Anti-sticky bottom method of electric kettle and electric kettle

An electric kettle and anti-sticking technology, which is applied to kitchen utensils, water boiling utensils, household appliances, etc., can solve problems such as inability to adjust, insufficient mixing, and sticky bottom, and achieve the effect of preventing sticky bottom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

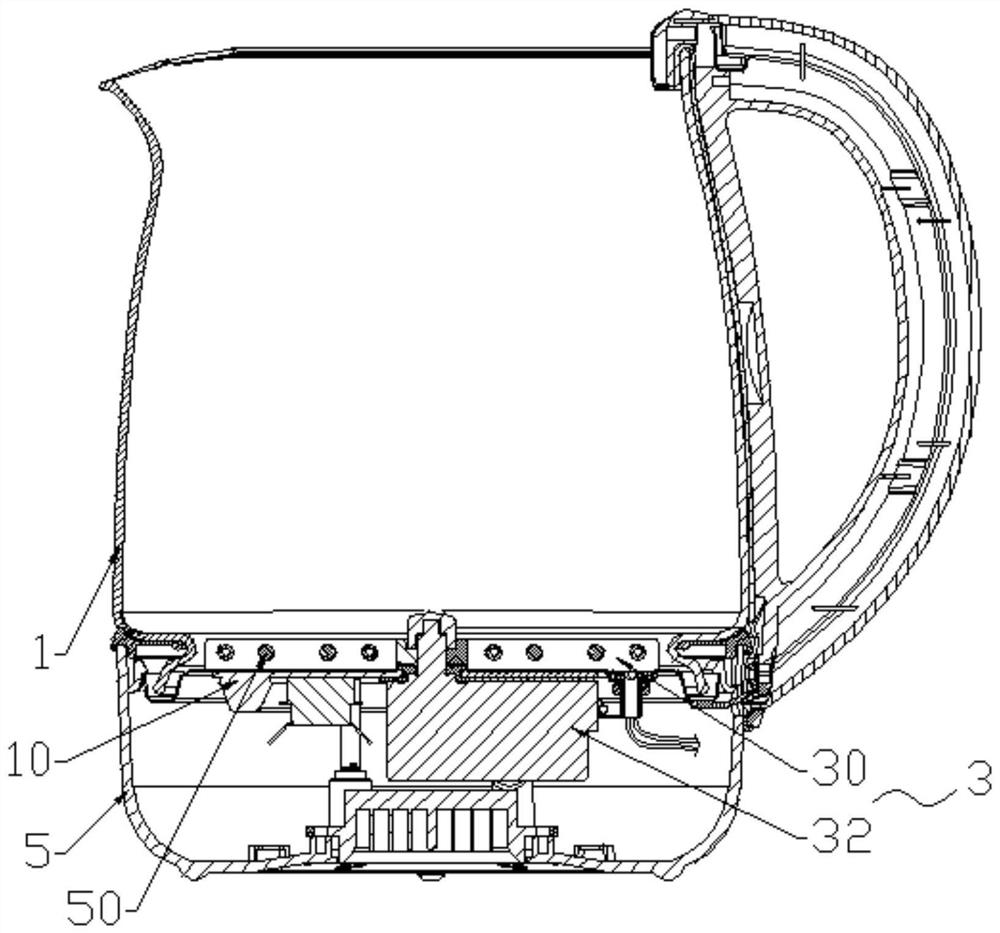

[0036] The present application will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

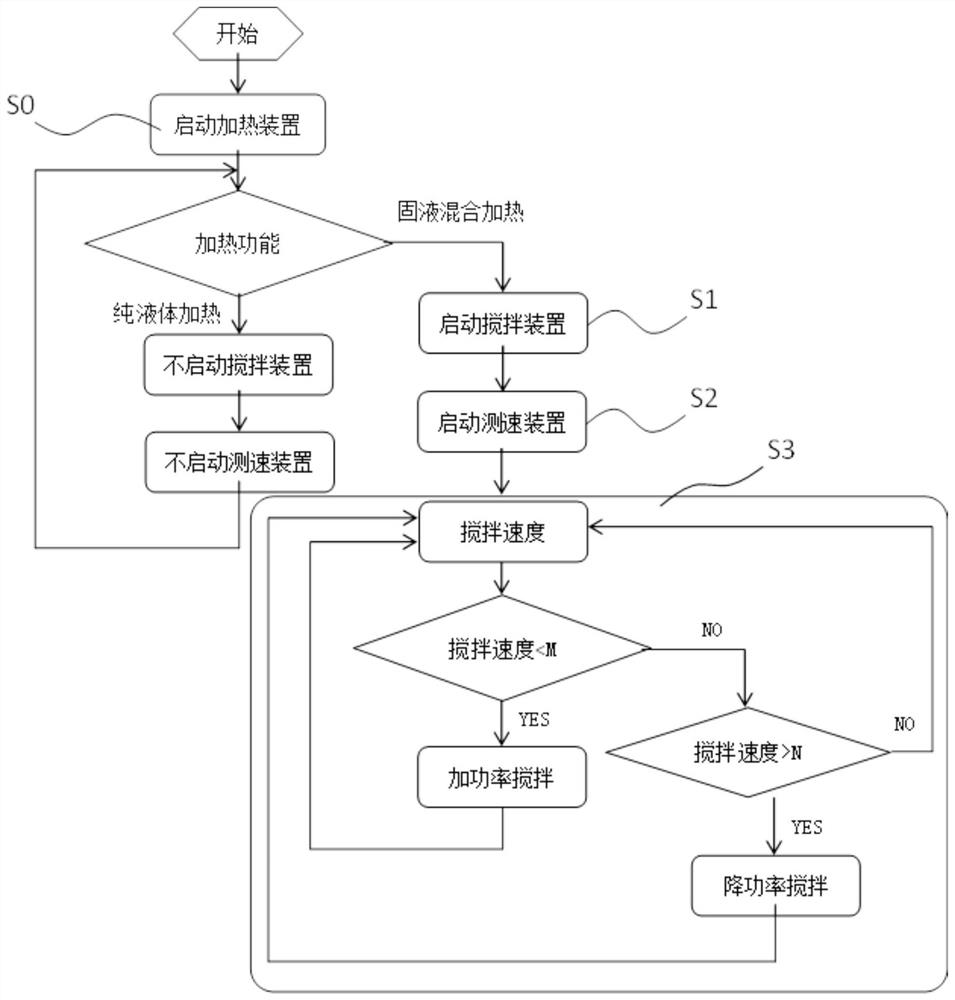

[0037] Such as figure 1 As shown, the embodiment of the present application provides a method for preventing sticky bottom of an electric kettle, which includes:

[0038] Step S0: Start the heating device, select the heating function, judge whether stirring is required according to the heating function, and proceed to step S1 if stirring is required;

[0039] Step S1: Start the stirring device, and the stirring device stirs the ingredients in the electric kettle according to the initial stirring power;

[0040] Step S2: start the speed measuring device, and the speed measuring device detects the stirring speed of the stirring device;

[0041] Step S3: The electric kettle is provided with a control chip, and the control chip adjusts the stirring power of the stirring device according to the stirring speed.

[0042] Specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com