Binderless nano ZSM-5/beta symbiotic molecular sieve catalyst

A ZSM-5, symbiotic molecular sieve technology, applied in molecular sieve catalysts, physical/chemical process catalysts, organic chemistry, etc., can solve the problems of poor catalyst stability, low yields of propylene and aromatic hydrocarbons, etc., and achieve good technical effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

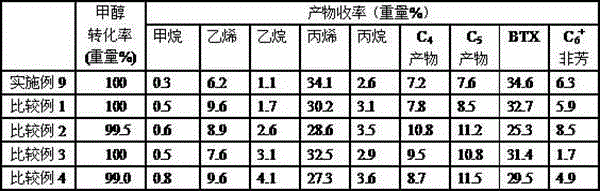

Examples

Embodiment 1

[0025] Weigh 30 grams of white carbon black and 4.8 grams of alumina, add 60 grams of silica sol (SiO 2 The mass percentage is 40%) for kneading and molding, and the shaped catalyst is baked at 100°C for 3 hours.

[0026] Add 20 grams of triethylamine, 10 grams of tetrapropylammonium hydroxide and 3 grams of distilled water in advance in the reactor, and place 60 grams of the above-mentioned cylindrical product in the reactor after sealing the porous stainless steel mesh top, and then heat it under hydrothermal conditions. Under the control of the growth rate of molecular sieve crystals, the gas-solid phase treatment was carried out at 120°C for 8 days. After the product was taken out, it was washed with distilled water, dried in the air and then calcined at 550°C in an air atmosphere. It was exchanged three times with 5% ammonium nitrate solution at 80°C, dried and calcined in a muffle furnace at 550°C for 8 hours to obtain a binder-free ZSM-5 / β symbiotic zeolite molecular s...

Embodiment 2

[0029] Weigh 40 grams of diatomaceous earth and 6.5 grams of aluminum sulfate, add 45.5 grams of silica sol (SiO 2 The mass percentage is 40%) for kneading and molding, and the shaped catalyst is baked at 100°C for 3 hours.

[0030] Add 10 grams of ethylenediamine, 20 grams of tetraethylammonium hydroxide and 10 grams of distilled water in advance in the reactor, place 50 grams of the above-mentioned cylindrical product in the reactor and seal it above the porous stainless steel mesh, and heat it under hydrothermal conditions. Under the control of the growth rate of molecular sieve crystals, the gas-solid phase treatment was carried out at 150°C for 5 days. After the product was taken out, it was washed with distilled water, dried in the air and then calcined at 550°C in an air atmosphere. Then, it was exchanged three times in 5% ammonium chloride solution at 90°C, and after drying, it was baked in a muffle furnace at 600°C for 4 hours to obtain a binder-free ZSM-5 / β symbioti...

Embodiment 3

[0034] Weigh 30 grams of rice husk ash and 4.8 grams of alumina, add 42.2 grams of silica sol (SiO 2 The mass percentage is 40%) for kneading and molding, and the shaped catalyst is baked at 100°C for 3 hours.

[0035] Add 10 grams of ethanolamine, 20 grams of tetrapropylammonium hydroxide and 20 grams of distilled water in advance in the reactor, place 30 grams of the above-mentioned cylindrical product in the reactor and seal it above the porous stainless steel mesh, under hydrothermal conditions, Control the growth rate of molecular sieve crystals, and perform gas-solid phase treatment at 160° C. for 3 days. After the product was taken out, it was washed with distilled water, dried in the air and then calcined at 550°C in an air atmosphere. Then, it was exchanged three times in 5% ammonium nitrate solution at 90°C, and after drying, it was baked in a muffle furnace at 500°C for 4 hours to obtain a binder-free ZSM-5 / β symbiotic molecular sieve catalyst with a grain size of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com