Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

195results about How to "Not easy to coke" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

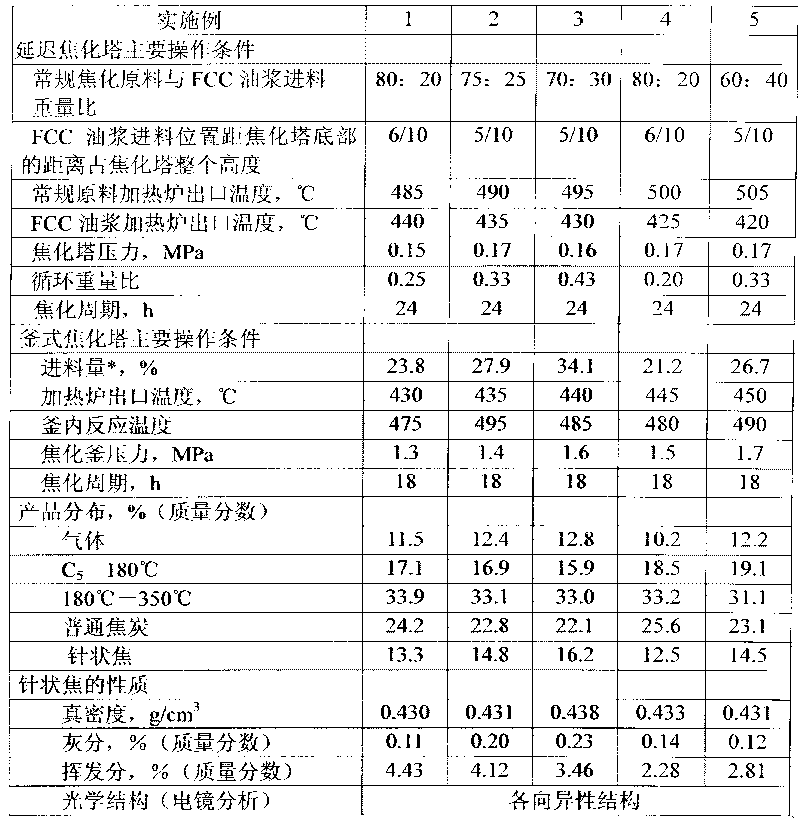

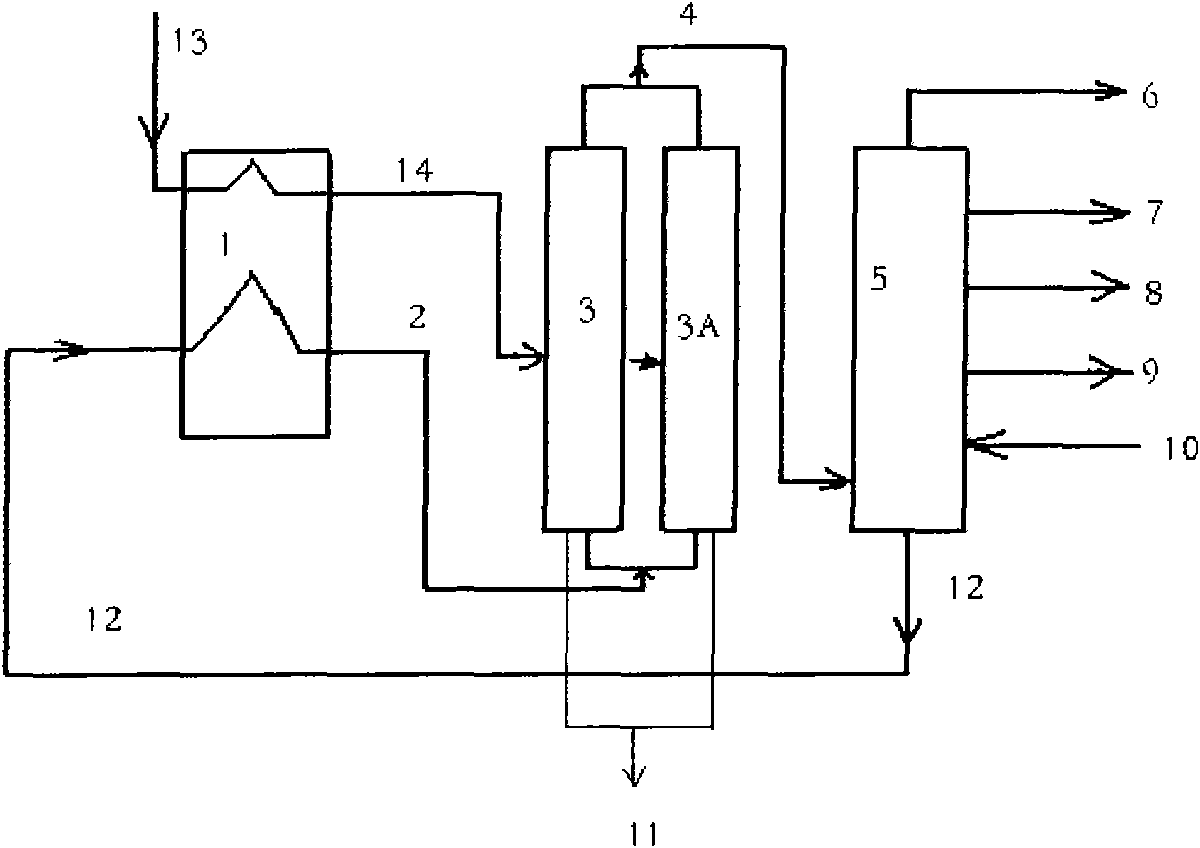

Production method of needle coke raw material

ActiveCN101724420AExpand sourceThe method flow is simpleCoking carbonaceous materialsDecompositionCoke rate

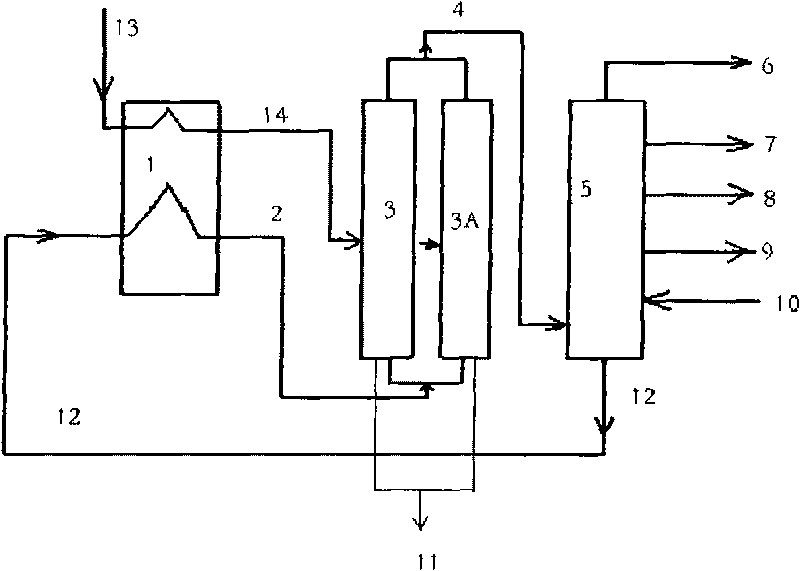

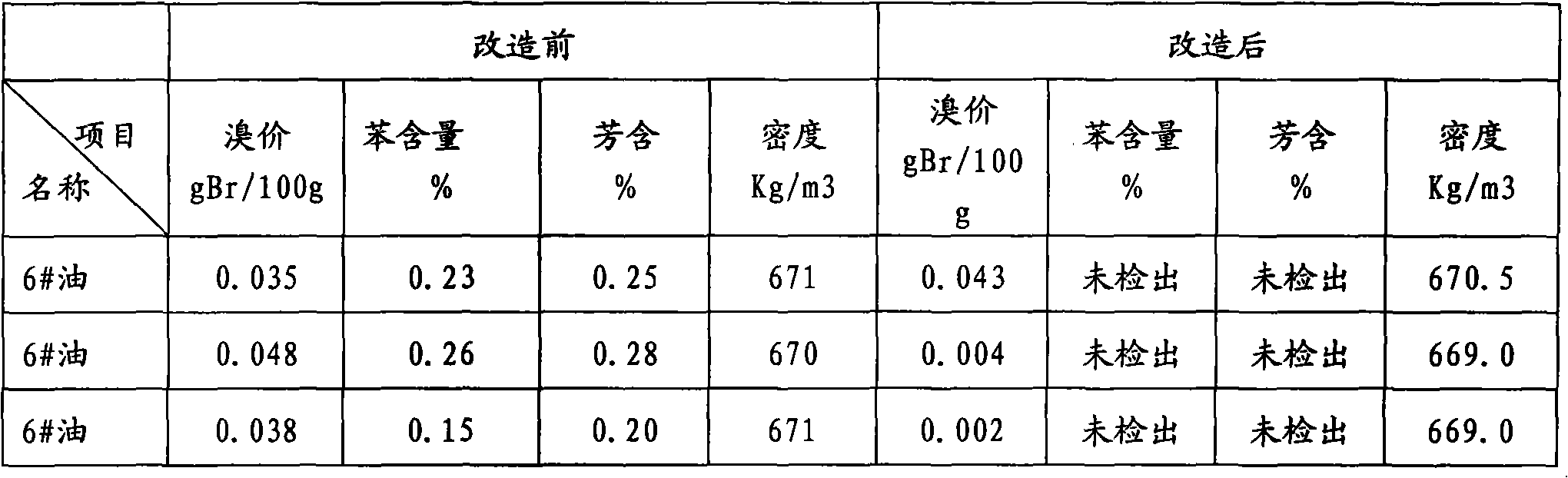

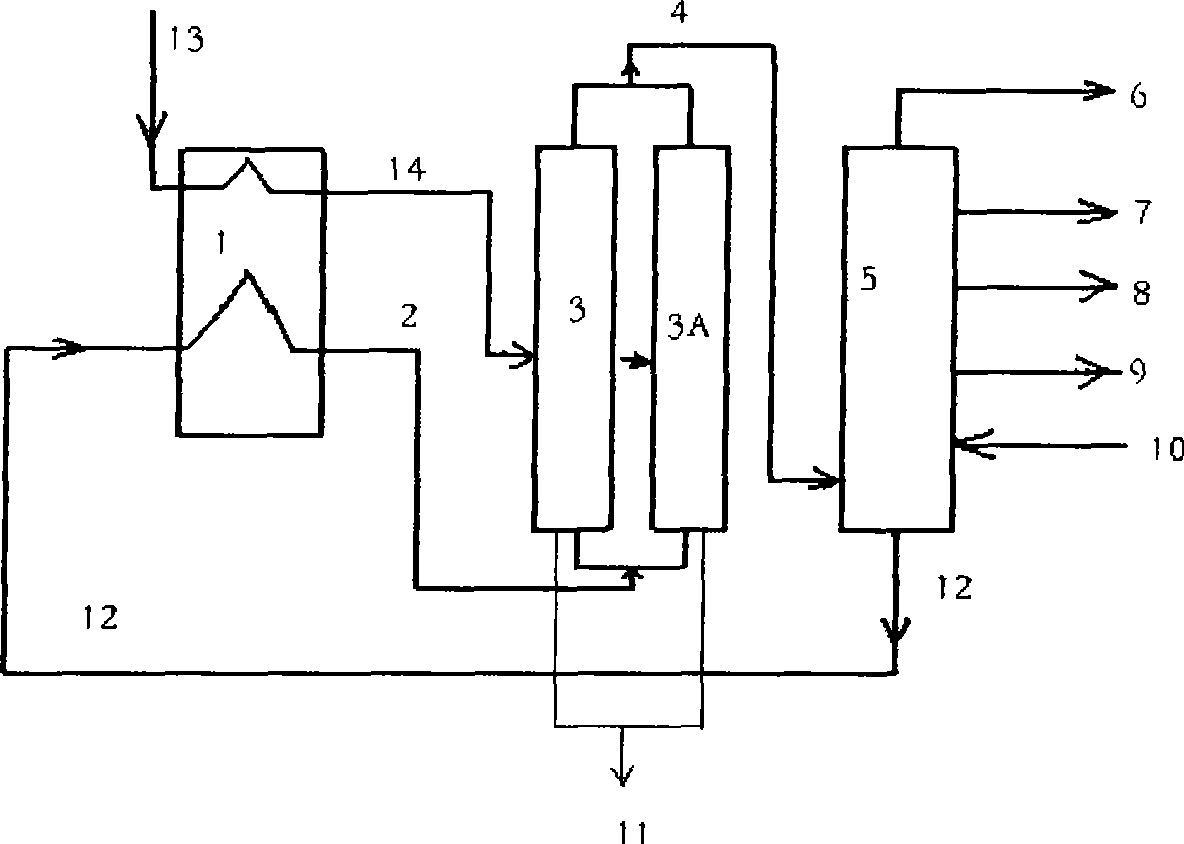

The invention discloses a method of needle coke raw material by using delay coking technique to treat FCC slurry oil and conventional coking raw material. The method comprises: introducing FCC slurry oil with low temperature into a delay coking tower from the upper part inside the tower, leading the introduced FCC slurry oil to be contacted with high temperature oil gas generated by the conventional coking raw material which is introduced into the tower from the bottom and treated by high temperature decomposition, and reacting under the condition of delay coking; and separating the generated oil gas in a coking fractionating tower, and obtaining the needle coke raw material. In the method, as the FCC slurry oil enters into the coking tower at the lower temperature, the decomposition temperature of the conventional coking raw material is lowered, the high temperature decomposition time of the raw material is shortened, the occurrence of secondary reaction is reduced, green coke rate is reduced, the stable operation cycle of a signal tower is prolonged, and light components which have high reaction activity and are not beneficial to producing the needle coke, heavy components with high polymerization activity, and a great deal of impurities such as catalyst powder, heavy metal and the like can be removed. The obtained needle coke has high yield and good properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

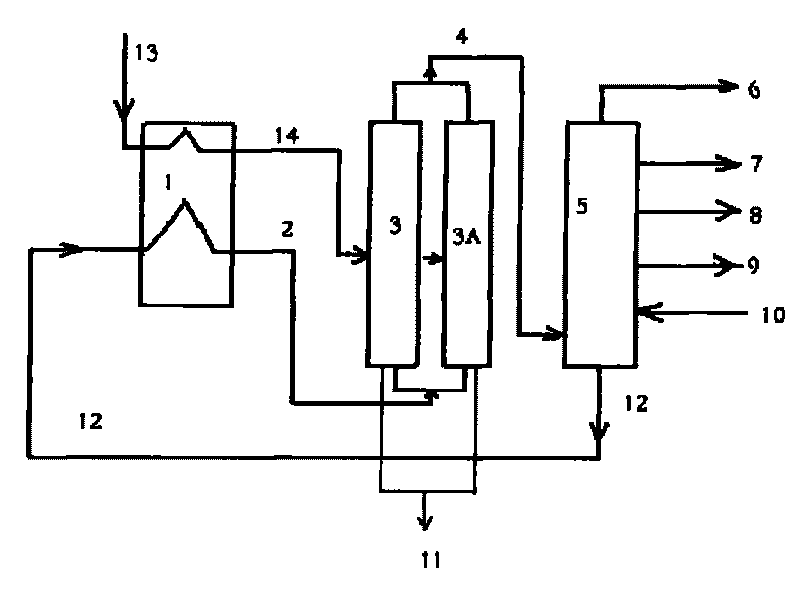

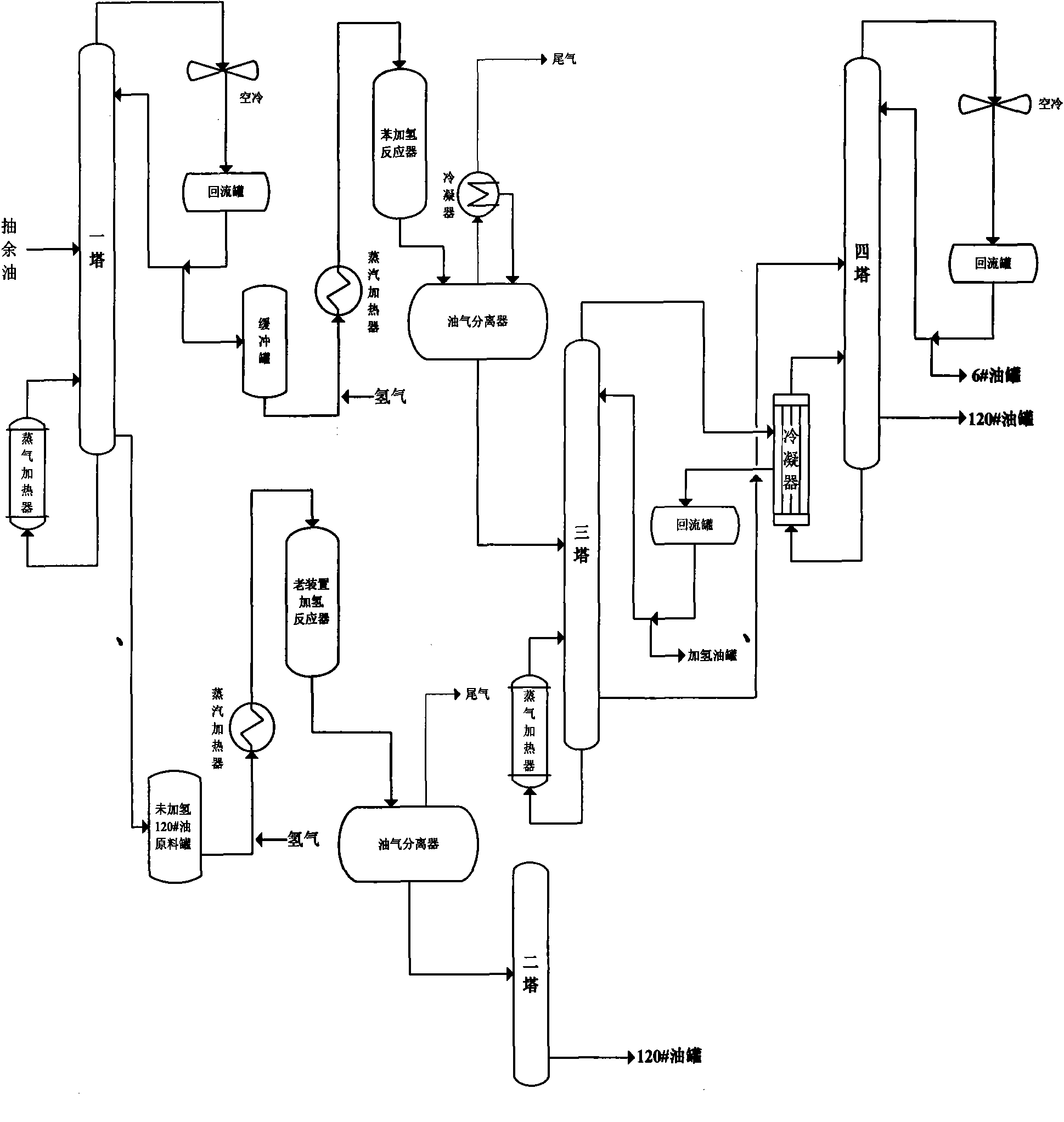

Hydrofining technology of heavy benzol

ActiveCN101712888ANot easy to cokeExtended operating cycleDistillation purification/separationTreatment with hydrotreatment processesBenzeneHydrogen

The invention discloses a hydrofining technology of heavy benzol, which is characterized in that heavy benzol is filtered and is mixed with hydrogen to successively enter a fixed bed pre-hydrogenation reactor and a fixed bed main hydrogenation reactor for selective hydrofining; the obtained hydrogenated oil is converted into solvent oil and industrial naphthalene after cooling, gas stripping, distillation, rectification and the like. The heavy benzol has favourable quality, high additional value and small pollution to environment when the heavy benzol is used, the device has long operation period, and the invention provides a new path for effectively using heavy benzol.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

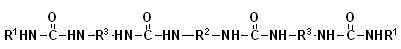

Urea grease composition and preparation method thereof

ActiveCN101368129AImprove water resistanceImprove performanceThickenersAdditivesSulfurExtreme pressure additive

The invention relates to a urea grease composition and a preparation method thereof; the urea grease composition consists of base oil, thickener and additive; wherein, the base oil is various mineral base oil, synthetic oil or the mixture of the mineral base oil and the synthetic oil, and the base oil accounts for 85 percent to 95 percent of the total amount of the grease; the thickener is composed of diurea compound and the amount of the thickener accounts for 4 percent to 15 percent of the total amount of the grease; the additive consists of T361A borate extreme pressure and antiwear additive, anti-oxidant and anti-corrosion additive and anti-oxidant; wherein, the addition amount of the borate extreme pressure and antiwear additive accounts for 1 percent to 3 percent of the total amount of the grease, the addition amount of the anti-oxidant and anti-corrosion additive accounts for 0.5 percent to 2 percent of the total amount of the grease and the addition amount of the anti-oxidant accounts for 0.3 percent to 1 percent of the total amount of the grease; the invention combines the advantages of the borate and the traditional sulfur-phosphorous additive and the urea grease added with the borate extreme pressure and antiwear additive still has excellent water resistance, thus improving the comprehensive performance of the product and reducing the cost.

Owner:杭州得润宝油脂股份有限公司

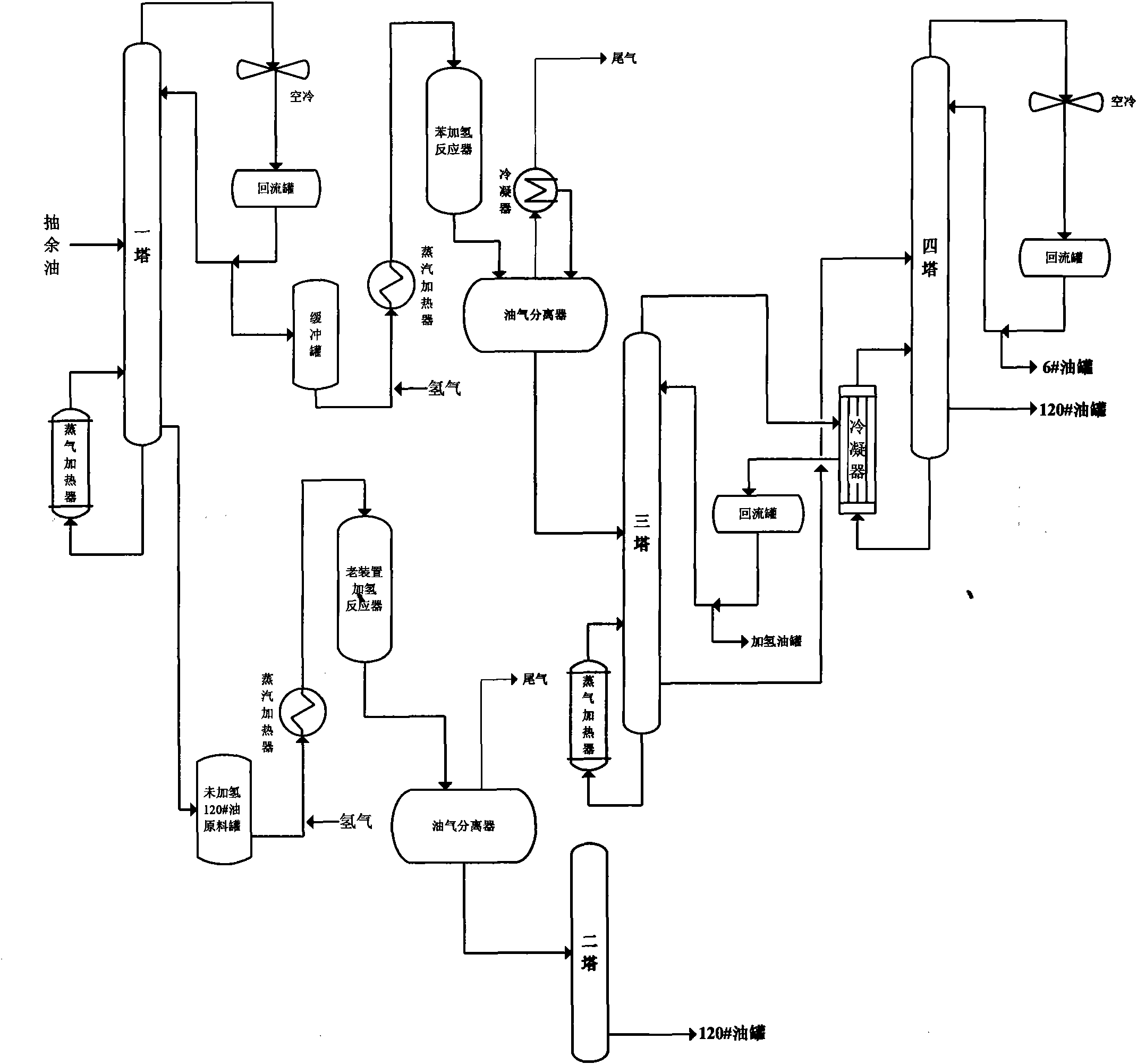

Process for producing solvent oil by removing aromatic hydrocarbon from raffinate oil

ActiveCN101974347ANot easy to cokeHigh activityTreatment with hydrotreatment processesBromine numberSulfolane

The invention discloses a process for producing solvent oil by removing aromatic hydrocarbon from raffinate oil, which comprises the following steps of: (1) rectifying raffinate oil, and removing sulfolane, water and colloid substances from the raffinate oil; (2) completely hydrogenating the raffinate oil obtained in the step (1) under the action of a benzene hydrogenation catalyst; and (3) removing excessive hydrogen from the product of the step (2) by separating, rectifying and collecting the product at the top of a rectifying tower to obtain solvent oil No.6 or normal hexane. In the method, all the raw materials are cleaned, hydrogenated and separated, reformed circulating hydrogen can be used, and the distillation range of the product is controllable. The content of aromatic hydrocarbon in the obtained product is trace, and the bromine number is lower than 100 mgBr / 100g.

Owner:TIANJIN JINGHUA PETROCHEM

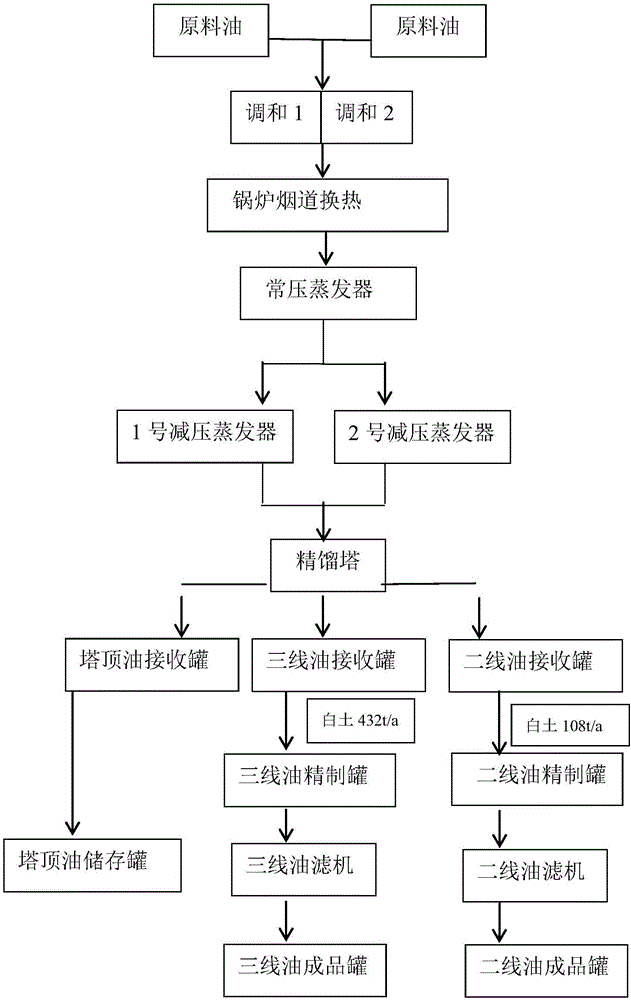

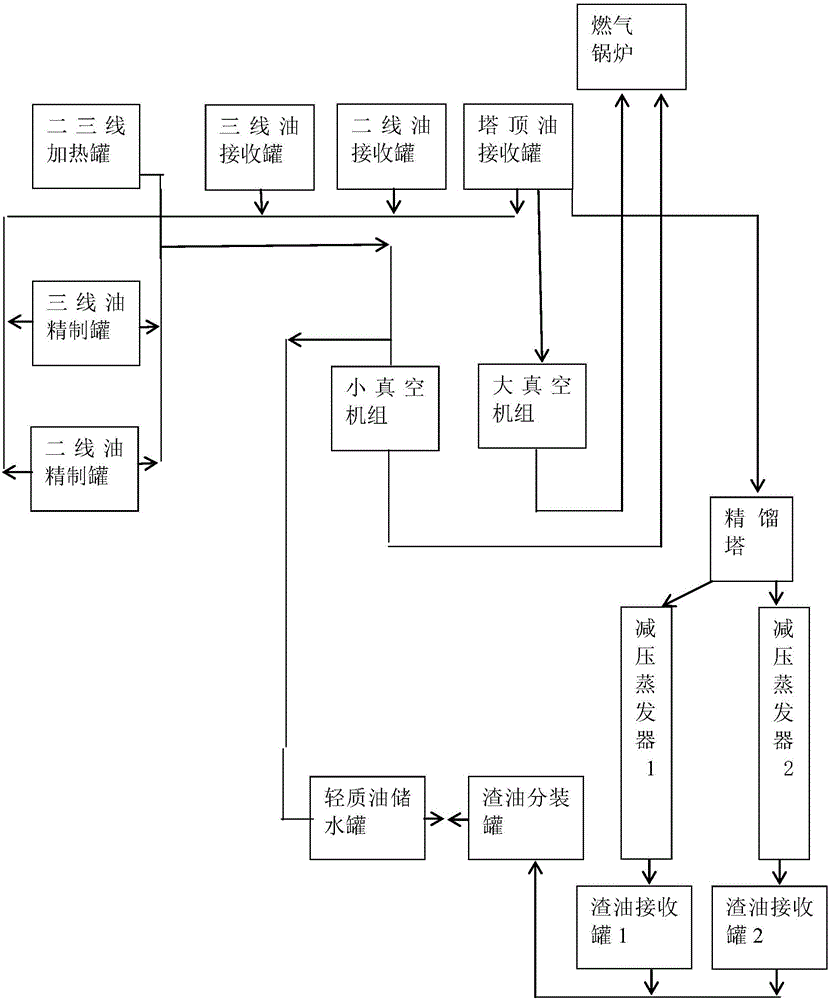

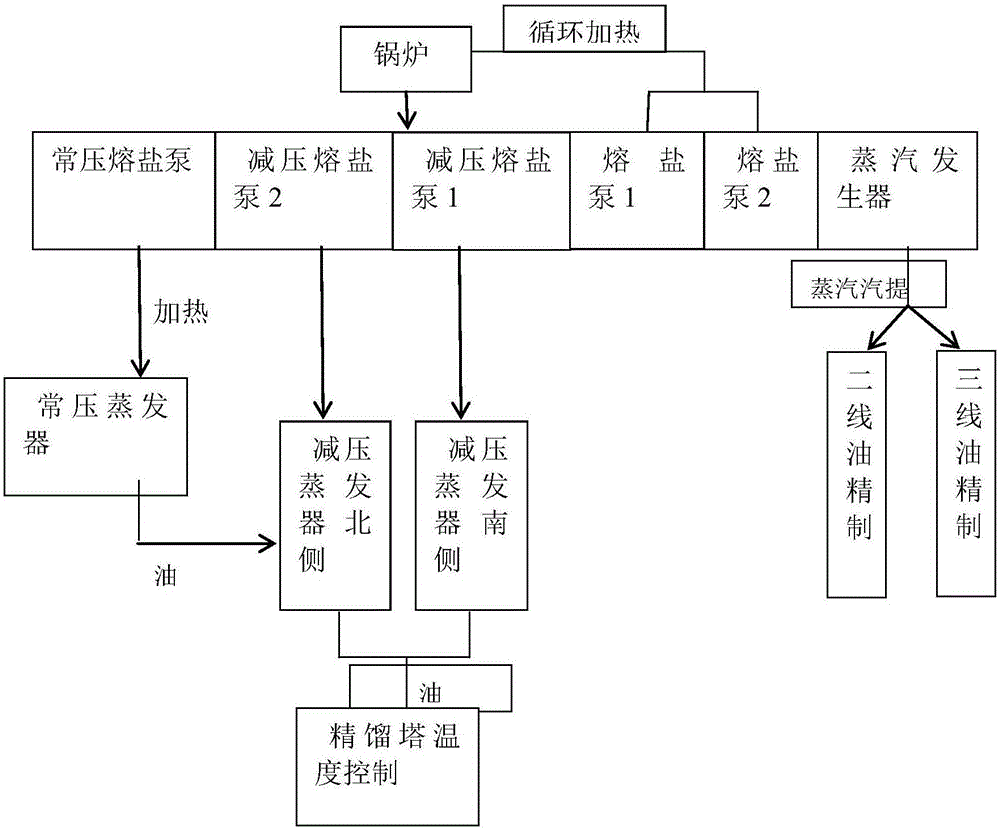

Refining technique of base oil regenerated from used lubrication oil

Disclosed is a refining technique of base oil regenerated from used lubrication oil, and the refining technique comprises the following steps of 1, removing solid waste, which includes removing solid waste from used lubrication oil by centrifugation; 2, solvent pretreatment, which includes extracting mixed impurities and moisture through a solvent and obtaining raw oil after removing upper oil; 3, flocculation treatment, which includes turning mixtures obtained from step 2 into a mixture of flocculation; 4, atomospheric distillation; 5, carrying out reduced pressure distillation; 6, carrying out rectification; 7, solvent refining: putting oil produced from a rectifying column into a treatment tank and when the height of the oil level in the treatment tank reaches 65%-75% of the height of the treatment tank, adding by mass 10%-40% of 1-Methyl-2-pyrrolidinone, and carrying out solvent refining. The refining technique of base oil regenerated from used lubrication oil has the advantages of low investment and high yield efficiency, meanwhile, the refining technique accords with the requirement of environmental protection, reduces vacuum residuum by 15%, improves product yield, facilitates the overhauling of equipment, prolongs the production period, largely improves production efficiency and appearance quality of minus line oil, and helps to obtain high quality regenerated base oil.

Owner:济南亿诺再生资源有限公司

Production method of needle coke raw material

ActiveCN101724420BHigh reactivityExpand sourceThermal non-catalytic crackingCoking carbonaceous materialsCoke rateDecomposition

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for disposing urban sludge through combustion

InactiveCN1632377ADon't waste energyReduce processing timeIncinerator apparatusMunicipal sewageBuilding material

The invention discloses a combustion treatment method of urban sludge, which is provided for overcoming the disadvantages of the existing incineration treatment of urban sludge, such as low burn-out rate, poor treatment of urban sludge, high energy consumption, and long treatment time. The pump pressurizes the ignition fuel into the furnace and ignites it in an atomized state; stirs and mixes the municipal sludge and finished coal-water slurry in a certain proportion to form a liquid fuel, pressurizes it with a slurry pump and injects it into the furnace through the burner, and sends the compressed air to The nozzle makes the liquid fuel in an atomized suspension state and is ignited by the ignition fuel, and the urban sludge can be disposed of. Using the above-mentioned process to treat municipal sludge does not require dehydration and drying treatment, and does not waste energy; liquid fuel burns fully and quickly in the state of atomization and suspension, with less residue and can be used as building materials, so municipal sludge can be thoroughly processed Clean, recycle the heat, turn waste into treasure, and dispose of the largest amount of urban sludge with the least amount of finished coal-water slurry fuel.

Owner:QINGDAO HAIZHONG ENVIRONMENTAL PROTECTION BOILER

Production method of needle coke

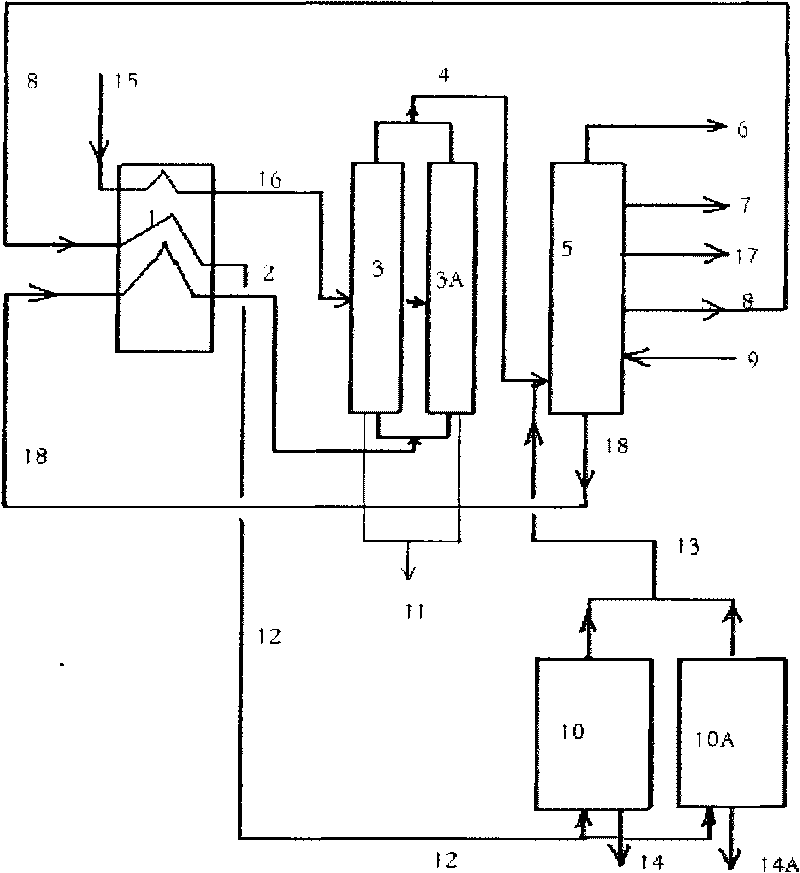

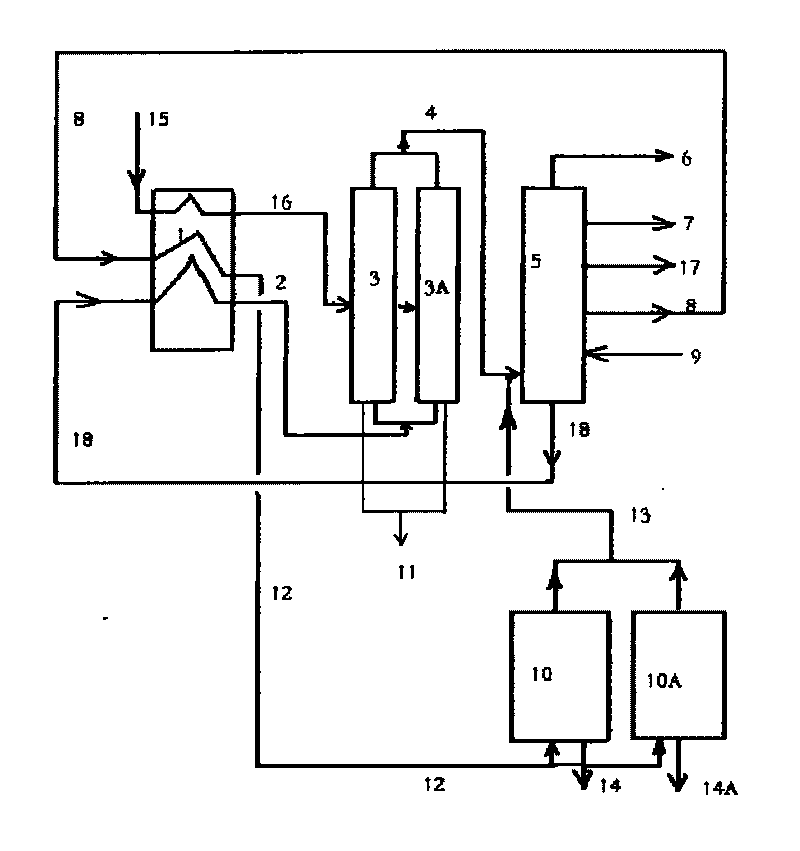

The invention discloses a method for producing needle coke by adopting the technique combining delay coking and kettle-type coking. The method comprises: when treating the conventional coking raw material by using the delay coking technique, introducing FCC slurry oil into a delay coking tower from the upper part inside the tower at the low temperature, and obtaining needle coke raw material by fractionating high temperature oil gas obtained by the reaction; and then, treating the needle coke raw material by using the kettle-type coking technique, and obtaining high quality needle coke. In the method, as the FCC slurry oil is injected into the coking tower at the lower temperature, the decomposition temperature of the conventional coking raw material is lowered, the high temperature decomposition time of the raw material is shortened, the occurrence of secondary reaction is reduced, green coke rate is reduced, the stable operation cycle of a signal tower is prolonged, and light components which have high reaction activity and are not beneficial to producing the needle coke, heavy components with high polymerization activity, and a great deal of impurities such as catalyst powder, heavy metal and the like can be removed. The obtained needle coke has high yield and good quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

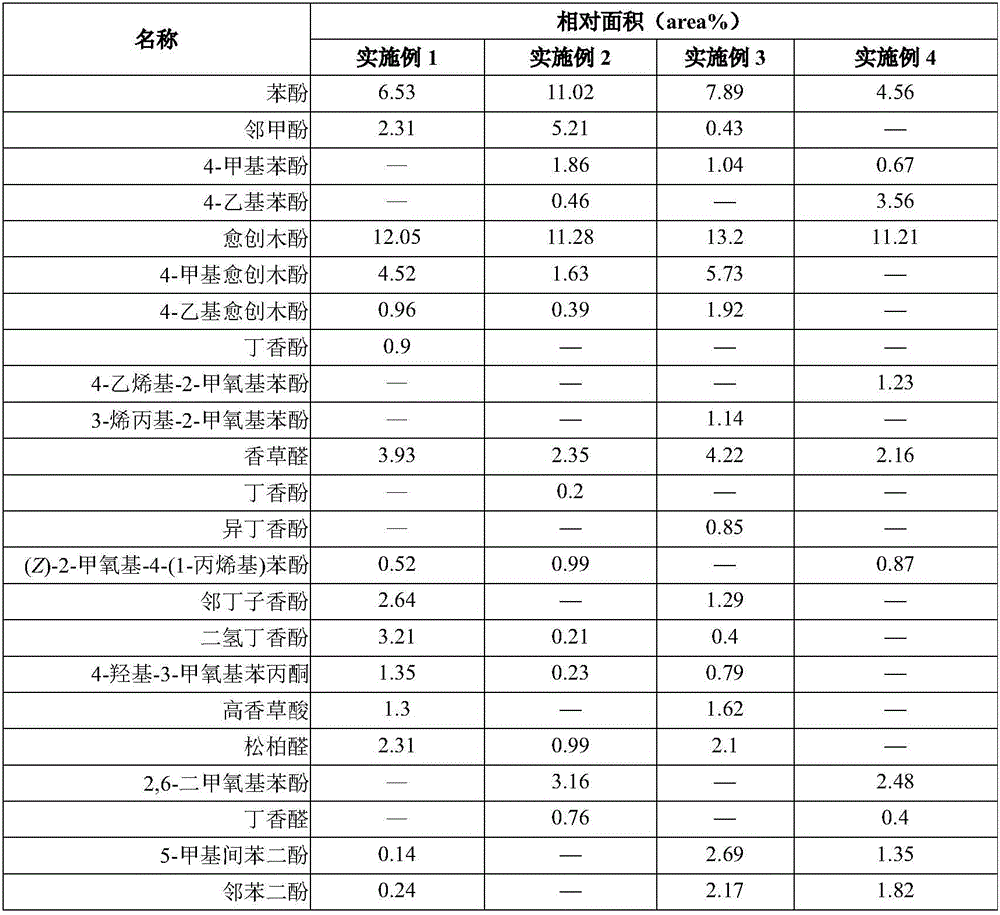

Method for preparing liquid product containing rich phenols and alcohols through microwave catalytic thermal cracking of forestry and agricultural residues

ActiveCN106635110AReserved functionImprove absorbing performancePhysical/chemical process catalystsLiquid hydrocarbon mixture productionLiquid productAlcohol

The invention discloses a method for preparing a liquid product containing rich phenols and alcohols through microwave catalytic thermal cracking of forestry and agricultural residues and belongs to the technical field of biomass energy. The method is a new method for obtaining the liquid product containing rich phenols and alcohols by organically combining microwave absorbent silicon carbide with a catalytic active metal component and through primary solid-phase microwave catalytic thermal cracking and secondary gas-phase cracking reaction, and resourceful conversion and high-value utilization of the forestry and agricultural residues are promoted.

Owner:SHAANXI UNIV OF SCI & TECH

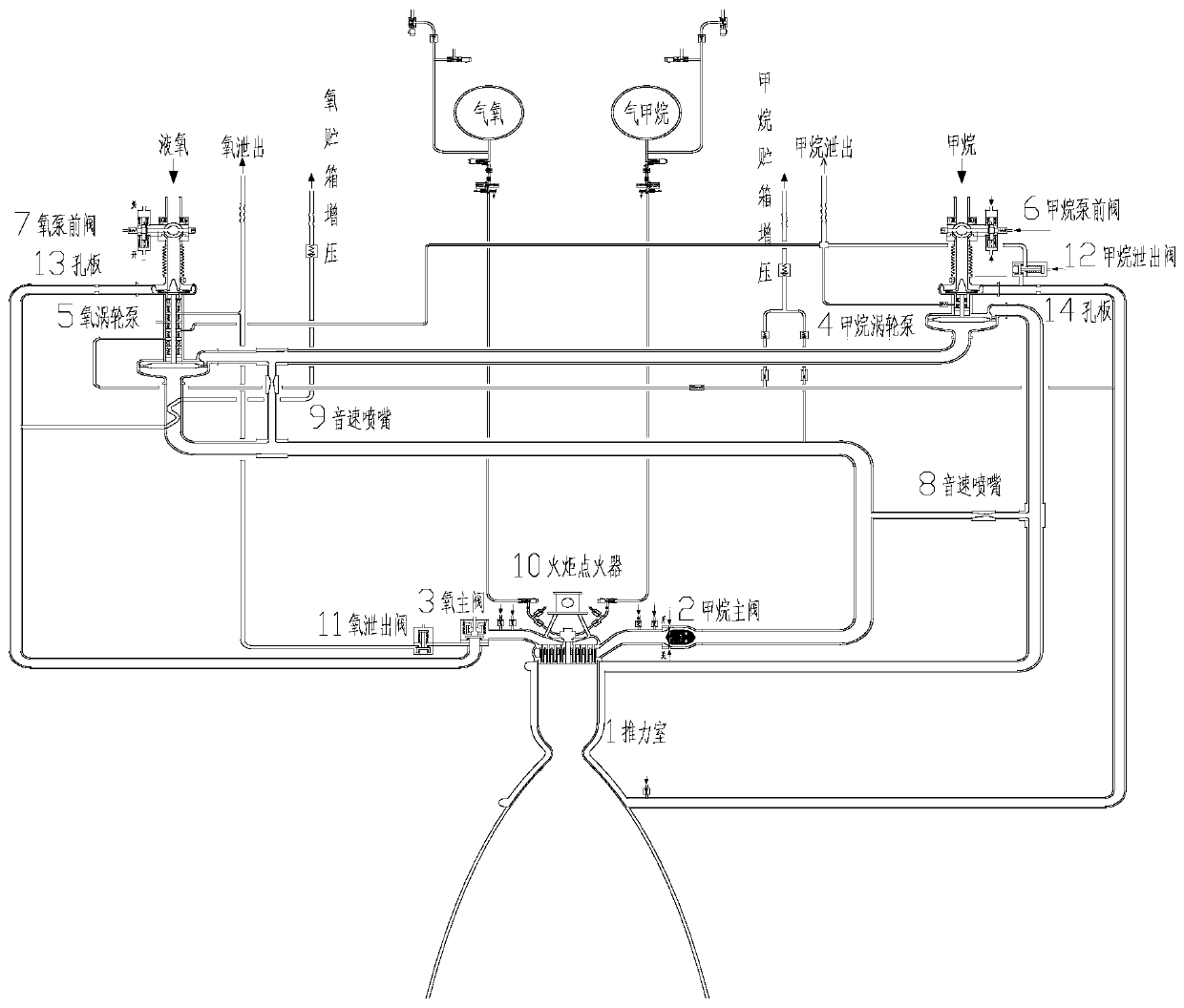

Expansion cycle liquid oxygen and methane upper-stage engine system

ActiveCN111005821ANo pollution in the processEasy to storeRocket engine plantsThrust chamberControl system

An expansion cycle liquid oxygen and methane upper-stage engine system comprises a propellant supply system, an ignition system and a thrust chamber. The propellant supply system comprises a methane supply system and a liquid oxygen supply system, the methane supply system pressurizes low-temperature liquid methane from an external storage tank and then supplies the low-temperature liquid methaneto the thrust chamber; the liquid oxygen supply system pressurizes the low-temperature liquid oxygen from the external storage tank and then supplies the low-temperature liquid oxygen to the thrust chamber; and the ignition system is located at the head of the thrust chamber and ignites under the control of a control system, liquid oxygen and methane entering the thrust chamber are ignited, and generated high-temperature gas is sprayed out of the nozzle of the thrust chamber to generate thrust force. The liquid oxygen and liquid methane are used as a propellant combination, and a closed expansion circulation system scheme is adopted, so the system is simple, the inherent reliability is high, the specific impulse performance is high, and repeated starting is easy to achieve.

Owner:BEIJING AEROSPACE PROPULSION INST

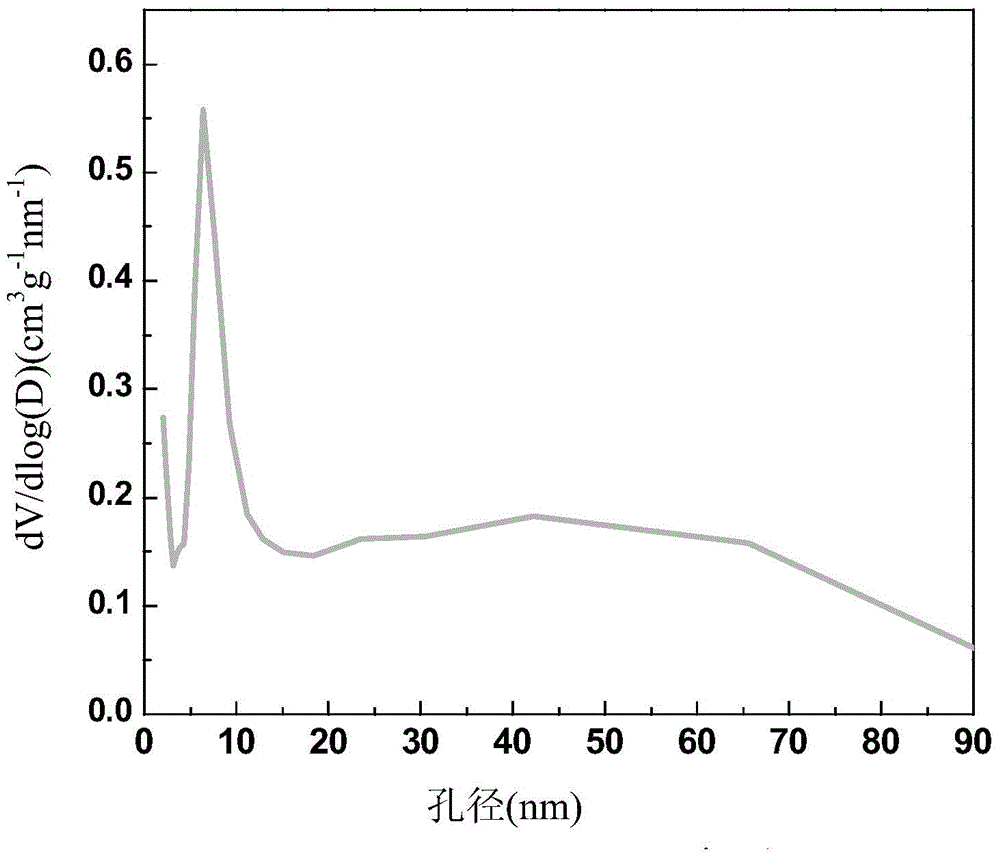

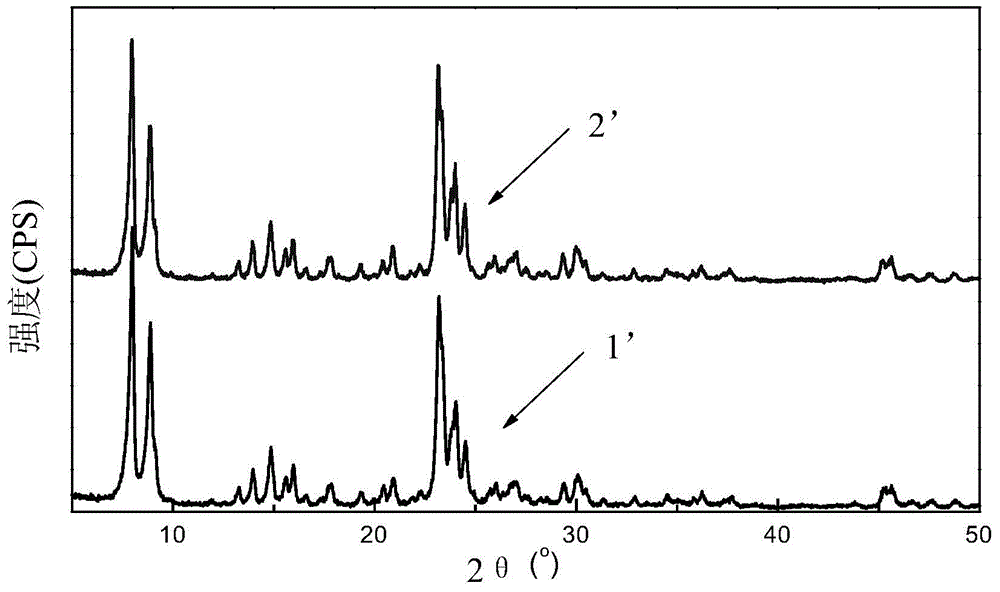

ZSM-5 zeolite catalyst for alkylation of benzene and methanol, preparation method and application thereof

ActiveCN105728018AHigh selectivityNot easy to cokeMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationChemistryMolecular sieve

The invention discloses a ZSM-5 zeolite catalyst for alkylation of benzene and methanol, a preparation method and an application thereof. The catalyst is composed of any one of [gamma]-Al2O3 or [eta]-Al2O3 and hierarchically-porous HZSM-5 molecular sieve as a carrier supporting MgO. On the basis that the total weight of the carrier is 100%, the carrier includes 50-80% of the HZSM-5 molecular sieve and 20-50% of any one of the [gamma]-Al2O3 or [eta]-Al2O3. The supporting load of the MgO is 1-12%. The catalyst has high selectivity on methylbenzene and dimethylbenzene and high stability.

Owner:PETROCHINA CO LTD

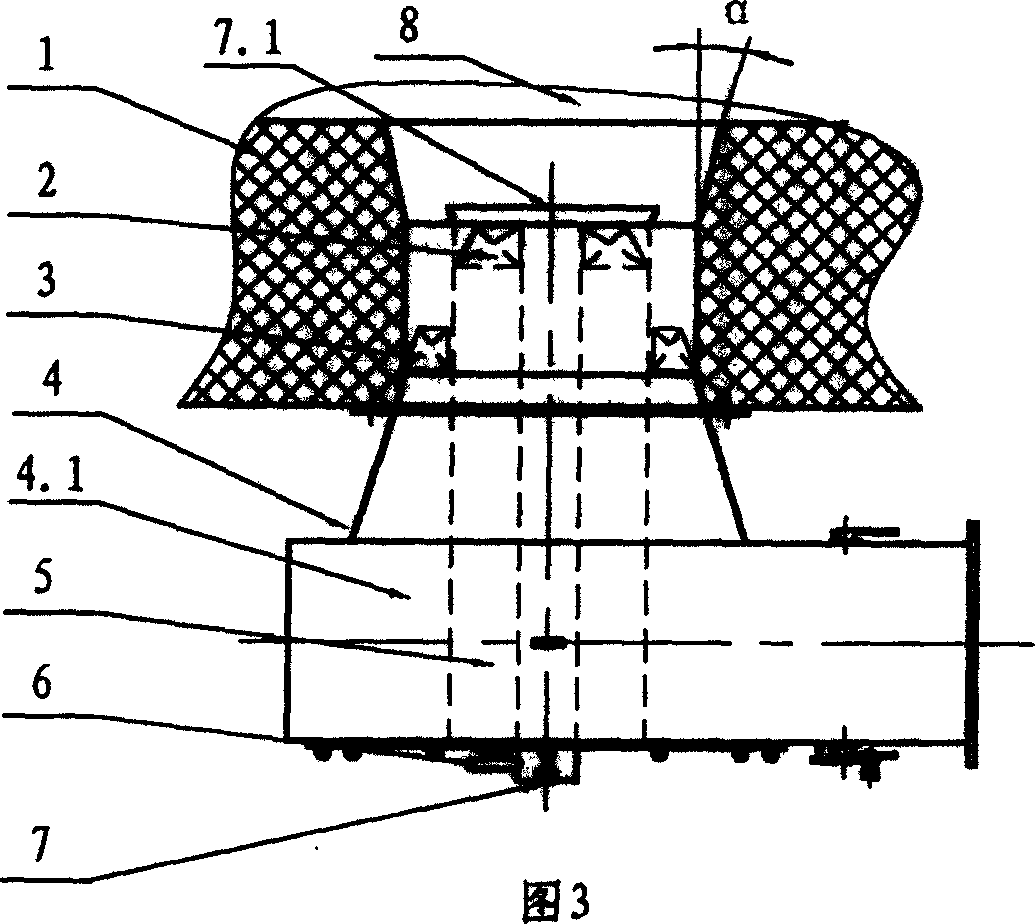

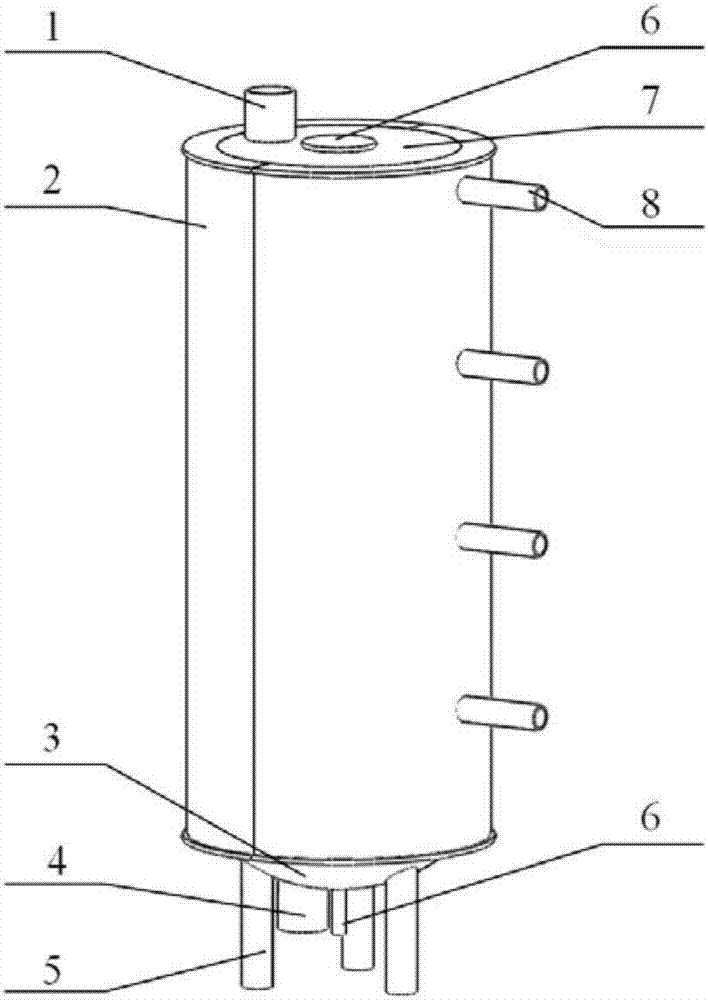

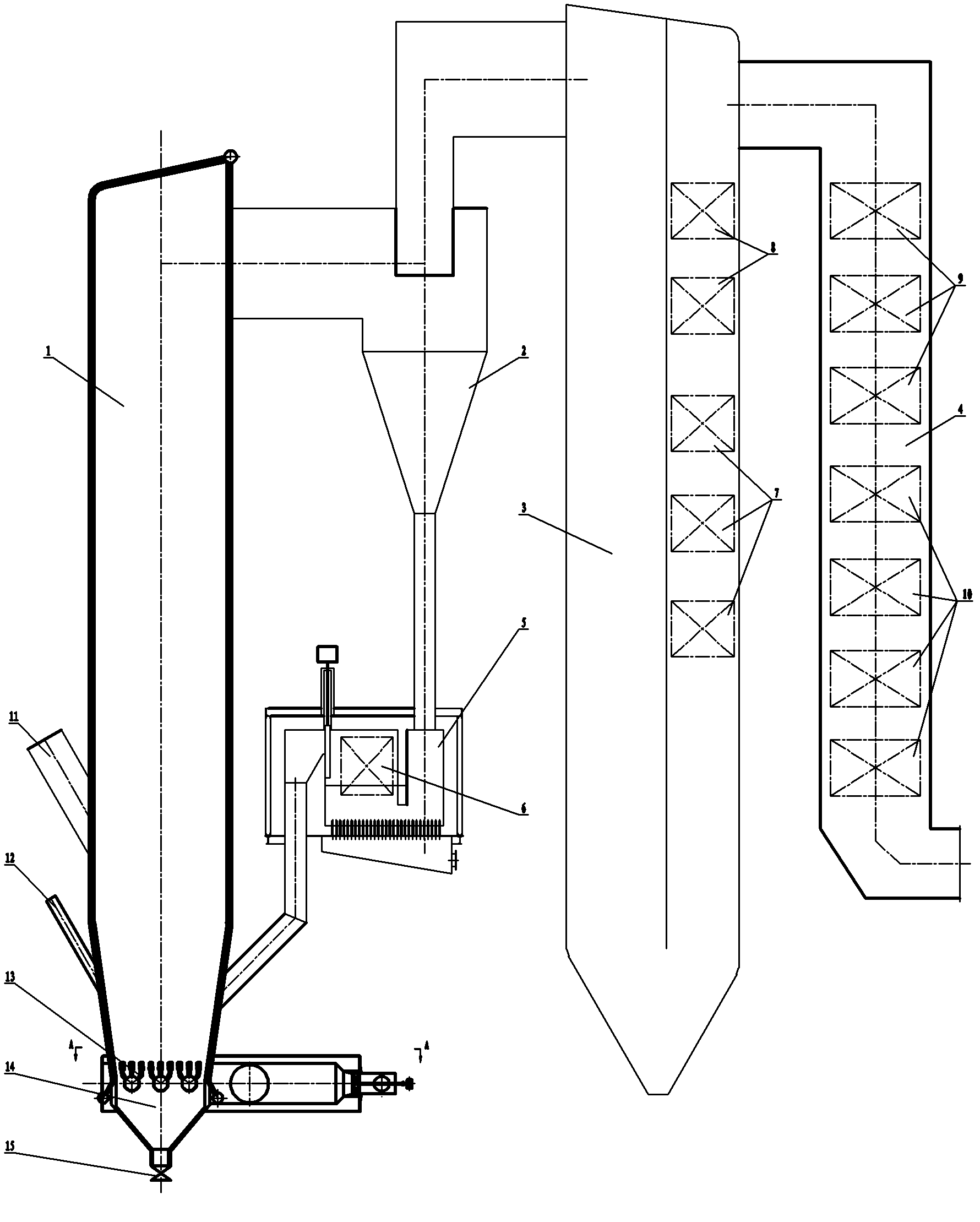

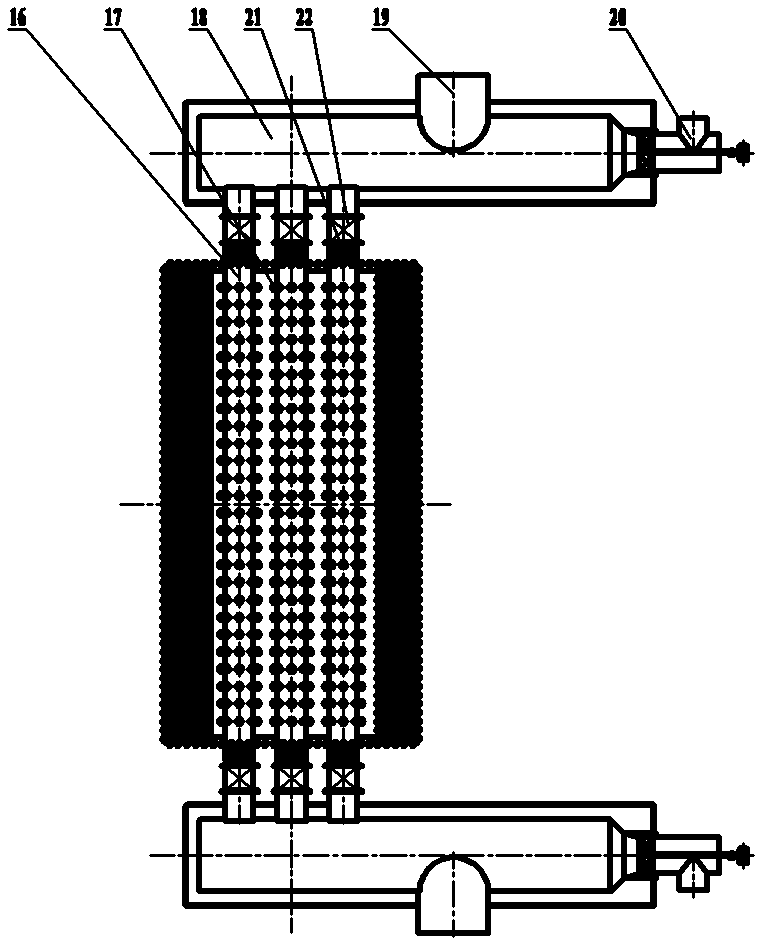

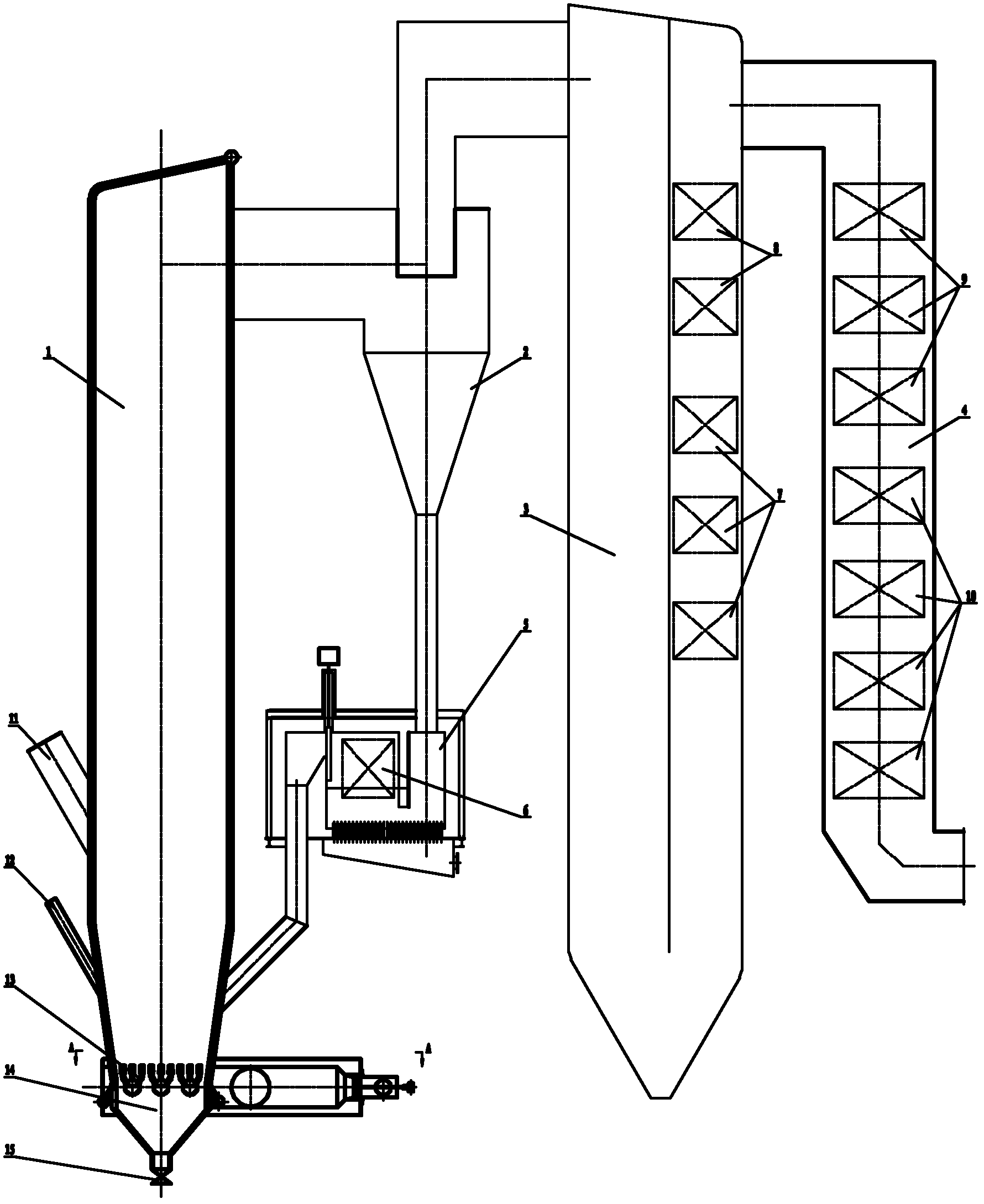

Vertical type pyrolysis device for solid organic waste

ActiveCN107446599ASmall footprintSuitable for places with high space requirementsOven incrustations prevention/removalIndirect heating destructive distillationThermal insulationDrive shaft

The invention relates to a vertical type pyrolysis device for a solid organic waste, and belongs to the technical field of pyrolysis of organic matters. The vertical type pyrolysis device for the solid organic waste comprises a furnace wall, a thermal insulation layer, a transmission shaft, a resistor disc, scraping plates, trays, guide plates, guide canopies, a feed port, a discharge port and a pyrolysis gas outlet; the resistor disc is arranged on the inner wall of the thermal insulation layer of the furnace wall; the feed port is formed in the upper part; the scraping plates arranged in a layered manner are fixed on the transmission shaft and on the trays arranged in a layered manner; the guide plates are fixed on the inner sides of the trays; the guide canopies are arranged on the lower sides of the guide plates; the pyrolysis gas outlet is formed in the furnace wall; and a residue produced after the pyrolysis is discharged from the discharge port in the bottom part. The vertical type pyrolysis device for the solid organic waste adopts a vertical structure, has the advantages of small occupied area, and is suitable for the working place having high space requirements, the multi-stage shearing is adopted, the heat transfer rate is high, coking is not caused easily, the distribution of heat is even, the heat loss is low, and the pyrolysis cost is lowered.

Owner:中海石油环保服务(天津)有限公司

Method for removing alkyl nitrite and nitrous oxide from tail gas

The invention relates to a method for removing alkyl nitrite and nitrous oxide from tail gas, and mainly solves the problems that an additional reducing agent is required to be added, the tail gas is difficult to reach the standard, a reduction catalyst is poor in stability and easy to deactivate, and the like in the prior art. According to the adopted technical scheme, he method comprises the following steps: (a) conveying industrial tail gas containing reducing gas into a deep freezer, cooling the tail gas to 10 DEG C below with freeze water, and recycling alkyl nitrite carried in the tail gas; (b) conveying the cooled tail gas into an absorption tower, and absorbing the alkyl nitrite in the tail gas with alkyl alcohol to obtain alkyl alcohol solution containing alkyl nitrite; and (c) conveying a gaseous discharge material from the top of the absorption tower into a reactor, reacting non-absorbed alkyl nitrite and nitrous oxide with the reducing gas in the industrial tail gas to generate nitrogen in the presence of a catalyst, so that the problems are well solved, and the method can be used for removing the alkyl nitrite and the nitrous oxide from the tail gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

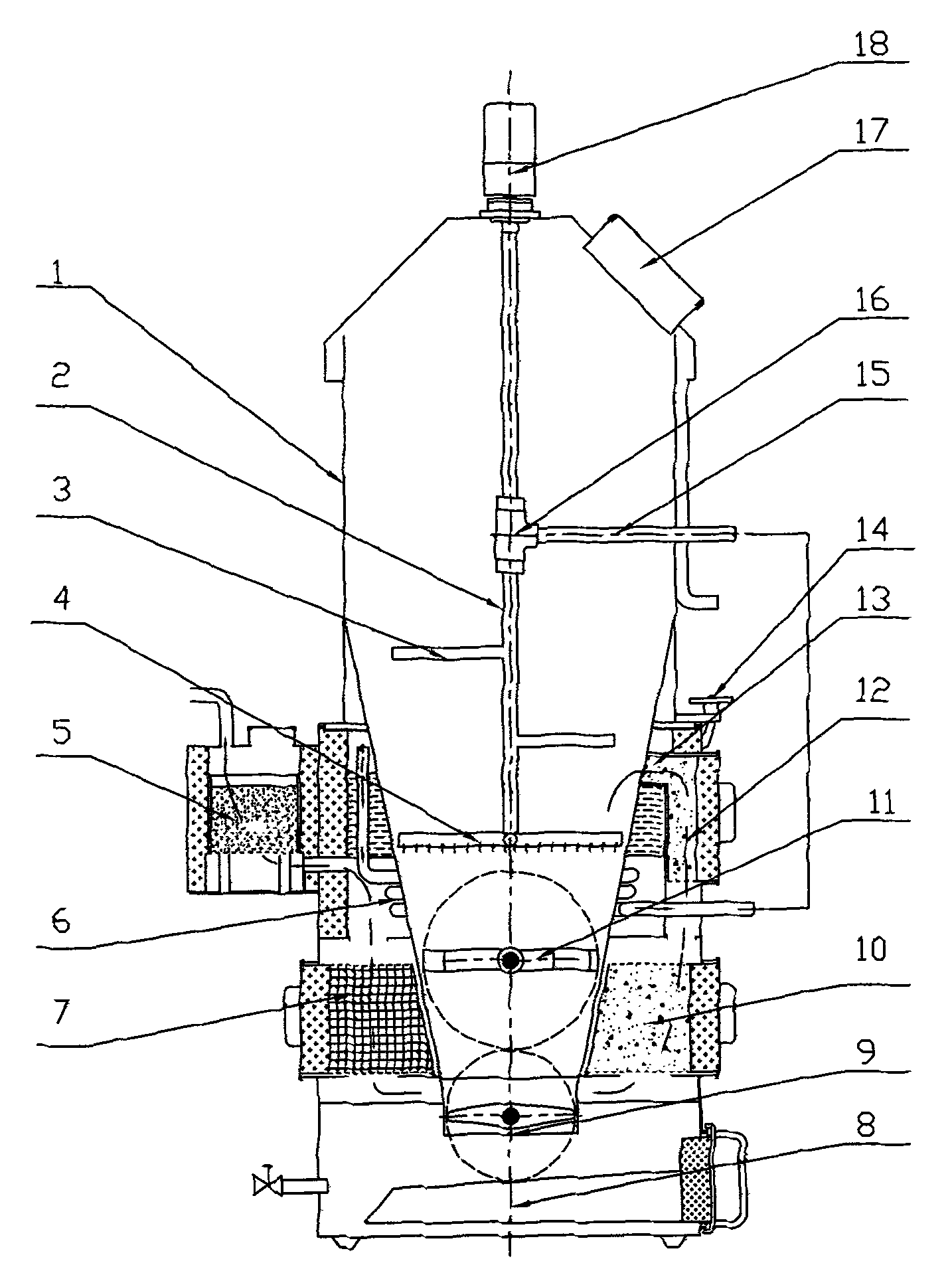

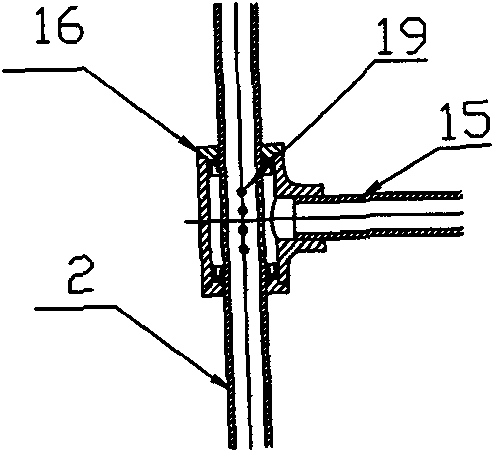

Gasification agent injection device of biomass gasifier

The invention discloses a gasification agent injection device of a biomass gasifier, which comprises a gasification agent inlet pipe, a gasification agent outlet pipe erected in a gasifier body, an electric or manual speed reducer positioned at the top of the gasifier and an air inlet three-way joint fixed in the gasifier body, wherein the upper part of the gasification agent outlet pipe runs through upper and lower ports of the three-way joint to be connected with a main shaft of the speed reducer and to rotate along with the main shaft of the speed reducer under the positioning of the gas inlet three-way joint; the part of the gasification agent outlet pipe in the three-way joint is provided with a plurality of air inlets; the lower end of the gasification agent outlet pipe is communicated with at least one gasification agent injection pipe with a plurality of air injection holes; a transverse port of the air inlet three-way joint is connected with the gasification agent inlet pipe;joints between the gasification inlet pipe and the port of the air inlet three-way joint and between the gasification agent outlet pipe and the port of the air inlet three-way joint are in the state of high-temperature oil seal; and the outer pipe wall of the gasification gas outlet pipe is also provided with a material stirring device.

Owner:周少海 +1

Treatment method of organic waste material for gasification cracking multi coproduction

InactiveCN1786112ASolve a single illImprove heat transfer performanceBiofuelsLiquid hydrocarbon mixture productionCatalytic pyrolysisSolid carbon

The present invention relates to an organic wastes gasification pyrolysis multiple coproduction integrated treatment process. Said process includes the following steps: physical pretreatment: feeding broken organics for gasification into gasification furnace to make gasification; discharging produced high-temperature gasified combustible gas from gasification furnace; heating pyrolysis furnace to pyrolysis temperature, feeding broken organics for pyrolysis into pyrolysis furnace to make pyrolysis reaction to produce oil-gas mixture and solid carbon; making oil-gas mixture undergo the process of heat exchange and be reached to proper temperature for making catalytic pyrolysis to make catalytic pyrolysis; feeding discharged oil-gas mixture into oil-gas fractional equipment so as to obtain fuel oil, non-condensable combustible gas and residuum.

Owner:南京绿展能源有限公司

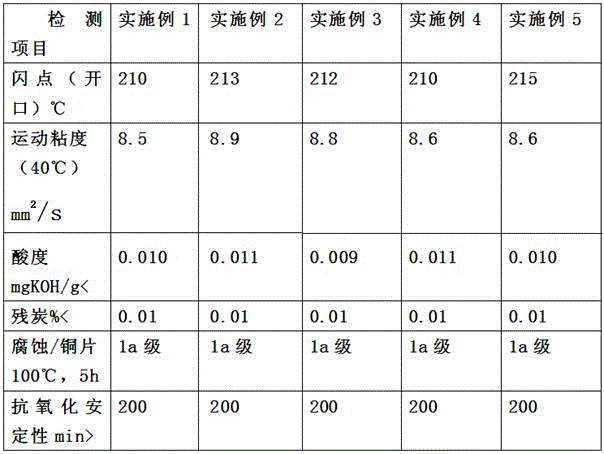

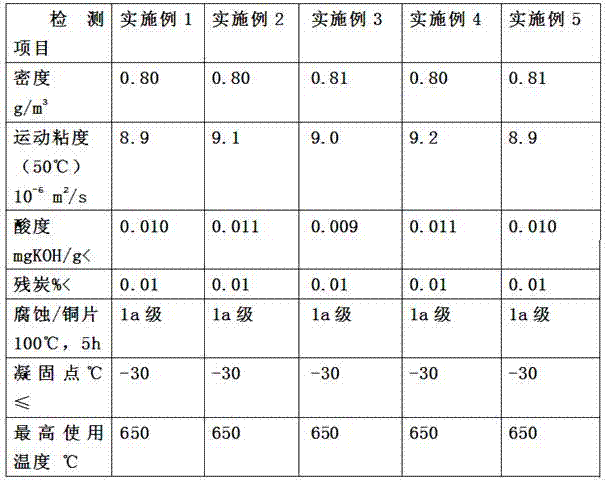

Conduction oil and preparing method thereof

InactiveCN106010463AThermo-oxidatively stableExtended service lifeHeat-exchange elementsBoiling pointAntioxidant

The invention belongs to the field of heat conduction oil, and relates to a heat conduction oil and a preparation method thereof, comprising: base oil, antioxidant, antirust agent, dispersant, coke inhibitor, surfactant, detergent, metal passivator; and The above formulation and base oil are mixed in portions at 65° C. and stirred for 3 hours to obtain heat transfer oil. In the present invention, by compounding antioxidant, detergent, dispersant, antirust agent, scorch inhibitor, metal deactivator, surfactant and base oil, the heat transfer oil with thermal oxidation stability has a long service life The invention has the advantages of prolongation and no coking, can reduce the generation and discharge of low boiling substances, is safe and environmentally friendly, has wide application, reasonable raw material compatibility, simple preparation method, and easy-to-obtain raw materials.

Owner:山东沾化莱斯特石油化工有限公司

Catalyst for synthesizing methyl isopropyl ketone and diethylketone, process for preparing the same and application thereof

InactiveCN1733360AHigh activityIncrease productivityOrganic compound preparationCarbonyl compound preparationMixed oxideMetallole

This invention provides new catalyst with high activity to synthesize methyl isopropenyl ketone and ethanone from MEK and carbinol, its preparation method and application in ketone preparation reaction. The catalyst comprises Zr, Mn, Zn and mixed oxide of alkali metal carried a little Pd. By this product, the reaction can run at very low temperature, does not coke easily, needs less raw material and the cost is lower.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Boiler decoking agent

The invention relates to a decoking agent capable of reducing and removing coke blocks and deposited ash which are positioned in a coal burning boiler and an industrial boiler. The decoking agent comprises the following components in percentage by weight: 3%-10% of potassium nitrate, 1%-5% of magnesium nitrate, 0.5%-2% of cupric nitrate, 5%-20% of ammonium sulfate, 0%-2% of picric acid and 0%-2% of borax. According to the decoking agent, an copper ion is a combustion-supporting catalyst, and can reduce the ignition point of deposited carbon and promote the sufficient combustion of coal powder; borax can crisp the coke blocks, promote the combustion of carbon contained in the coke blocks and realize the falling of the coke blocks; the nitrate is an oxidizing agent, can release oxygen for combustion support under the condition of high temperature and can clean coke and the deposited ash by synergically generating explosion effect with picric acid. The decoking agent disclosed by the invention has the advantages of low cost and easiness for obtaining of raw materials, simple preparation process and convenience for use without causing any corrosion or generating any secondary pollution on the boilers.

Owner:聂冰晶 +1

Environmentally-friendly energy-saving combustion improver for coal

The invention relates to an environmentally-friendly energy-saving combustion improver for coal, comprising the following components in parts by weight: 1-50 parts of sodium chloride, 20-60 parts of sodium hydroxide, 20-60 parts of sodium carbonate, 20-50 parts of potassium carbonate, 20-40 parts of potassium nitrate, 15-60 parts of manganese dioxide, 25-75 parts of barium hydroxide, 30-80 parts of nickel oxide, 20-60 parts of magnesium sulphate, 50-100 parts of magnesium nitrate, 30-80 parts of strontium hydroxide and 30-50 parts of calcium carbonate. Multiple tests show that: combustion time of coal is prolonged, the coal can be completely combusted, and ignition temperature is reduced, thus the coal is difficult to coke, coked substances in a container are eliminated, and dust and smoke are eliminated and desulphurization is carried out, thus the coal is fully burned, the thermal efficiency is improved, non-metallic elements such as sulphur in the coal burning are effectively deposited into the coal, emission of harmful gas in acid gases such as nitric oxide and sulphur dioxide and the dust is reduced, and environmental pollution is reduced. Thus the aims of protecting the environment and saving energy sources are achieved. The environmentally-friendly energy-saving combustion improver is convenient, safe and reliable to use and has obvious economic benefit and social benefit.

Owner:张云佳 +1

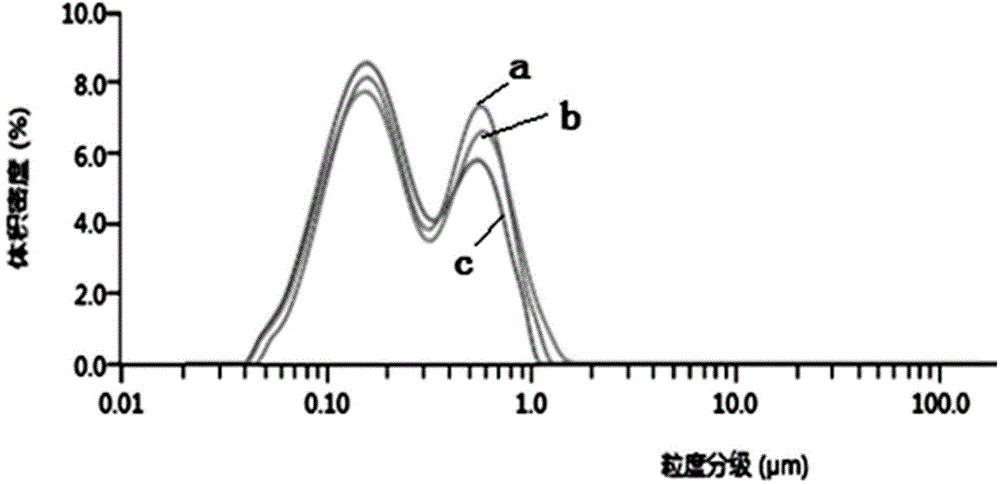

High-stability coconut and cow milk beverage and preparation method thereof

The invention discloses a high-stability coconut and cow milk beverage and a preparation method thereof. Raw materials of the preparation method comprise: 36-50 percent of raw milk, 1.0-6.5 percent of a coconut milk raw material, 0.05-0.15 percent of glycerin monostearate, 0.03-0.06 percent of sucrose fatty acid ester, 0.05-0.15 percent of sodium caseinate, 0.015-0.25 percent of a stabilizer, 0.01-0.04 percent of edible buffer salt, 2-8 percent of a sweetening agent and the balance being water. The preparation method comprises the following steps: (1) mixing raw materials; (2) homogenizing for the first time, refrigerating, mixing after standing, and homogenizing for the second time; and (3) sterilizing and cooling. The high-stability coconut and cow milk beverage disclosed by the invention is clear and cool in taste, and high in stability. According to the preparation method of the high-stability coconut and cow milk beverage, the phenomenon of high-temperature coking in a preparation process is effectively reduced.

Owner:BRIGHT DAIRY & FOOD

High-conductivity heat-conduction oil

InactiveCN107434969AImprove thermal efficiencyLow toxicityHeat-exchange elementsAntioxidantHigh heat

The invention belongs to the field of chemical technology and specifically relates to high-conductivity heat-conduction oil. The high-conductivity heat-conduction oil comprises the following ingredients (by weight): 80-120 parts of base oil, 5-8 parts of a purification dispersant, 5-10 parts of a high-temperature antioxidant, 5-8 parts of an oxidation and corrosion inhibitor, 2-5 parts of an oiliness agent, 1-3 parts of an anticoking agent, 1-3 parts of a pour-point depressant, 1-3 parts of a viscosity index improver, 1-2 parts of a metal passivator, 1-3 parts of an antirust agent and 1-3 parts of nanoparticles. The high-conductivity heat-conduction oil has advantages of high safety, low toxicity, wide source of available raw materials and low cost. The synthetic oil has good thermal stability, high thermal efficiency and long service life, is not easy for coking, is safe and environmentally friendly, and is widely used.

Owner:山东沾化莱斯特石油化工有限公司

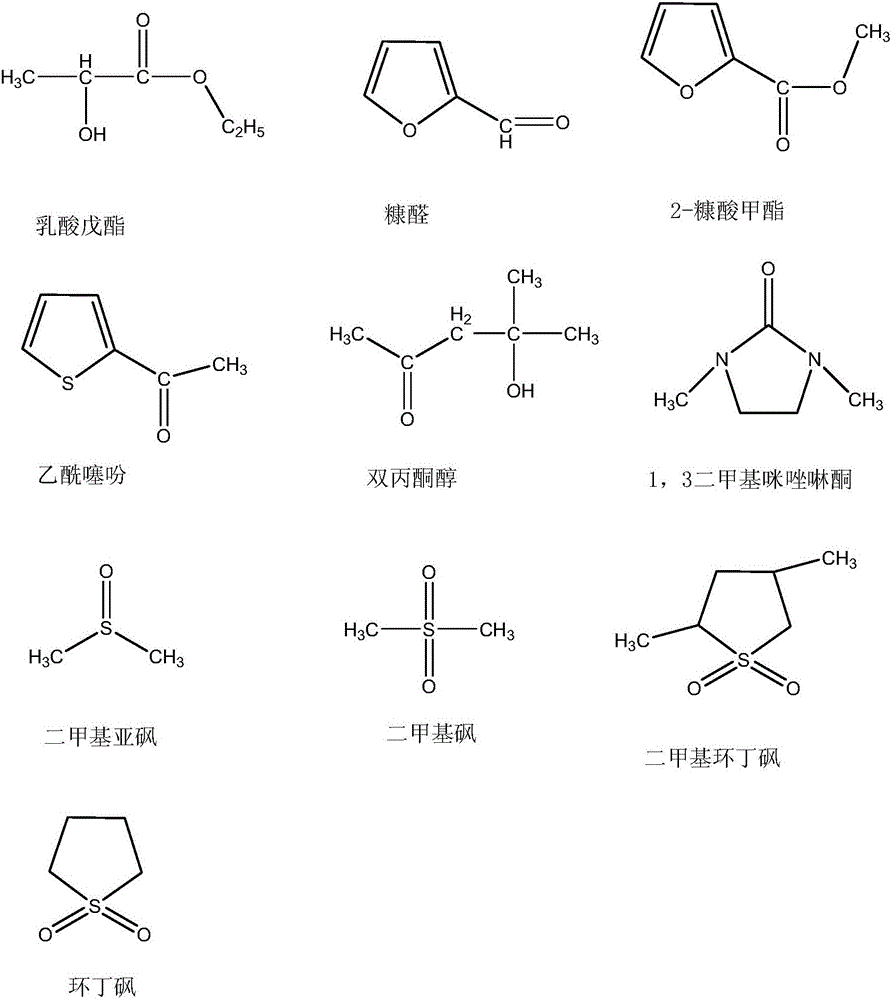

Method of extracting and separating crude oil

InactiveCN106833719AAvoid cokingInhibit aggregationRefining by solvent de-asphaltingHydrocarbon oils treatmentDistillationSolvent

The invention provides a method of extracting and separating crude oil. The method comprises the step of extracting the crude oil by adopting a selective solvent, wherein the selective solvent comprises a polar non-proton solvent. According to a polarity effect and hydrogen-bond interaction, the crude oil is divided into polar and nonpolar two components. During solvent separation, an inorganic salt component in the crude oil is enriched, and corrosion of Cl to equipment is reduced. A demulsifier can be added into the solvent extraction process so that moisture in the crude oil can be removed through the solvent better. While the crude oil is separated, the content of S, N and metal in a light component can be reduced at the same time, and the processing pressure of subsequent devices is reduced. According to the method of extracting and separating the crude oil, not only is energy consumption far lower than that of distillation, but also coking, polymerization or dissociation of heavy distillates of petroleum in the process can be avoided, a high-vacuum apparatus during reduced pressure distillation is not needed either, and the operation cost and equipment cost are remarkably reduced.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

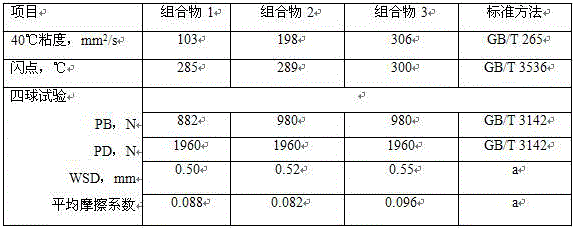

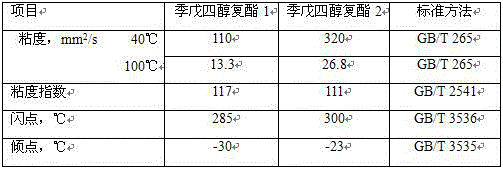

Chain oil composition with excellent high temperature abrasion resistance

InactiveCN105419910AHigh flash pointHigh viscosity indexAdditivesBase-materialsDistillationPhosphate

The invention discloses a chain oil composition with excellent high temperature abrasion resistance. The composition is prepared from, by mass, 92%-96% of dipentaerythritol ester, 1%-3% of antioxygen composition, 2%-4% of abrasion resisting agent composition, 0.2%-0.8% of corrosion inhibitor and 0.2%-0.6% of antirust agent. Dipentaerythritol ester is prepared through the steps that pentaerythritol, binary acid and unitary saturated fatty acid react for 12-16 h at the temperature of 160 DEG C to 200 DEG C at the presence of a catalyst, and then reduced pressure distillation, hargil adsorption and filtering are carried out. The antioxygen composition is a composition of diphenylamine antioxygen, naphthylamine antioxygen and an amine antioxygen oligomer. The abrasion resisting agent composition is a composition of phosphite ester, phosphate and dialkyl dithiocarbamic acid molybdenum. Dipentaerythritol ester is adopted as base oil of chain oil, and the advantages of being high in flash point, low in frequency point, high in viscosity index, low in evaporation loss, not likely to coke and the like are achieved. Dipentaerythritol ester is reasonably compounded with an additive, and the high-temperature chain oil composition with the excellent high temperature abrasion resistance is obtained.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Circulating fluid bed waste incineration boiler with open-type furnace chamber

InactiveCN102305406AEasy to wrapLong continuous running timeIncinerator apparatusCooling chamberSuperheater

The invention relates to a circulating fluid bed waste incineration boiler with an open-type furnace chamber. The circulating fluid bed waste incineration boiler comprises the open-type furnace chamber, a cyclone separator, a cooling chamber and a tail convection flue which are connected with one another in turn, wherein the lower end of the cyclone separator is connected with an external heat exchanger, and the other end of the external heat exchanger is connected with the open-type furnace chamber; a high-temperature over-heater is arranged in the external heat exchanger; a plurality of air distribution tubes are arranged on the same horizontal plane equidistantly to form an open-type air distribution plate which is arranged at the bottom of the open-type furnace chamber; an ash hopper is connected below the open-type air distribution plate; a fuel ash valve is arranged below the ash hopper; the open-type air distribution plate separates the upper part of the open-type furnace chamber and the ash hopper; and the open-type air distribution plate consists of the plurality of air distribution tubes. The circulating fluid bed waste incineration boiler can successfully discharge materials which can be easily wound on an air cap, or large-particle or even blocky materials such as iron wires, iron nails and the like in wastes, can uniformly distribute air, is difficult to coke and clinker, and fulfills the aims of prolonging the continuous operation time of the waste incineration boiler and saving energy resources.

Owner:WUXI TAIHU BOILER

Cotton picker spindle oil and preparation method thereof

InactiveCN101845354AImprove performanceNo damageAdditivesBase-materialsAgricultural engineeringProcess engineering

The lubricating grease prepared by the invention not only is applicable to cotton picker spindle oil, but also has the advantages of good shear reversibility, high and low temperature, extreme pressure wear resistance, rust resistance, compatibility (with other lipid) and the like and thereby has wide scope of application, can realize very good lubrication action under adverse working conditions,can be widely applied to agricultural machinery, building machinery, railways, ball mills and other equipment as well as steel making, cement, power generation, packaging, chemical engineering, automobile and other industrial fields. Lubricating grease products increasingly develop to the direction of high drop point, high efficiency, long service and environmental friendliness. Ti-based composite resin is just adaptable to the trend of the lubricating grease, now has become the focus of attention in the lubricating grease industry, represents the international advanced level of the lubricating grease, and is a development direction of high-performance lubricating grease variety in the world nowadays.

Owner:新疆五家渠现代石油化工有限公司

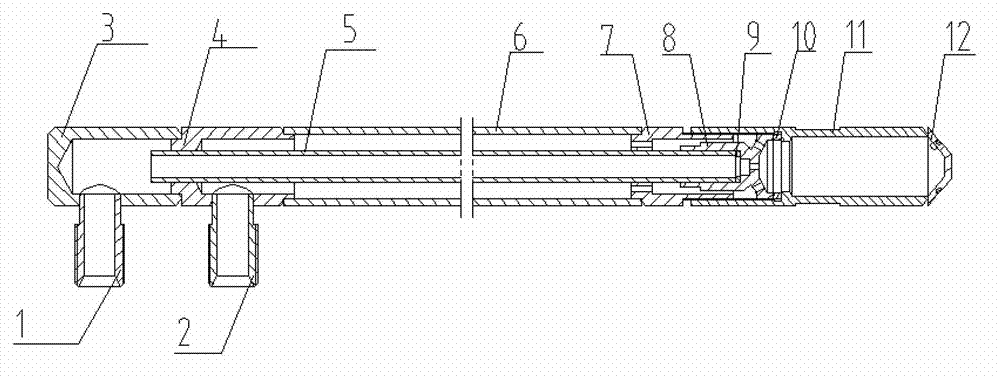

Micro-explosion atomization oil gun

The invention discloses a micro-explosion atomization oil gun, belonging to the field of thermal energy power. The micro-explosion atomization oil gun comprises an oil interface, a gas interface, an oil chamber and a gas chamber, wherein the oil chamber is communicated with the oil interface; the gas chamber is communicated with the gas interface; the oil chamber is communicated with an inner tube; the gas chamber is communicated with an outer tube; flow mixers are arranged at the front ends of the inner tube and the outer tube; the flow mixers are communicated with the front end of the inner tube through a small copper pad; the flow mixers are communicated with the front end of the outer tube through an air pipe interface; the front ends of the flow mixers are connected with a premixing chamber through a larger copper pad; and an atomization head is communicated with the front end of the premixing chamber. The micro-explosion atomization oil gun has the beneficial effects of small automation granularity and combustion sufficiency, so that the combustion efficiency is increased, the combustion oil is saved, the pollutants in combustion products are reduced, and the automation head is unlikely to be blocked and coked.

Owner:徐州艾迪科技有限公司

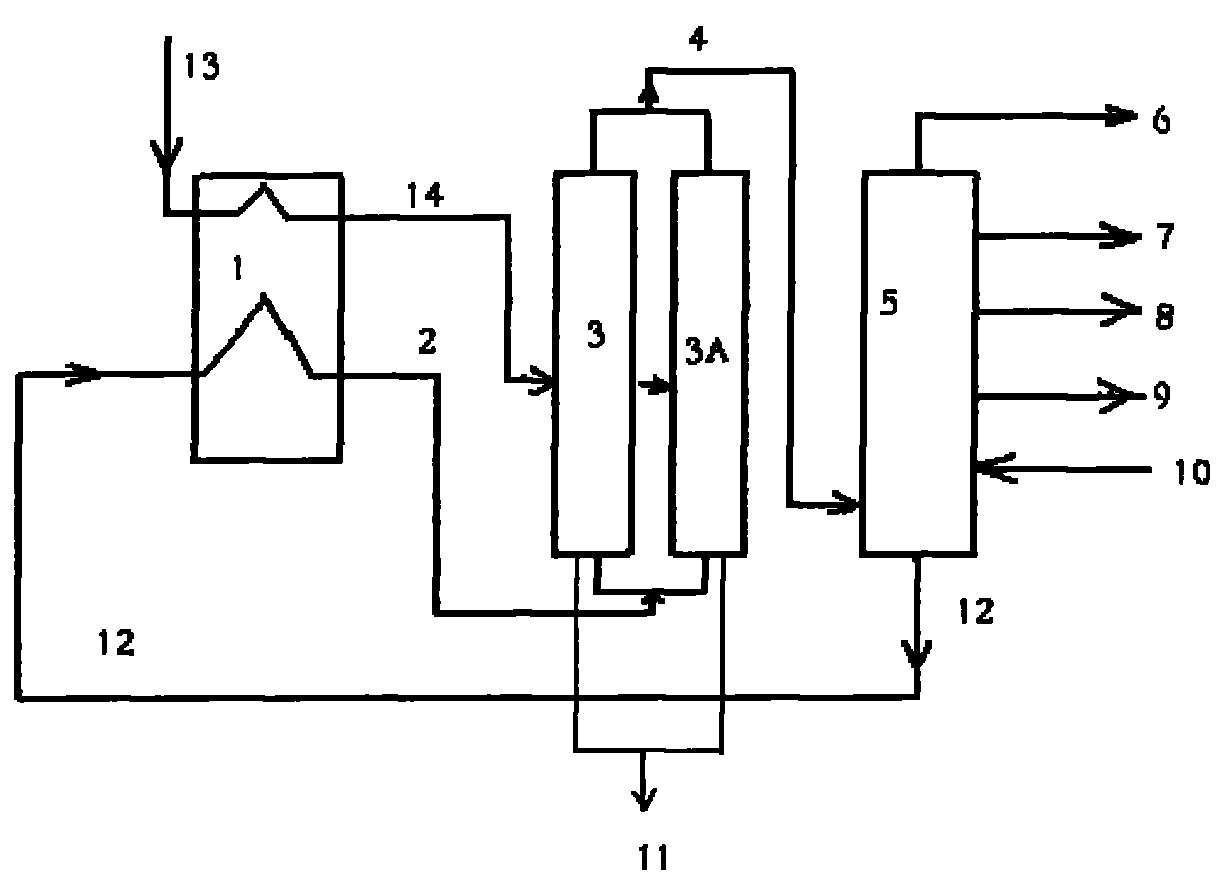

Method for producing needle coke raw material by using delayed coking process

ActiveCN102041013AExpand sourceThe method flow is simpleCoking carbonaceous materialsGeneration rateDesorption

The invention discloses a method for producing a needle coke raw material by using a delayed coking process. In the method, full-range coal tar is imported to the top and the middle and a high-temperature conventional coking raw material is imported to the bottom; the high-temperature oil gas generated by the conventional coking raw material via high-temperature cracking is mixed with the full-range coal tar with lower temperature at the top and the middle of a reactor so that the full-range coal tar can crack hydrocarbon molecules with high reaction activity at a proper high temperature to achieve the aim of desorption; for the full-range coal tar, under the condition of the delayed coking process, asphaltene and partial colloid are condensed to form coke which is deposited in a coking tower so as to remove the components going against the production of the needle coke; furthermore, by means of the injection of the low-temperature full-range coal tar, the cracking temperature of the conventional coking raw material is reduced, the high-temperature cracking time of the conventional raw material is shortened, the secondary reaction is decreased, the coke generation rate is reduced and the stable operation period of a single tower is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-temperature resisting heat conductive oil

InactiveCN107090335AImprove thermal efficiencyLow toxicityHeat-exchange elementsLubricant compositionEnvironmental resistanceChemical industry

The invention belongs to the technical field of chemical industry and especially relates to a high-temperature resisting heat conductive oil. The high-temperature resisting heat conductive oil contains the following components in parts by weight: 80-120 parts of base oil, 1-3 parts of cleaning agent, 5-8 parts of dispersing agent, 5-10 parts of high-temperature antioxidant, 1-3 parts of anti-coking agent, 1-3 parts of pour point reducer, 1-3 parts of viscosity reducer and 1-2 parts of metal deactivator. The high-temperature resisting heat conductive oil is higher in safety, low in product toxicity, wide in raw material resource and low in cost. The compounded oil is high in thermal stability, low in low temperature viscosity and high in thermal efficiency, has the advantages of long service life and difficulty in coking, is capable of reducing generation and emission of low-boiling point substance, is safe and environment-friendly and is wide in application.

Owner:山东沾化莱斯特石油化工有限公司

Polytetraurea lubricant grease

InactiveCN105779083AStrong viscosity retention at high temperatureLow pour pointLubricant compositionFood industryAntioxidant

The invention discloses polytetraurea lubricant grease. The polyurea lubricant grease disclosed by the invention is obtained through taking low-viscosity lubricating oil prepared from ester oil and poly alpha olefin as base oil, taking synthesized polytetraurea as a thickener and adding a friction modifier and an antioxidant. According to the ureido-based lubricant grease disclosed by the invention, the thickening effect is greatly increased without increasing the cost, the comprehensive performance is good, and the lubricant grease can be applied to machinery in the fields of electrical appliance industry, metallurgical industry, food industry, paper-making industry, automobile industry, airplane industry and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Biomass smokeless boiler

InactiveCN103206703ANot easy to cokeExtended service lifeSolid fuel combustionAir/fuel supply for combustionDynamic fieldCyclone

The invention relates to a biomass smokeless boiler comprising an automatic-control unit, a feeding mechanism, a combustion mechanism, an air-supply mechanism, an air-inducing mechanism and a boiler body. The boiler body at least includes a main boiler body, a first heat-absorption boiler body and a second heat-absorption boiler body, and the main boiler body, the first heat-absorption boiler body and the second heat-absorption boiler body are eccentrically connected with one another. A plurality of cyclone tubes are arranged on the periphery of the main boiler body, and one tangential hole is formed between each of the cyclone tubes and the main boiler body. The biomass smokeless boiler has the advantages that the biomass smokeless boiler, as compared with a conventional boiler, has larger heat-absorption area and is not prone to dust formation after a plurality of boiler bodies are adopted, and temperature of the smoke is reduced to less than 100 DEG C due to lengthening of a smoke duct; the cyclone tubes facilitate intensive mixing of the biomass fuel and the air prior to high-intensity combusting of biomass fuel, and good air dynamic field inside the boiler is guaranteed by the aid of an air-inducing device and an air blower; since the biomass fuel is pushed when the center rotates, coking inside the boiler is avoided, and ash-removing can be performed automatically; and boiler surface is evenly galvanized, and therefore, service life of the boiler is greatly prolonged.

Owner:陈海洋

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com