Anisotropic SmCo/MnBi composite magnet, and preparation method thereof

A composite magnet and anisotropic technology, applied in the manufacture of inductors/transformers/magnets, magnetic objects, magnetic materials, etc., can solve the problems of low saturation magnetization, large remanence temperature coefficient, and low maximum energy product of magnets, etc., to achieve Improve the density, increase the degree of orientation, and suppress the effect of interdiffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

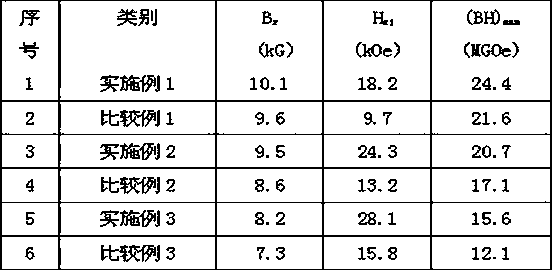

Examples

Embodiment 1

[0017] 1) Preparation of SmCo-based magnetic powder: according to the mass ratio of Sm 22 co 39 tm 39 (TM=Fe, Cu, Zr) batching and induction smelting into ingots, then rolling ball milling into 2-5μm magnetic powder, orientation molding to make compacts, and sintering solid solution treatment at 1190ºC+1140ºC for 10 hours , and then aging treatment, first at 750 ºC for 20h, then cooled to 400 ºC for 0.5h and then quenched. Finally, the magnet was crushed to 60 μm by a planetary ball mill to obtain SmCo-based magnetic powder.

[0018] 2) Preparation of MnBi magnetic powder: according to the chemical formula Mn 21 Bi 79 Batching and induction smelting into ingots, the MnBi quenching belt was prepared by the melt quenching method, the roll speed was 30m / s; then the MnBi quenching belt was subjected to aging treatment at 350ºC, and the aging time was 0.5h; The quenched band was broken down to 10 μm.

[0019] 3) The magnetic powder prepared in step (1) (2) is uniformly mixed ...

Embodiment 2

[0027] 1) SmCo magnet preparation: by mass ratio Sm 25 co 47 tm 28 (TM=Fe, Cu, Ti, Cr) batching and induction smelting into ingots, then rolling ball milling into 2-5 μm magnetic powder, orientation forming into compacts, and sintering and solid solution treatment at 1210ºC+1170ºC for the compacts, the time is 8h, then aging treatment, first at 830ºC for 10h, then cooled to 400ºC for 10h and then quenched. Finally, a planetary ball mill was used to crush the magnet to 200 μm magnetic powder.

[0028] 2) Preparation of MnBi magnetic powder: according to the chemical formula Mn 23 Bi 72 TM5 (TM=Ti, Zr, Ni) was batched and melted into ingots by induction melting, and the MnBi quenching strip was prepared by the solution quenching method with a roll speed of 40m / s; then the MnBi quenching strip was subjected to aging treatment at 250ºC, and the aging time 0.5h; use the planetary ball milling process to crush the quenching zone to 30μm.

[0029] 3) The magnetic powder prepare...

Embodiment 3

[0037] 1) SmCo magnet preparation: according to the chemical formula Sm 30 co 57 tm 13 (TM=Cu, Fe, Zr, Ni) batching and induction melting into ingots, then rolling ball milling into 2-5μm magnetic powder, orientation molding into green compacts, sintering solid solution treatment at 1240ºC+1200ºC for 5 hours , and then aging treatment, first at 900ºC for 0.5h, then cooled to 400ºC for 20h and then quenched. Finally, a planetary ball mill was used to crush the magnet to 500 μm magnetic powder.

[0038] 2) Preparation of MnBi magnetic powder: according to the chemical formula Mn 25 Bi 65 tm 10 (TM=Cu, Ti, Ni) batching and induction melting into ingots, the MnBi quenching belt was prepared by the solution quenching method, the roll speed was 50m / s; then the MnBi quenching belt was subjected to aging treatment at 350ºC, and the aging time was 0.5h; use the planetary ball milling process to crush the quenching zone to 50μm.

[0039] 3) The magnetic powder prepared in step (1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com