Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1272 results about "Liquid extract" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquid extracts have been used for centuries in wellness practices. Early cultures used herbs in teas to extract their wellness properties, over the years other methods have yielded tinctures and liquid extracts. These extracts have been part of homemade and traditional wellness practices since the time of their conception.

Process for producing a plant extract containing plant powder

InactiveUS20040161524A1Increase contentEasy to crushSolid waste disposalAnimal feeding stuffHas active ingredientAdditive ingredient

The present invention relates to a method for producing a liquid plant extract containing plant powder, which comprises concentrating a liquid extract containing an active ingredient in the presence of the plant powder, the liquid extract being obtained from a plant containing the active ingredient; a process for producing a plant extract containing plant powder, which is characterized by comprises concentrating and drying a liquid extract containing an active ingredient in the presence of the plant powder, the liquid extract being obtained from a plant containing the active ingredient; a liquid plant extract or plant extract containing plant powder which comprises a liquid extract or plant extract containing the active ingredient obtained from a plant containing the active ingredient and comprises plant powder, and in which the content of the active ingredient in the liquid extract or plant extract is higher than that in the plant; and a food and drink or feed to which the liquid plant extract or plant extract containing plant powder is added.

Owner:KYOWA HAKKO BIO CO LTD

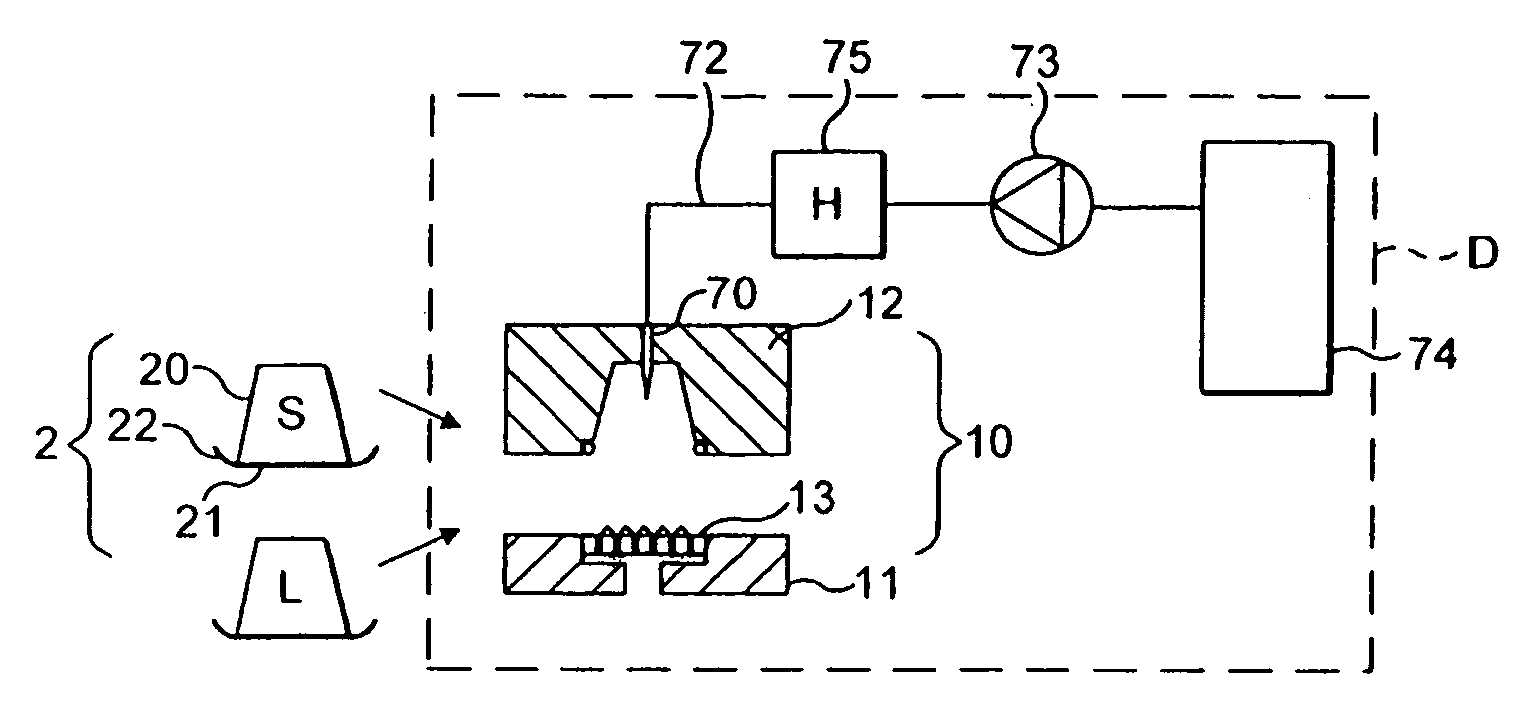

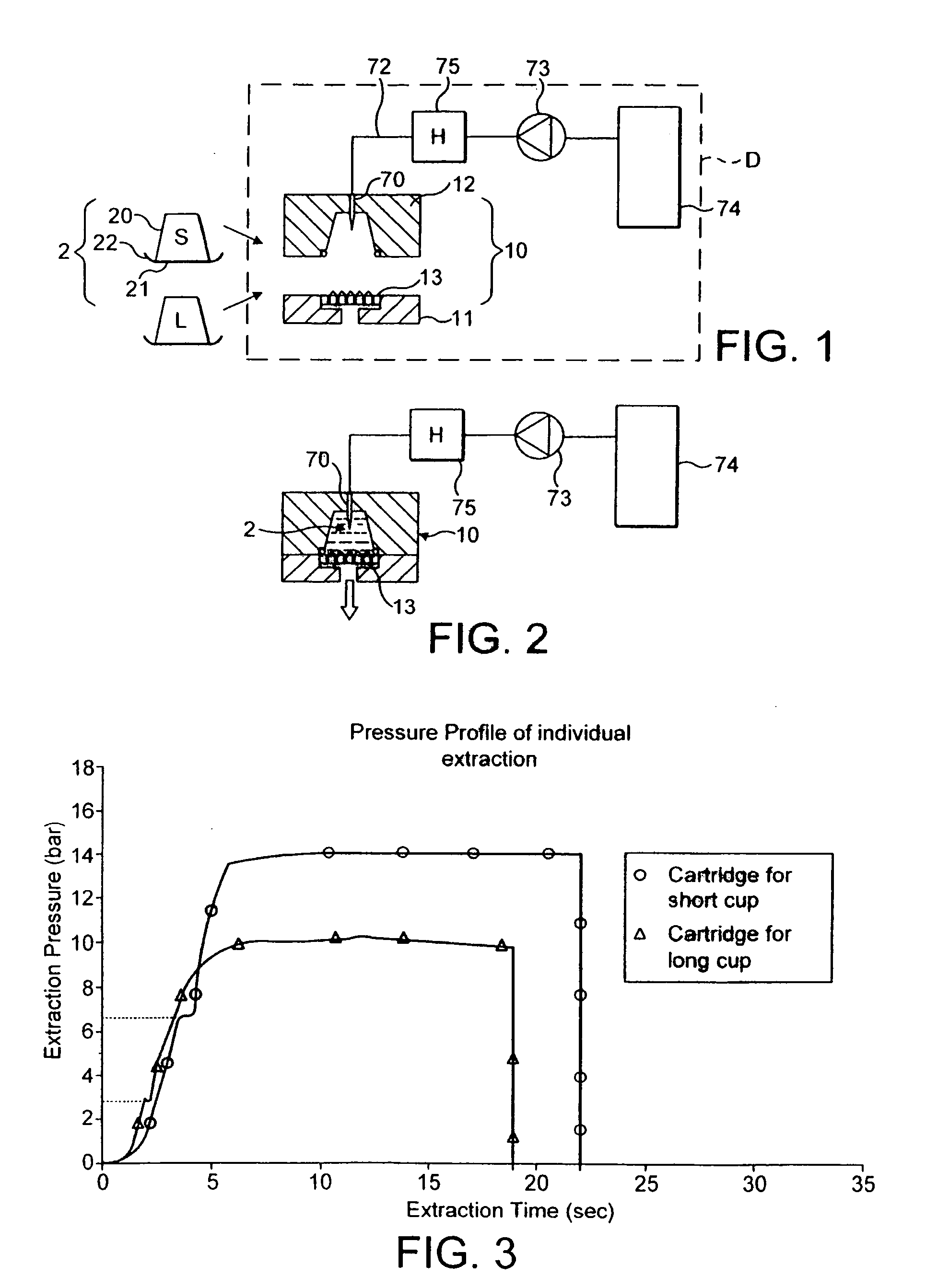

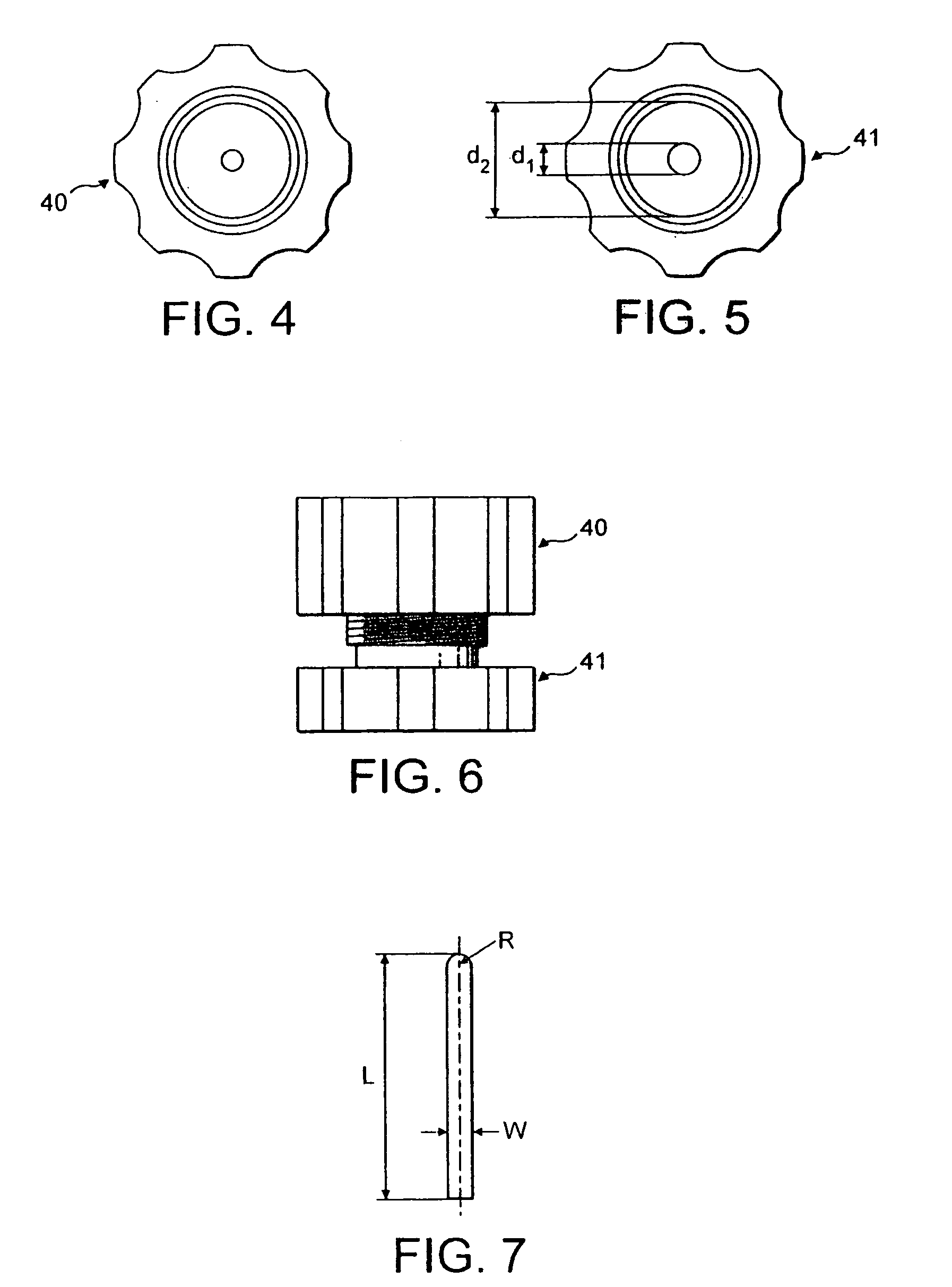

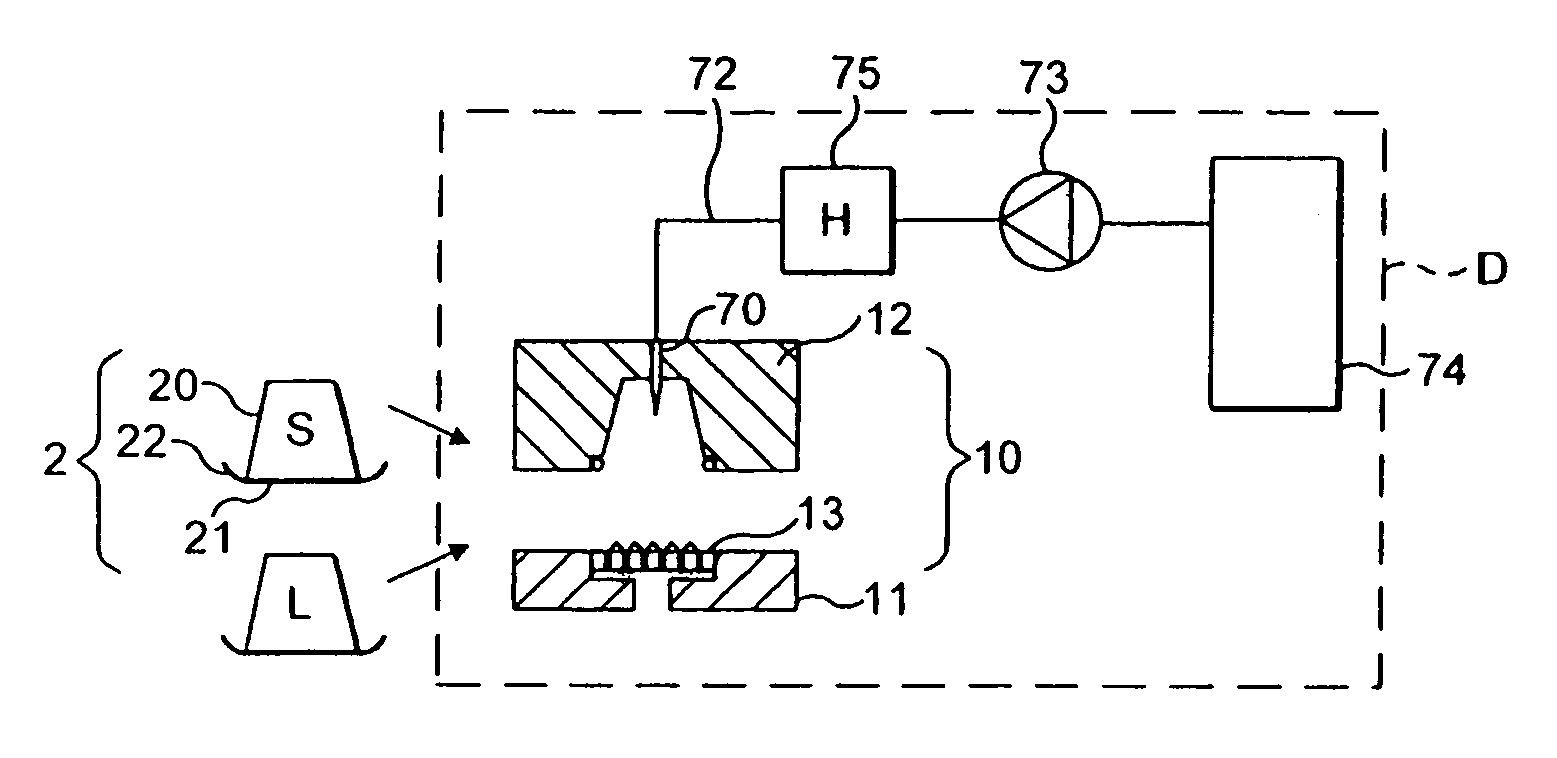

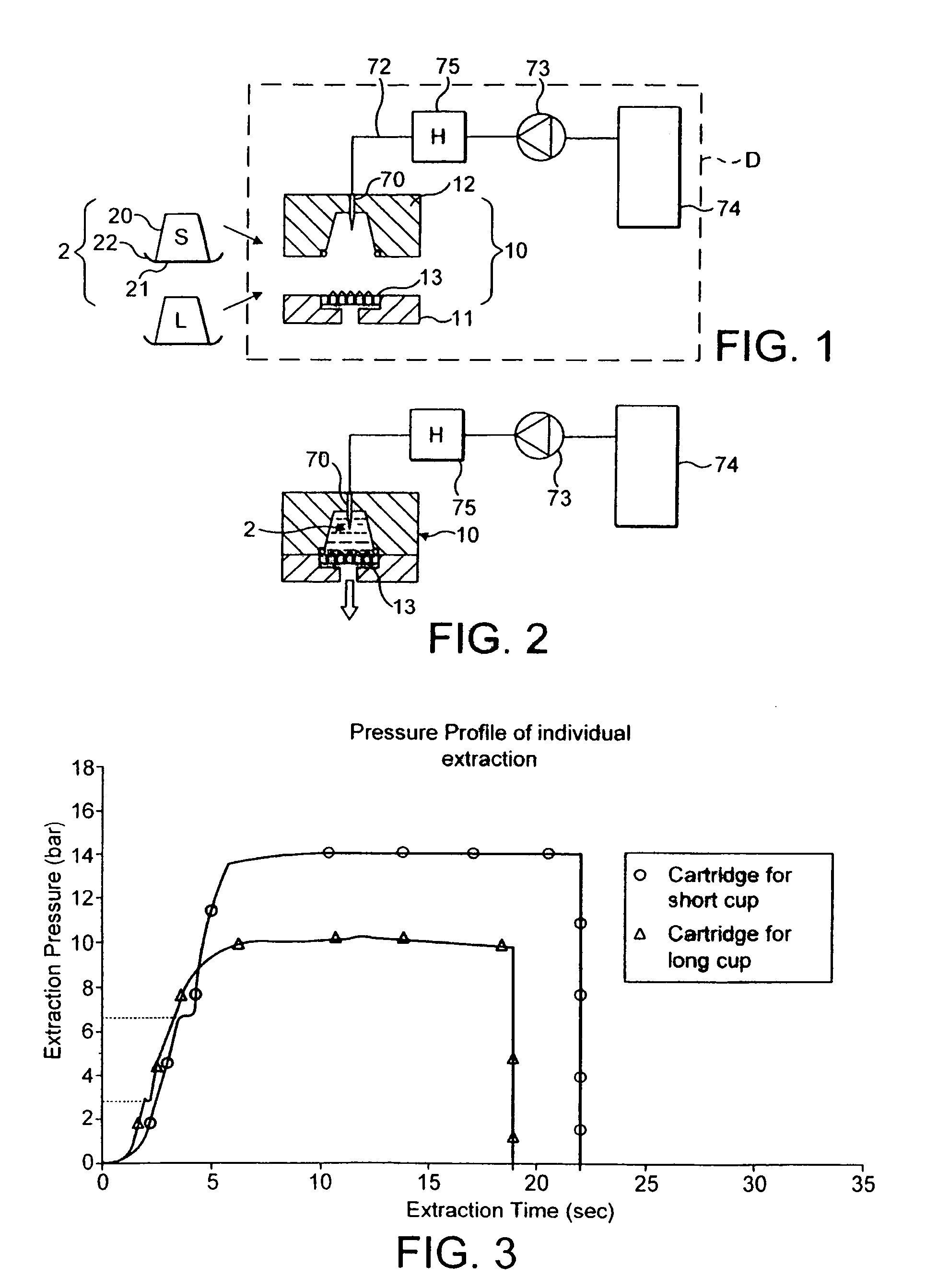

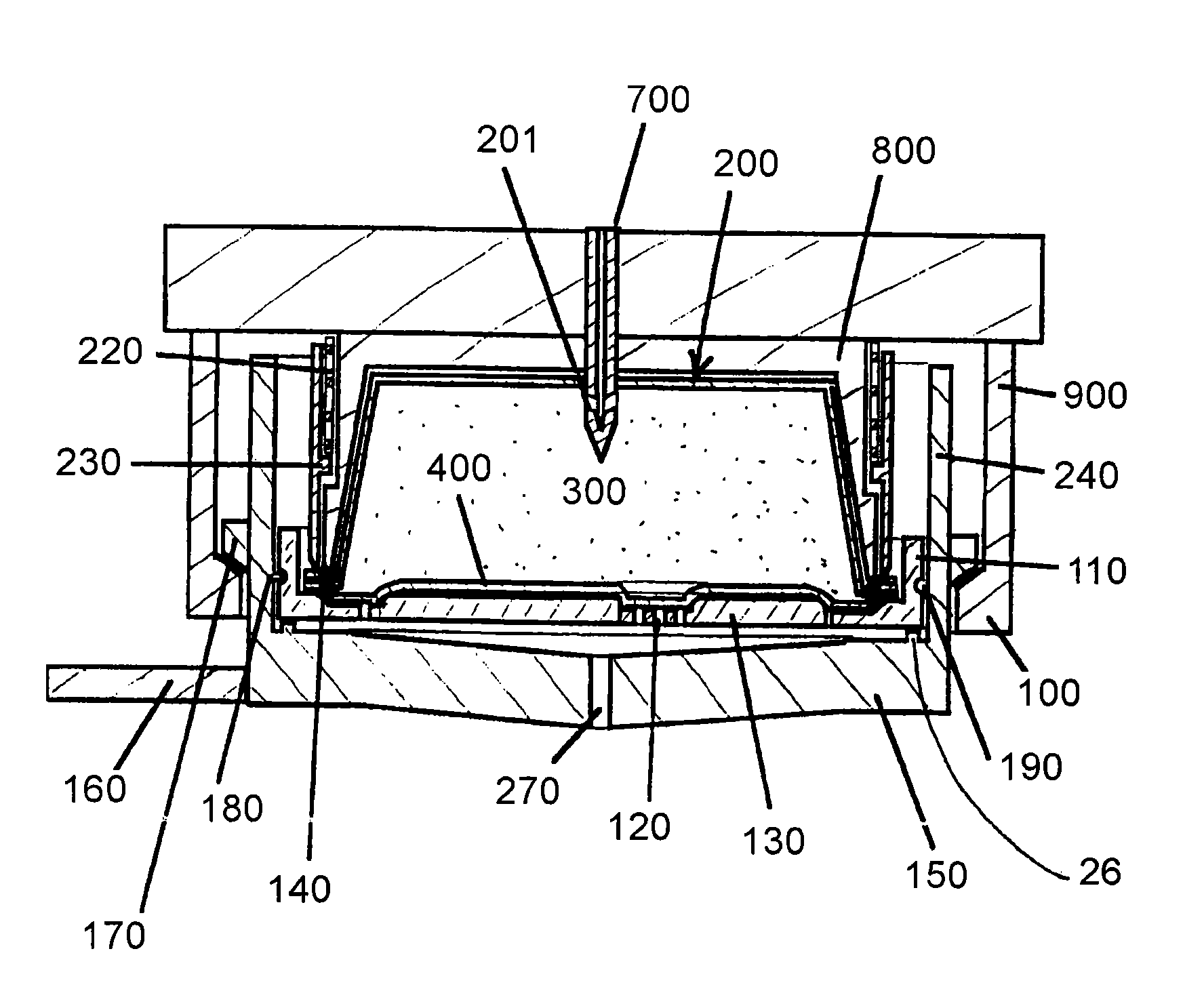

System for dispensing short and long coffee beverages

A beverage system for selectively delivering, in a same coffee extraction device, short coffee liquid extracts and long coffee liquid extracts comprising: cartridges containing ground coffee; a receiving device for receiving one cartridge at a time and pumping means or injecting water under pressure in the cartridge; means for opening the cartridge wherein these means comprises retaining means to retain the liquid under pressure in the cartridge and engaging means which engage the retaining means to open the cartridge and deliver the coffee liquid extract; wherein the system comprises at least a first cartridge adapted to deliver a short coffee liquid extract, wherein the system comprises at least a second cartridge which has substantially the same external configuration and shape as the first cartridge so as to be capable of being received in the same receiving device as the first cartridge and which is adapted to deliver a longer coffee liquid extract upon allowing a larger amount of water to flow there trough, wherein the second cartridge for the longer coffee liquid extract is configured so that water flows through it at a higher rate than in the first cartridge during extraction.

Owner:SOC DES PROD NESTLE SA

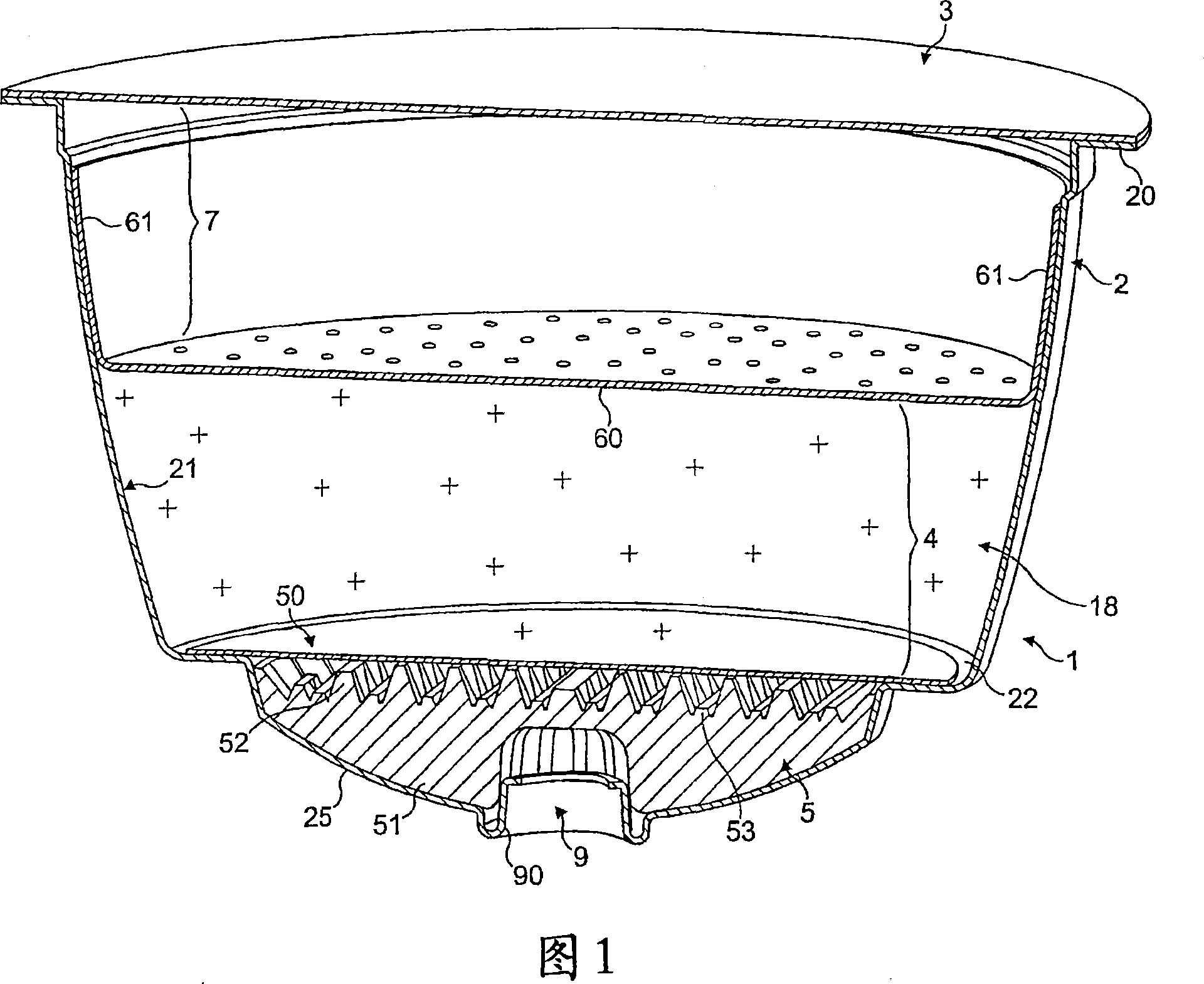

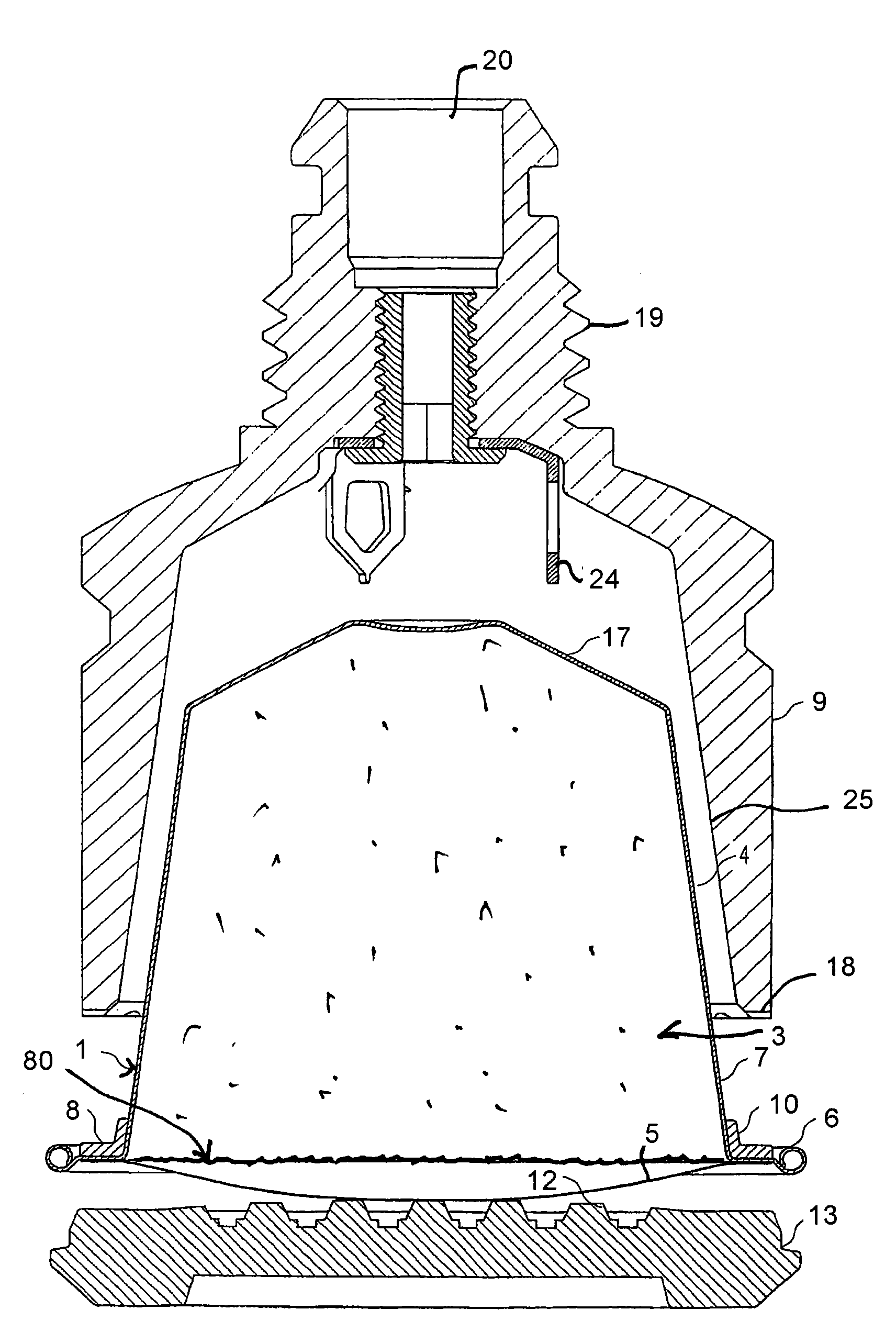

Capsule for preparing and delivering a drink by injecting a pressurized fluid into the capsule

InactiveCN101014513ADoes not cause precipitationAvoid mixingPackagingMultiple formsInternal pressure

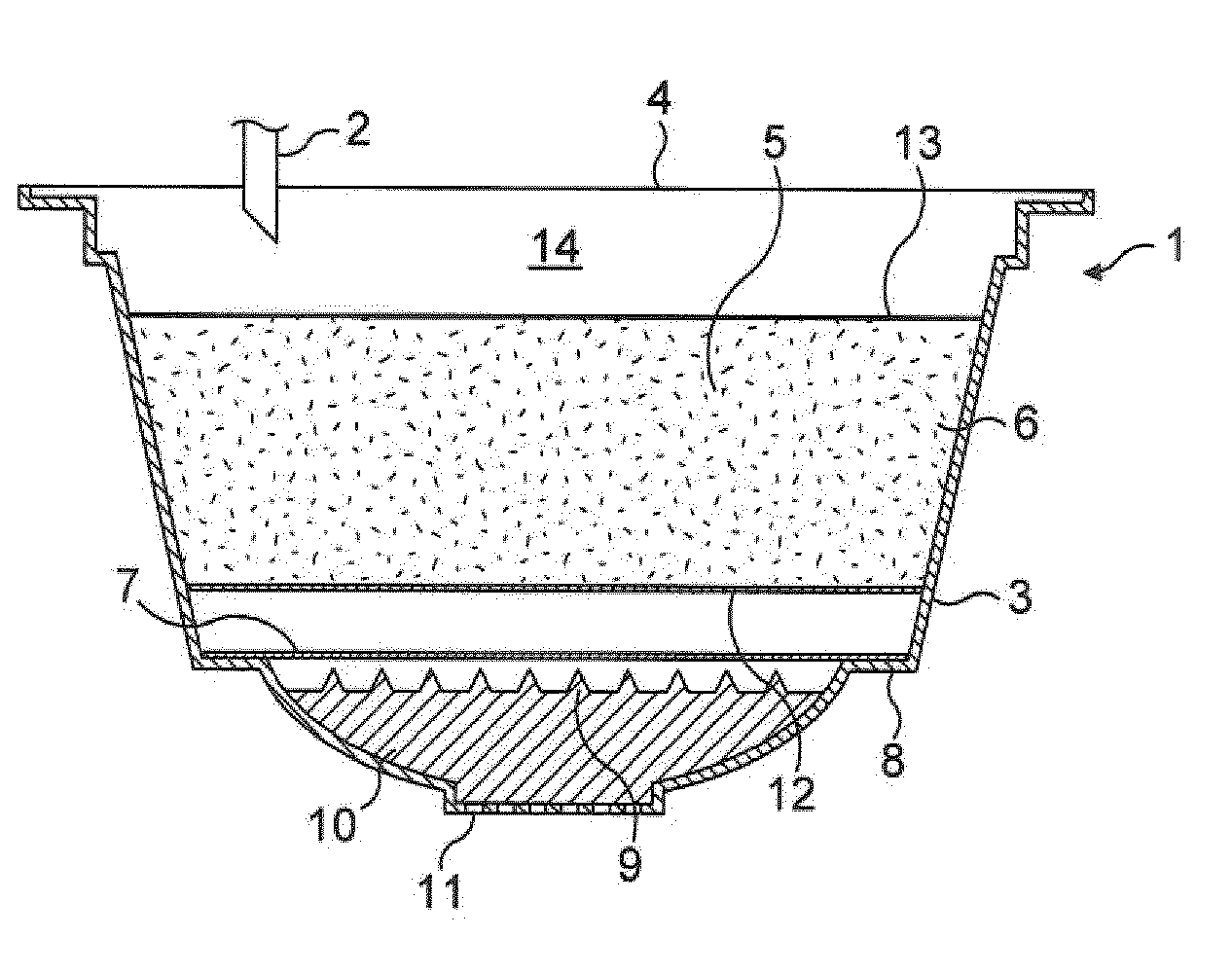

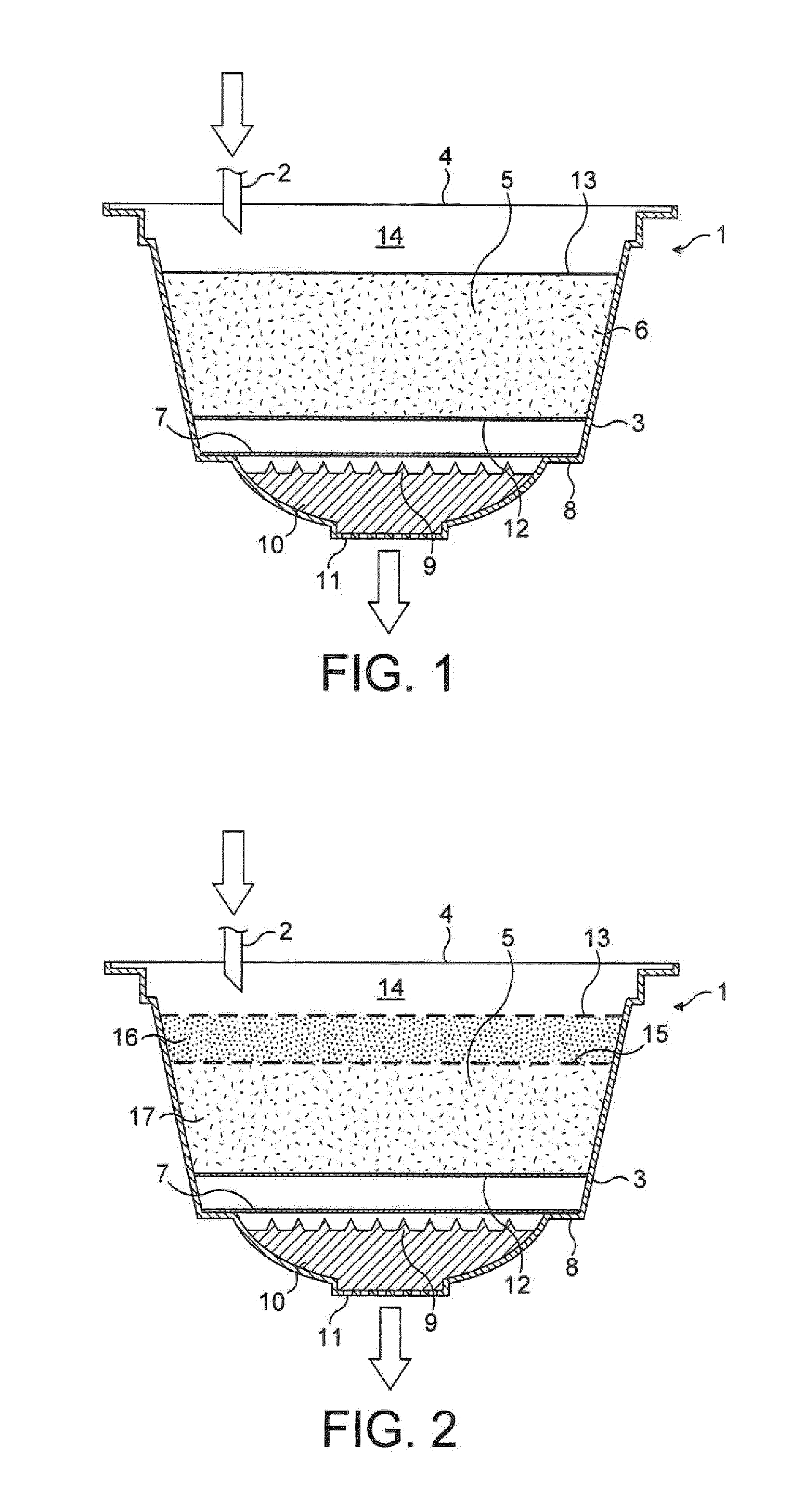

The invention relates to a capsule for delivering a drink by injecting a pressurized fluid comprising a body (2), an injection wall (3), a chamber (4) containing a bed of food substance to be extracted, means for retaining the internal pressure (5) in the said chamber. The improvement consists in the provision of an injection space (7) allowing a means of injecting fluid in the form of at least one jet of fluid to be introduced through the injection wall and in providing a means (6) for breaking the jet of fluid and distributing the distribution of fluid at a reduced speed across the surface of the bed of substance. These means may adopt various forms such as that of a rigid or flexible perforated wall, or a layer of discrete elements or a spongy layer. Such a capsule improves the flow of liquid extract through the pressure retaining means (5) and improves the extraction conditions.

Owner:NESTEC SA

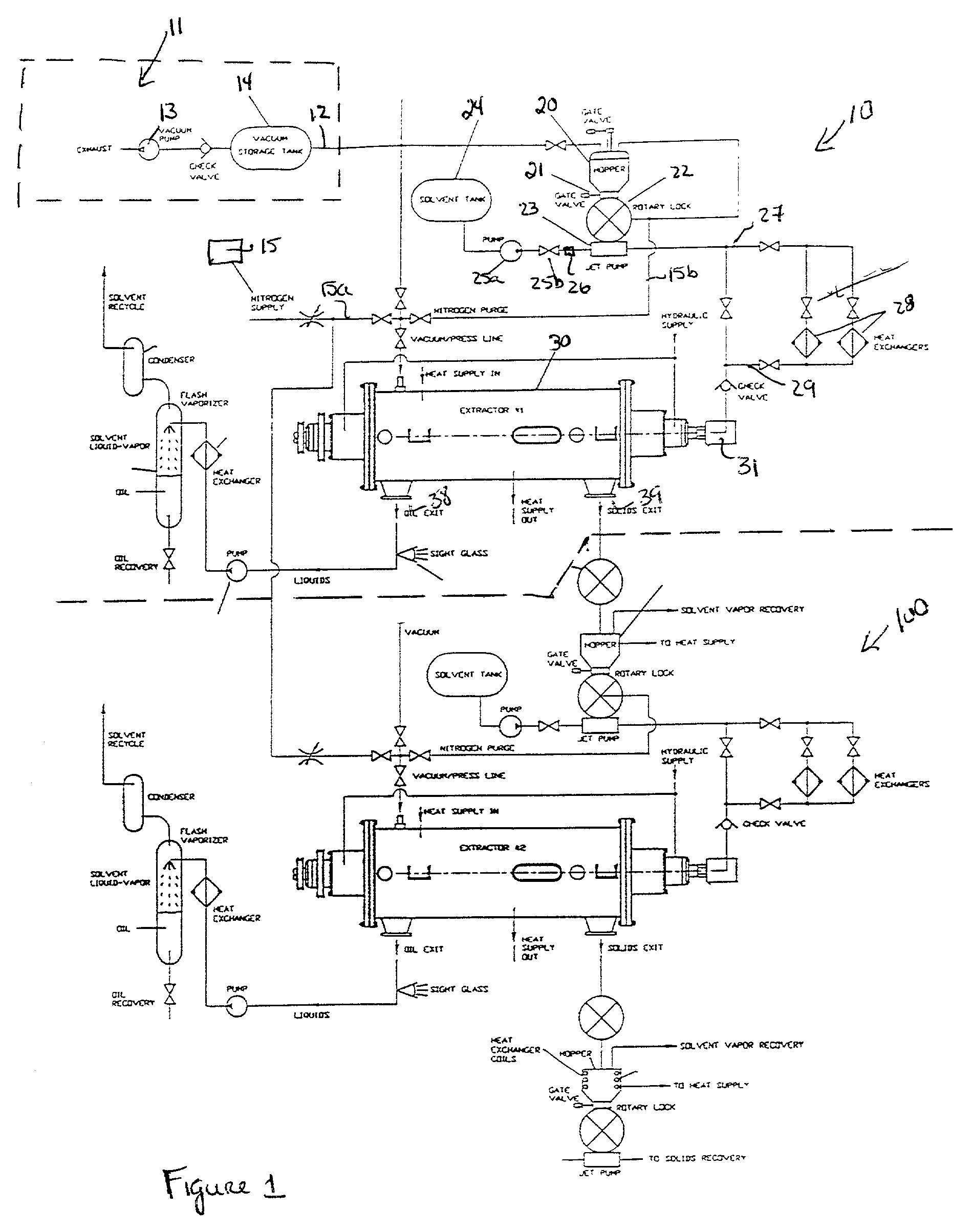

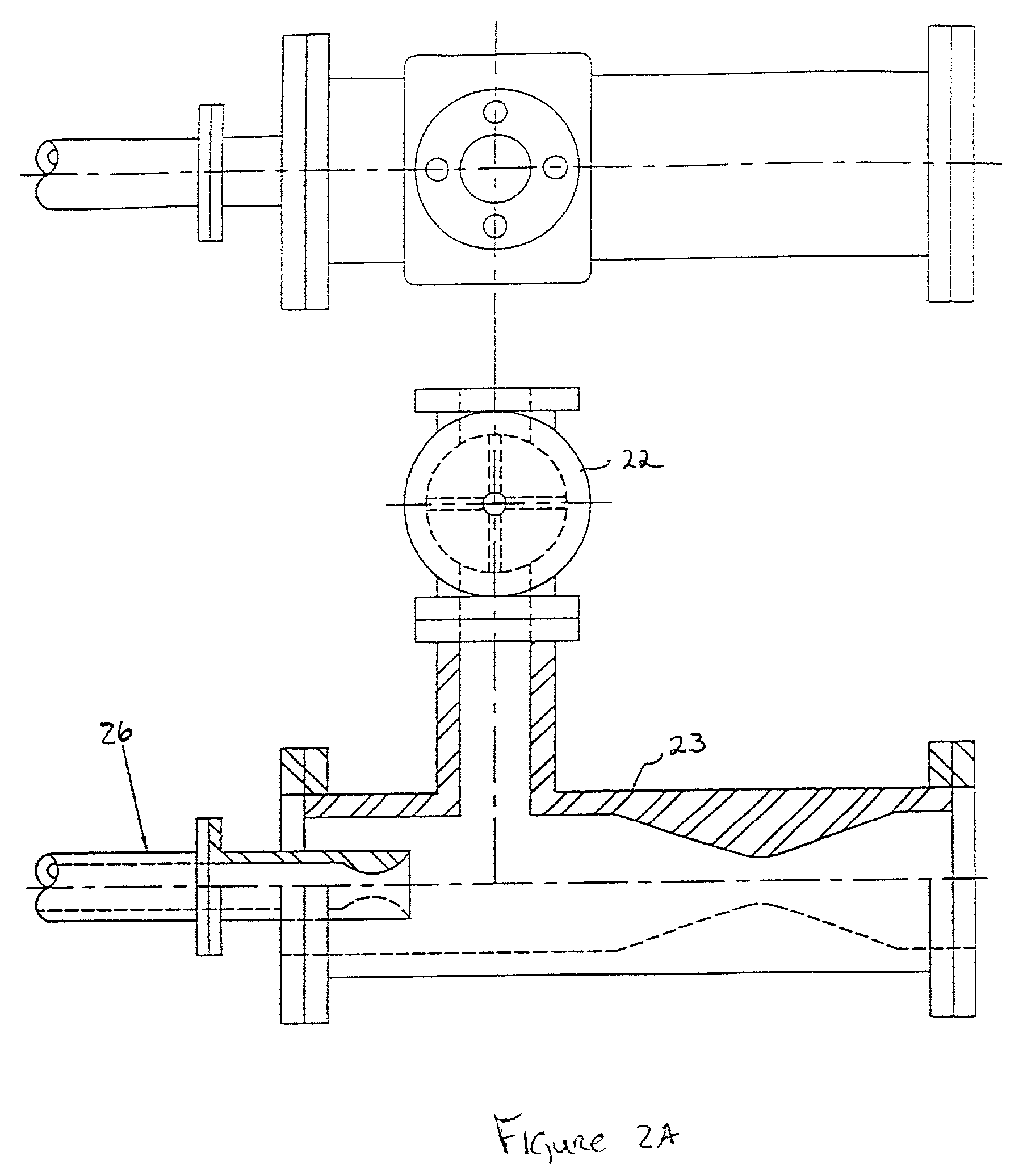

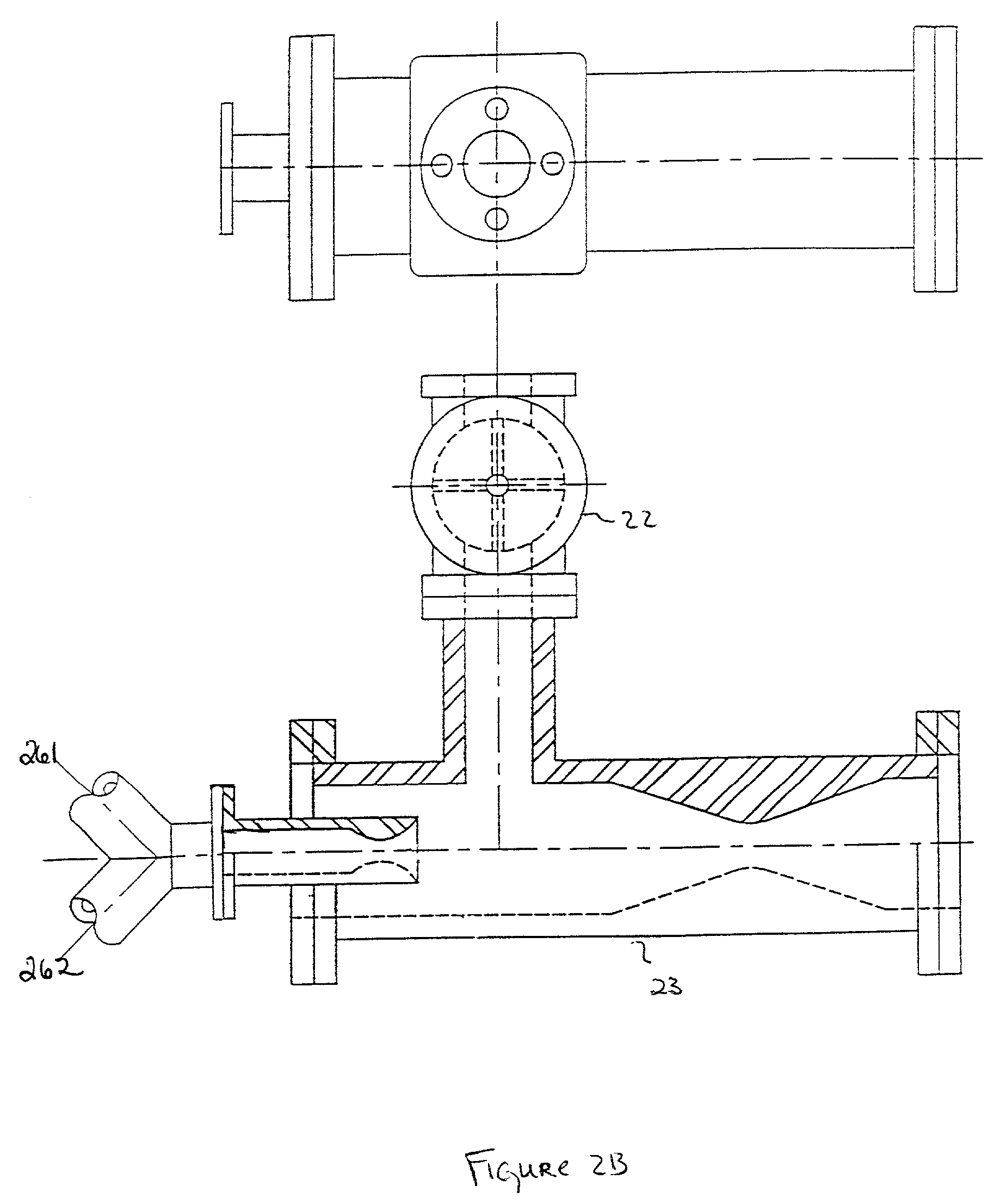

Process and system for continuously extracting oil from solid or liquid oil bearing material

InactiveUS7008528B2Eliminating formationEasy to optimizeRefining with acid-containing liquidsLiquid hydrocarbon mixture productionSufficient timeLiquid state

A process for continuously extracting oil from a solid or liquid oil-bearing material comprises (a) removing air from the extraction system, (b) introducing an inert gas into the extraction system at a pressure sufficient to maintain a normally gaseous solvent in liquid state, (c) introducing an oil-bearing material into a silo, (d) passing the oil-bearing material from the to a jet pump mixing device, (e) introducing a liquified normally gaseous solvent into the jet pump mixing device, (f) mixing the oil-bearing material and the solvent in the jet pump mixing device for a time sufficient to permit complete wetting of oil-bearing material by the solvent to form a mixture, (g) heating the mixture to near supercritical conditions; (h) passing the mixture through an extractor having a screw conveyor adapted to rotate at a first rpm range and a centrifugal drum adapted to rotate at a second rpm range, (i) treating the mixture within the extractor in such a manner that supercritical temperature and pressure are attained, wherein treating the mixture includes a combination of increasing the rpms of the centrifugal drum, increasing the temperature inside the extractor and increasing the inert gas pressure inside the extractor, (j) extracting oil from the mixture by pressure diffusion provided by the combination of increased rpms, increased temperatures and increased inert gas pressures at supercritical conditions, (j) removing liquids extracted from the mixture through a liquids exit port, and (k) removing solids extracted from the mixture through a solids exit port.

Owner:MITCHELL ALLEN R +1

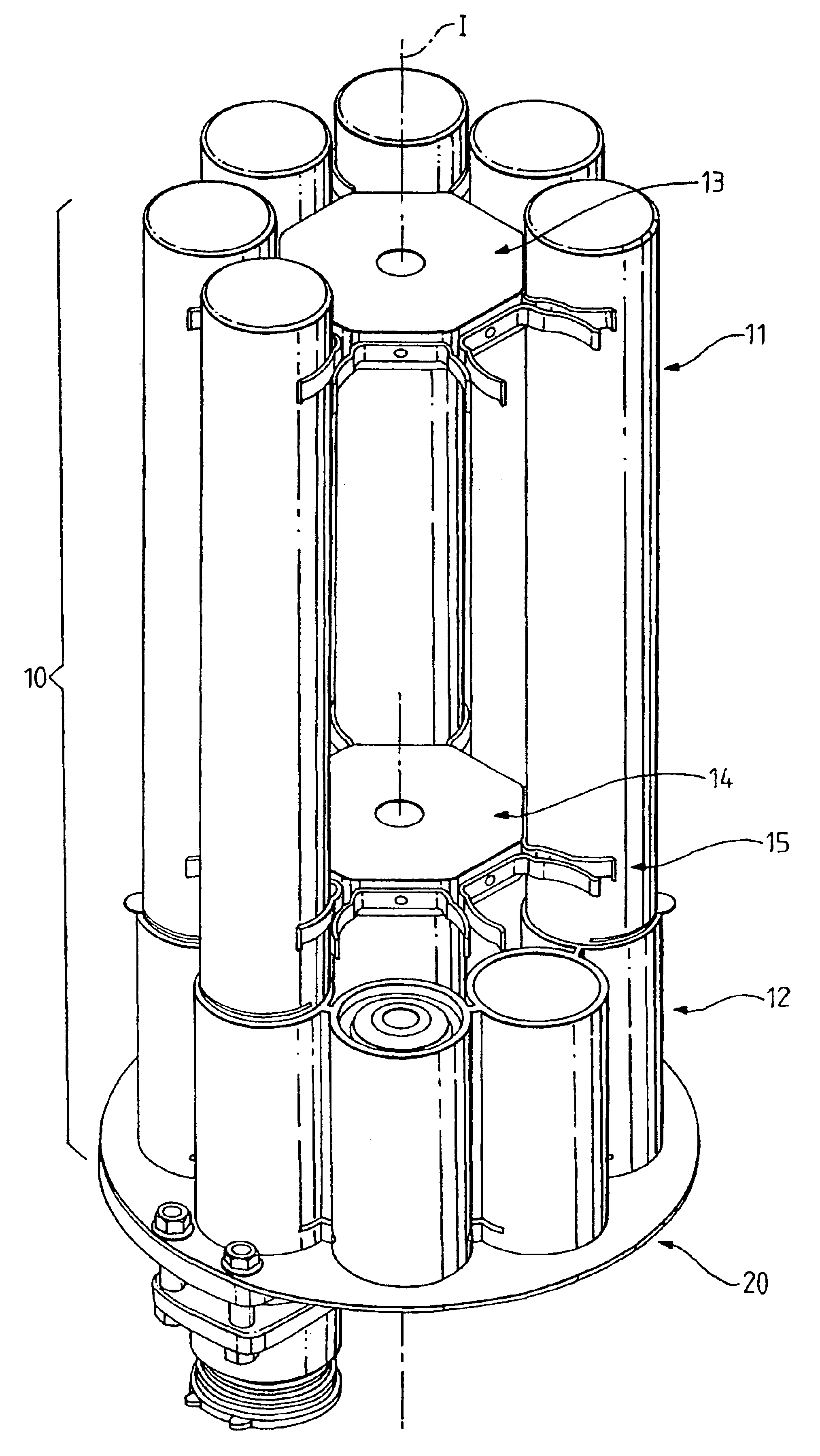

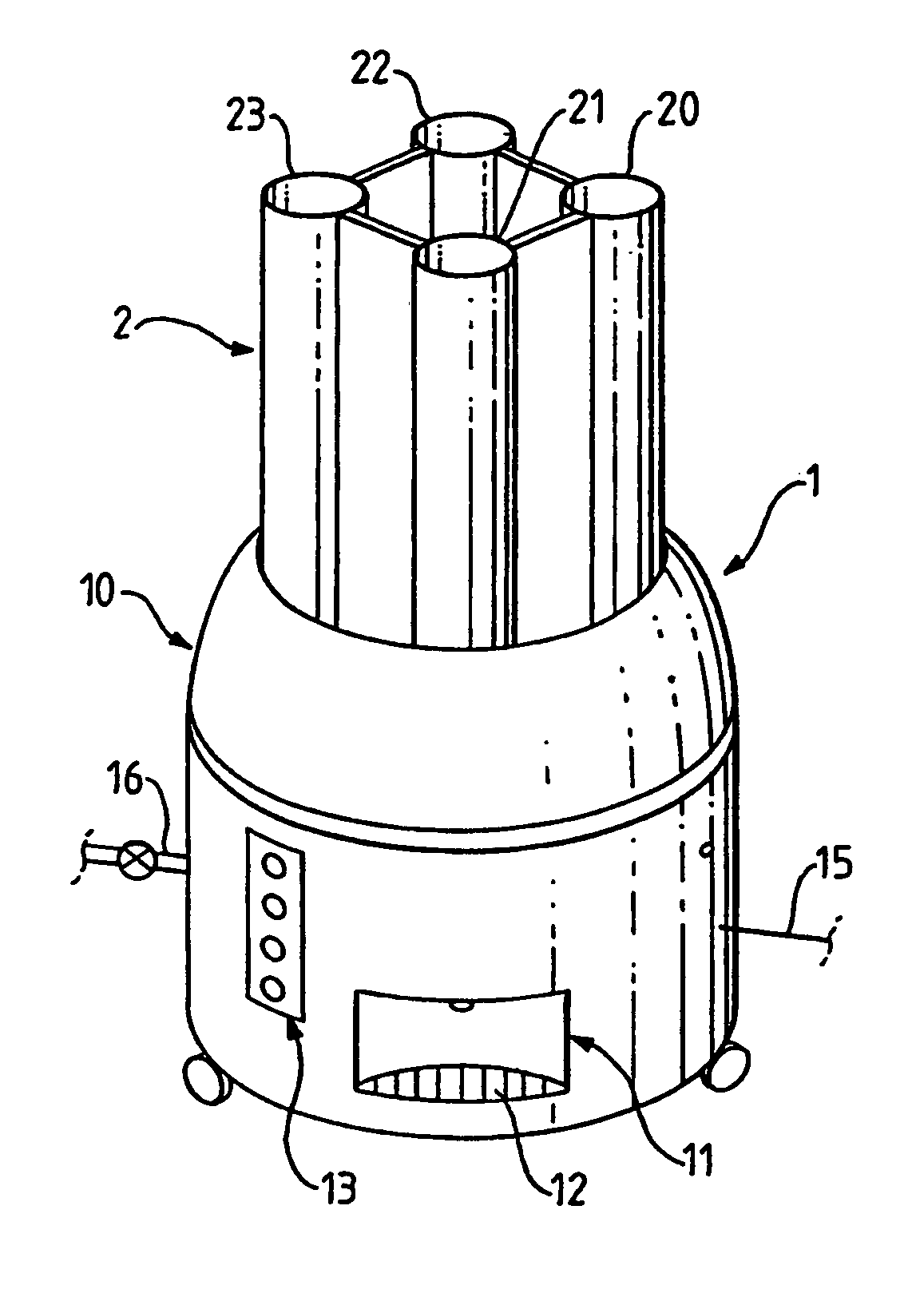

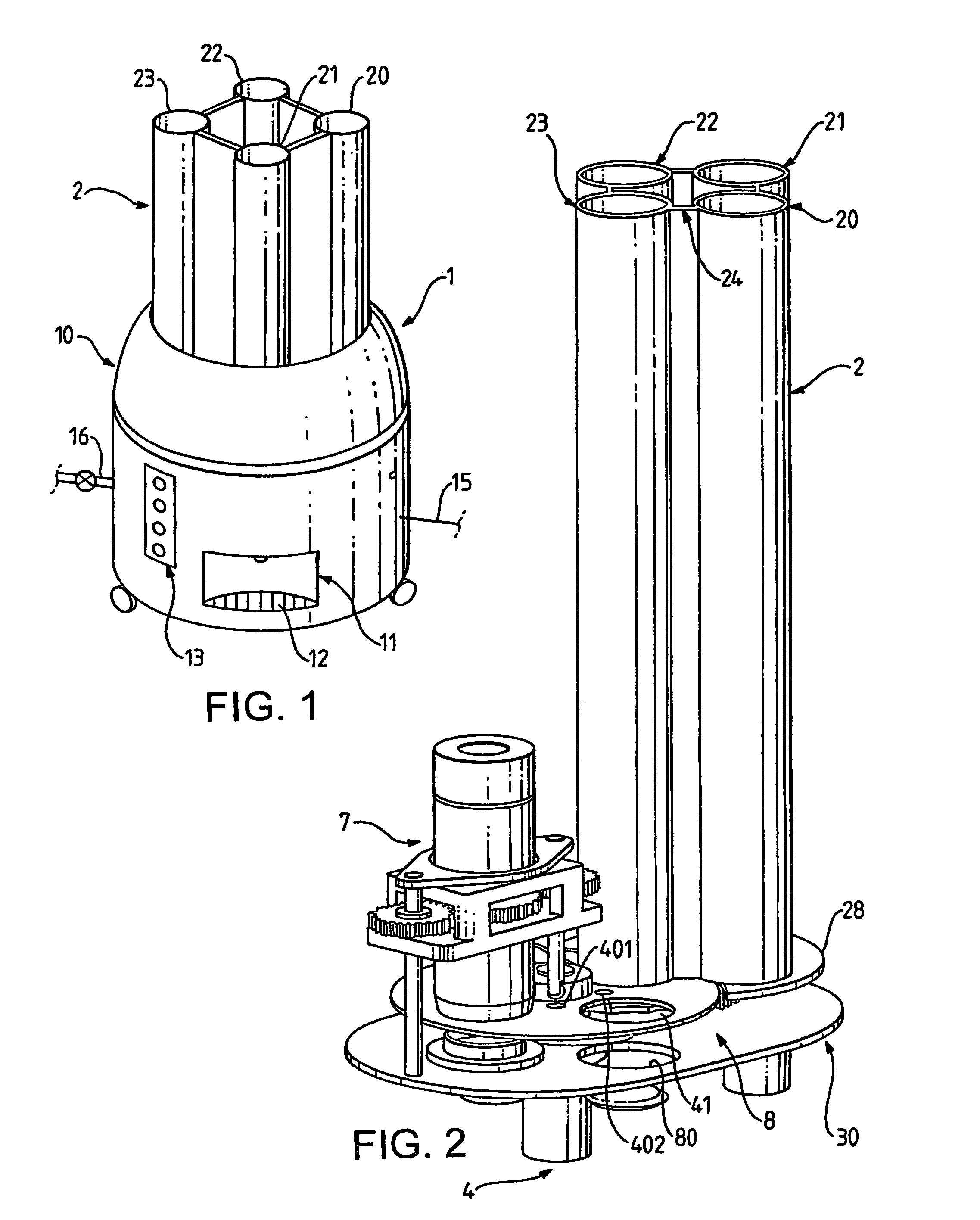

Extraction device with built-in capsule loading system

InactiveUS6941855B2Simpler and small and reliable in useCoin-freed apparatus detailsBeverage vesselsBiomedical engineeringLiquid extract

The invention relates to a device for feeding capsules containing a substance to be extracted in an extraction system under pressure for the preparation of a drink. The device includes a supply of capsules arranged in several series, and a mechanism for individually unloading one capsule into a reception part of the extraction system. The extraction system injects water into the capsule to form the drink as a liquid extract of the substance. The reception part is arranged beneath the unloading mechanism in such a way as to allow the direct descent of the released capsule into the reception part and includes structure for opening the capsule for releasing the liquid extract therefrom.

Owner:SOC DES PROD NESTLE SA

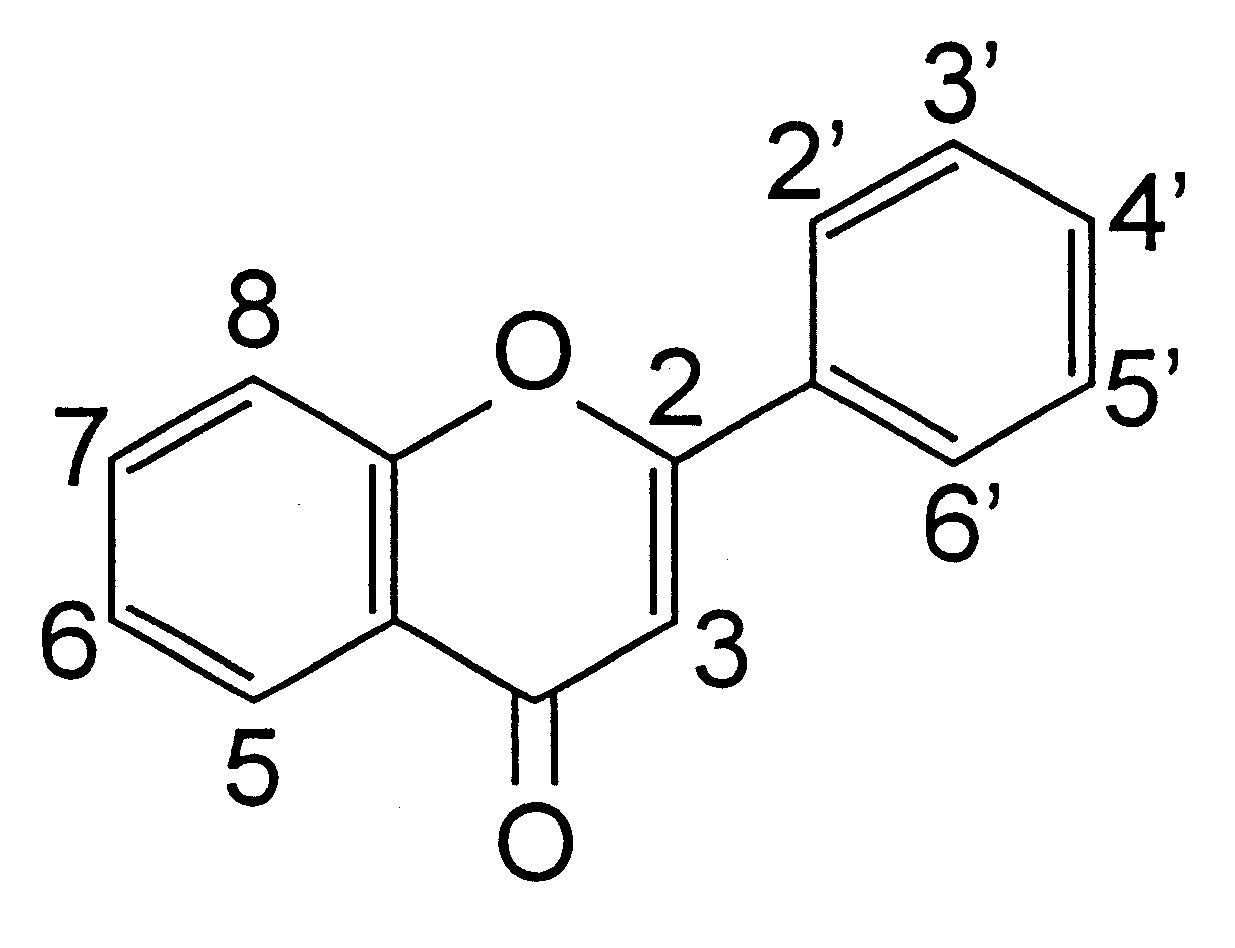

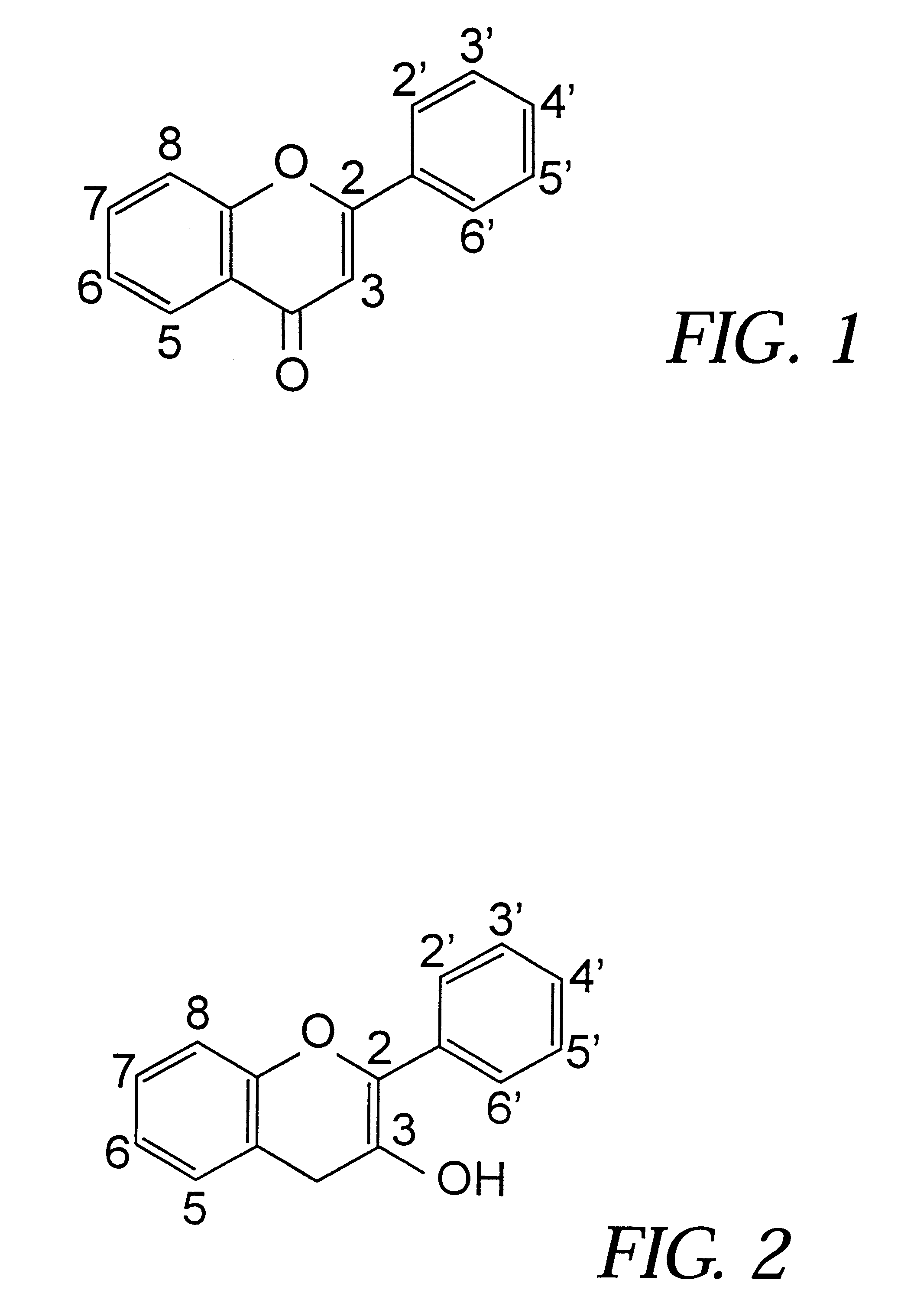

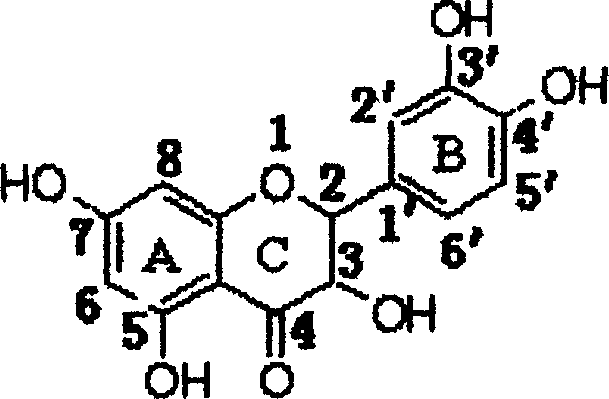

Method of producing high flavonol content polyphenol compositions

Disclosed is a method of producing a polyphenol-containing composition derived from grapes, the method including: preparing a liquid grape extract which includes polyphenols; contacting the liquid extract with a separation medium which fractionates the components of the extract; and recovering that fraction in which the polyphenols are present. Also disclosed is a method of enriching the composition with added flavonol.

Owner:HOWARD FOUND

System for dispensing short and long coffee beverages

A beverage system for selectively delivering, in a same coffee extraction device, short coffee liquid extracts and long coffee liquid extracts comprising: cartridges containing ground coffee; a receiving device for receiving one cartridge at a time and pumping means or injecting water under pressure in the cartridge; means for opening the cartridge wherein these means comprises retaining means to retain the liquid under pressure in the cartridge and engaging means which engage the retaining means to open the cartridge and deliver the coffee liquid extract; wherein the system comprises at least a first cartridge adapted to deliver a short coffee liquid extract, wherein the system comprises at least a second cartridge which has substantially the same external configuration and shape as the first cartridge so as to be capable of being received in the same receiving device as the first cartridge and which is adapted to deliver a longer coffee liquid extract upon allowing a larger amount of water to flow there trough, wherein the second cartridge for the longer coffee liquid extract is configured so that water flows through it at a higher rate than in the first cartridge during extraction.

Owner:SOC DES PROD NESTLE SA

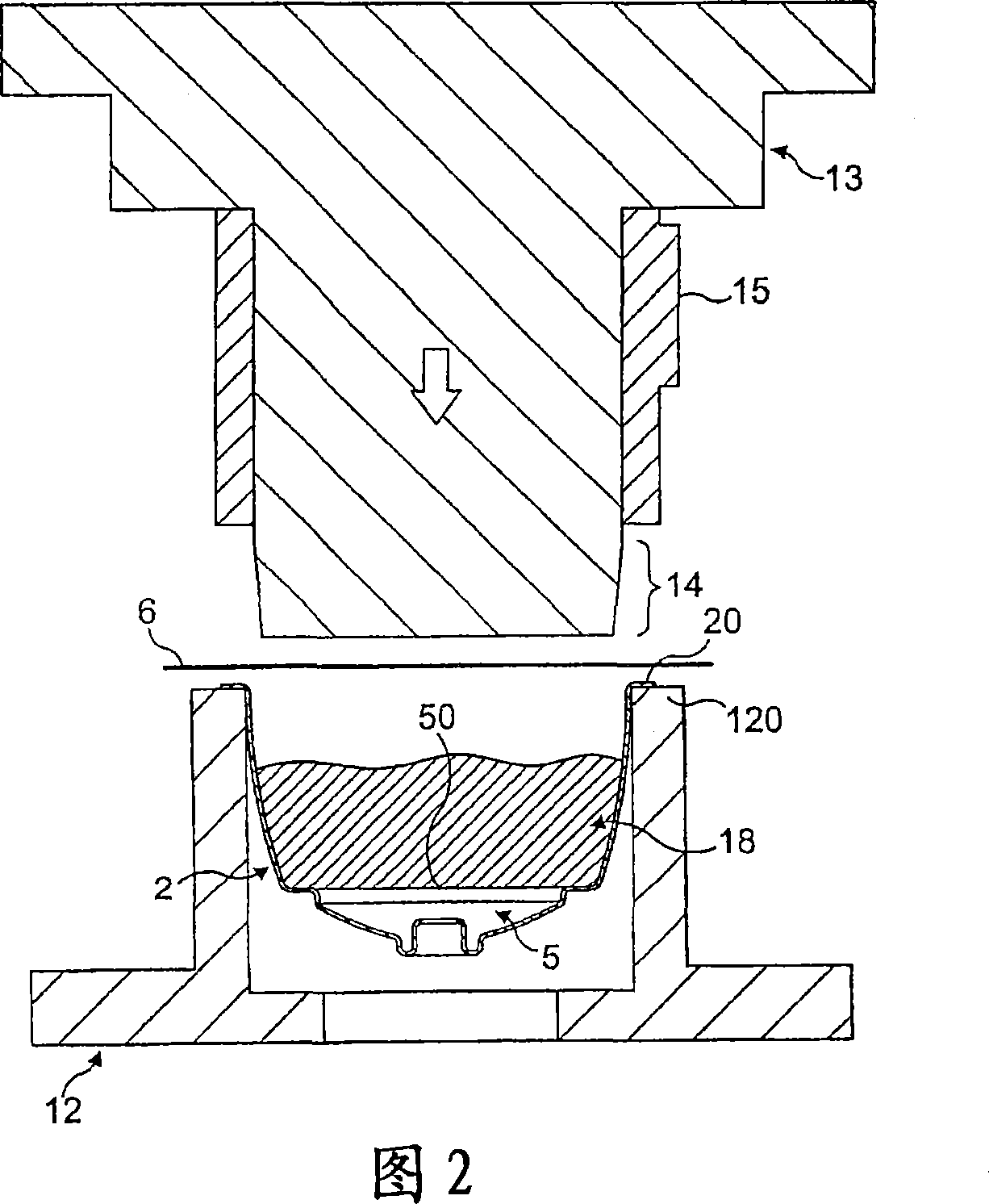

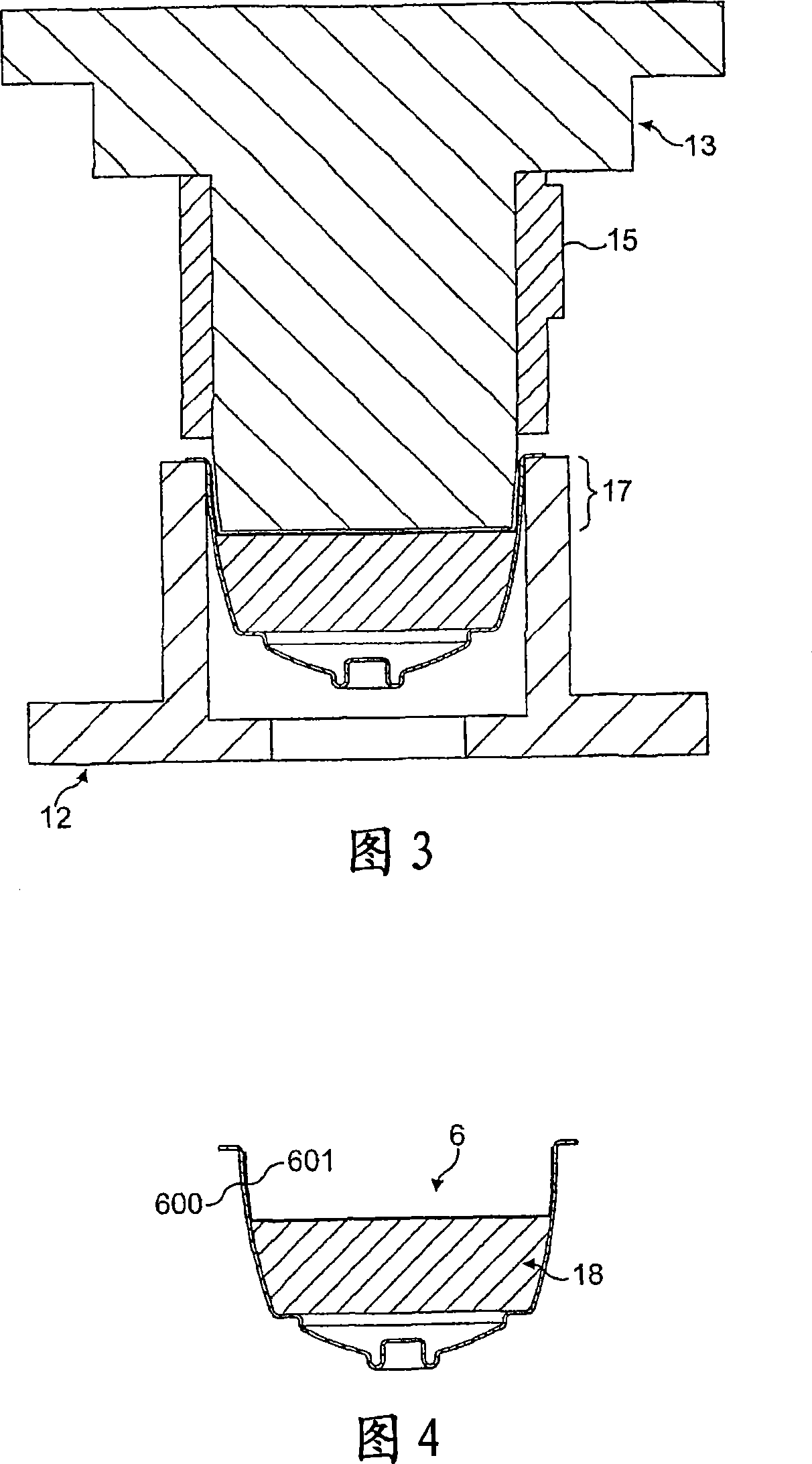

Capsule for preparation of a beverage

InactiveUS20130216663A1Control deformationReady-for-oven doughsContainers with multiple articlesInternal pressureInjection device

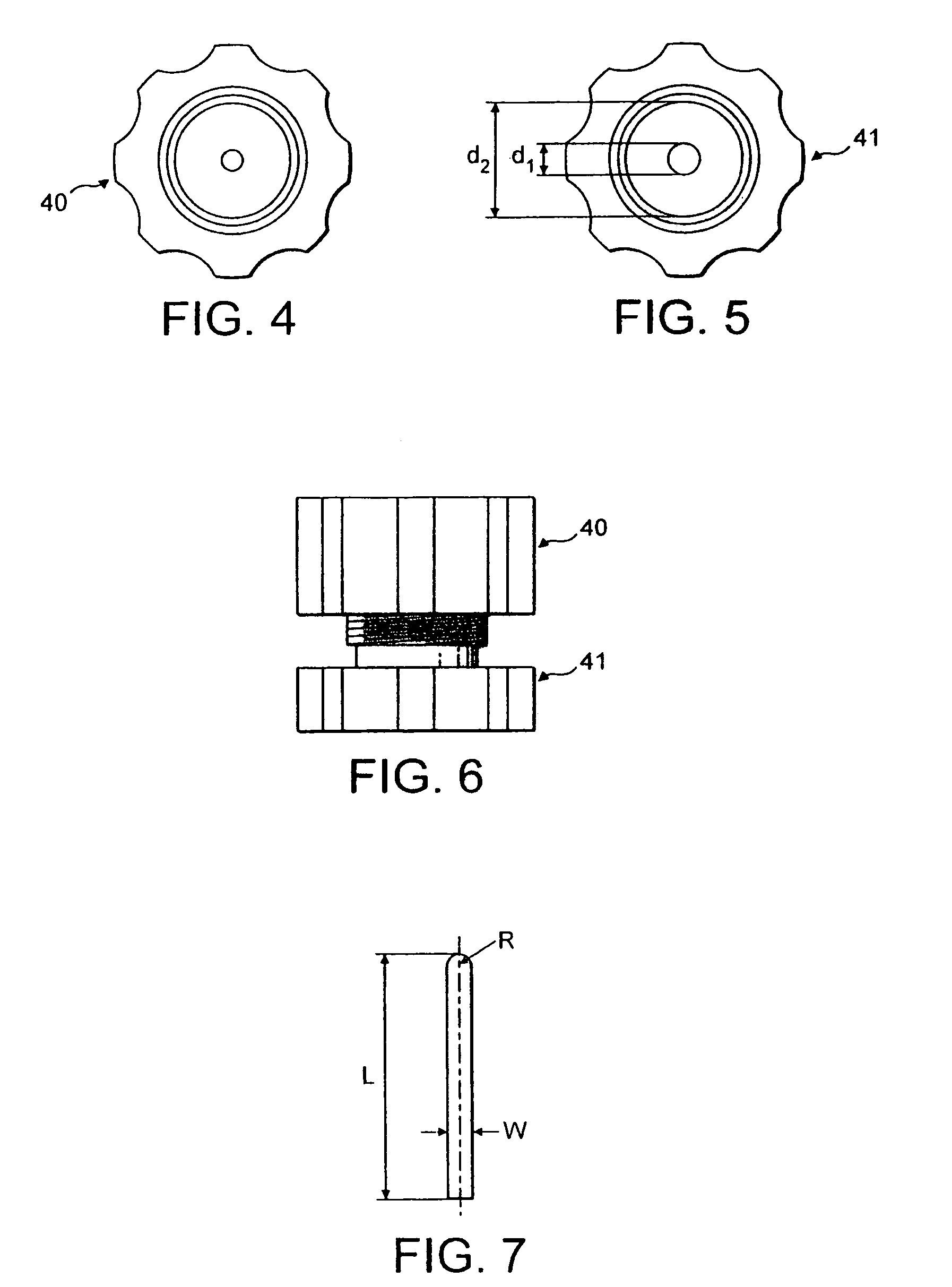

The present invention is directed to a capsule (1) for delivering a drink by injecting a pressurized fluid into the capsule comprising: a hollow body and an injection wall (4) which is impermeable to liquids and to gas and which is attached to the body and adapted to be punctured by an injection means (2) foreign to the capsule, a chamber (5) containing a bed of at least one food substance to be extracted, means (7, 9, 10) for retaining the internal pressure in the said chamber, said means comprising a pierceable membrane (7), characterized in that said capsule (1) further comprises a secondary means (12) for maintaining the bed of substance at a distance d from said pierceable membrane (7), said distance d being at least 1 mm, preferably at least 2 mm, more preferably at least 3 mm, and in that the pressure retaining means comprise: the pierceable membrane (7), raised elements (9) which open the said membrane (7) in order to create punctures and allow the liquid extract to pass through the punctures; the punctures in the membrane (7) being obtained under the effect of the rise in pressure in the chamber (5) of the capsule (1).

Owner:NESTEC SA

Method for extracting tobacco essence perfume

InactiveCN1899141AImprove qualityImprove inner qualityTobacco treatmentEssential-oils/perfumesFlavorReflux

The tobacco flavor extracting process includes the following steps: 1. crushing tobacco and setting in extracting tank; 2. adding solvent in 2-16 times the weight of tobacco to the extracting tank; 3. decompression reflux extracting at 20-60deg.c temperature and 0.020-0.098MPa vacuum degree for 1-8 hr; and 4. separating the liquid extract through filtering, and decompression concentrating the filtrate at vacuum degree of 0.020-0.098MPa to obtain the tobacco flavor of density 1.1-1.4g / ml. The extracting process is simple, safe, environment friendly, high in extracting efficiency and low in production cost, and the extracted tobacco flavor has the physical and chemical properties of natural tobacco components and may be added to cigarette to improve flavor, raise quality and lower tar.

Owner:宋光泉 +1

Water Dispersible Composition and Method for Preparing Same

InactiveUS20080254153A1Promotes skin healthProtect the skinOrganic active ingredientsCosmetic preparationsFood supplementWater dispersible

The invention pertains to a water dispersible, preferably a powder composition of water extractible bioactive components of exclusively fruit or vegetable or plant origin. These components are obtainable by: a) subjecting a selected fruit or vegetable or plant material to homogenisation in weak alkaline conditions and at moderate temperature; b) separating the liquid extract from the homogenised mass and subsequently bringing it to neutrality; and c) eventually concentrating or drying, preferably by freeze drying, the neutralized liquid extract. The composition can be used as primary composition in the preparation of a food product for oral administration, a food supplement, a pet food product, a pet food supplement, a cosmetic preparation or a pharmaceutical preparation.

Owner:NESTEC SA

Extract powder of indigo plant, and its preparation and uses

InactiveUS20100034757A1Easy to handleScarcely hygroscopicAntibacterial agentsCosmetic preparationsHydrolysateLiquid extract

The present invention has objects to provide an extract powder of indigo plant, which has a relatively low hygroscopicity, satisfactory fluidability, and improved storage stability; a process thereof; and a composition incorporated with the extract powder. The objects are solved by a process for producing an extract powder of indigo plant, which comprises incorporating a partial starch hydrolyzate with a dextrose equivalent of 10.2 or lower into one part by weight, on a dry solid basis, of an indigo plant extract contained in a liquid extract of indigo plant in an amount of not lower than 0.25 part by weight but not higher than 5 parts by weight, on a dry solid basis, and drying the resulting mixture; an extract powder of indigo plant prepared thereby; and a composition incorporated with the extract powder.

Owner:HAYASHIBARA BIOCHEMICAL LAB INC

Once process for extracting and separating Ni, Mg and Co from nickel sulfate solution recovered from waste nickel-hydrogen and nickel-cadmium cells

ActiveCN1752232AEliminates steps to remove magnesiumLow costProcess efficiency improvementHydrogenKerosene

A process for extracting Ni, Mg and Co from the used NiH or NiCd battery includes such steps as immersing the positive electrodes of used NiH or NiCd batteries in sulfuric acid to obtain liquid extract, regulating pH=4.5-5.0, fractionating to transfer Mg and Co in the organic phase prepared from bis-(2-ethylhexyl) phosphonate mono-(2-ethylhexyl) ester and kerosene and to retain Ni in water phase, respectively washing Ni and Mg, and draining the Mg washing liquid from another outlet.

Owner:广东芳源新材料集团股份有限公司

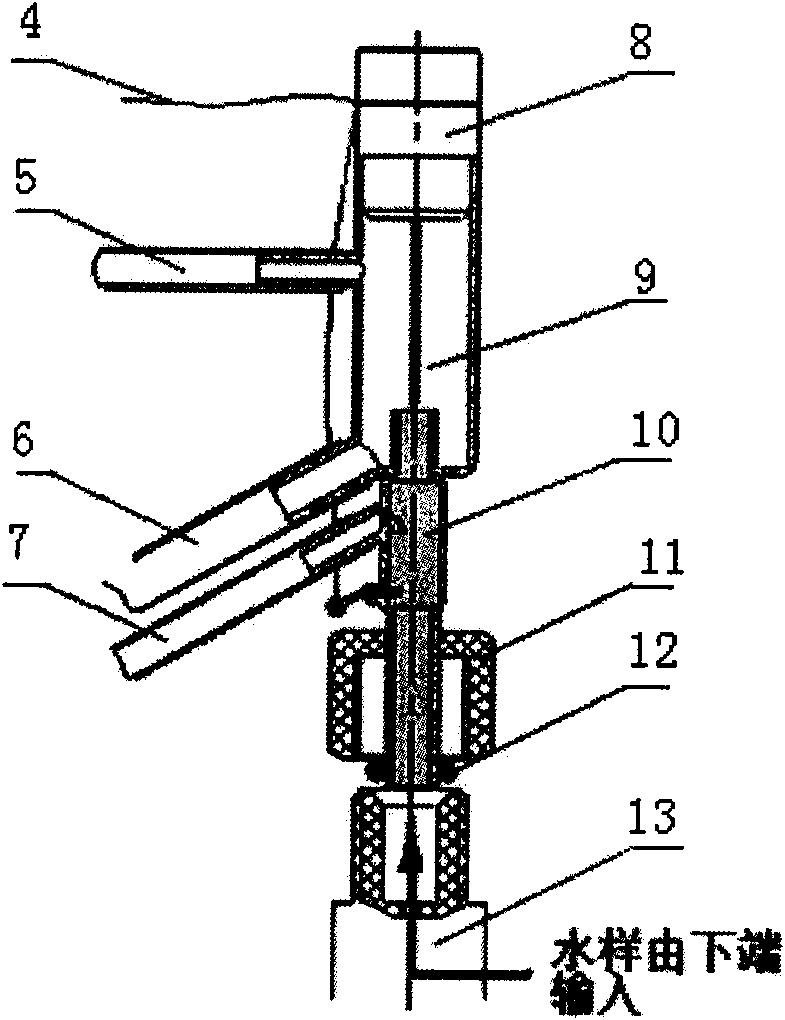

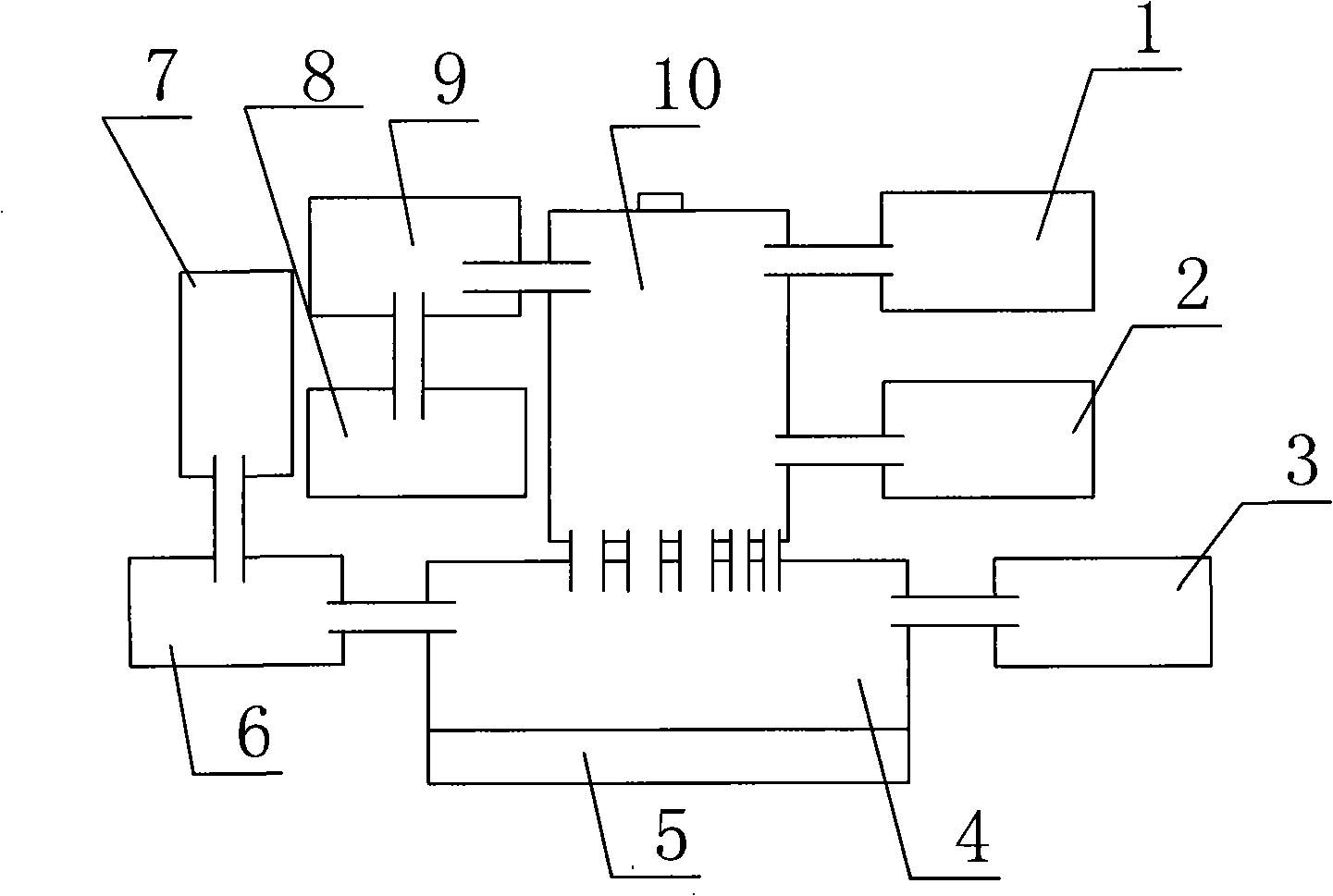

Accurate liquid extracting and metering device and method

ActiveCN101655423AEfficient screeningSimple program controlWithdrawing sample devicesCapacity measurement calibrationEngineeringLiquid extract

The invention discloses an accurate liquid extracting and metering device and a method. The device comprises a pump, a valve unit, an electromagnetic stop valve, a liquid storing unit, a testing module, a liquid detector A and a liquid detector B, wherein the valve unit is provided with a liquid inlet passage, a testing passage, a liquid discharging passage and a common passage connected with theliquid storing unit; the liquid inlet passage of the valve unit is connected with liquid; the testing passage is connected with the testing module; the liquid discharging passage is connected with a waste liquid collecting device; the common passage is connected with one end of the liquid detector A by the electromagnetic stop valve, and the other end of the liquid detector A is connected with oneend of the liquid storing unit; the other end of the liquid storing unit is connected with one end of the liquid detector B, and the other end of the liquid detector B is connected with the pump.

Owner:YIWEN ENVIRONMENTAL SCI & TECH GUANGZHOU

Method of extracting phenolic components from chinese medicine red sage root and its freeze dried powder injection agent

ActiveCN1513848AAvoid damageImprove transfer ratePowder deliveryOrganic active ingredientsSalvia miltiorrhizaAcetic acid

A process for extracting danshinolic acids A and B from red sage root includes soaking in hot water, collecting liquid extract, centrifugal separating, ultrafiltering of supernatant, extracting by reverse-phase column or acetate, acidifying, separating organic phase to recover solvent, and separating by reverse-phase column. A freeze dried injection for preventing and treating liver injury and hepafibrosis is prepared from said danshinolic acids A and B and additives. Its advantages are high purity and high output rate.

Owner:YANGTZE RIVER PHARM GRP CO LTD

Extract of mulberry twig and its extracting process and novel usage

An extract of mulberry twigs is dislcosed, which can be used to prepare the food or the medicine to cure hyperuricemia and gout diseases. The said extract is prepared from mulberry twigs through extracting in solvent (aqueous solution of alcohol, chloroform, acetone, etc) at 10-100 deg.C more than one time, mergint the liquid extracts, recovering solvent, regulating pH value to 7.5-9.5, centrifugal separation to obtain supernatant, regulating pH value to 4-6, deposition, water washing wand drying. Several other approaches for purifying it are also disclosed.

Owner:NANJING UNIV +1

Extracting process for seaweed plant growth hormone

InactiveCN1351830AImprove qualityIncrease productionPlant growth regulatorsBiocideBetaineEvaporation

The present invention relates to an extracting process of biochemical matter and is an extraction of betaine and its analog from seaweed. The technological scheme has a technological process including six steps, that is, washing fresh seaweed to remove impurities, adding absolute alcohol before pulping and filtering, extraction, evaporation to remove water, alcohol and pigment, centrifugation to separate salt and obtain crude liquid extract, and adding excessive fulminate for precipitation. The present invention has the advantages of simple technological process, low extraction cost, comprehensive utilization of seaweed resource, etc.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

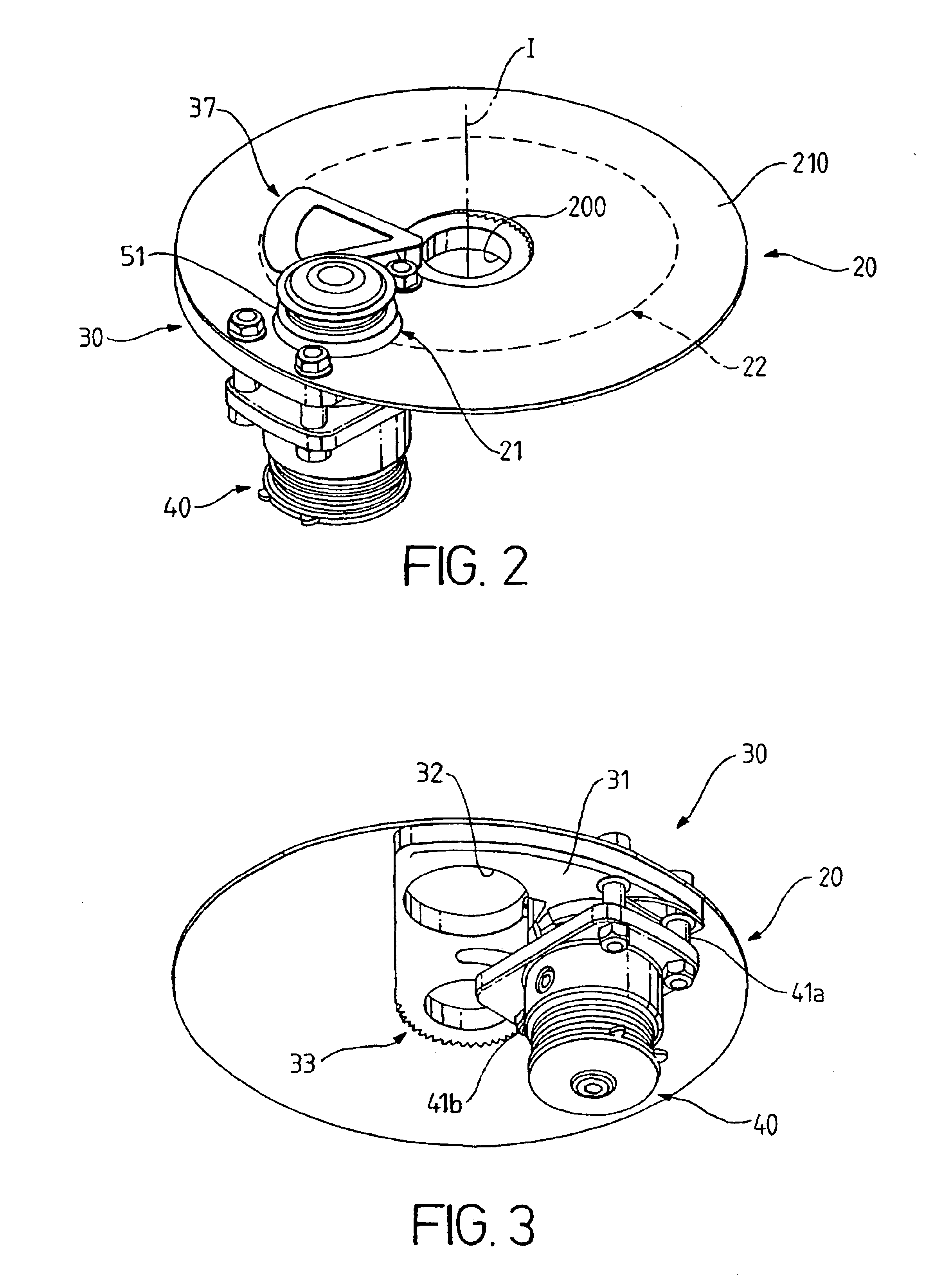

Method and system for preparing a liquid extract from a cell using centrifugal forces

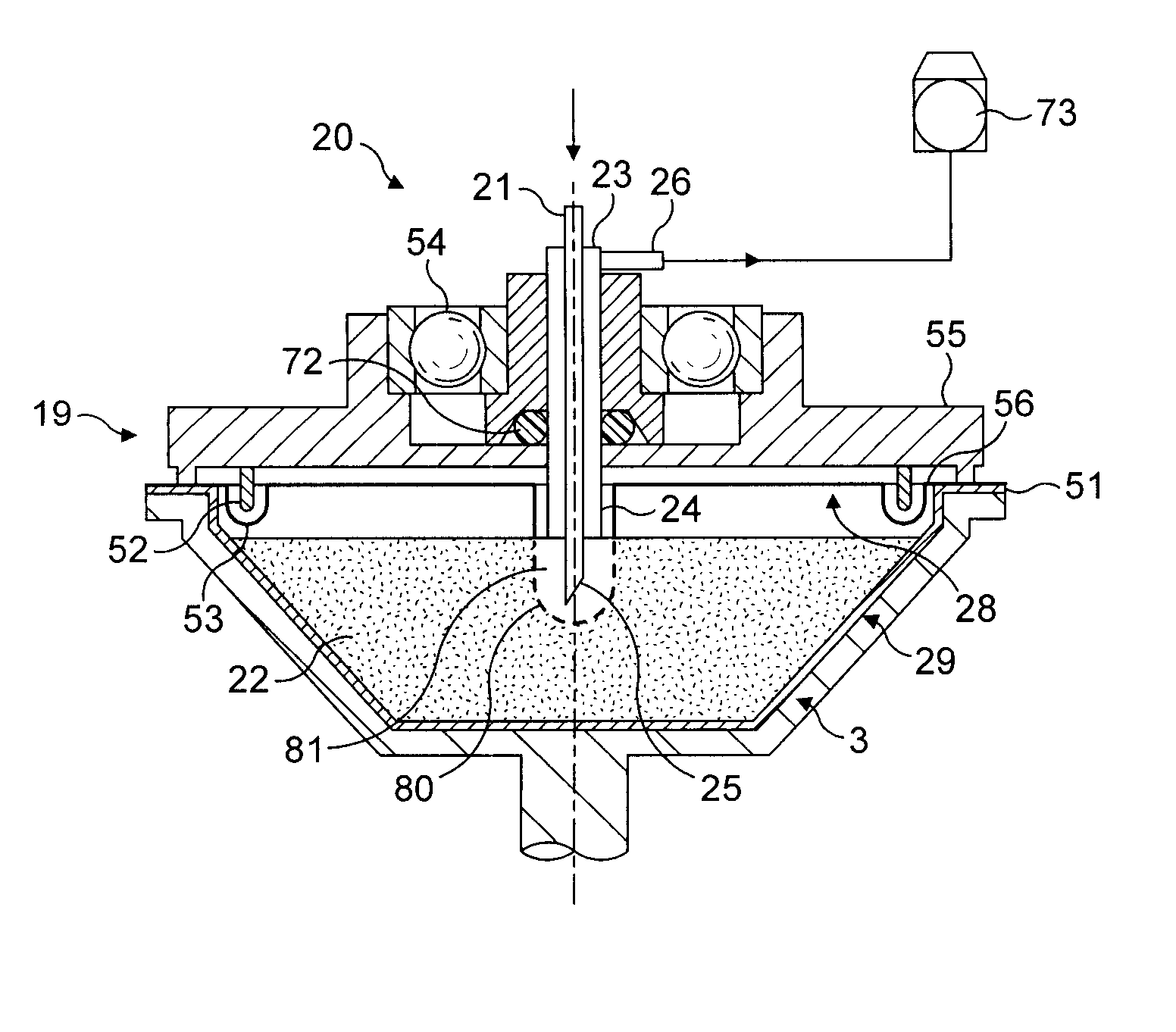

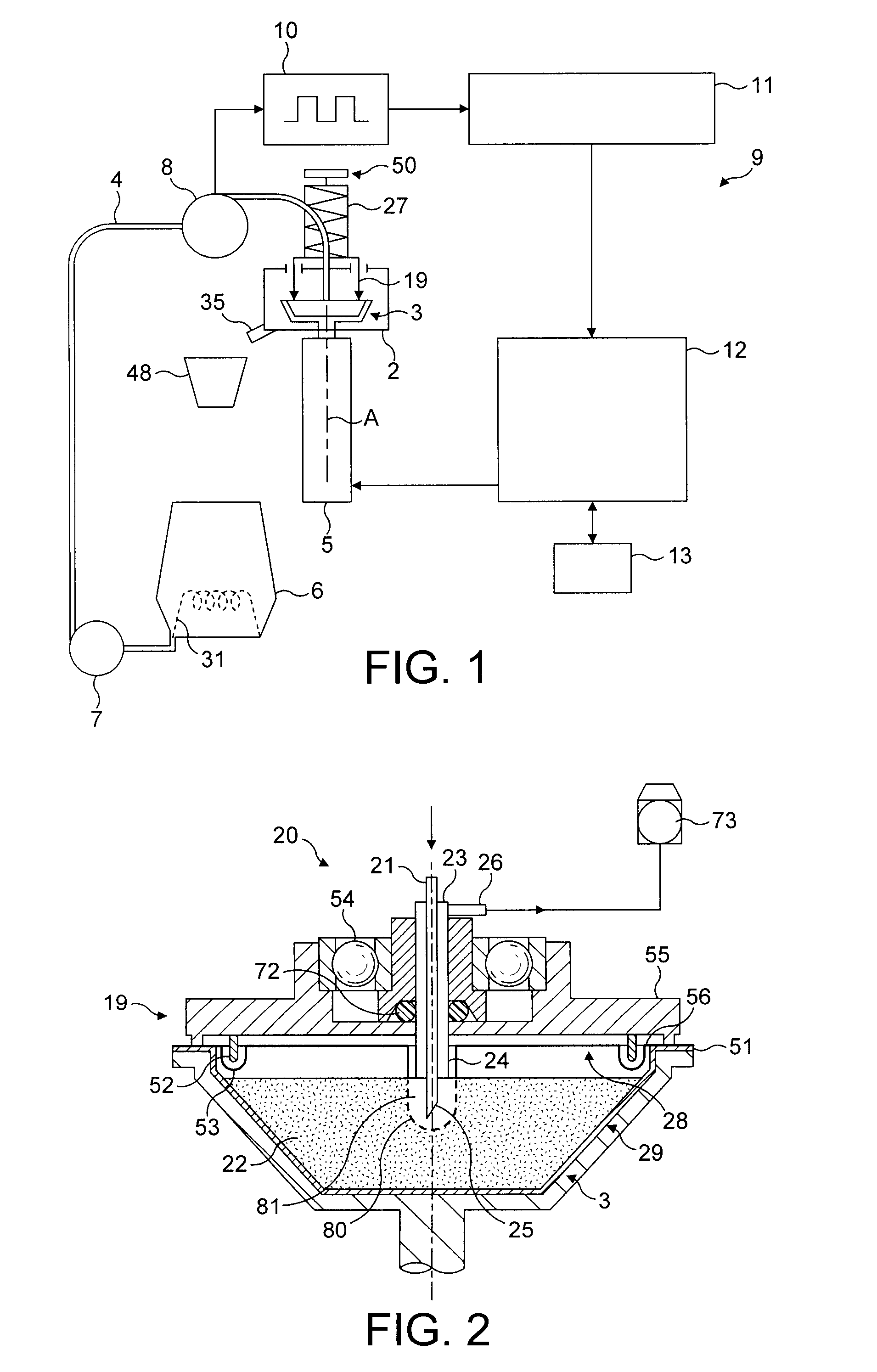

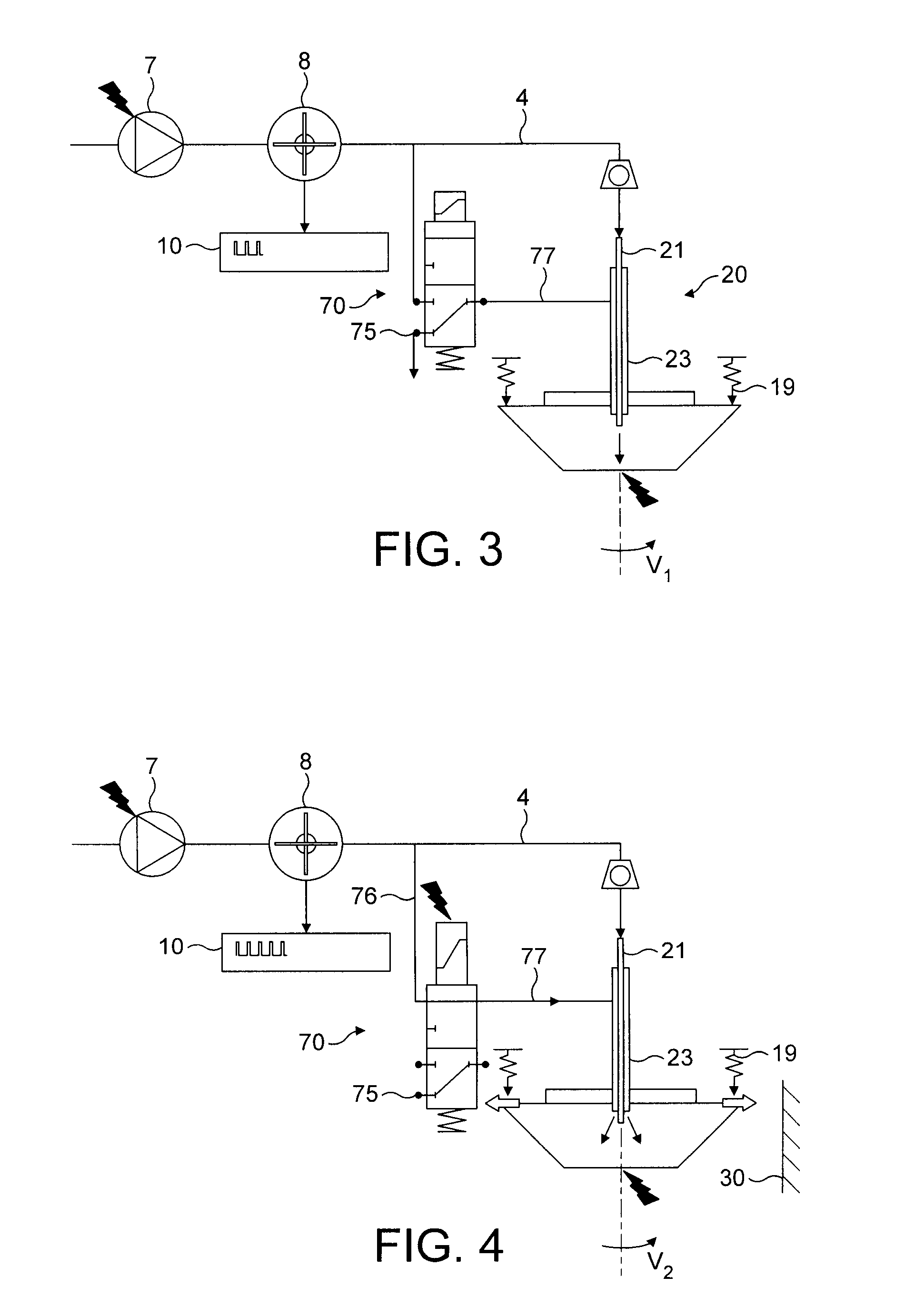

InactiveUS8475860B2Prevent exitEasy extractionMixing methodsBeverage vesselsSubstance useProduct gas

A method for preparing a liquid comestible from a cell by passing liquid through the substance using centrifugal forces, wherein gas contained in the cell is controllably purged from the cell as liquid fills the cell. In one embodiment, the method includes prewetting the substance in the cell by filling liquid in the cell and rotating the cell at a first rotational speed; and then extracting the liquid comestible from the cell in an extraction phase which comprises continuing to fill liquid into the cell and rotating the cell at a second rotational speed that is higher than the first rotational speed. The invention also discloses a cell for use in these methods which cell includes a filter for preventing solids from being carried by gas during the gas purge.

Owner:SOC DES PROD NESTLE SA

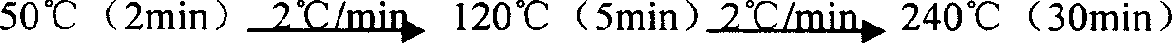

Method of manufacturing cordyceps sinensis (Berk.) sacc polysaccharide by liquid state fermentation of rice bran and bran complete feed

A manufacturing method for cordyceps sinensis (Berk.) sacc polysaccharide relates to the technical field of food microorganism application, and comprises the following steps: weighing raw materials, wherein rice bran is 1-3 g per 100 ml, bran is 1-3 g per 100 ml, potassium dihydrogen phosphate is 0.09-0.18 g per 100 ml, and magnesium sulphate is 0.04-0.08 g per 100 ml; material filling with natural pH after adding required water, and sterilizing and cooking at the temperature of 121 DEG C for 30 min; inoculating cordyceps sinensis (Berk.) sacc CCTCCM2013285 liquid seed after cooling, wherein the inoculation amount is 8-10%, the fermentation temperature is 23-28 DEG C, and the fermentation time is 4-7 d; respectively obtaining exopolysaccharides and mycelia polysaccharide after conducting deproteinization, alcohol precipitation, centrifugal separation, and vacuum drying on centrifugal separation liquid extracted through breaking cell wall hot water of fermentation material centrifugal separation liquid and hypha. The method better realizes the purpose that rice bran and bran are efficiently and high-valuedly transformed to cordyceps sinensis (Berk.) sacc polysaccharide after being subjected to liquid state fermentation.

Owner:JIANGSU UNIV

Comprehensive treatment method of high-sulphur high-COD (Chemical Oxygen Demand) caustic sludge waste liquid

ActiveCN103045288AReduce CODMild operating conditionsOrganic chemistryOrganic compound preparationLiquid wasteHigh concentration

The invention relates to a comprehensive treatment method of high-sulphur high-COD (Chemical Oxygen Demand) caustic sludge waste liquid. The comprehensive treatment method comprises the steps of: 1, acidizing high-sulphur high-COD caustic sludge waste liquid by using an N2 / SO2 mixed gas, when the pH value of the waste liquid reaches 2-6, stopping acidizing; 2, sending tail gas discharged in the acidizing process in the step 1 to a sulphur production device for preparing sulphur; 3, settling the waste liquid generated in acidizing treatment in the step 1and recovering an oil phase; 4, further reducing the COD of the waste liquid by adopting an extraction method when the COD of the waste liquid after the oil phase is separated in the step 3 is always high; and 5, regenerating the waste liquid extracted in the step 4 by using lime. The comprehensive treatment method is low in investment, is mild in operation conditions, is capable of recycling the caustic sludge waste liquid, avoiding the impact of the high-concentration wastewater on a wastewater treatment field, is also capable of recovering sulfide and crude carbolic acid from the caustic sludge waste liquid, and has a certain economic benefit.

Owner:CHINA PETROLEUM & CHEM CORP +1

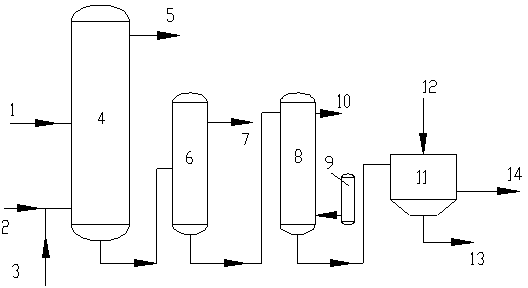

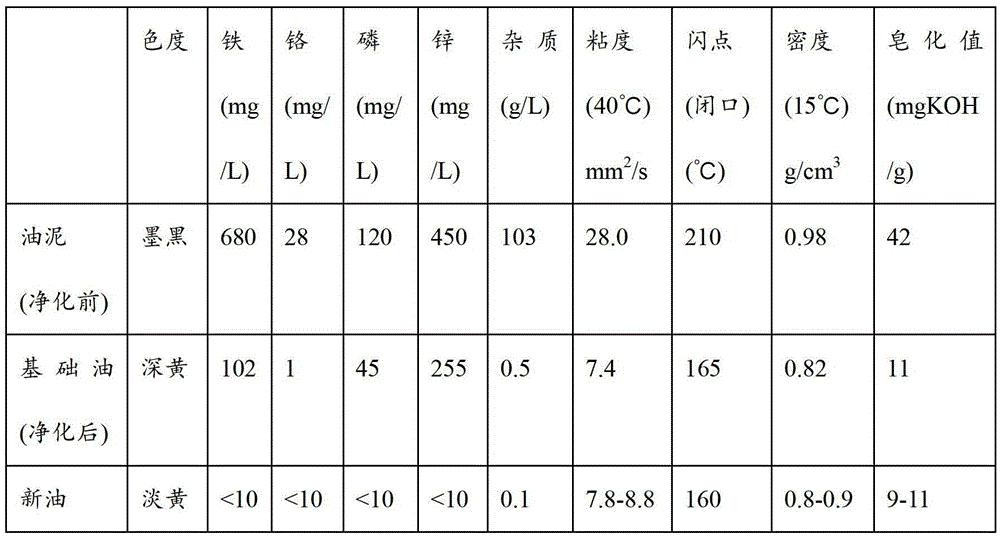

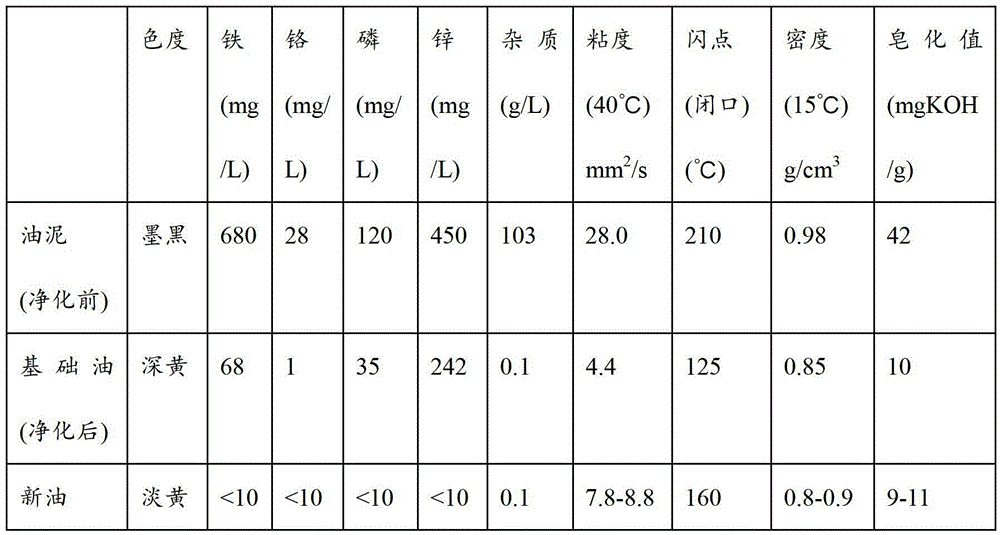

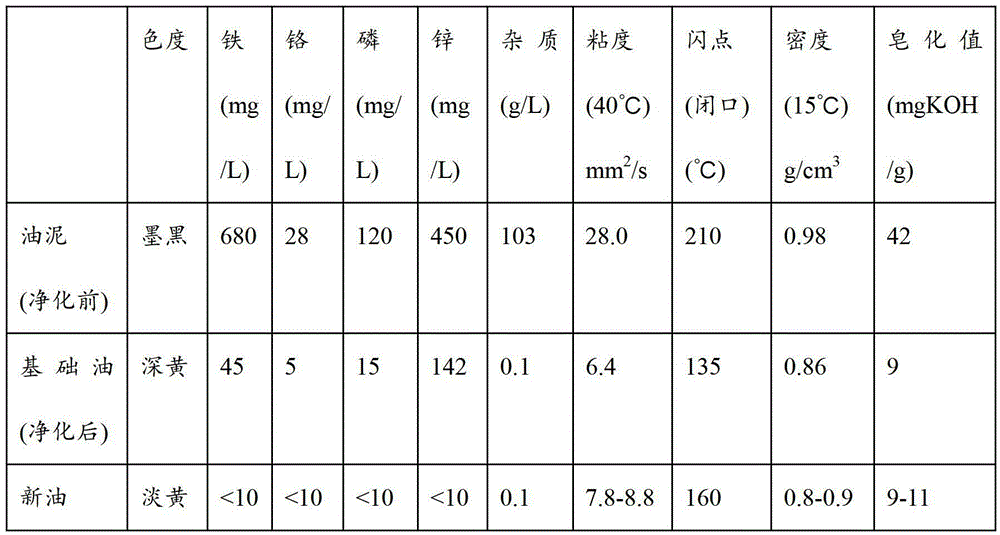

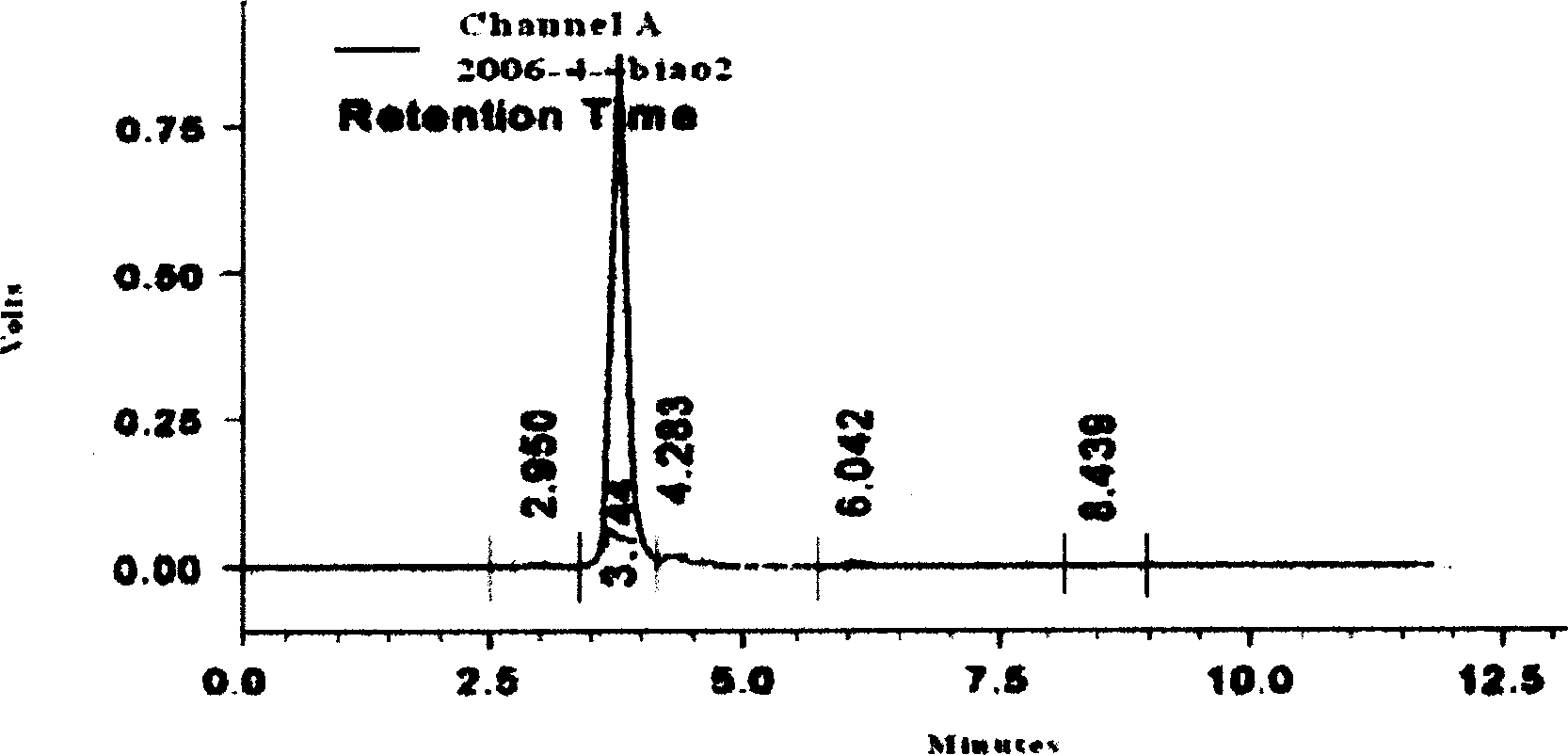

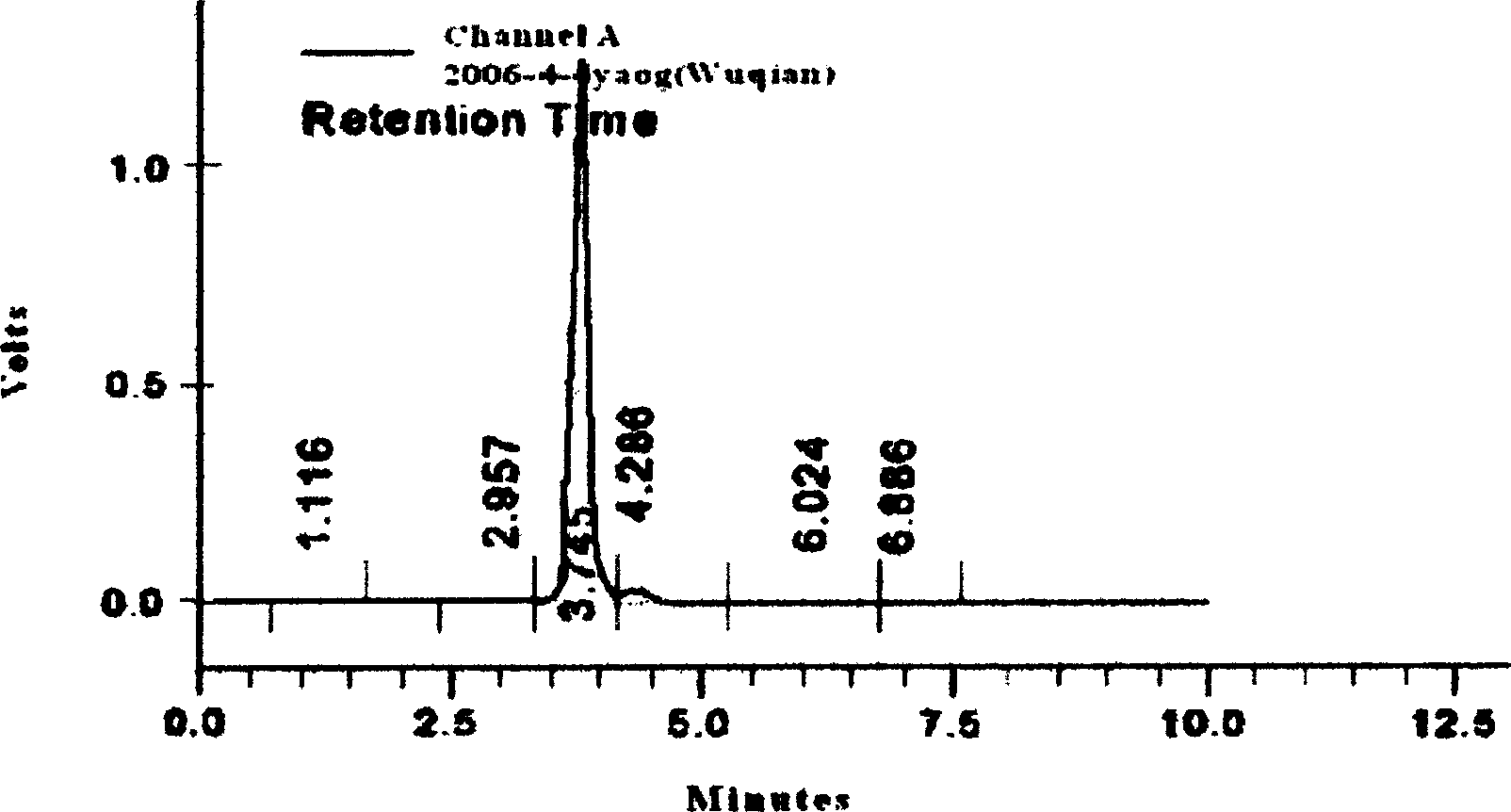

Rolled oil sludge purifying method

InactiveCN104004581AShort regeneration timeReduce the impactLubricant compositionFlocculationSorbent

The invention discloses a rolled oil sludge purifying method. The method comprises the following steps: 1, natural settlement: naturally settling the rolled oil sludge, and extracting the upper layer oil liquid to obtain settled oil residues; 2, modification: adding a modifier into the settled oil residues obtained after the natural settlement, stirring, and allowing the obtained mixture to stand; 3, flocculation: adding a flocculating agent to the modified oil residues, stirring, and allowing the flocculated oil residues to stand; 4, centrifugation: centrifuging the flocculated oil residues to obtain a centrifuged oil liquid; 5, membrane separation: carrying out membrane separation on the upper layer oil liquid extracted after the natural settlement and the centrifuged oil liquid obtained after the centrifugation to obtain a clear oil liquid; 6, adsorption: adding an adsorbent to the clear oil liquid obtained after the membrane separation, and stirring; and 7, filtration: filtering the adsorbed oil liquid to obtain base oil. The rolled oil sludge purifying method has the advantages of no release of harmful gases, small influences on the environment, and short waste oil regeneration time.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for extracting dihydro-quercetin from larch

InactiveCN1844095AGood technical effectImprove stabilityOrganic chemistrySolventMethyl tert-butyl ether

The invention provides a method of extracting dihydroquercetin from eastern larch, this method using water as extractant, extracting xingan eastern larch contains dihydroquercetin, liquid-liquid extracting the produced aquosity extract, adsorption decolouring methyl tert-butyl ether tobacco extract by activated char or active clay, stripping the dissolvant of decolourized methyl tert-butyl ether tobacco extract in vaccum, the grease thing of water stripped is crystallization purified by water and getting rude product of dihydroquercetin. According to need, the getted rude product of dihydroquercetin can be recrystallization purified by water and getting elaboration product of dihydroquercetin. The method of this invention has prominant technique effect, not only the yield is as high as 1.69%-2.0%, but also the getted rude product of dihydroquercetin's purity is as high as 95%-96%, the purified elaboration product of dihydroquercetin can reach the purity of 99%.

Owner:GUANGZHOU UNIVERSITY

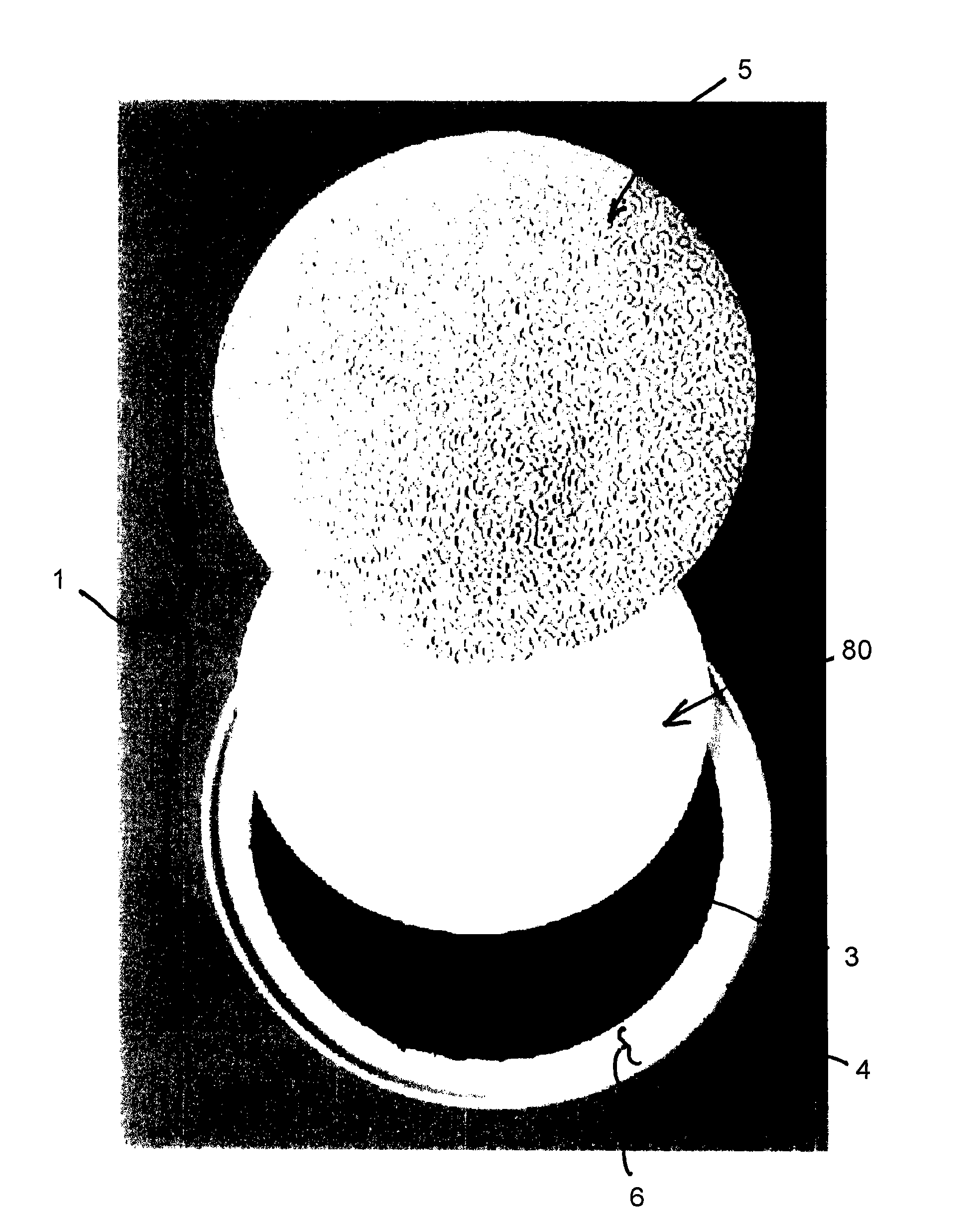

Capsule with flow control and filtering member

A sealed capsule contains a beverage ingredient in powder form, in particular, ground coffee. The capsule comprises a base body (4) and a foil member (5) tightly attached to the base body (4), the foil member (5) being made from a material allowing the production of a multitude of perforations in the foil member (5) when the foil member (5) is thrust, via the pressure caused by injecting a liquidor a liquid / gas mix into the capsule, against a relief plate of a beverage production machine, wherein the capsule is provided with a flow control porous member (80), the flow control porous member (80) being positioned between at least a portion of ingredients (3) and the foil member (5). The flow control porous member provides a faster and more consistent flow of the liquid extract through the capsule and significantly reduces the resurgence of non-soluble solids.

Owner:SOC DES PROD NESTLE SA

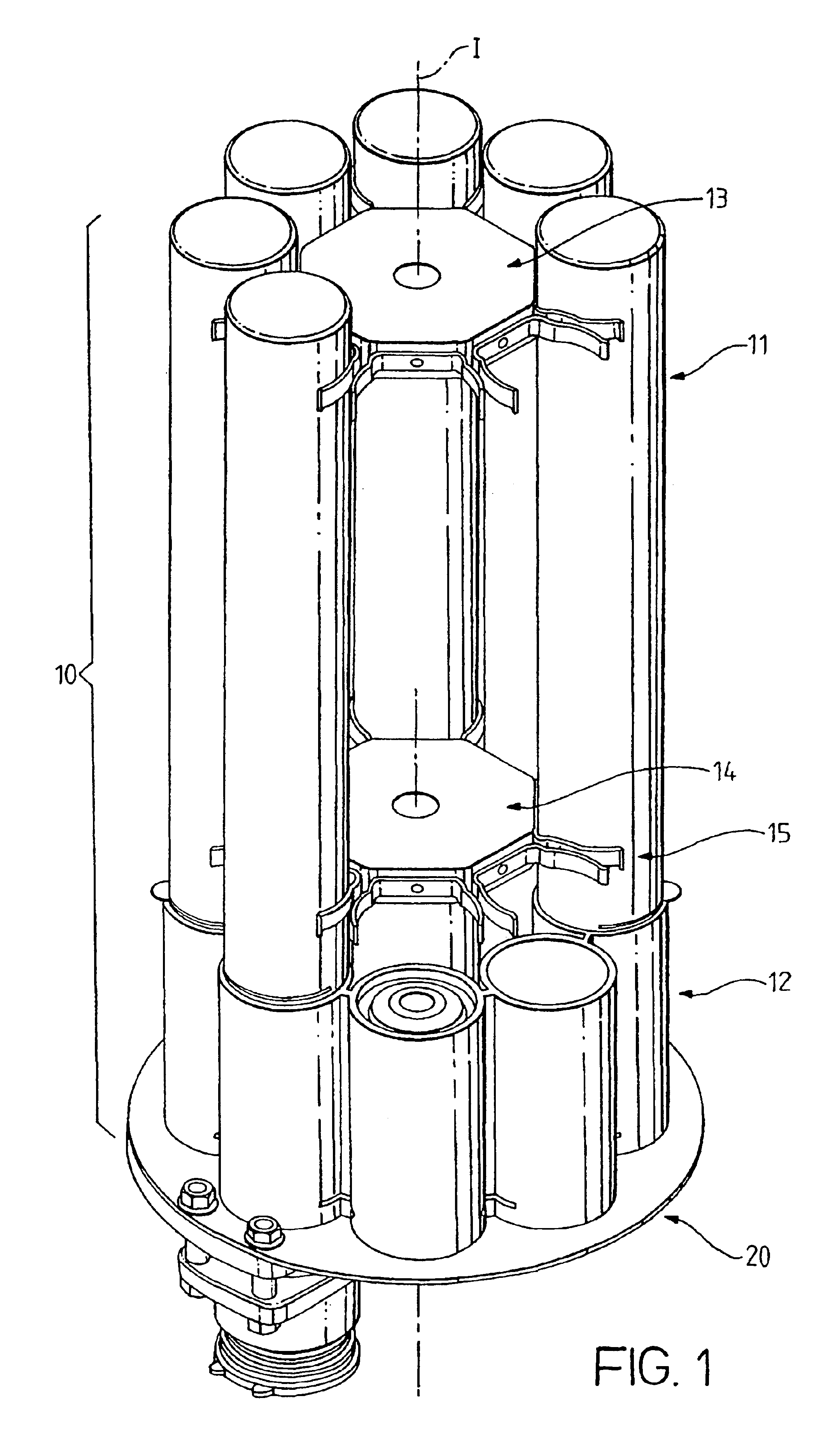

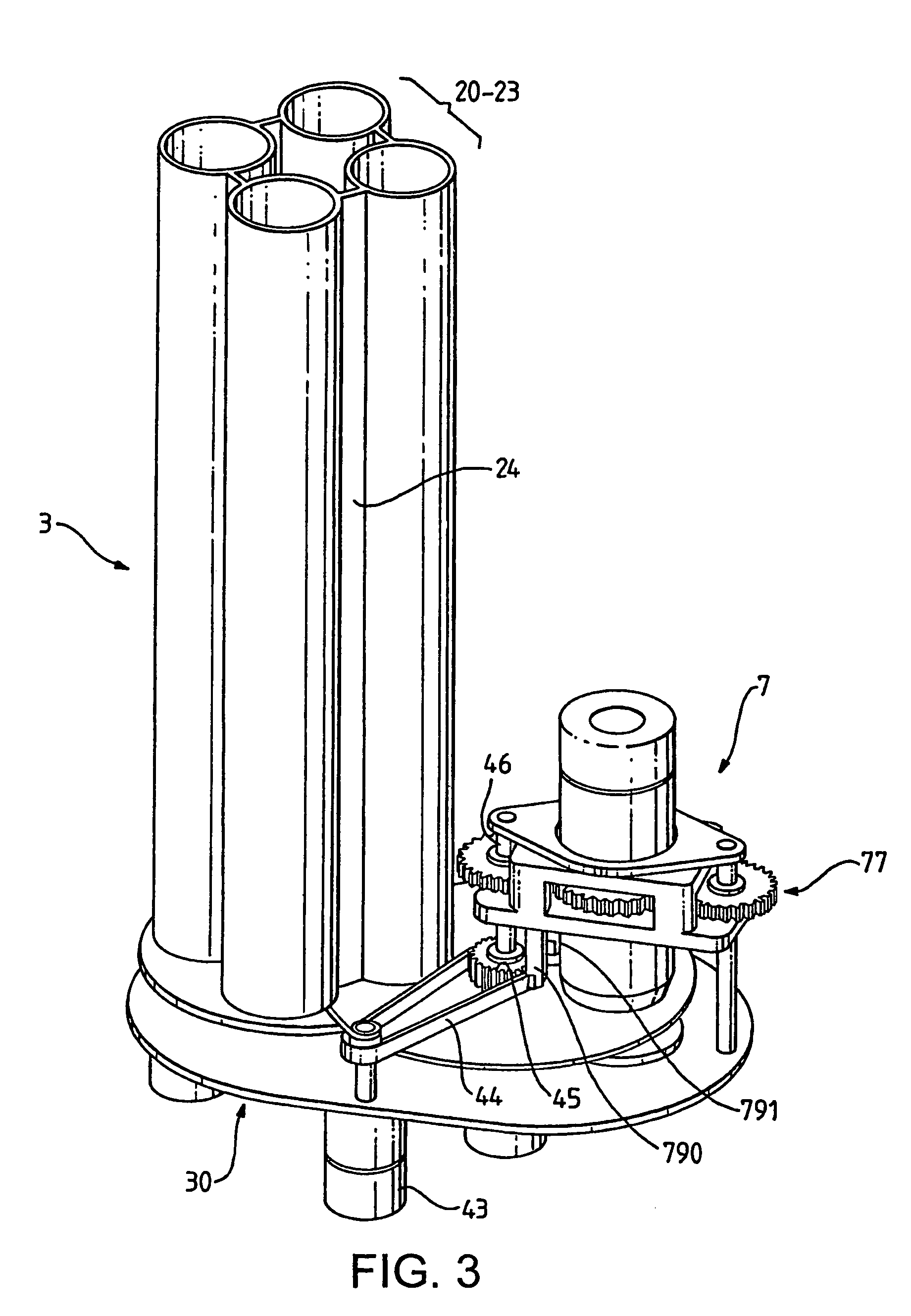

Device and method for selecting and brewing the contents of a capsule to prepare a beverage

InactiveUS7673559B2Reliable and rapid mannerEasy to useLiquid flow controllersBeverage vesselsFunctional connectivityEngineering

A device for preparing drinks that incorporate a capsule selection function connected to a system for brewing the contents of the capsules to enable brewing to take place under optimal conditions. The device includes a storage system comprising capsules arranged in several sets, a mechanism for capturing a capsule individually from a set and releasing the capsule into a brewing system. The capture mechanism is able to move between the storage system and the brewing system and is designed in such a way as to adopt at least two positions, a first or reception position in which the capsule is held and is able to be transferred by the capture means and a second or release position in which the capture means can be opened to release the capsule from the capture mechanism. The device provides advantages in the handling of the capsule after its selection, in particular, its transfer, the brewing of its contents, and, optionally, the ejection of the spent capsule in a reliable, rapid and automated manner. In addition, the invention provides more reliable usage with no problems of pouring and draining the liquid extract.

Owner:NESTEC SA

Preparation technology of yak bone collagen oligopeptide

InactiveCN105385737ALow costHigh purityPeptide preparation methodsFermentationEnzymatic hydrolysisHydrolysate

The invention discloses a preparation technology of yak bone collagen oligopeptide. The preparation technology comprises the following steps: grinding yak bones, which have been dried in the shade, into powder with a size of 50 meshes, processing yak bone powder by alkali and acid, removing fat and other impurities, extracting yak bone powder to obtain high purity yak bone collagen liquid extract; subjecting the yak bone collagen liquid extract to two-step enzymatic hydrolysis, after enzymatic hydrolysis, purifying the enzymatic hydrolysate by a centrifuge under the assistance of a multi-stage membrane separation system so as to obtain a yak bone collagen oligopeptide solution; spray-drying the yak bone collagen oligopeptide solution to obtain yak bone collagen oligopeptide; wherein the purity of yak bone collagen oligopeptide is more than 90%, and the molecular weight of yak bone collagen oligopeptide is less than 1000 Da. The yak processing byproduct namely yak bone is utilized to prepare collagen oligopeptide, the cost is low, the collagen extraction rate is more than 85%, the impurity removing effect and condensing effect are good, and the method is suitable for massive industrial production.

Owner:QINGDAO ARCTIC YAK BIOLOGICAL TECH CO LTD

Externally used medical ointment for treating dermatosis, uses, preparation method and apparatus thereof

InactiveCN101342240AGood treatment effectQuick resultsInorganic active ingredientsAerosol deliveryDiseaseTreatment effect

The invention provides a green external ointment for remedying skin disease, which is prepared by pure natural material. The invention has the components and the weight percentage content of 20 to 30 of ozone, 100 of olive oil or flaxseed oil, 0.01 to 0.03 of lipophilic complex nano silver and 5 to 15 of hydrogenated castor oil.The external ointment has the following use method: cleaning the afflicted part, extruding the ointment on a dressing and then sticking the dressing on the afflicted part for 2 to 3 times everyday. The dressing is a sticking film with a groove in the middle. Non-woven cloth is embedded in the groove. The invention also provides the preparation method and the device of the external ointment. The invention has the advantages of good and quick treatment effect, small toxic and side effect, fast recovery and no operation trauma. The liquid extracted from the pure natural material stores the ozone molecule of a certain thickness with special technology and uses the ozone to remedy skin disease. The invention uses physical process and manufacture method without any chemical reaction.

Owner:浙江易生医疗科技有限公司

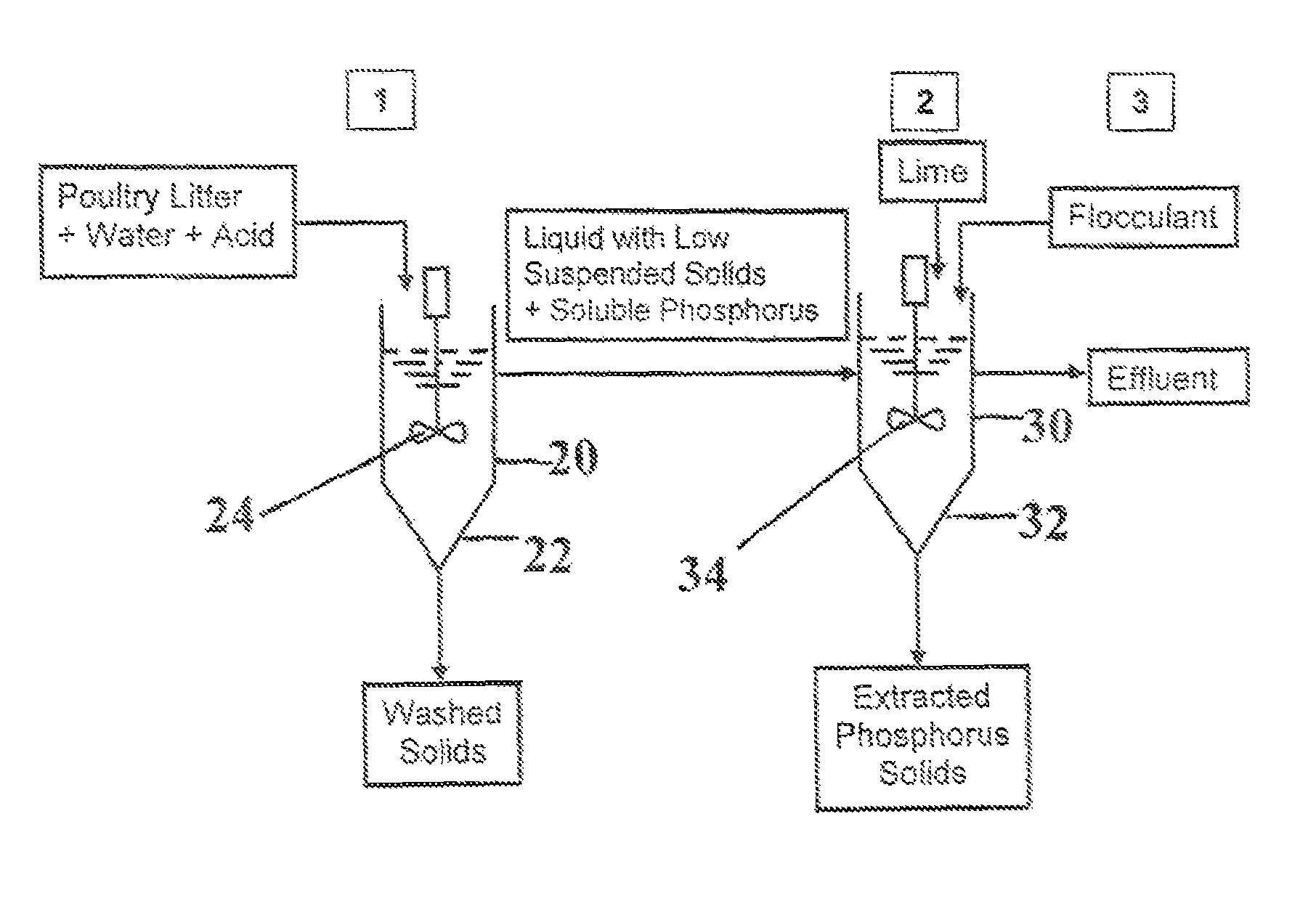

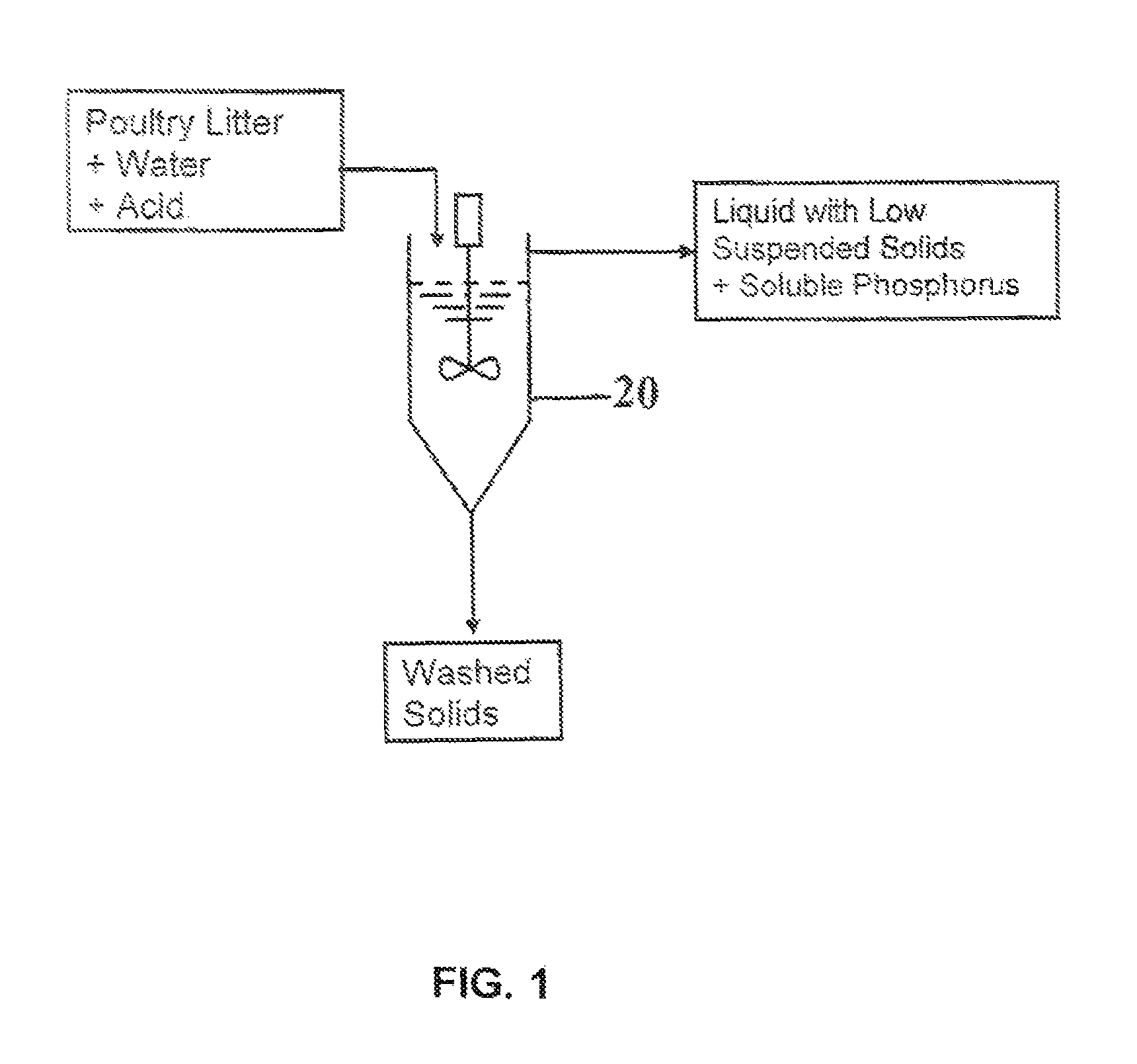

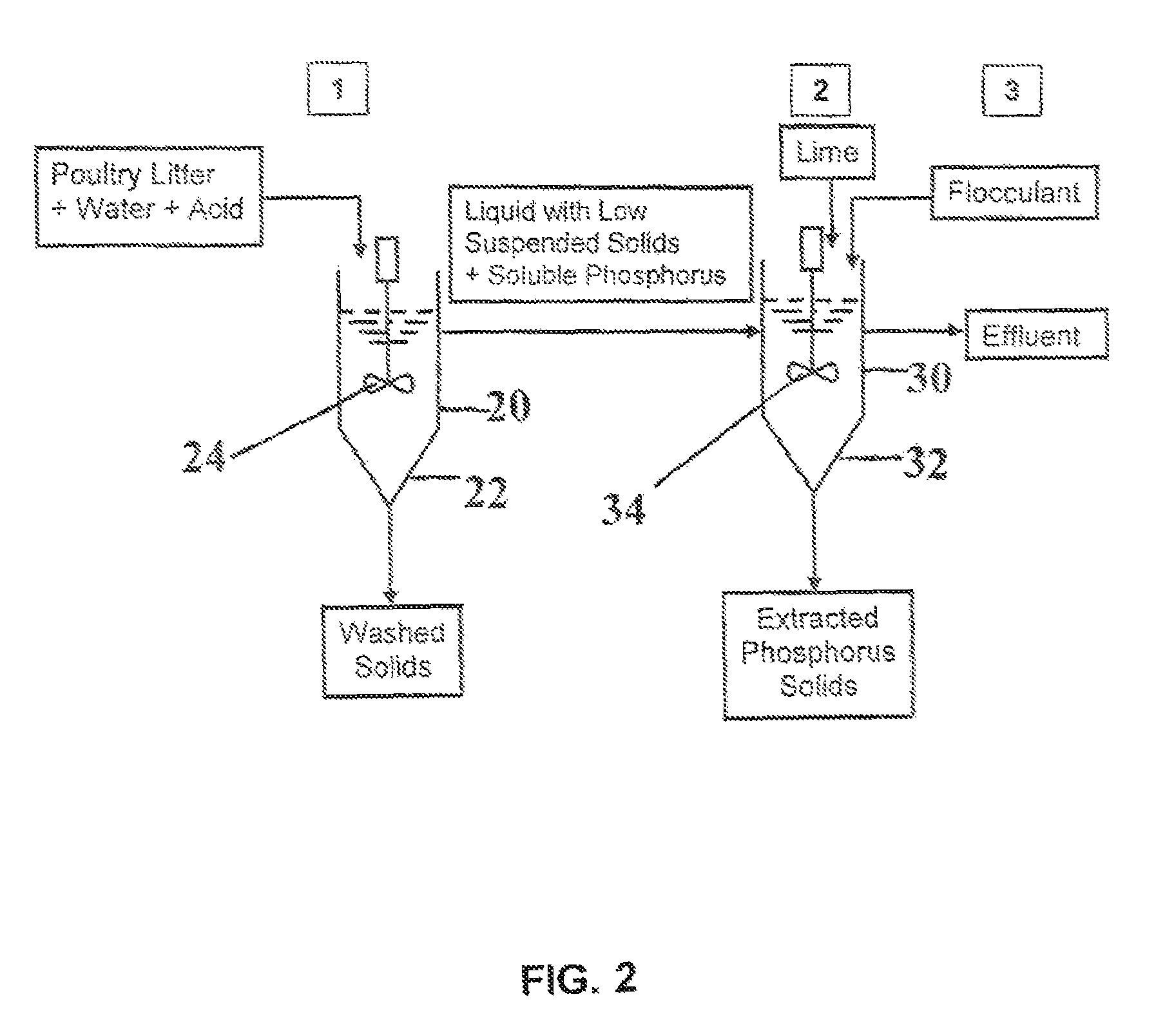

Process for removing and recovering phosphorus from animal waste

A process for removing phosphorus from solid poultry or animal wastes involving (a) mixing solid poultry or animal wastes with water and acid at a pH lower that about 5.0 and higher than about 3.0 to form (i) a liquid extract that contains suspended solids of about 3.5 g / L and soluble phosphorus and (ii) a washed solid residue (having a N:P ratio of at least more than 4 expressed on an elemental basis), (b) separating the liquid extract from the washed solid residue to form separated liquid extract and separated washed solid residue, (c) mixing the separated liquid extract with an alkaline earth base to a pH of about 8.0 to about 11.0, (d) mixing the liquid extract with a flocculant to form (i) precipitated phosphorus solids with P2O5 content greater than about 10% and (ii) a liquid, and (e) separating the precipitated phosphorus solids from the liquid to form separated phosphorus solids and separated liquid. The process is conducted at a temperature greater than about 5° C. and less than about 50° C. The solid poultry or animal wastes are not pretreated prior to mixing the solid poultry or animal wastes with water and acid; such pretreatments include those that may cause the complete or partial loss of oxidizable organic carbon and nitrogen.

Owner:US SEC AGRI

Method for large-scale preparation of penicillic acid from Penicillium sp. HK1-6

ActiveCN107841466APossess the conditions for industrialized mass productionFungiMicroorganism based processesPenicillium bilaiaeChromatographic separation

The invention specifically relates to a method for large-scale fermentation preparation of penicillic acid from Penicillium sp. HK1-6, belonging to the field of utilization of marine microbial resources. The method comprises the following steps: (1) subjecting Penicillium sp. HK1-6 to culture in a medium for the strain; (2) subjecting the Penicillium sp. HK1-6 cultured in the step (1) to fermentation culture in a fermentation medium; (3) separating fermentation broth and thalli in a fermentation product obtained in the step (2), extracting the fermentation broth with an organic solvent, combining obtained liquid extracts of the fermentation broth, then carrying out pressure-reduced concentration so as to obtain an extract of the fermentation broth, extracting the thalli with an organic solvent, combining obtained liquid extracts of the thalli, then carrying out pressure-reduced concentration so as to obtain an extract of the thalli, combining the extract of the fermentation broth withthe extract of the thalli, and carrying out chromatographic separation so as to obtain a crude product; and (4) subjecting the crude product obtained in the step (3) to recrystallization or chromatographic separation so as to obtain a pure penicillic acid product which has a purity of 98.0% or above and yield of as high as 500 to 650 mg / L.

Owner:YANGZHOU UNIV

Method for separating and purifying salvianolic acid from red sage root liquid extract by one step

InactiveCN101186572ACarboxylic compound separation/purificationPlant ingredientsProcess dynamicsSalvianolic acid B

The invention relates to a method for furthering separating and purifying salvianolic acid from Danshen extract fluid, which comprises that prepares, breaks and extracts Danshen via water solution, acidifies extract to adjust pH and adds salt to process post-treatment, processes dynamic continuous adsorption and elution on the treated extract at chromatography column stuffed with resin adsorbent, elutes via water, collects and concentrates eluent, elutes via gradient ethanol solution, segmented collects and concentrates eluent, and dries the concentrates solution to obtain product. The invention can simply, effectively and quickly separate and purify various salvianolic acids, wherein test on different salvianolic acid products shows that the highest yields of tanshinol, alkannic acid, rosmarinic acid, salvianolic acid A and salvianolic acid B are 35. 55%, 70.65%, 99.27%, 82.78%, and 89.34%, and relative highest purities are 95.32%, 65.05%, 29.40%, 33.93%, and 82.35%, which are near or higher than the result of purification on the goal of single component.

Owner:TIANJIN UNIV

Plant-derived protein compositions

InactiveUS20070207255A1Protein composition from vegetable seedsVegetable proteins working-upAlcoholProtein composition

Owner:SPECIALTY PROTEIN PRODRS +1

Cosmetics based on nitric oxide

ActiveCN101028229AAvoid infectionImprove local immunityCosmetic preparationsToilet preparationsOrganic acidChemical reaction

A novel cosmetic based on No for promoting the metabolism of skin and beautifying skin is composed of nitrogen component (nitrite or concentrated vegetative liquid extract rich in nitrite) and acid component (organic or inorganic acid), which can take part in chemical reaction to release No.

Owner:北京富丽华德生物医药科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com