Natural gas desulfuration and liquid-removing device and desulfuration technology thereof

A technology of desulfurization device and desulfurization process, applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve problems such as cost increase, liquid discharge pipeline blockage, safety accidents, etc., achieve improved effect, realize solid-liquid separation, and avoid U-shaped The effect of tube clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

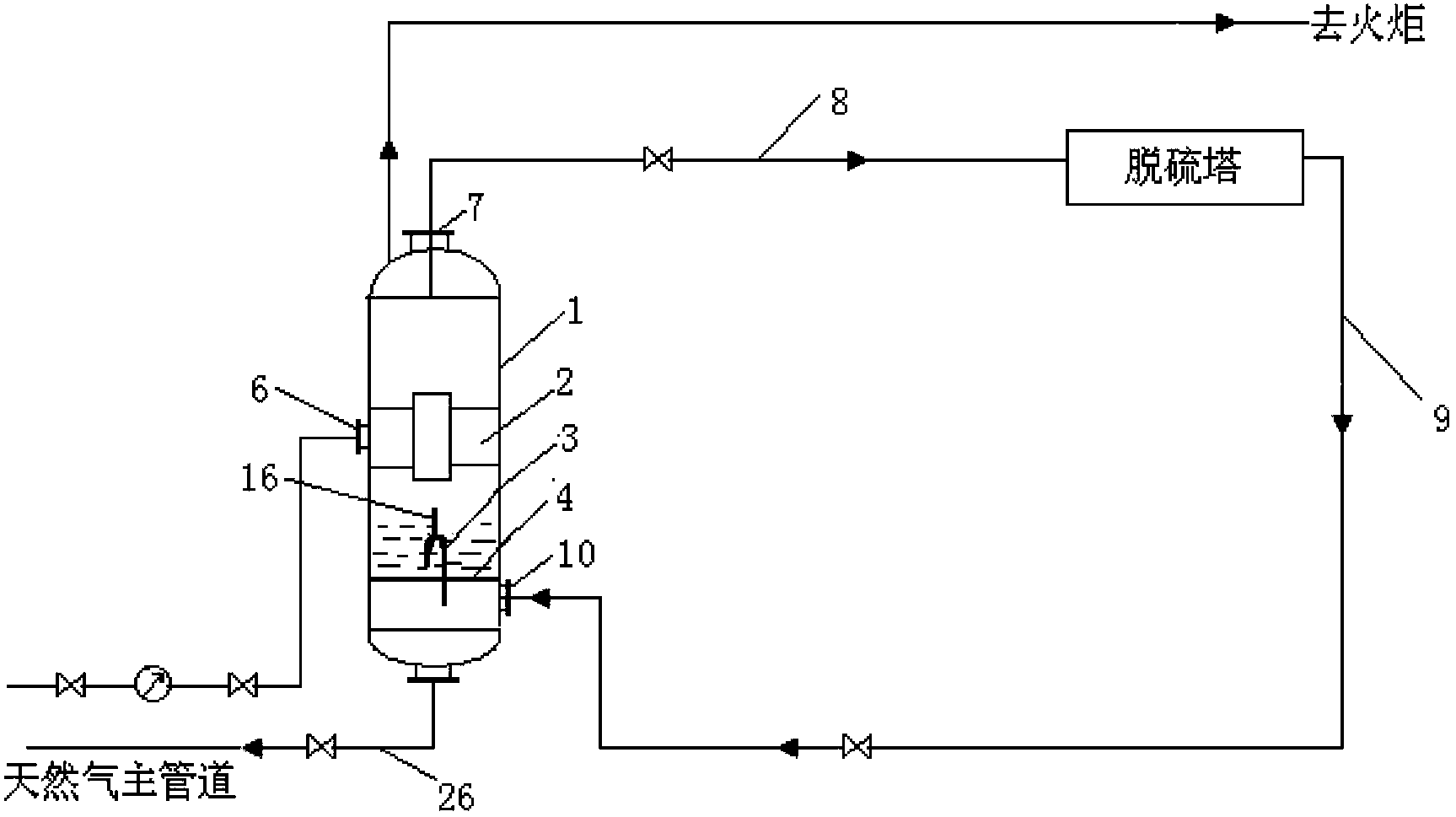

Embodiment 1

[0055] The natural gas deliquefaction and desulfurization device includes a gas-liquid separation tank 1, a gas-liquid separator 2 is arranged in the gas-liquid separation tank 1, and the gas-liquid separator 2 selects a cyclone separator, and the cyclone separator combines the The inner space of the gas-liquid separation tank 1 is divided into a gas collection chamber and a liquid collection chamber, the gas collection chamber is located at the top of the cyclone separator, and the liquid collection chamber is located at the bottom of the cyclone separator; The middle part of the liquid separation tank 1 is provided with a first natural gas inlet 6, and the first natural gas inlet 6 communicates with the cyclone separator; the top of the gas-liquid separation tank 1 is provided with a first natural gas outlet 7. The bottom of the liquid separation tank 1 is provided with a liquid outlet; the natural gas deliquification and desulfurization device also includes a desulfurization...

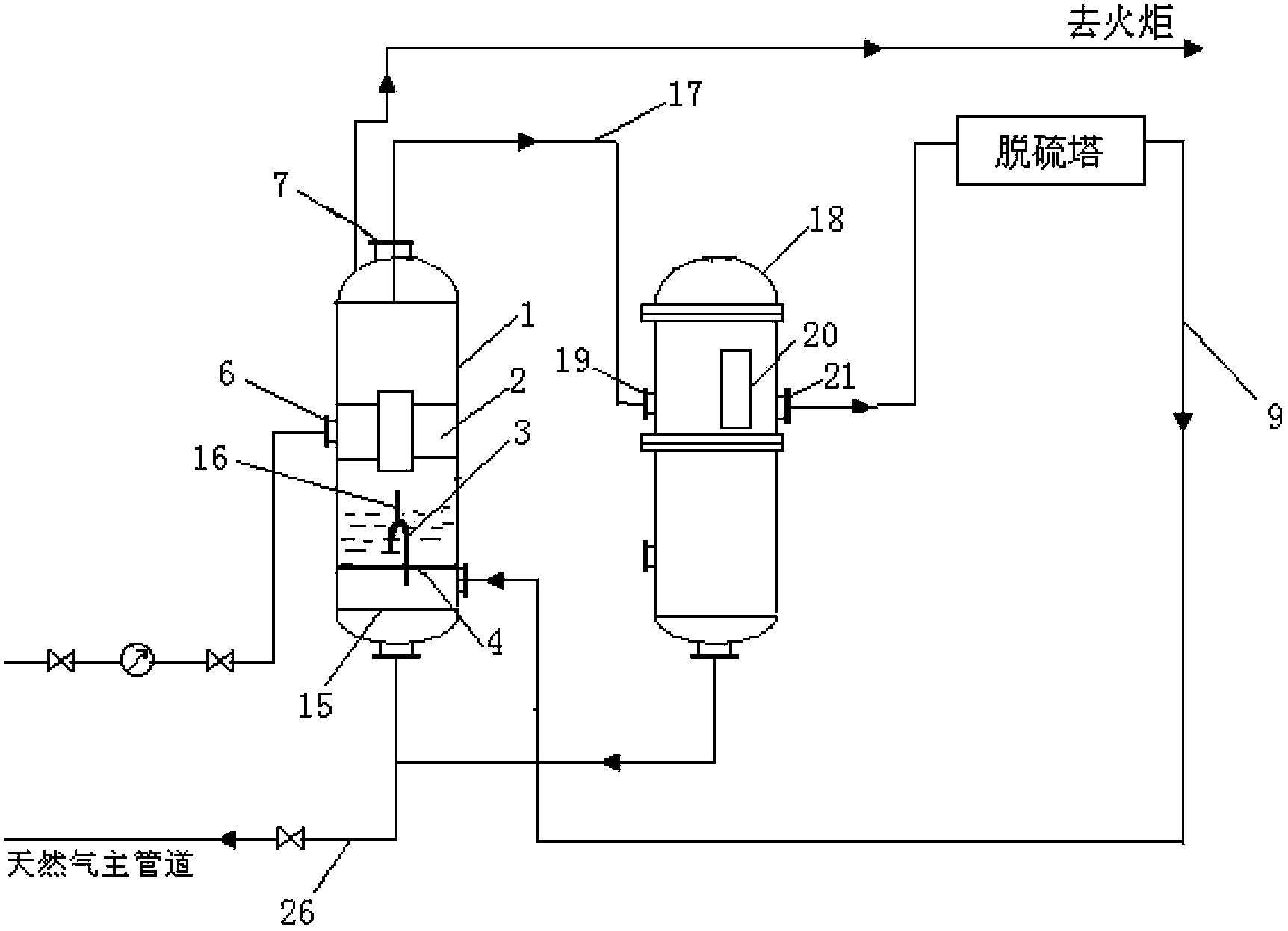

Embodiment 2

[0058] The natural gas deliquefaction and desulfurization device described in this embodiment, on the basis of Embodiment 1, selects the cyclone gas-liquid separator as the gas-liquid separator in this embodiment, between the cyclone gas-liquid separator and the desulfurization tower A coalescing tank 18 is also arranged between them, and the first natural gas outlet 7 of the gas-liquid separation tank 1 is connected to the natural gas inlet 19 provided on the side wall of the coalescing tank 18 through a pipeline 17, and the natural gas inlet 19 is connected to the The coalescing inner core 20 provided in the coalescing tank 18 is connected; the side wall of the coalescing tank 18 is provided with a natural gas outlet 21, and the natural gas outlet 21 is connected with the gas inlet of the desulfurization equipment; the coalescing A liquid outlet is provided at the bottom of the tank 18 .

[0059] In this embodiment, when the natural gas deliquefaction and desulfurization dev...

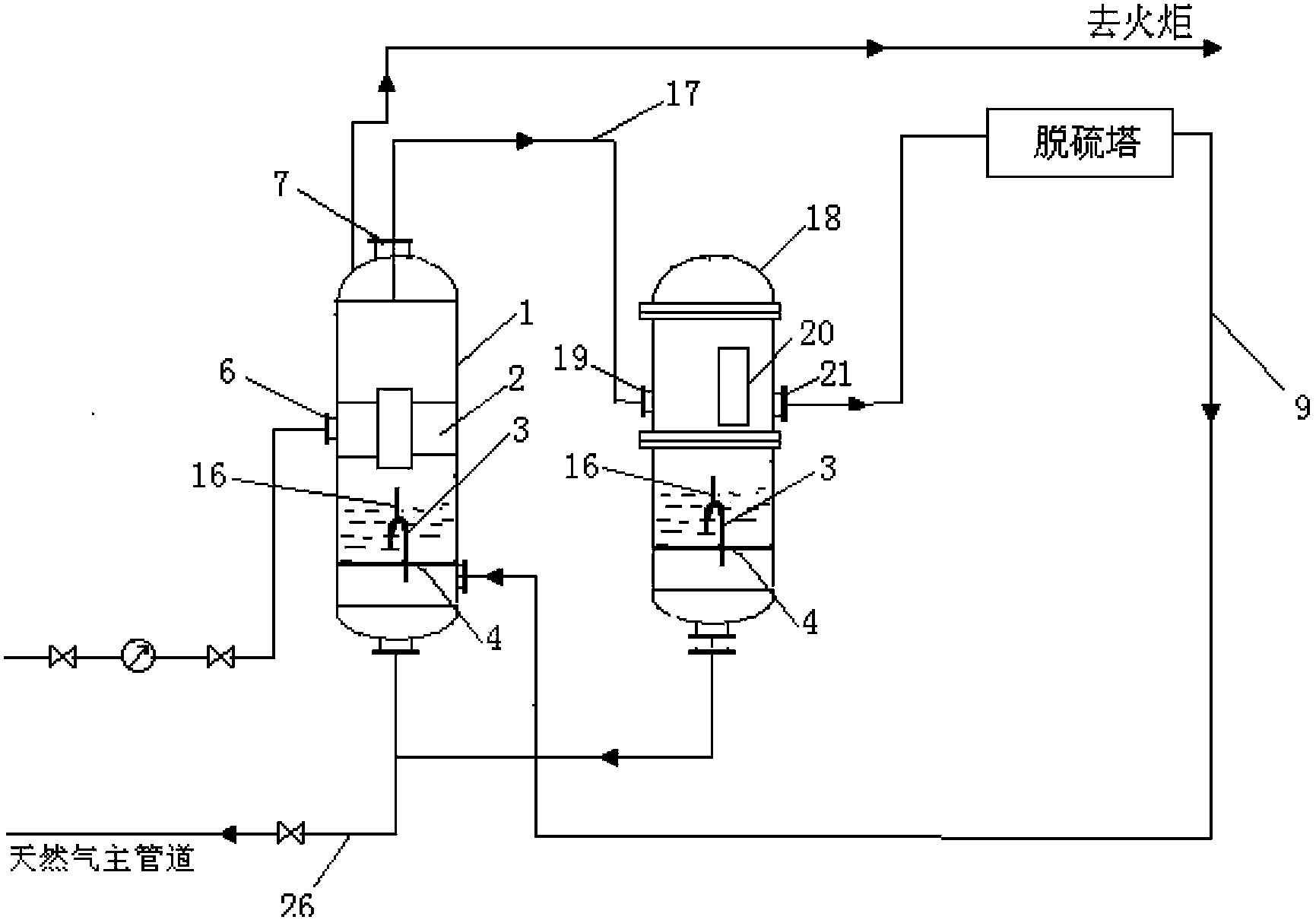

Embodiment 3

[0061] The natural gas deliquefaction and desulfurization device described in this embodiment, on the basis of Embodiment 2, is provided with a liquid collecting plate 4 at the lower part of the coalescing tank 18, and the liquid collecting plate 4 divides the lower part of the coalescing tank 18 into an upper part Liquid collection chamber and lower liquid discharge chamber; an inverted U-shaped tube 3 with an inner diameter of 6mm is arranged in the liquid collection chamber, and one end of the inverted U-shaped tube 3 is placed above the liquid collection plate 4, and is located in the liquid collection chamber. Below the liquid surface in the cavity, the other end extends through the liquid collecting plate 4 into the discharge cavity; the middle part of the top of the inverted U-shaped tube 3 is also provided with a vertical pipeline 16 communicating with the inside of the U-shaped tube, so The inner diameter of the vertical pipeline 16 is 6mm, and the top of the vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com