Food processing method of motor under-set-type food processing machine and food processing machine

A food processing machine, food processing technology, applied in the field of food processing, can solve the problems of uneven heating, easy to produce bottom paste, insufficient, etc., to achieve the effect of easy crushing, prevent bottom paste, and improve fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

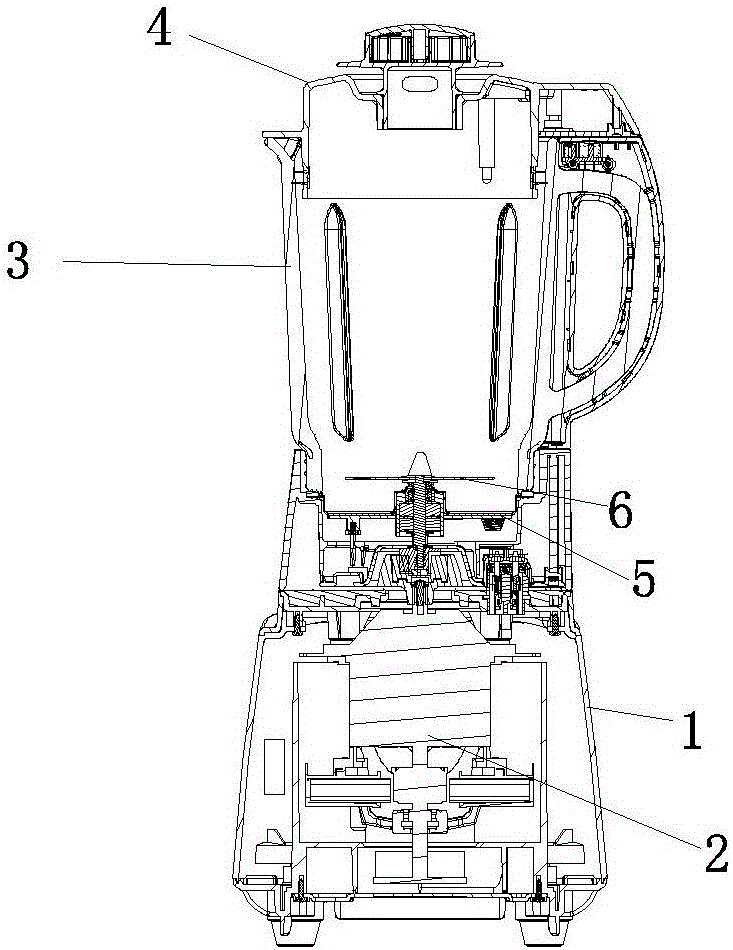

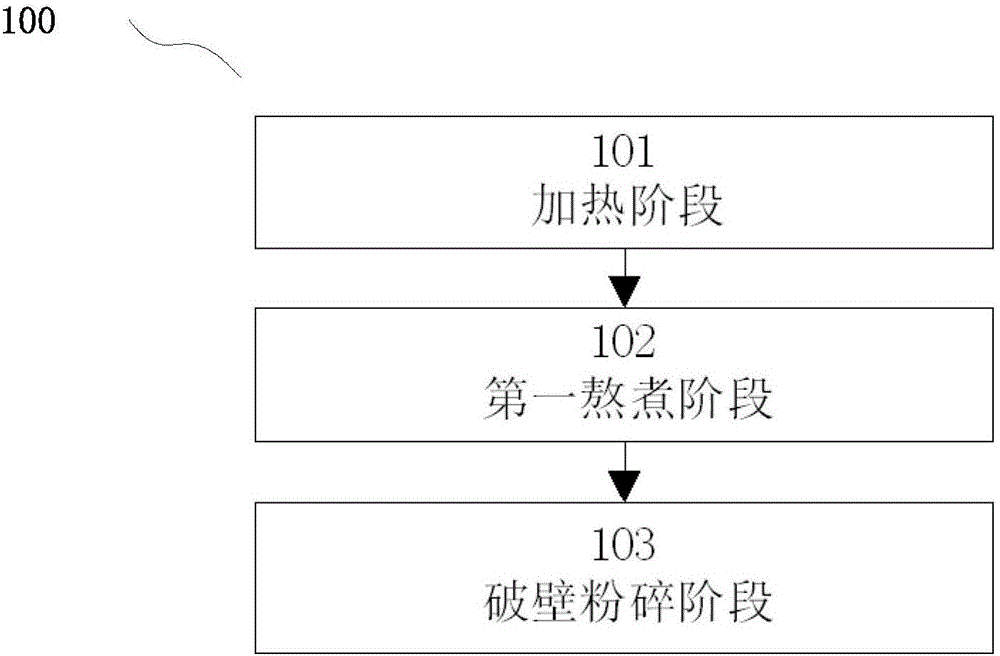

[0043] As a first embodiment of the present invention, such as figure 1 , figure 2 As shown, a food processing method of a food processing machine with a motor under it, the food processing machine includes a motor 2, a heating device 5, a crushing knife 6 and a stirring cup 3, wherein the food processing method 100 at least includes:

[0044] Heating stage 101: the heating device 5 heats the food in the mixing cup 3 to boiling, and the power of the heating device 5 at this stage is p1, 300w≤p1≤1000w;

[0045] The first cooking stage 102: the heating device 5 cooks the food in the mixing cup 3 to make it fully mature, and the cooking time is t1. During the cooking process, the motor 2 drives the pulverizer 6 to rotate intermittently at a first speed; At this stage, the power of the heating device 5 is p2, 250w≤p2<300w;

[0046] Wall-breaking and pulverizing stage 103: the motor 2 drives the pulverizing knife 6 to rotate at a second rotational speed to pulverize the cooked f...

Embodiment 2

[0057] The difference between this embodiment and Embodiment 1 is that: Figure 4 As shown, there is a second boiling stage 104 between the first boiling stage 102 and the wall breaking and crushing stage 103: the heating device 5 boils the food in the mixing cup 3 with the third power p3, and the cooking time is t2, and the third power p3 is smaller than the second power p12; during the cooking process, the motor 2 drives the pulverizer 3 to rotate intermittently at the first speed n1, so as to prevent the bottom from sticking and make the heating more uniform.

[0058] There is a pause step 107 between the second boiling stage 104 and the wall breaking and pulverizing stage 103: the heating device 5 and the motor 2 stop working for a period of time, and the time is t4, 30s≤t4≤60s.

[0059] understandable, such as Figure 5 As shown, there is a third cooking stage 105 after the wall-breaking and pulverizing stage 103: the heating device 5 cooks the food in the mixing cup 3 w...

Embodiment 3

[0061] The difference between the present embodiment and the second embodiment is that: Image 6 As shown, the wall breaking stage 103 includes an intermittent crushing step 106: the motor 2 drives the crushing knife 6 to beat the food in the mixing cup 3 for a period of time, and then the motor 2 stops working for a period of time, and the stop time is t5, And 30s≤t5≤60s, the intermittent crushing step 106 is cycled at least once.

[0062] The food processing method 100 of the present invention will be described in detail below in conjunction with a more specific embodiment.

[0063] By applying the food processing method 100 of the present invention, foods such as soymilk, rice paste, porridge, and thick soup are processed. This processing method does not paste the bottom and heats evenly.

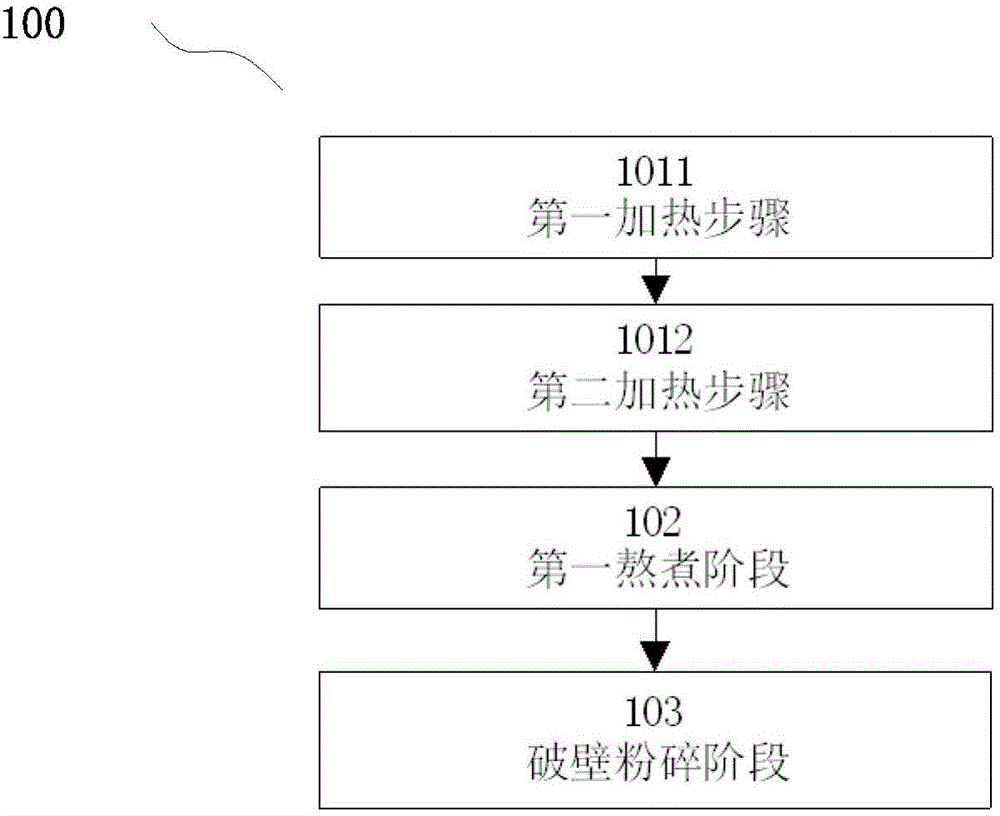

[0064] The heating stage 101 is carried out in two steps. More specifically, in the first heating step 1011, 700w≤p11≤1000w, for example, p11=700w, the food is heated to a temperature T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com