Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Avoid sticky bottom" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

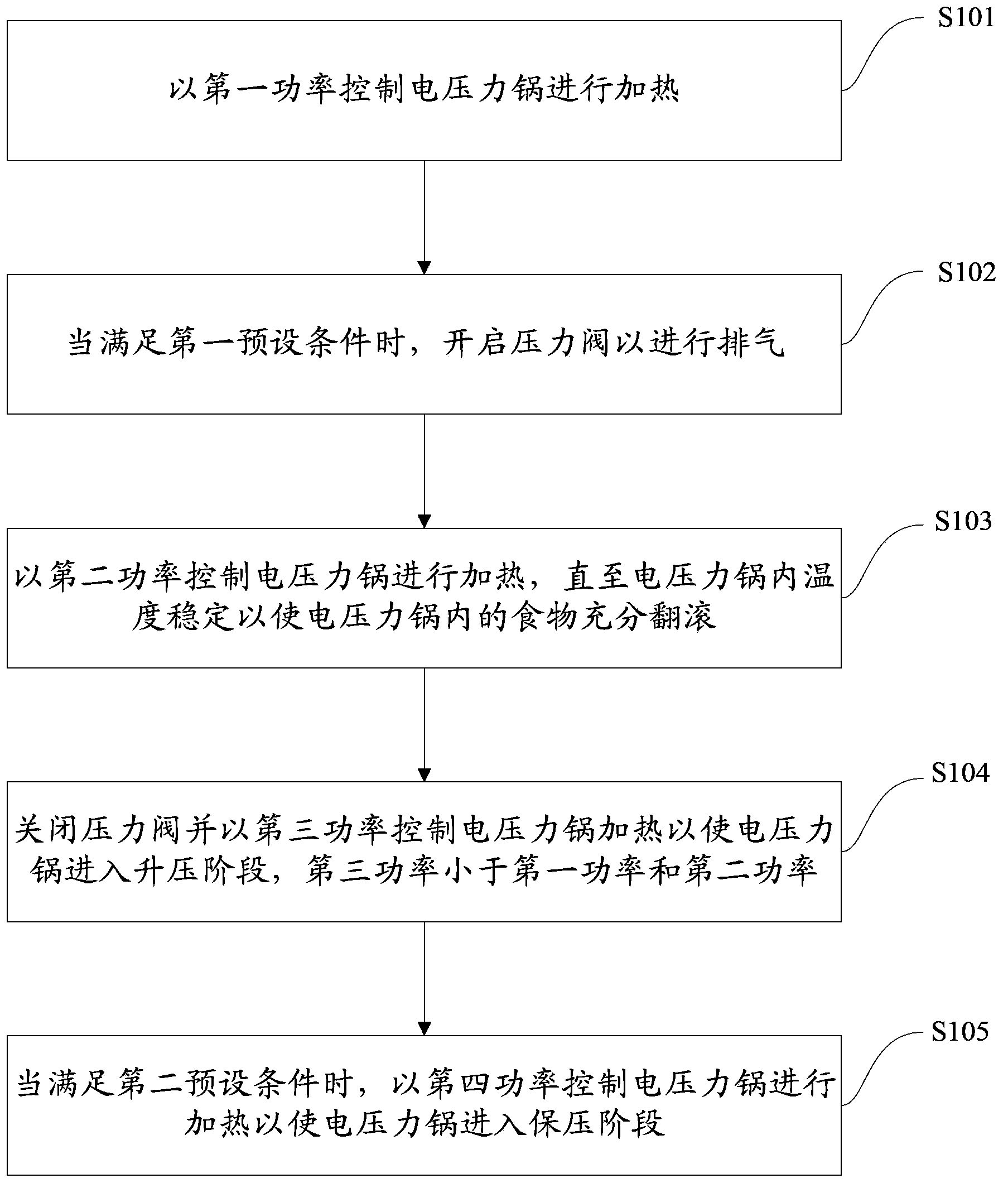

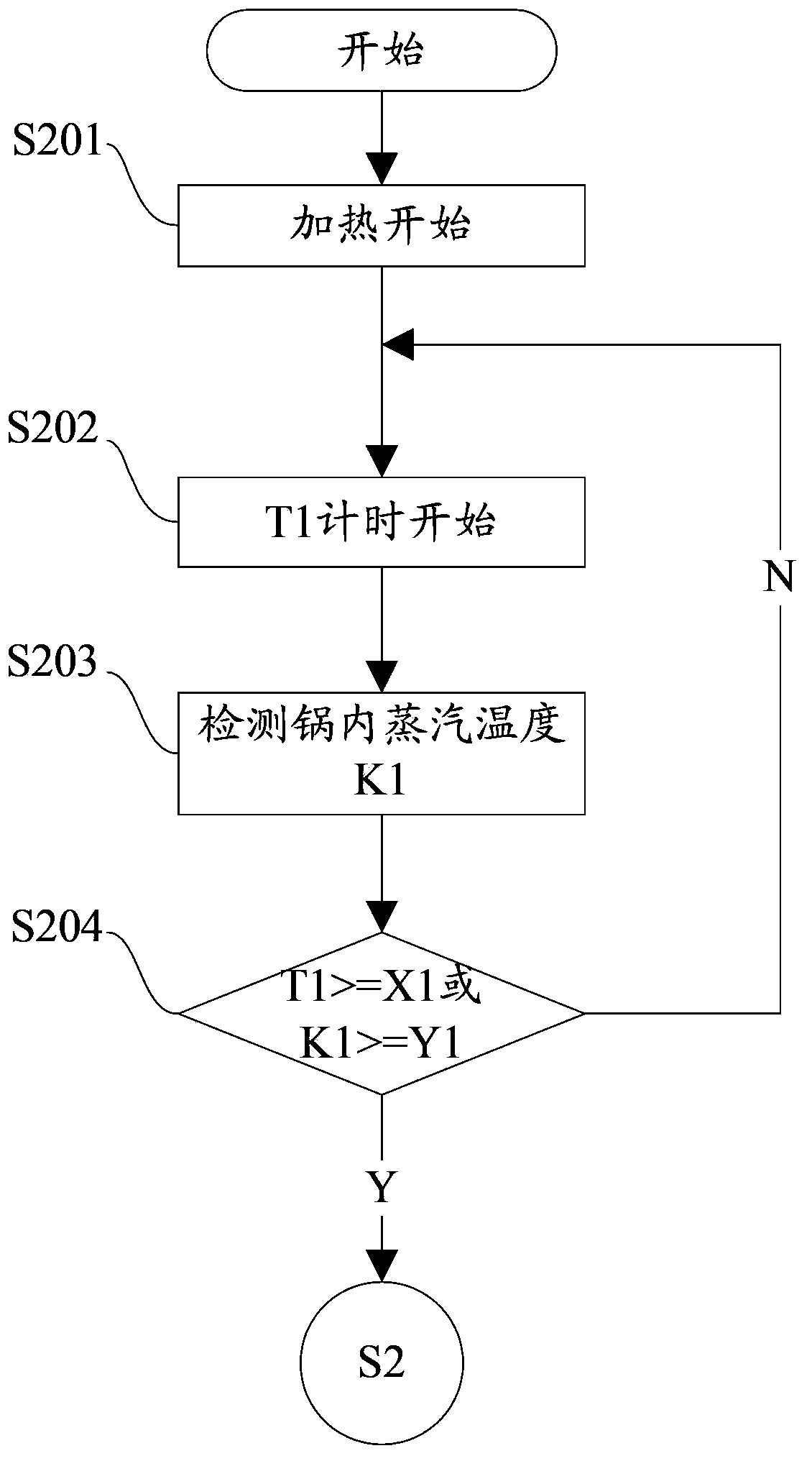

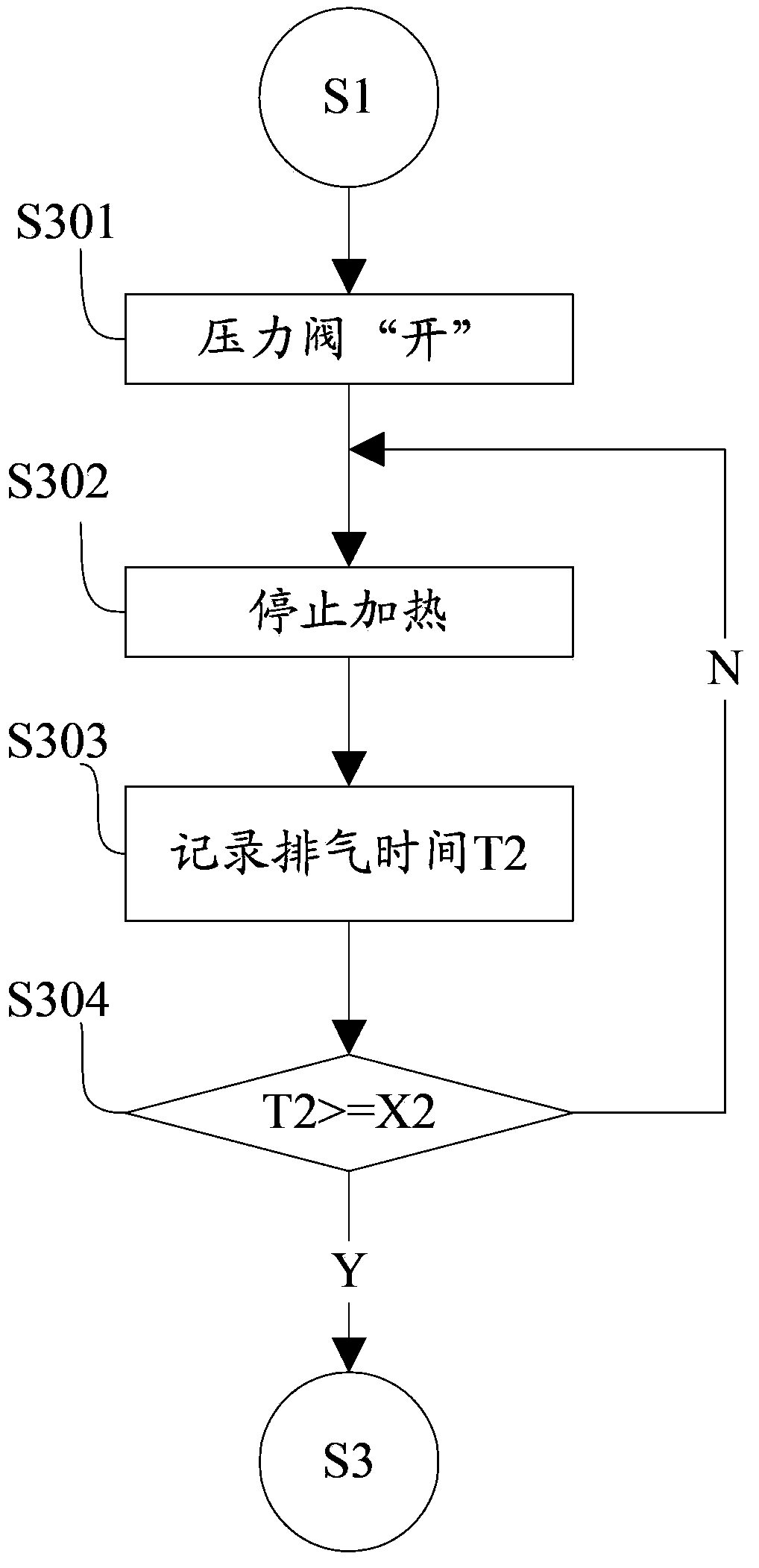

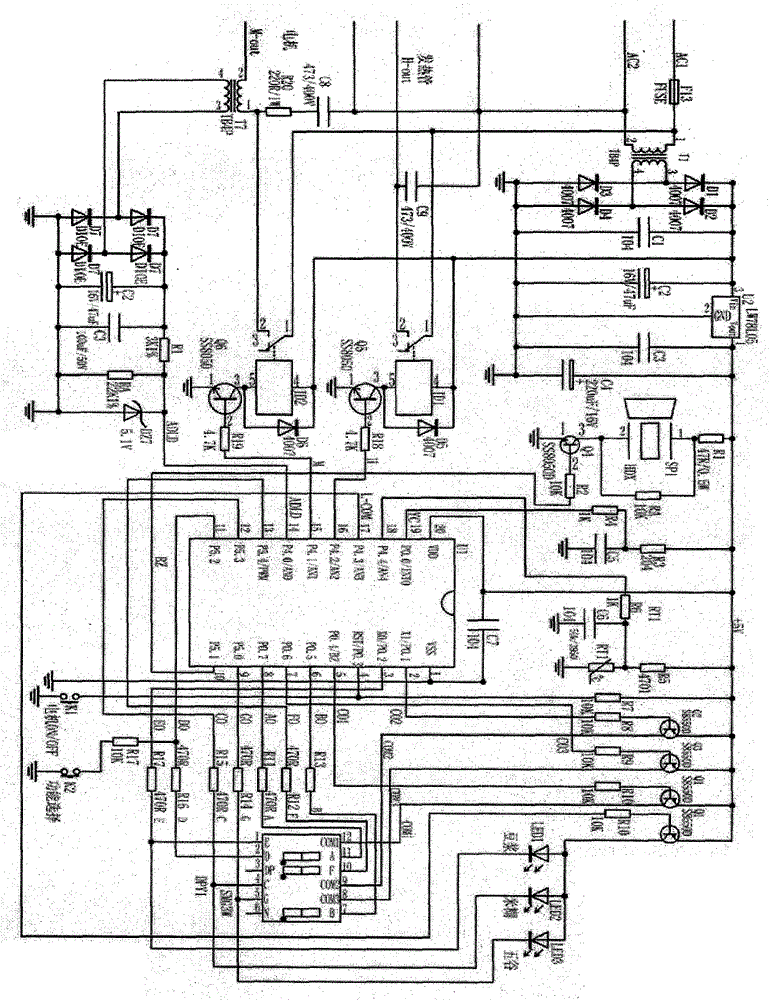

Electric pressure cooker control method and electric pressure cooker

ActiveCN103654373AUniform surface hardnessSufficient flexibilityPressure-cookersEngineeringCooked food

The invention provides an electric pressure cooker control method which comprises the following steps that an electric pressure cooker is controlled to heat with first power; when a first preset condition is met, a pressure valve is opened, so that air is discharged; the electric pressure cooker is controlled to heat with second power until the temperature in the electric pressure cooker is stable and food in the electric pressure cooker is made to be turned over completely; the pressure valve is closed and the electric pressure cooker is controlled to heat with third power, so that the electric pressure cooker enters a boosting stage, and the third power is smaller than the first power and the second power; when a second preset condition is met, the electric pressure cooker is controlled to heat with fourth power, so that the electric pressure cooker enters a pressure maintaining stage. According to the electric pressure cooker control method, the cooked food is complete, moisture is sufficient, the hardness is even, the taste is good, and the cooked food is prevented from pasting the bottom of the cooker and overflowing out of the cooker. The invention further provides the electric pressure cooker.

Owner:MIDEA GRP CO LTD

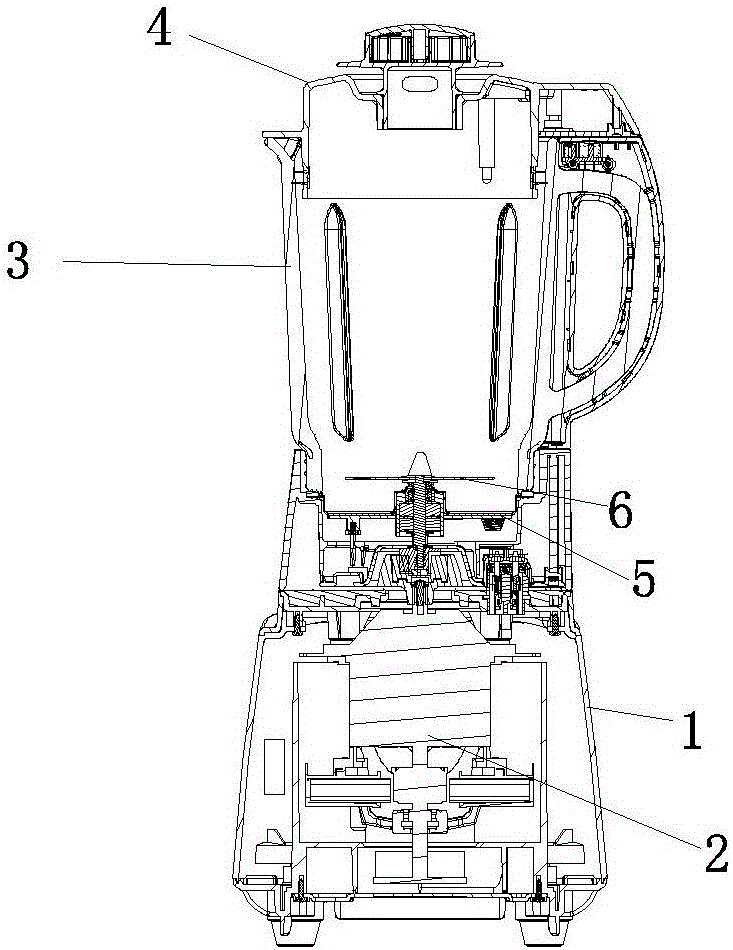

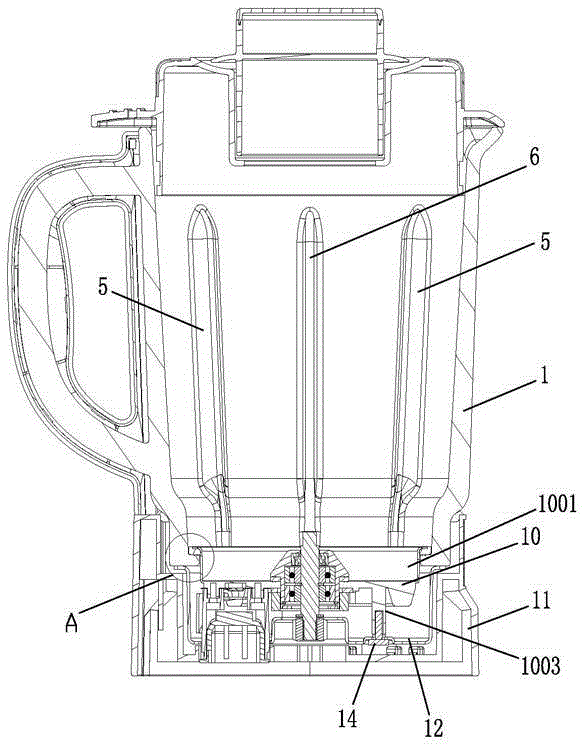

Food processing method of motor under-set-type food processing machine and food processing machine

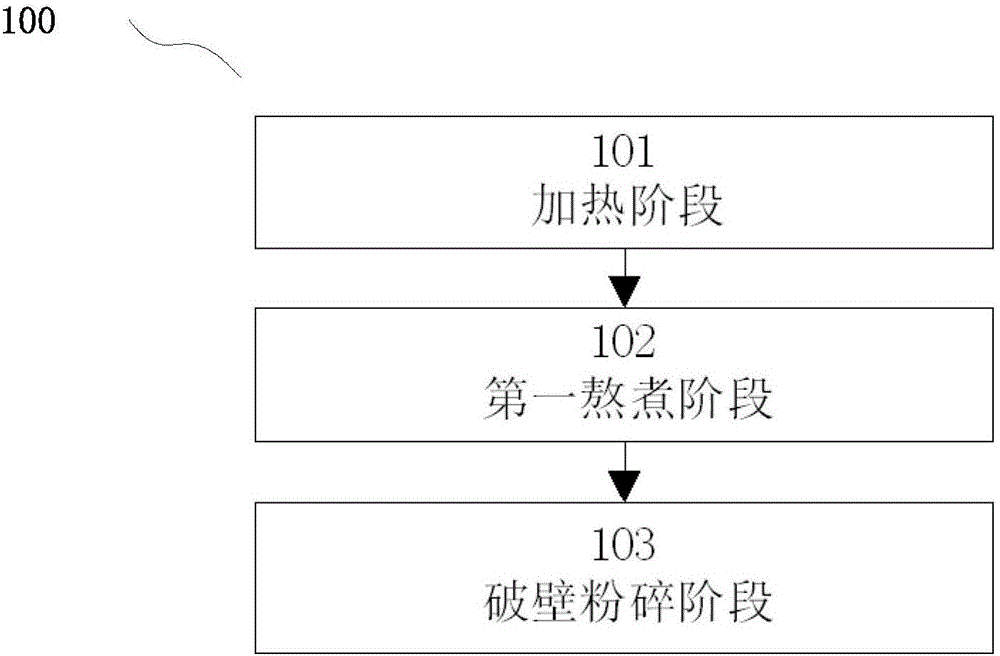

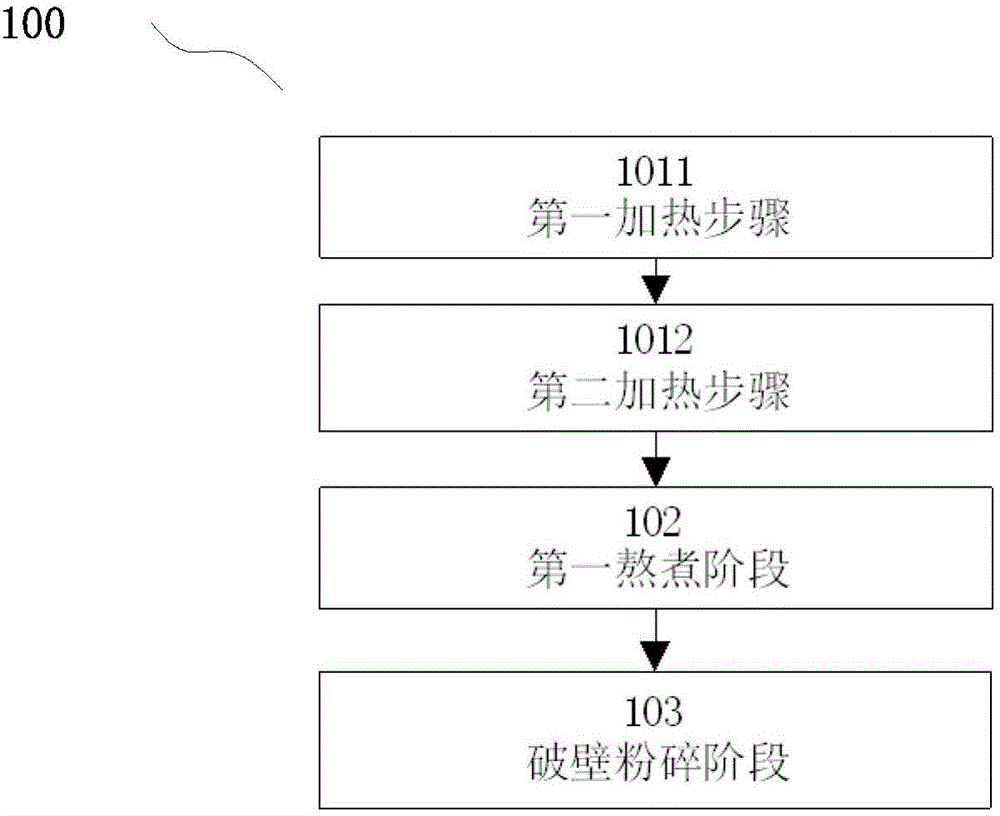

The invention relates to a food processing method of a motor under-set-type food processing machine and the food processing machine, and belongs to the field of food processing. The food processing method at least comprises a heating stage, a first cooking stage and a wall-breaking and grinding stage, wherein in the heating stage, food in a stirring cup is heated to be boiling by virtue of a heating device; in the first cooking stage, the food in the stirring cup is cooked for a duration of t1 by virtue of the heating device until the food is completely cooked, and during cooking, a grinding cutter is driven to do intermittent rotation at a first rotating speed by virtue of a motor; and in the wall-breaking and grinding stage, the grinding cutter is driven to rotate at a second rotating speed by virtue of the motor so as to grind the cooked food in the stirring cup, and the second rotating speed, which ranges from 20000r / min to 40000r / min, is greater than the first rotating speed, wherein the power of the heating device in the first cooking stage is less than that in the heating stage. The food processing machine using the food processing method provided by the invention can uniformly heat the food, and the phenomenon of over-burnt bottom and spillover cannot occur easily.

Owner:JOYOUNG CO LTD

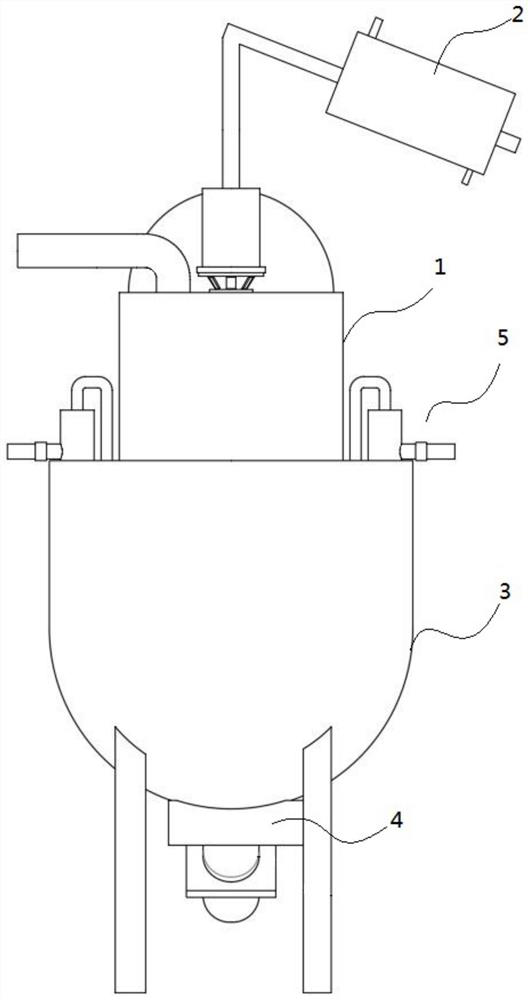

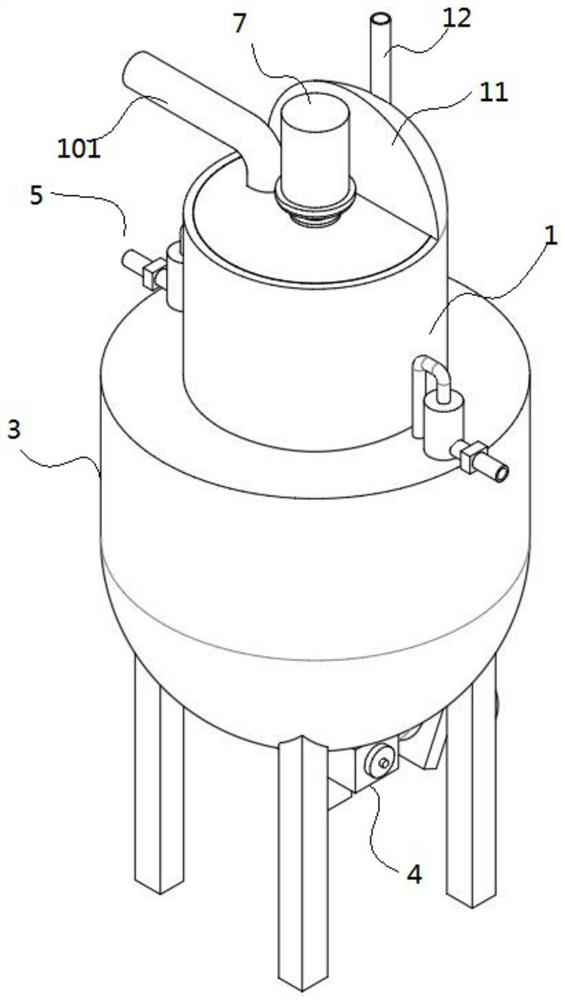

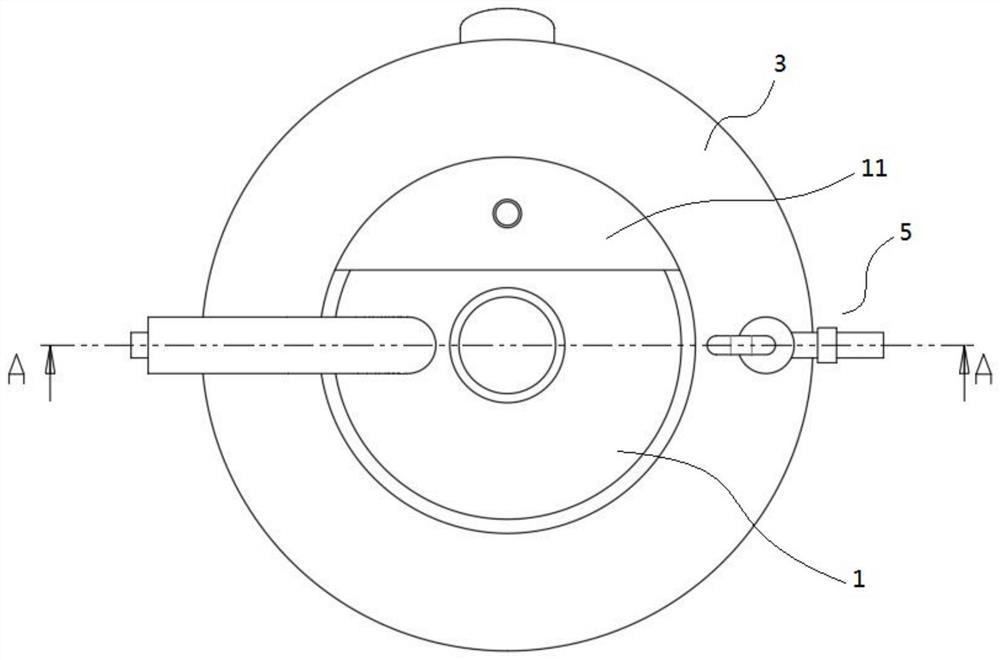

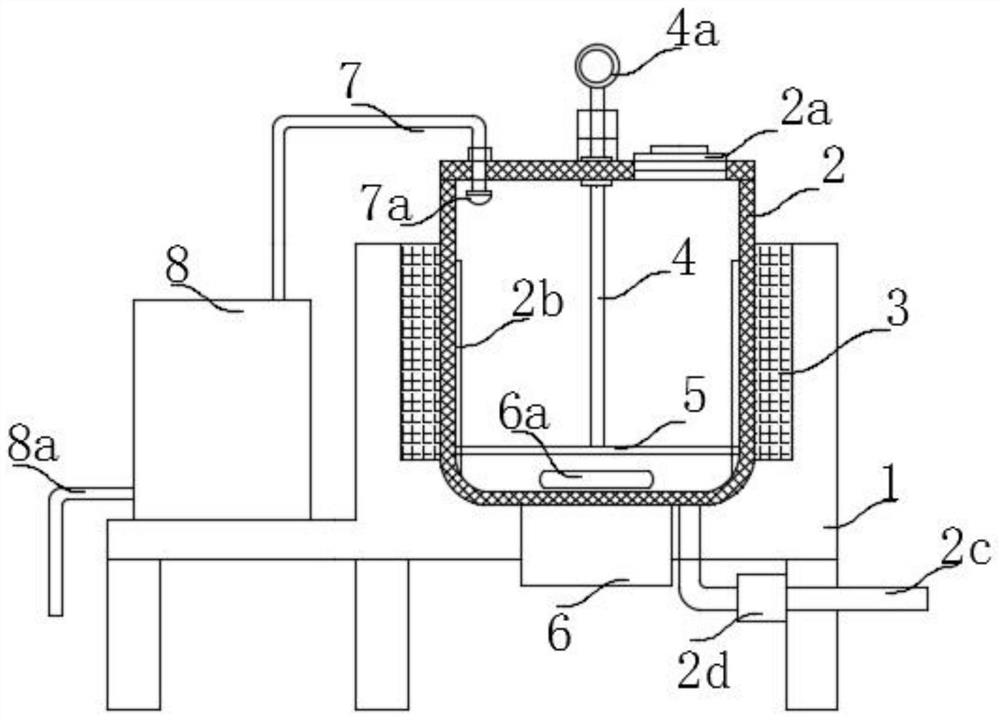

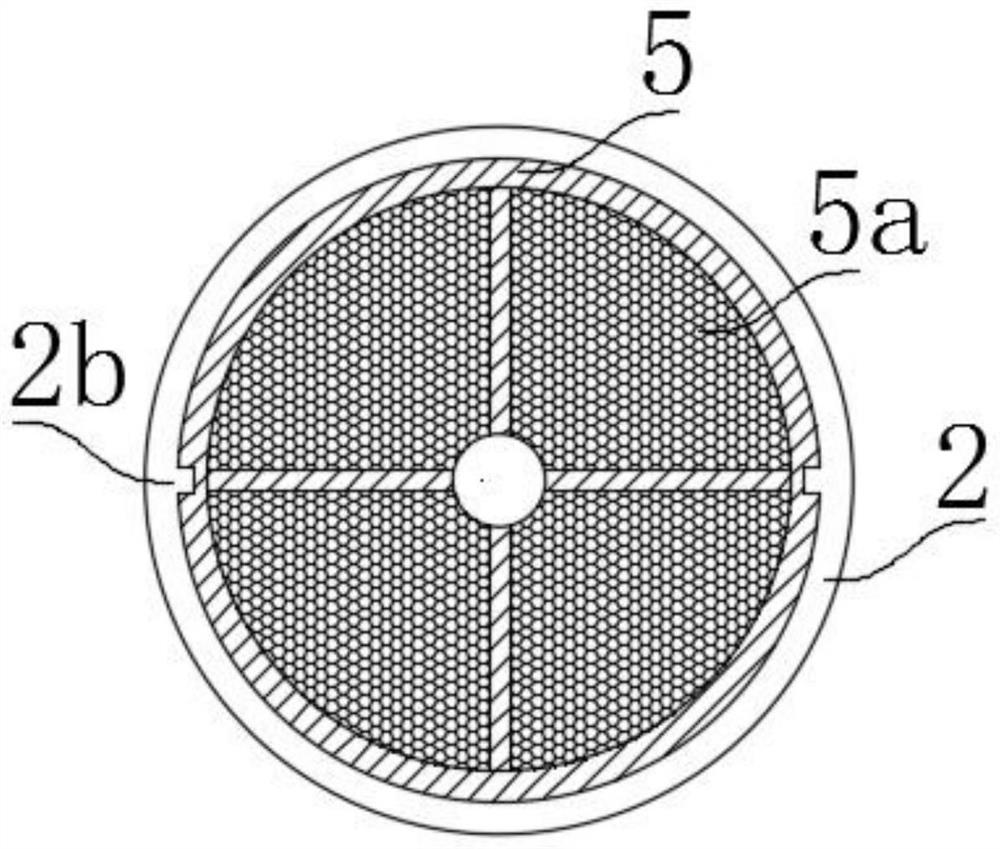

Anti-sticky bottom soybean milk machine and its cooking method

ActiveCN102273516AAvoid sticky bottomGreat tasteBeverage vesselsMilk substitutesProcess engineeringSlurry

The invention discloses a cooking method for a soymilk machine with an anti-sticky bottom. The soymilk machine comprises a water tank, a pulverizing container, a water adding pipeline, a slurry discharging pipeline, a cooking cup, a crushing device located in the pulverizing container, and a device for controlling the flow of the pulp discharging pipeline. The first control switch for disconnecting and the second control switch for controlling the on-off of the water supply pipeline include the following steps: open the second control switch, when the water in the water tank enters the crushing container through the water supply pipeline, the first control switch is simultaneously opened, and the After adding a certain amount of water to the pulp cup, turn off the first control switch, and the pulp cooking cup starts to preheat; after adding a preset amount of water to the crushing container, turn off the second control switch, start the crushing device, and place it in the crushing container After the crushing is completed, the first control switch is controlled to be turned on, and the slurry is discharged to the pulp cooking cup through the pulp discharge pipe. After discharge, the first control switch is turned off, and the pulp is boiled, and the pulping is completed. The invention can effectively prevent the paste bottom of the cooking pulp cup.

Owner:MIDEA GRP CO LTD

Food processing method of food processor and food processor

InactiveCN108652478ALower oxygen levelsReduce churnVessels with intergral heatingVacuum pumpingStopped work

The invention discloses a food processing method of a food processor and the food processor, and relates to the field of food processing. The food processor comprises a machine base provided with a motor and a circuit board, a vacuum pump, a mixing cup, a grinding cutter, a pressure relief module used for pressure relief of the mixing cup and a sealing module used for sealing the mixing cup. The circuit board is provided with a control circuit. The food processing method at least comprises the steps that a intermittent vacuum extraction step is performed, specifically, the sealing module sealsthe mixing cup, then the vacuum pump works to extract air in the mixing cup to enable the mixing cup to be in a negative pressure state and then the vacuum pump stops working, then the pressure relief module performs pressure relief on the mixing cup, and the intermittent vacuum pumping step is executed repeatedly; and a crushing step is performed, specifically, the motor drives the grinding cutter to rotate to crush materials in the mixing cup. According to the food processing method, no burnt bottom and less foam are achieved, and the noise is low.

Owner:JOYOUNG CO LTD

Novel food processer

Owner:广东昌盛电器有限公司

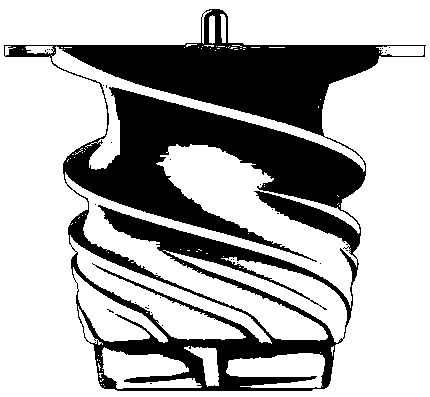

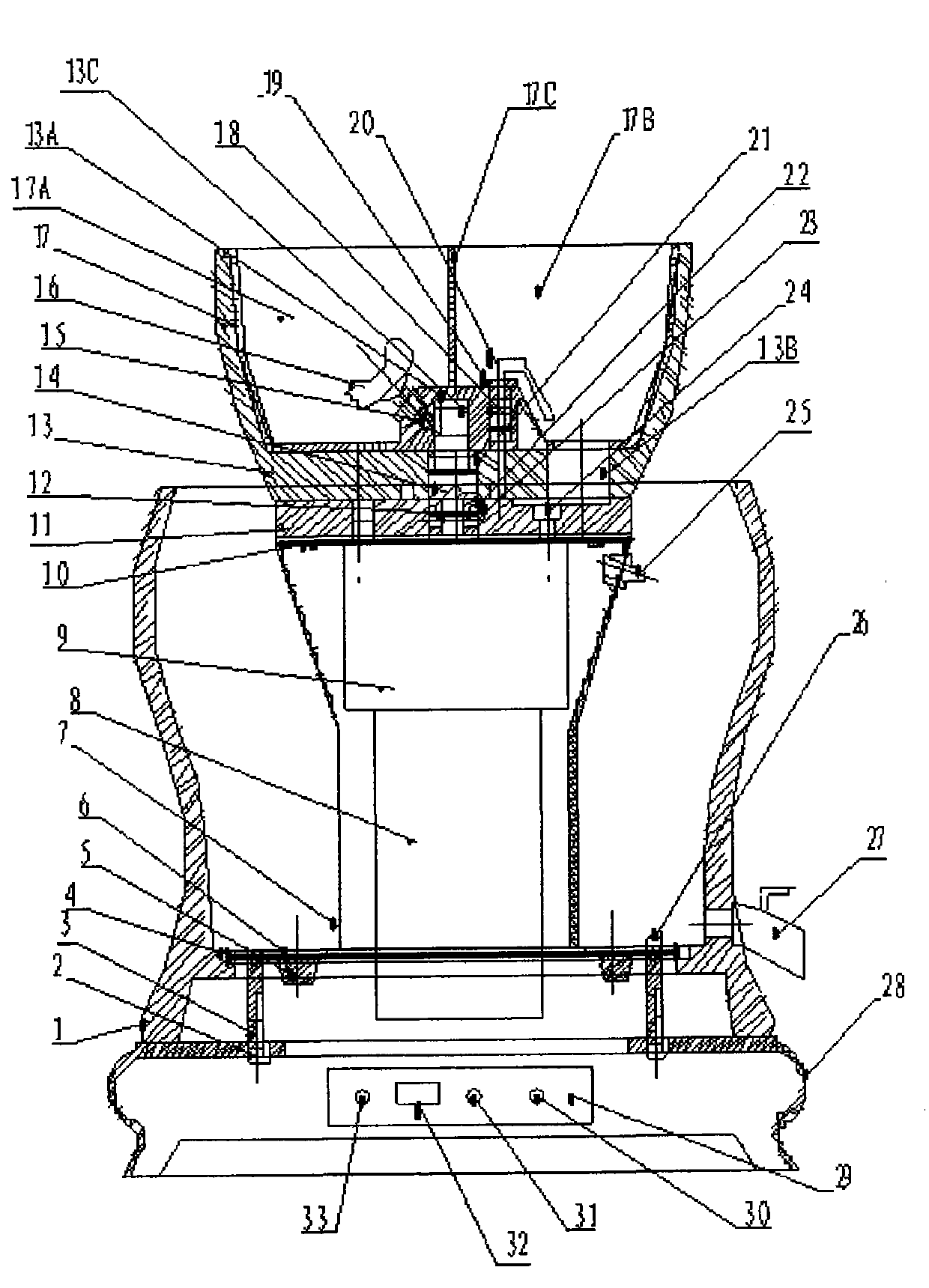

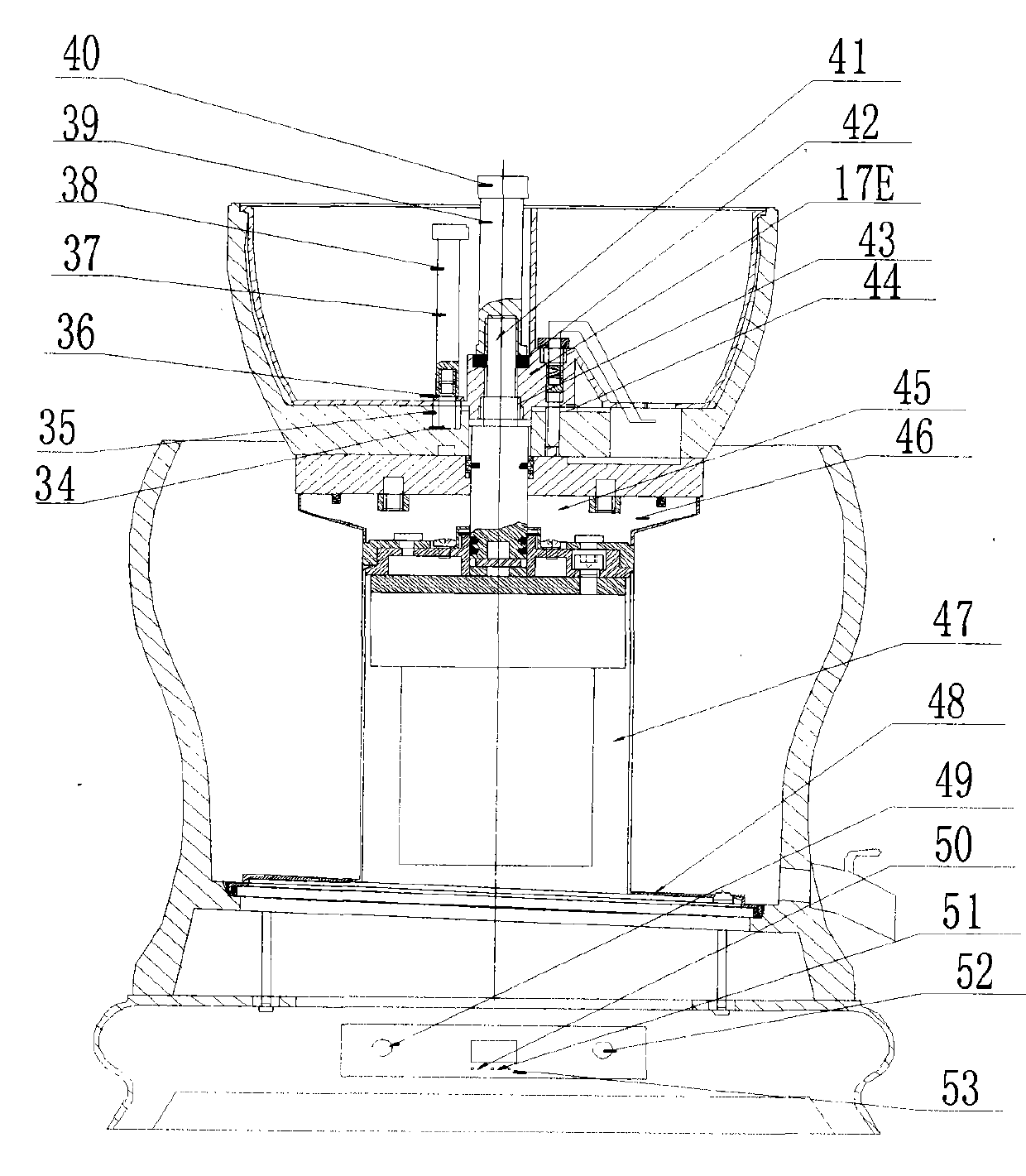

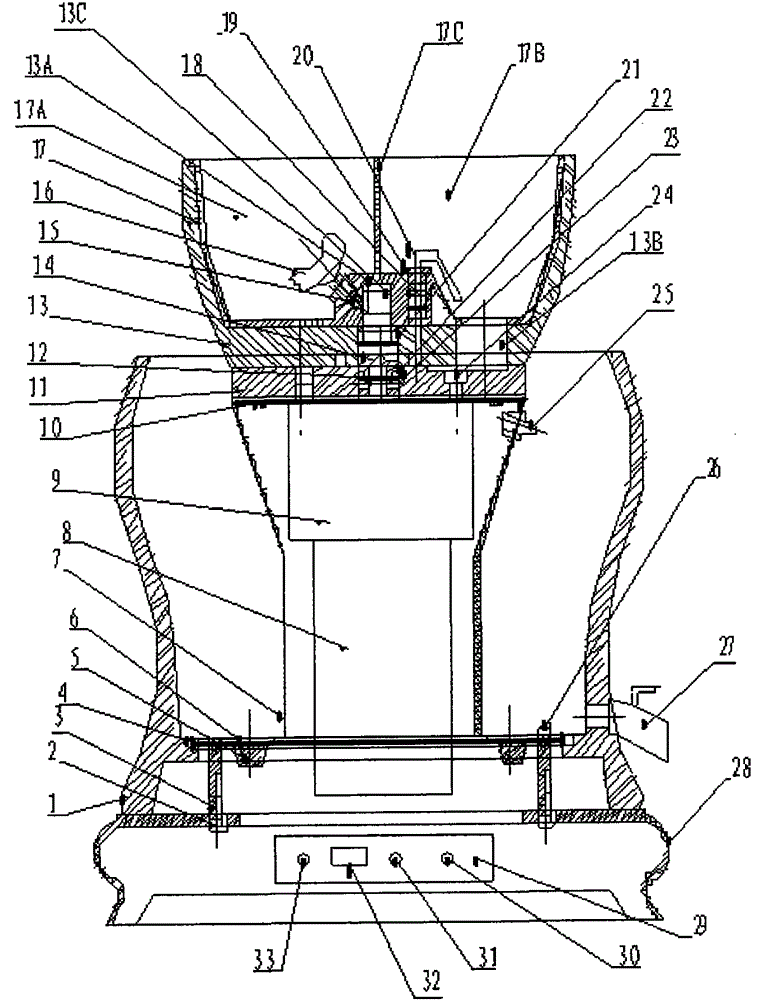

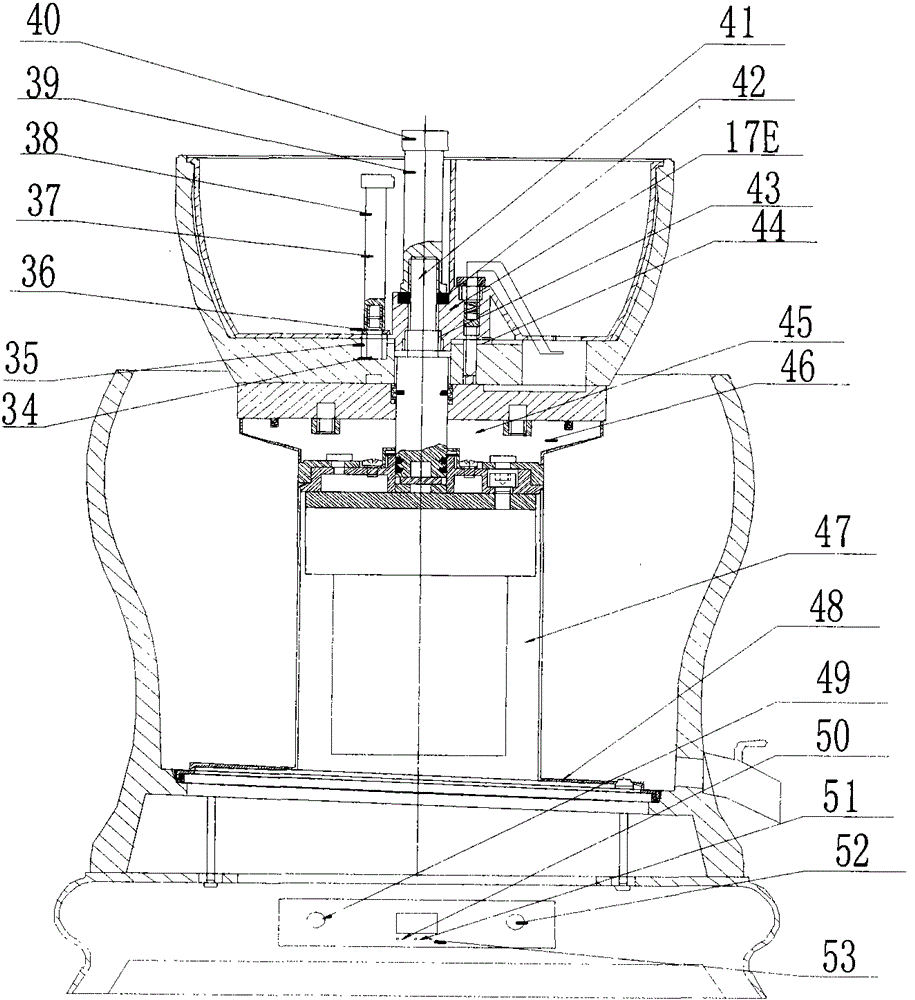

Improved automatic slurry grinding machine

The present invention relates to an improved automatic slurry grinding machine, and belongs to food machinery. The improved automatic slurry grinding machine comprises a slurry storage tank 1, a lower grinding disc pillar 7, an upper grinding disc 13, a base 28 and the like, wherein the fastener coupling device 45 comprises an upper fastener 46 and a lower fastener 47, the lower fastener 47 comprises a lower fastener bracket 64, a lower fastener sleeve 65, a fastener nail 66, a sealing cover 68, a sealing ring 69, a reduction gearbox 9 and a motor 8, the water outlet gate device 38 comprises a water outlet gate screw 34, a water outlet gate hole 35, a water outlet gate rubber ring 36, an adjustment nut 37 and a water tank 44, the locking device 39 of the upper grinding disc 13 comprises a locking bolt 40, a central long shaft 41, a flat pad rubber ring 42 and an upper grinding disc inner hexagonal hole 43, and the stirring rod device 73 comprises a stirring rod horizontal handle 74 and a stirring rod long handle 75. According to the present invention, the upper grinding disc can be removed, such that human hands can directly insert into the slurry storage tank so as to clean; no slurry is remained on the bottom of the slurry storage tank; and the slurry is ensured, bottom pasting does not appear, and the beverage quality can be improved.

Owner:文树雄 +3

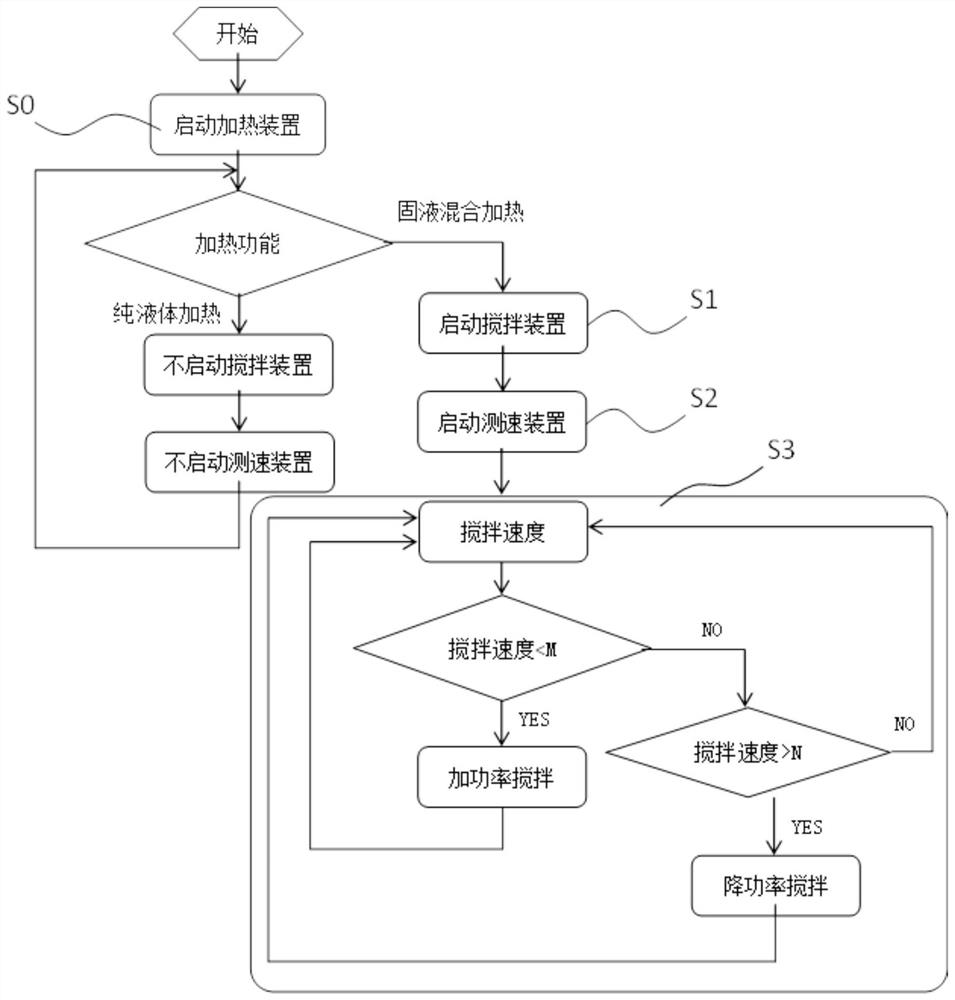

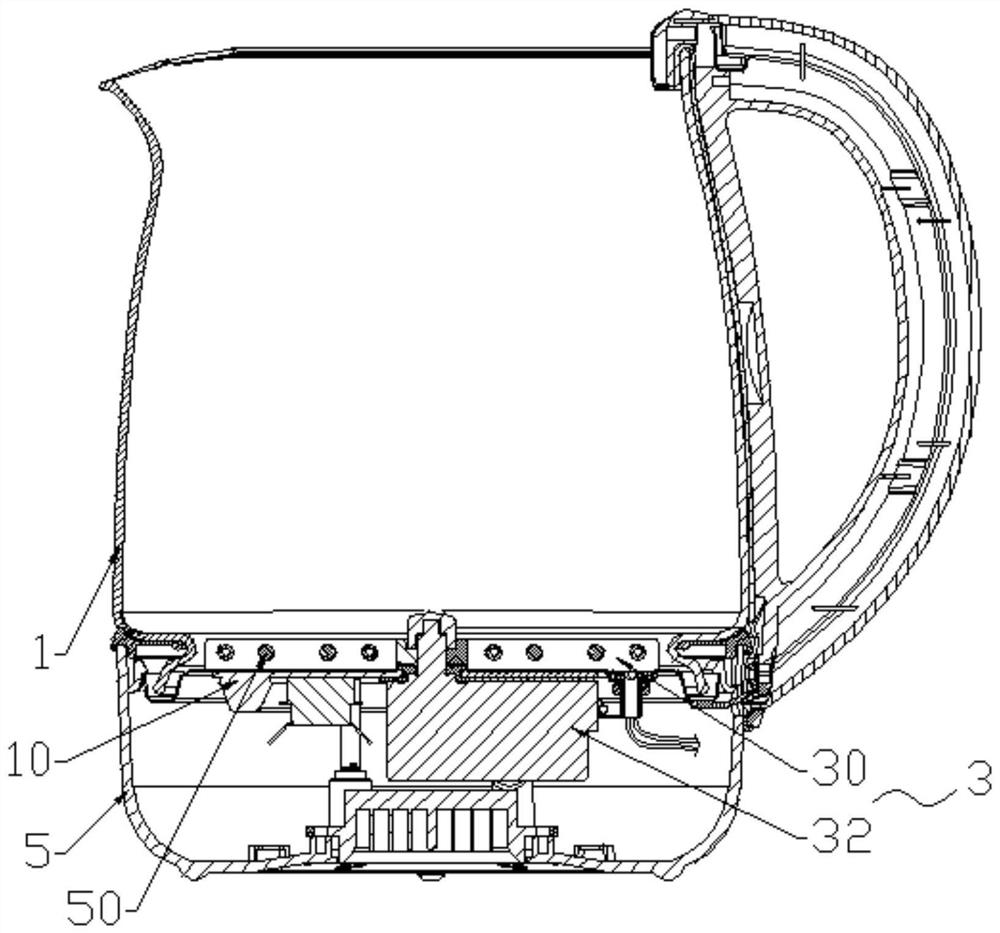

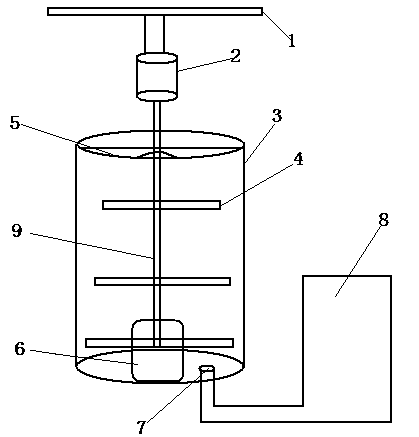

Electric kettle bottom-burning preventing method and electric kettle

The application provides an electric kettle bottom-burning preventing method and an electric kettle. The method includes: step S1, starting a mixing device to mix a food material in the electric kettle according to an initial mixing power; step S2, starting a speed detecting device to detect the mixing speed of the mixing device; and step S3, adjusting the mixing power of the mixing device by a control chip arranged in the electric kettle according to the mixing speed. The electric kettle bottom-burning preventing method can indirectly reflect the viscosity of the food material by detecting the mixing speed, and adjust the mixing power of the mixing device to prevent the electric kettle bottom from burning.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

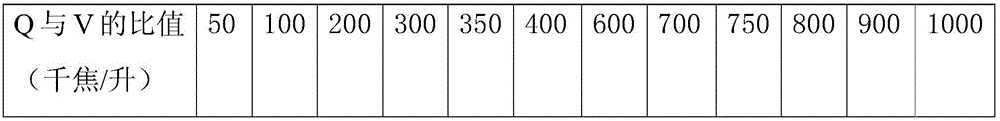

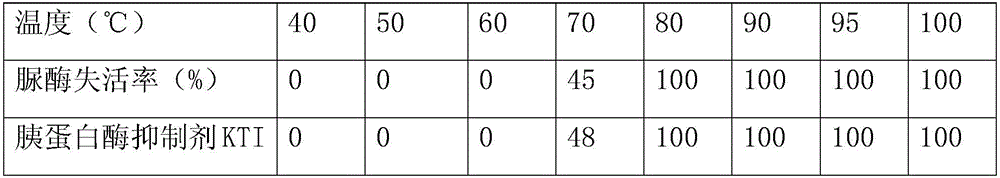

Method for preparing safe and nutritional soybean milk

ActiveCN105935084AImprove inactivation efficiencyFacilitate conductionMilk substitutesFood scienceStopped workRadiation-Total

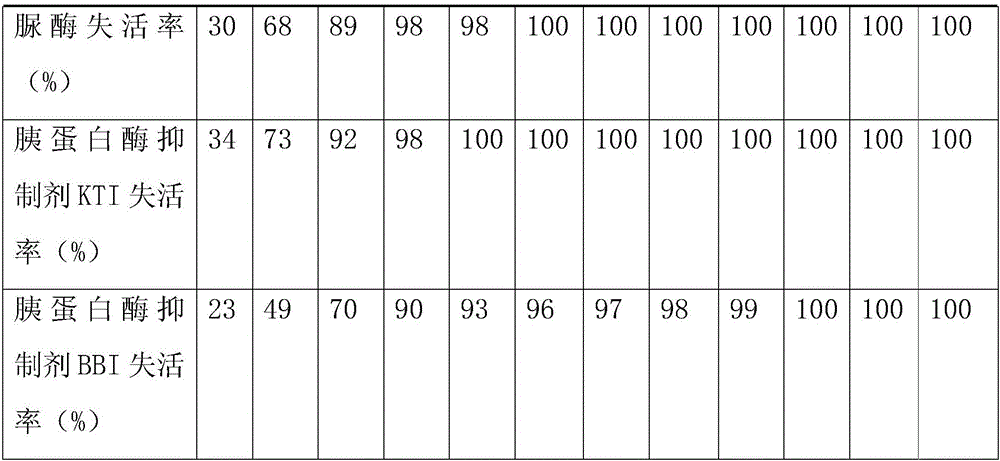

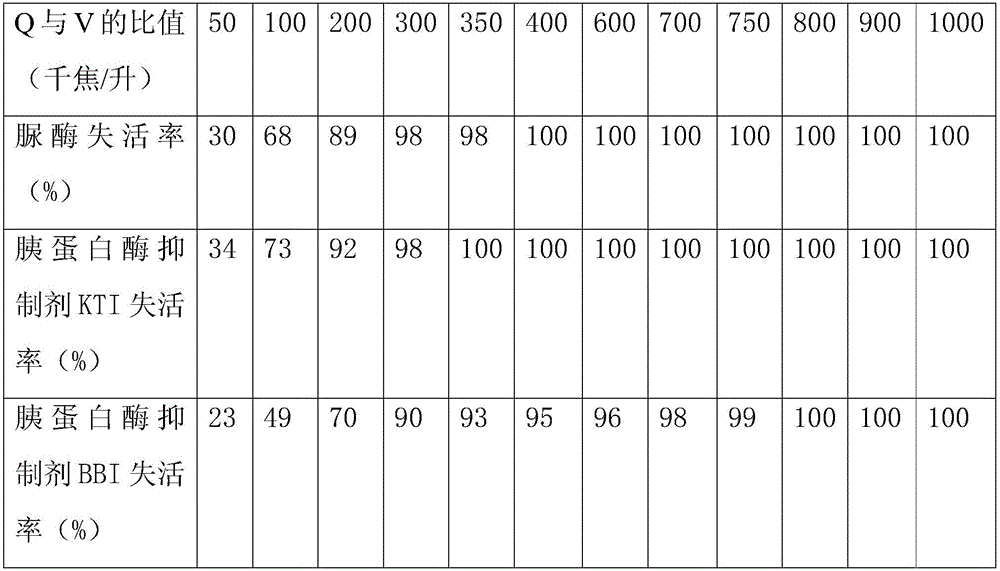

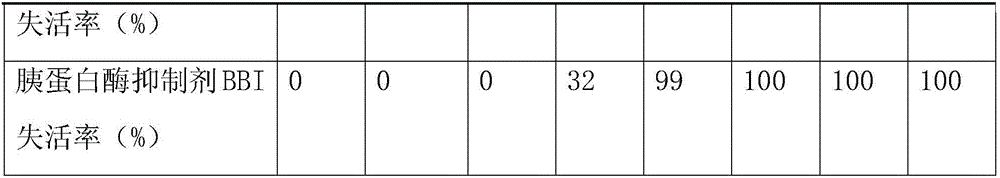

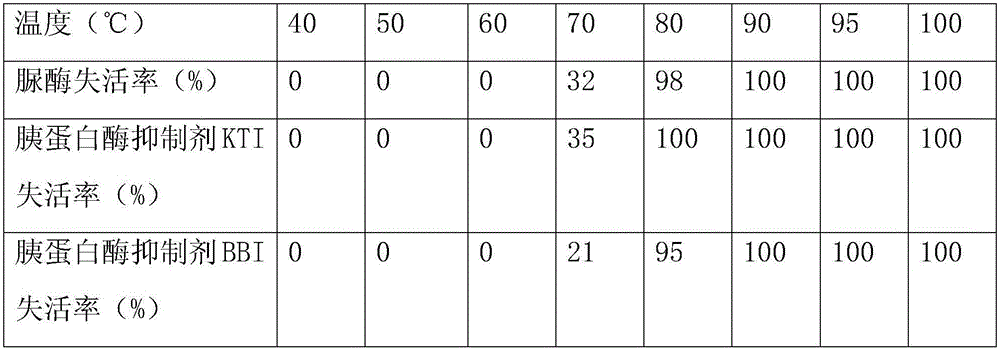

The invention relates to a method for preparing safe and nutritional soybean milk; a motor, a crushing cutter, a heating device and a cup body are provided; the method at least includes the following several stages: (1) a crushing stage including a step of adopting the motor to drive the crushing cutter to rotatingly crush a material and a step of allowing the motor to stop working; and (2) a heating stage including a step of adopting the heating device to heat a liquid in the cup body and a step of allowing the heating device to stop heating. In the method for preparing the safe and nutritional soybean milk, the radiation total heat of the heating device is Q, the soybean milk preparing total amount is V, and the ratio of Q to V is 300-800 kJ / L. Therefore, urease and trypsin inhibitors in the soybean milk can be fully inactivated, and thus the soybean milk is allowed to be more nutritional and safer.

Owner:JOYOUNG CO LTD +1

Pulping method of food processor

Owner:JOYOUNG CO LTD

Overheating protecting method of food processing machine

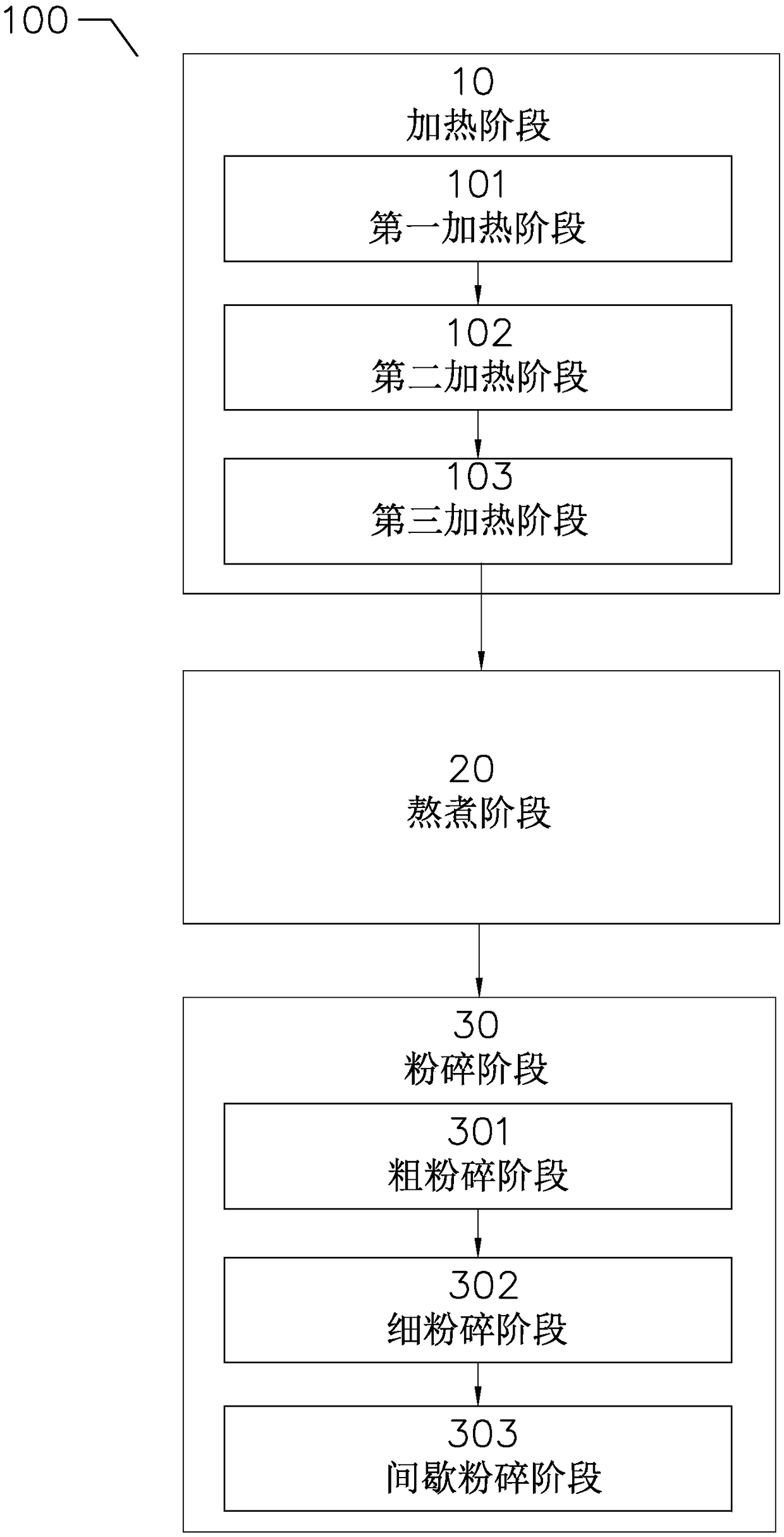

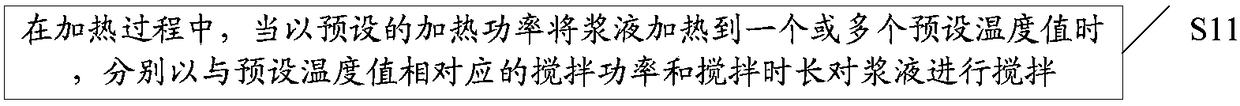

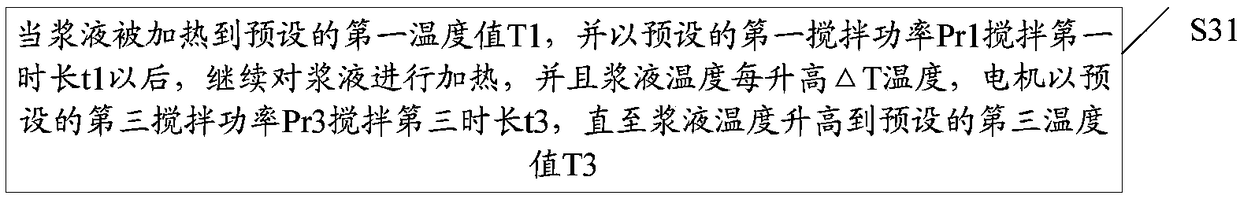

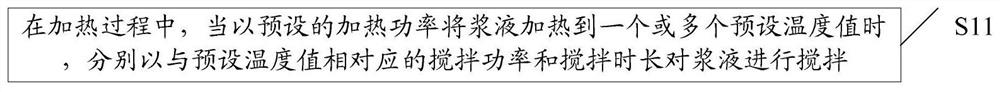

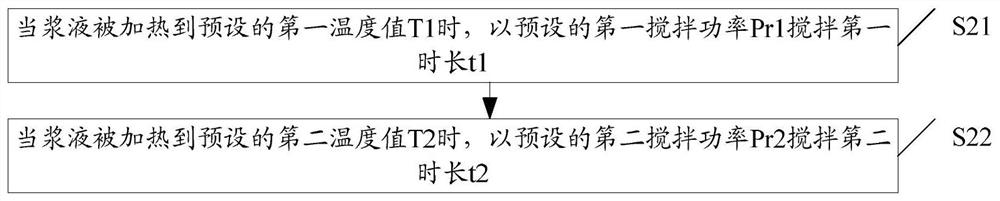

According to the embodiment, the invention discloses an overheating protecting method of a food processing machine. The food processing machine comprises a crushing cup and a motor, wherein a heatingdevice is arranged on the crushing cup; and thermal fuse link protectors, which are serially connected to the heating device, are each arranged at two ends of the heating device. The method comprisesthe following steps: in a heating process, when pulp is heated to one or more preset temperature values by preset heating power, stirring the pulp by stirring power and stirring duration correspondingto the preset temperature values. According to the embodiment, production cost is lowered and potential risks are reduced, and error operations of the thermal fuse link protectors in overheating protection are reduced.

Owner:JOYOUNG CO LTD

Fermenting process of potato wine

The invention discloses a fermenting process of potato wine. The fermenting process includes the steps of 1, steaming or boiling potatoes, mashing the potatoes, cooling the mashed potatoes to normal temperature, adding distiller's yeast, performing uniform mixing before containerizing without sealing, and allowing microorganisms in air to participate in fermenting; 2, adding water after 48 hours, 0.6 jin of water per jin of raw material, sealing an opening of a container, and allowing fermenting for 21 days before steaming. The fermenting process has the advantages that the process with aerobic fermentation prior to anaerobic fermentation is for the potatoes, original liquor produced from steaming is thicker and refreshing in taste and is more complete in nutritional value than completely anaerobic fermentation.

Owner:GUANGXI YOUQINGMIYI AGRI PROD CO LTD

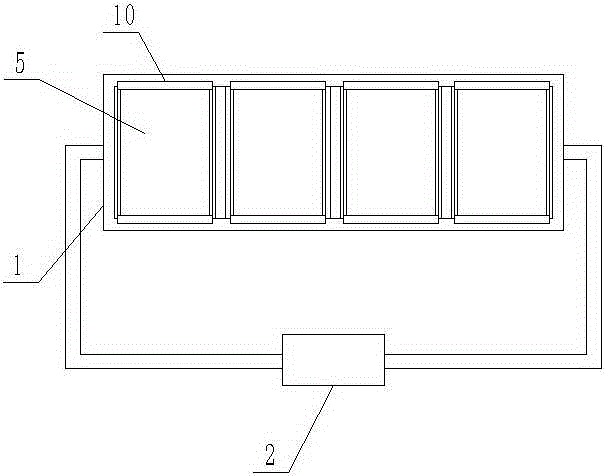

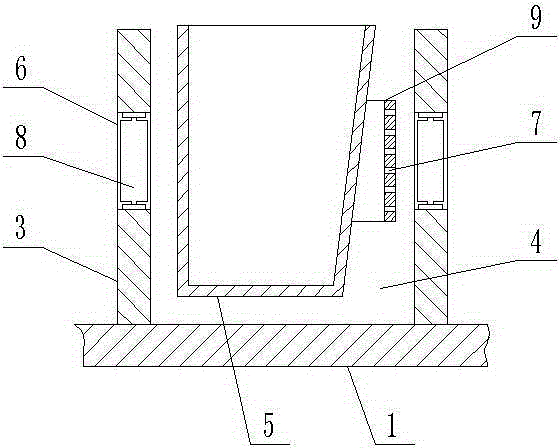

Take-out type heating thermal-insulation dining table

The invention discloses a take-out type heating thermal-insulation dining table. The dining table comprises a dining table body and a circulating water pump. A strip-shaped groove is formed in the upper surface of the dining table body in a concaved mode, multiple vertical partitioning plates are arranged at intervals inside the strip-shaped groove in the length direction and divide the strip-shaped groove into multiple partitioning cavities, a blue plate used for containing dishes is placed inside each partitioning cavity, gaps are formed between the walls of the blue plates and the side walls of the partitioning cavities, connecting holes communicated with the adjacent partitioning cavities are formed in the partitioning plates, and a water inlet hole and a water outlet hole are formed in the groove walls of the two ends, in the length direction, of the strip-shaped groove respectively. A water inlet of the circulating water pump is communicated with the water outlet, and a water outlet of the circulating water pump is communicated with the water inlet. Heating bodies used for heating circulating water are fixedly connected inside the connecting holes and the water inlet hole. Through the circulating water, the blue plates are heated, and the dining table is simple in structure and convenient to use, heats meals inside the blue plates more evenly, preserves heat of the meals and keeps the delicacy of the foods.

Owner:CHONGQING DIANGUOCHENG IND CO LTD

Method for preparing safe and nutritional soybean milk

PendingCN105935083AImprove inactivation efficiencyImprove thermal stabilityMilk substitutesFood scienceStopped workTrypsin inhibitor

The invention relates to a method for preparing safe and nutritional soybean milk; a motor, a crushing cutter, a heating device and a cup body are provided; the method at least includes a crushing stage and a heating stage; the crushing stage includes a step of adopting the motor to drive the crushing cutter to rotatingly crush a material and a step of allowing the motor to stop working; the heating stage includes a step of adopting the heating device to heat a liquid in the cup body and a step of allowing the heating device to stop heating, wherein after the temperature of the liquid in the cup body is 80 DEG C or more, the total time for heating the liquid in the cup body by the heating device is 4 to 15 minutes. Therefore, urease and trypsin inhibitors in the soybean milk can be fully inactivated, and thus the soybean milk is allowed to be more nutritional and safer.

Owner:JOYOUNG CO LTD

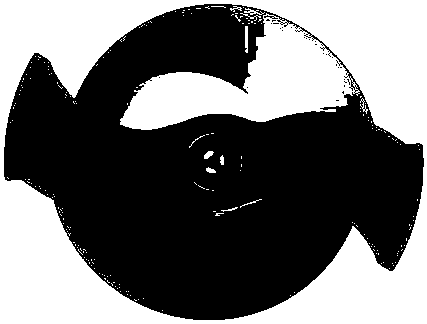

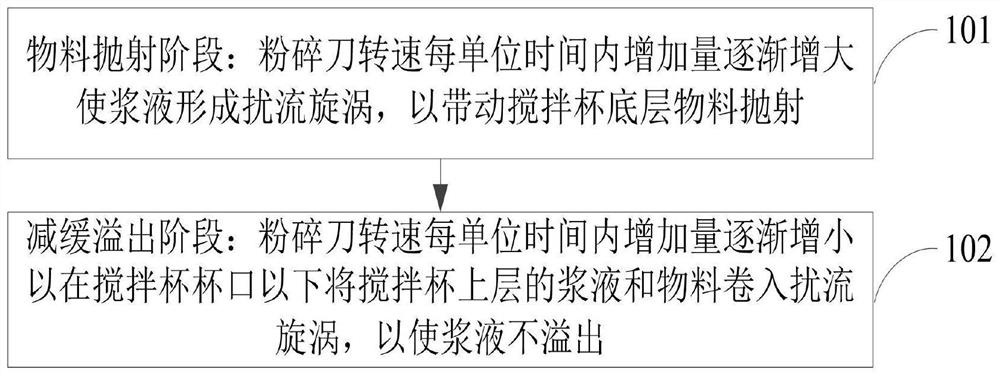

Processing method of food processor and food processor

ActiveCN113520183AAvoid stickingAvoid getting stuck in the seam of the bottom of the cup and avoid sticking the bottomKitchen equipmentElectric machineryProcess engineering

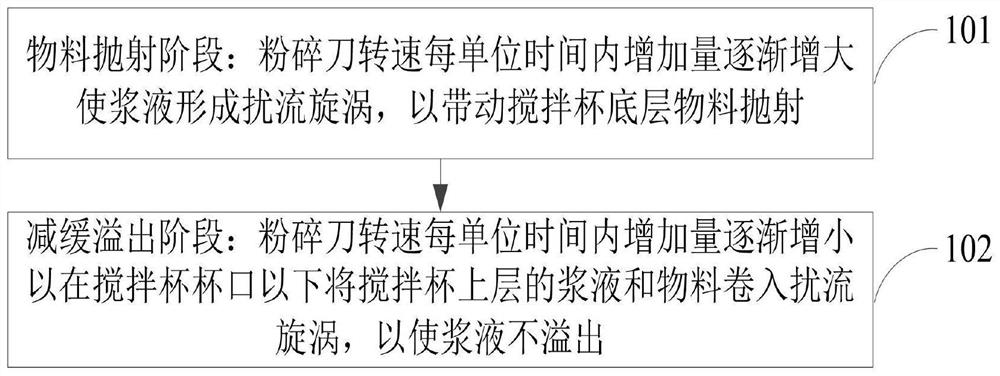

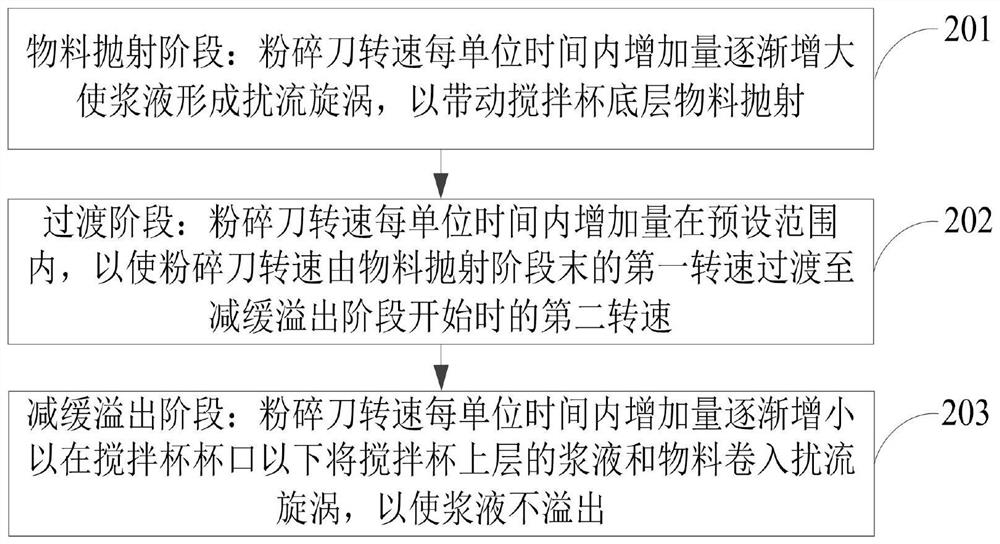

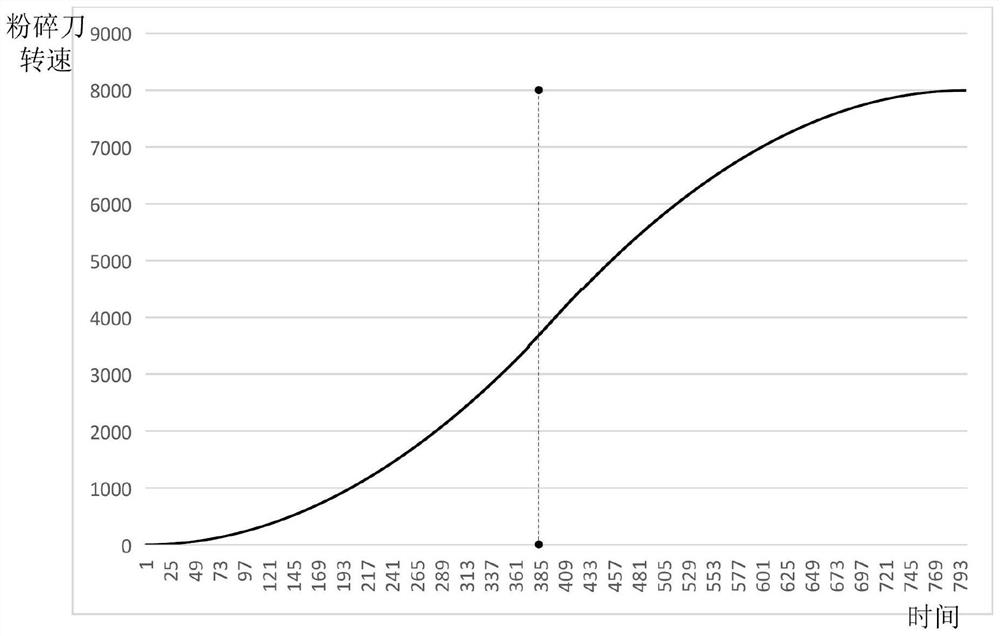

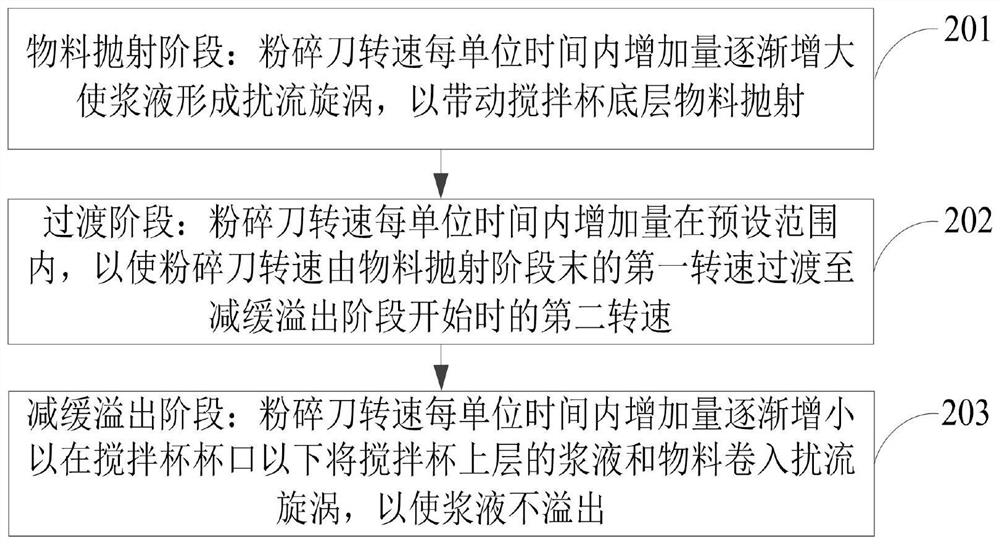

The invention provides a processing method of a food processor and the food processor. The food processor comprises a machine body, a processor, a stirring cup, a motor and a crushing cutter driven by the motor. The processing method comprises the steps of a material throwing stage in which the increment of the rotating speed of the crushing cutter per unit time is gradually increased to enable slurry to form a turbulent flow vortex, thereby driving materials at the bottom layer of the stirring cup to cast; and an overflow slowing stage in which the increment of the rotating speed of the crushing cutter in each unit time is gradually reduced so as to enable the slurry and the materials on the upper layer of the stirring cup to be involved into the turbulent flow vortex below the cup opening of the stirring cup, thereby avoiding overflow of the slurry. In the pulping process of the food processor, the food processor is beneficial to quickly forming turbulent flow vortexes of pulp and driving materials on the bottom layer of the stirring cup to be thrown, the thrown materials can be drawn into the turbulent flow vortexes, and the risk that the pulp overflows due to the fact that the rotating speed fluctuation is too large when the wall breaking machine is in a high rotating speed state is avoided.

Owner:JOYOUNG CO LTD

Extraction and production technology method of Xinhui dried tangerine peel paste

InactiveCN111298012AGreat tasteFull of nutritionOrganic active ingredientsDigestive systemLilium browniiSugar

The invention discloses an extraction and production technology method of a Xinhui dried tangerine peel paste. The extraction and production technology method of the Xinhui dried tangerine peel pastecomprises the following raw materials in parts by weight: a Xinhui dried tangerine peel extract, pomelo peel, honey, brown sugar, red dates, fructus lycii, black tea, lilium brownii, lotus seeds, pyrus ussuriensis, chrysanthemum lavandulifolium, rock candy, hawthorns and radix glycyrrhizae. The production method comprises the following steps: (1) selecting raw materials; (2) producing the Xinhui dried tangerine peel extract; (3) producing sugared pomelo peel; (4) boiling the red dates, the fructus lycii and the black tea together to produce thick juice; (5) after the chrysanthemum lavandulifolium is boiled with water, adding the lilium brownii, the lotus seeds, the pyrus ussuriensis and the rock candy, and boiling the mixture together; (6) grinding the hawthorns; (7) producing radix glycyrrhizae extraction liquid; (8) mixing the materials obtained from the steps (2) to (8), and boiling the mixture to produce a thick paste; and (9) conducting drying to produce the hard blocky Xinhui dried tangerine peel paste. The extraction and production technology method of the Xinhui dried tangerine peel paste has the advantages that dried tangerine peel is individually extracted to produce drygranules, and the dry granules are long in shelf life, not liable to go bad, can be taken whenever needed, and can be directly dissolved in liquid to produce the dried tangerine peel paste. The driedtangerine peel paste produced through the extraction and production technology method of the Xinhui dried tangerine peel paste is rich in nutrient, tastes sour, sweet and delicious, and can have effects of aiding digestion, strengthening the spleen and the stomach, benefiting qi and blood, maintaining beauty and keeping young.

Owner:杨斌

Control method for preventing burnt bottom of cooking utensil and cooking utensil

ActiveCN110448147AImprove liquidityAvoid sticky bottomVessels with intergral heatingTime-controlled ignitorsFood materialProcess engineering

The invention discloses a control method for preventing burnt bottom of a cooking utensil and the cooking utensil. The cooking utensil comprises a pot body, a heating disc for heating food materials in the pot body and a main control panel used for controlling the cooking utensil to work; the heating disc comprises an aluminum disc, an outer heating pipe located on an outer ring of the aluminum disc and an inner heating pipe located in an inner ring of the aluminum disc; and the main control panel comprises a main control chip; and the main control chip communicates with the outer heating pipeand the inner heating pipe and is used for controlling the outer heating pipe and / or the inner heating pipe to perform heating according to the temperature of the bottom of the pot body. According tothe control method for preventing the burnt bottom of the cooking utensil and the cooking utensil, the two heating pipes located at different positions are arranged, so that the flowability of food can be enhanced, and the burnt bottom is avoided.

Owner:JOYOUNG CO LTD

Fish soluble concentration device

ActiveCN113274748AUniform concentration processImprove efflux efficiencyEvaporator accessoriesHollow article cleaningFisheryEngineering

The invention discloses a fish soluble concentration device, which relates to the technical field of fish soluble preparation. The device comprises a reaction tank for concentration and a condenser for steam liquefaction, wherein a liquid storage box body of which the upper end is a plane and in which liquid is used for heat conduction is mounted on the peripheral side surface of the lower half part of the reaction tank; a through hole is formed in the lower end of the liquid storage box; an oil bath electric heater is welded and fixed at the edge of the through hole; steam generators which are symmetrically arranged relative to the axis of the reaction tank are mounted in the liquid storage box body; and the two ends of the steam generator penetrate through the upper side of the liquid storage box. A liquid storage box body and an oil bath electric heater are mounted at the lower part of the reaction tank for heating so as to conduct heat to the whole reaction tank, a steam generator provides steam and hot air to the interior of the lower end of the reaction tank, and the interior and exterior of fish soluble in the reaction tank are simultaneously heated and are matched with a crushing stirring disc, a separating and mixing stirring disc and a scraping disc for stirring and scraping; the concentration process of the fish soluble in the reaction tank is uniform, and the steam condensed and discharged by the external condenser accelerates the discharge efficiency and accelerates the concentration efficiency.

Owner:ZHEJIANG FENGYU MARINE BIOLOGICAL PROD

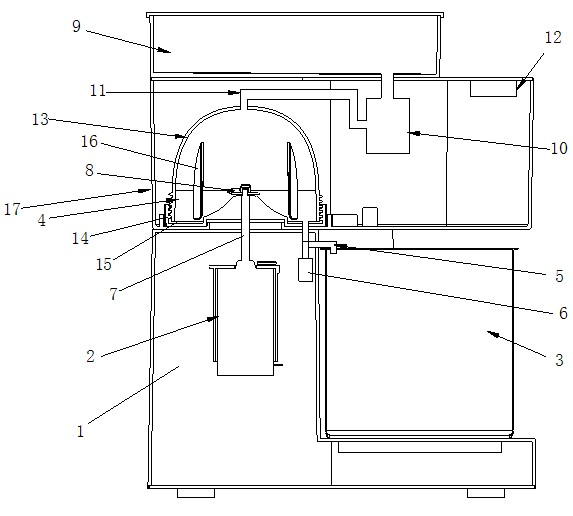

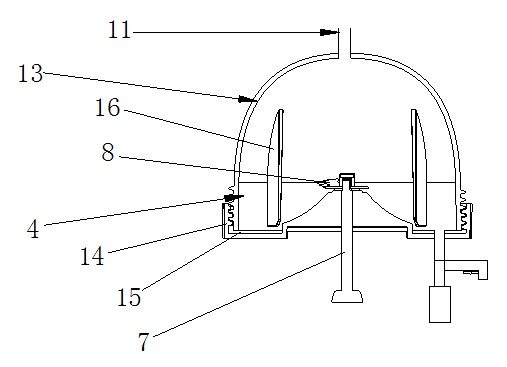

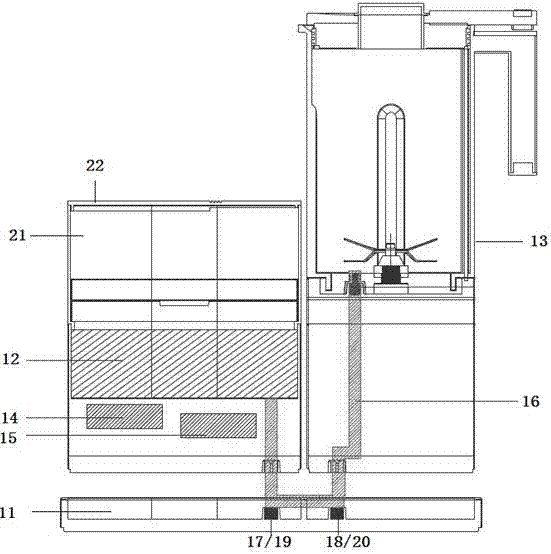

Steam-heated high-speed food processor

The invention discloses a steam-heated high-speed food processor, aiming at solving the technical problem of an existing food processor that food materials, when heated, can adhere to the bottom of the food processor. The food processor comprises a base, a water tank and a stirrer, wherein both the water tank and the stirrer are arranged on the base; a heating module, an air pump and a water tankcontrol module are arranged at the bottom of the water tank; a water passage pipeline is connected to the bottom of the water tank and the bottom of the stirrer; the heating module, under the controlof the water tank control module, is used for heating water in the water tank; and the air pump is used for pumping a water-vapor mixed body, which is heated until steam appears, into the water passage pipeline, so that the water-vapor mixed body enters the stirrer from the bottom of the stirrer. When the stirrer needs to be injected with water for heating food materials, steam and water, which are heated in the water tank, pass through the water passage pipeline and are injected from the bottom of the stirrer by virtue of the water pump, so that the food materials, when heated, are turned from bottom, and the food materials are prevented from adhering to the bottom of the food processor in a heating process; and a steaming box is arranged at the upper side of the water tank, and the foodmaterials in the steam box are heated by virtue of the steam in a stirring process, so that an effect of simultaneously implementing stirring and steaming is achieved.

Owner:青岛卡萨帝智慧生活家电有限公司

Porridge cooking method

ActiveCN112773207AAvoid sticky bottomCooking insertsTime-controlled ignitorsTemperature controlControl cell

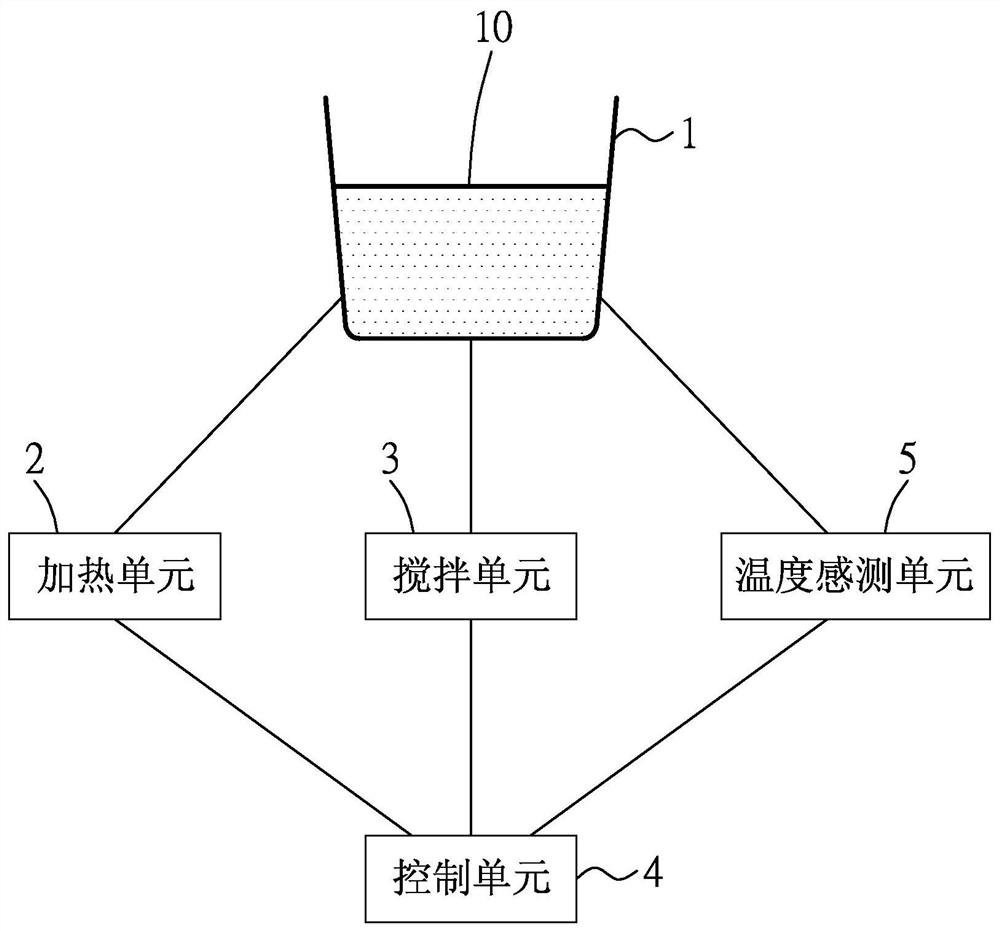

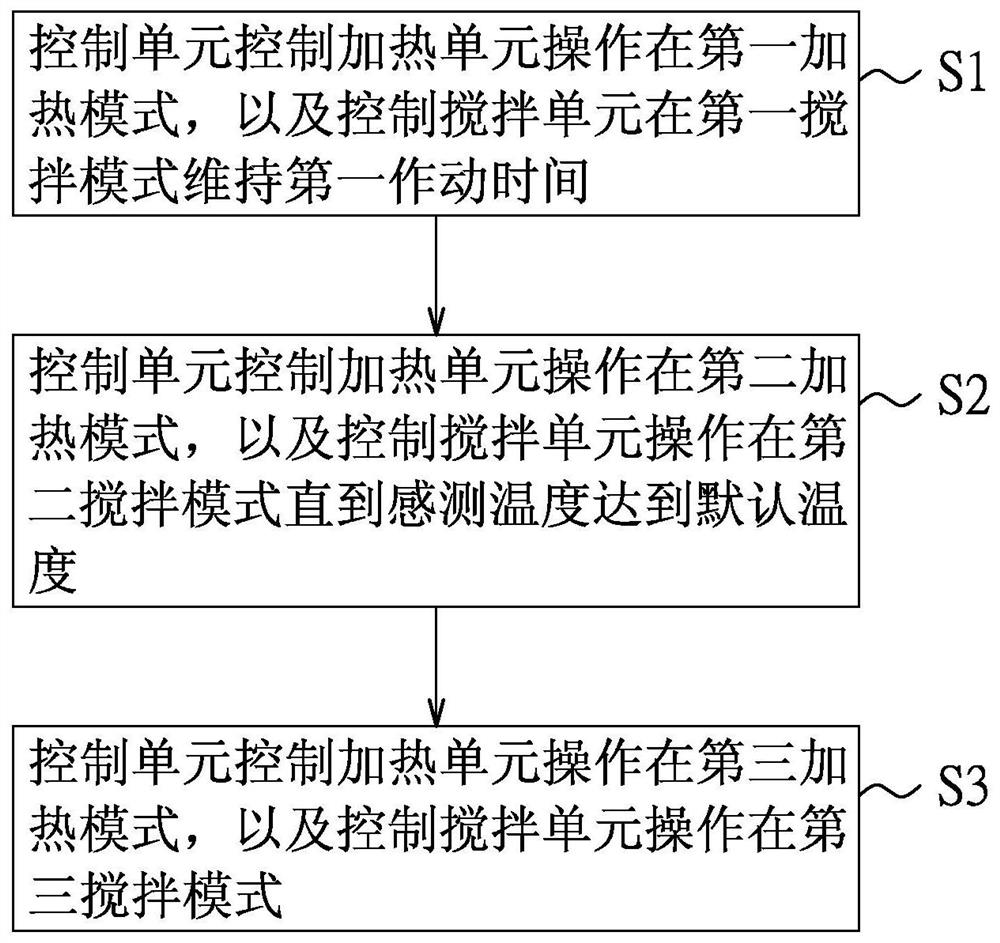

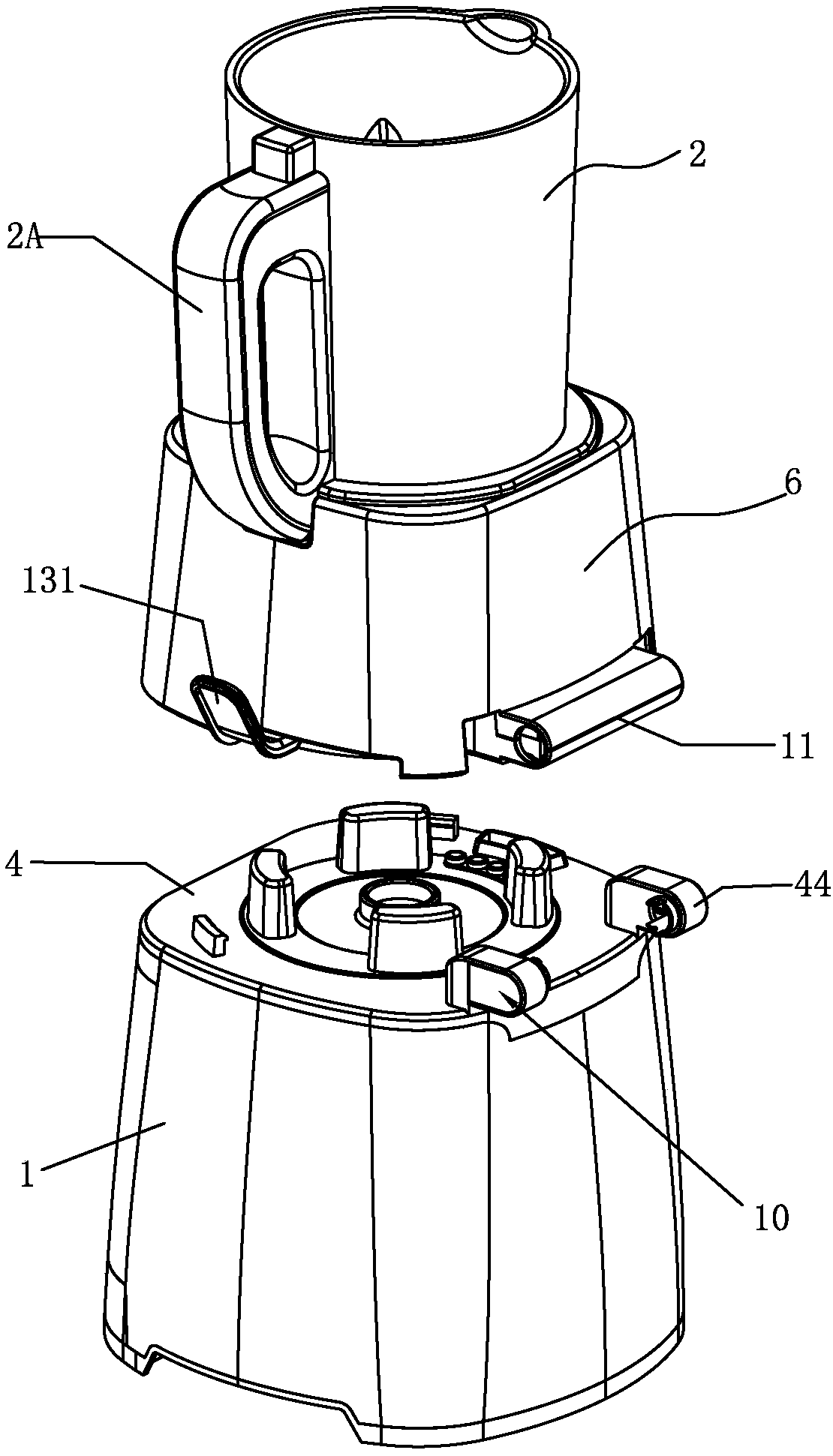

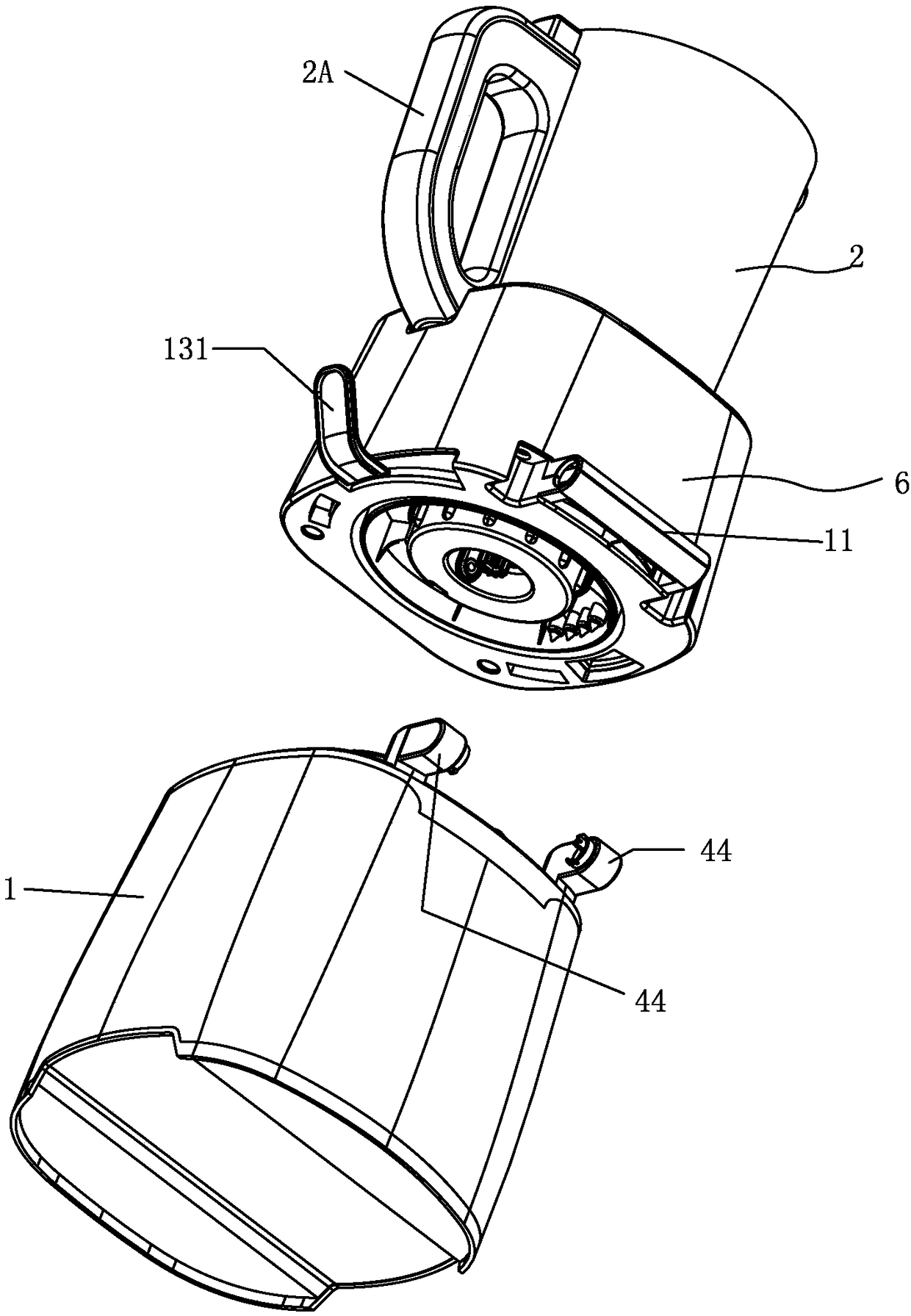

The invention relates to a porridge cooking method, which is executed by a cooking device comprising a container for accommodating to-be-cooked objects, a heating unit, a stirring unit and a control unit. The porridge cooking method comprises the following steps: the control unit controls the heating unit to operate in a first heating mode, and controls the stirring unit to maintain a first actuation time in a first stirring mode. The control unit controls the heating unit to be operated in the second heating mode from the first heating mode, and controls the stirring unit to be operated in the second stirring mode from the first stirring mode until the temperature of the to-be-cooked object reaches the default temperature. The control unit controls the heating unit to be operated in the third heating mode from the second heating mode and controls the stirring unit to be operated in the third stirring mode from the second stirring mode. Due to the fact that the second stirring speed is larger than the first stirring speed and the third stirring speed, large-particle food materials in the to-be-cooked objects can be cut up, the stirring unit continuously conducts stirring action in the stirring mode, and bottom pasting can be effectively prevented.

Owner:MATSUSHITA ELECTRIC (TAIWAN) CO LTD

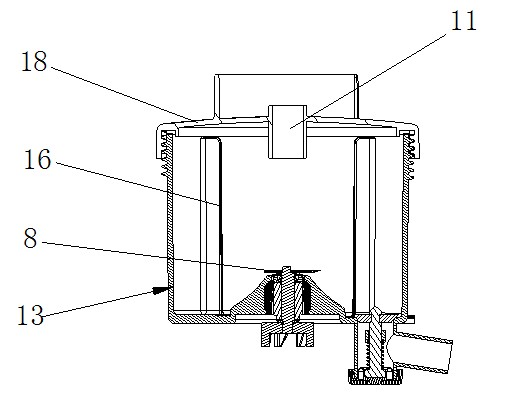

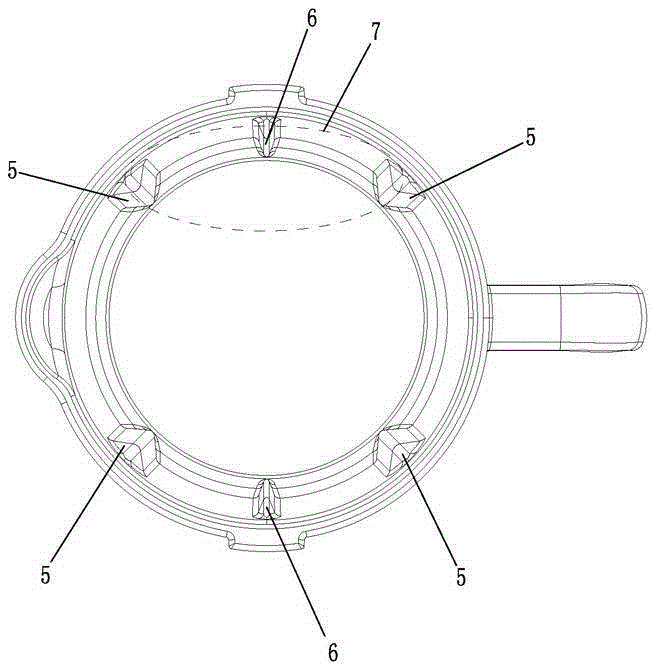

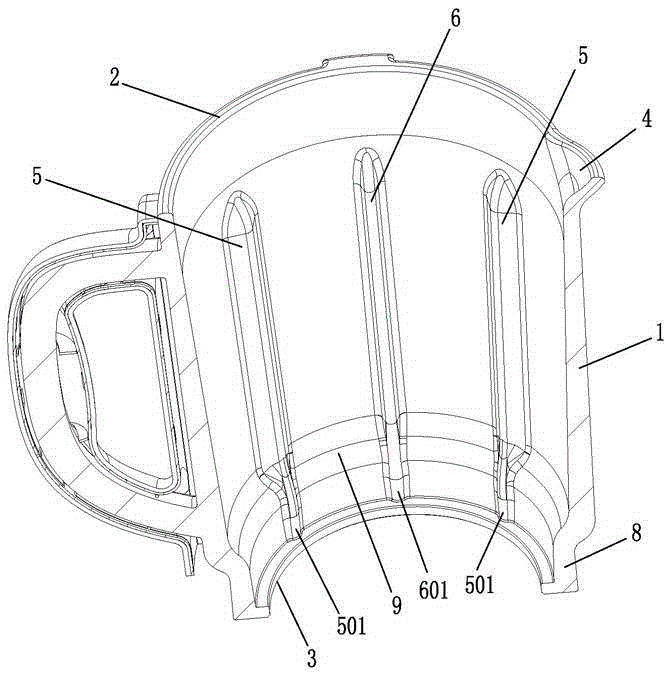

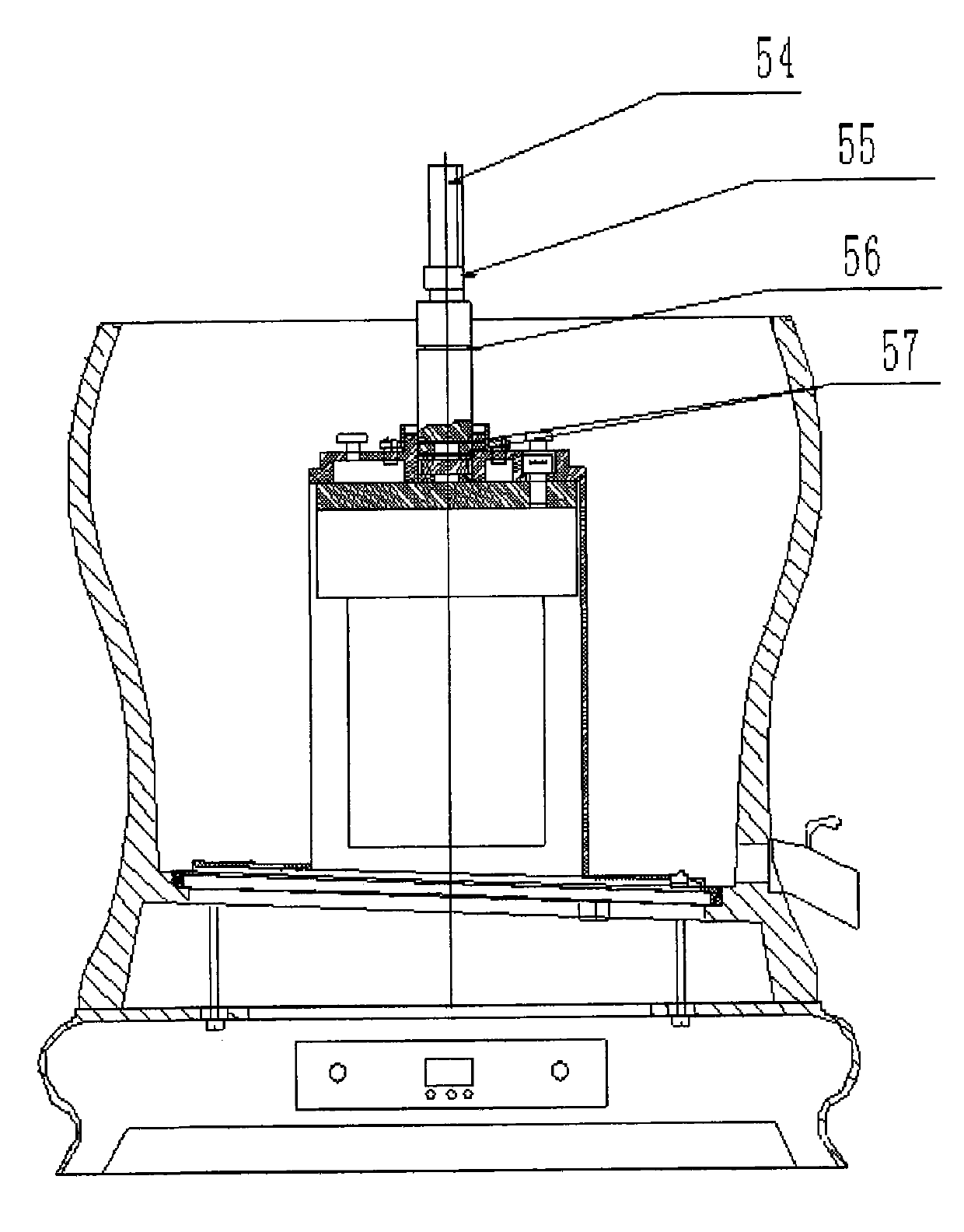

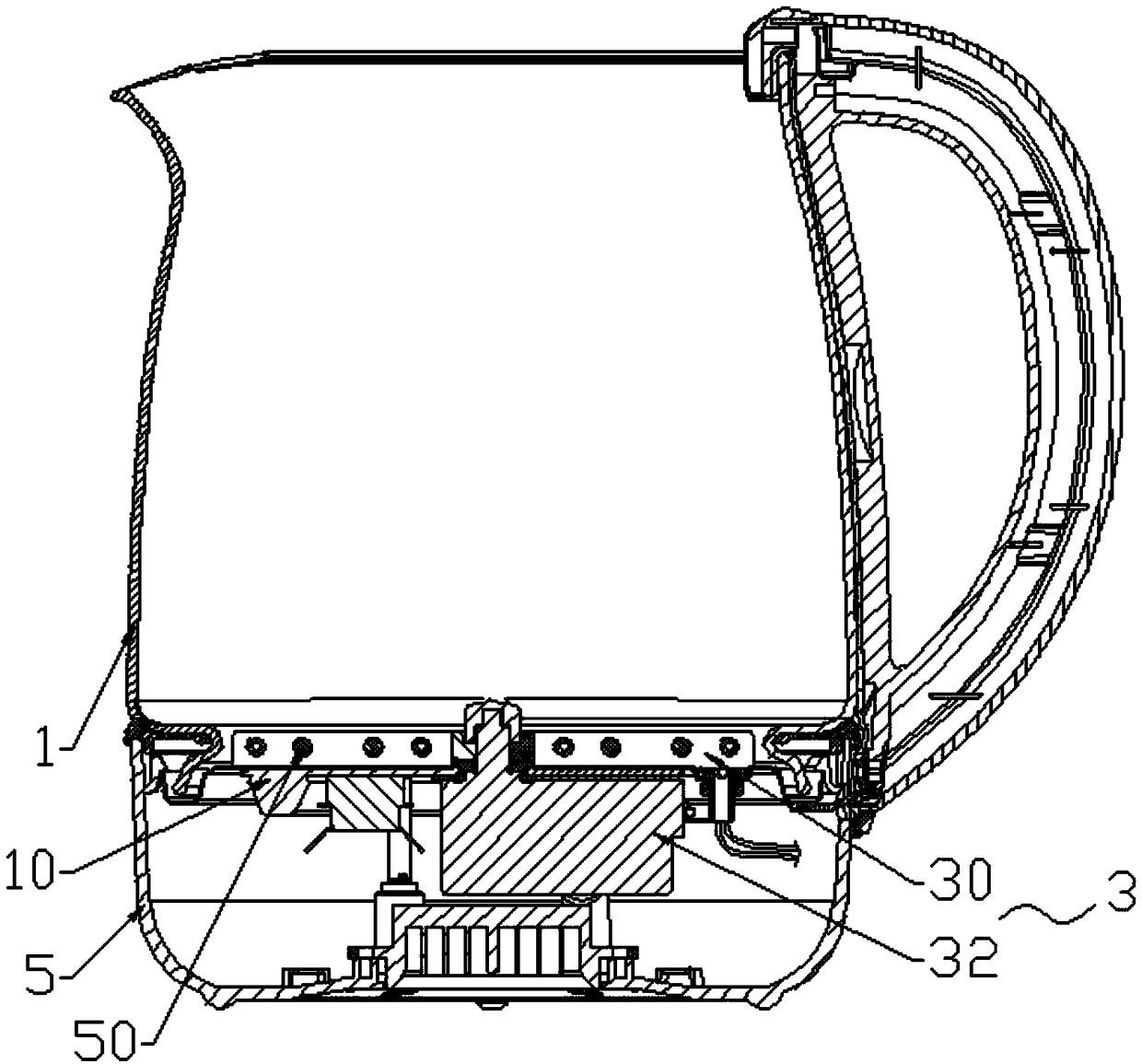

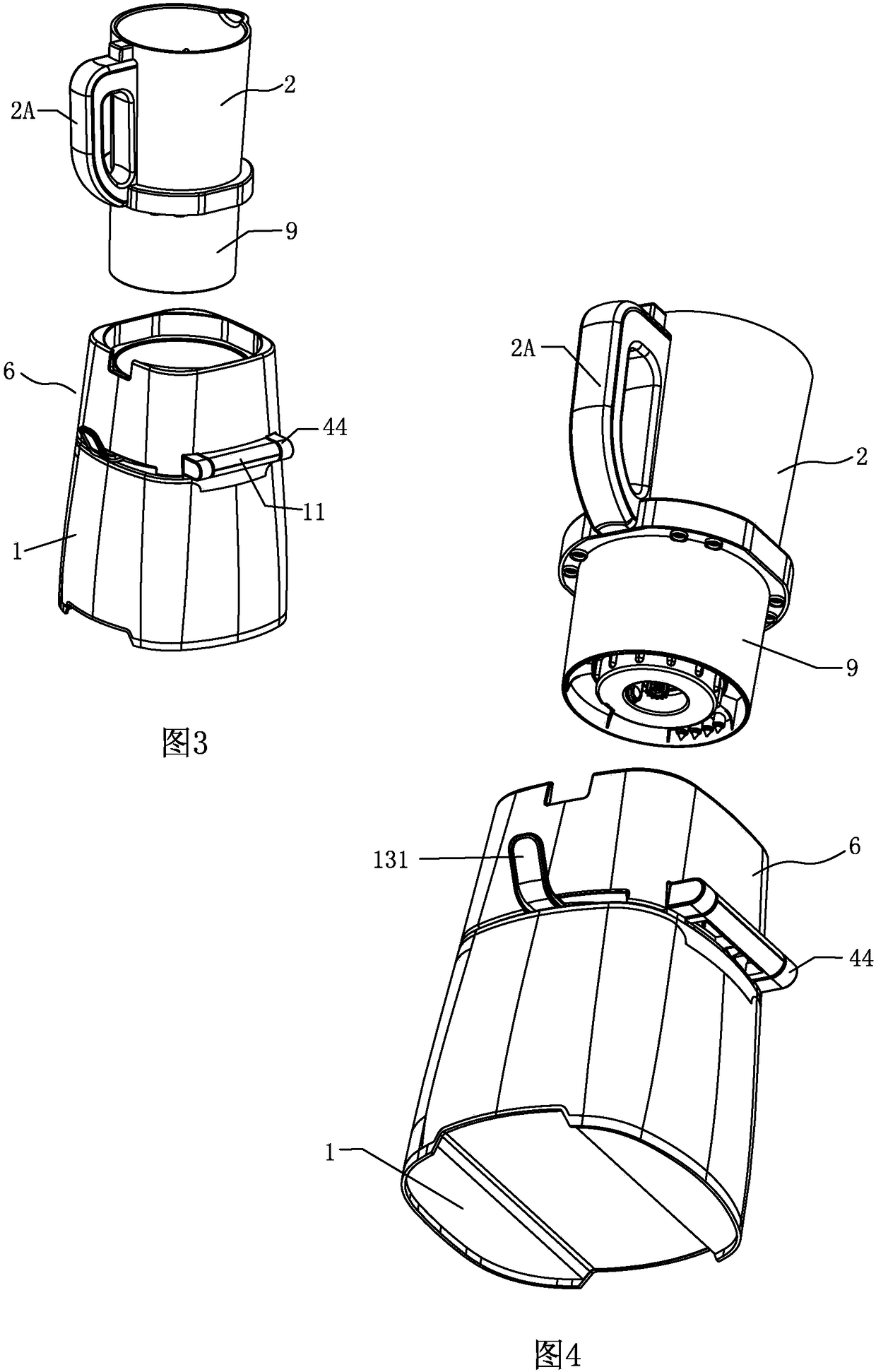

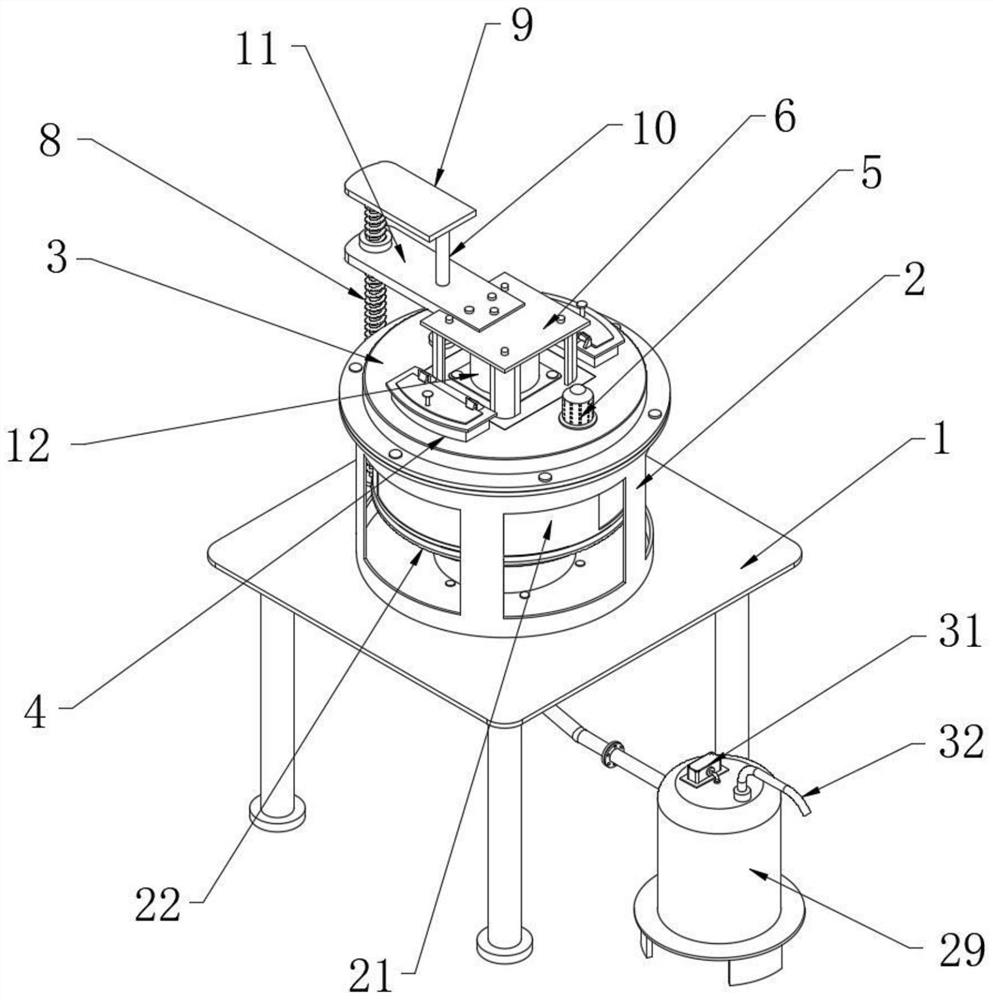

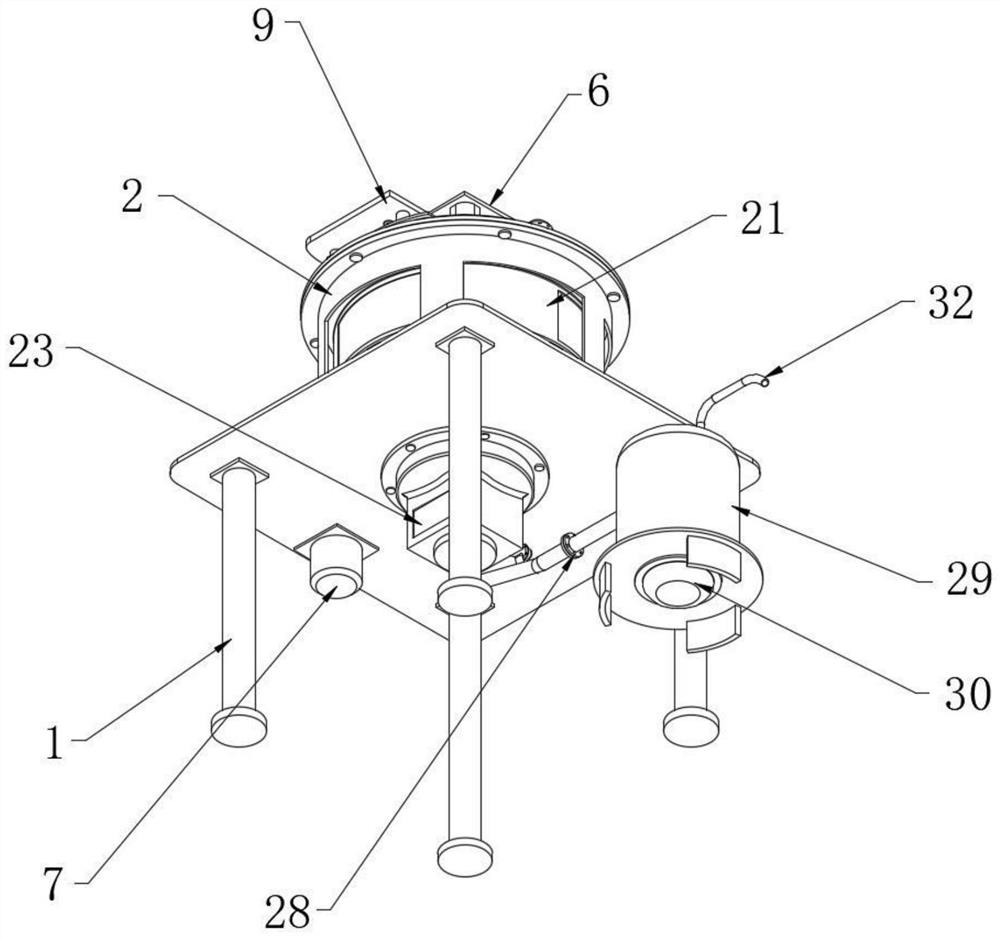

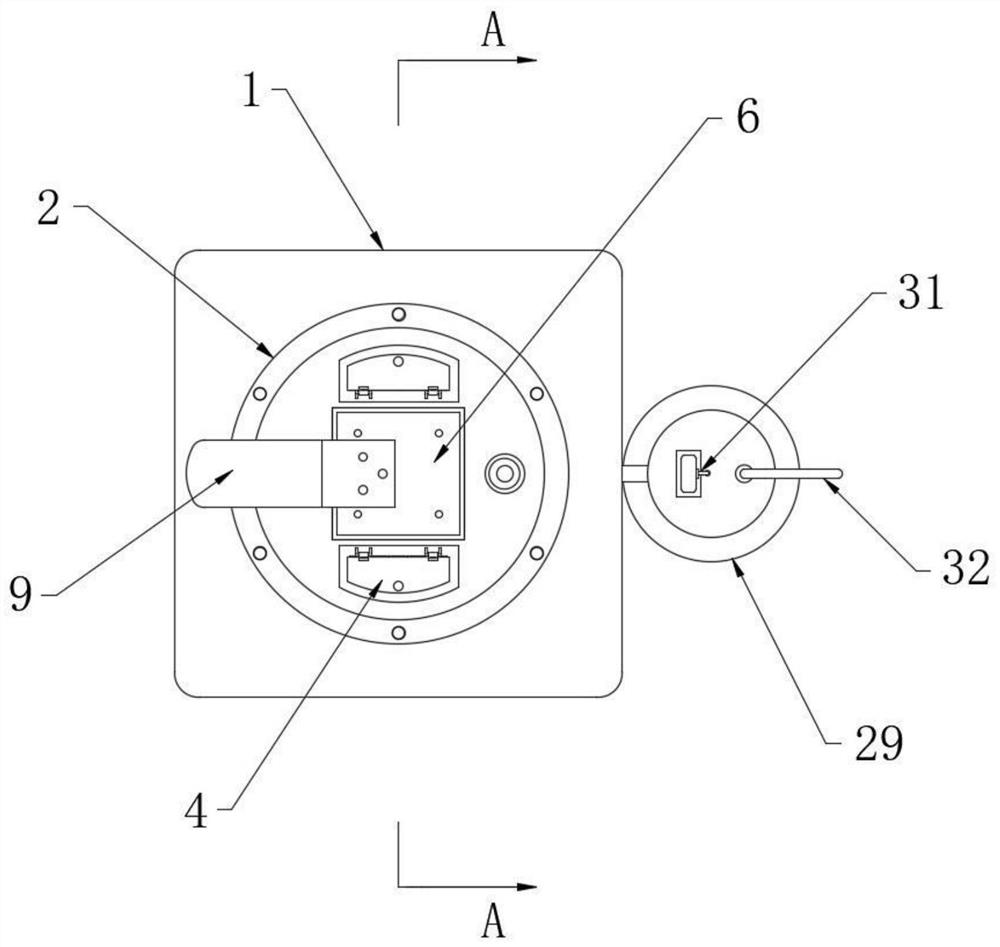

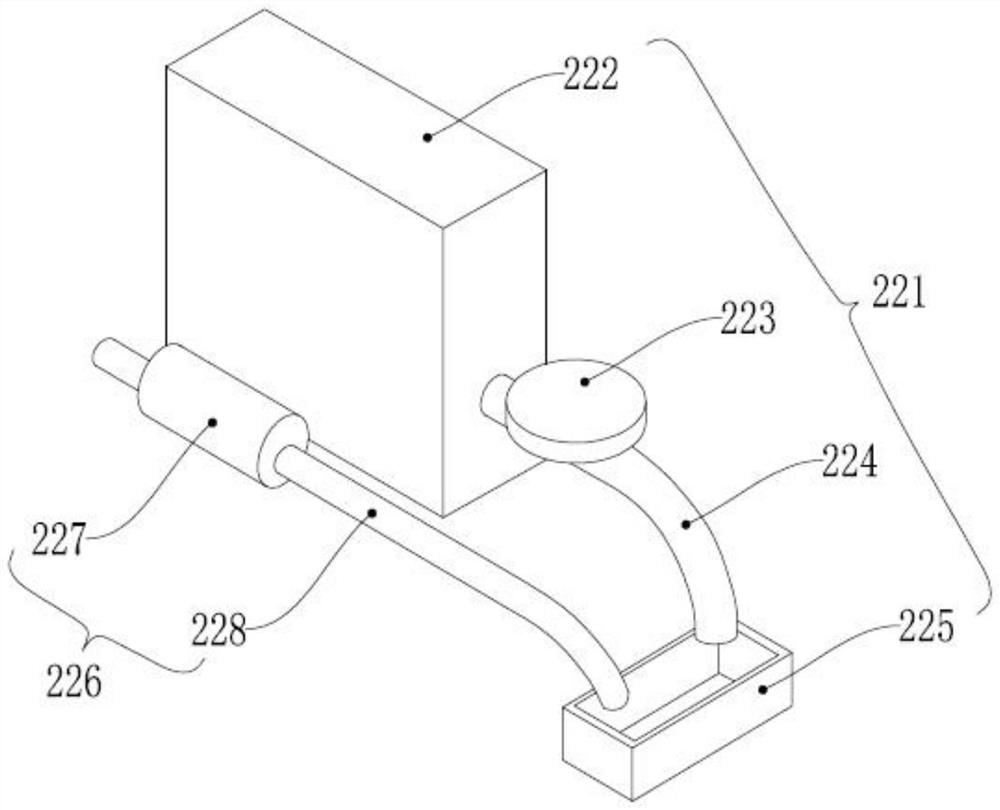

An electromagnetic heating cooking machine

ActiveCN106037525BHeating fastAvoid sticky bottomKitchen equipmentEngineeringElectromagnetic heating

The invention provides an electromagnetic heating type food processor. The electromagnetic heating type food processor comprises a machine base, a cup, a cup cover and a knife assembly, wherein the knife assembly comprises a base body, a knife shaft and a blade group; the electromagnetic heating type food processor further comprises a base plate, a connector, a hollow support base with upper and lower openings, a coil rack, a coil, and a cup support sleeve arranged on the cup, and a plurality of insertion grooves are formed in the cup support sleeve; the connector is embedded in the cup support sleeve, lower cotter pins are inserted into the insertion grooves and are fixed together; the base plate is fixed to the top of the machine base; a body of the coil rack is inserted into the support base, the upper end of the body is connected with an annular plate, the lower end of a connecting post is inserted into a counter bore, a screw penetrates through a flange and a support pillar to be screwed to the connecting post, the base plate supports and is detachably connected with the flange and the lower end of the support base; the cup support sleeve penetrates through the upper opening of the support base and is inserted into the body of the coil rack, and the connector supports the lower end of the cup support sleeve. Due to the adoption of the structure, the electromagnetic heating type food processor has the advantages that the electromagnetic heating is provided, the mounting is convenient, the heating area of the cup is large, and the heating is rapid.

Owner:ZHONGSHAN KONLON ELECTRICAL TECH CO LTD

Medicinal material decocting equipment

ActiveCN111920685AAvoid dangerEfficient mixingPharmaceutical product form changeDomestic articlesMedicinal herbsPesticide

The invention discloses medicinal material decocting equipment which structurally comprises a platform plate; an induction cooker is fixedly arranged on the upper end surface of the platform plate; amedicine barrel abuts against the upper end surface of the induction cooker; an open pesticide barrel inner cavity is formed in the medicine barrel; the platform plate is internally provided with a connecting and overturning device for overturning the medicine barrel in a connecting rod pushing mode; and a stirring and filtering device for stirring and filtering a liquid medicine in the inner cavity of the medicine barrel is arranged on the upper side of the inner cavity of the medicine barrel. The equipment adopts the design of the connecting and overturning device, the stirring and filteringdevice and the lifting and matching connecting device, so that medicinal materials can be efficiently stirred when being decocted in water, it can be guaranteed that medicine residues are separated from the liquid medicine after the liquid medicine is poured out, personnel can continuously operate and use the equipment conveniently, and the danger caused by manual operation of the personnel is avoided.

Owner:湖南雅湘精萃医药科技有限公司

Bean product processing equipment

The invention provides bean product processing equipment, and relates to the technical field of food processing and making. The soybean product processing equipment comprises a soybean milk pool, wherein a fan is arranged above the soybean milk pool, a steam heating chamber is arranged at the bottom of the soybean milk pool, and steam pipes and condensation pipes are connected to the steam heating chamber. The soybean product processing equipment has the beneficial effects of uniform heating and relatively high production efficiency.

Owner:开远市诚和豆制品工贸有限公司

Processing method of a food processing machine and food processing machine

ActiveCN113520183BAvoid stickingAvoid sticky bottomKitchen equipmentElectric machineryProcess engineering

Owner:JOYOUNG CO LTD

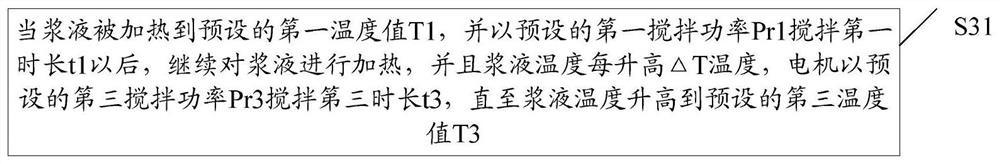

A kind of overheat protection method of food processing machine

ActiveCN108185848BReduce misuseReduce manufacturing costKitchen equipmentElectric machineryProcess engineering

The embodiment of the present invention discloses an overheat protection method for a food processor. The food processor includes: a crushing cup and a motor. A heating device is arranged on the crushing cup. A thermal fuse connected in series with the heating device is respectively arranged at both ends of the heating device. A body protector, the method includes: during the heating process, when the slurry is heated to one or more preset temperature values with a preset heating power, respectively using the stirring power and the stirring time corresponding to the preset temperature value The slurry is stirred. Through the solution of this embodiment, the production cost is reduced, potential safety hazards are reduced, and misoperation of the thermal fuse protector in overheating protection is reduced.

Owner:JOYOUNG CO LTD

Novel traditional Chinese medicine decocting device

InactiveCN114869765AAvoid sticky bottomFull use of valuePharmaceutical product form changeDomestic articlesMedicinal herbsOfficinal

The invention discloses a novel traditional Chinese medicine decocting device which comprises a mounting base, a medicine decocting kettle arranged on the mounting base, a heater used for heating the medicine decocting kettle, a magnetic stirrer arranged on the mounting base and located at the bottom of the medicine decocting kettle, and a filter frame arranged in the medicine decocting kettle and capable of being adjusted in a lifting mode. According to the medicine decocting device, the filtering frame which is installed in the medicine decocting kettle and is adjusted to ascend and descend through the lifting adjusting rod is utilized, medicinal materials can be prevented from pasting the bottom, meanwhile, medicine residues can be conveniently taken out, and medicine liquid is filtered; in addition, steam containing medicinal components generated in the medicine decocting kettle is condensed and recycled by means of a steam collecting pipe, the value of medicinal materials can be fully utilized, and medicinal loss is reduced.

Owner:XIEHE HOSPITAL ATTACHED TO TONGJI MEDICAL COLLEGE HUAZHONG SCI & TECH UNIV

Stock solution oil tea production device and production process capable of automatically blending materials

PendingCN113785888AEasy to processIncrease elasticityPre-extraction tea treatmentTea extractionRubber materialCamellia oleifera

The invention discloses a stock solution oil tea production device and production process capable of automatically blending materials. The stock solution oil tea production device comprises a base and a liquid storage tank. According to the stock solution oil tea production device, a chassis is arranged, and the chassis is connected with an inner shell through a spline, so that the chassis is always kept in a static state in the processing process; when a second motor shaft drives a movable part to rotate, connecting rods can be driven to slide along the top of the chassis, the three connecting rods can slide upwards along the inclined surface part of a ratchet structure at the top end of the chassis in the rotating process until the connecting rods are separated from the ratchet structure and swing downwards under the action of gravity and a reset spring; a pressing roller which swings up and down is used for beating raw materials, so that a manual beating mode is simulated, and the raw materials are extruded; the pressing roller is made of a heat-resistant rubber material and has good elasticity, and the pressing roller is not in contact with the inner wall of the inner shell; and meanwhile, the minimum distance between the outer wall of the pressing roller and the inner wall of the inner shell is smaller than the average thickness of tea leaves, so that the pressing roller cannot excessively beat the inner wall of the inner shell in the swinging process.

Owner:贺鹃

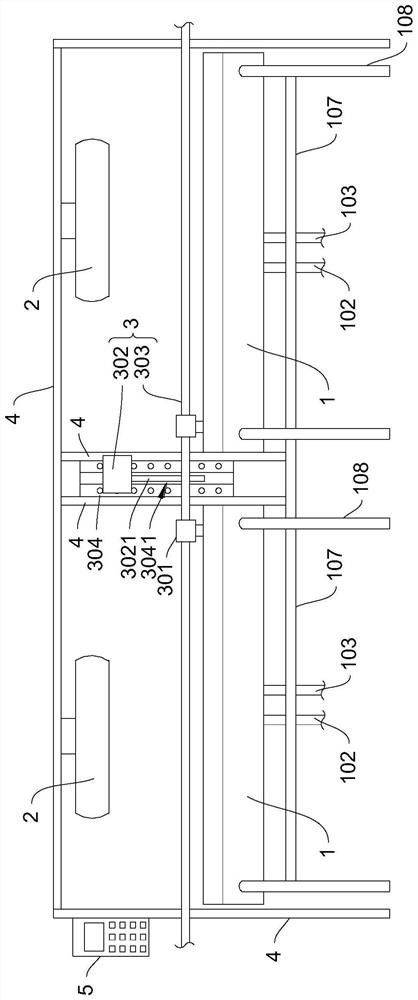

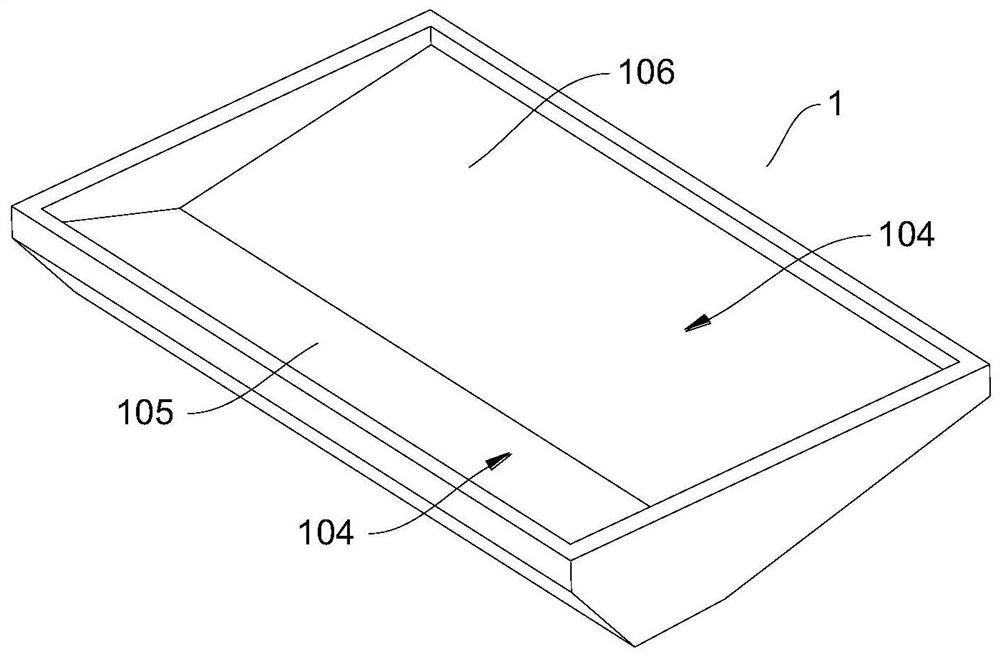

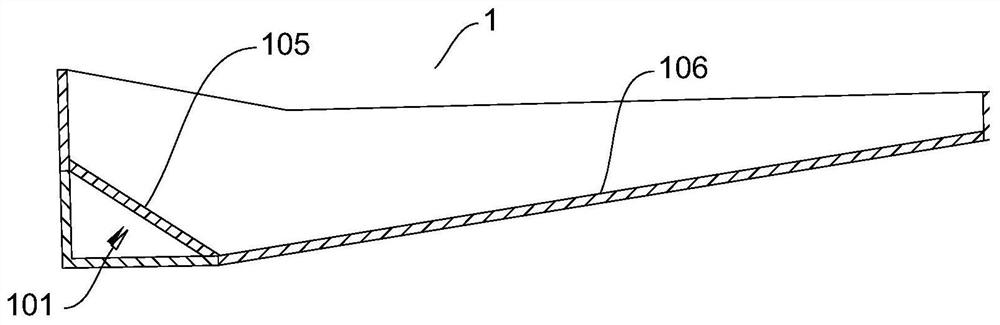

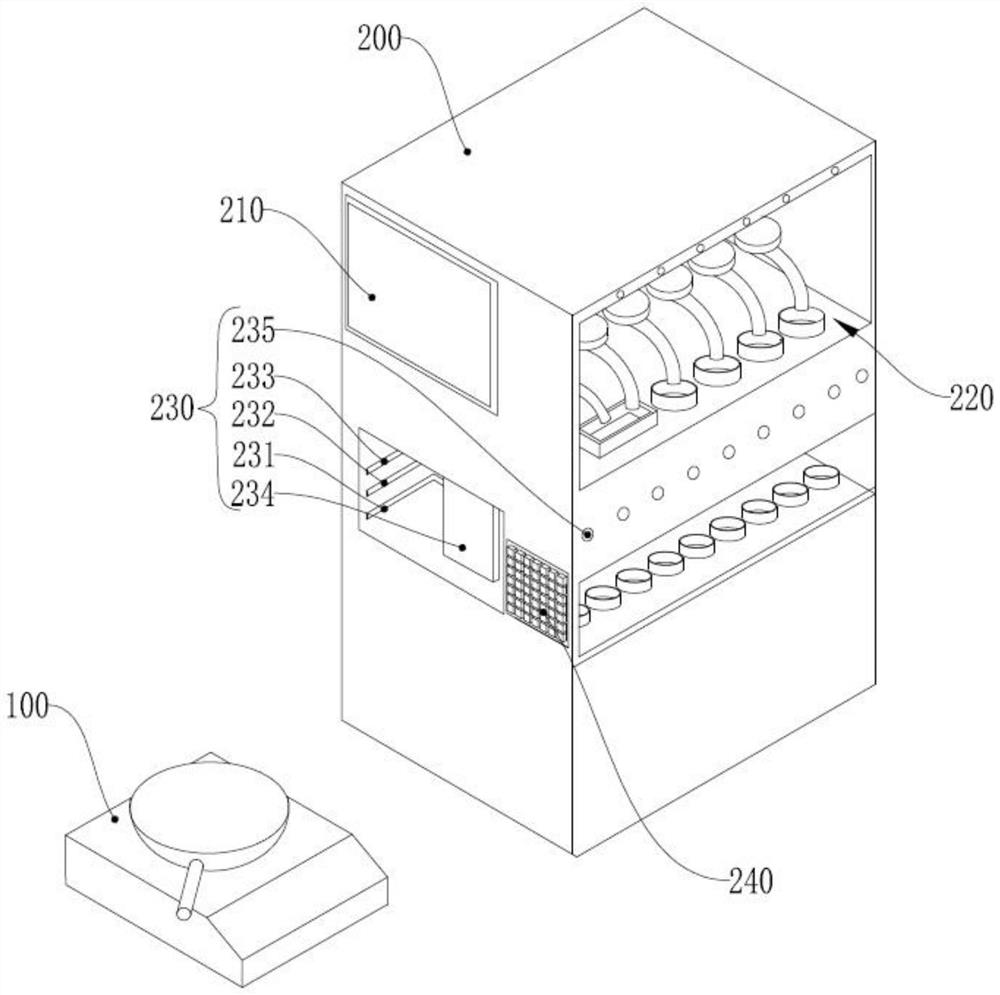

Automatic cooking teaching device and method

PendingCN114373342ALower the cooking thresholdSuccessfully madeKitchen equipmentElectrical appliancesEngineeringFood material

The invention discloses an automatic cooking teaching device and method, and relates to the technical field of cooking equipment. According to the invention, the user can complete the corresponding cooking operation according to the sound signal and the light signal of the acousto-optic teaching mechanism, and does not need to consider the limitation of cooking duration and cooking time conditions, thereby greatly reducing the cooking threshold of the user, and facilitating a beginner to smoothly cook delicious dishes. Through the automatic seasoning configuration mechanism, accurate seasoning configuration is achieved, the situation that due to the fact that a user puts wrong seasoning types and weights in a mixed mode, the taste of dishes is poor is effectively avoided, the cooking process of the user is further simplified through automatic seasoning configuration, cooking of the user is greatly facilitated, and the cooking time of the user is effectively saved. The acousto-optic teaching mechanism is used for guiding the strength and frequency of stir-frying the food materials to the user, the user is guided to stir-fry the food materials through the visual light effect, it can be ensured that the food materials are heated evenly, and meanwhile the food materials can be effectively prevented from being burnt at the bottom.

Owner:广东新起点智能数据科技有限公司

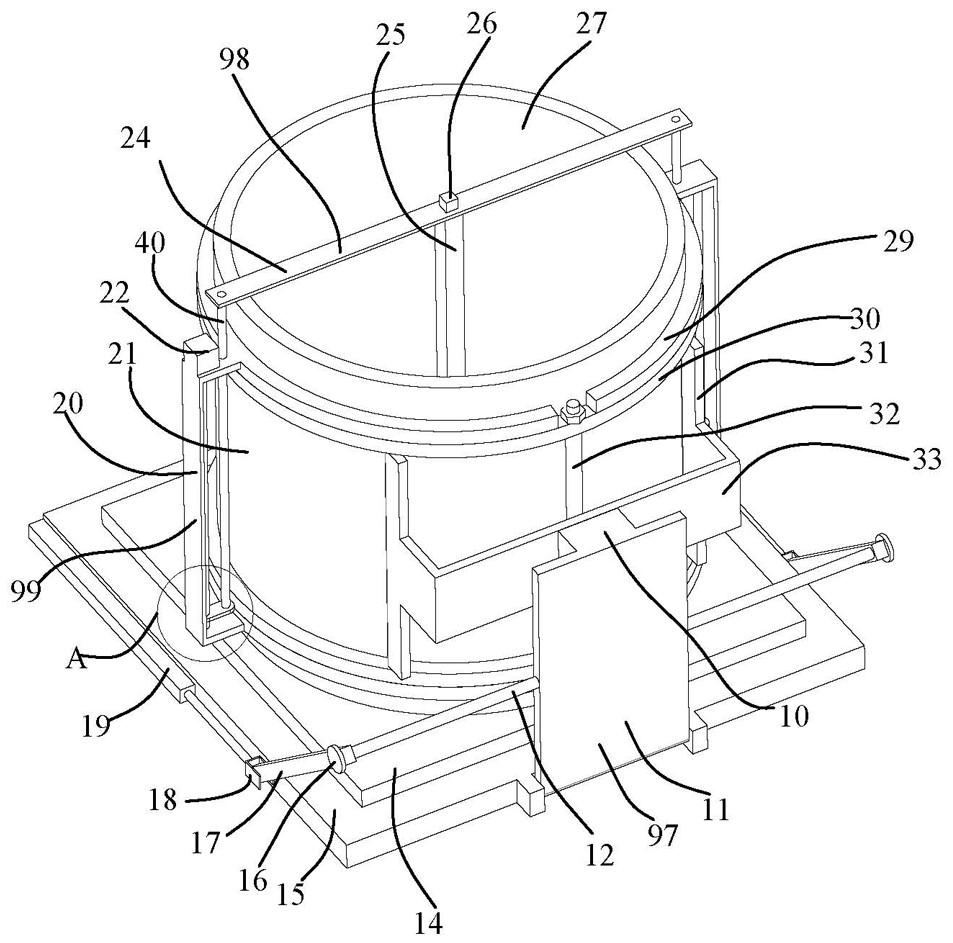

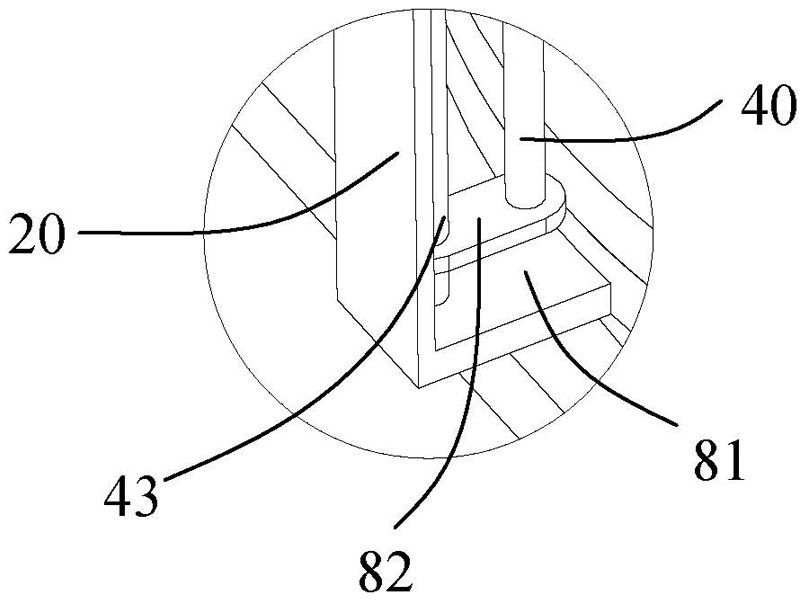

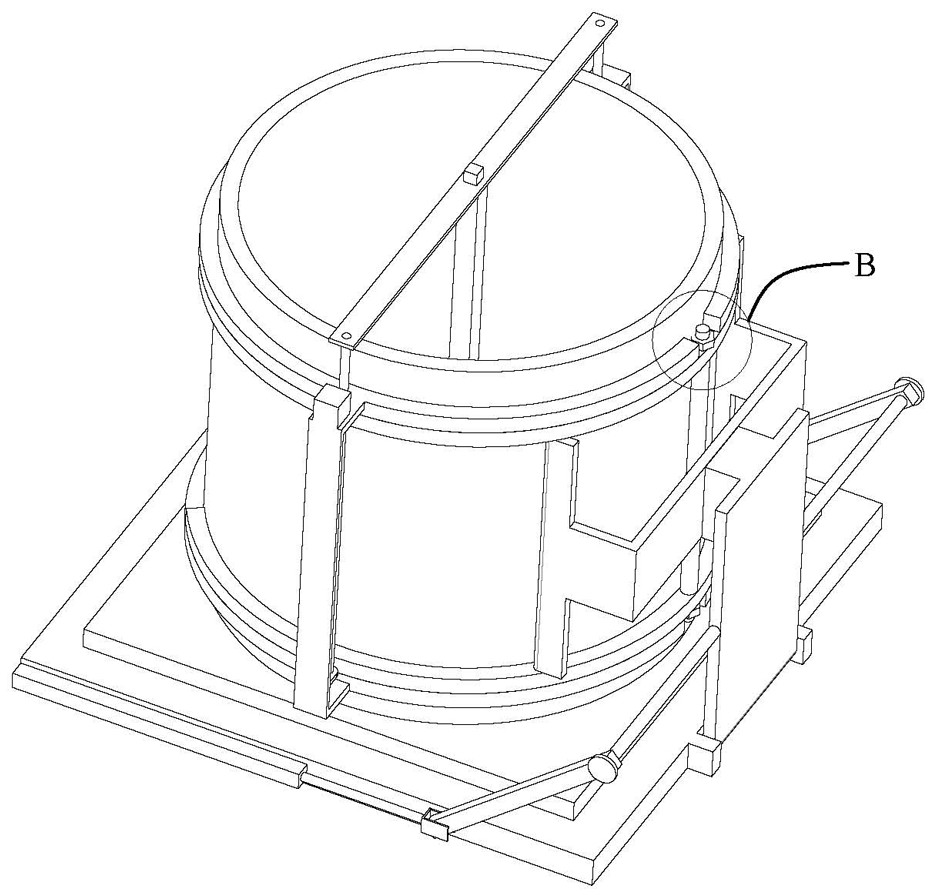

An Improved Automatic Refiner

The present invention relates to an improved automatic slurry grinding machine, and belongs to food machinery. The improved automatic slurry grinding machine comprises a slurry storage tank 1, a lower grinding disc pillar 7, an upper grinding disc 13, a base 28 and the like, wherein the fastener coupling device 45 comprises an upper fastener 46 and a lower fastener 47, the lower fastener 47 comprises a lower fastener bracket 64, a lower fastener sleeve 65, a fastener nail 66, a sealing cover 68, a sealing ring 69, a reduction gearbox 9 and a motor 8, the water outlet gate device 38 comprises a water outlet gate screw 34, a water outlet gate hole 35, a water outlet gate rubber ring 36, an adjustment nut 37 and a water tank 44, the locking device 39 of the upper grinding disc 13 comprises a locking bolt 40, a central long shaft 41, a flat pad rubber ring 42 and an upper grinding disc inner hexagonal hole 43, and the stirring rod device 73 comprises a stirring rod horizontal handle 74 and a stirring rod long handle 75. According to the present invention, the upper grinding disc can be removed, such that human hands can directly insert into the slurry storage tank so as to clean; no slurry is remained on the bottom of the slurry storage tank; and the slurry is ensured, bottom pasting does not appear, and the beverage quality can be improved.

Owner:文树雄 +3

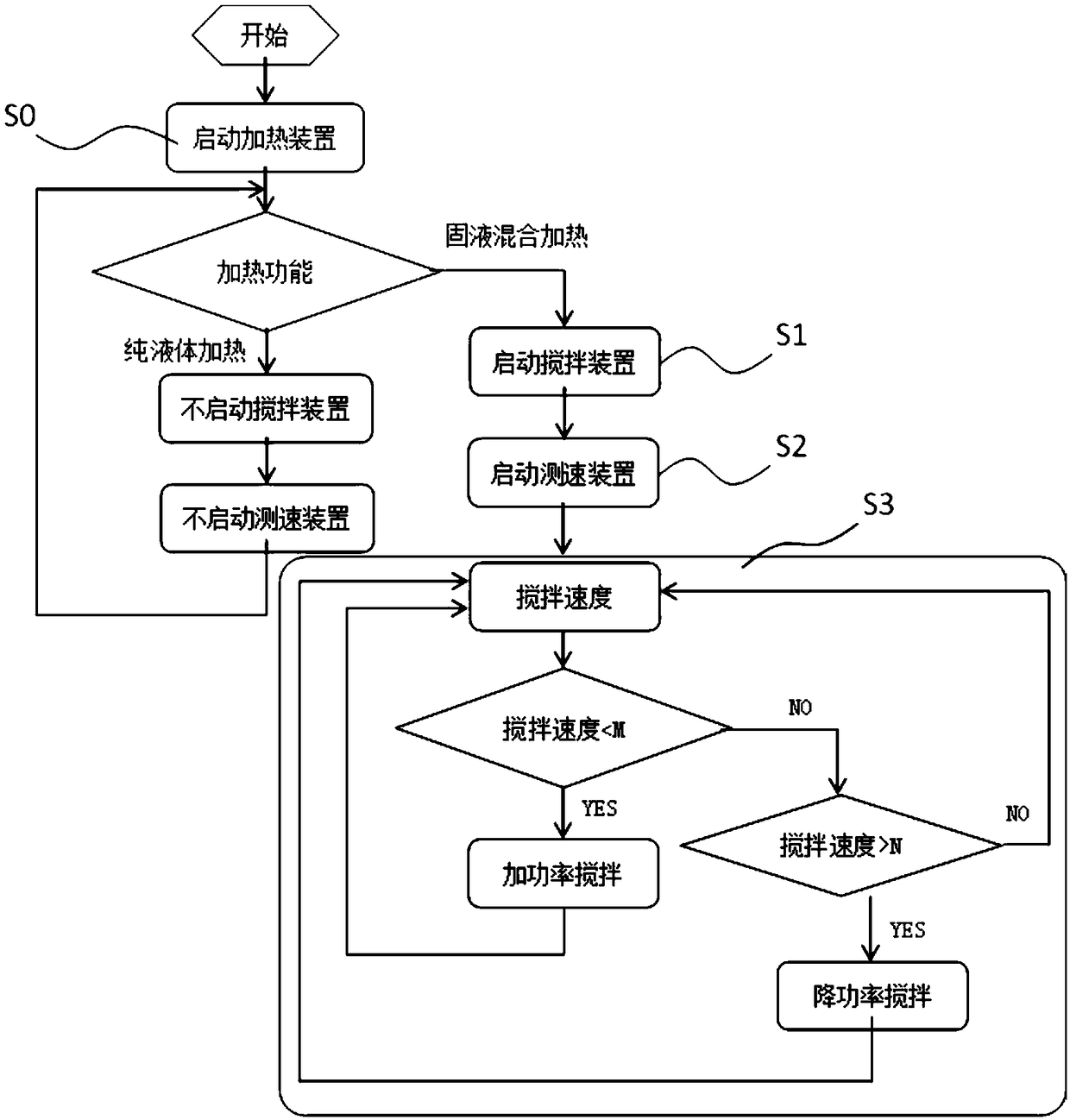

Anti-sticky bottom method of electric kettle and electric kettle

ActiveCN108888108BAvoid sticky bottomIncrease stickinessWater-boiling vesselsProcess engineeringMechanical engineering

The present application provides a method for preventing sticky bottom of an electric kettle and an electric kettle. The method includes: step S1: start a stirring device, and the stirring device stirs the ingredients in the electric kettle according to the initial stirring power; step S2: start a speed measuring device, The speed measuring device detects the stirring speed of the stirring device; step S3: the electric kettle is provided with a control chip, and the control chip adjusts the stirring power of the stirring device according to the stirring speed. The application can indirectly reflect the viscosity of the ingredients by detecting the stirring speed, and adjust the stirring power of the stirring device to prevent the bottom of the electric kettle from sticking.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

Device for dressing bean vermicelli with starchy sauce

InactiveCN103947912AAvoid injuryImprove uniformityRotary stirring mixersTransportation and packagingEngineeringFood item

The invention relates to a device for dressing bean vermicelli with starchy sauce, and belongs to the field of food processing machinery. The device for dressing the bean vermicelli with the starchy sauce comprises an electric motor, a barrel, and a stirring rod, wherein the stirring rod is inserted in the barrel and is used for stirring, the electric motor drives the stirring rod, a feeding cover is arranged at the upper end of the barrel, a discharging hole is formed in the lower end of the barrel, an air hole is formed in the bottom of the barrel and is connected with a steam boiler through a pipeline, and stirring fins are arranged on the stirring rod, and are sequentially increased from top to bottom. By adopting the device, a worker can be prevented from being hurt during operation, the efficiency of dressing the bean vermicelli with the starchy sauce is increased; steam is introduced into the bottom of the barrel for dressing the beam vermicelli with the starchy sauce, the required temperature is provided, heat can be more uniformly transferred, the bottom is prevented from being pasted; and by adopting a design of sequentially increasing the stirring fin from the top to the bottom, the efficiency of dressing the bean vermicelli with the starchy sauce is improved effectively and the uniformity of the starchy sauce is improved.

Owner:娄志

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com