A preparation method for enhancing the coercive force of sintered NdFeB by organic heavy rare earth complexes

A neodymium-iron-boron and heavy rare earth technology, which is applied in the manufacture of inductors/transformers/magnets, magnetic objects, metal processing equipment, etc., can solve the problems of excessive heavy rare earth doping, grain growth, increased cost, etc. Simple, high coercivity, cost-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

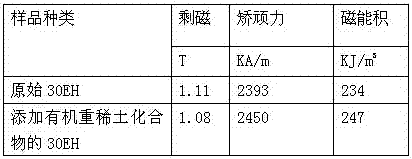

Embodiment 1

[0024] Preparation of brand 30EH NdFeB magnets by sintering method:

[0025] 1) Casting sheet: NdFeB quick-setting sheet is prepared by conventional quick-setting casting technology. The condensed sheet is broken into NdFeB alloy powder with an average particle size of 3.8 microns;

[0026] 2) Powder making: While further crushing the NdFeB alloy powder treated by the hydrogen crushing process to make powder, inject a mixture of acetone, isopentene and butadiene in a pouring manner, acetone, isopentene and butadiene The volume ratio of alkene is 6:1:4, and the mixture accounts for 0.1% of the total weight of NdFeB alloy powder;

[0027] 3) Mixing: inject the mixed liquid of organic heavy rare earth complex and ether into the NdFeB alloy powder by spraying, accounting for 0.1% of the total amount of NdFeB alloy powder. Among them, the organic heavy rare earth compound is a triadrocene heavy rare earth metal organic compound and a neodecanoic acid heavy rare earth, and their v...

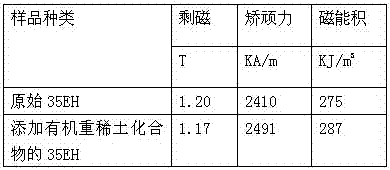

Embodiment 2

[0038] Preparation of brand 35EH NdFeB magnets by sintering method:

[0039] 1) Casting sheet: NdFeB quick-setting sheet is prepared by conventional quick-setting casting technology. The condensed sheet is broken into NdFeB alloy powder with an average particle size of 4.1 microns;

[0040] 2) Powder making: While further crushing the NdFeB alloy powder treated by the hydrogen crushing process to make powder, inject a mixture of acetone, isopentene and butadiene in a pouring manner, acetone, isopentene and butadiene The volume ratio of alkene is 6:13:1, and the mixture accounts for 0.5% of the total weight of NdFeB alloy powder;

[0041] 3) Mixing: inject the mixed liquid of organic heavy rare earth compound and ether into the NdFeB alloy powder by spraying, accounting for 1% of the total amount of NdFeB alloy powder. Among them, the organic heavy rare earth complexes are only three organic heavy rare earth metal organic compounds, accounting for 30% of the total weight of the...

Embodiment 3

[0052] Preparation of brand N48 NdFeB magnets by sintering method

[0053] 1) Casting sheet: NdFeB quick-setting sheet is prepared by conventional quick-setting casting technology. The condensed sheet is broken into NdFeB alloy powder with an average particle size of 4.3 microns;

[0054] 2) Powder making: While further crushing the NdFeB alloy powder treated by the hydrogen crushing process to make powder, inject a mixture of acetone, isopentene and butadiene in a pouring manner, acetone, isopentene and butadiene The volume ratio of alkene is 6:1:4, and the mixture accounts for 0.3% of the total weight of NdFeB alloy powder;

[0055] 3) Mixing: inject the mixed liquid of organic heavy rare earth complex and ether into the NdFeB powder by spraying, accounting for 0.5% of the total amount of NdFeB alloy powder. Among them, the organic heavy rare earth compound is only tricene heavy rare earth metal organic compound and neodecanoic acid heavy rare earth, and their volume ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com