Binder-free ZSM-5 molecular sieve catalyst, and preparation method and use thereof

A ZSM-5, binder-free technology, applied in the field of binder-free ZSM-5 molecular sieve catalyst, preparation and application, can solve the problems of poor catalyst stability, low yield of propylene and aromatics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

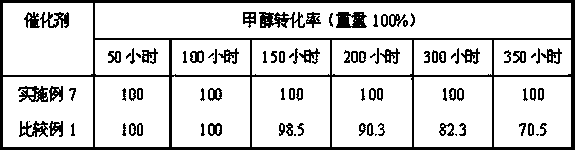

Examples

Embodiment 1

[0032] With tetrapropylammonium bromide as the template, aluminum nitrate as the aluminum source, and silica sol as the silicon source, the raw materials are first molarally mixed with SiO 2 / Al 2 o 3 =200;OH - / SiO 2 =0.3; R / SiO 2 =0.5;H 2 O / SiO 2 = 40 mixed in a ratio of 40, hydrolyzed completely at room temperature, put into a stainless steel reactor, controlled the growth direction of molecular sieve crystals under hydrothermal conditions, and crystallized at 100°C for 60 hours to obtain the molar ratio of silicon to aluminum SiO 2 / Al 2 o 3 NaZSM-5 molecular sieve with a shape index of 200 and a shape index of 50.

[0033] Weigh 70 grams of the above silicon-aluminum molar ratio SiO 2 / Al 2 o 3 200, NaZSM-5 molecular sieve with a shape index of 50, 5 grams of white carbon black, 6.5 grams of alumina, and 62.5 grams of silica sol (SiO 2 The mass percentage is 40%) for kneading and molding, and the shaped catalyst is baked at 100°C for 3 hours. 15 grams of trie...

Embodiment 2

[0037] Tetrapropylammonium hydroxide is used as a template, aluminum sulfate is used as an aluminum source, water glass is used as a silicon source, and raw materials are molar ratios of SiO 2 / Al 2 o 3 =500;OH - / SiO 2 =0.05; R / SiO 2 =1.5;H 2 O / SiO 2 = 10, using the method described in Example 1, crystallized at 80°C for 100 hours to obtain the molar ratio of silicon to aluminum SiO 2 / Al 2 o 3 NaZSM-5 molecular sieve with a shape index of 500 and 3.

[0038] Weigh 50 grams of the above silicon-aluminum molar ratio SiO 2 / Al 2 o 3 NaZSM-5 molecular sieve with a shape index of 50 and 3, 2.8 grams of sodium metaaluminate, and 90 grams of silica sol (SiO 2 The mass percentage is 40%) for kneading and molding, and the shaped catalyst is baked at 100°C for 3 hours. 50 grams of triethylamine and 10 grams of distilled water were pre-added in the reaction kettle, and 60 grams of the above-prepared cylindrical product was placed in the reaction kettle above the porous sta...

Embodiment 3

[0043] Tetrapropylammonium hydroxide and ammonia water are used as templates, sodium aluminate is used as aluminum source, silica sol is used as silicon source, and the raw materials are molar ratio SiO 2 / Al 2 o 3 =300;OH - / SiO 2 =0.08; R / SiO 2 =0.5;H 2 O / SiO 2 = 20, using the method described in Example 1, crystallized at 180°C for 40 hours to obtain the molar ratio of silicon to aluminum SiO 2 / Al 2 o 3 NaZSM-5 molecular sieve with a shape index of 300 and a shape index of 60.

[0044] Weigh 10 g of the above SiO 2 / Al 2 o 3 300, NaZSM-5 molecular sieve with a shape index of 60, 120 grams of white carbon black, 4.2 grams of aluminum sulfate, adding 175 grams of silica sol (SiO 2 The mass percentage is 40%) for kneading and molding, and the shaped catalyst is baked at 100°C for 3 hours. A mixture of 30 grams of ethylamine and 3 grams of distilled water was added in advance to the reaction kettle, and 20 grams of the cylindrical product prepared above was placed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com