System and method for preparing crude ethanol through hydrogenation of hydrogenation raw materials and application

A technology for the preparation of crude ethanol and hydrogen, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve problems such as insufficient heat utilization, increased equipment cost, and incomplete separation, and achieve improved gas-liquid separation Effect, reduce corrosion, reduce the effect of equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

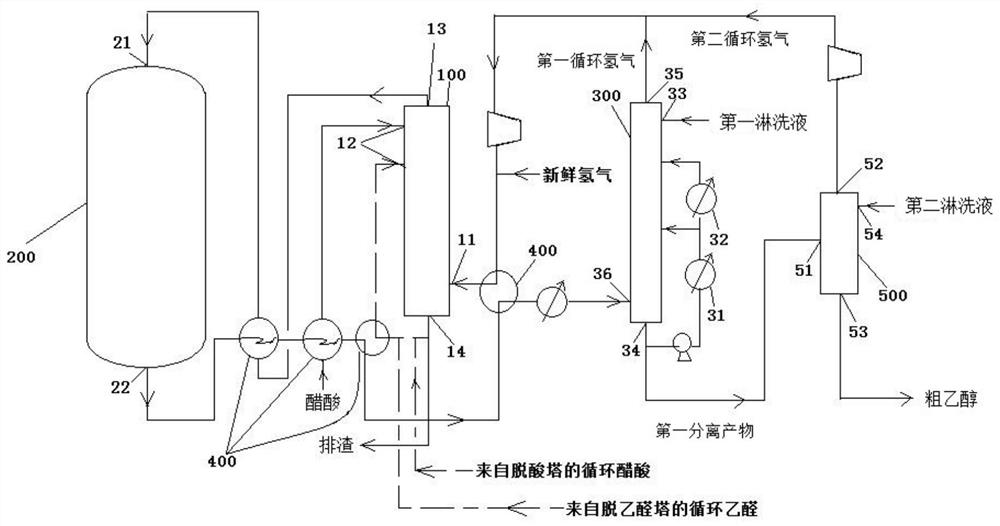

[0082] according to figure 1 Shown flow process, utilize system and method provided by the invention to carry out hydrogenation of acetic acid to prepare crude ethanol, the implementation process is as follows:

[0083] (1-1) The fresh acetic acid as hydrogenation raw material and the circulating acetic acid from the external deacidification tower and the circulating acetaldehyde from the external deacidification tower are respectively carried out in the heater 4 with the high-temperature reaction product from the reaction product outlet 22 Heat exchange, preheating the hydrogenation raw material to 110°C and entering the upper part of the gasification device 100 from the hydrogenation raw material inlet 12 for spraying;

[0084] (1-2) Mix the fresh hydrogen with the circulating hydrogen after the pressurization of the compressor as the hydrogen raw material, and exchange heat with the high-temperature reaction product from the reaction product outlet 22 in the heater 4, and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com