Vertical type pyrolysis device for solid organic waste

A technology of organic waste and pyrolysis, which is used in special forms of dry distillation, indirect heating dry distillation, petroleum industry, etc., can solve the problems of high sealing requirements of reactors, high pretreatment requirements, and unsuitable for industrial applications, so as to reduce heat Dissipated, reduced pyrolysis cost, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

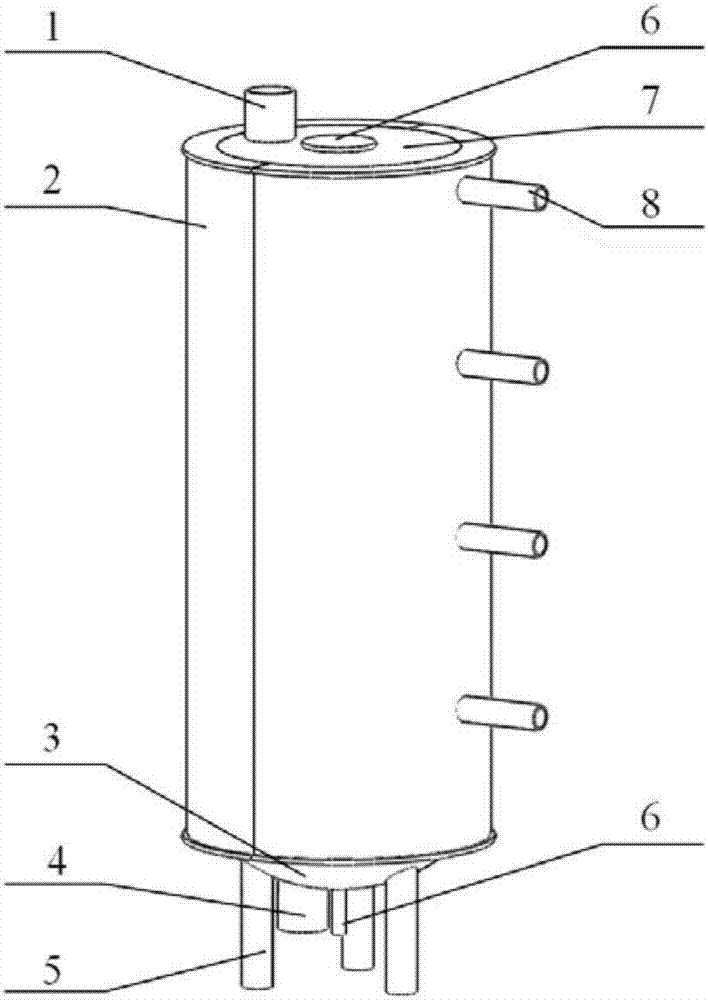

[0031] A vertical pyrolysis device for solid organic waste consists of a feed port 1, an insulation layer 2, a furnace bottom 3, a discharge port 4, a column 5, a transmission shaft 6, a furnace wall 7, a pyrolysis gas outlet 8, and a resistance sheet 9. Scraper 10, pallet 11, deflector 12, deflector canopy 13, bottom scraper 14 are formed. The feed port 1 is located above the tray 11; the resistor sheet 9 is placed between the insulation layer 2 and the furnace wall 7; the tray 11 is hollow and placed between the furnace walls 7, which can be welded or flanged; the middle of the deflector 12 is The shape of a triangular prism has three blades along the surface of the prism, which are fixed on the tray 11 and do not rotate with the transmission shaft 6; the scraper 10 is in the shape of a hook and rotates with the transmission shaft 6; The bottom surface is tangent; the deflector umbrella cover 13 is in the shape of an umbrella cover, connected to the transmission shaft 6, tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com