Improved automatic slurry grinding machine

A refiner and automatic technology, applied in cocoa, grain processing, food science, etc., can solve the problems of sticky bottom, excessive up and down jump, long cleaning tools, etc., to improve work efficiency, quality and function Simplified button keys and convenient cleaning operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

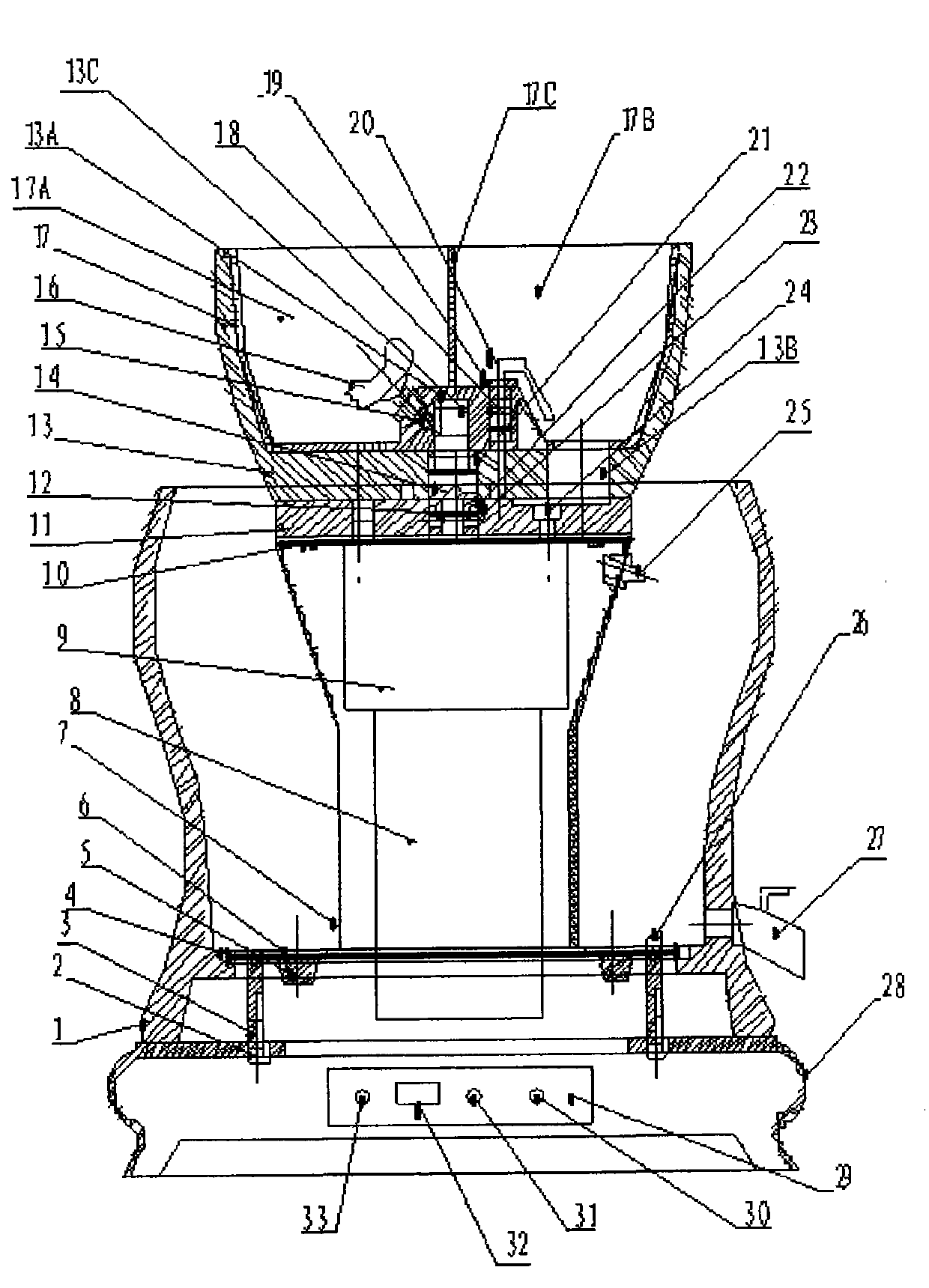

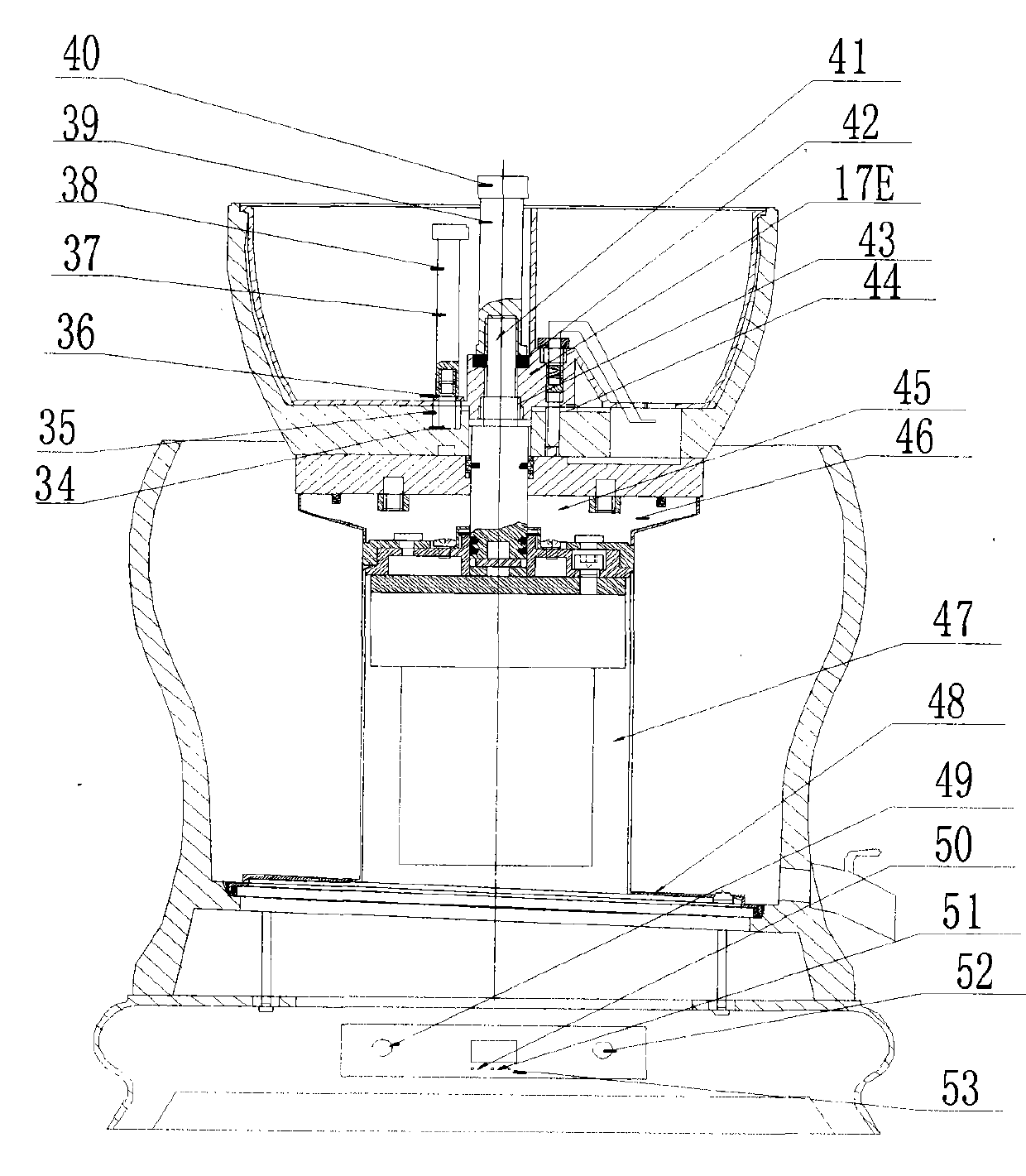

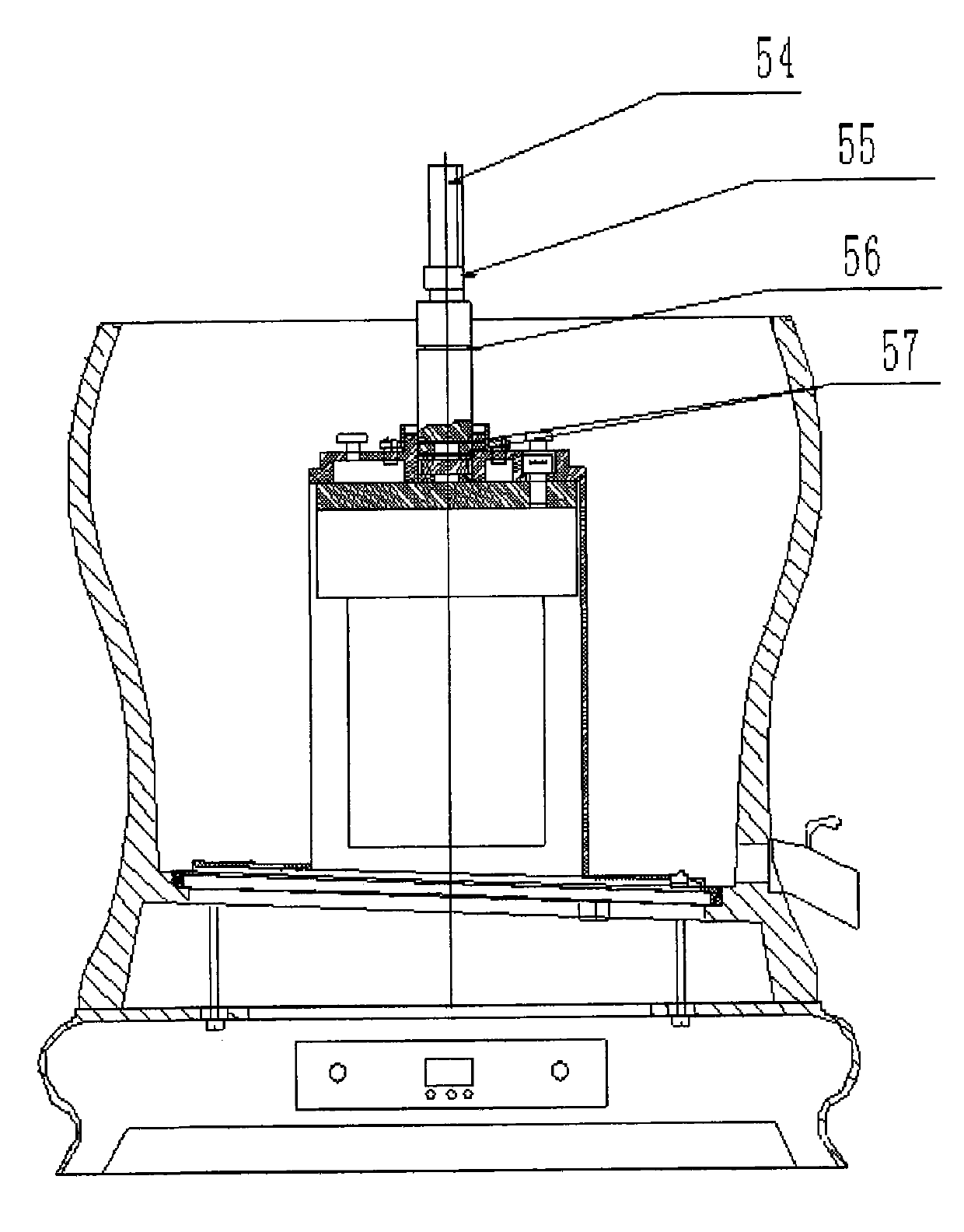

[0040] Below in conjunction with accompanying drawing, the present invention is explained in detail, figure 2 It is a front view of an improved automatic refiner structure of the present invention. image 3 is the central long axis structure diagram. Figure 4A It is the front view of the upper fastener structure. Figure 4B It is the side view of the upper fastener structure. Figure 5A It is the front view of the lower fastener structure. Figure 5B It is a top view of the lower fastener structure. Image 6 It is a diagram of the stirring rod device. Figure 7 Is the electric control schematic diagram.

[0041] As can be seen from the figure, an improved automatic refiner includes a slurry storage tank 1, a lower millstone pillar 7, an upper millstone 13, a slurry outlet 27, a base 28, a control circuit board 29, an electric motor 8, and a reduction box 9. Electric motor 8, reduction box 9, wherein, connecting rod shaft 14 is connected with upper grinding disc 13 by s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com