Refining technique of base oil regenerated from used lubrication oil

A technology for regenerating base oils and waste lubricating oils, applied in lubricating compositions, etc., can solve problems such as ineffective removal of acidic substances, non-compliance with environmental protection requirements, acid corrosion, etc., to maximize product benefits, improve appearance quality, The effect of efficient fractionation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

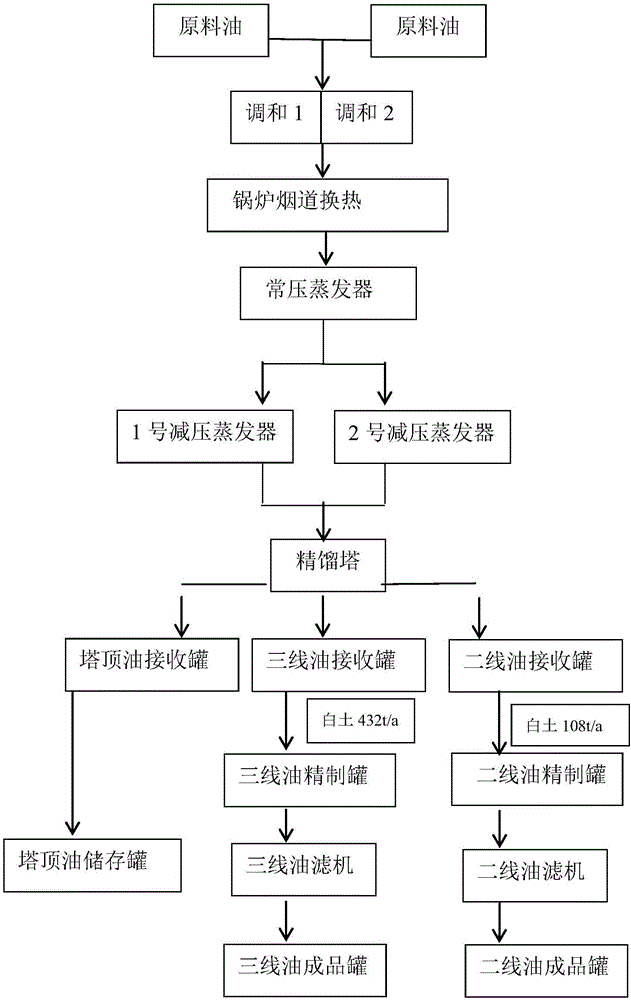

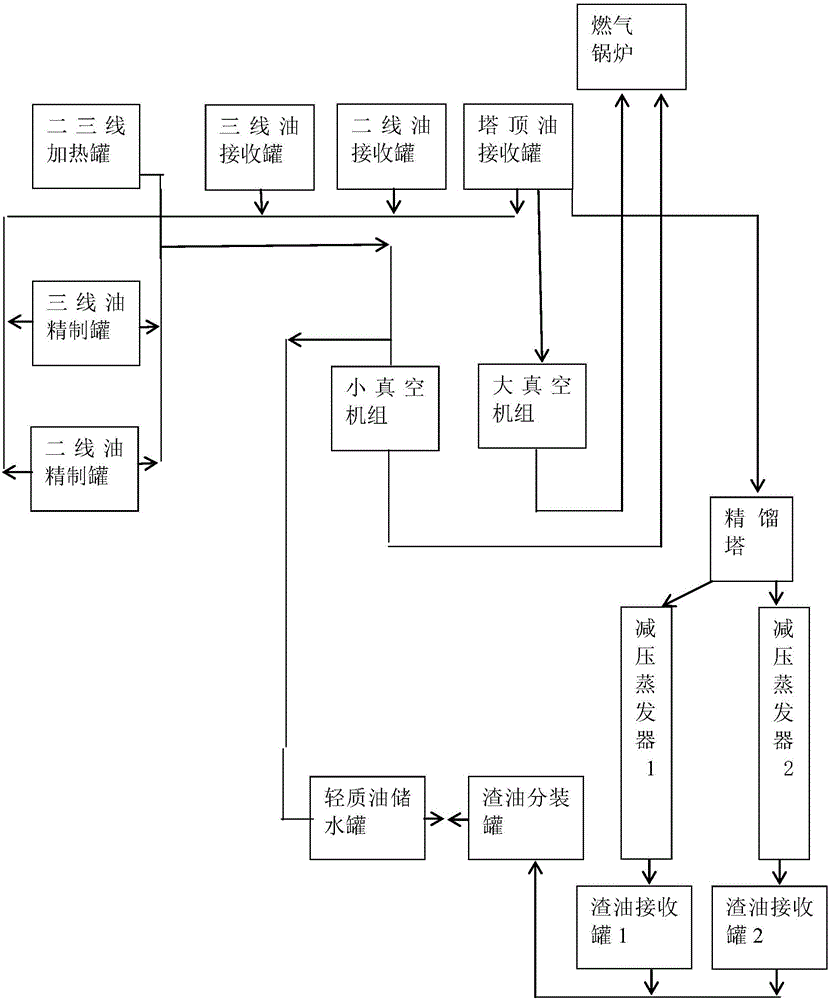

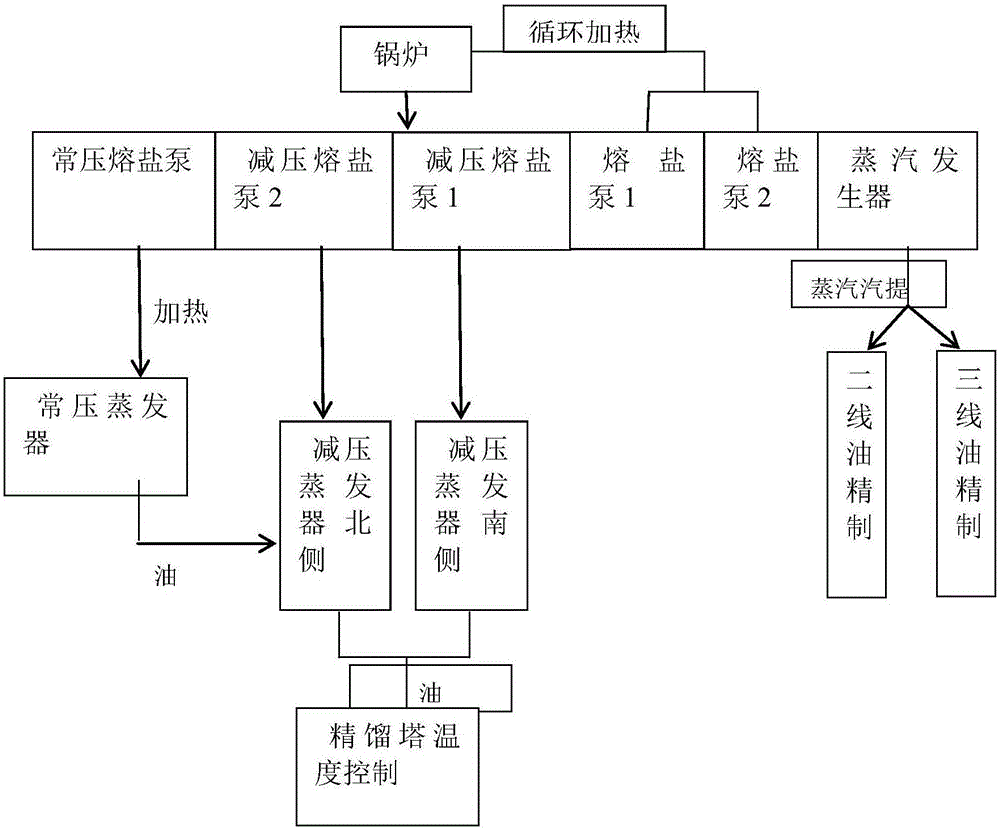

[0040] like figure 1 and figure 2 In the process flow diagram given, the refining process of waste lubricating oil regenerated base oil of the present invention includes solid waste removal, solvent pretreatment, flocculation treatment, atmospheric distillation, vacuum distillation, rectification and solvent refining stages. The specific process is as follows stated.

[0041] (1) Remove solid waste

[0042] The collected waste lubricating oil is poured into a high-speed centrifuge, and the solid waste in the waste lubricating oil is removed by centrifugation to obtain waste lubricating oil without solid impurities, which effectively avoids coking after it enters the heating equipment.

[0043] (2) Solvent pretreatment

[0044] Mix No. 120 solvent oil and methyl tert-butyl ether in a mass ratio of 1:1 to 1:5 to make a mixed solvent, and waste lubricating oil and mixed solvent in a mass ratio of 1:1.5 to 1:2 Proportional mixing, stirring for 0.5-1 hour, standing for 5-8 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com