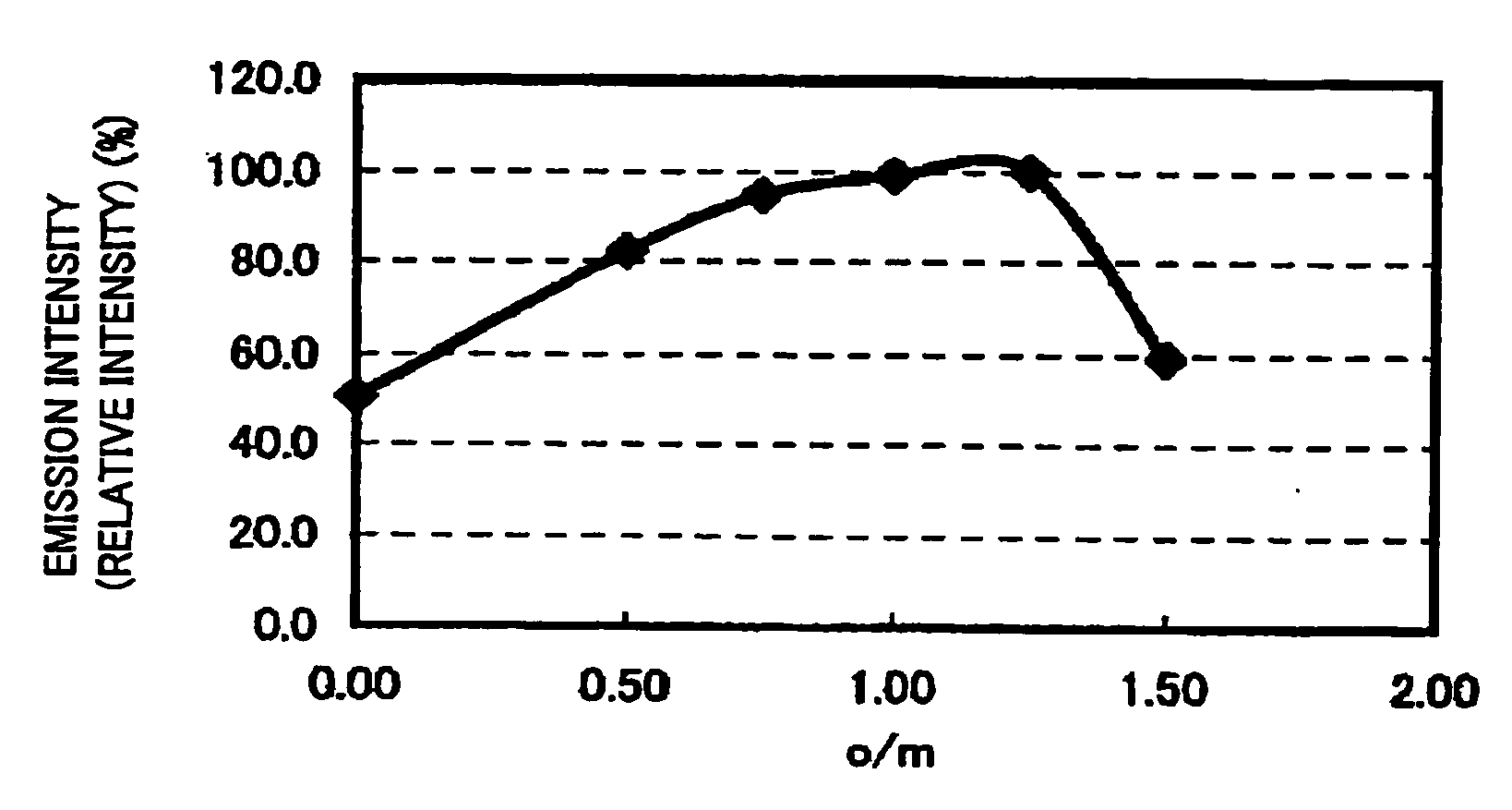

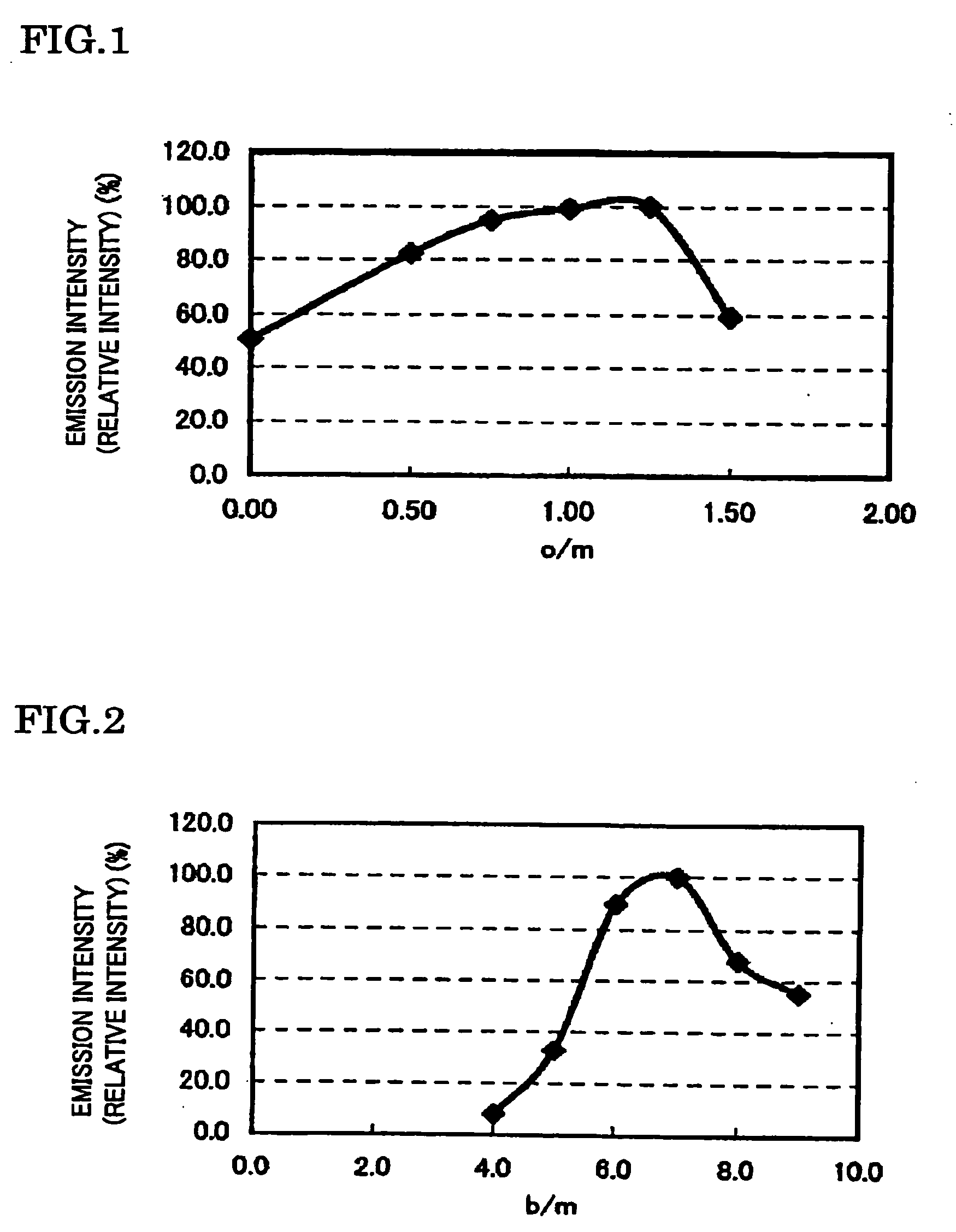

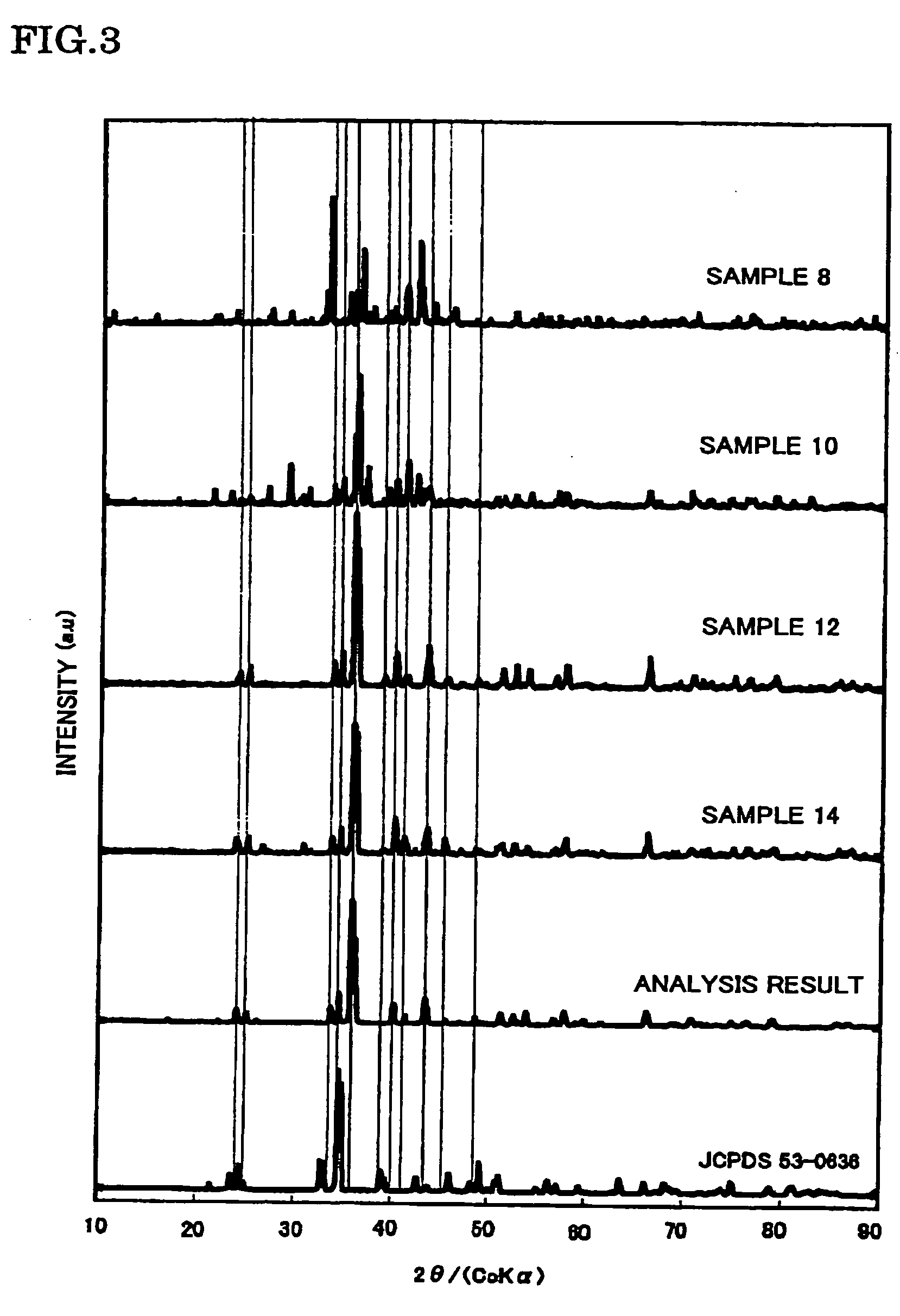

To provide a phosphor having a broad emission spectrum in a range of blue color (peak wavelength from 400 nm to 500 nm), having a broad and flat excitation band in the range of near ultraviolet / ultraviolet, and having excellent emission efficiency and emission intensity / luminance. The phosphor is expressed by a general composition formula MmAaBbOoNn:Z (where element M is more than one kind of element having bivalent valency, element A is more than one kind of element having tervalent valency, element B is more than one kind of element having tetravalent valency, O is oxygen, N is nitrogen, and element Z is more than one kind of element acting as an activator.), satisfying 5.0<(a+b) / m<9.0, 0≦a / m≦2.0, 0≦o<n, n=2 / 3m+a+4 / 3b−2 / 3o, and having an emission spectrum with a maximum peak wavelength from 400 nm to 500 nm under an excitation of the light in a wavelength range from 350 nm to 430 nm.

Owner:MITSUBISHI CHEM CORP

Phosphor and manufacturing method of the same, and light emitting device using the phosphor

InactiveUS20060220520A1Improve efficiencyIncrease intensityDischarge tube luminescnet screensLamp detailsLuminous intensityUltraviolet

To provide a phosphor having an emission spectrum with a broad peak in a range of blue color (peak wavelength range from 400 nm to 500 nm) and a broad and flat excitation band in a range of near ultraviolet / ultraviolet, and having an excellent emission efficiency and emission intensity / luminance, a manufacturing method of the same, and a light emitting device using the phosphor. The phosphor is provided, which is given as a general composition formula expressed by MmAaBbOoNn:Z, (where element M is the element having bivalent valency, element A is the element having tervalent valency, element B is the element having tetravalent valency, O is oxygen, N is nitrogen, and element Z is more than one kind of element acting as an activator.), satisfying 5.0<(a+b) / m<9.0, 0≦a / m≦2.0, 0≦o<n, and n=2 / 3m+a+4 / 3b−2 / 3o, and having an emission spectrum with a maximum peak wavelength from 400 nm to 500 nm under an excitation of the light in a wavelength range from 350 nm to 430 nm.

Owner:MITSUBISHI CHEM CORP

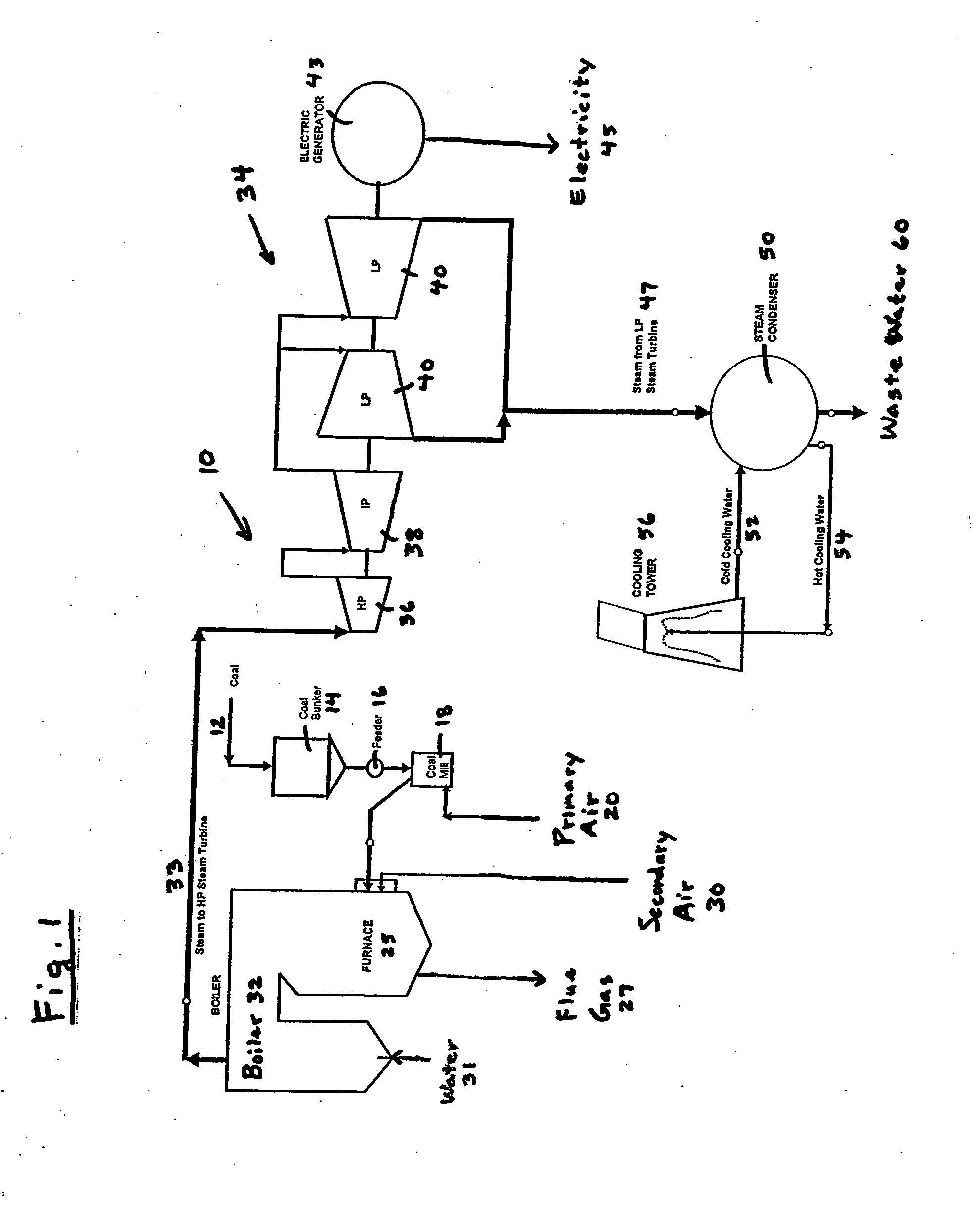

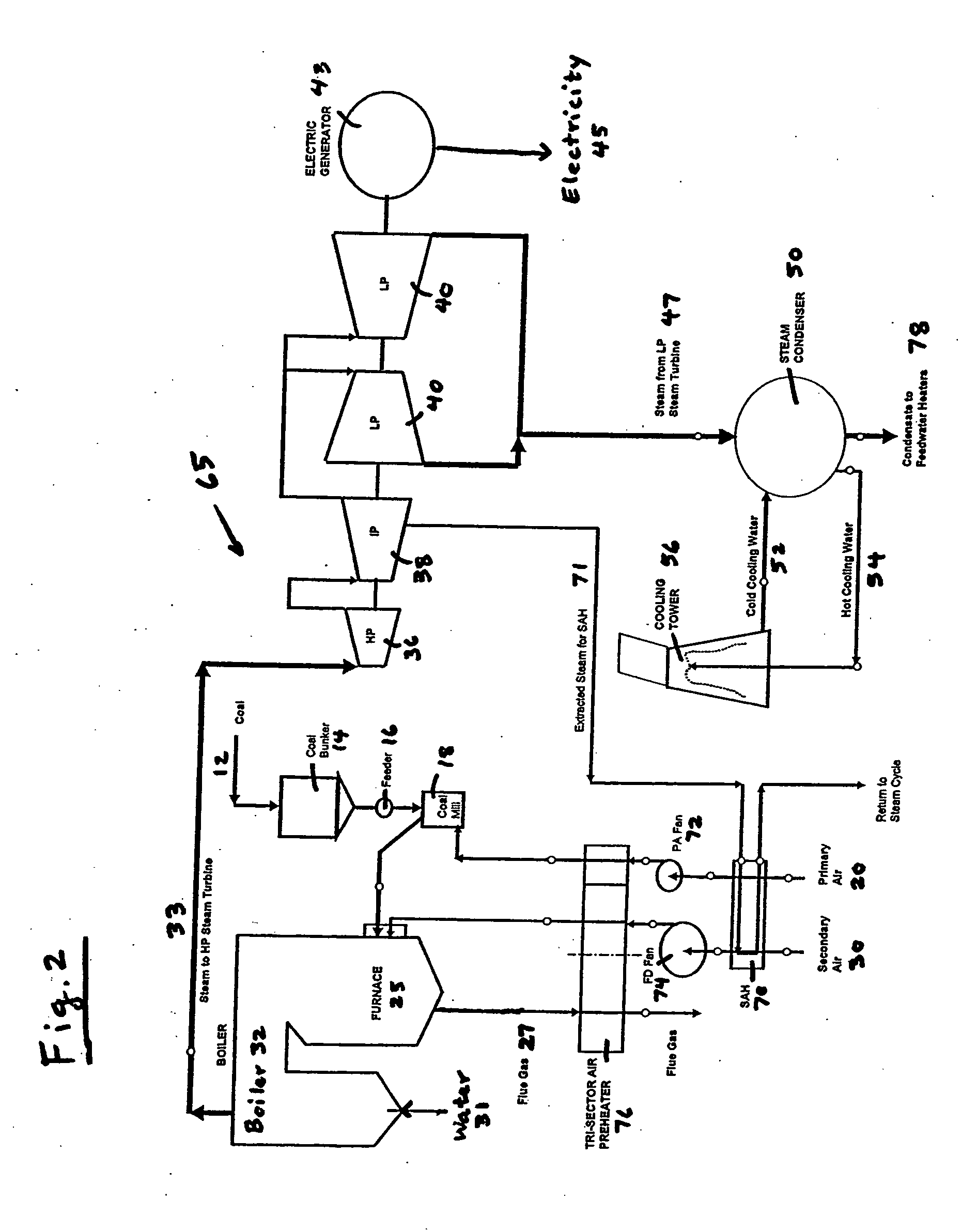

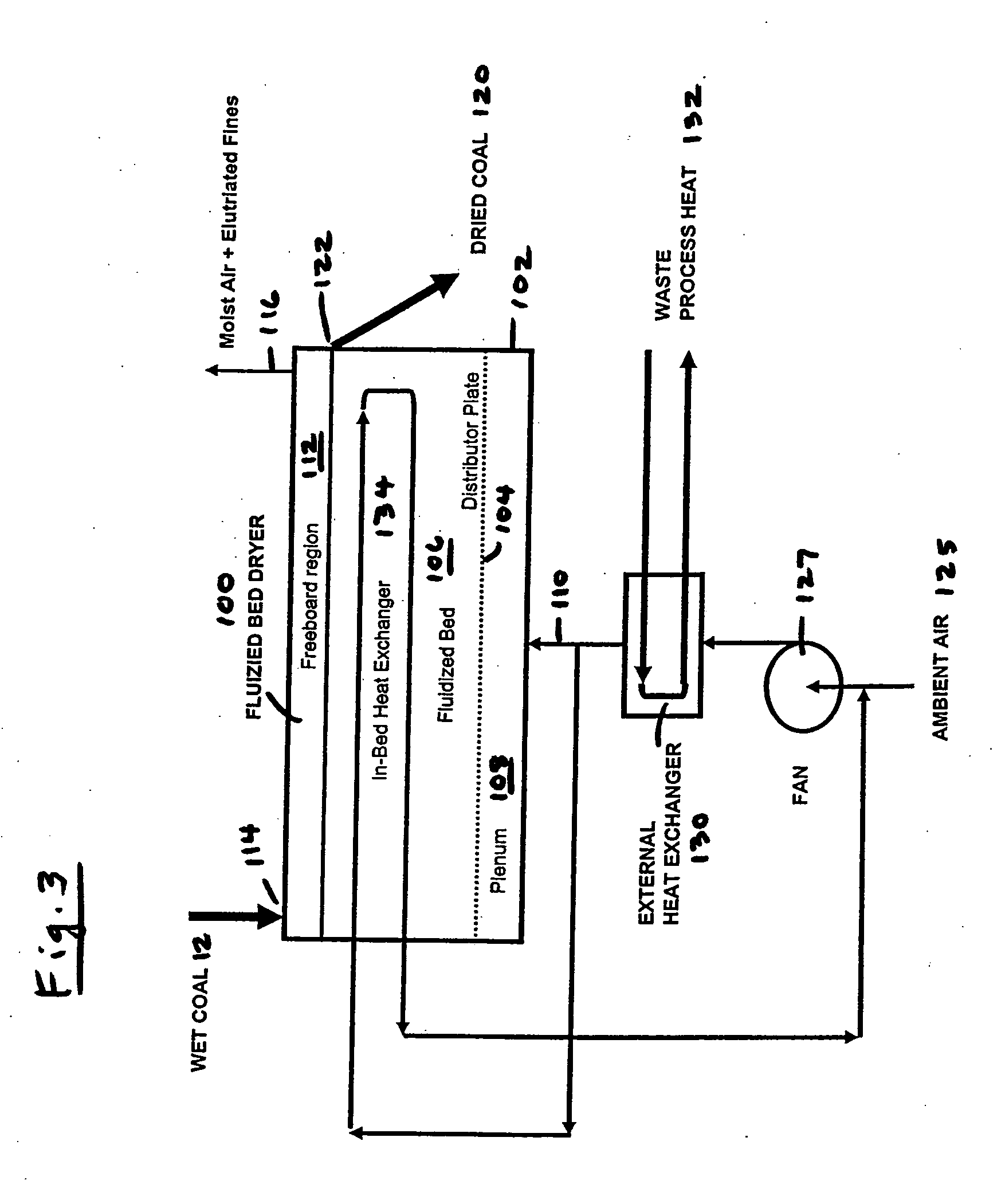

Method of enhancing the quality of high-moisture materials using system heat sources

ActiveUS20060075682A1Eliminates potential harmEmission reductionDrying solid materials with heatSolid fuelsFluidized bed dryingHeat flow

The present invention harvests and utilizes fluidized bed drying technology and waste heat streams augmented by other available heat sources to dry feedstock or fuel. This method is useful in many industries, including coal-fired power plants. Coal is dried using the present invention before it goes to coal pulverizers and on to the furnace / boiler arrangement. Coal can be intercepted on current coal feed systems ahead of the pulverizers. Drying fuel, such as coal, is done to improve boiler efficiency and reduce emissions. A two-stage bed utilized in the process first “pre-dries and separates” the feed stream into desirable and undesirable feedstock. Then, it incrementally dries and segregates fluidizable and non-fluidizable material from the product stream. This is all completed in a low-temperature, open-air system. Elevation of fan room air temperature is also accomplished using waste heat, thereby making available to the plant system higher temperature media to enhance the feedstock drying process.

Owner:RAINBOW ENERGY CENT LLC

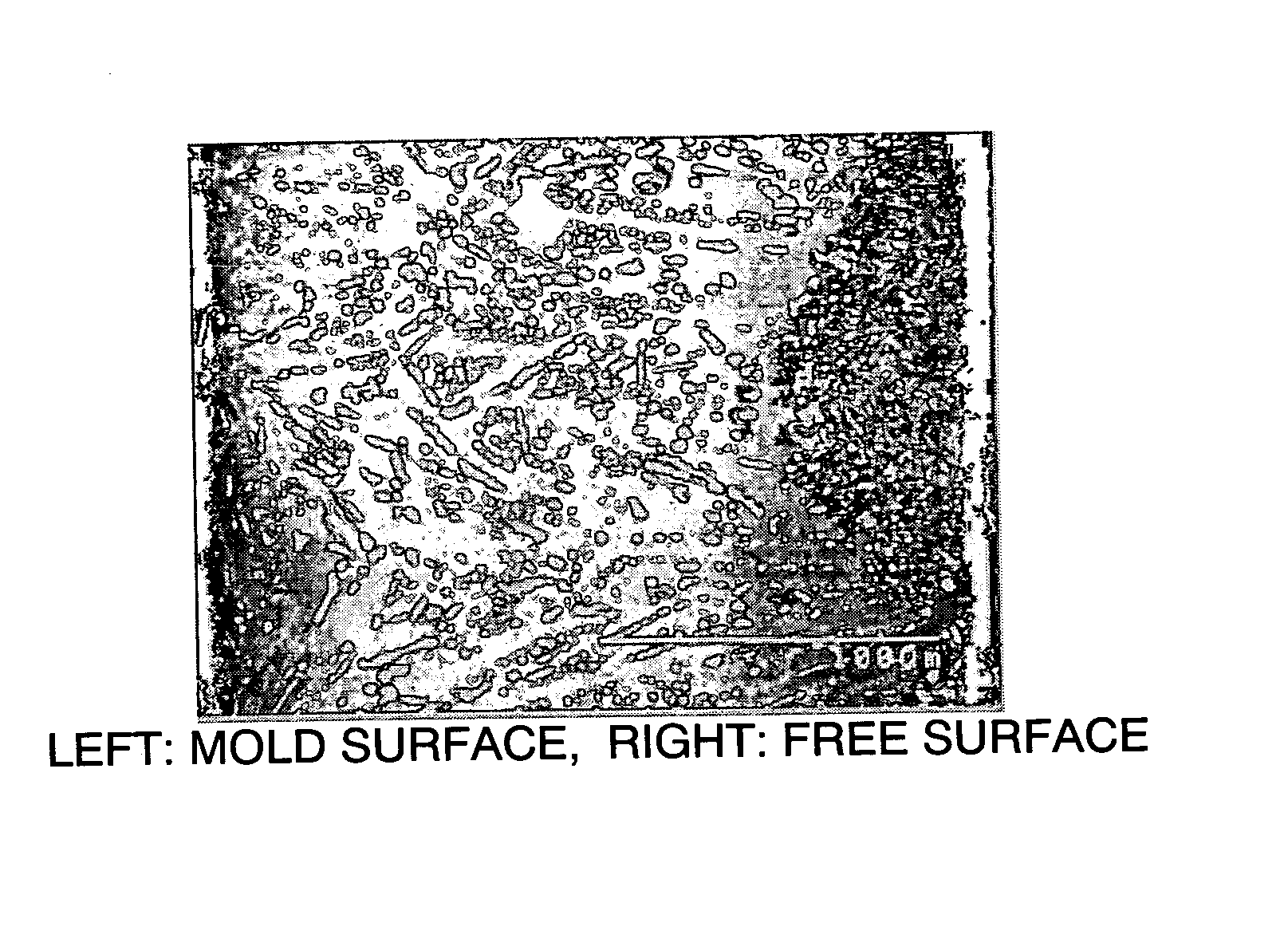

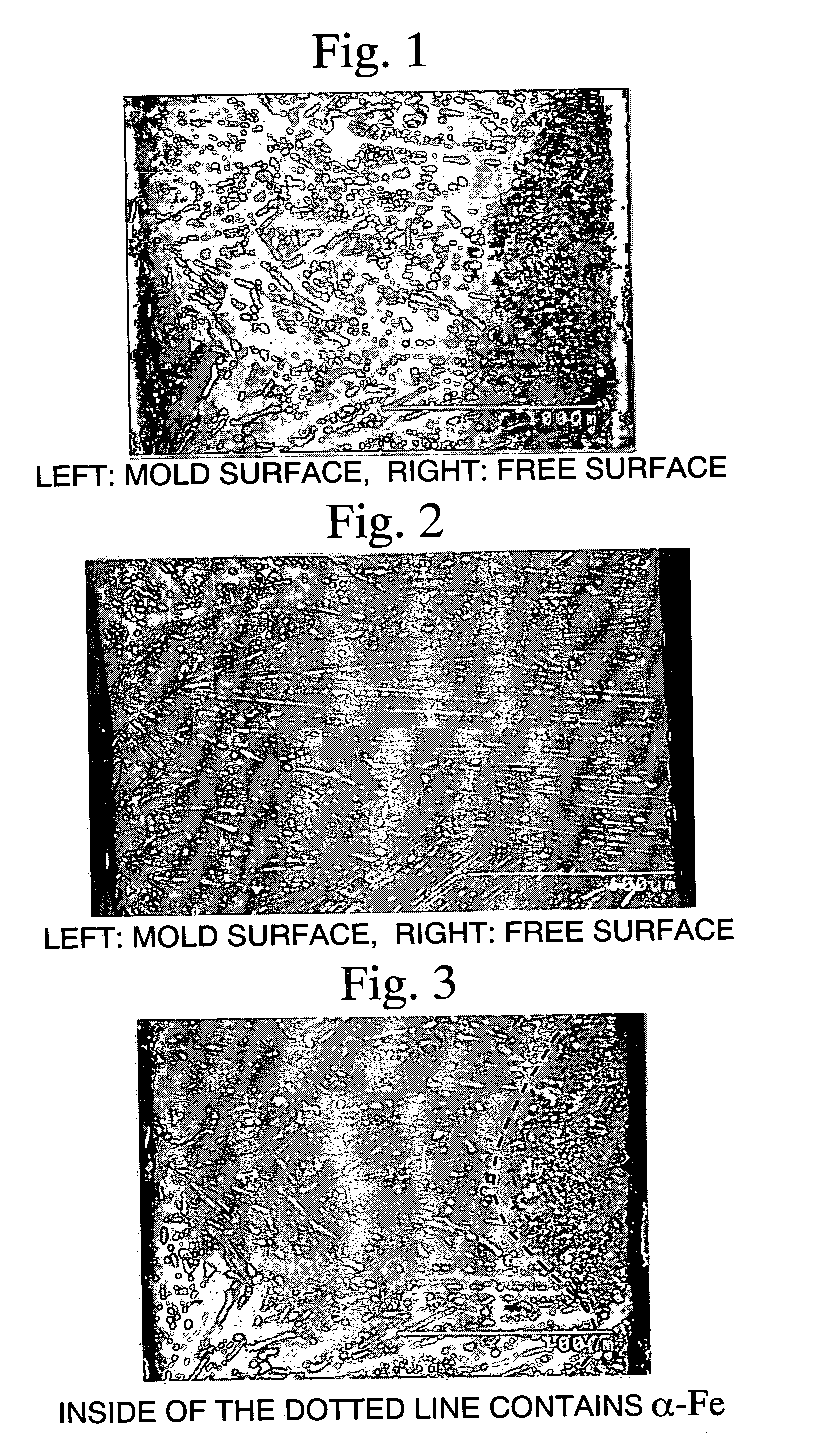

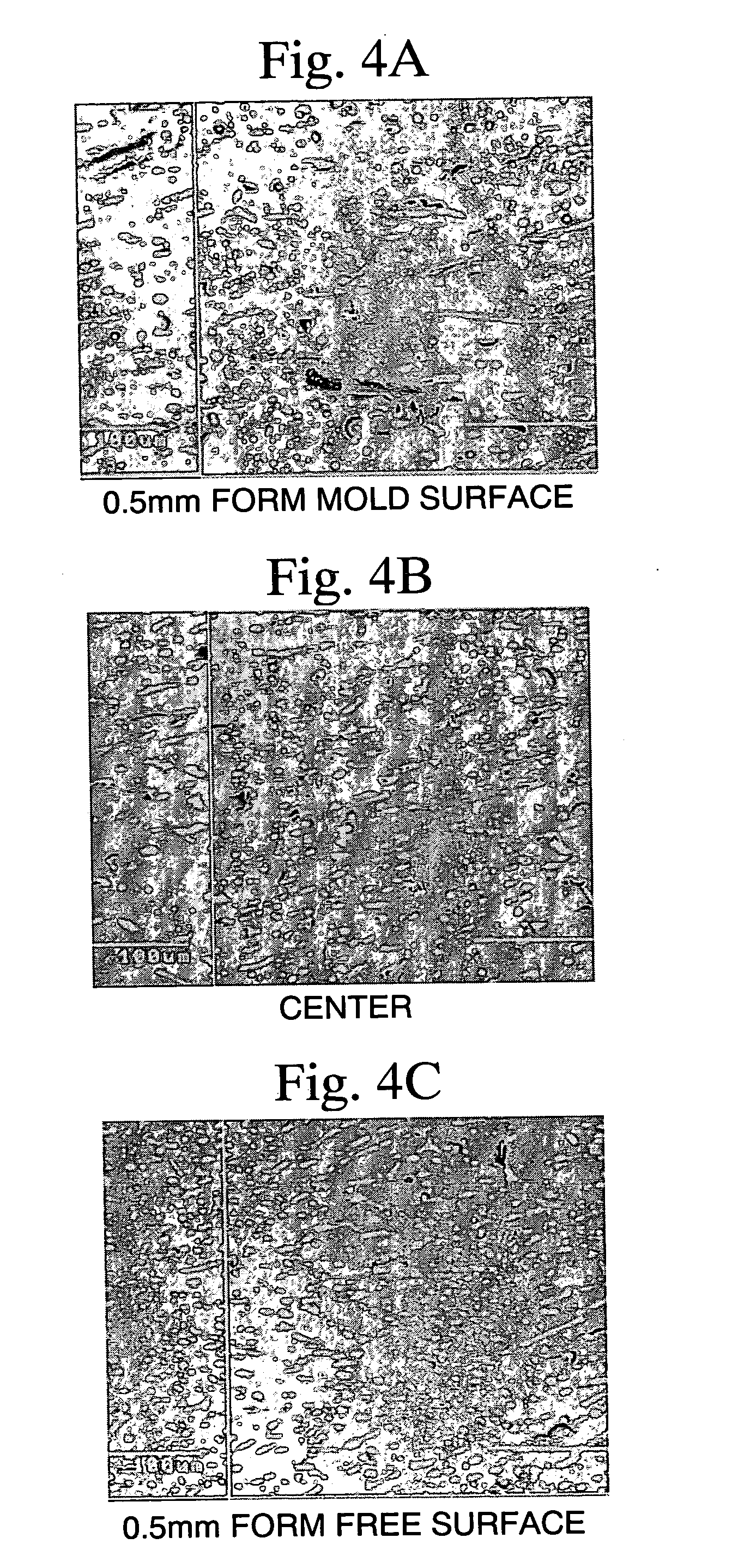

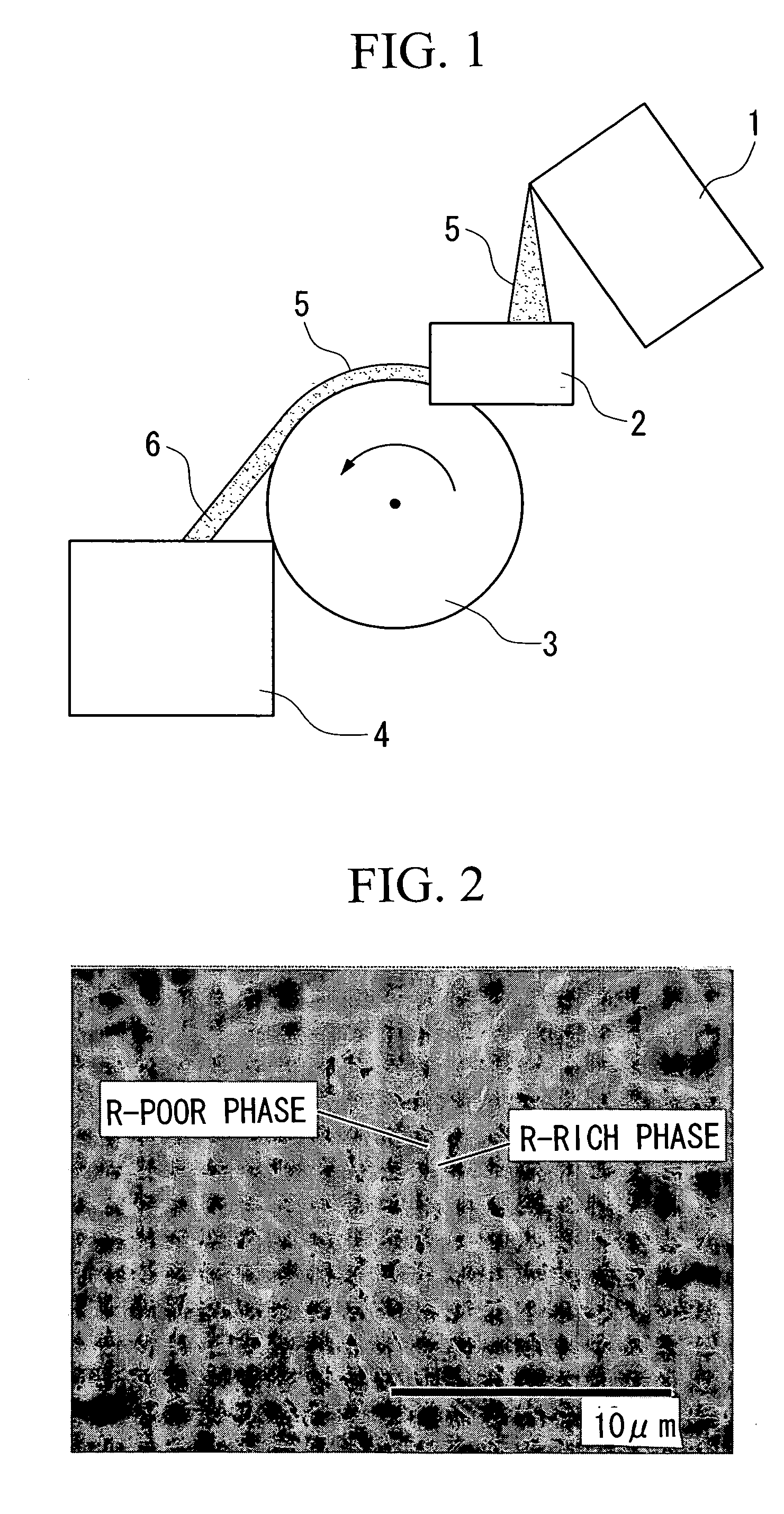

Alloy flake for rare earth magnet, production method thereof, alloy powder for rare earth intered magnet, rare earth sintered magnet, alloy powder for bonded magnet and bonded magnet

ActiveUS20050028892A1Low amountLow costTransportation and packagingMetal-working apparatusRare-earth elementThin sheet

Disclosed is a rare earth magnet in the R-T-B (rare earth element-transition metal-boron) system that is made from an improved composition and properties of main phase alloy in the R-T-B system containing Pr and a boundary alloy. Disclosed also is a manufacturing method of the rare earth magnet alloy flake by a strip casting method with improved rotating rollers such that the alloy flake has a specified fine surface roughness and has a small and regulated amount of fine R-rich phase regions. Consequently, the alloy flake for the rare earth magnet does not containing α-Fe and has a homogeneous morphology so that the rare earth magnet formed by sintering or bonding the alloy flakes exhibits excellent magnetic properties.

Owner:TDK CORPARATION

Phosphor, Phosphor Sheet, and Manufacturing Method Therefore, and Light Emission Device Using the Phosphor

InactiveUS20090026915A1High efficient excitation bandImprove emission efficiencyDischarge tube luminescnet screensLamp detailsUltravioletEmission efficiency

To provide a phosphor having a broad emission spectrum in a range of blue color (in a peak wavelength range from 400 nm to 500 nm), having a broad flat excitation band in a near ultraviolet / ultraviolet range, and having excellent emission efficiency and emission intensity / luminance. The phosphor is given as a general composition formula expressed by MmAaBbOoNn:Z, (where element M is the element having bivalent valency, element A is the element having tervalent valency, element B is the element having tetravalent valency, O is oxygen, N is nitrogen, and element Z is more than one kind of element acting as an activator), satisfying 5.0<(a+b) / m<9.0, 0≦a / m≦2.0, 0≦o≦n, n=2 / 3m+a+4 / 3b−2 / 3o, and has an emission spectrum with a maximum peak in the wavelength range from 400 nm to 500 nm under an excitation of the light in a wavelength range from 250 nm to 430 nm.

Owner:MITSUBISHI CHEM CORP

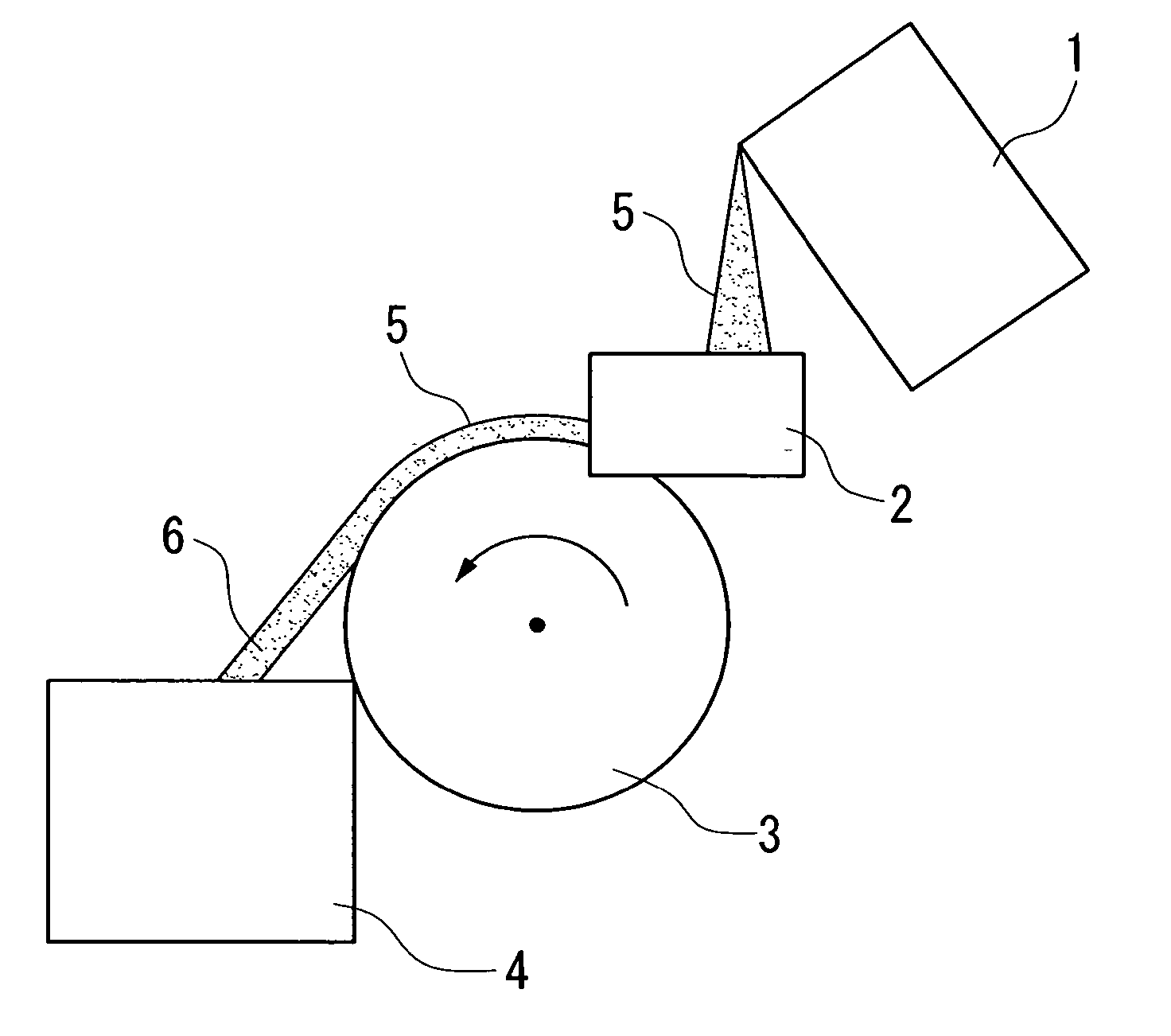

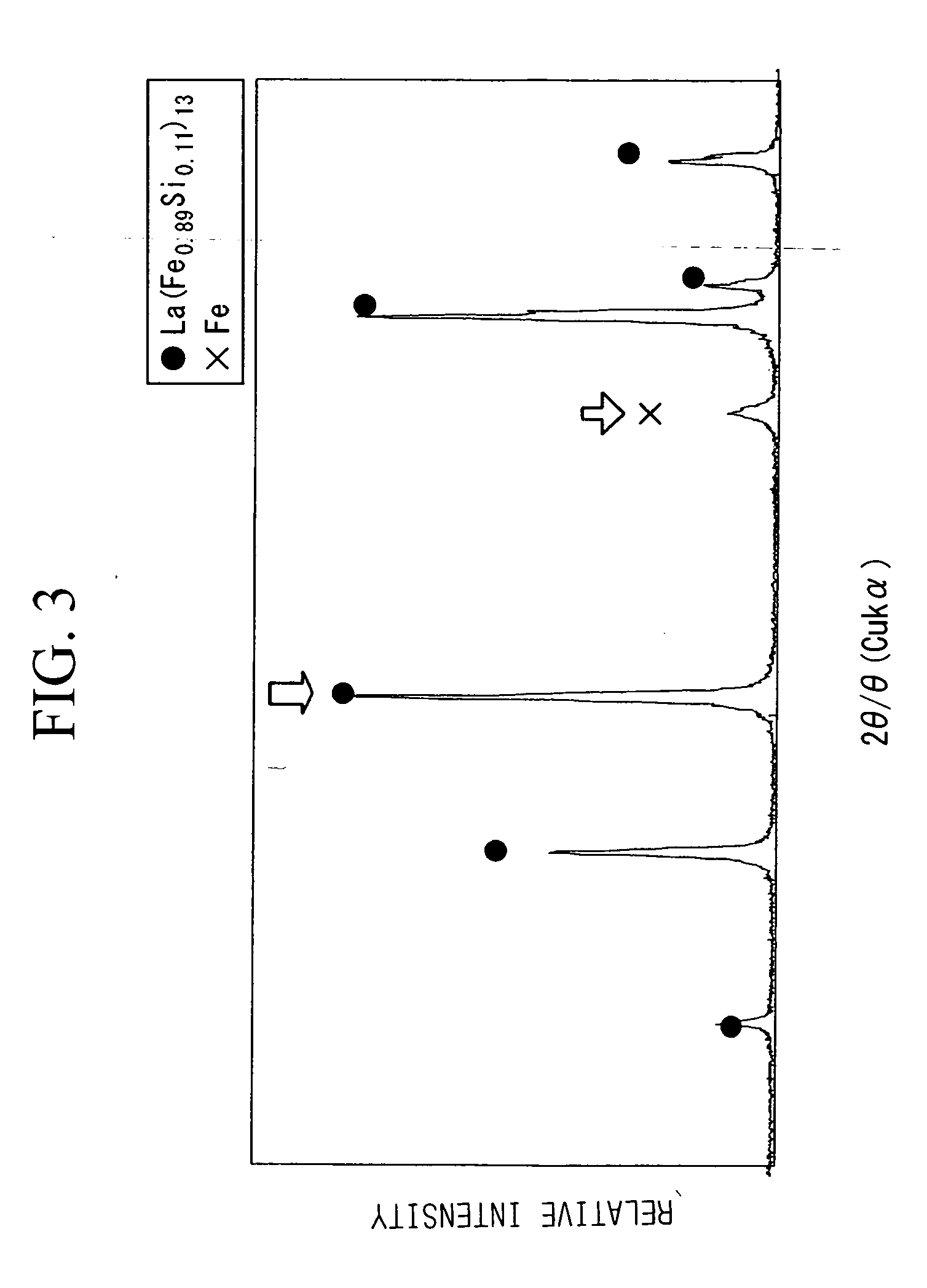

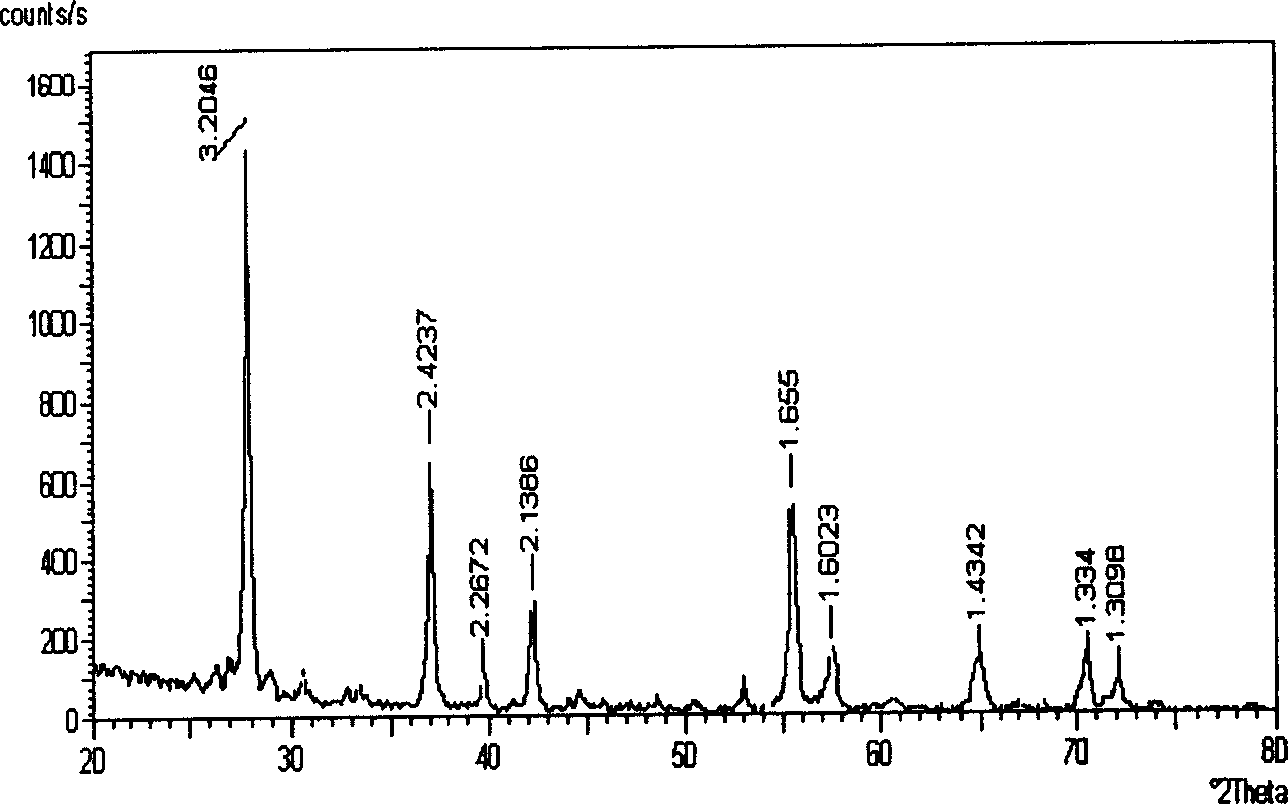

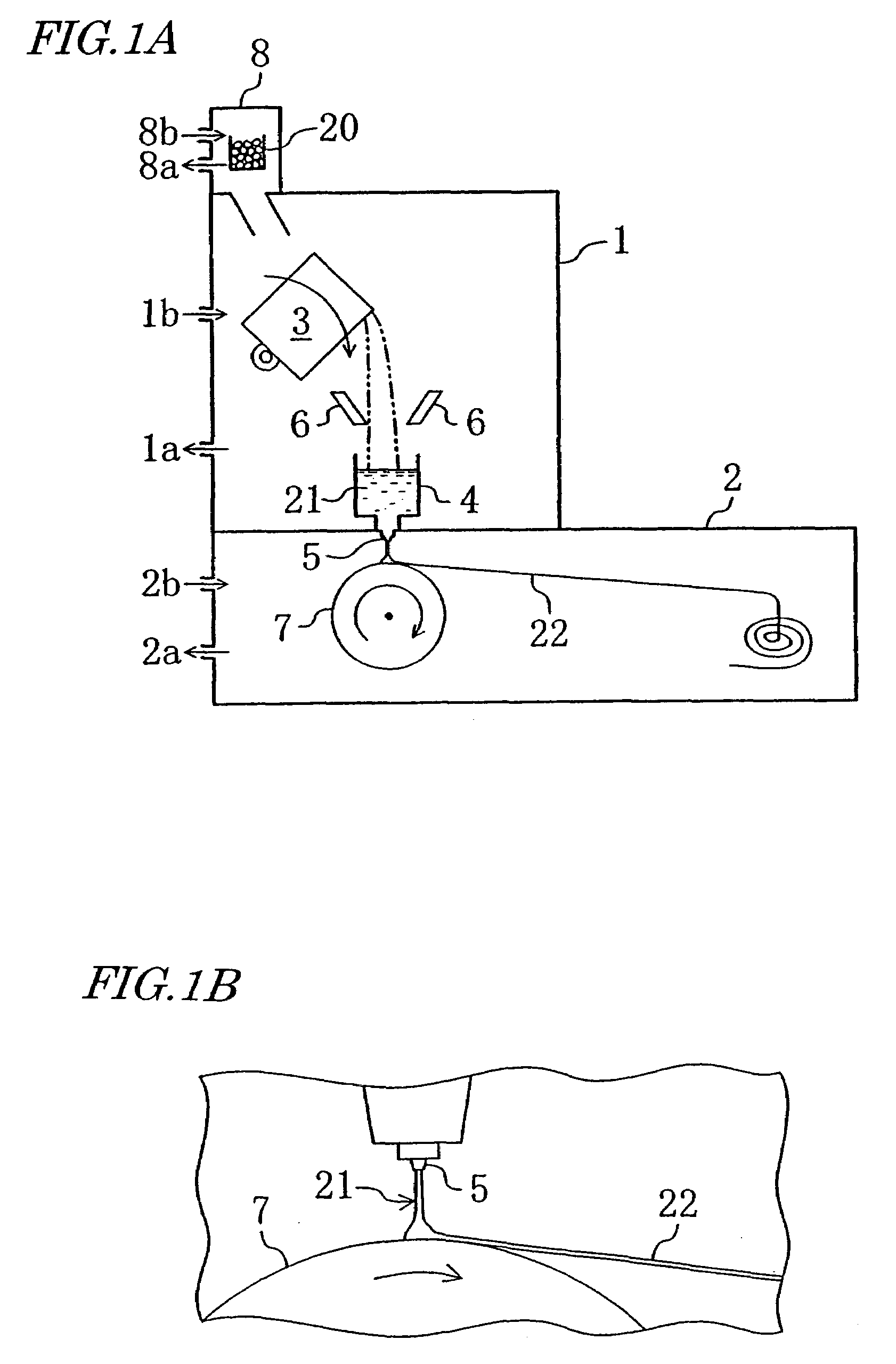

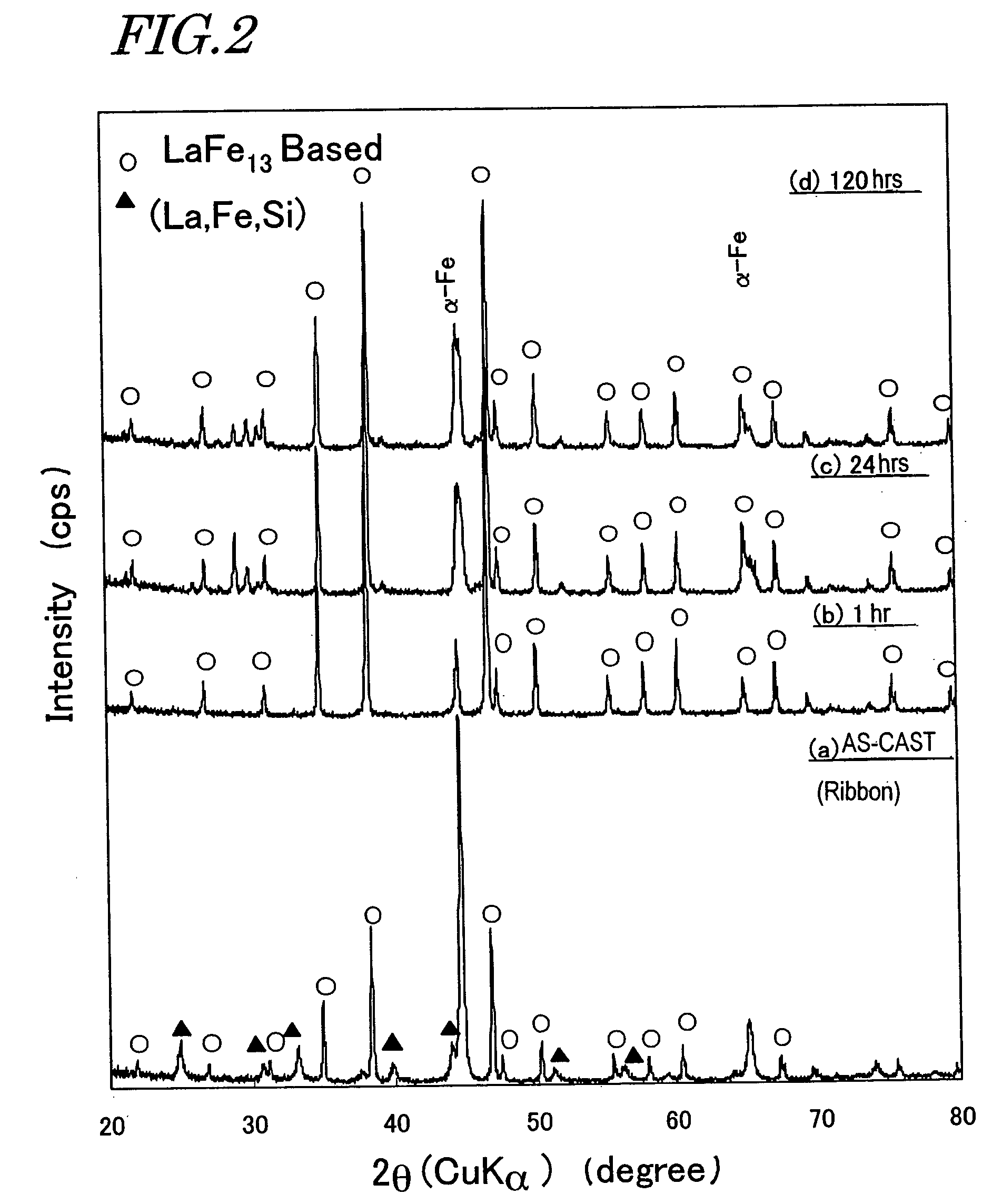

Alloy containing rare earth element, production method thereof, magnetostrictive device, and magnetic refrigerant material

InactiveUS20060076084A1Improve efficiencyReliably producedEnergy efficient heating/coolingInorganic material magnetismRare-earth elementCrystal structure

A method for producing an RE-containing alloy represented by formula R(T1−xAx)13−y (wherein R represents Ce, etc.; T represents Fe, etc.; and A represents Al, etc; 0.05≦x≦0.2; and −1≦y≦1) including a melting step of melting alloy raw materials at 1,200 to 1,800° C.; and a solidification step of rapidly quenching the molten metal produced through the above step, to thereby form the first RE-containing alloy, wherein the solidification step is performed at a cooling rate of 102 to 104° C. / second, as measured at least within a range of the temperature of the molten metal to 900° C.; and an RE-containing alloy, which is represented by a compositional formula of RrTtAa(wherein R and A represent the same meaning as above, T represents Fe, etc.; 5.0 at. %≦r≦6.8 at. %, 73.8 at. %≦t≦88.7 at. %, and 4.6 at. %≦a≦19.4 at. %) and has an alloy microstructure containing an NaZn13-type crystal structure in an amount of at least 85 mass % and α-Fe in an amount of 5-15 mass % inclusive.

Owner:ERASTEEL

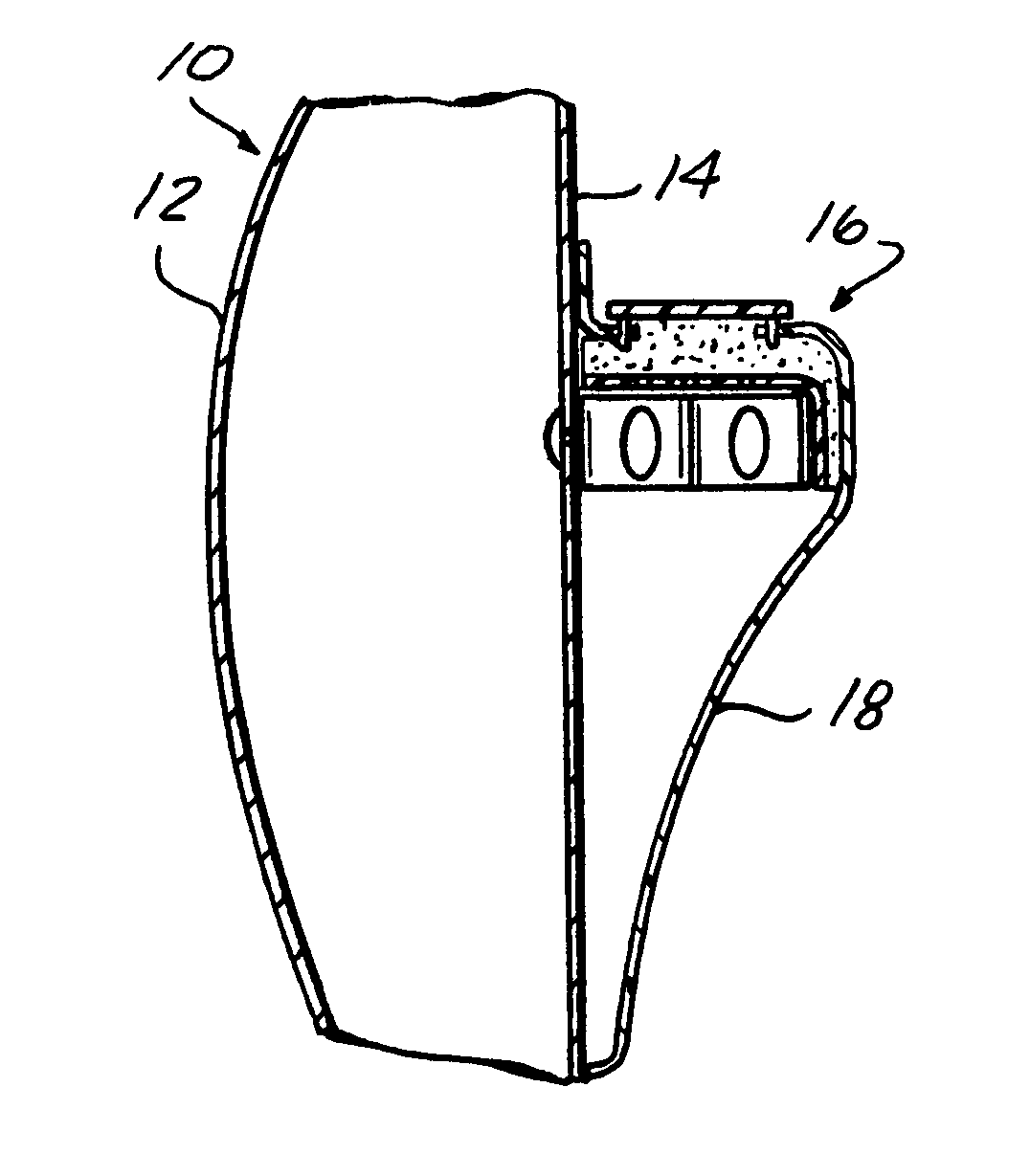

Comminution device and method for comminuting residue in a dishwasher

ActiveUS7497222B2Reduce manufacturing costEasy to crushTableware washing/rinsing machine detailsElectrostatic cleaningEngineeringComminution

A dishwashing machine including a comminution device and a method for comminuting residue in the dishwasher. The comminution device at minimal manufacturing costs, makes it possible to easily comminute the coarse contaminants or residue accumulating during the rinse cycle in the dishwashing machine, flush it out of the dishwasher and at the same time reduce the danger of clogging the sieve(s) placed in the dishwasher. The comminution device preferably is actuated by the lye pump of the dishwashing machine. In this manner the comminution device is actuated easily and efficiently, which both enables cost-effective manufacture of the dishwashing machine, and improves its operating safety and ease of maintenance. In the process the rinse residue can first collect during the rinse cycle in uncomminuted form on the floor of the rinsing container and only then be comminuted when the washing liquid is pumped out and flushed out of the dishwashing machine.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

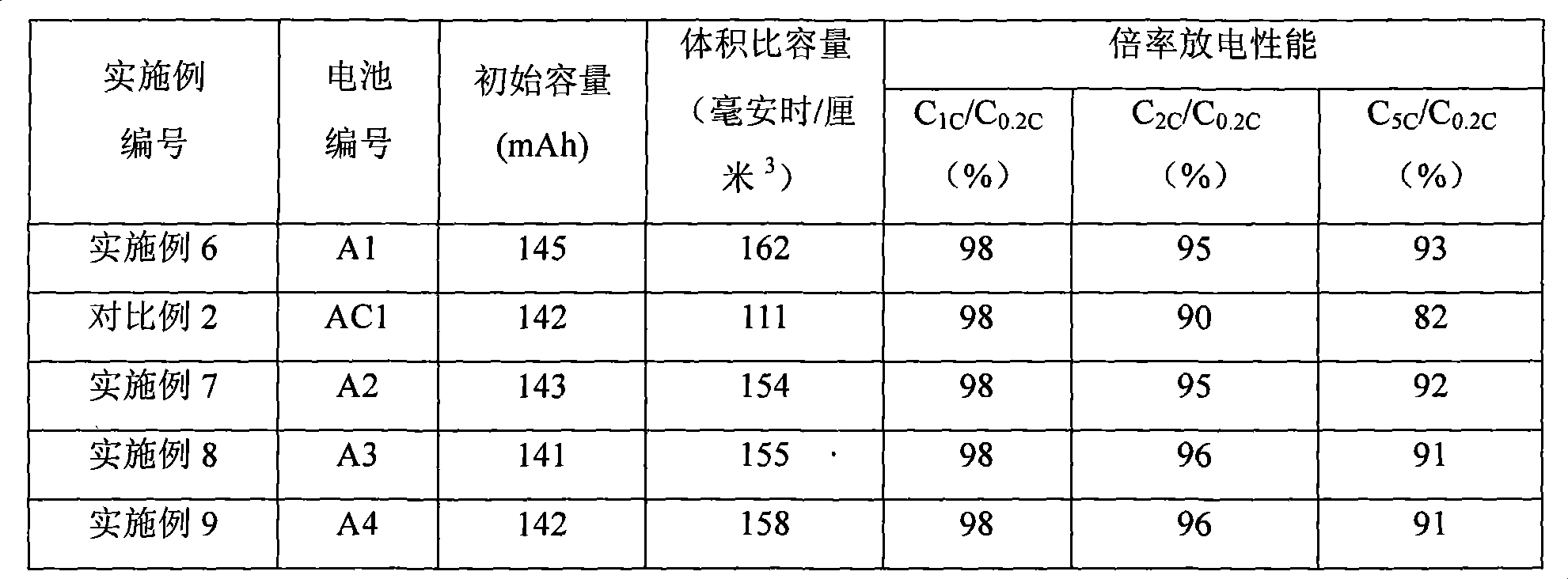

Modified composite material containing silicon-base material, preparation method thereof, and application thereof in lithium ion battery

PendingCN109301184AImprove performanceEasy to crushMaterial nanotechnologyCell electrodesStructural stabilitySide reaction

The invention discloses a modified composite material containing silicon-base material, a preparation method thereof, and an application thereof in a lithium ion battery. The composite material includes a silicon-base core and a modifying layer covering same. The modifying layer includes a polymer covering film and a nano-conductive material embedded therein. The modified composite material not only can isolate an electrolyte to inhibit side reactions of the electrolyte on the surface of the material, thus improving overall performance of the battery, but also can improve electric conductivityand improve structural stability due to the unique structure by embedding the nano-conductive material in the polymer. Tension is absorbed by means of deformation, so that problems of breaking and pulverization and stripping of the electrode during processing and use of the silicon-base negative material are solved. The problems of pulverization and stripping of the electrode due to large expansion during charge / discharge processes of the silicon-base material are solved, thus stabilizing the structure of the electrode and improving cycle performance of the cell.

Owner:JIANGSU ZENIO NEW ENERGY BATTERY TECH CO LTD

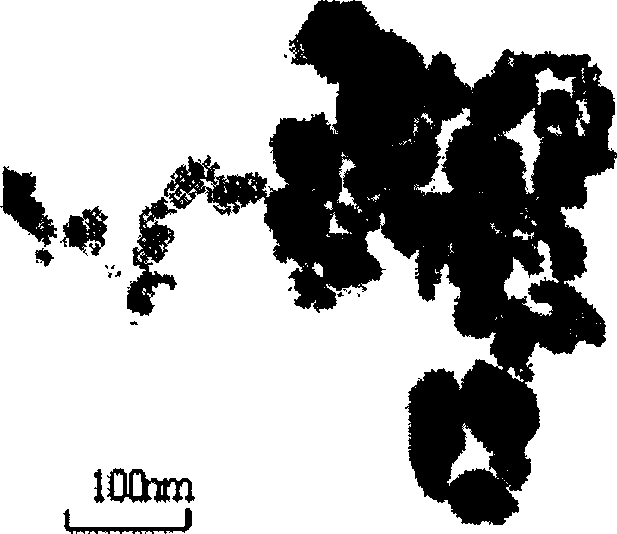

Process for preparing vanadium dioxide nano powder

A process for preparing VO2 nanoparticles includes such steps as proportionally adding V2O5 and oxalic acid to reactor, adding water, stirring at 40-70 deg.C while reaction, evaporating to obtain solid vanadium oxalate, vacuum heating to 350-500 deg.C, holding the temp for 20-40 min for thermodecomposing, and cooling. It is possible to add MoO3 or N5H37W6O24 for preparing the doped product.

Owner:SICHUAN UNIV

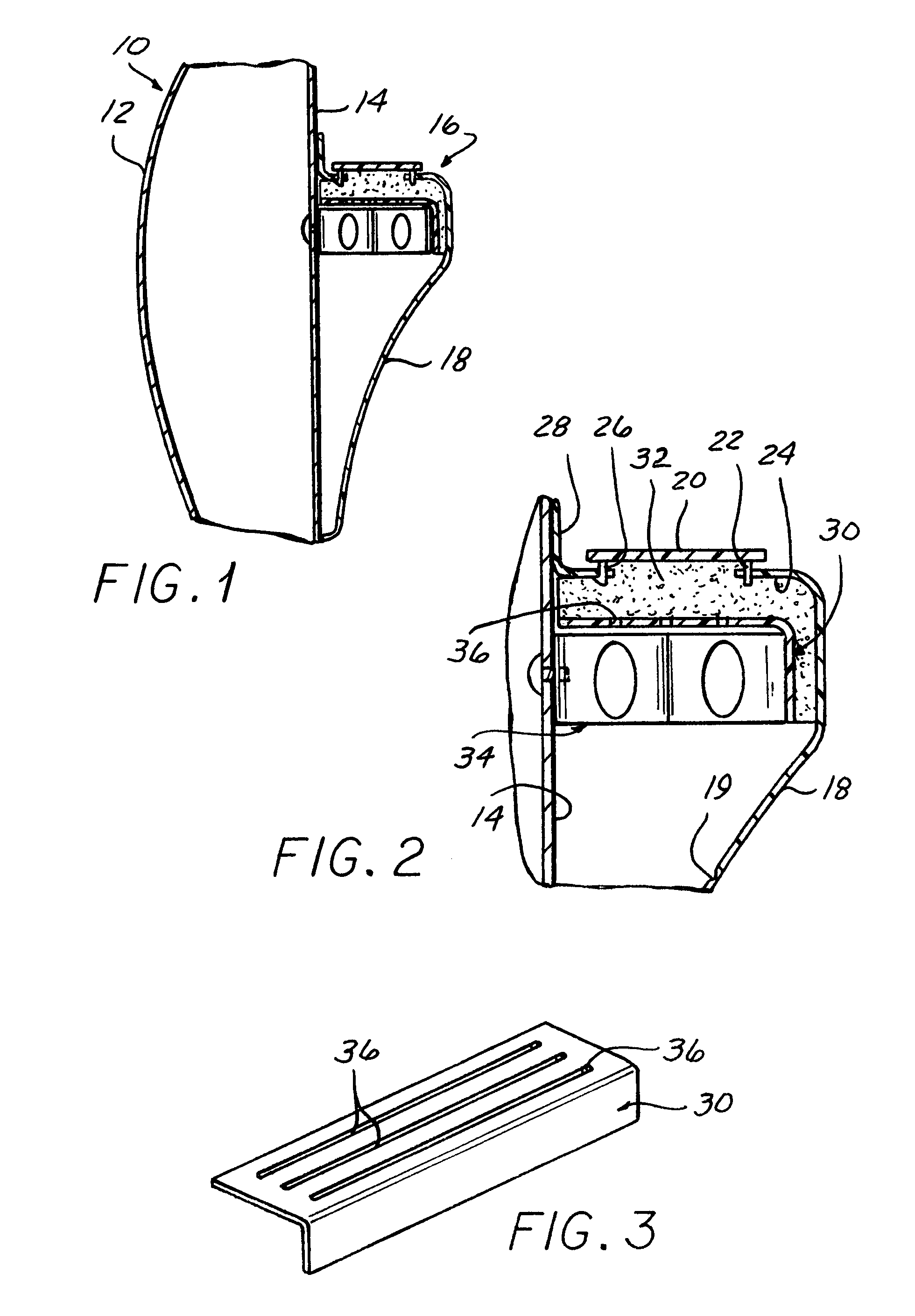

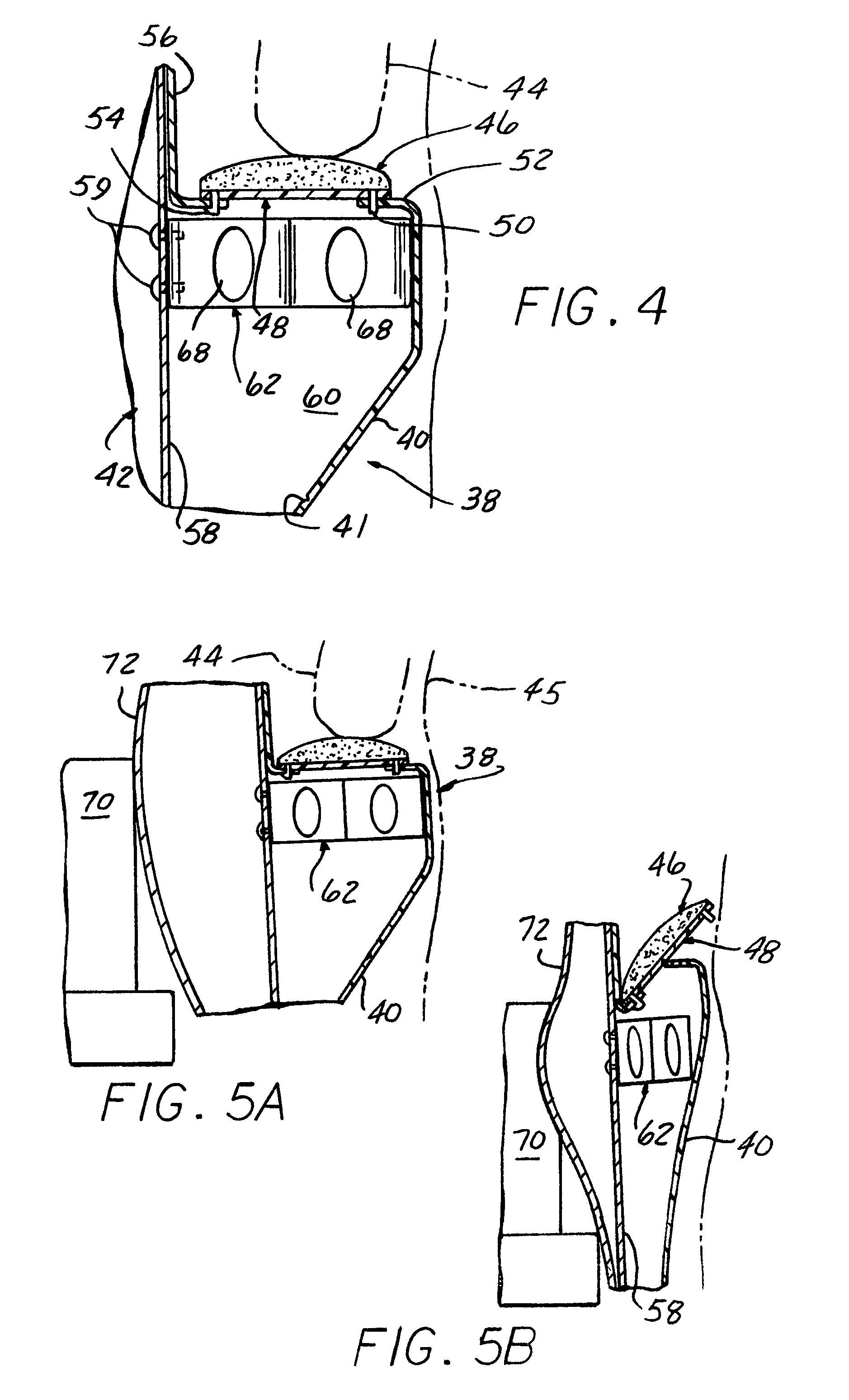

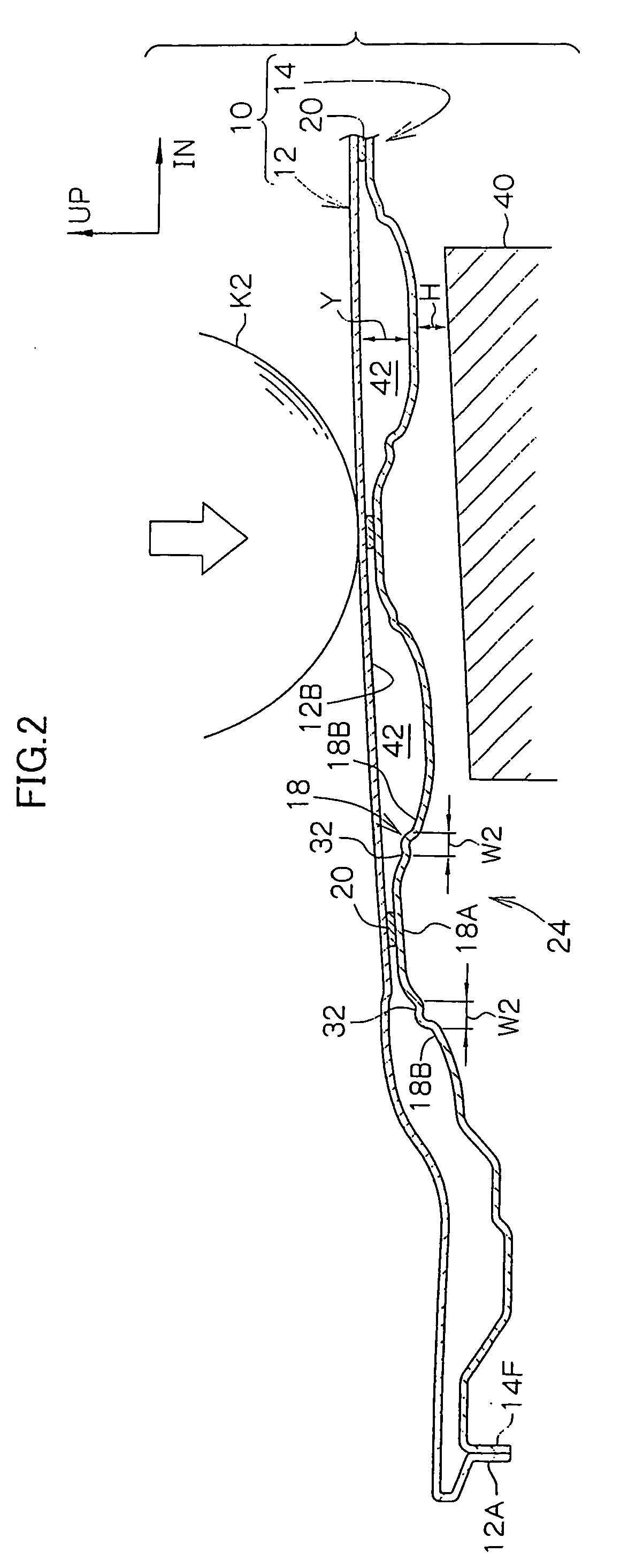

Crushable armrest and pelvic structures for motor vehicle side impacts

InactiveUS7503621B2Relieve pressureMinimize injuryVehicle seatsPedestrian/occupant safety arrangementEngineeringVertical load

Owner:MANI AYYAKANNU

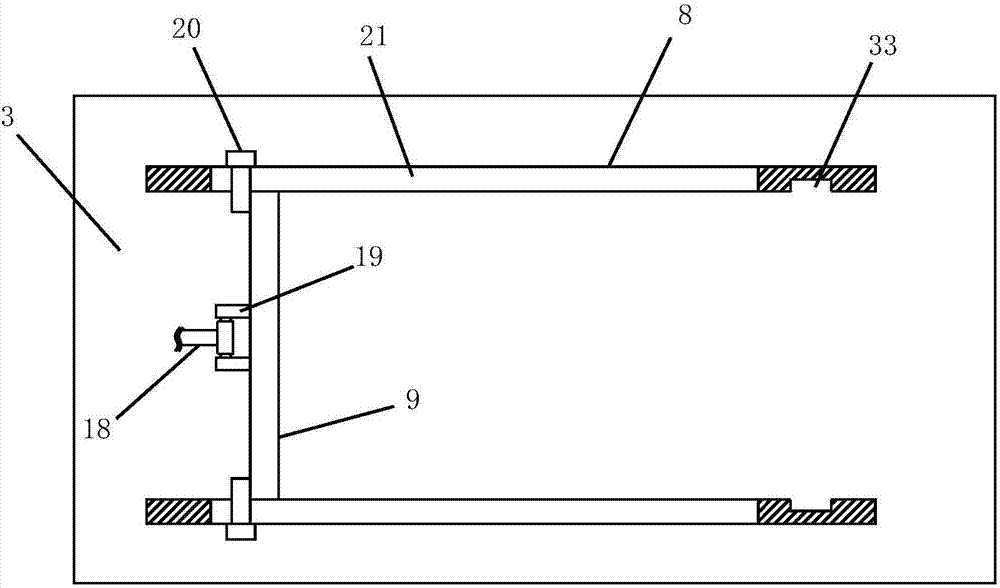

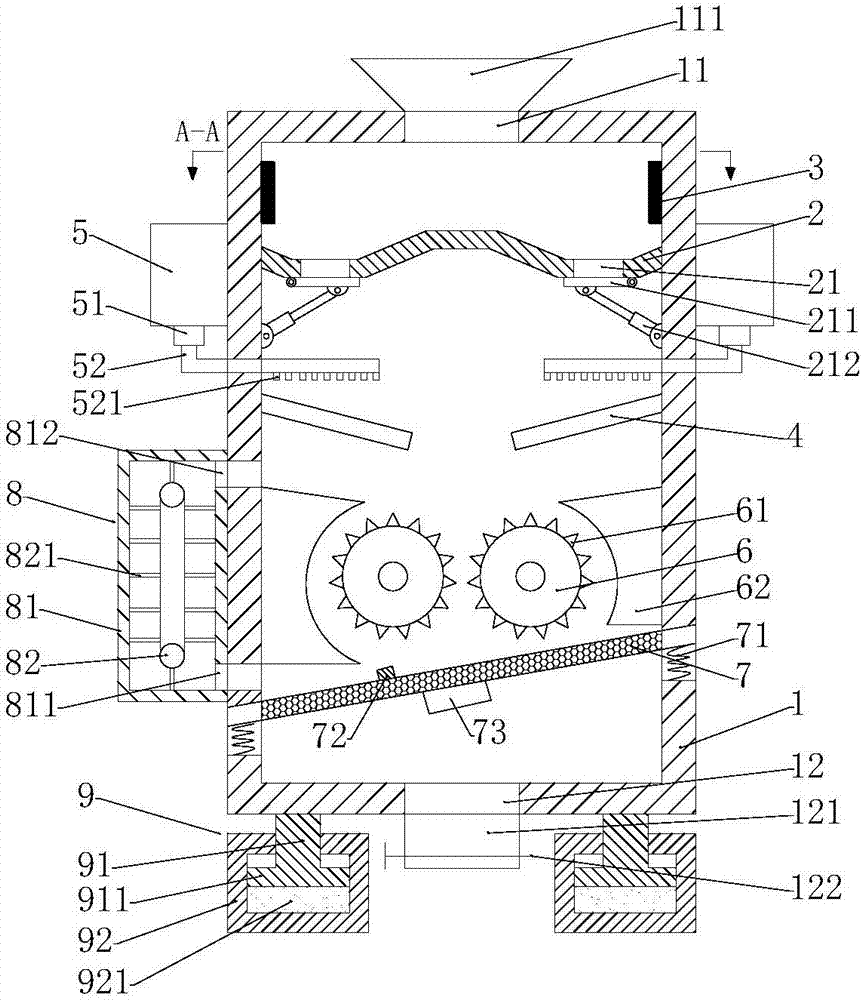

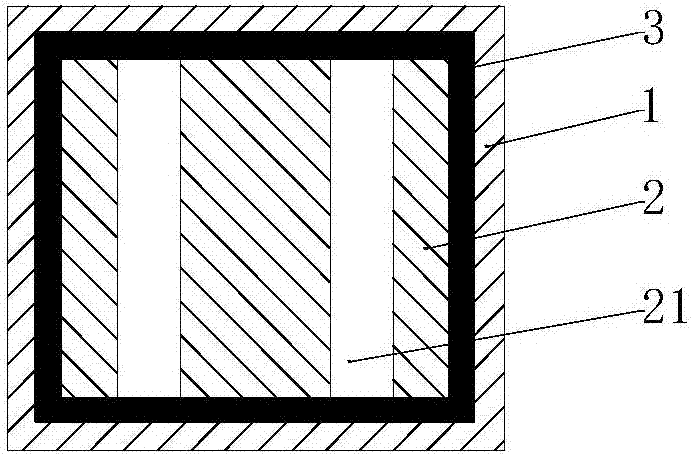

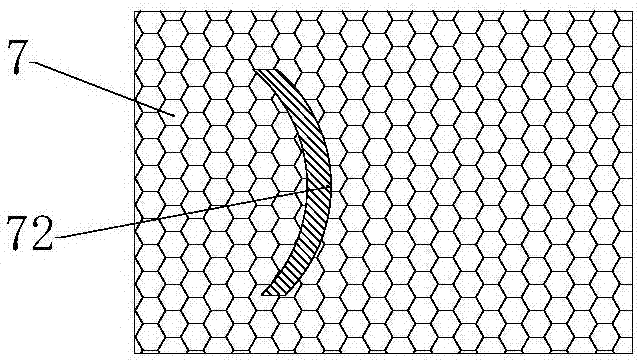

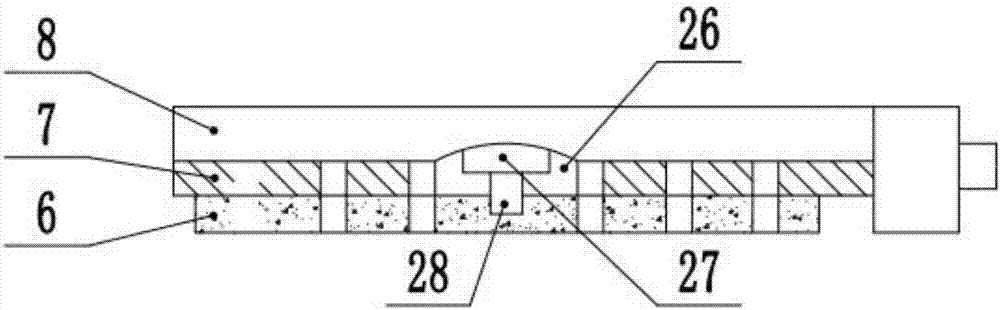

Waste Cable Recovery System

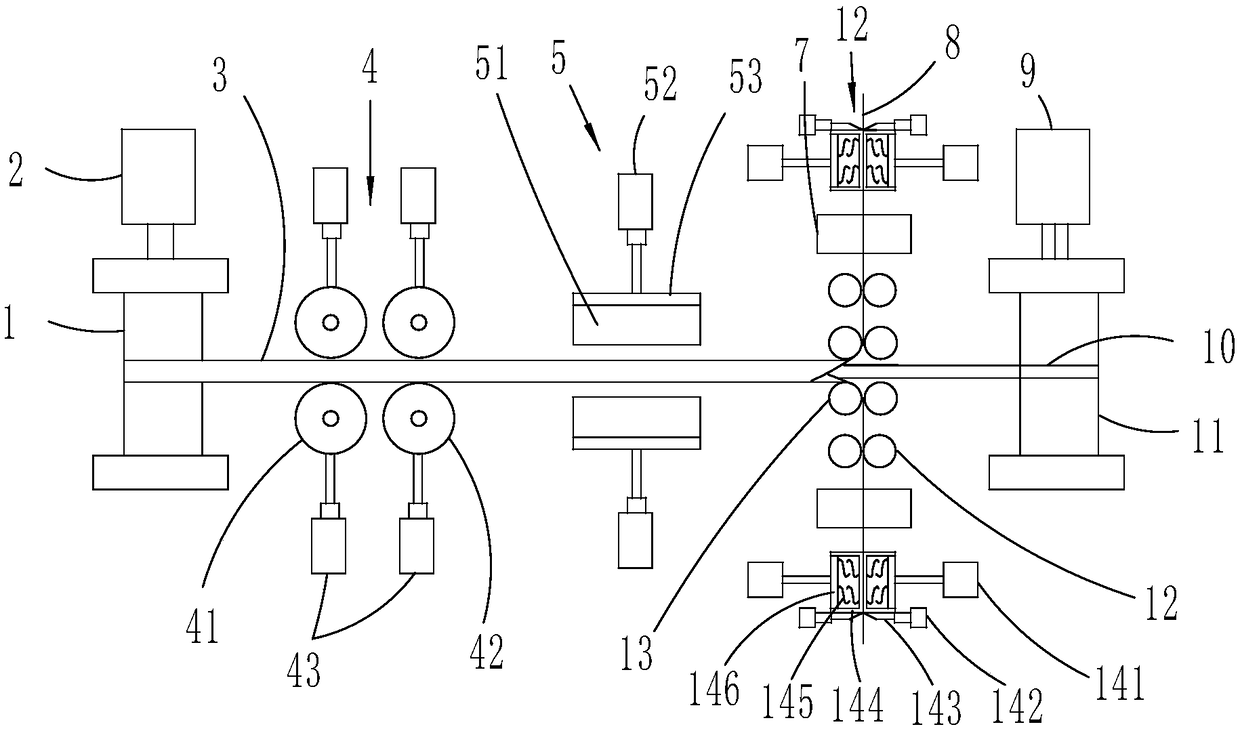

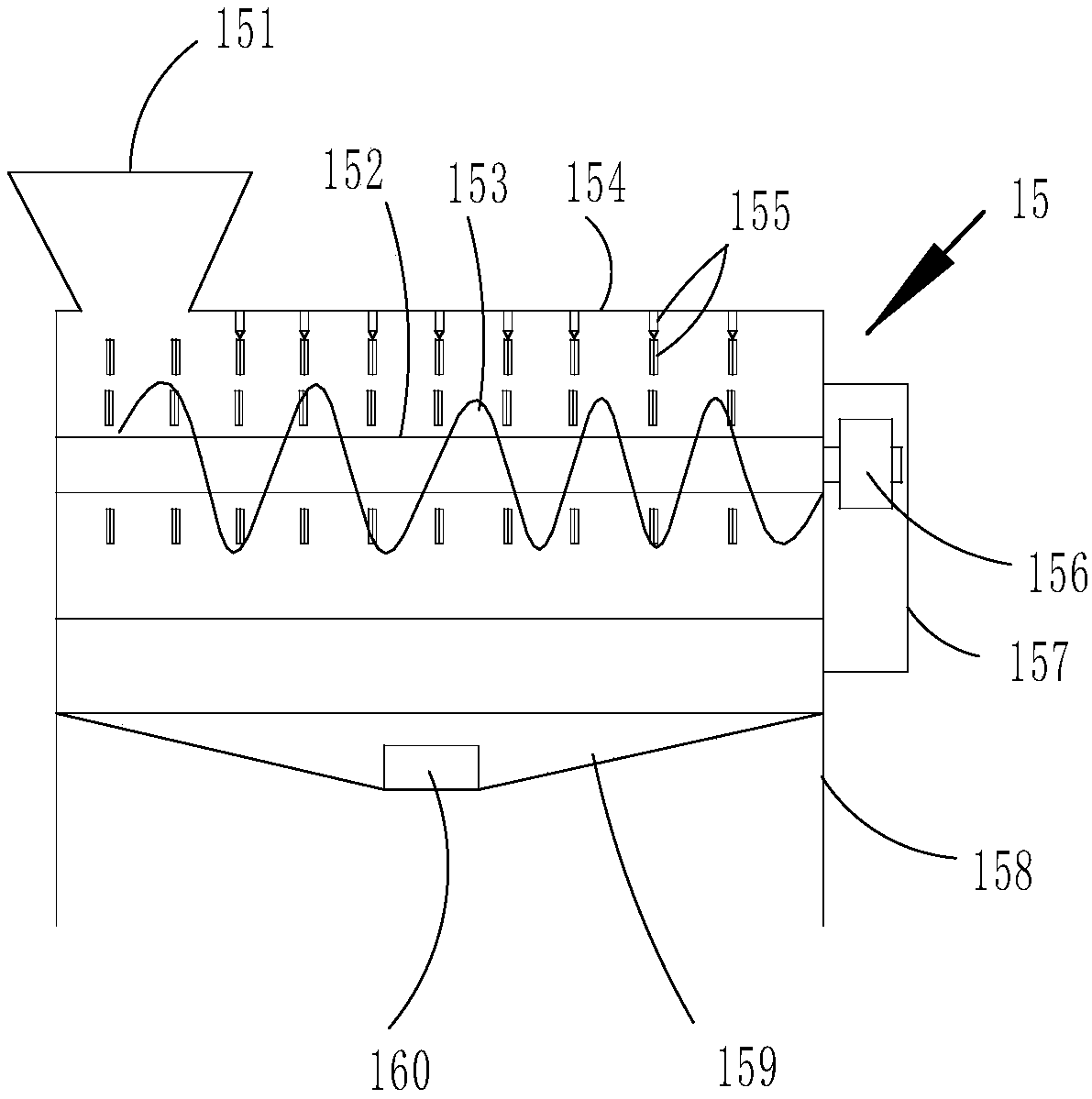

ActiveCN109036736AImprove recycling effectAvoid stickingBasic electric elementsApparatus for removing/armouring cablesEngineeringCopper

The invention provides a waste cable recovery system and belongs to the technical field of waste cable reuse. The system includes frame, pay-off roll, straightening device, cutting device, cop core winding roller, two cooling devices, two cutting devices and crushing device. A let-out roller, a straightening device, a cutting device and a cop core winding roller are arranged in sequence from one end of that frame, two cooling device and two cutting devices are arranged between the cutting device and the cop core winding roller and are symmetrically arranged on both sides of the frame, the cooling device is close to the frame, and the cutting device is far away from the frame. The invention provides a waste cable recovery system, by carrying out straightening first, and Cutting, Cut off thecable sheath after cooling, the cable sheath after the cutting-off falls into the lower crushing device for crushing, copper core is wound on the copper core winding roller along a straight line, after straightening the cable sheath, adhesion and incessant cutting of the cable sheath can be avoided, thereby avoiding scratching the copper core, the cable sheath is cut off after cooling, and is easy to cut and crushing.

Owner:STATE GRID HEBEI ELECTRIC POWER CO LTD +1

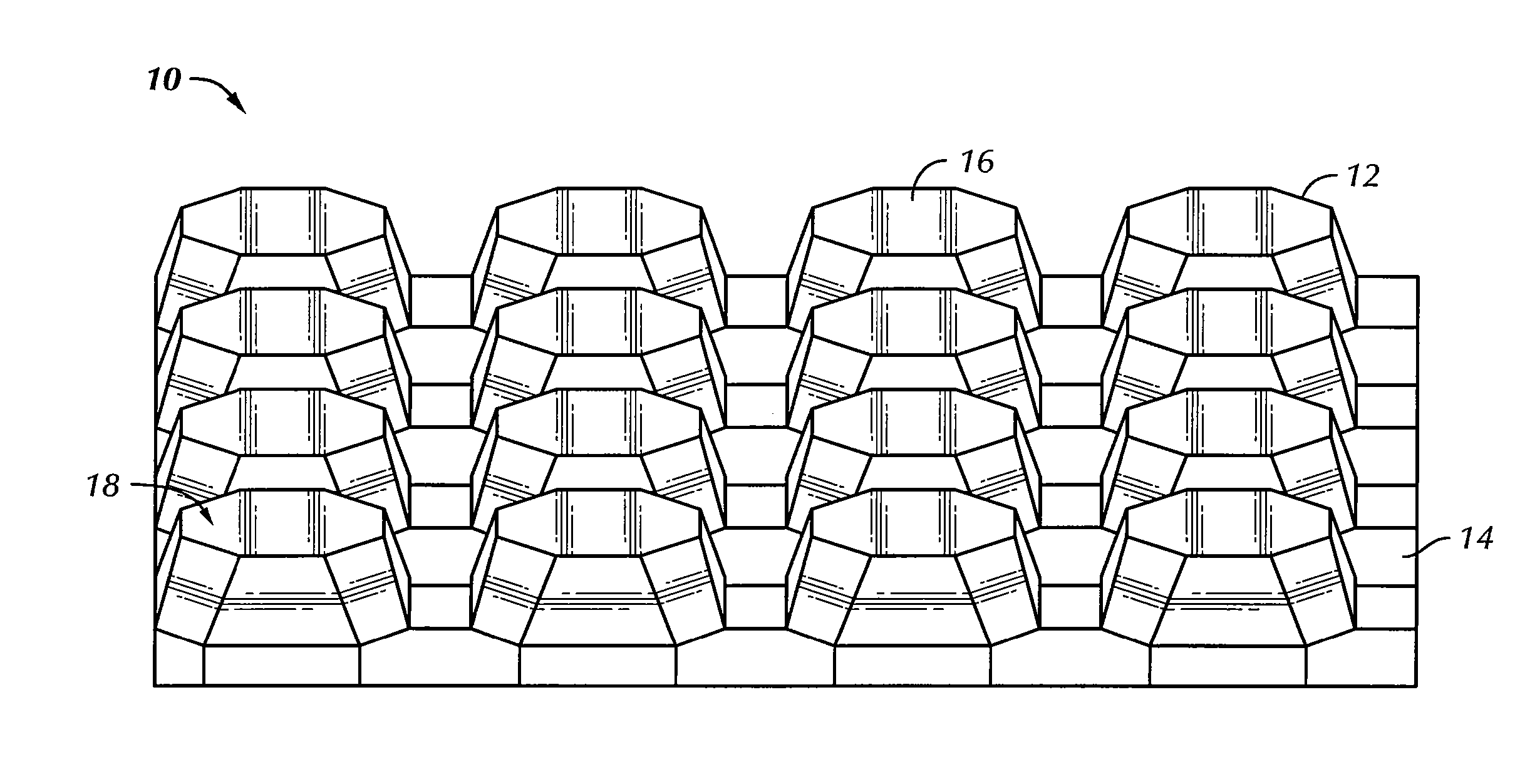

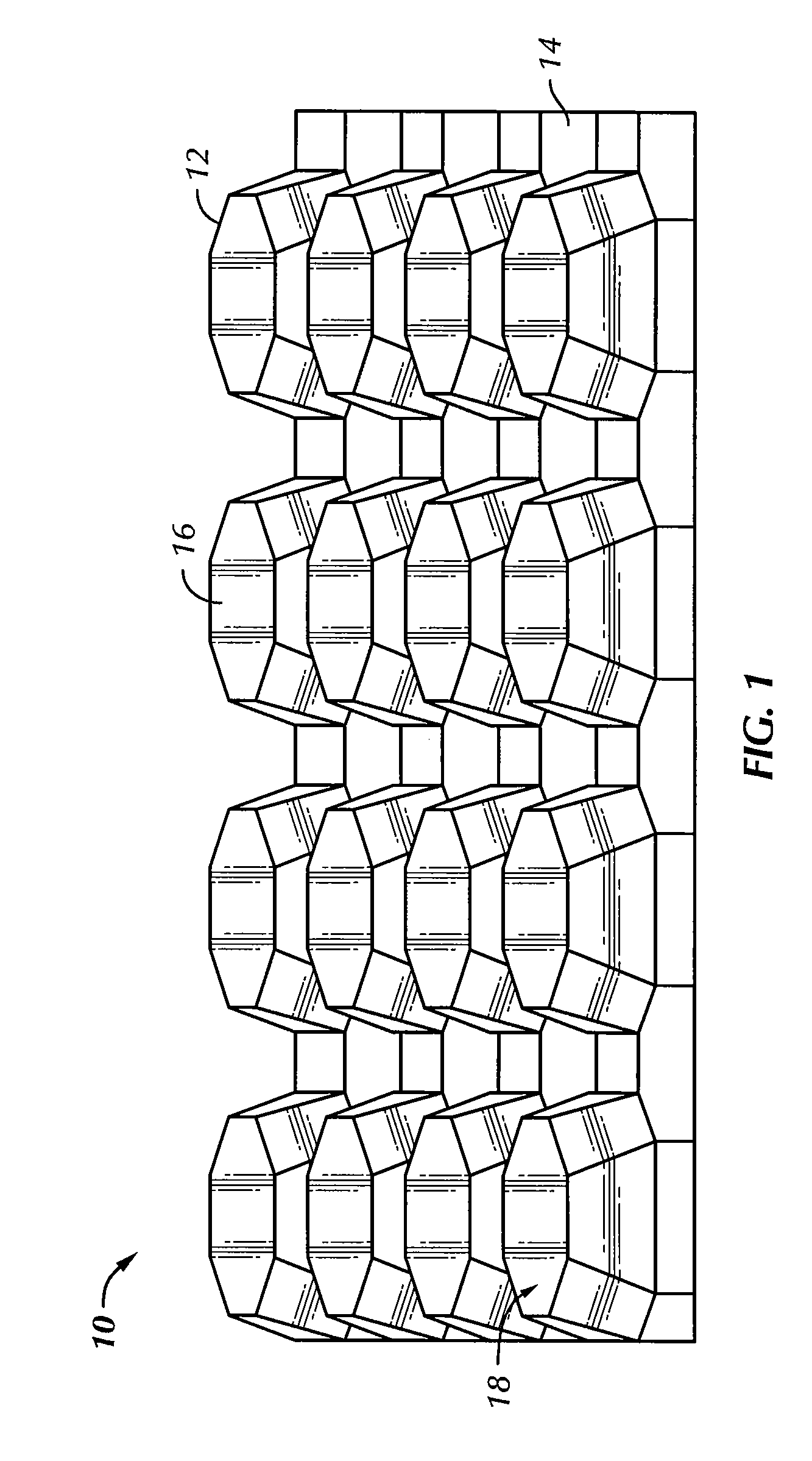

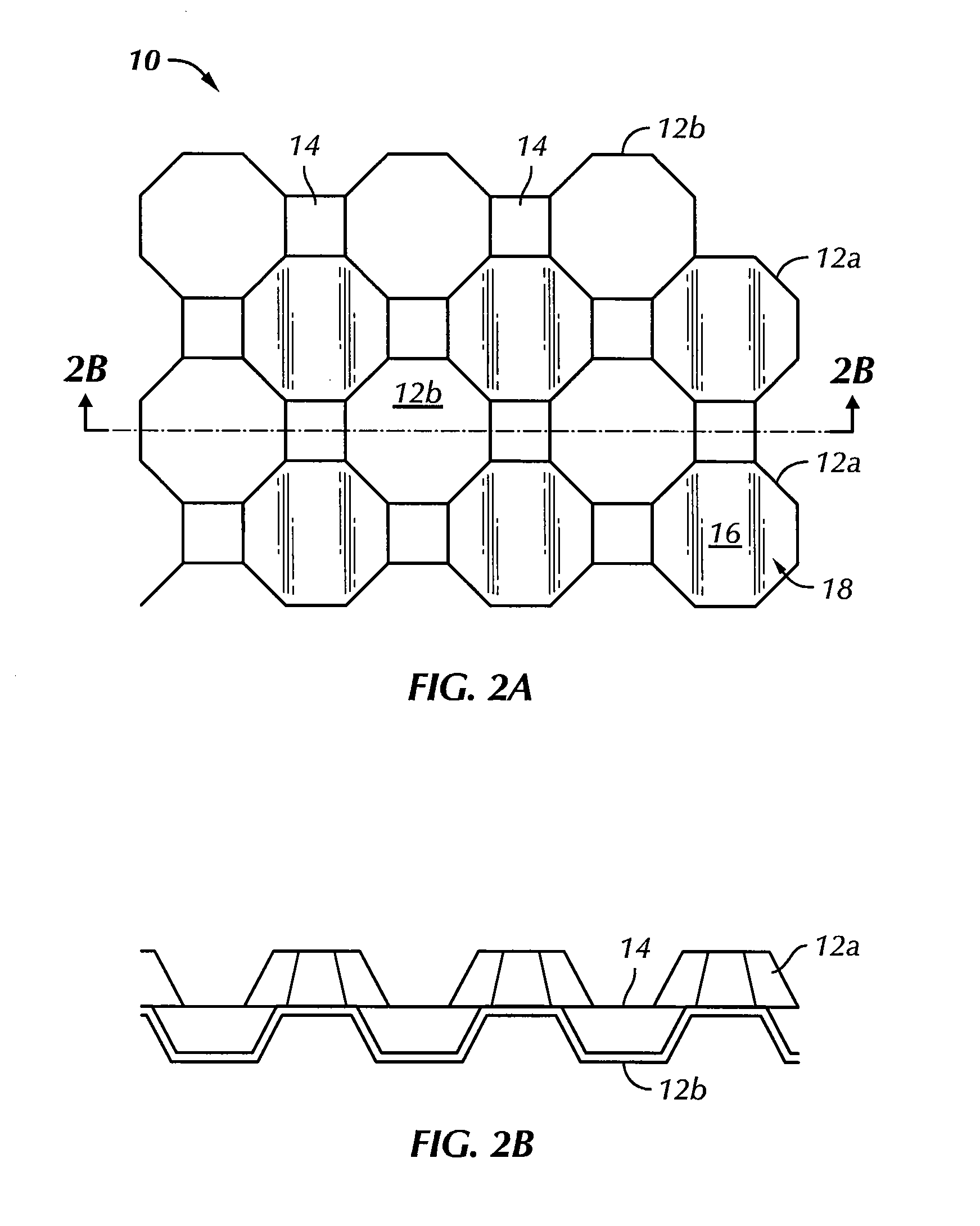

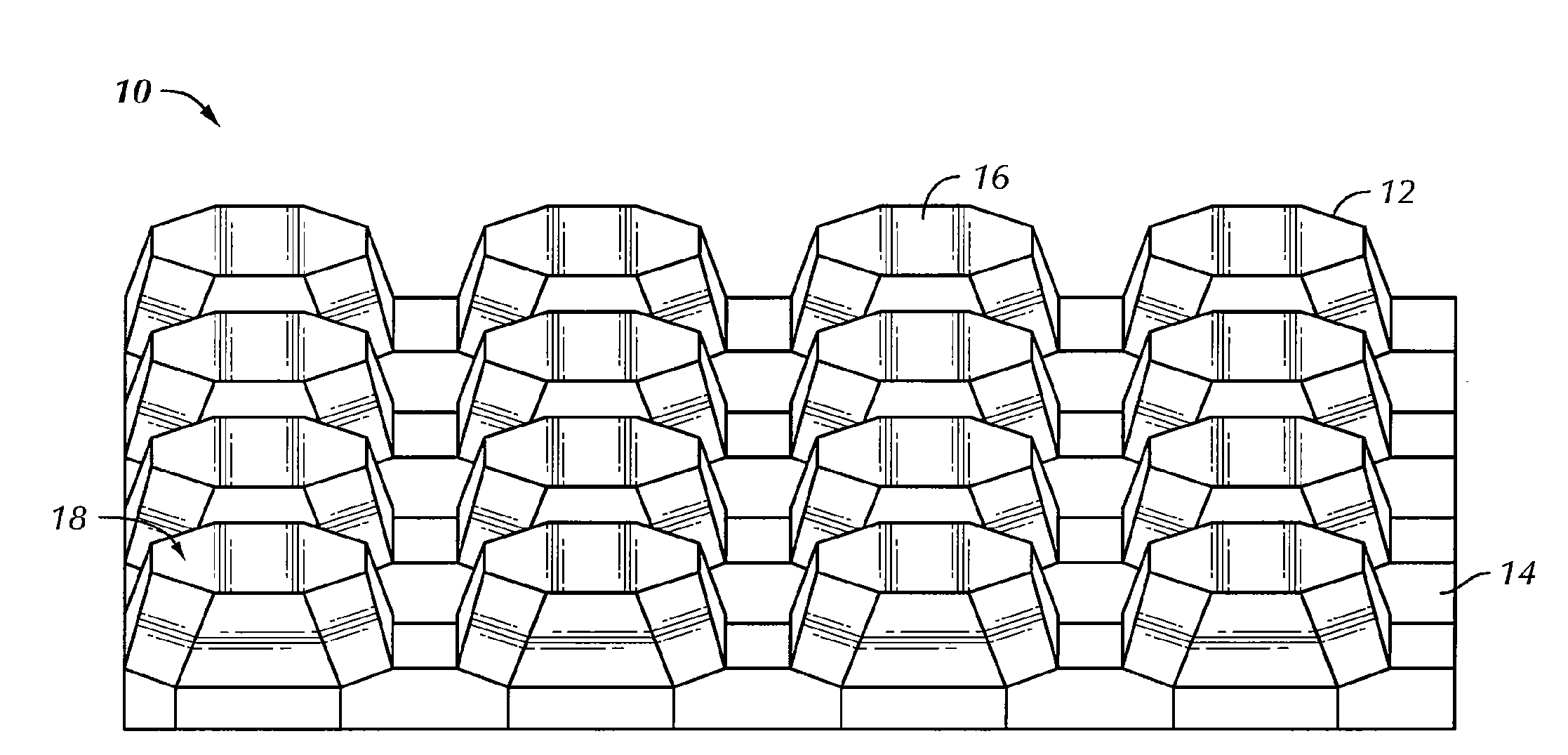

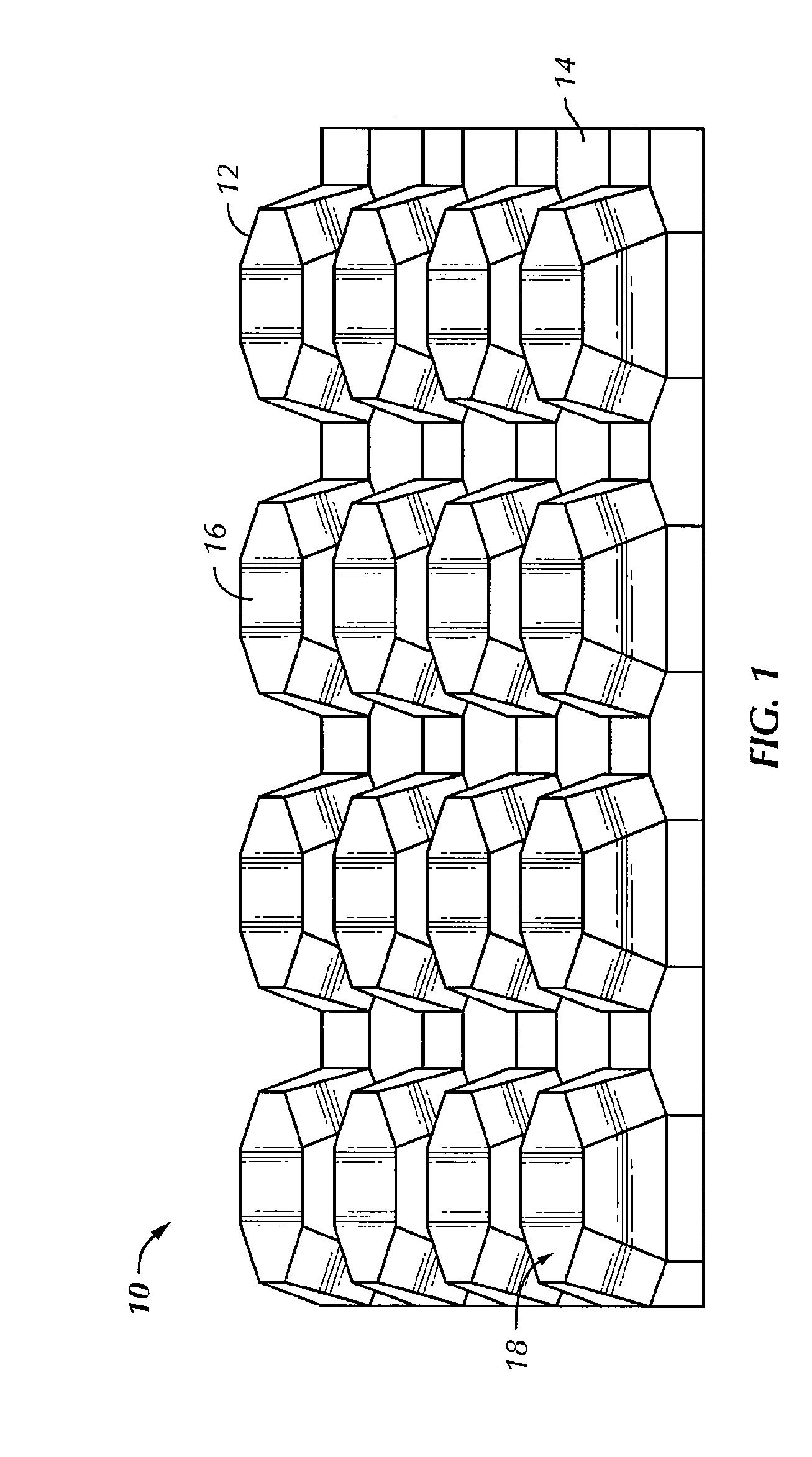

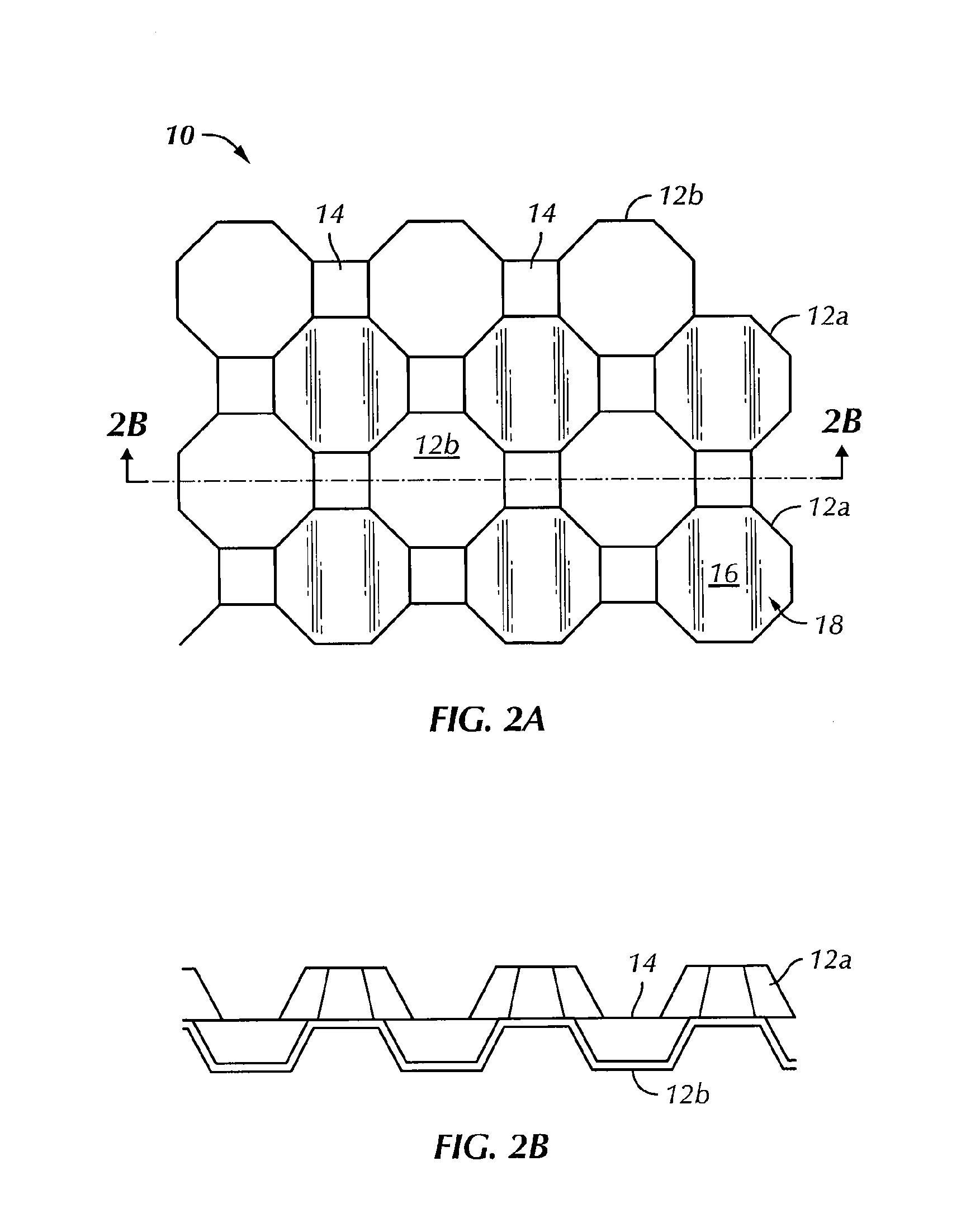

Formed core sandwich structure and method and system for making same

InactiveUS20070243408A1Easy and economical to manufactureEnhanced capillary actionPrinted circuit assemblingSoldering apparatusEngineeringMetal sheet

A method and apparatus for producing a metal core sandwich structure that is lightweight and many times stiffer than regular sheet metal, and which is easily formable into curved structures as well as structures having compound curves. In one embodiment, a formed metal core includes a plurality of cells comprising alternating front and rear projections extending outwardly in front of and behind a median plane, with each projection having a bonding surface area or land configured to be brazed or bonded with corresponding external metal sheets on both sides of the formed metal core. A plurality of micro-abrasions or indentations are formed on the bonding lands, allowing stronger brazing or bonding joints to be formed between the metal core and the external metal sheets by facilitating improved capillary action by the metal core during the brazing or bonding process.

Owner:CELLTECH METALS INC

Preparing method of anode active material lithium iron phosphate for lithium ionic secondary cell

ActiveCN101399343AEasy to crushImprove high current charge and discharge performanceElectrode manufacturing processesSecondary cellsLithium iron phosphateBall mill

The invention provides a preparation method of lithium iron phosphate of a lithium-ion secondary battery positive electrode active material, the method comprises: a ferrous source compound, a phosphorus source compound, a lithium source compound and a carbon source compound are mixed, the first sintering is carried out on the obtained mixture under the protection atmosphere, products in the first sintering are ball-milled and dried, the second sintering is further carried out to obtain the lithium iron phosphate, wherein, the method further comprises the heating of the mixture at the temperature of 60-250 DEG C under the oxidation atmosphere before the first sintering or after the first sintering. The lithium iron phosphate which is obtained by adopting the method can have both high volume specific capacity and excellent high-current discharge performance.

Owner:TAICANG RONGCHI MOTOR

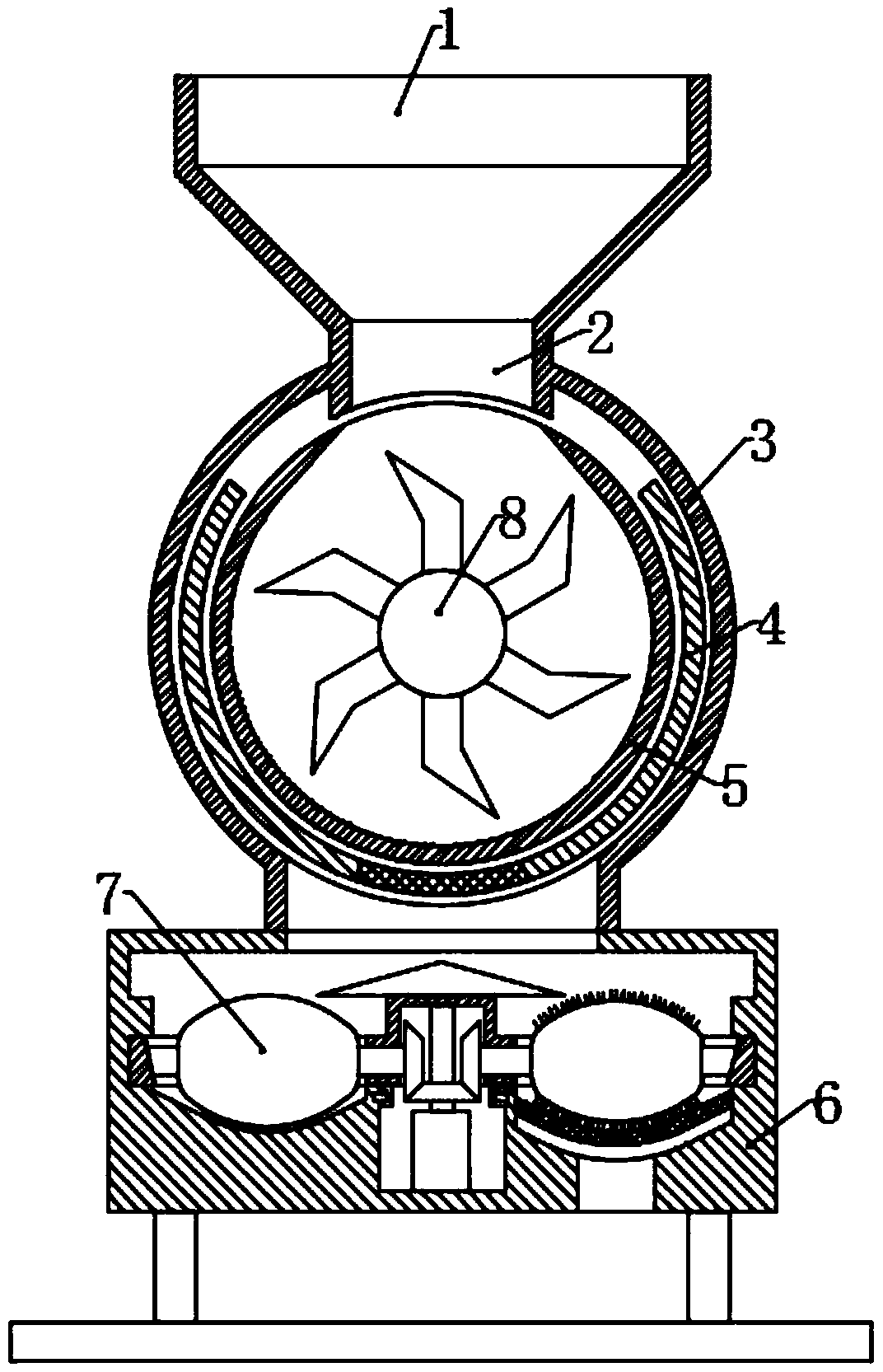

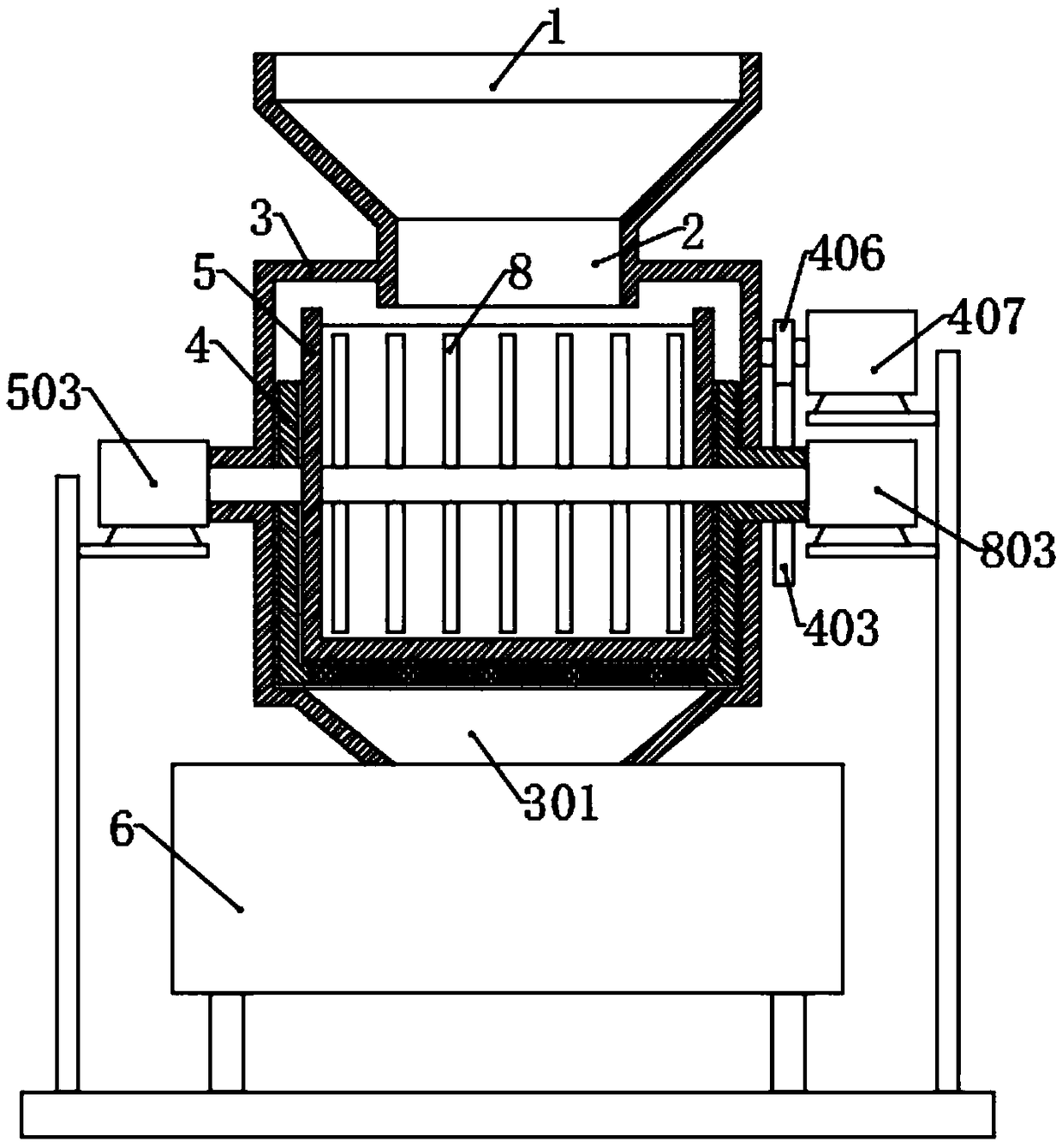

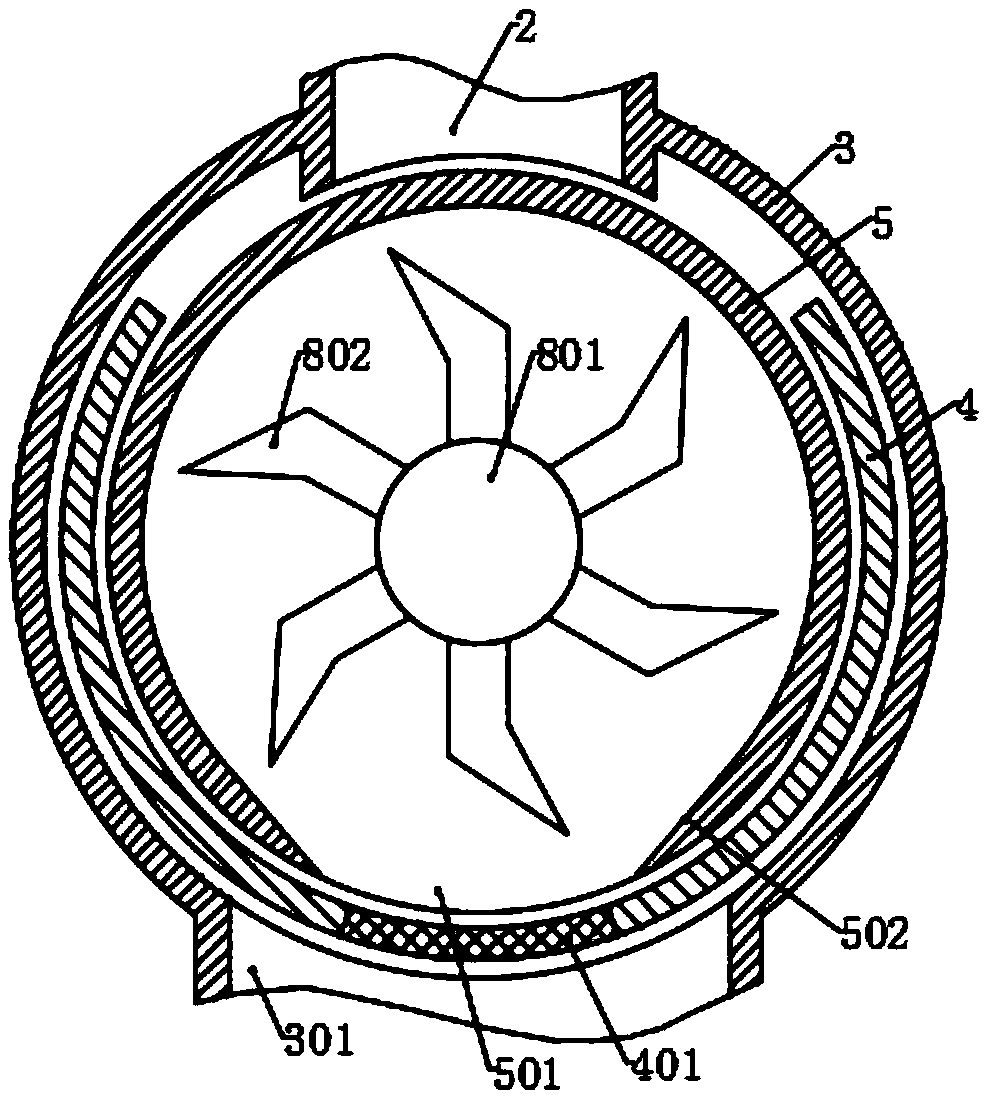

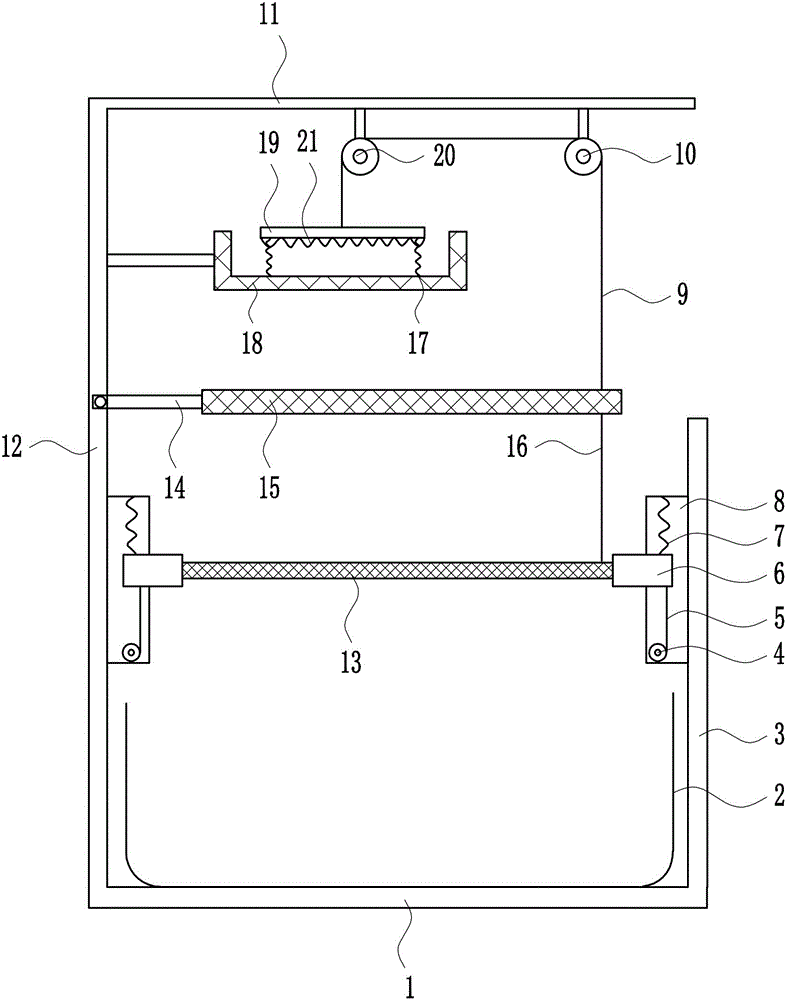

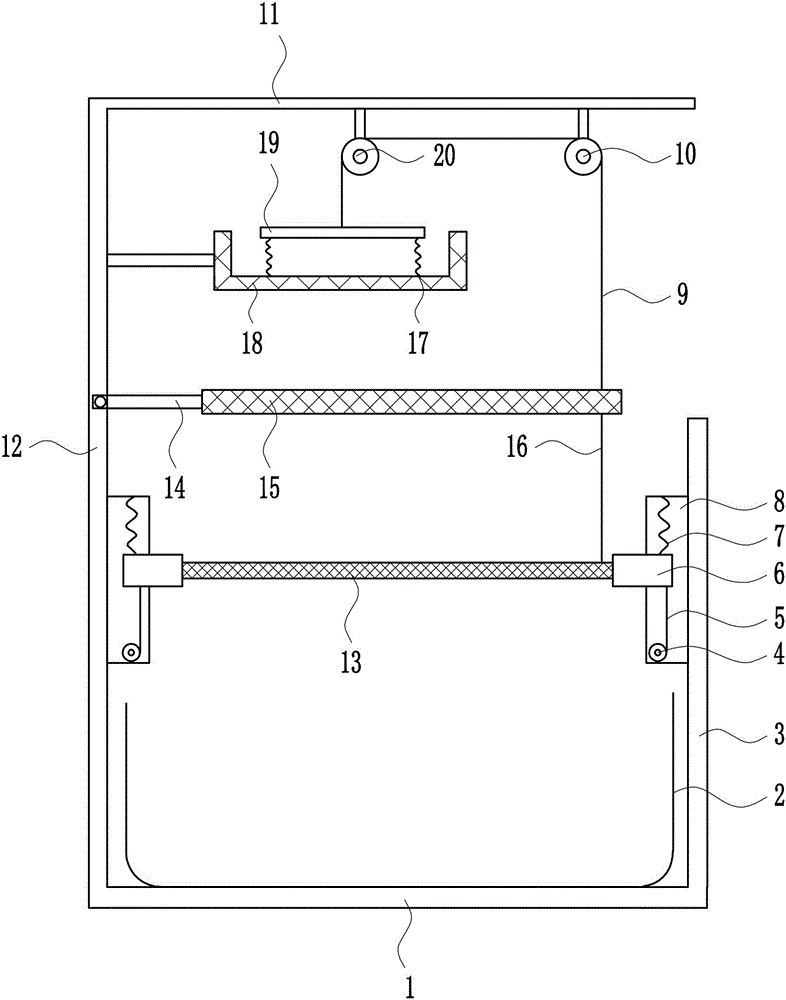

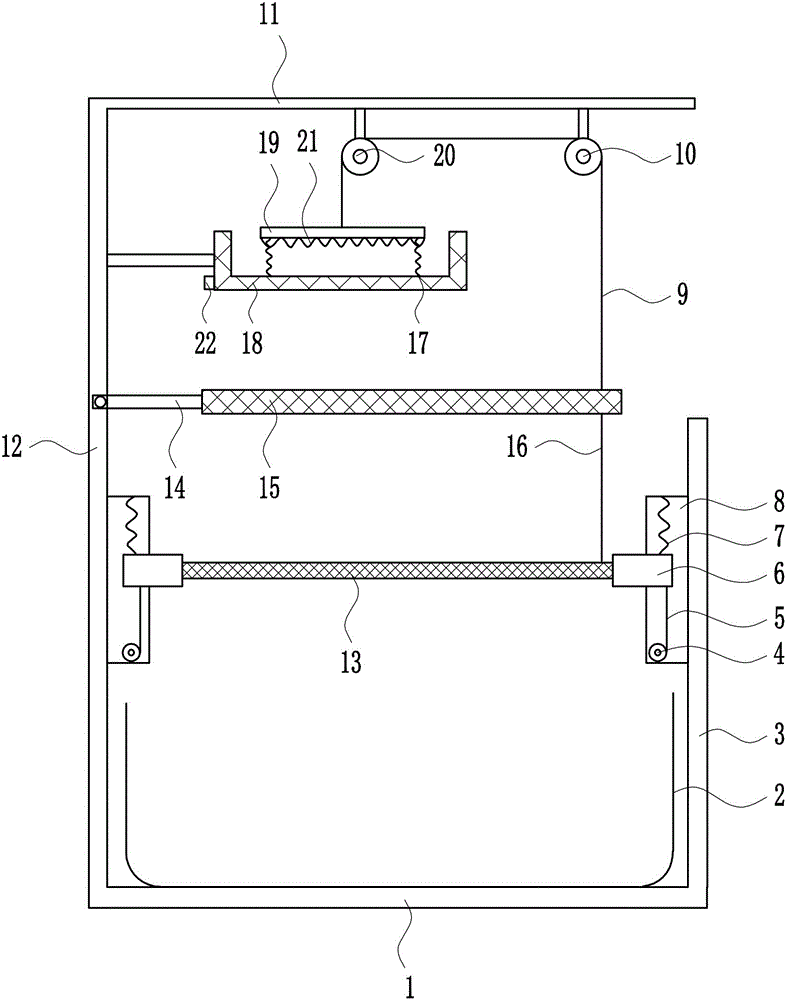

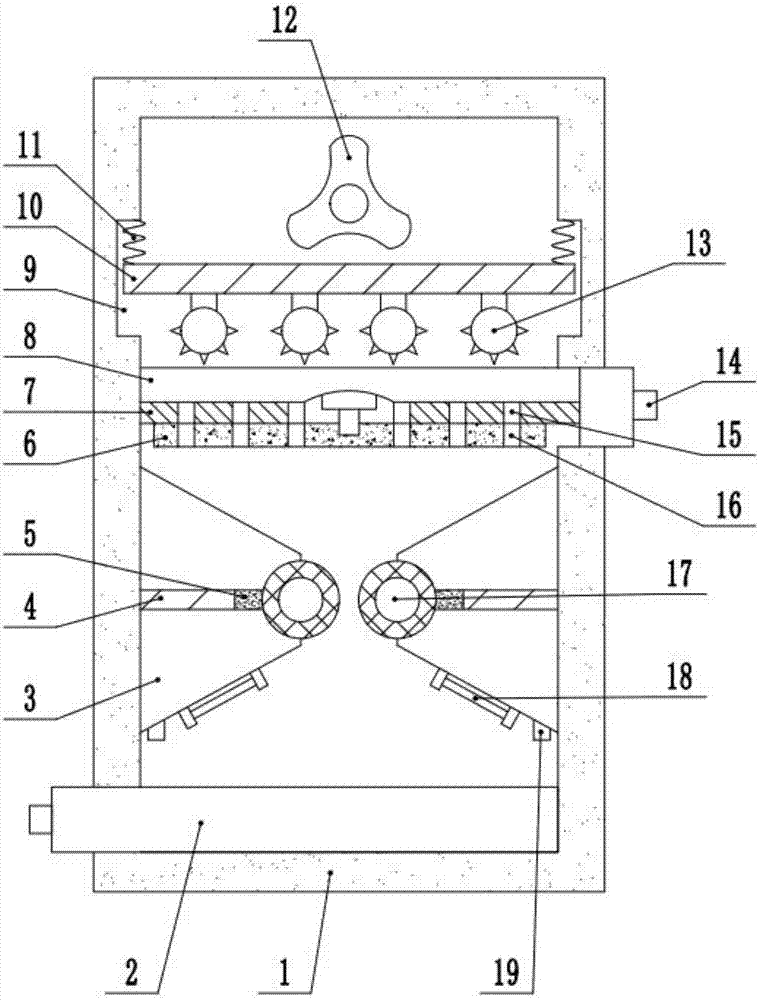

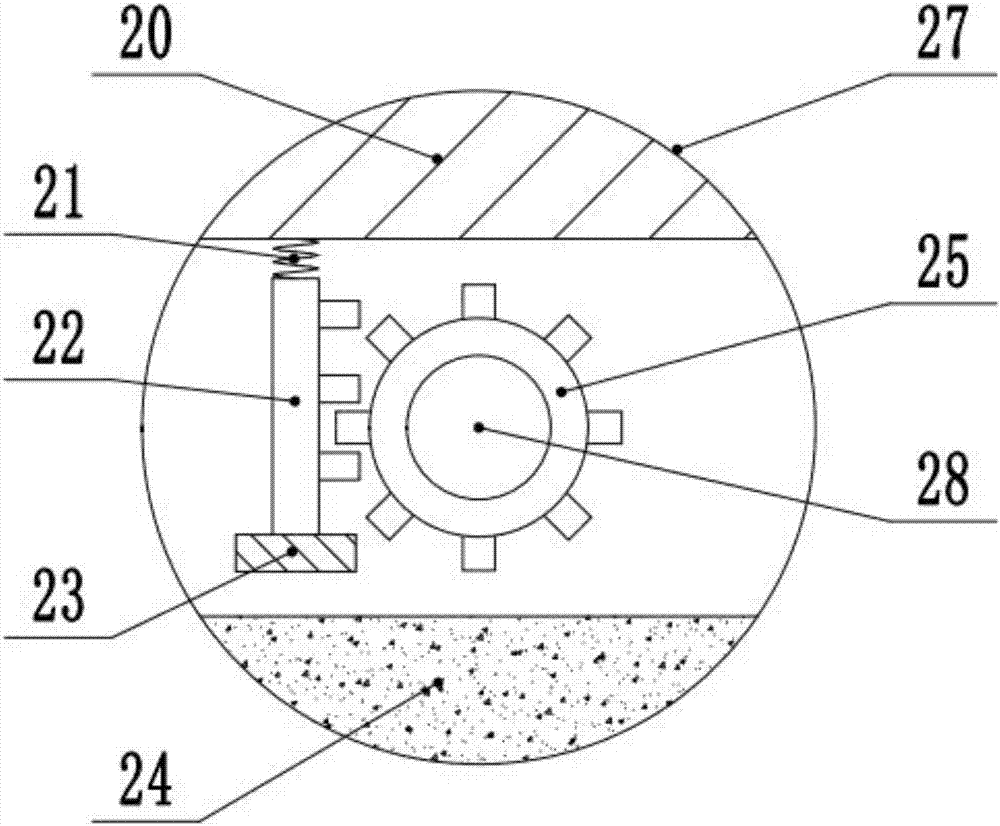

Crushing and grinding device for production and processing of traditional Chinese medicinal materials

InactiveCN108940503AAvoid enteringImprove subsequent grinding efficiencyGrain treatmentsEngineeringMaterials processing

The invention discloses a crushing and grinding device for production and processing of traditional Chinese medicinal materials in the technical field of traditional Chinese medicinal material processing. The crushing and grinding device comprises a feeding hopper, a feeding pipe, a fixing case, a screening case, a crushing case and a grinding case. According to the crushing and grinding device, the traditional Chinese medicinal materials are put into the feeding hopper and then enter the crushing case along the feeding pipe, a crushing mechanism is used for crushing the traditional Chinese medicinal materials, and a feeding inlet of the crushing case conducting crushing rotates to face downwards; the traditional Chinese medicinal materials are screened through the screening case, and thenthe feeding inlet of the crushing case is rotated to face upwards; the traditional Chinese medicinal materials which do not penetrate through a first screening mesh return to the crushing case through the shovel face at the feeding inlet and are subjected to secondary crushing along with next batch of to-be-crushed medicinal materials, and the traditional Chinese medicinal materials enter the grinding case and are ground through a grinding mechanism; and meanwhile, completely ground medicine powder is fed into a powder outlet through a rotating brush, so that the situation that powder particles are too fine due to the fact that ground medicine powder is left in a grinding groove and ground repeatedly is avoided, and the grinding effect is good.

Owner:周意

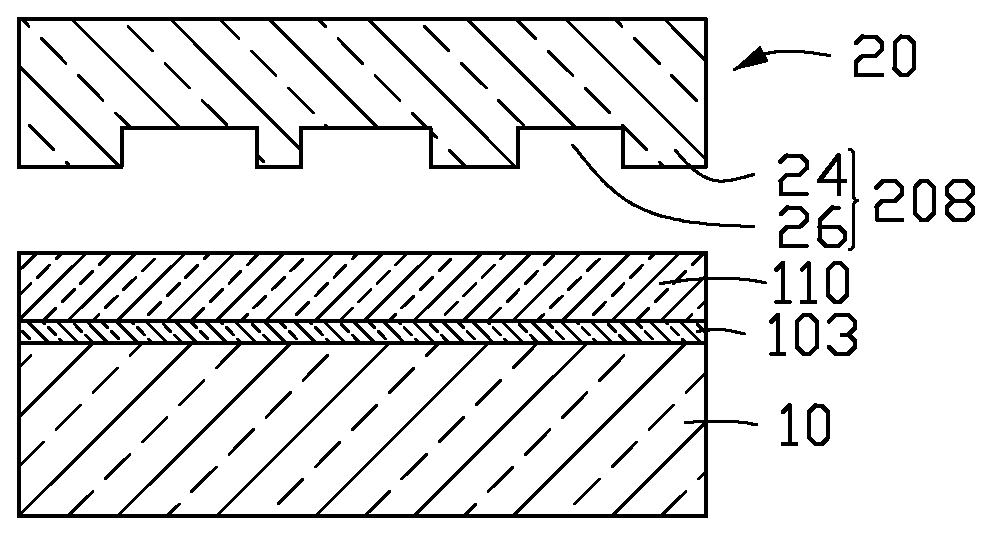

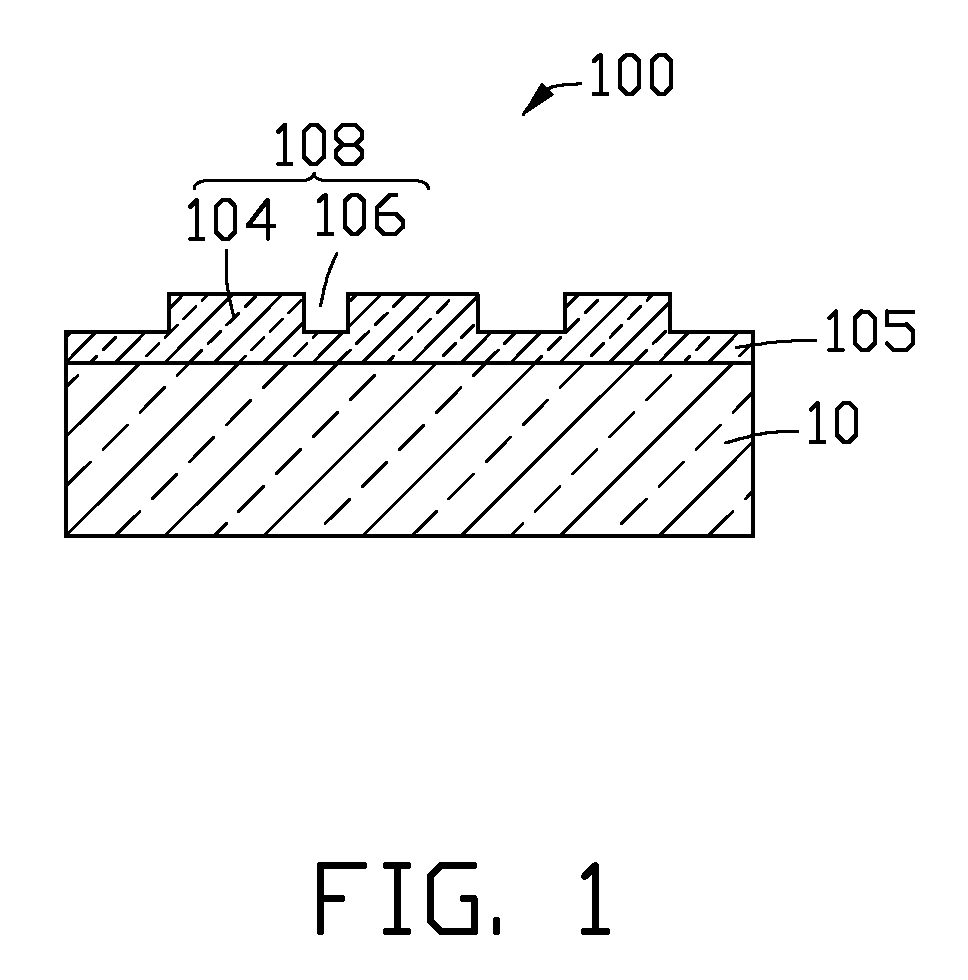

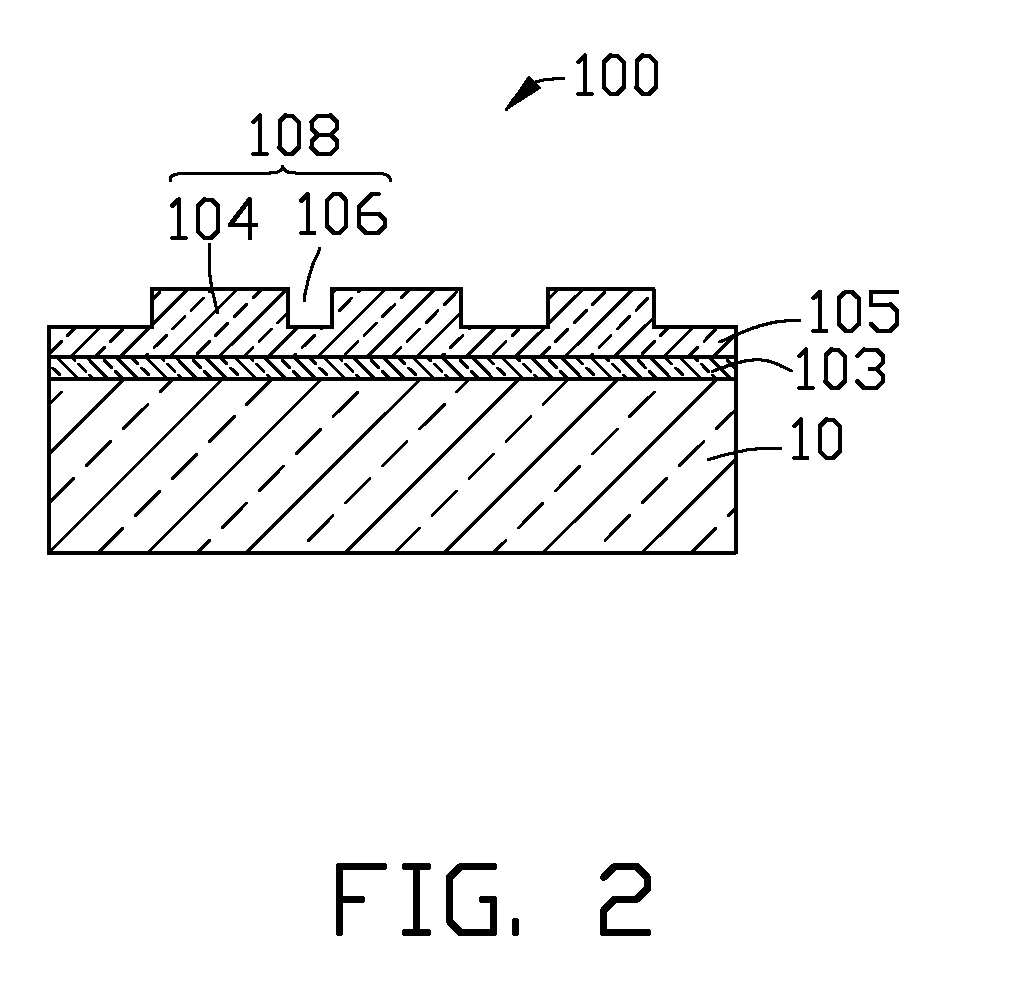

Nanoimprint resist, nanoimprint mold and nanoimprint lithography

ActiveUS20100308008A1Low modulusEasy to crushDecorative surface effectsNanoinformaticsResistOligomer

A nanoimprint resist includes a hyperbranched polyurethane oligomer (HP), a perfluoropolyether (PFPE), a methylmethacrylate (MMA), and a diluent solvent. A method of a nanoimprint lithography is also provided.

Owner:TSINGHUA UNIV +1

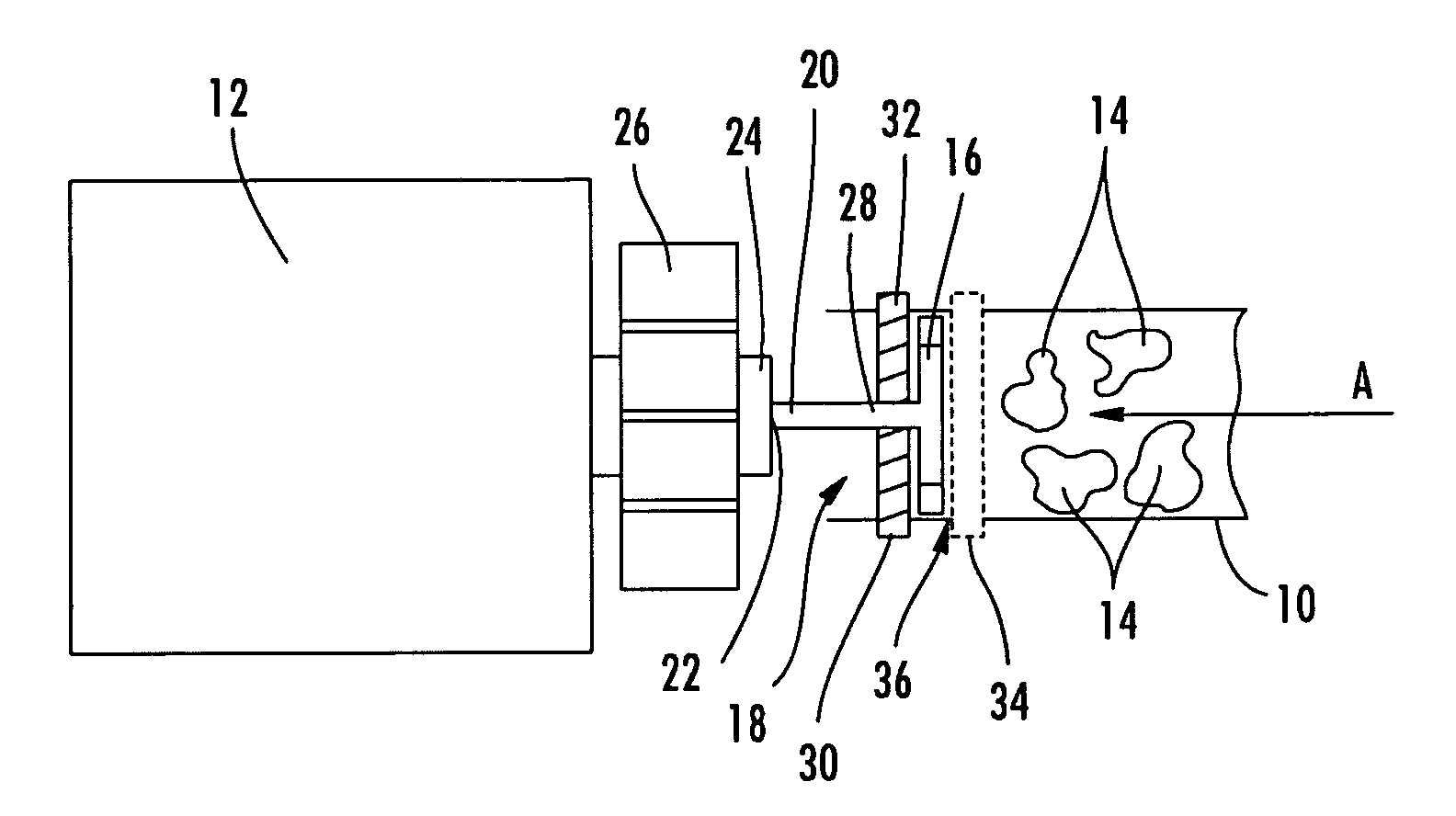

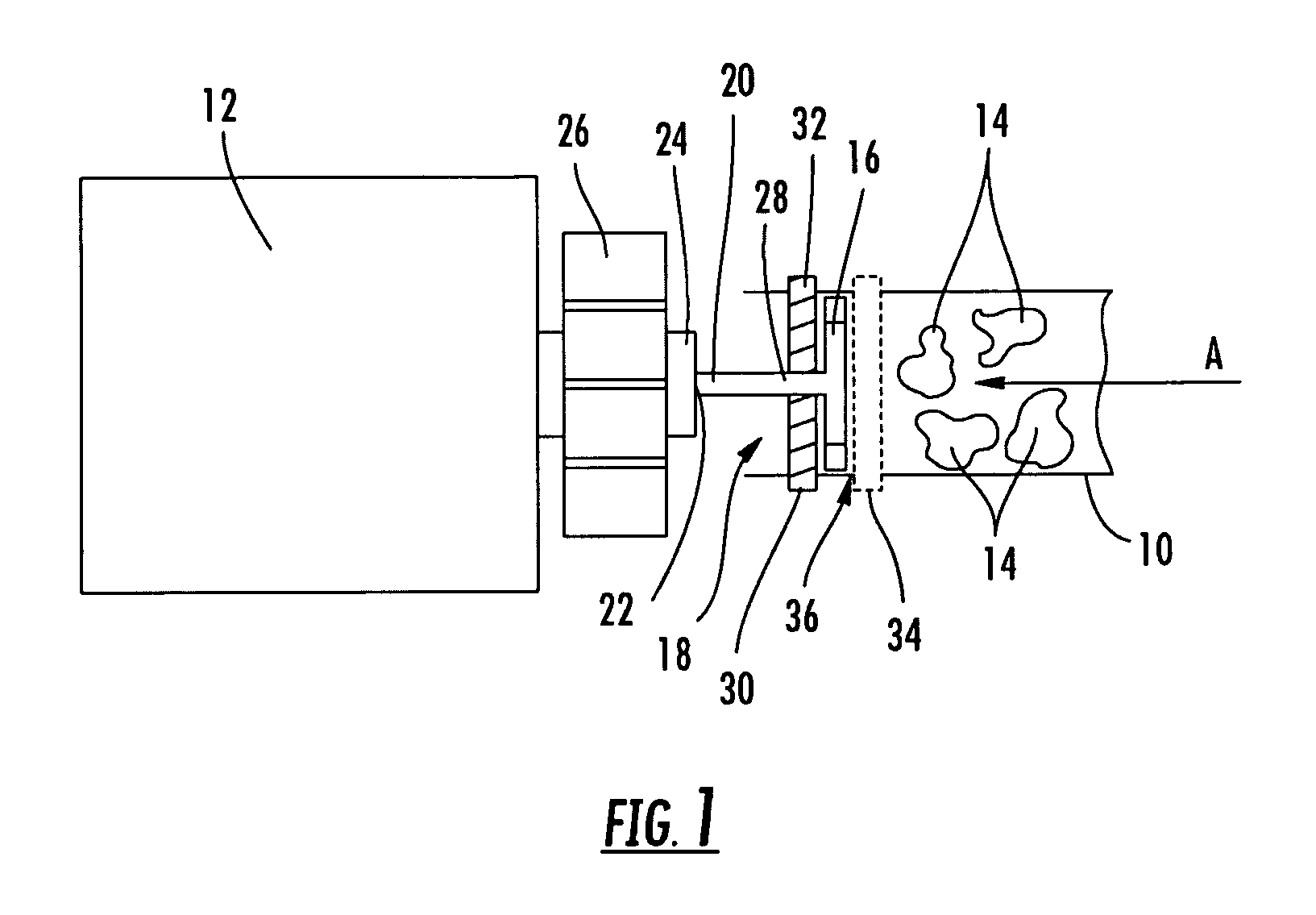

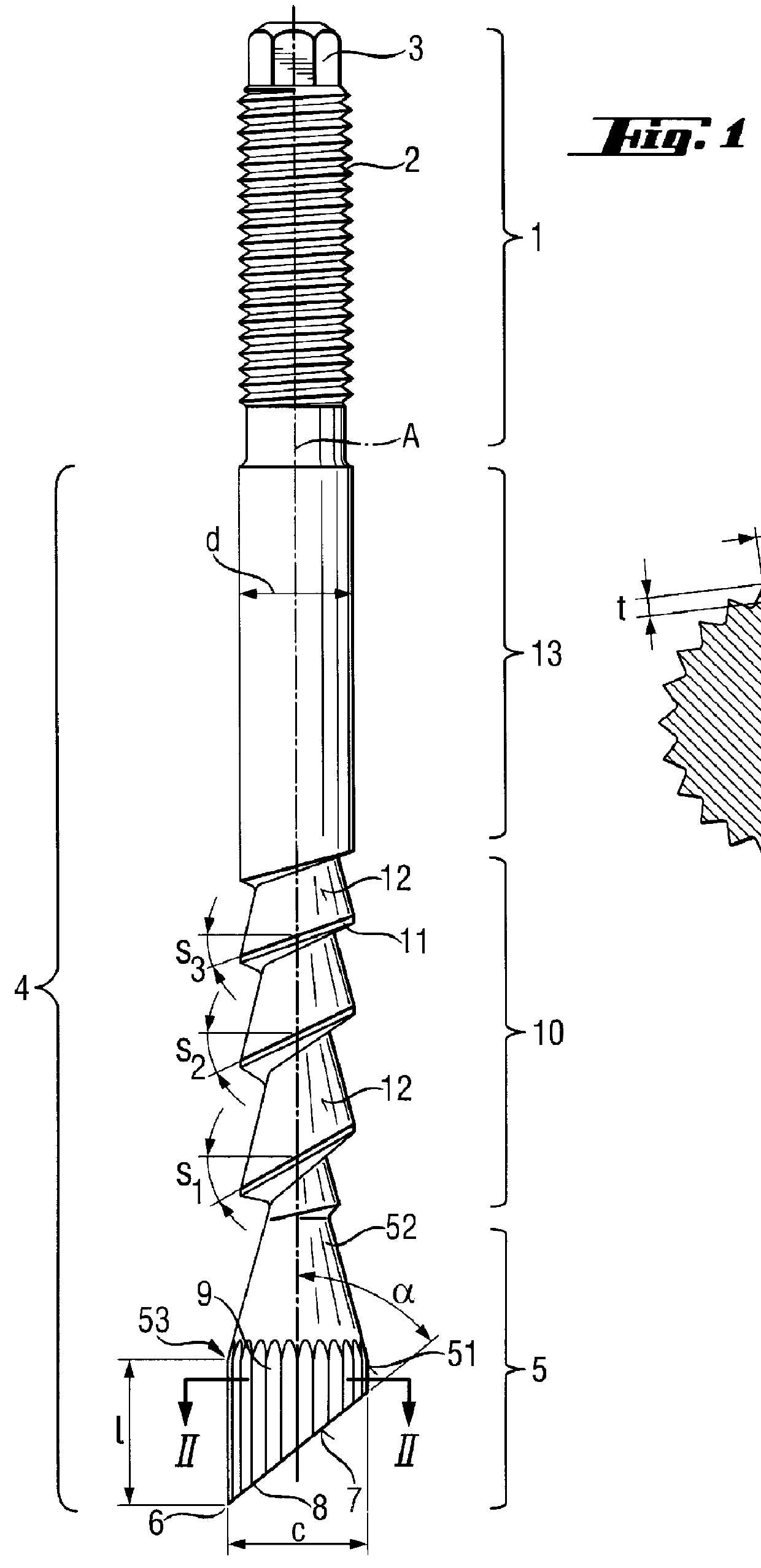

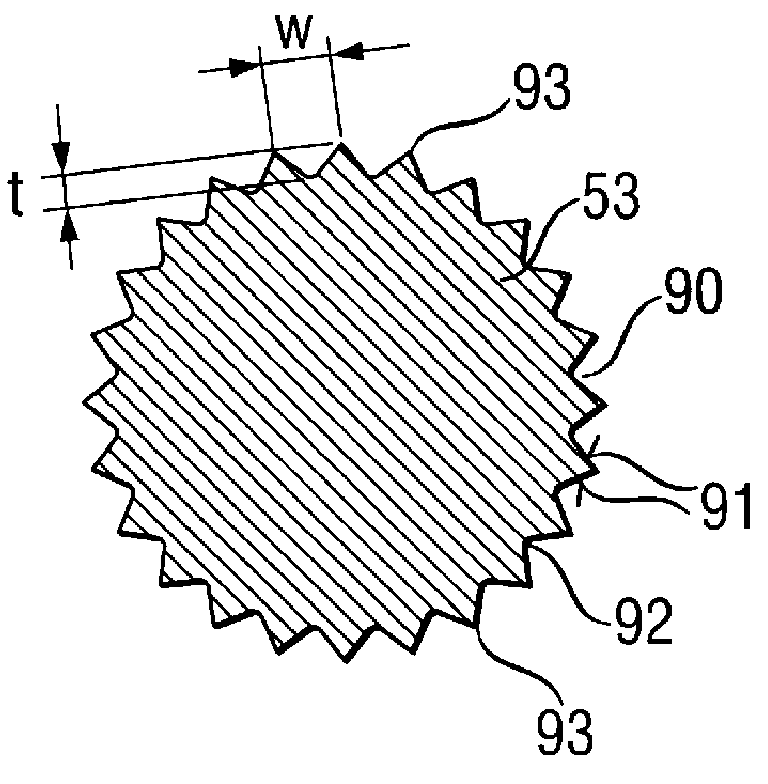

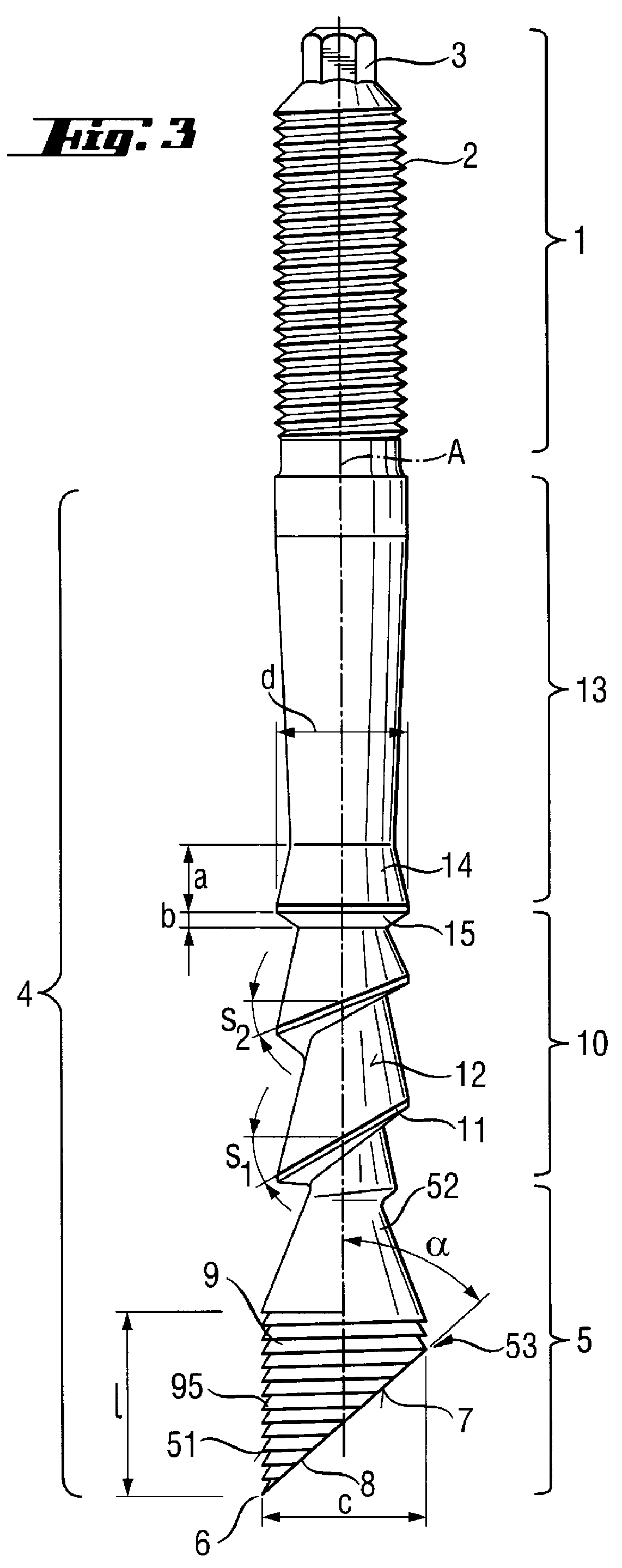

Anchor rod for an attachment anchor

An anchor rod for an attachment anchor including a trailing region (1) provided with a load application element (2), and an anchoring region (4) submergeable in a hardenable inorganic and / or organic mortar mass and having a mixing section formed of a head portion (5) provided at its free end (6) with a cutter (7) extending substantially transverse to the axis (A) of the anchor rod, a transporting section (10) adjoining the mixing section, and a compression section (13) adjoining the transporting section (10), with the head portion (5) having a region (53), the outer diameter (c) of which is larger than the largest diameter (d) of the transporting and compression sections (10,13) of the anchoring region (4), and provided with a mortar mass transporting arrangement (9).

Owner:HILTI AG

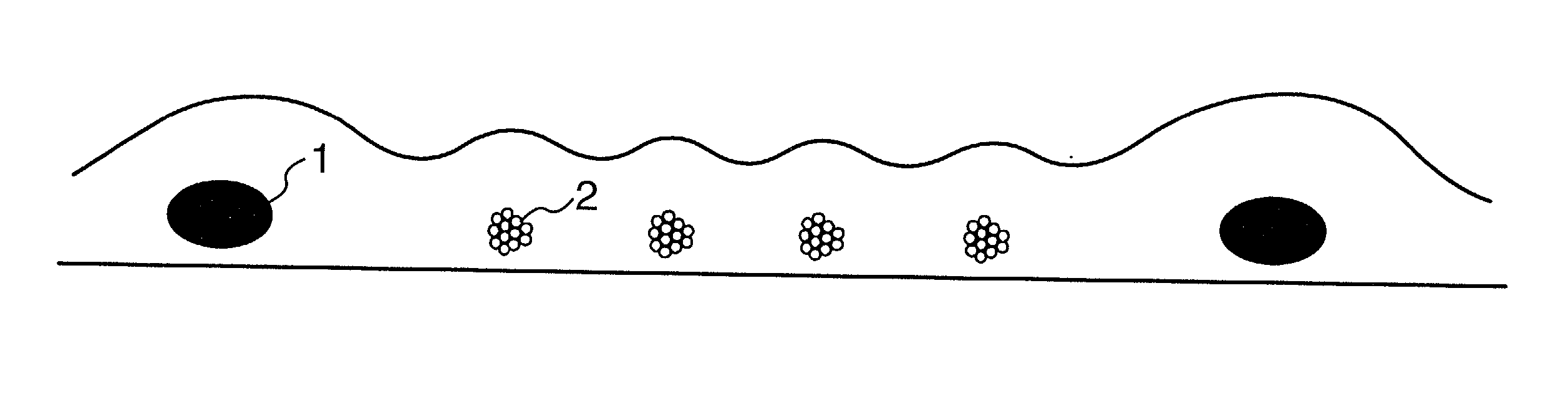

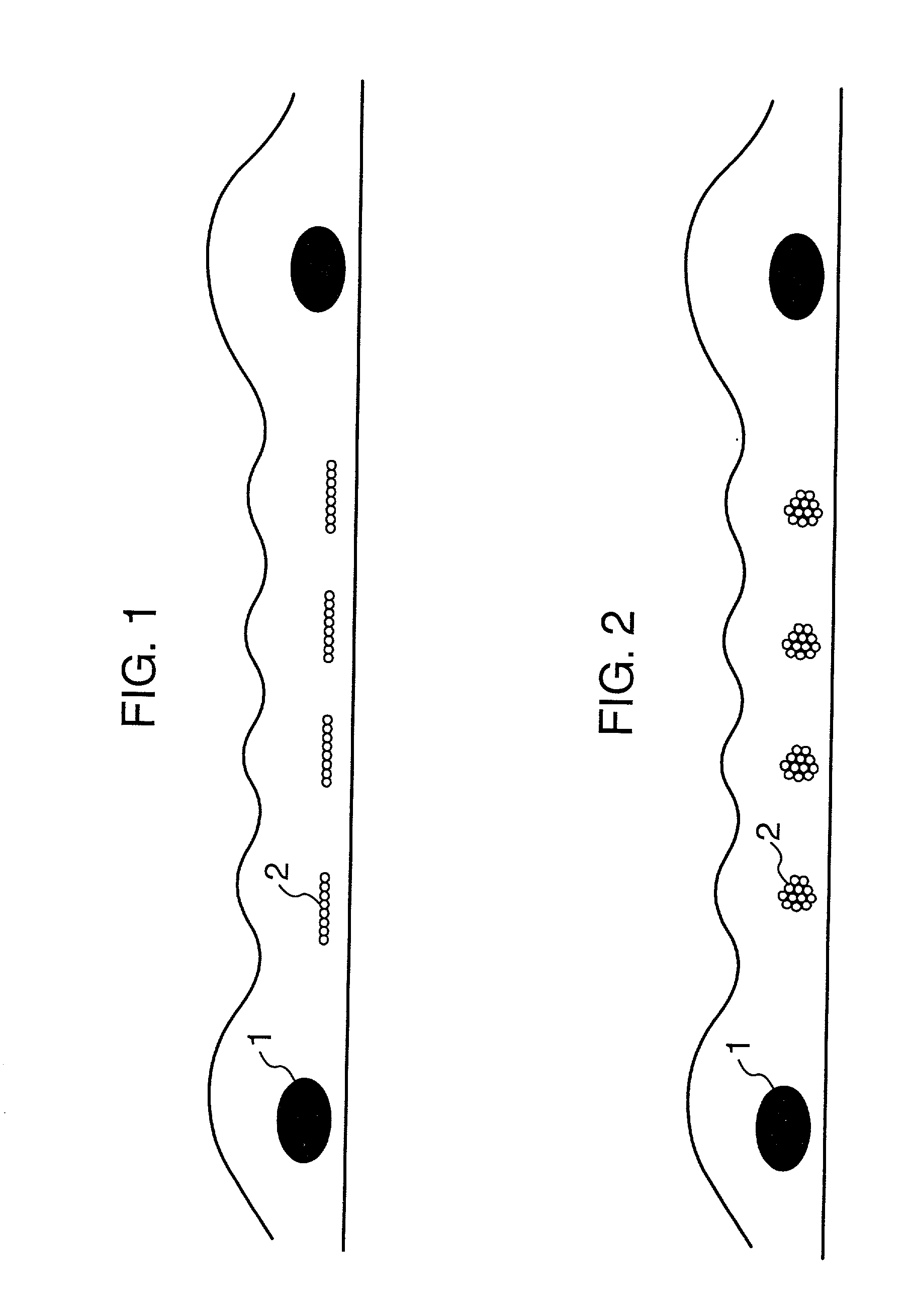

Reinforced cation exchange membrane and production process thereof

InactiveUS20020034904A1Prevent leakageEasily setIon-exchange process apparatusOrganic diaphragmsPlain weaveCationic exchange

A cation exchange membrane wherein a plain weave reinforced cloth is embedded in a fluorinated polymer having a sulfonic acid group and / or a carboxylic acid group, characterized by possessing therein a tubular path which is formed in a direction of a warp and a weft of the plain weave reinforced cloth and has a cross section flat to a direction of thickness of the membrane.

Owner:ASAHI KASEI KK

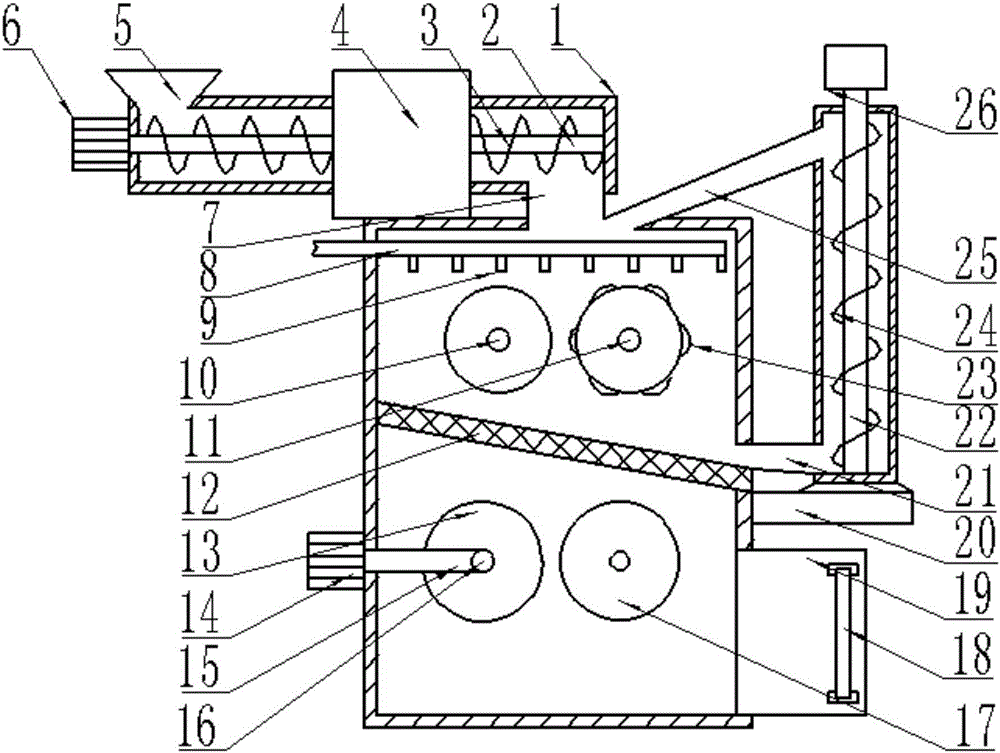

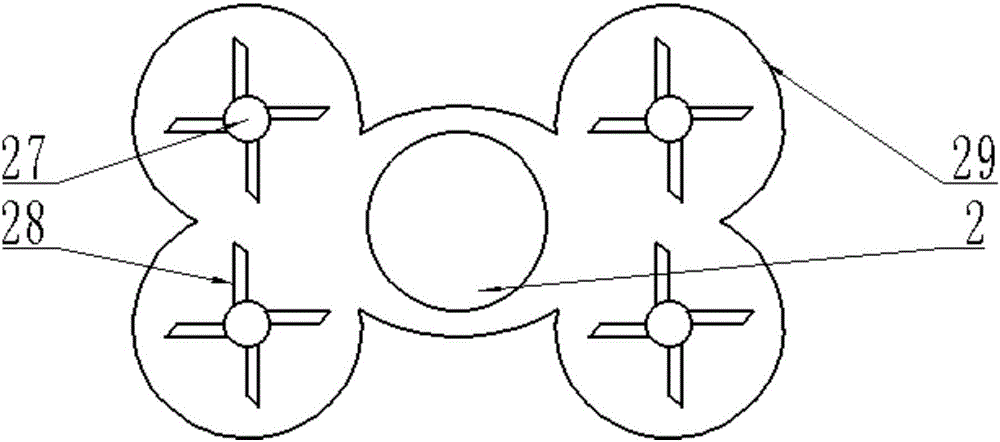

Construction waste smashing and recycling device

The invention provides a construction waste smashing and recycling device which comprises a discharging device, a smashing device, a cleaning device, a cycle delivery device and a bin door. The discharging device comprises a first motor, a feeding hopper and a pre-smashing mechanism. The pre-smashing mechanism is arranged in the middle of the discharging device, and comprises a hobbing rotary shaft and a groove. The smashing device comprises a left breaking roller, a right breaking roller and a second motor. The cleaning device comprises a water inlet pipe and a sprayer. The cycle delivery device comprises a feed pipe, a discharge pipe and a third motor, and a storage plate is arranged at the lower end of the cycle delivery device. A third rotary shaft is arranged at the lower end of the third motor, and the third rotary shaft is provided with a second spiral blade. The storage plate is fixed to the right end of a bin body in a welded manner. The bin door is arranged at the right end of the bin body and provided with a handle. The construction waste smashing and recycling device can carry out smashing to avoid blocking, can carry out cycle smashing to achieve thorough smashing and can also carry out fine smashing to achieve complete smashing.

Owner:郑州吉音动漫科技有限公司

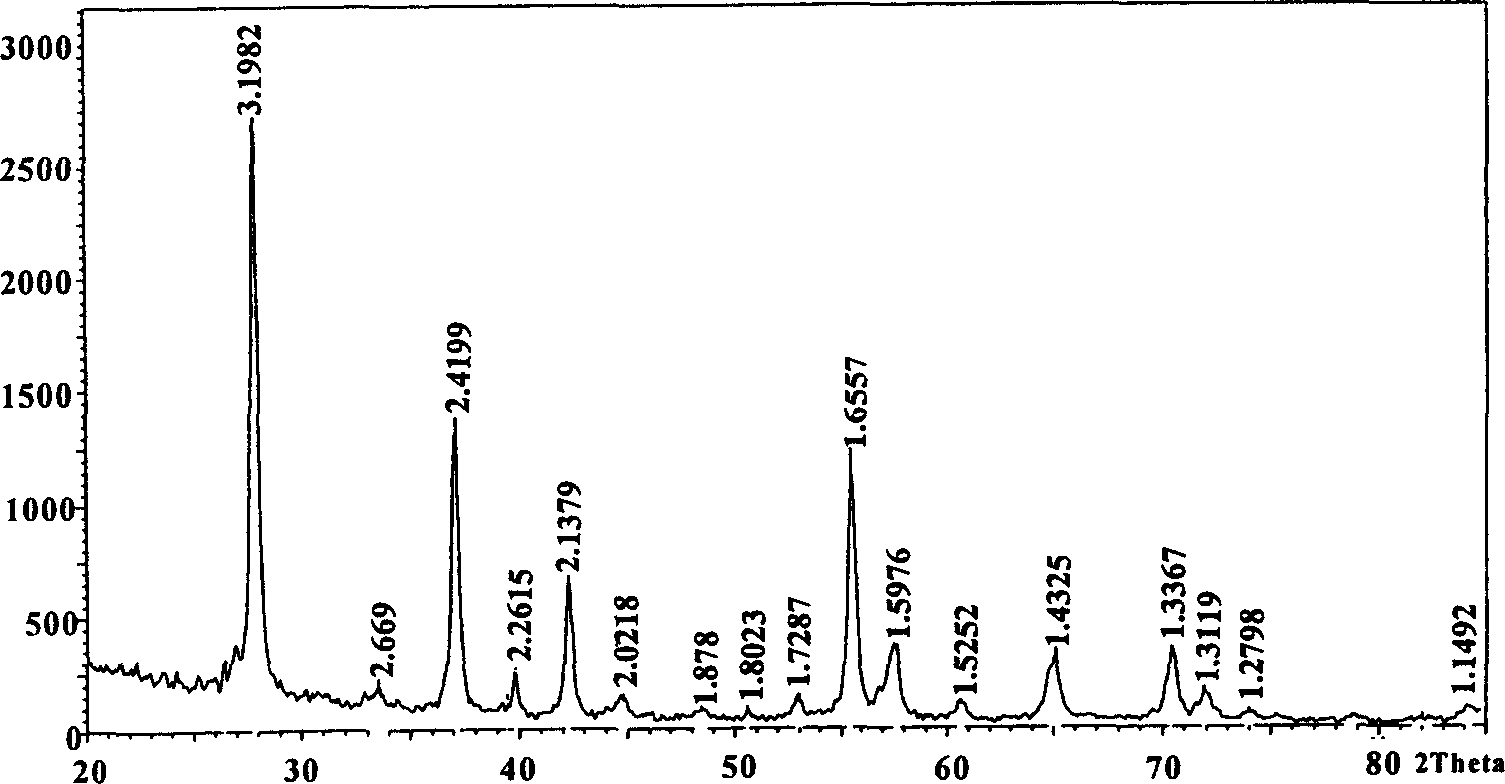

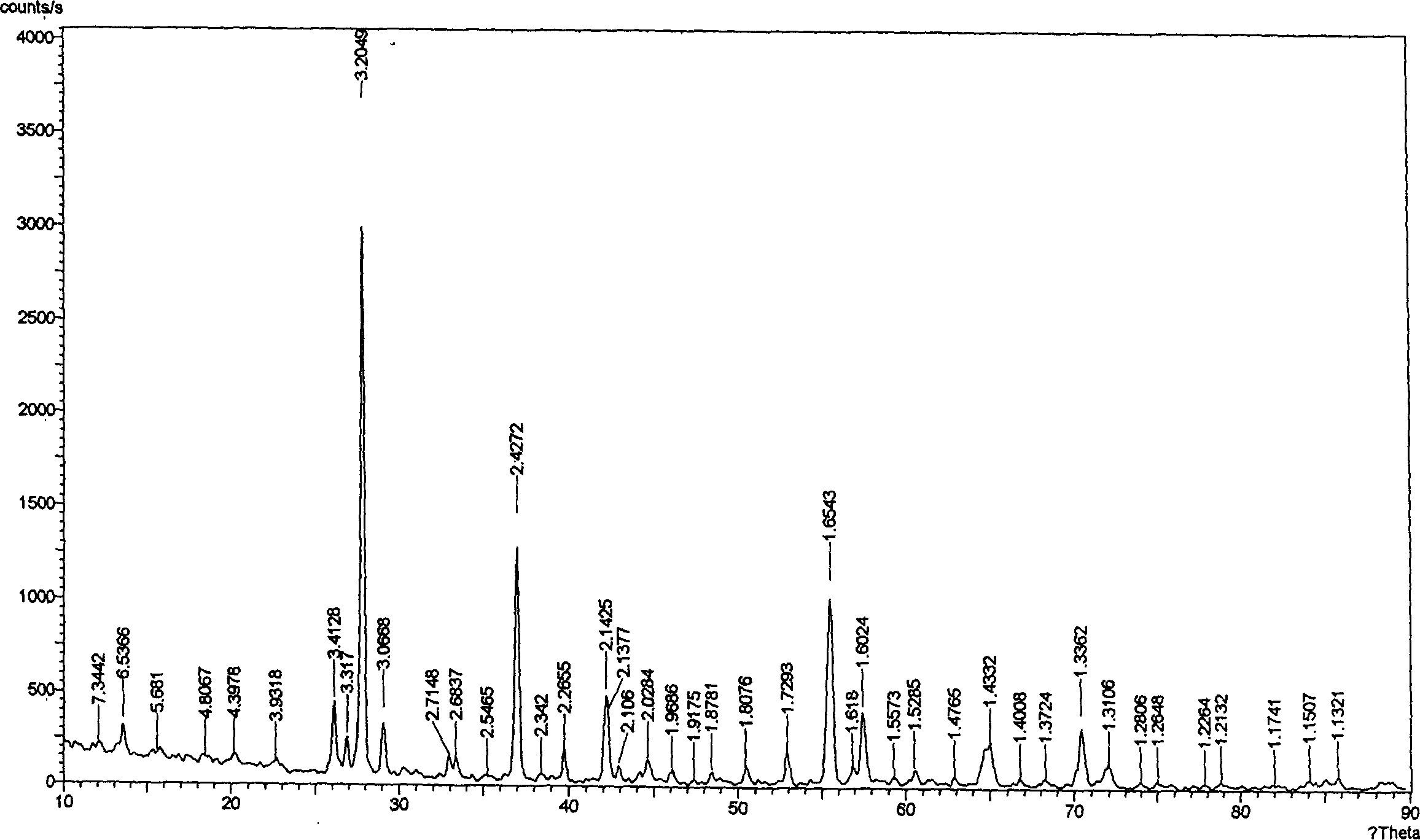

Magnetic alloy material and method of making the magnetic alloy material

ActiveUS7186303B2Easy to useEasy to crushInorganic material magnetismRare-earth elementCrystal structure

A method of making a magnetic alloy material includes the steps of: preparing a melt of an alloy material having a predetermined composition; rapidly cooling and solidifying the melt to obtain a rapidly solidified alloy represented by: Fe100-a-b-cREaAbTMc where RE is at least one rare-earth element selected from La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er and Tm and including at least about 90 at % of La; A is at least one element selected from Al, Si, Ga, Ge and Sn; TM is at least one transition metal element selected from Sc, Ti, V, Cr, Mn, Co, Ni, Cu and Zn; and 5 at %≦a≦10 at %, 4.7 at %≦b≦18 at % and 0 at %≦c≦9 at %; and producing a compound phase having an NaZn13-type crystal structure in at least about 70 vol % of the rapidly solidified alloy.

Owner:SUMITOMO SPECIAL METAL CO LTD

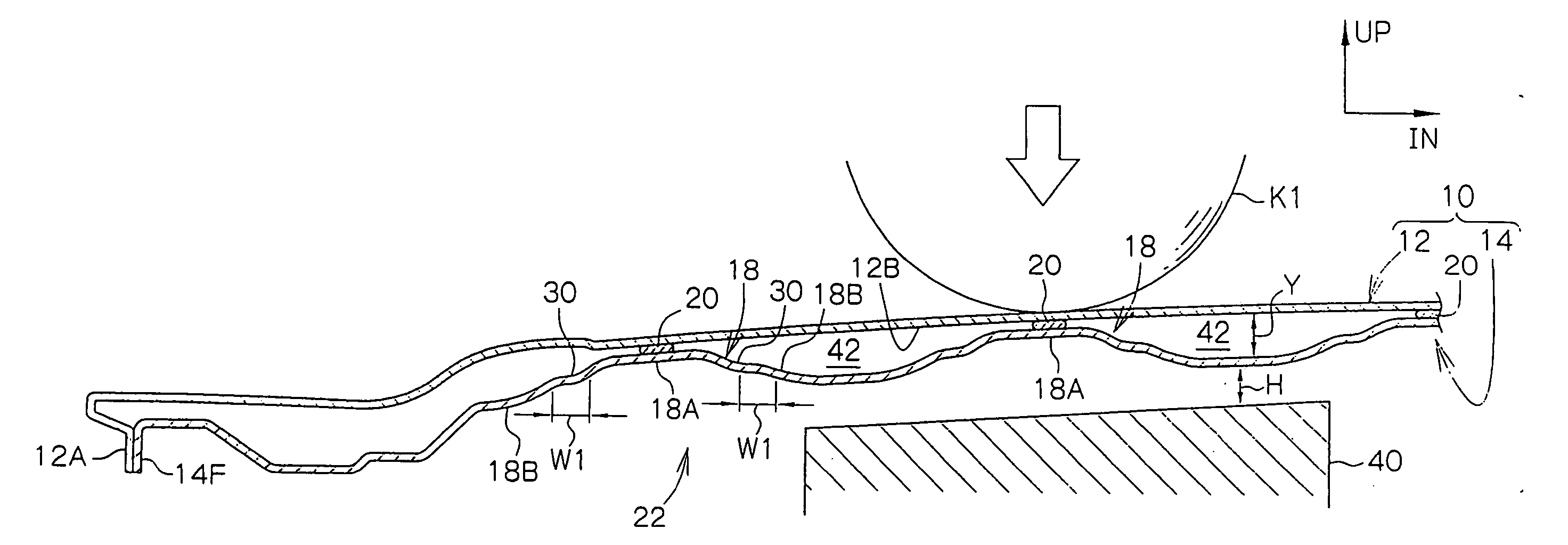

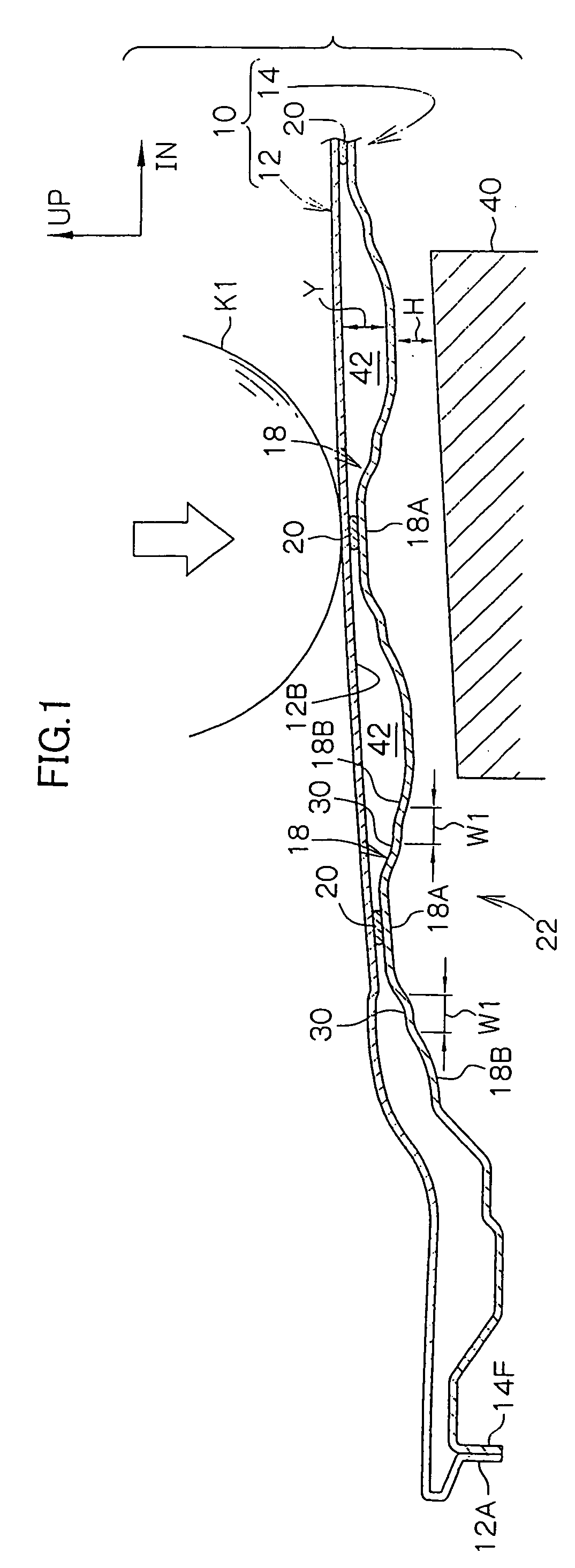

Vehicle hood structure

ActiveUS20060163915A1Sufficient energy absorptionImprove rigidityVehicle seatsPedestrian/occupant safety arrangementEngineeringMechanical engineering

Owner:TOYOTA JIDOSHA KK

Beverage containing fine pulp, process for producing the same and edible material

A beverage containing fine pulp, produced at least with the use of, as a pulp component, a fine pulp wherein the content of less-than-250 μm fine pulp fraction is 5 vol. % or more while the content of 1000 μm-or-more fine pulp fraction is 60 vol. % or less. In the crushing of raw pulp by means of a homogenizer into fine pulp, it is preferable that the homogenizer pressure be 5 kg / cm2 or greater. As a result, the fine pulp component and liquid component form a thorough mix, thereby enabling realization of a novel taste simultaneously realizing two mouthfeels, “viscous” and “sandy” mouthfeels.

Owner:SUNTORY HLDG LTD

Agricultural soil block crushing device

The invention relates to a crushing device, in particular to an agricultural soil block crushing device. The agricultural soil block crushing device is capable of achieving crushing easily, convenient to operate and high in crushing speed. The agricultural soil block crushing device comprises a bottom plate, a collection box, a right frame, electric wheels, pulling ropes, sliding blocks, springs I, sliding rails, a steel wire rope II, a rolling wheel I, a top plate, a left frame, a filter screen III, a connecting rod, a filter screen II, a steel wire rope I, springs II, a filter screen I, a pressing block and a rolling wheel II. The left frame, the collection box and the right frame are arranged at the top of the bottom plate from left to right in sequence. The top plate is arranged at the top of the right side of the left frame. The rolling wheel II and the rolling wheel I are sequentially arranged at the bottom of the top plate from left to right. The filter screen I is connected to the upper portion of the right side of the left frame. By the adoption of the agricultural soil block crushing device, the effects that crushing is easy, operation is convenient and the crushing speed is high are achieved, and soil blocks can be crushed rapidly.

Owner:奉节县仙鑫蜜蜂养殖有限公司

Formed core sandwich structure and method and system for making same

ActiveUS20080292898A1Easy and economical to manufactureEnhanced capillary actionSoldering apparatusVehicle componentsEngineeringCapillary action

A method and apparatus for producing a sandwich structure that is lightweight and many times stiffer than regular sheet metal, and which is easily formable into curved structures as well as structures having compound curves. In one embodiment, a formed core includes a plurality of cells comprising alternating front and rear projections extending outwardly in front of and behind a median plane, with each projection having a bonding surface area or land configured to be bonded with corresponding external sheets on both sides of the formed core. A plurality of micro-abrasions or indentations are formed on the bonding lands, allowing stronger bonding joints to be formed between the core and the external sheets by facilitating improved capillary action by the core during the bonding process.

Owner:CELLTECH METALS INC

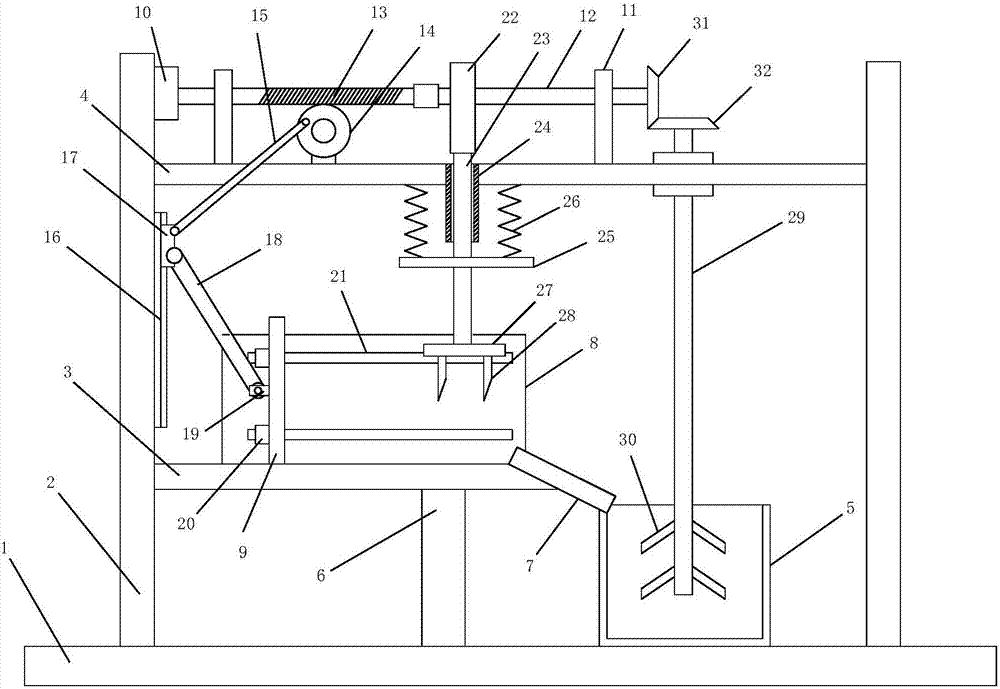

Efficient straw cutting and crushing device for animal husbandry

InactiveCN106900300AImprove cutting and crushing efficiencyHigh cutting and crushing efficiencyCuttersCamAnimal husbandry

The invention discloses an efficient straw cutting and crushing device for animal husbandry. The efficient straw cutting and crushing device comprises a bottom plate, an obliquely downward connecting groove is formed in a right side of a supporting plate, a rotating shaft and a worm are respectively arranged on two brackets, a worm wheel engaged with the worm is arranged below the worm, a first connecting rod is arranged on a side face of the worm wheel, a vertically downward slide rail is arranged on a vertical plate, a vertical push plate is arranged on an upper end face of the supporting plate, baffles are arranged on two sides of the push plate, a second connecting rod having one end hinged with a mounting frame is arranged on the mounting frame, a cam is arranged on one end of the rotating shaft close to the worm, a vertically downward push rod is arranged on a lower end of the cam, a cutting tool is installed on a tool mounting frame, a crushing rotating shaft is arranged on a top plate, and a crushing tool is installed on the lower end of the crushing rotating shaft. The efficient straw cutting and crushing device disclosed by the invention has a simple structure and can cut and crush straws at the same time, the straw cutting and crushing efficiency is relatively high, the crushing effect is good, and no manual operation is required, thereby saving labor. The practicability is relatively high.

Owner:惠安县长捷机械科技有限公司

Low-loss building stone smashing device for construction site

The invention discloses a low-loss stone crushing device for construction sites, which includes a box body; a partition is fixed on the upper part of the inner cavity of the box, an electric heating plate is arranged on the inner cavity wall of the box body above the partition, and a through hole A flip-type cover plate is arranged at the bottom; two chutes are arranged symmetrically under the partition, and the chutes are arranged inclined inward; a spray pipe is arranged above the chute; Crushing rollers, the gap between the crushing rollers on both sides is facing the sliding opening formed by the chute; a screen is arranged under the crushing rollers, and the screen is movably embedded on the side wall of the inner cavity of the box, and the bottom of the screen is A spring is connected between the two ends and the inner cavity wall of the box, and an exciter is installed at the bottom of the screen. The crushing device of the present invention makes the stone easy to crush by performing thermal expansion and contraction treatment on the stone, thereby reducing equipment loss and prolonging the service life of the equipment.

Owner:杜鑫

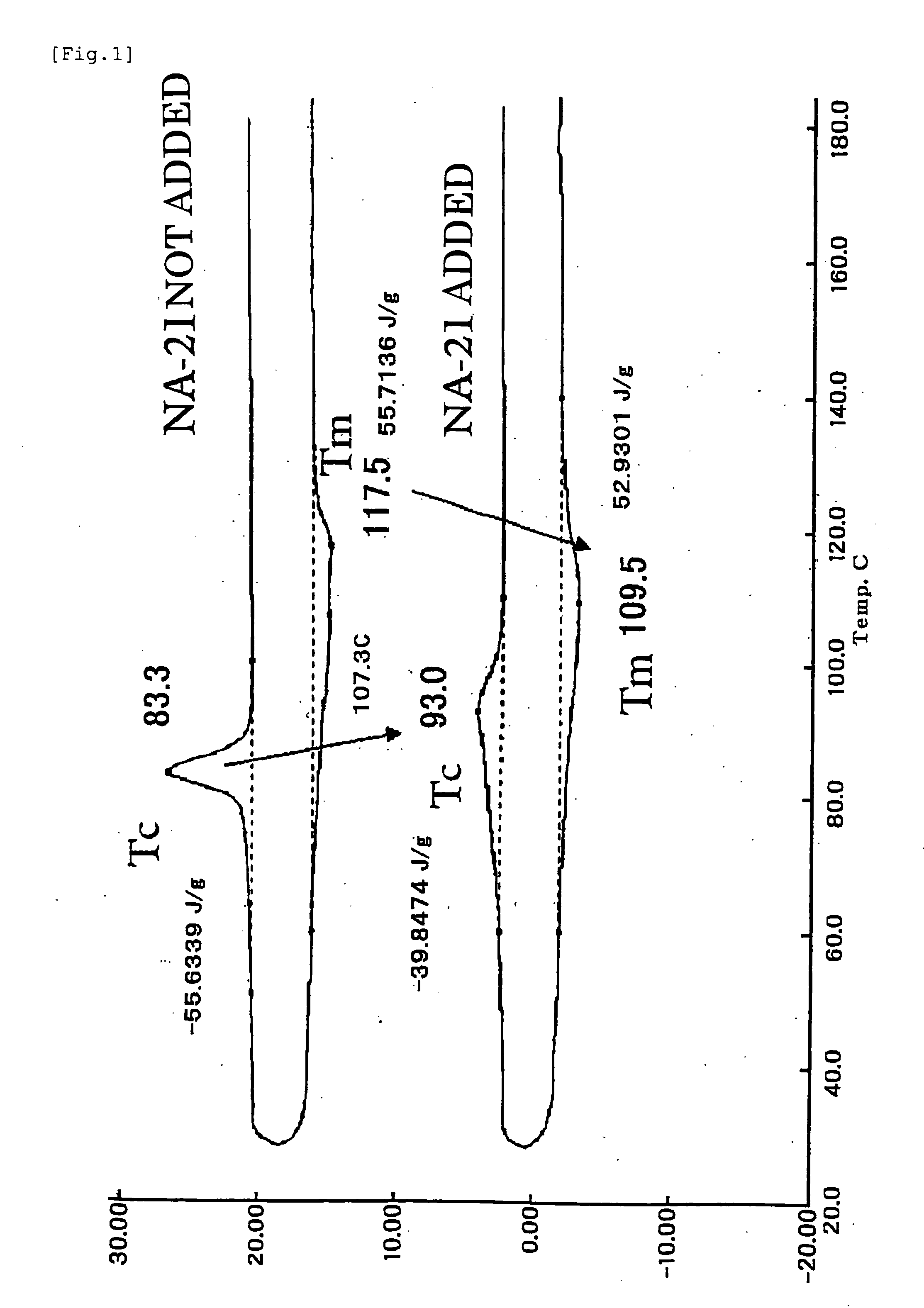

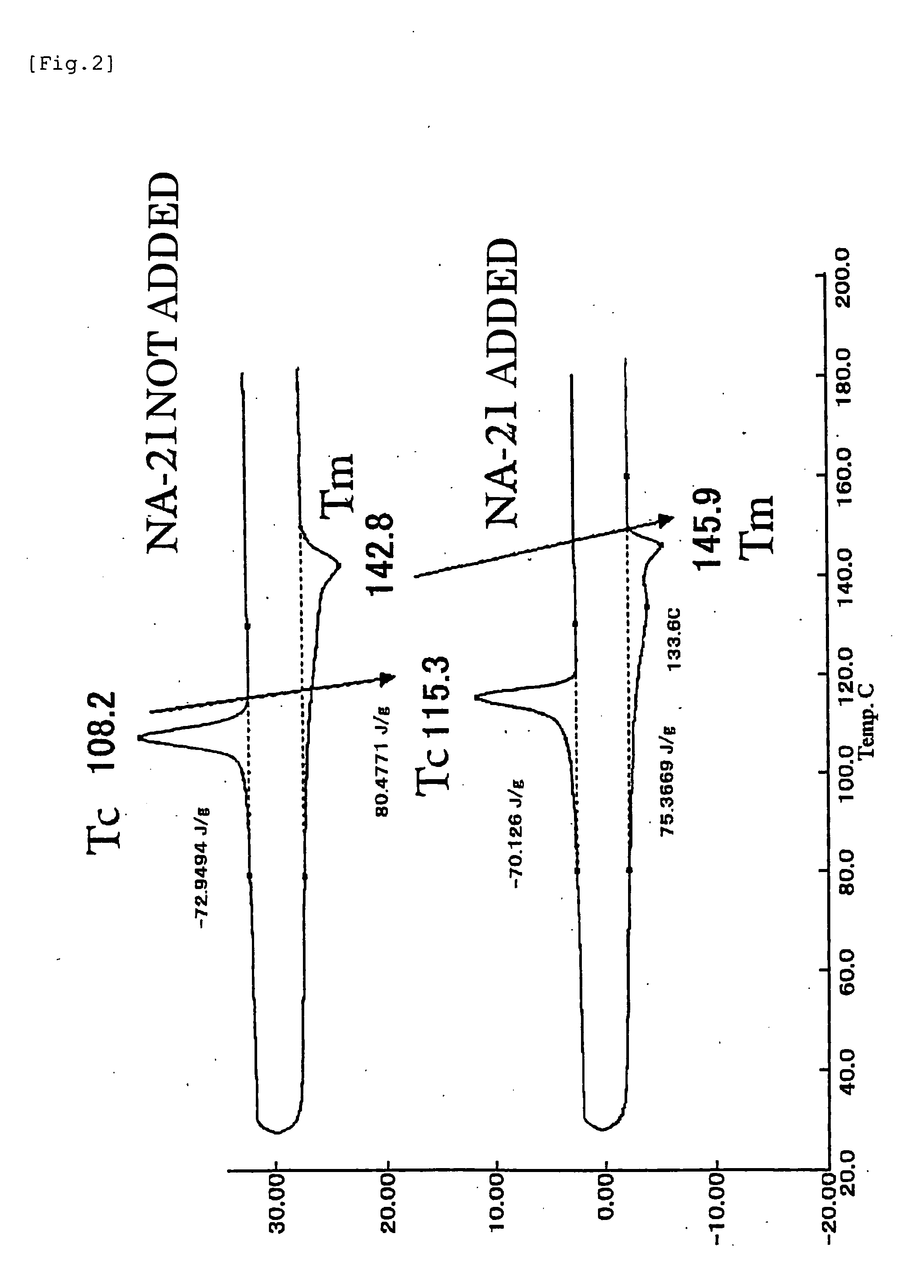

Polypropylene resin and blow molded container

ActiveUS20100040813A1Increase flexibilityIncrease resistanceSynthetic resin layered productsThin material handlingPliabilityUltimate tensile strength

Polypropylene resins of the present invention give blow molded containers excellent in transparency, impact resistance and flexibility. Stretch blow molded containers obtained from the polypropylene resins enable volume reduction and weight reduction. A polypropylene resin includes a random polypropylene (P1) having MFR (ASTM D 1238, 230° C., 2.16 kg load) of 0.5 to 100 g / 10 min and an ethylene content of 3.0 wt % to less than 7.0 wt %, (i) the resin containing the random polypropylene (P1) at not less than 80 wt %, (ii) the resin showing a broad DSC melting curve which has a single melting point peak and in which the maximum intensity peak temperature (Tm) is not more than 120° C. and the half-value width on a higher temperature side from the maximum intensity peak is not less than 20° C.

Owner:MITSUI CHEM INC +1

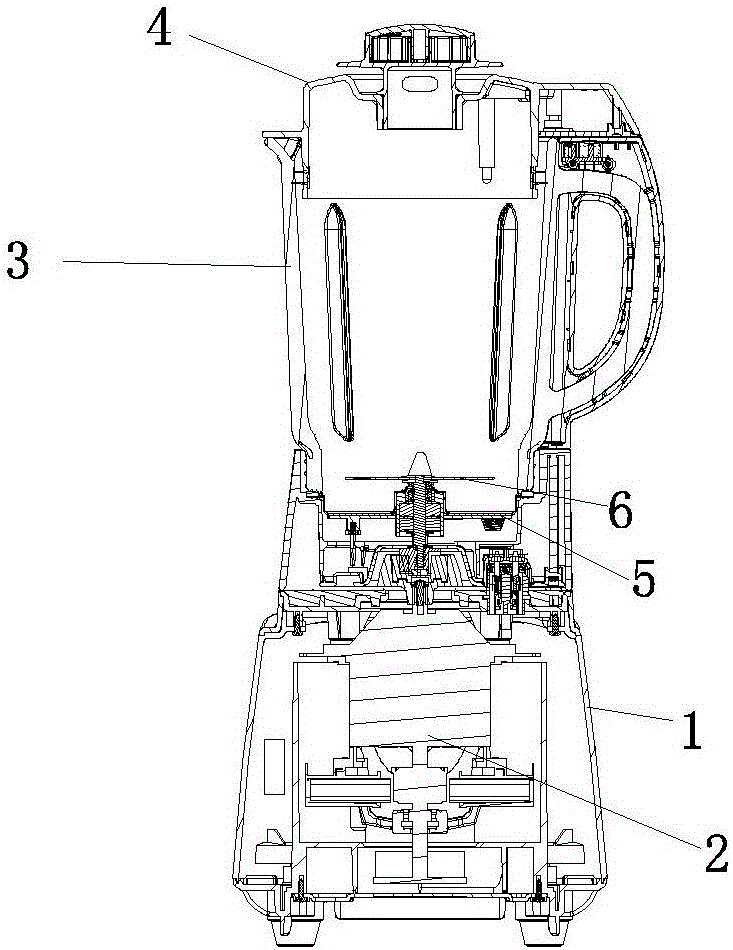

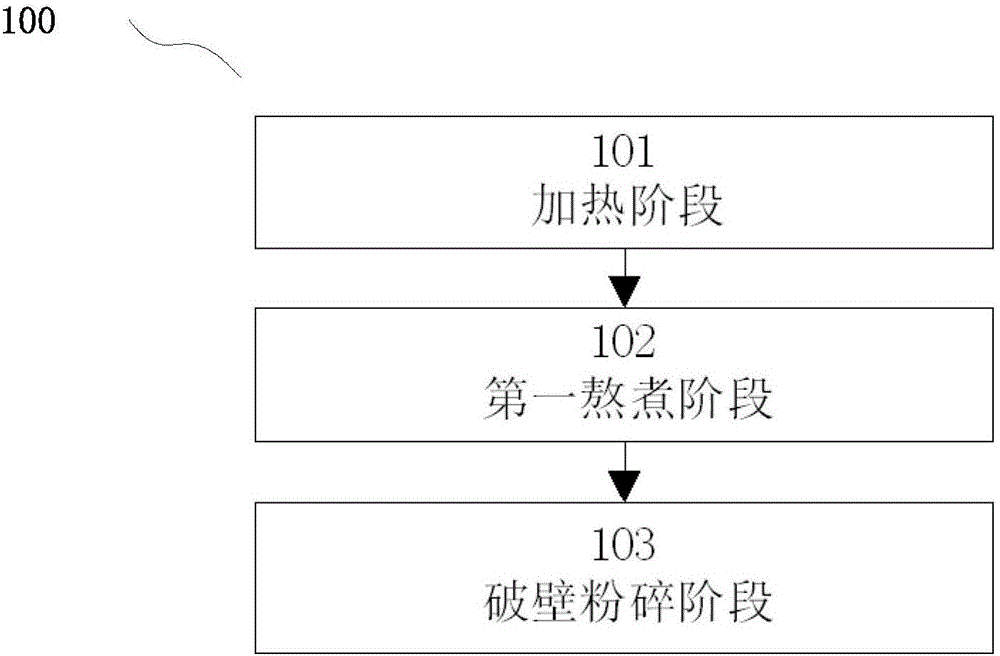

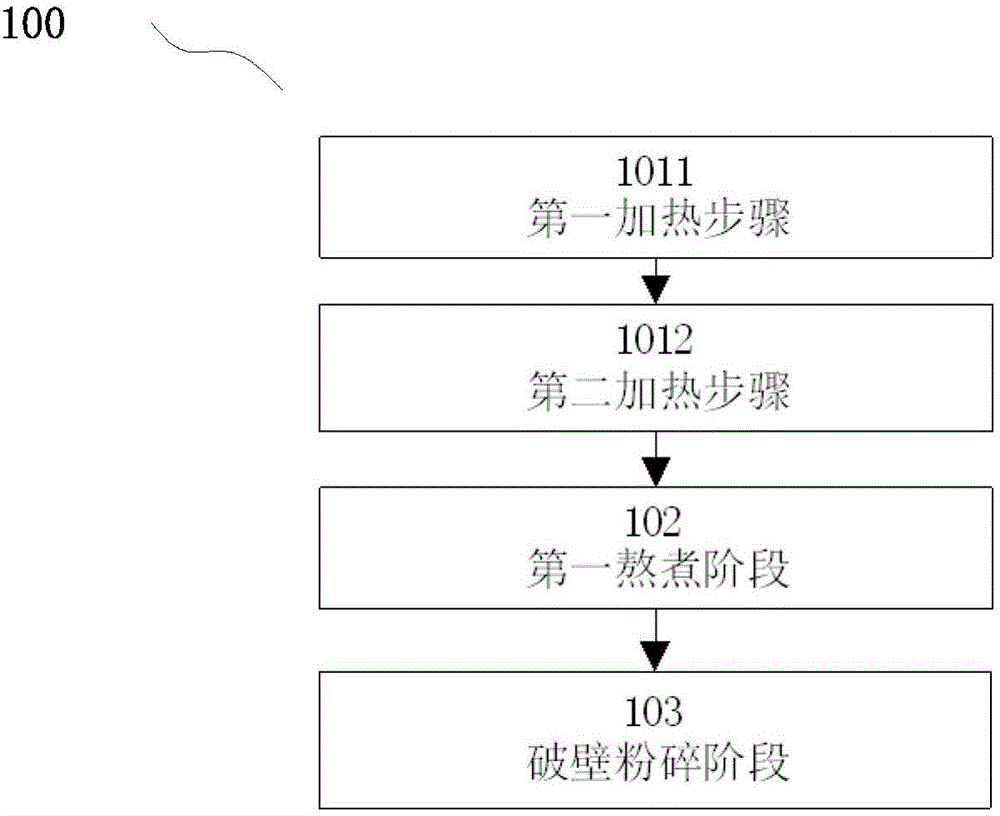

Food processing method of motor under-set-type food processing machine and food processing machine

The invention relates to a food processing method of a motor under-set-type food processing machine and the food processing machine, and belongs to the field of food processing. The food processing method at least comprises a heating stage, a first cooking stage and a wall-breaking and grinding stage, wherein in the heating stage, food in a stirring cup is heated to be boiling by virtue of a heating device; in the first cooking stage, the food in the stirring cup is cooked for a duration of t1 by virtue of the heating device until the food is completely cooked, and during cooking, a grinding cutter is driven to do intermittent rotation at a first rotating speed by virtue of a motor; and in the wall-breaking and grinding stage, the grinding cutter is driven to rotate at a second rotating speed by virtue of the motor so as to grind the cooked food in the stirring cup, and the second rotating speed, which ranges from 20000r / min to 40000r / min, is greater than the first rotating speed, wherein the power of the heating device in the first cooking stage is less than that in the heating stage. The food processing machine using the food processing method provided by the invention can uniformly heat the food, and the phenomenon of over-burnt bottom and spillover cannot occur easily.

Owner:JOYOUNG CO LTD

Drawer type medical glass pulverizing device

The invention discloses a drawer-type medical glass crushing device, which comprises a body, a discharge drawer, a cleaning brush, a feed drawer, a cam and an ultraviolet lamp; a movable plate is arranged under the cam, and a number of crushing devices are uniformly arranged on the bottom of the movable plate. Hammer; the bottom of the feed drawer is provided with a base, and a turntable is installed on the lower side of the base; two bosses are symmetrically installed on the inner wall of the body, and two grinding rollers are also symmetrically arranged inside the body There are two ultraviolet lamps, and the two ultraviolet lamps are respectively installed on the lower side of the boss; the discharge drawer is slidably installed on the bottom of the body through a chute. The present invention is provided with a drawer-type feed port and a discharge port to facilitate the crushing of medical glass waste; it is also provided with a grinding roller and an ultraviolet lamp, which can grind the glass waste into powder and sterilize it, preventing the glass waste from polluting the environment and harming people. healthy.

Owner:金波

Composite mixed vanadium dioxide nano powder material and its preparation process

InactiveCN1693211AImprove transmittanceLower phase transition temperatureVanadium oxidesVanadium dioxideOxalate

A process for preparing the doped composite VO2 nanoparticles with low phase-change temp (25-30 deg.C) and improved physical propoerties includes such steps as preparing the metal element and non-metal element doped solid vanadium oxalate as precursor from V2O5 and oxalic acid, and vacuum thermodecomposing. Its molecular formula is V1-xMxO2-yZy, where x=0-0.08, y=0-0.1, M is metal element and Z is non-metal element.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com