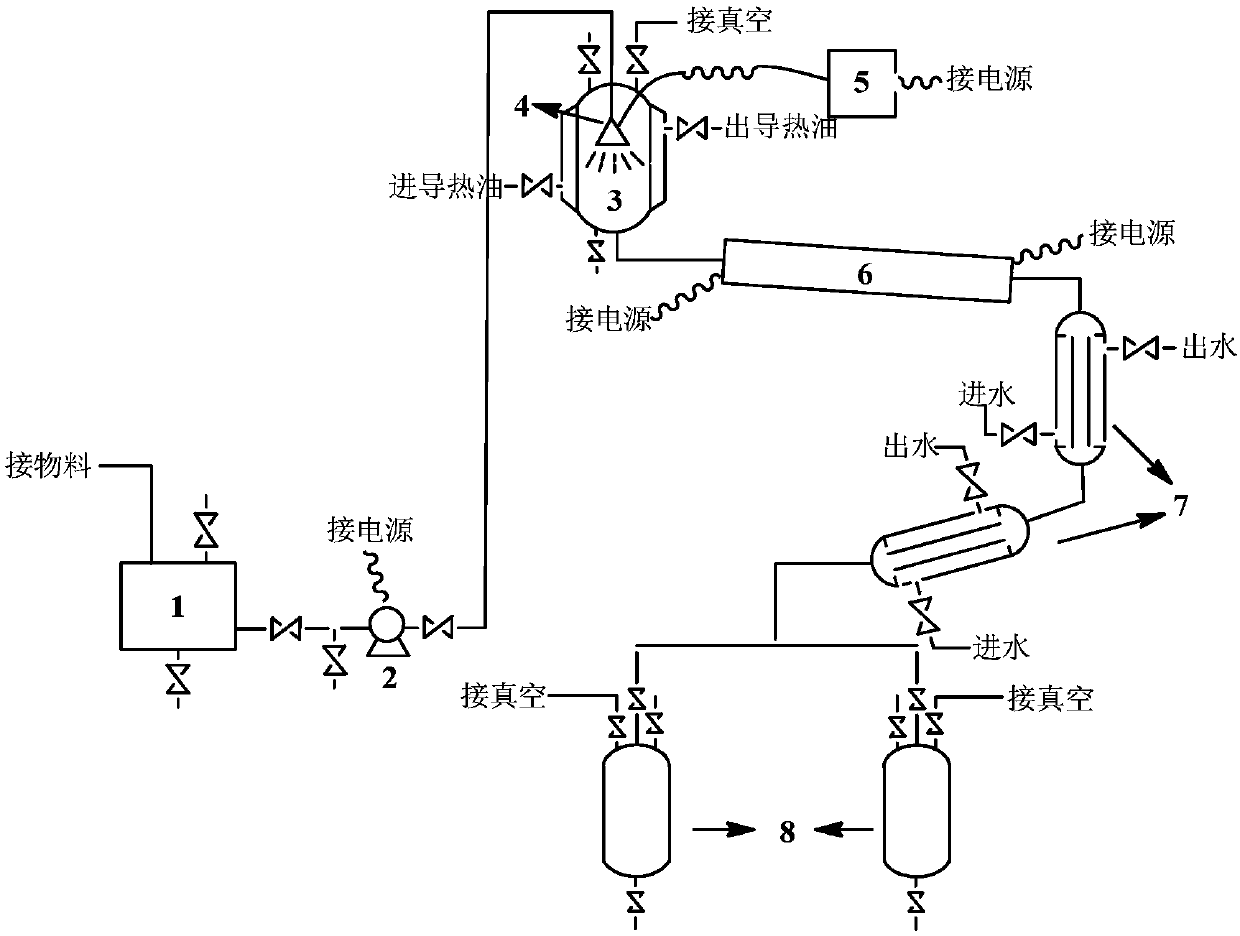

Process and device for producing myrcene by thermal cracking of beta-pinene

A technology of thermal cracking and laurelne, which is used in organic chemistry, heterogeneous hydrocarbons and other directions, which can solve the problems of failure to achieve long -term continuous production, complex equipment composition, and large energy consumption. The effect of simple and gasification temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Turn on the vacuum system to 0.07MPa; set the metering feed pump value to 100kg / h; set the power of the ultrasonic atomization device to 500W, and set its frequency to 30kHz; turn on the heating system of the vaporizer and cracking tube, and the temperature of the vaporizer is 155°C , the cracking tube temperature is 510°C. β-pinene enters the gasifier from the material storage tank through the ultrasonic atomizing nozzle, and enters the cracking tube to react after gasification, and the reaction liquid enters the product collector after condensation. When the liquid level reaches 2 / 3 of the collector, replace another collector, release the vacuum of the collector, and release the material. The mass yield of myrcene is 95.6%, and the purity is 79.6%.

Embodiment 2

[0028] The frequency of the ultrasonic atomization device was set to 15 kHz, and other process conditions were the same as in Example 1. The mass yield of myrcene is 95.2%, and the purity is 79.2%.

Embodiment 3

[0030] The gasifier temperature is set to be 150° C., and the other process conditions are the same as in Example 1. The mass yield of myrcene was 95.0%, and the purity was 78.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com