Preparation method of low-oxygen-content molybdenum powder

A low oxygen content, molybdenum powder technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of limiting the performance of molybdenum alloy products, achieve large-scale production and environmental protection, obvious oxygen content, and unlimited production capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

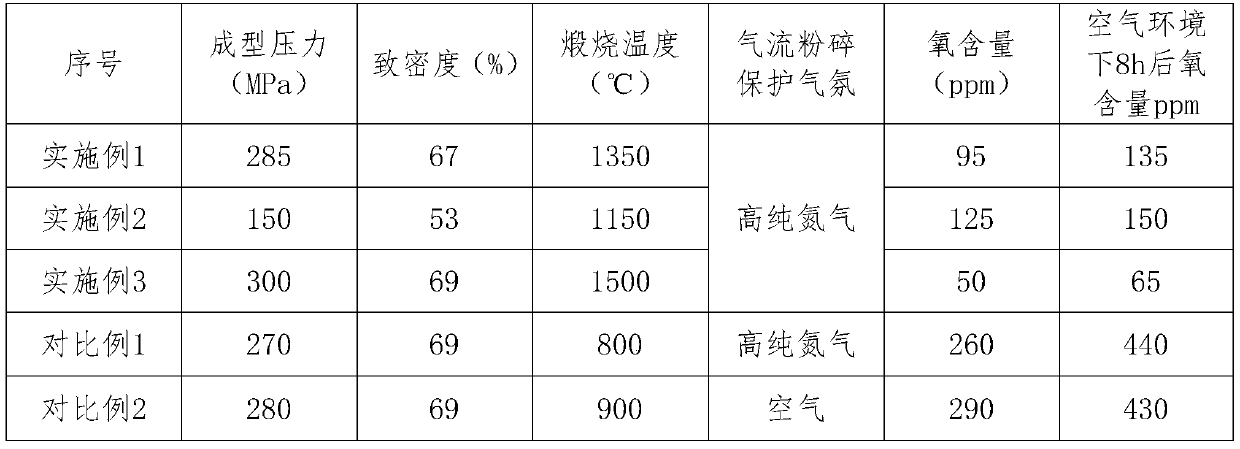

[0031] A method for preparing molybdenum powder with low oxygen content, comprising the following steps: using 2-10 micron molybdenum powder as a raw material, forming it through a cold isostatic press at 150-300 MPa, and then crushing it to 100-200 mesh with a disc grinder and passing through 100 mesh Sieve, hydrogenate the powder at 1000-1500°C, keep it warm for 1-5h, cool the powder to room temperature, crush it in a nitrogen atmosphere, and pass through a 100-mesh sieve to obtain molybdenum powder with an average particle size of 100 mesh and an oxygen content of 50-150ppm. Such as figure 1 shown.

[0032] The molybdenum powder used in the present invention is molybdenum oxide, ammonium molybdate and other molybdenum powder obtained after hydrogen reduction at a high temperature of 500-1200 ° C. The raw material of this molybdenum powder generally has a particle size of 2-10 microns. The use of products is also because the preparation process determines that the particle ...

Embodiment 1

[0037] The molybdenum powder raw material is selected as molybdenum powder with D50=4.5 microns, and the oxygen content is 680ppm.

[0038] Weigh 15kg of molybdenum powder into the rubber sheath, and vibrate it with a vibration platform. After sealing, mold it in a cold isostatic press at 285MPa, and the pressure holding time is 2 minutes. After the pressing is completed, the density of the molybdenum block is tested as 67%.

[0039] Continue to put the molybdenum block into the rubber sheath and hit it with a hammer to break the molybdenum block into small pieces, then transfer the molybdenum block to a zirconia grinding machine for further crushing, and the crushed particles pass through a 100-mesh sieve network.

[0040] Place the crushed and sieved molybdenum powder on a molybdenum boat tray with a size of 300*500mm to prevent uniformity, and then calcinate and keep it warm for 3 hours in a hydrogen environment at 1350°C.

[0041] After the calcination is completed, lowe...

Embodiment 2

[0044] The molybdenum powder raw material is selected as molybdenum powder with D50=4.5 microns, and the oxygen content is 680ppm.

[0045] 1. Weigh 15kg of molybdenum powder into the rubber sheath, and vibrate it with a vibration platform. After sealing, mold it in a cold isostatic press at 150MPa. The holding time is 2 minutes. After pressing, test the molybdenum block. The density is 53%.

[0046] 2. Continue to put the molybdenum block into the rubber sheath, hit it with a hammer to break the molybdenum block into small pieces, and then transfer the molybdenum block to a zirconia grinding machine for further crushing. The crushed particles are over 100 mesh screen.

[0047] 3. Place the crushed and sieved molybdenum powder on a molybdenum boat tray with a size of 300*500mm to prevent uniformity, and then calcinate and keep it warm for 2 hours in a hydrogen environment at 1150°C.

[0048] 4. After the calcination is completed, lower it to room temperature, crush the bonde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com