Catalytic coal gasification catalyst dispersion method

A coal catalytic gasification and catalyst technology, which is applied in the chemical industry, can solve the problems of accelerating the process of sample preparation, and the catalyst components cannot be effectively dispersed and preparation time-consuming. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

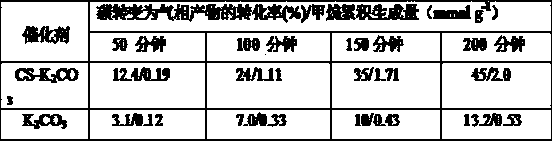

[0019] Example 1 : CS-K 2 CO 3 Catalytic Performance of Catalyst for Catalytic Gasification of Zhundong Coal

[0020] Weigh 0.177 g K 2 CO 3 , transferred to the beaker, then measure 20 ml of distilled water with a measuring cylinder, and drop the measured distilled water into the above beaker, stir it with a glass rod to fully dissolve it, then weigh 0.5 g Zhundong coal, and then It is added to a beaker, and then the beaker is placed in an ultrasonic generator with a fixed frequency of 50 kHz, the power is 60 W, and the action time is 50 min. Finally, the beaker is transferred to an oven for drying treatment, and crushed after tableting Sieve to 40 mesh -80 mesh, the catalyst is marked as CS-K 2 CO 3 .

[0021] Coal catalytic gasification reaction conditions: distilled water flow rate 1.0 ml / min, reaction temperature 973 K, reaction system pressure 3.4 MPa. The change curve of carbon conversion rate on the catalyst with time and CH 4 See attached table 1 for the cumu...

Embodiment 2

[0022] Example 2 :K 2 CO 3 Catalytic Performance of Catalyst for Catalytic Gasification of Zhundong Coal

[0023] Weigh 0.177 g K 2 CO 3 , transferred to the beaker, then measure 20 ml of distilled water with a measuring cylinder, and drop the measured distilled water into the above beaker, stir it with a glass rod to fully dissolve it, then weigh 0.5 g Zhundong coal, and then It is added into a beaker, and then placed on a magnetic stirrer for stirring for 6 h. Finally, the beaker is transferred to an oven for drying treatment. After tableting, it is crushed and sieved to 40 mesh-80 mesh. The catalyst is marked as K 2 CO 3 .

[0024] Coal catalytic gasification reaction conditions: distilled water flow rate 1.0 ml / min, reaction temperature 973 K, reaction system pressure 3.4 MPa. The change curve of carbon conversion rate on the catalyst with time and CH 4 The accumulated precipitation amounts are shown in Table 1, respectively.

Embodiment 3

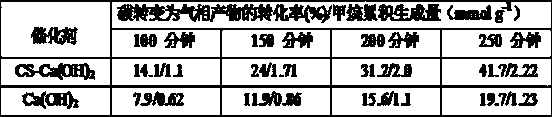

[0025] Example 3 : CS-Ca(OH) 2 Catalytic Performance of Catalyst for Catalytic Gasification of Zhundong Coal

[0026] Weigh 0.185 g Ca(OH) 2 , transferred to a beaker, then measure 40 ml of distilled water with a measuring cylinder, and add the measured distilled water dropwise to the above beaker, stir for a period of time with a glass rod, weigh 0.5 g of Zhundong coal, and add it Then place the beaker in an ultrasonic generator with a fixed frequency of 50 kHz, the power is 80 W, and the action time is 40 min. Finally, the beaker is transferred to an oven for drying treatment, crushed and sieved after tableting To 40 mesh -80 mesh, the catalyst is marked as CS-Ca(OH) 2 .

[0027] Coal catalytic gasification reaction conditions: distilled water flow rate 1.0 ml / min, reaction temperature 973 K, reaction system pressure 3.4 MPa. The change curve of carbon conversion rate on the catalyst with time and CH 4 The accumulated precipitation amounts are shown in Table 2, respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com