Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

149results about How to "Extend service time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-healing environmental barrier coating on member surface and preparation method thereof

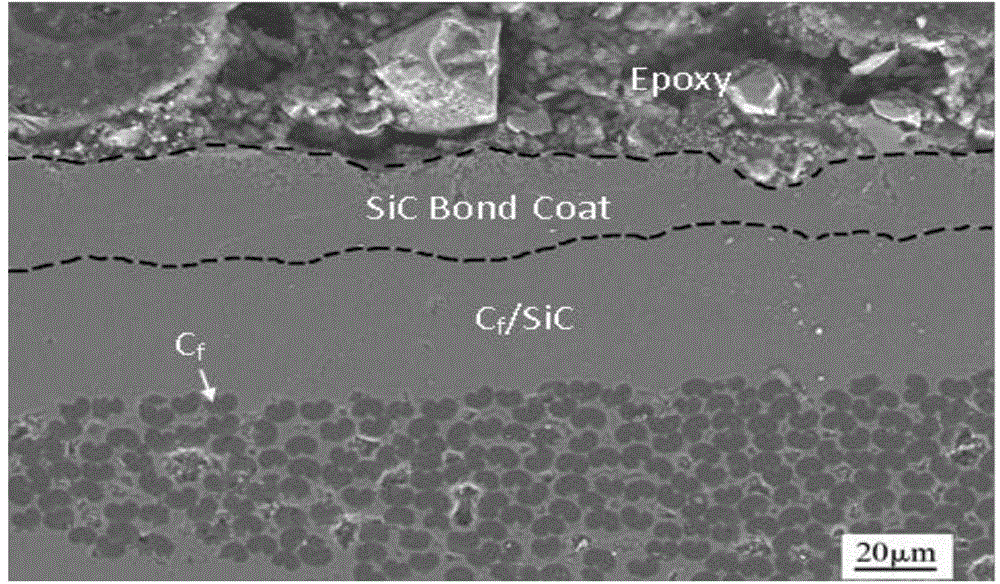

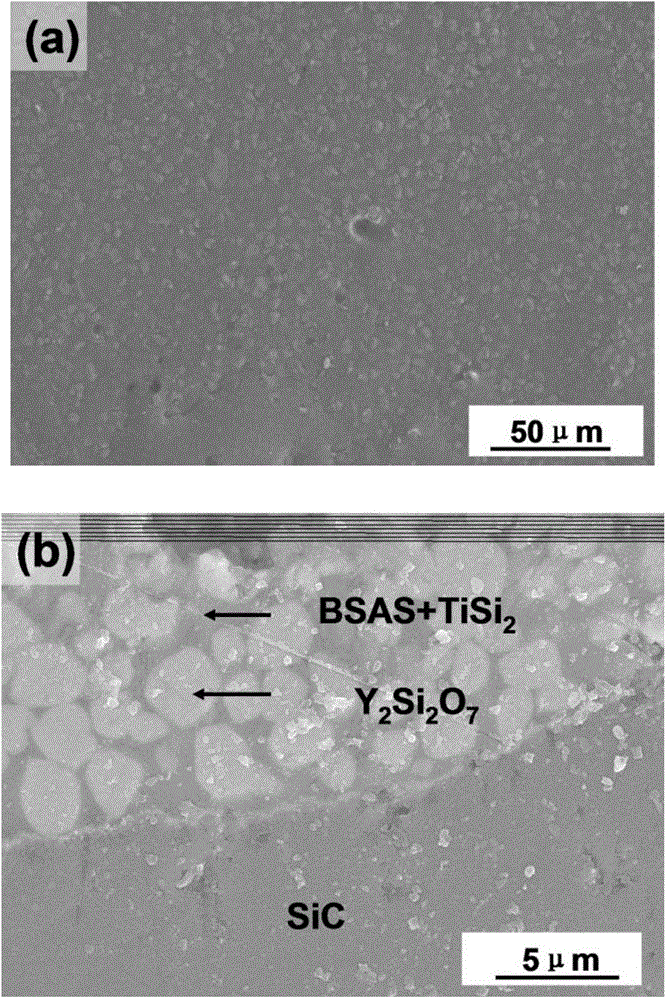

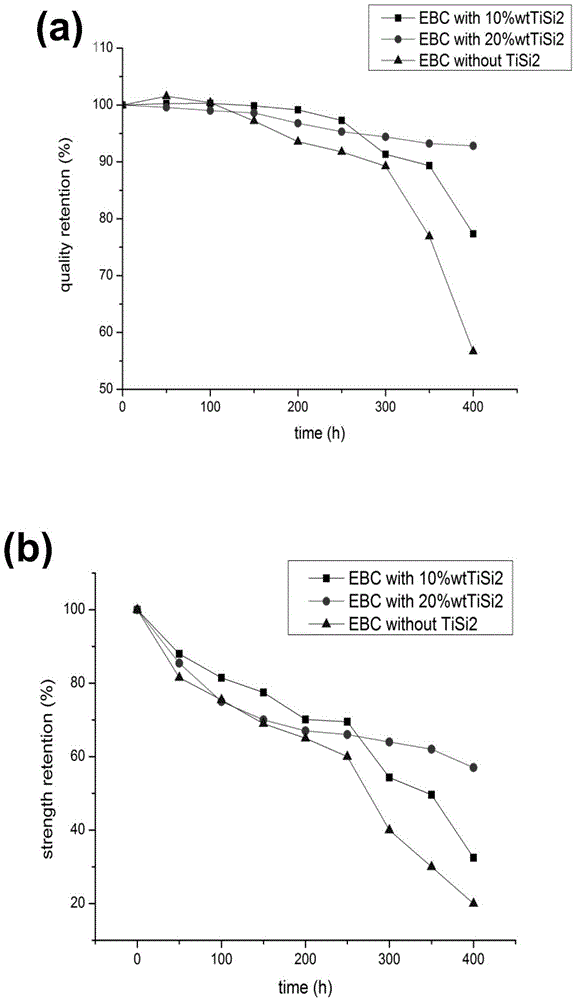

The invention relates to a self-healing environmental barrier coating on the member surface and a preparation method thereof. The theory basis is that: when silicide is added into present EBC, if cracks appear in coating used in a combustion gas environment, silicide on the crack surface or near the crack will be rapidly oxidized to generate silicon dioxide (SiO2) or another oxide, thus the SiO2 can be used as a mobile phase to seal the cracks; furthermore, the volume expansion caused by the oxidation reactions and the high expansion coefficient of the silicide generate pressure stress on the cracks to accelerate the healing of the cracks; so the prepared environmental barrier coating has a good self-healing ability.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

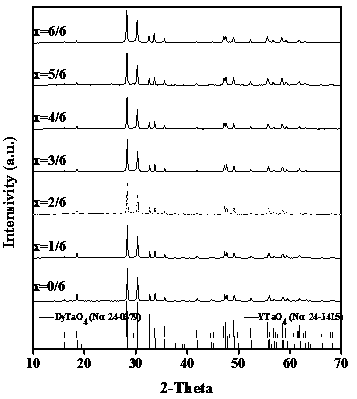

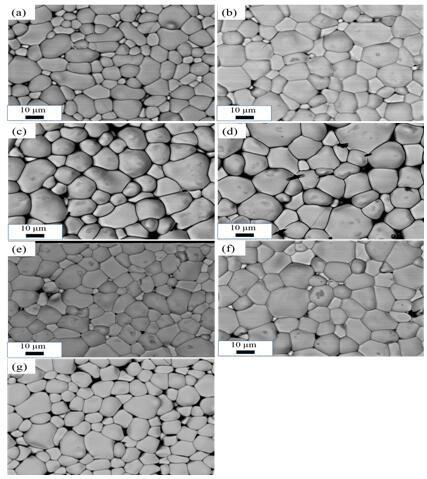

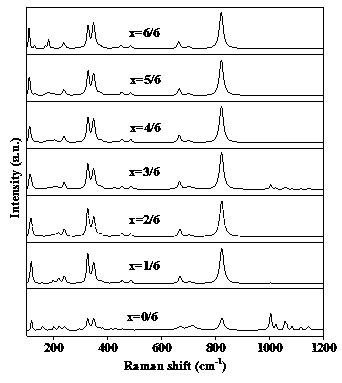

Compact ferroelastic dual rare earth tantalate solid solution high-temperature ceramic and preparation method thereof

The invention discloses compact ferroelastic dual rare earth tantalate solid solution high-temperature ceramic and a preparation method thereof, and belongs to the technical field of high temperatureresistant material of thermal barrier ceramic coating. The structural formula is (Y1-xDyx)TaO4 (x=0.1-0.9). Previously dried rare earth oxides (Y2O3, Dy2O3) and tantalum pentoxide (Ta2O5) are weighedaccording to the stoichiometric ratio required. Then, the materials are ball milled with ethanol as a solvent to obtain mixed powder A; the mixed powder A is sieved and compacted in a mold, and then ablank undergoes isostatic cool pressing to prepare a compact blank; and finally, the compact blank undergoes pressureless sintering to obtain the compact dual rare earth tantalate solid solution high-temperature ceramic. The dual rare earth tantalate solid solution high-temperature ceramic prepared by the method has characteristics of high process purity, low impurity content, high compactness, uniform grain size, low heat conductivity, large coefficient of thermal expansion, good toughness and the like.

Owner:KUNMING UNIV OF SCI & TECH

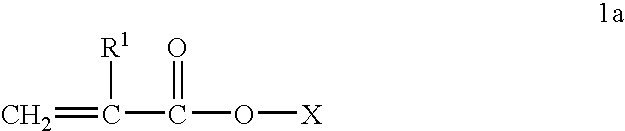

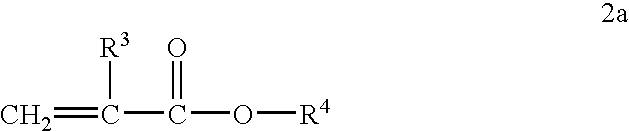

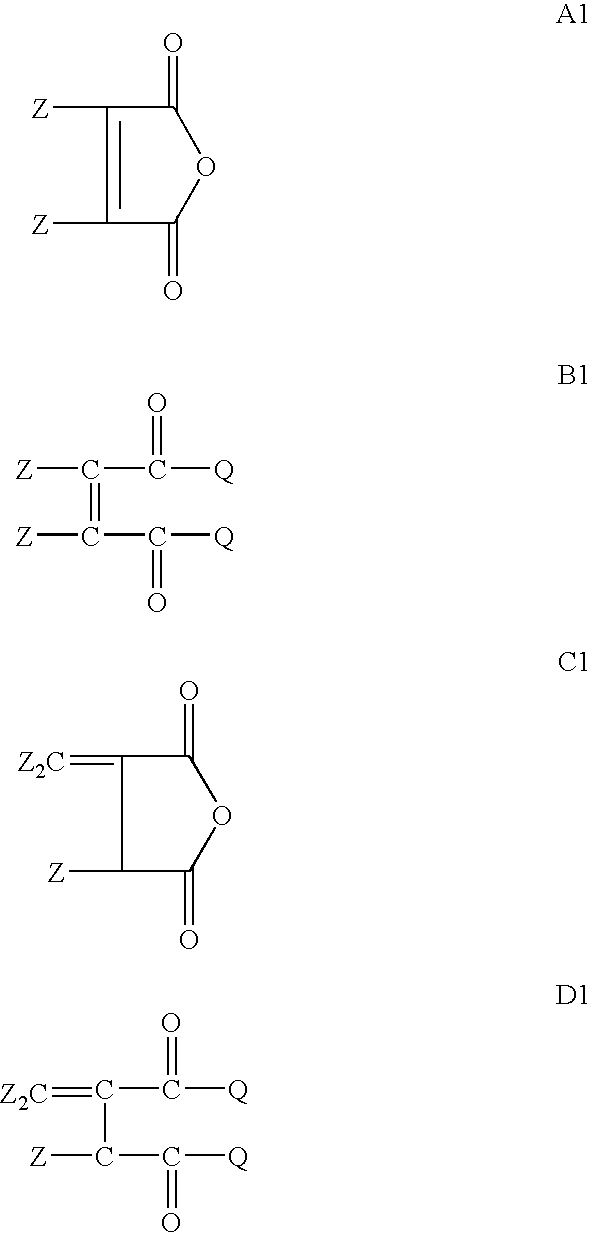

Alkyl acrylate copolymer vi modifiers and uses thereof

InactiveUS20080026964A1Extend service timeEnhancing oxidative stability and dispersancyThickenersAdditivesFunctional polymersRadical polymerization

A novel a multi-functional polymer viscosity modifier comprising an additive reaction product obtained by reacting a first monomer comprising an alkylacrylate with a second monomer comprising an olefinic carboxylic acylating agent under conditions effective for free radical polymerization of the first and second monomers to provide a base polymer comprising an acylated alkylacrylate copolymer, and wherein the base polymer optionally may be further reacted with an amine compound to provide a multi-functional polyalkylacrylate copolymer. The base polymer has good thickening efficiency. The multi-functional polyalkylacrylate copolymer dispersant viscosity modifier has good thickening efficiency. The base polymer and the multi-functional polyalkylacrylate copolymer viscosity modifier have good thickening efficiency, low temperature properties, dispersancy, and antioxidancy properties. They also have no precipitation or sedimentation, nor cause or encourage such formations in finished fluids incorporating them.

Owner:AFTON CHEMICAL

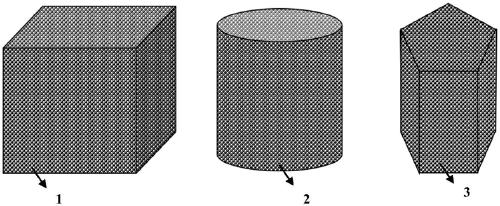

High alloy matrix metal-ceramic composite and preparation method thereof

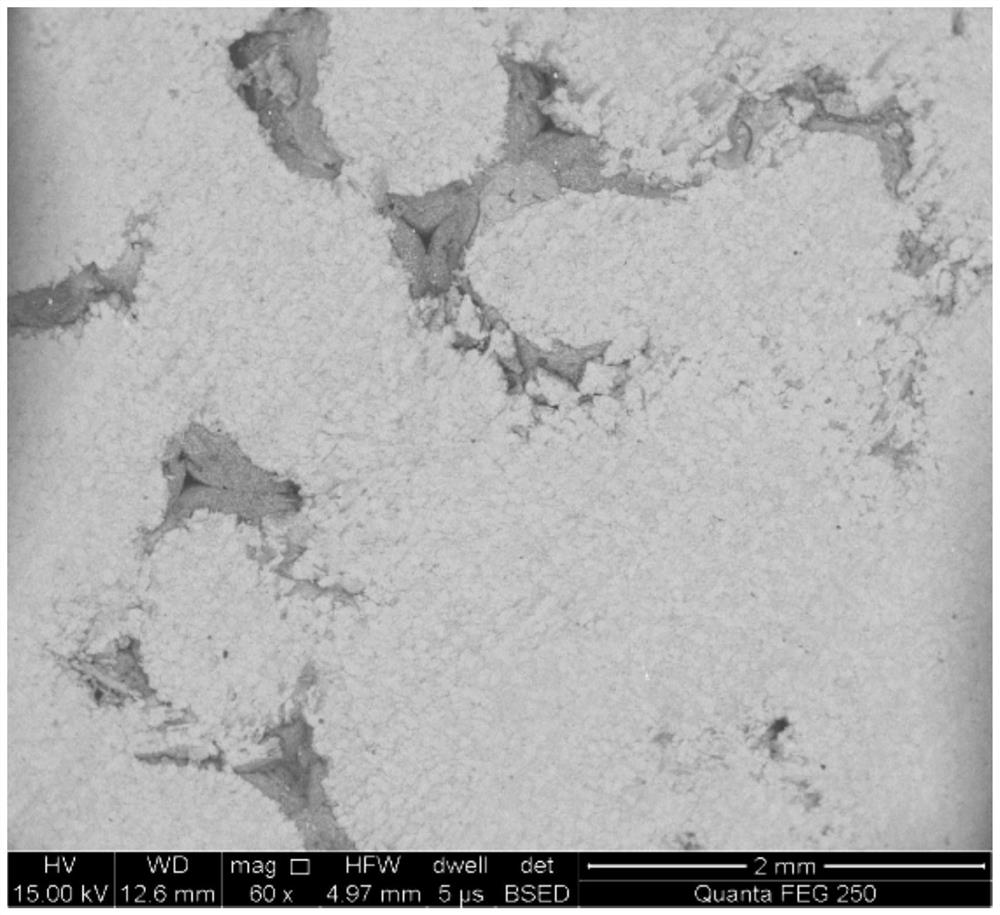

The invention discloses a high alloy matrix metal-ceramic composite and a preparation method thereof, and belongs to the field of wear-resistant materials. According to the high alloy matrix metal-ceramic composite, the volume ratio of high alloy matrix materials to metal-ceramic reinforced particles is (1-10):1; the high alloy matrix materials comprise 1-8% of C, main alloying elements, minor additive elements and the balance Fe and unavoidable impurities; the main alloying elements comprise 0-60%of Ni, 0-60% of Mo, 0-40% of Cr, 0-30% of Mn, 0-20% of V, 0-20% of Ti, 0-15% of W and 0-15% of Nb; and the minor additive elements are one or more of B, Si, Zr, Cu, Co, Al and rare earth. The preparation method adopts a programmed temperature-controlled liquid phase sintering method for preparation and can be used directly for wear-resisting materials, or for wear-resisting materials after subsequent heat treatment; and the metallurgical bonding interface between the reinforced phase and thehigh alloy matrix in the composite reaches 40[mu]m-1mm, no cracks occurs after the integral heat treatment, and the service conditions in the wear-resistant material field are met.

Owner:NORTHEASTERN UNIV

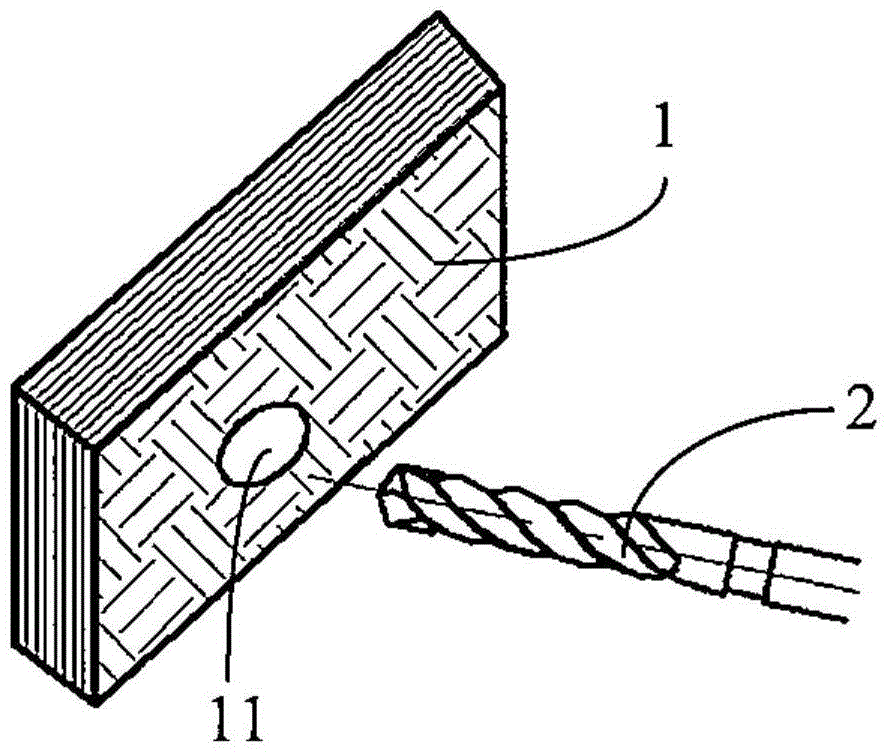

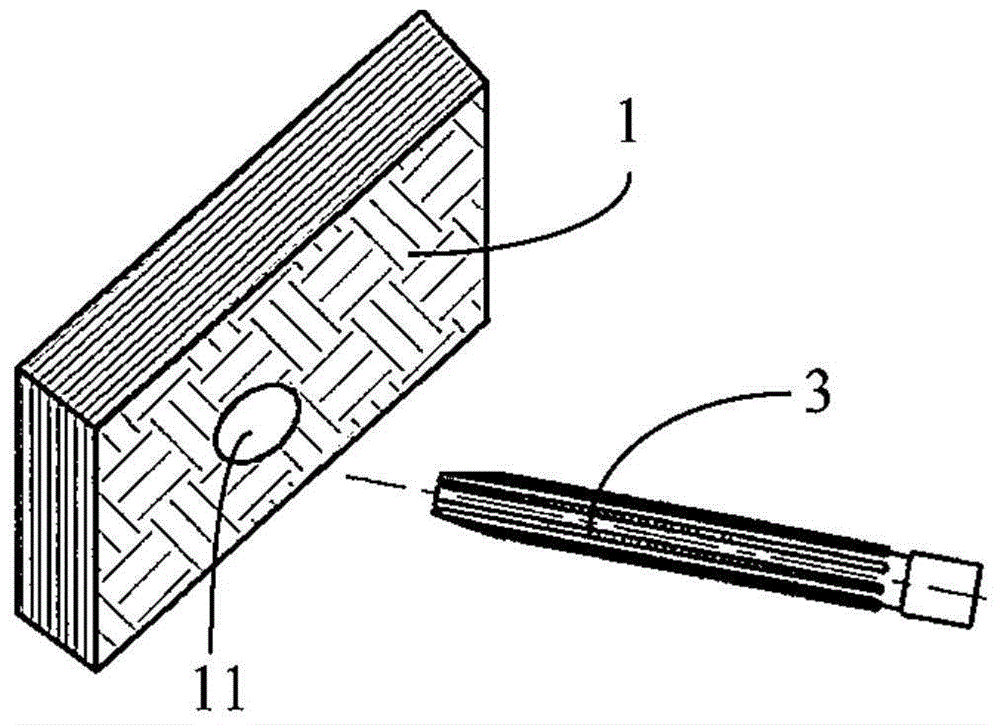

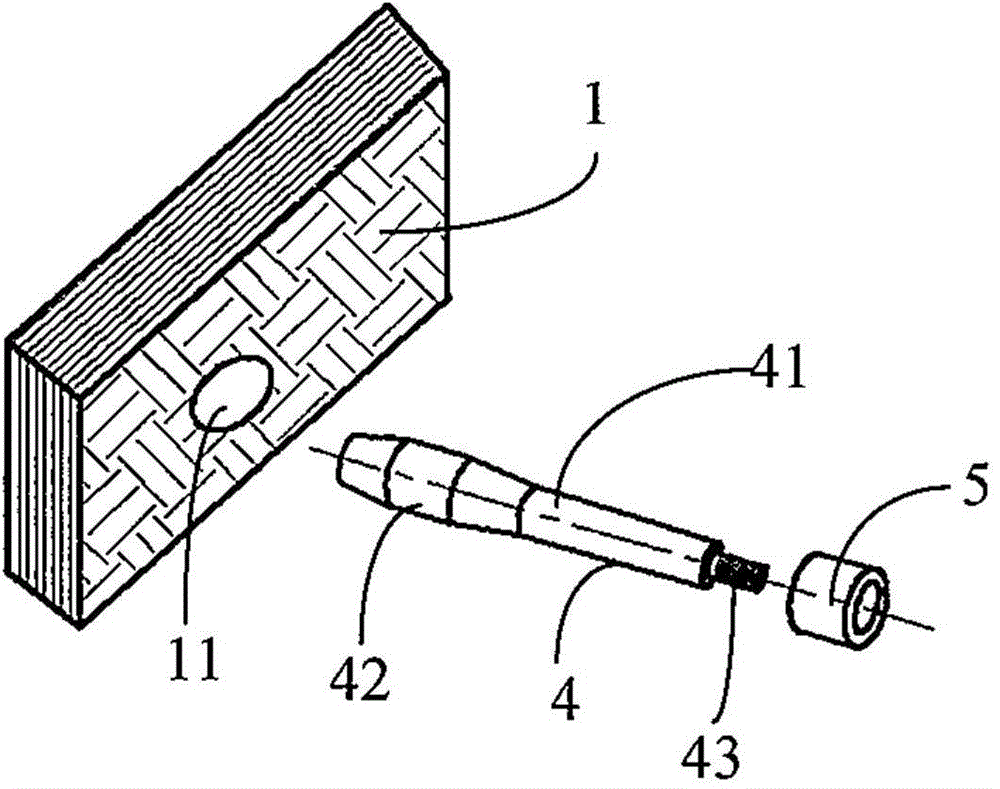

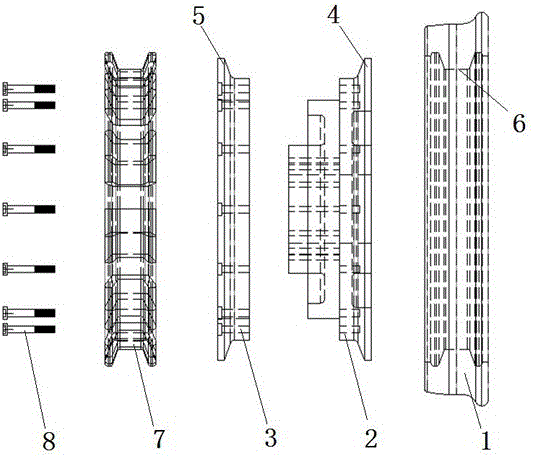

Cold extrusion strengthening method for assembling hole of CFRP composite material laminate

InactiveCN104626726AImprove fatigue lifeEasy maintenanceLamination ancillary operationsLaminationEngineeringAxial force

The invention provides a cold extrusion strengthening method for an assembling hole of a CFRP composite material laminate. The method comprises the following steps: (a) providing a bush, wherein the bush can be assembled in the assembling hole; (b) providing a metal core rod with the taper, and inserting the core rod into the bush; (c) arranging the bush in the assembling hole; (d) applying axial force to the core rod by virtue of extrusion equipment, so that the bush is extruded by the part, with the largest diameter, of the core rod; and (e) removing the core rod, so that the bush is fixedly arranged in the assembling hole. Aiming at the assembling hole of the CFRP composite material laminate, the bush is adopted and is matched with a cold extrusion strengthening process, so that the fatigue life of parts can be effectively prolonged, and the service time of an aircraft is prolonged. Because the bush is fastened in the assembling hole, the wear resistance of the connecting structure is improved, and the detachment of assembling fasteners and the maintenance of the parts can be promoted.

Owner:COMAC +1

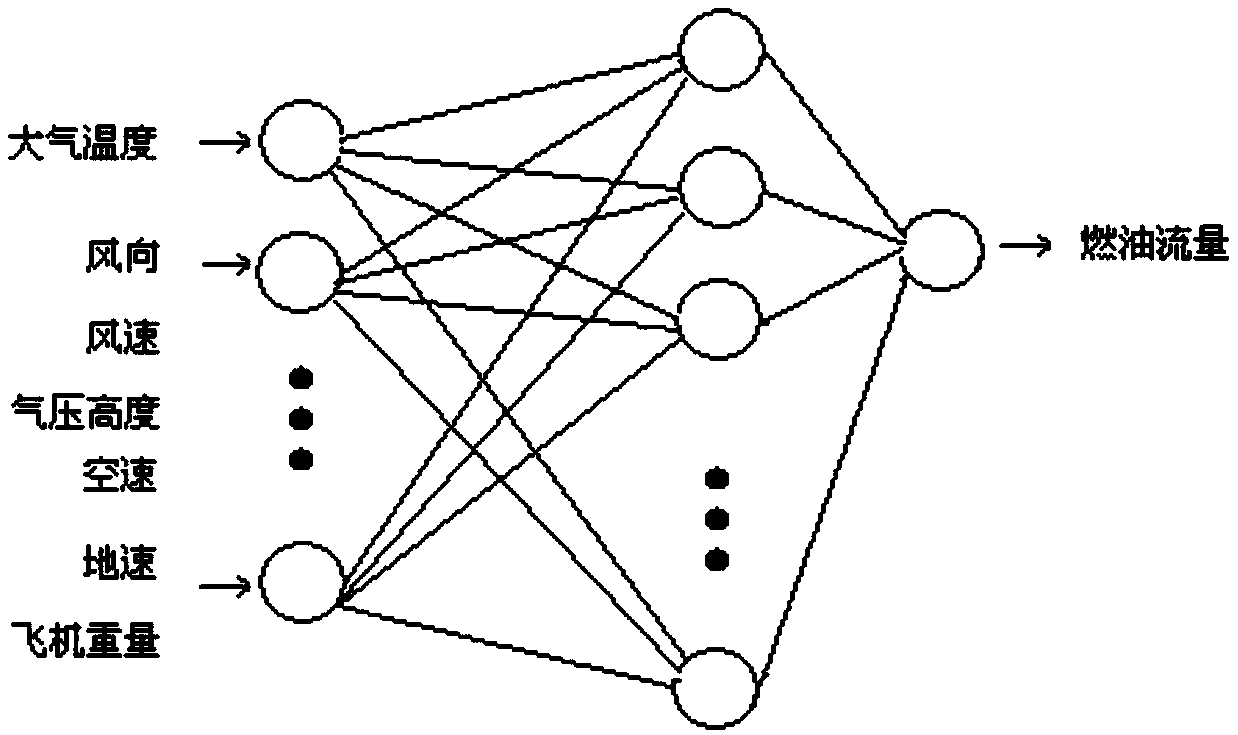

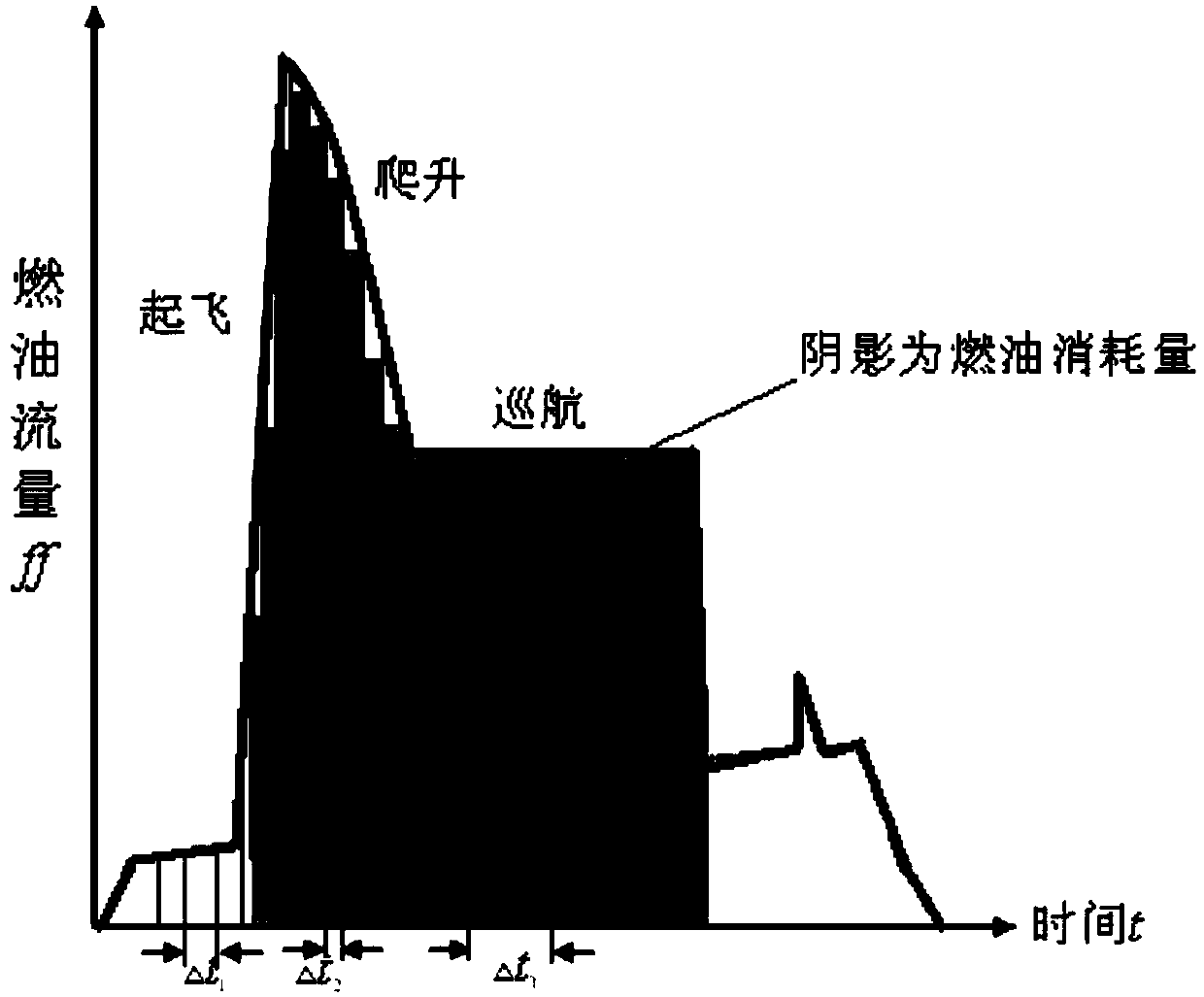

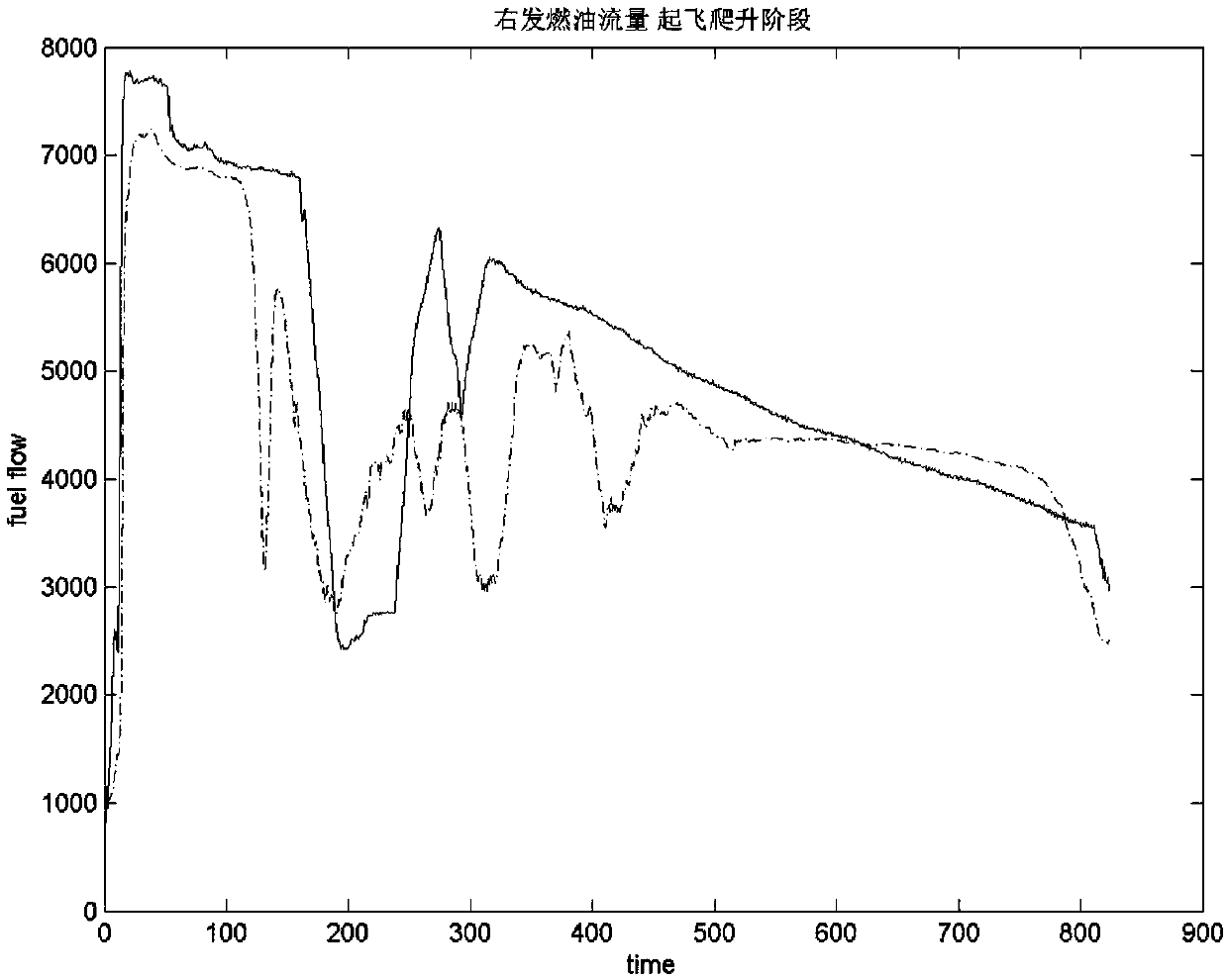

Airborne fuel system fuel consumption estimation and health monitor method

InactiveCN109598815AExtend service timeImprove fuel efficiencyRegistering/indicating working of vehiclesNeural learning methodsJet aeroplanePacket loss

The invention relates to an airborne fuel system fuel consumption estimation and health monitor method. The method comprises the following steps of: processing a data sample; building and training a fuel consumption estimation model; integrating the whole leg by taking a fuel flow predicted value and flight time as marks, so as to obtain a predicted value of a fuel consumption gross of a flight inone flight; on the basis of an obtained fuel flow model, adding channels of flight faults and abnormal events for an output layer; inputting obtained training data sample into the fuel flow model improved in the fourth step as a training sample, and carrying out training to obtain fuel flow model which is capable of monitoring airplane faults and abnormities according to airplane data; and inputting data of unmarked faults and abnormities which only undergo packet loss and addition / deletion processing into the fuel flow model improved in the fifth step as test data, so as to monitor the dataof unknown faults and abnormities.

Owner:CHINESE AERONAUTICAL RADIO ELECTRONICS RES INST

High-arc resistance epoxy insulating material and preparation method thereof and insulator

ActiveCN105504685AGood arc resistanceIncrease the number of pressure operationsPlastic/resin/waxes insulatorsMetallic oxidesPolyethylene glycolGlass transition

The invention discloses a high-arc resistance epoxy insulating material and a preparation method thereof and an insulator. The epoxy insulating material is prepared from the following raw materials in parts by mass: 1 part of composite epoxy resin, 0.51-0.55 part of curing agent methyl tetrahydrophthalic anhydride and 3.25-3.45 parts of aluminum oxide, wherein the composite epoxy resin is a mixture of phenolic aldehyde modified bisphenol A epoxy resin, polyethylene glycol modified bisphenol A epoxy resin and diphenolic acid modified bisphenol A epoxy resin. The epoxy insulating material is equivalent to traditional materials in glass-transition temperature, tensile strength and electric strength, the arc resistance reaches 237s, and after a 252kV circuit breaker is switched on / off under voltage for over 3243 times, flashover appears behind; and the epoxy insulating material has excellent arc resistance, the operation times of a high-voltage circuit breaker under voltage is remarkably increased, the service lives of internal epoxy insulating components are prolonged and reliability of the internal epoxy insulating components is improved, and the maintenance and overhauling cost of a power station is reduced.

Owner:PINGGAO GRP +2

Hollow braided pipe modification method and hollow fiber film preparation method

ActiveCN108273392AImprove stabilityEnhanced interactionSemi-permeable membranesMembranesFiberCrosslinked polymers

The invention provides a hollow braided pipe modification method, which comprises: modifying a hollow braided pipe by using a modification solution containing a polyphenol compound and a cross-linkedpolymer. The present invention further provides a hollow fiber film preparation method, which comprises: A, modifying the hollow braided pipe as a support material by using the modification method; B,carrying out mineralization treatment on the hollow braided pipe treated in the step A with a salt solution; and C, carrying out surface coating on the hollow braided pipe treated in the step B witha film forming liquid. According to the present invention, the preparation process is simple, the used raw materials are cheap, and the method is suitable for industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

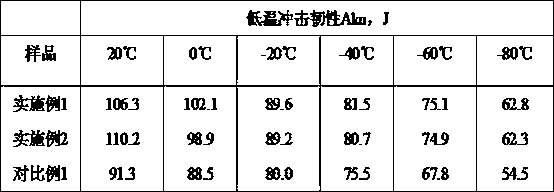

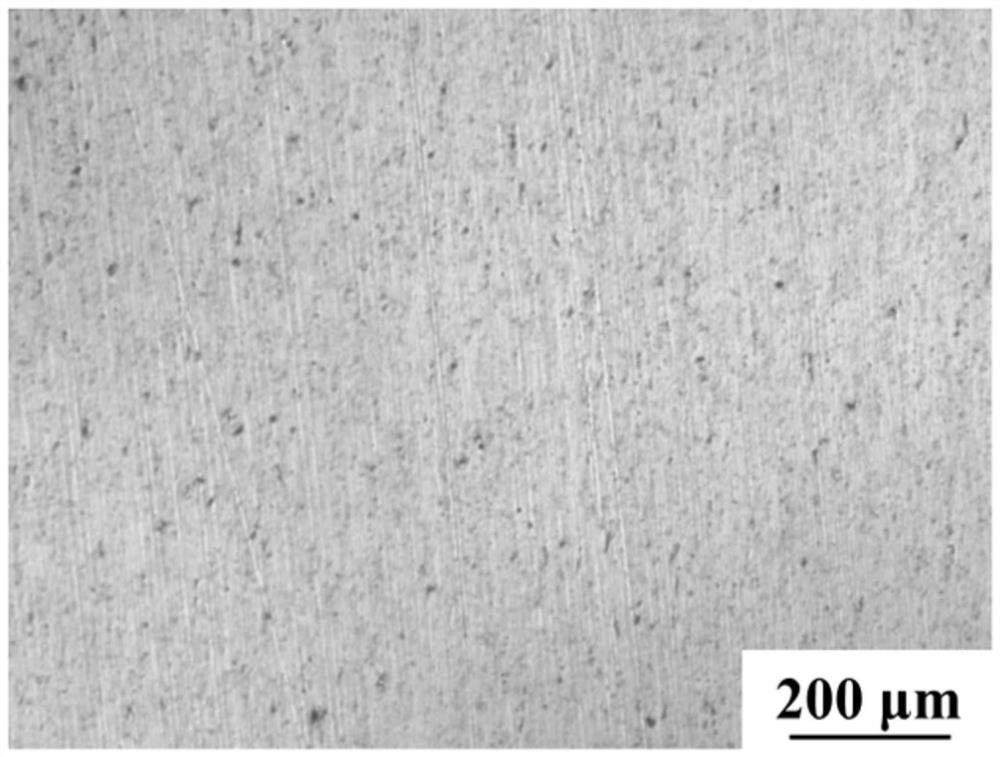

Method for improving low temperature impact toughness of 40CrNiMoA material

InactiveCN103103320AImprove low temperature impact toughnessExtend service timeChemistryComposite material

The invention discloses a method for improving the low temperature impact toughness of a 40CrNiMoA material. The method comprises: first cooling the 40CrNiMoA material to a temperature ranging from -80DEG C to -85DEG C at a rate of 2-3DEG C / min, conducting heat preservation for 0.5h-1h; then performing further cooling to a temperature ranging from -180DEG C to -185DEG C, and conducting heat preservation for 2h-3h; and then, raising the temperature to 160DEG C-170DEG C still at a rate of 2-3DEG C / min, conducting heat preservation for 1h-2h, and finally performing cooling along with a furnace. The low temperature impact toughness of the 40CrNiMoA material treated by the method provided in the invention is higher than that of materials that do not undergo deep cooling and low temperature tempering treatments. Thus, the method provided in the invention has great industrial application prospects.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI +1

Method for laser cladding Ni-based alloy+B4C wild phase on Q550 steel

InactiveCN103924238AImprove performanceIncrease productivityMetallic material coating processesSlagRoom temperature

The invention discloses a method for laser cladding Ni-based alloy+B4C wild phase on Q550 steel. The method comprises the following steps: grinding the surface of Q550 steel to remove greasy dirt and rust; cladding an enhancement layer on the surface of Q550 steel by using an optical fiber laser, wherein the technical parameters are as follows: the power is 2.0-4.0Kw, the cladding speed is 10-50cm / min, the laser heat source pattern can be circular spot with diameter being 5mm or rectangular spot with specification of 1.5mm*17mm; laser cladding the surface in forms of circular and rectangular spots, wherein the powder feeding rates are respectively 20-100g / min and 30-150g / min; and removing slag from the surface of the cladding layer, cooling to room temperature and processing chemically. The method disclosed by the invention realizes firm metallurgical combination of the Q550 steel and wild phase alloy powder, so that the method is high in production efficiency and convenient and agile to operate. The obtained cladding layer has fine texture, is free of cracks, pores and slag and also has excellent performance.

Owner:SHANDONG UNIV

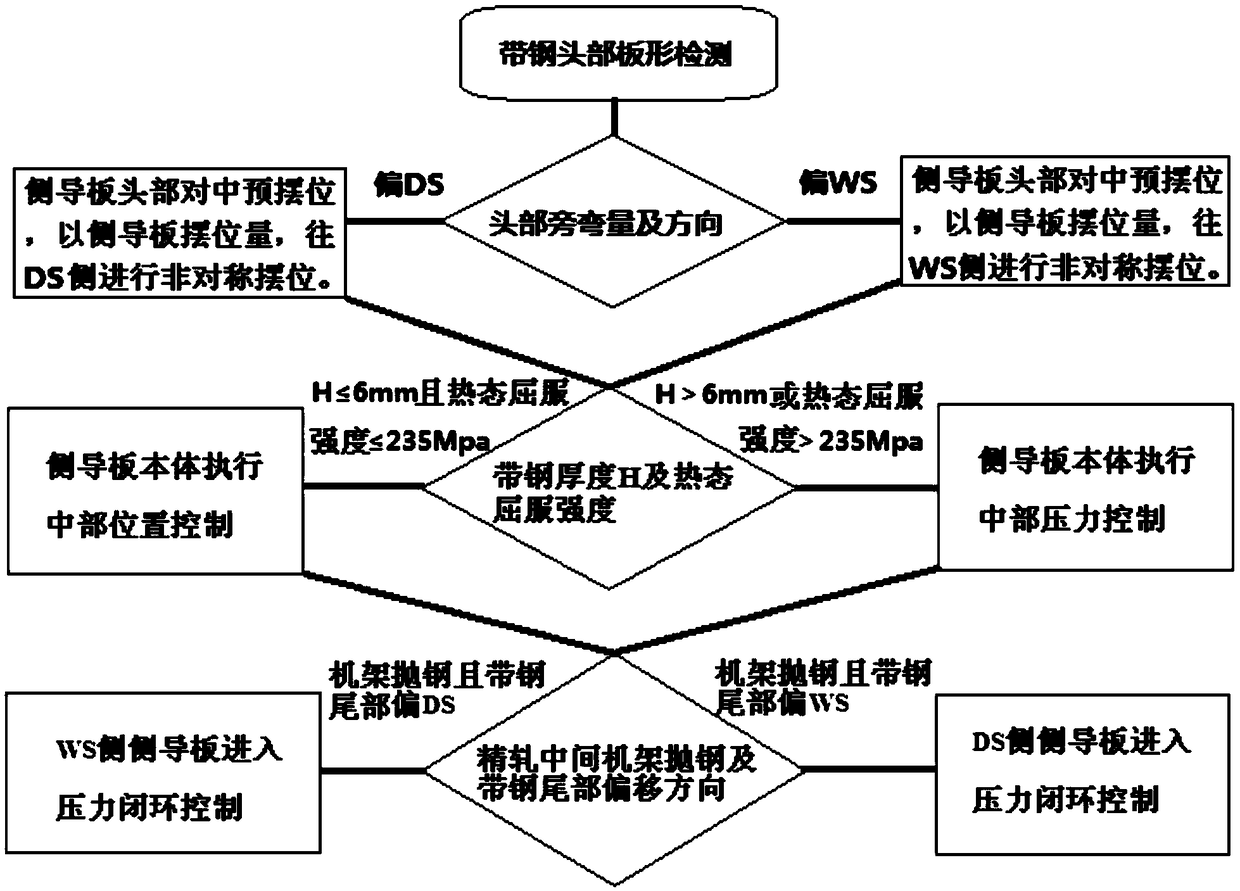

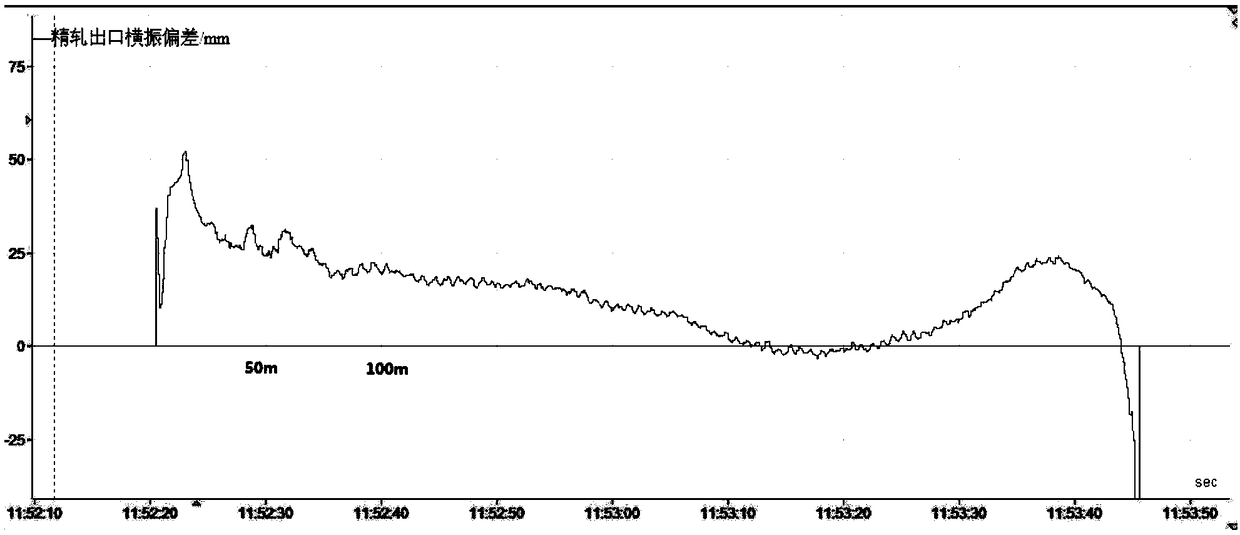

Comprehensive control method for pressure position of hot continuous rolling rolled side guide plate

ActiveCN108714629AReduce wearExtended service periodTension/compression control deviceMetal rolling arrangementsCarbon steelService time

The invention discloses a comprehensive control method for the pressure position of a hot continuous rolling rolled side guide plate. At the head of all-variety strip steel, side guide plate head alignment pre-positioning control is conducted according to the finish rolling incoming material plate shape and the transverse vibration situation; for thin-specification plain carbon steel, the cold state width value is calculated at the corresponding rolling target temperature through an instrument, side guide plate middle position control is achieved; for thick-specification high-strength steel, side guide plate middle pressure closed-loop control is achieved; and at the tail of the all-variety strip steel, automatic side guide plate tail pressure closed-loop control is achieved according to the strip steel tail deflection direction. In the whole rolling period, the actual positions of the head and the tail of the strip steel are tracked in real time, and accordingly corresponding actionsare executed. Since the comprehensive control method is input, the on-machine service time of a rolled side guide plate is seven days; the cold-rolled raw material edge breaking material return rate is reduced to 0.46%, the thin-specification plain carbon steel roll head tower-form maximum value is reduced to 30 mm, and steel roll middle maximum roll-shaped sawteeth are reduced to 2 mm; and the abnormal roll shape occurrence rate is reduced to 1.52%.

Owner:武汉钢铁有限公司

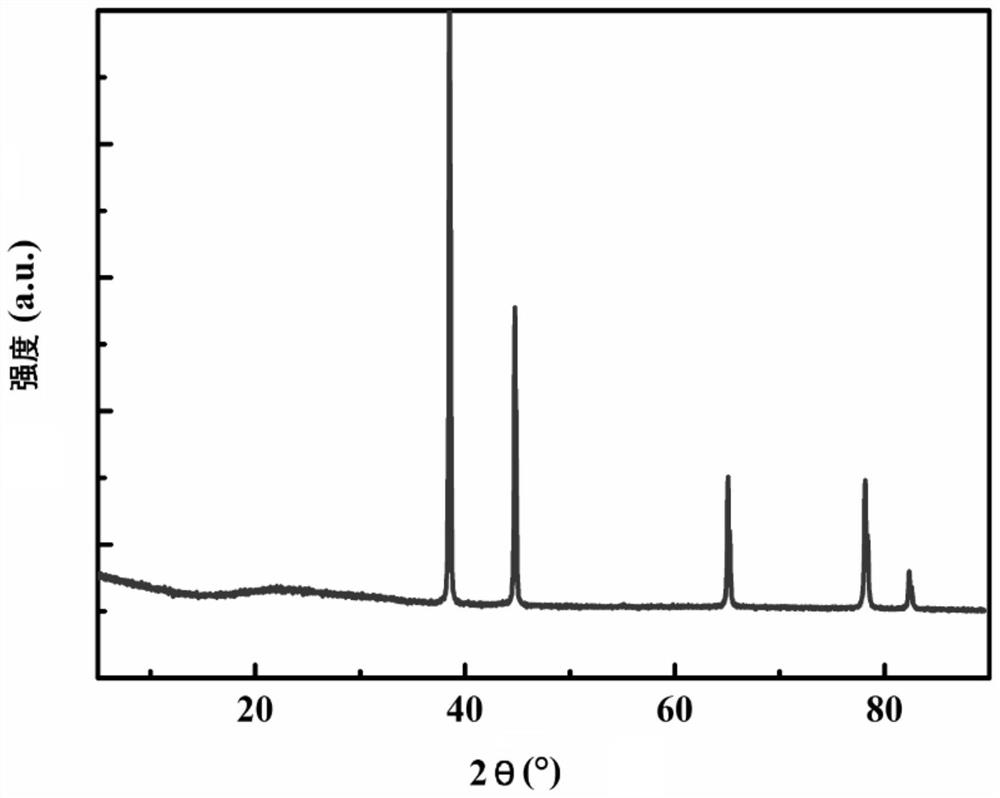

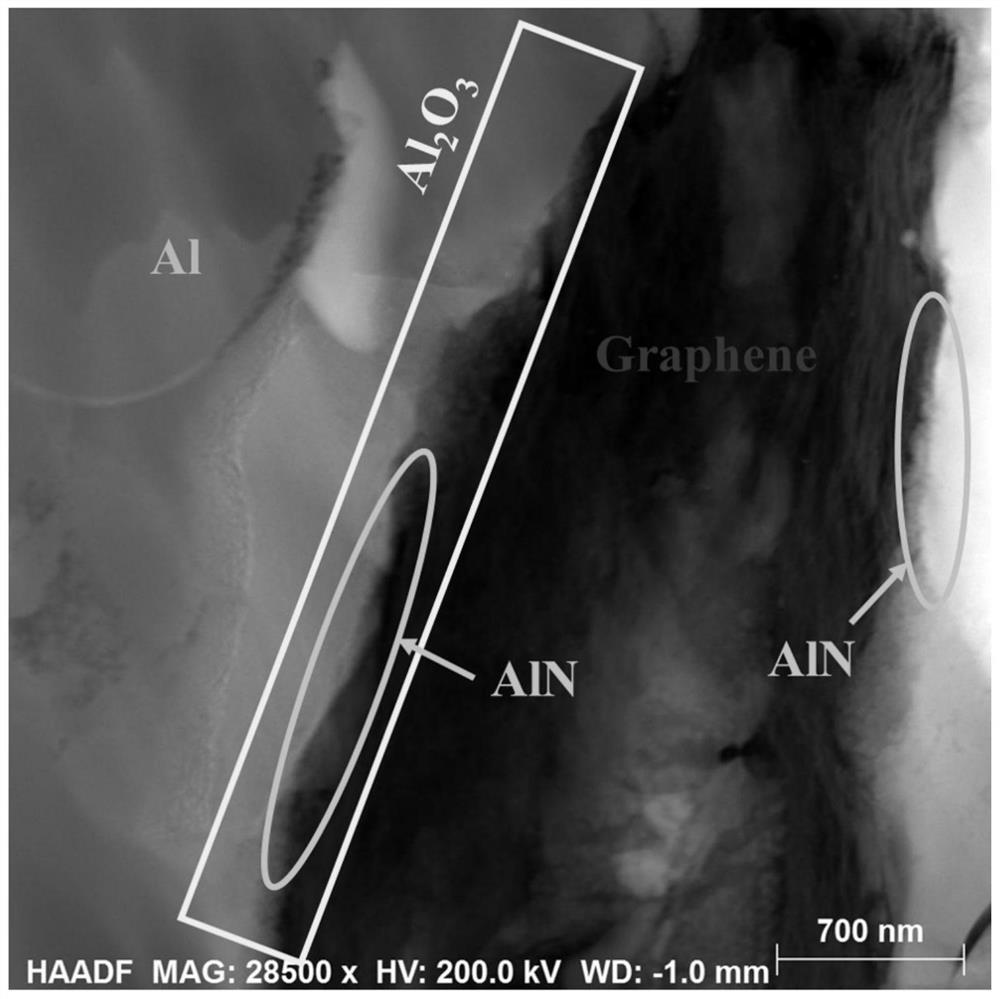

Preparation method of in-situ synthesized aluminum oxide-aluminum nitride synergetic graphene enhanced aluminum-based composite material

ActiveCN111996406AEvenly dispersedAvoid reunionTemperature control deviceGrapheneAluminum metalNitrogen gas

The invention relates to a preparation method of an in-situ synthesized aluminum oxide-aluminum nitride synergetic graphene enhanced aluminum-based composite material and relates to a preparation method of a graphene enhanced aluminum-based composite material. The preparation method aims to solve the problem that the graphene enhanced aluminum-based composite material prepared by an existing method has a lot of brittle phases. The preparation method comprises the following steps of mixing and ball-milling graphene and aluminum metal powder, dispersing the powder in an ethanol aqueous solution,adding a dispersant to obtain graphene-aluminum mixed powder, and performing cold pressing to obtain a graphene-aluminum preform; performing infiltration in a mixed gas condition of nitrogen and oxygen to obtain a composite material cast ingot; finally, performing large plastic deformation treatment and component homogenization treatment. In a sintering process, oxygen-nitrogen mixed gas is introduced and dispersed and enters into graphene-aluminum interface layers to form a mixed thin layer of aluminum oxide and aluminum nitride, so that interface bonding is guaranteed and generation of harmful products on the interface is avoided. The preparation method provided by the invention is suitable for preparing the aluminum-based composite material.

Owner:HARBIN INST OF TECH

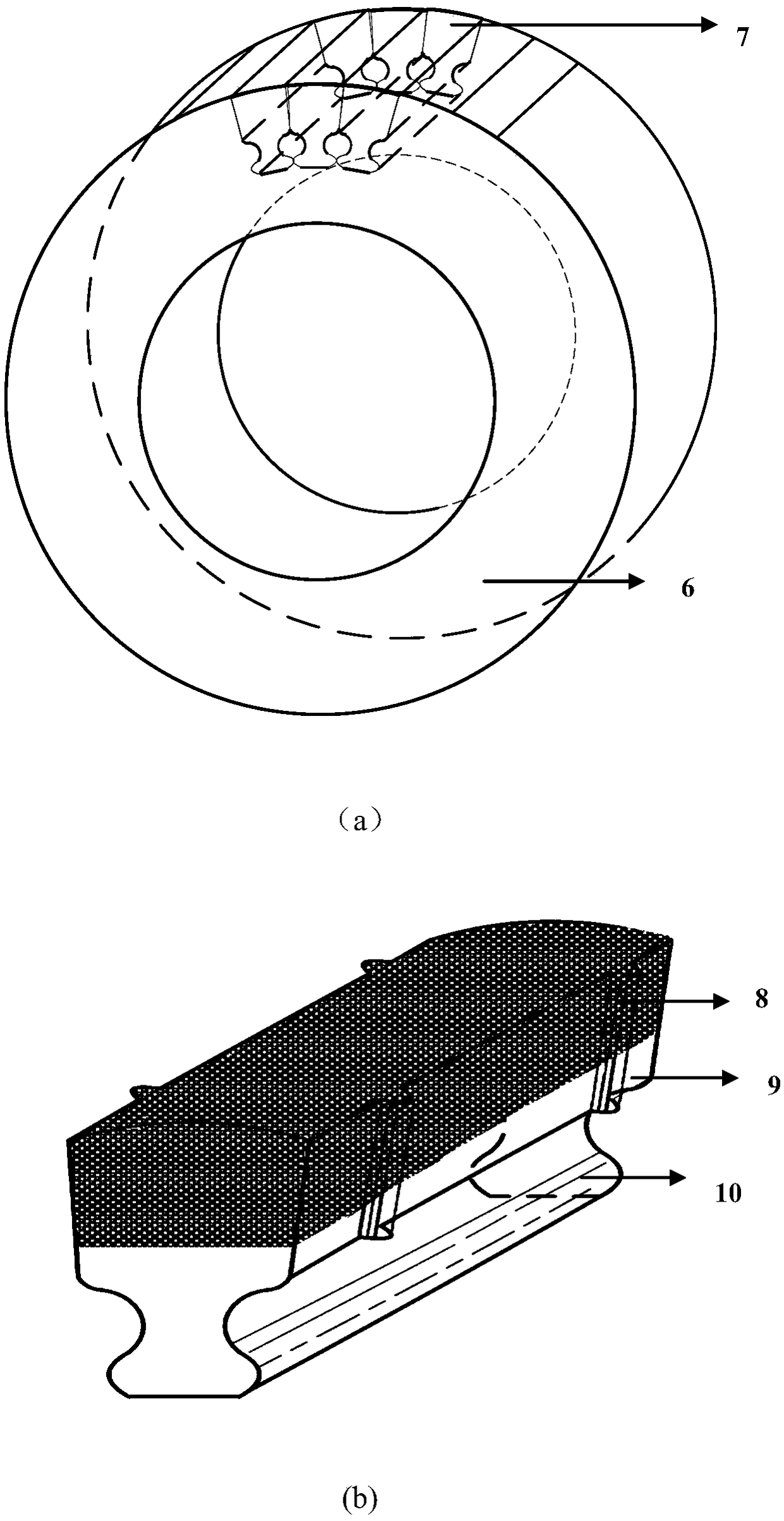

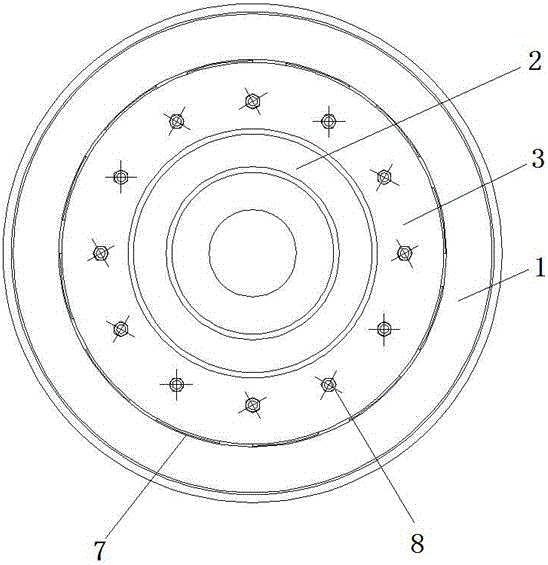

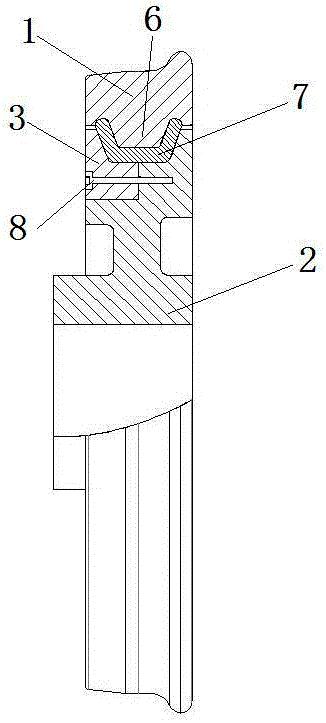

Damping and noise-reducing wheel for rail transportation

InactiveCN106004225AExtended service lifeReduce stress concentrationRail-engaging wheelsInterference fitEngineering

The invention relates to a damping and noise-reducing wheel for rail transportation. The damping and noise-reducing wheel comprises a hub, a wheel center and a press ring, wherein the press ring is pressed on one side of the wheel center and fixed through threads, and a wheel center convex shoulder and a press ring convex shoulder constitute U-shaped space; the wheel center and the press ring are sleeved with the hub, an annular convex body is arranged in the center of an inner circular end surface of the hub, and an annular closed U-shaped groove is formed between the convex body and the U-shaped space; multiple U-shaped rubber bodies are annularly distributed in the U-shaped groove at equal intervals and are in interference fit with the U-shaped groove under the condition that the wheel is unloaded, and the interference magnitude interval is 6%-14% of the thickness of all positions of the U-shaped rubber bodies; the U-shaped rubber bodies are integrally formed, and included angles between the bottom surface and two side surfaces of each U-shaped rubber body are both 110 degrees. On the basis that the application performance of a traditional resilient wheel is guaranteed, vibration and noise are reduced obviously, unsprung mass of the wheel is reduced, meanwhile, the wheel is convenient to mount, dismount and maintain, heat dissipation is facilitated, and the disperse degree of performance is reduced, so that the service time of the wheel is prolonged.

Owner:XIAN TECHNOLOGICAL UNIV

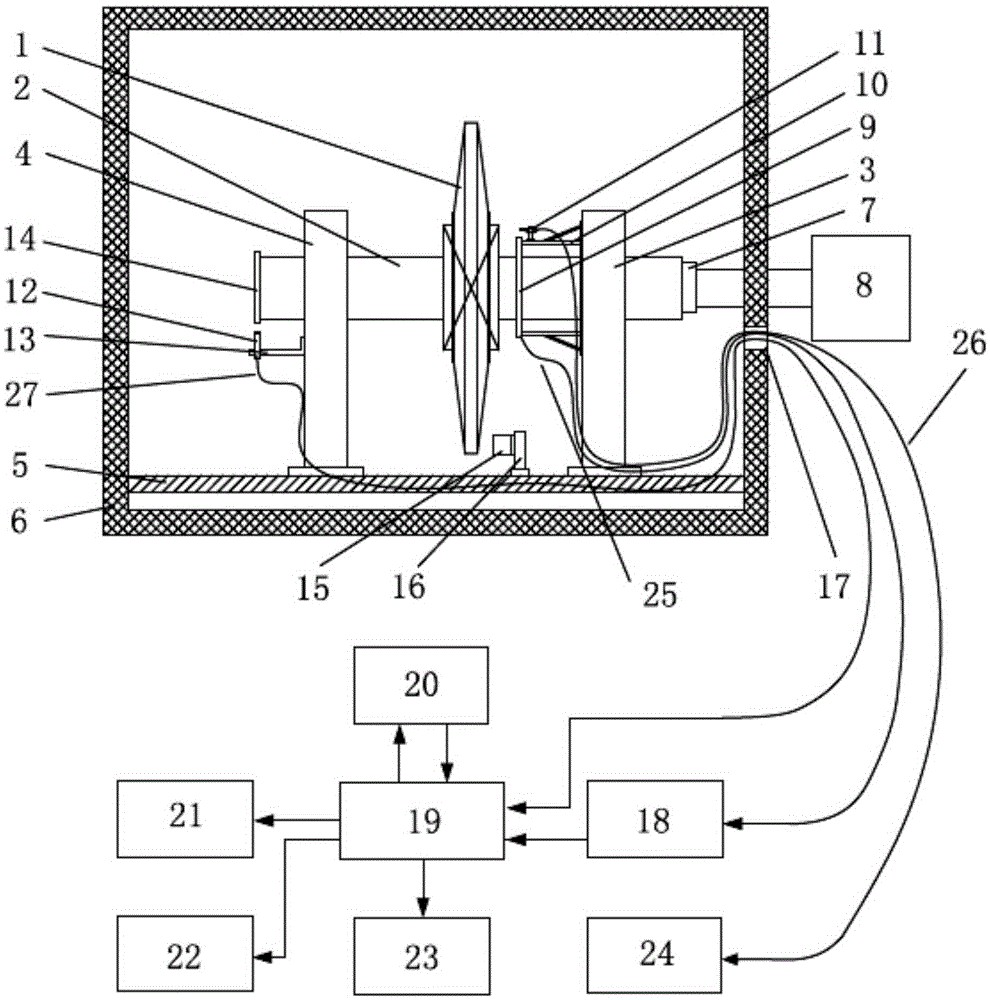

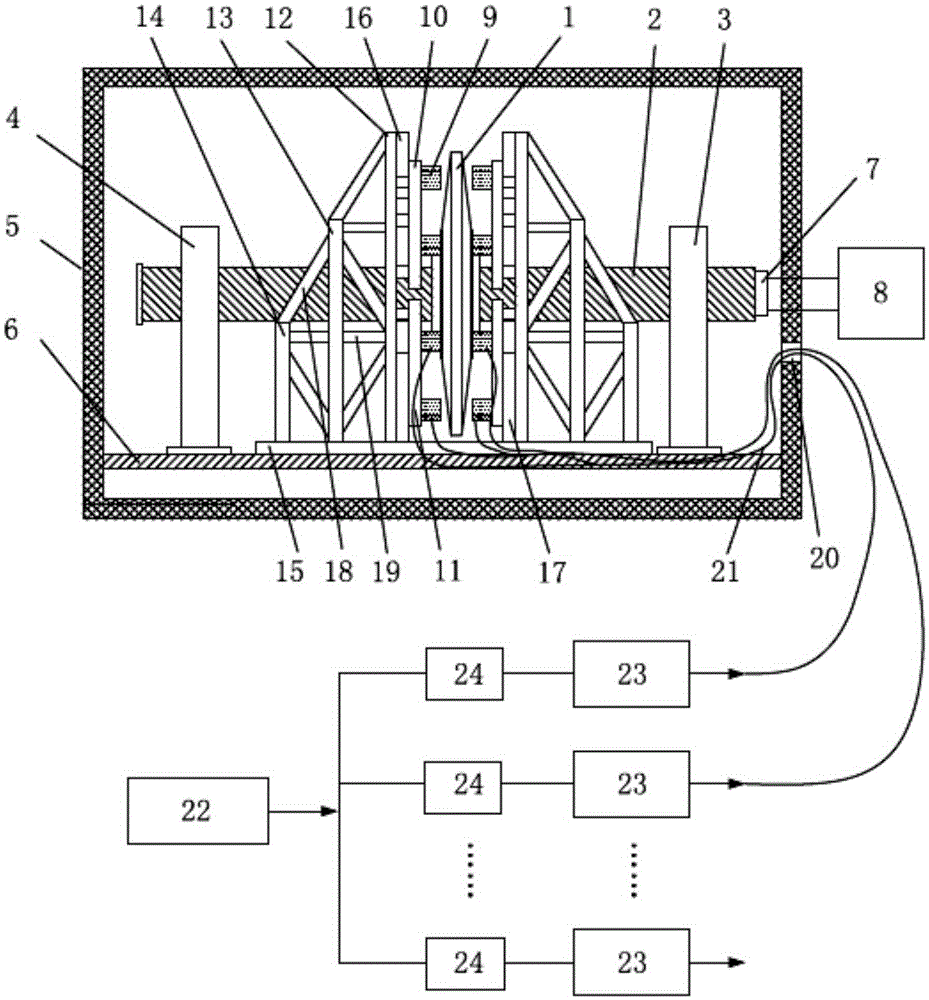

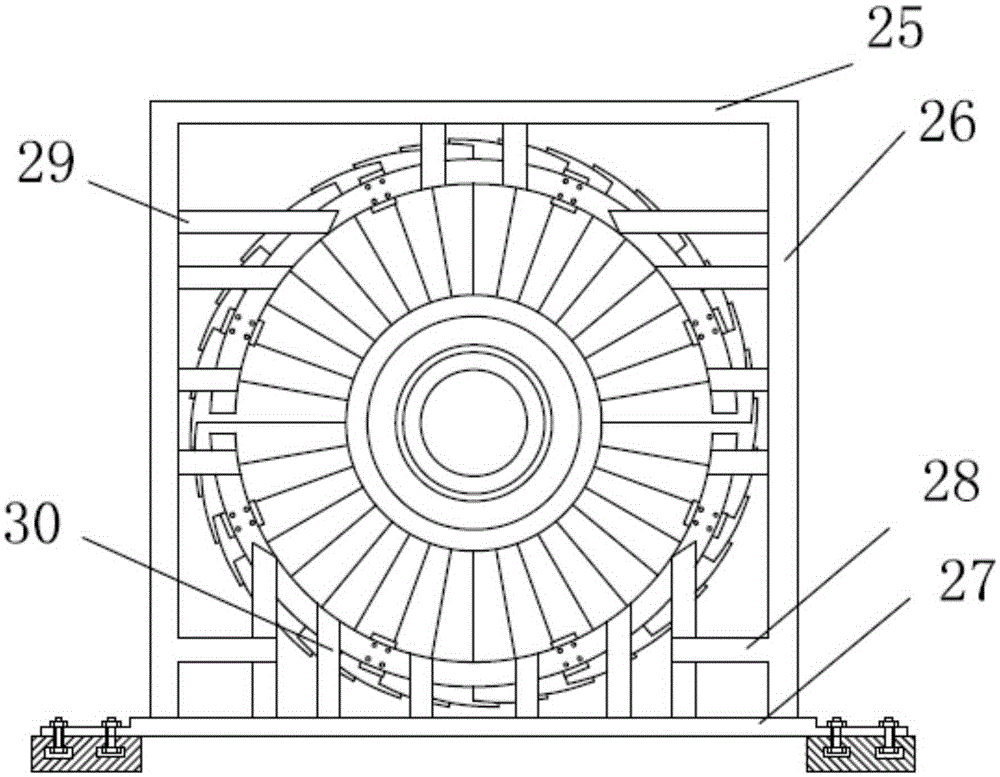

Blade dynamic frequency test apparatus using magnetic excitation

Disclosed is a blade dynamic frequency test apparatus using magnetic excitation. A magnetic exciter is used for applying an excitation force to a rotating blade, a strain gage is used for sensing blade vibration information, a signal transmitter transmits the blade vibration information sensed by the strain gage in real time via radio, and a signal receiver receives the collected blade vibration information in real time via a receiving antenna and transmits the blade vibration information to a multi-channel controller. Multiple input and output channels of a magnetic tape recorder are connected with the multi-channel signal controller and used for storing the blade vibration information of each channel. The multi-channel signal controller selects one- or multi-channel signals for a data analyzer for analyzing blade vibration characteristics. A thermometer, a tachometer and an oscilloscope are used for monitoring the temperature near the signal transmitter, the rotor velocity and signals of different channels in real time respectively. The invention solves the problem that a blade vibration frequency test using gas excitation would cause over temperature of equipment, and the invention is simple in structure, high in safety, low in cost, pollution-free, and capable of meeting blade vibration frequency test requirements.

Owner:XIAN THERMAL POWER RES INST CO LTD

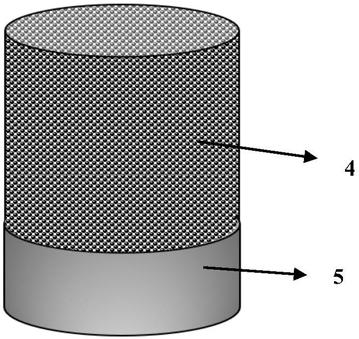

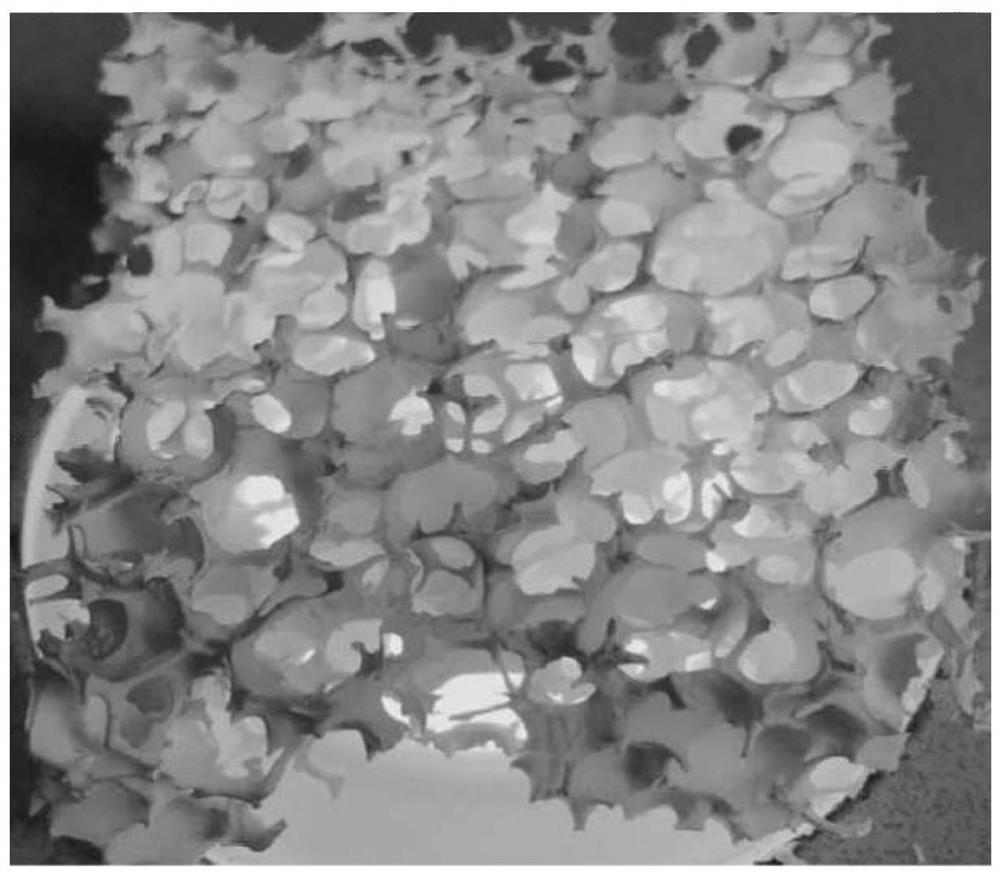

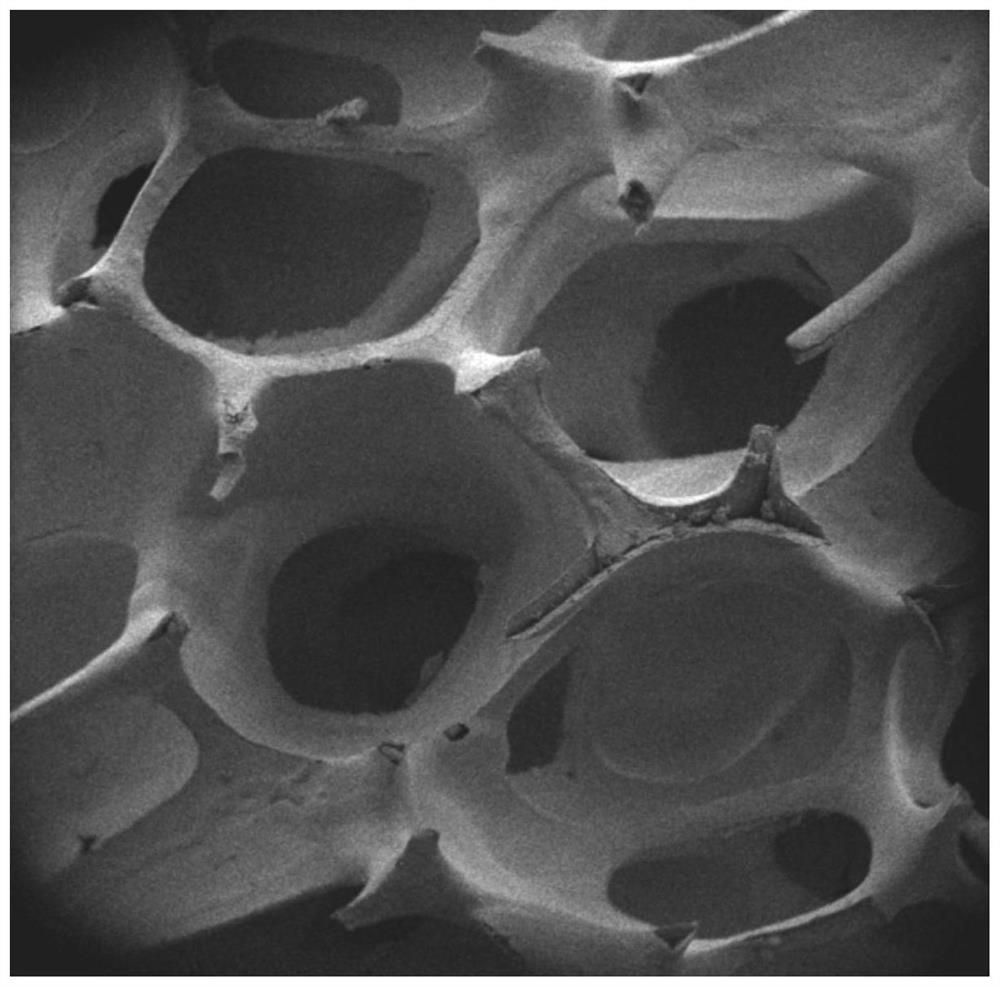

Preparation method of high-performance ceramic reinforced iron-based composite material

ActiveCN112481541AGood wear resistanceGood impact resistanceLiquid/solution decomposition chemical coatingCeramicwareOxide ceramicAluminium oxide

The invention relates to a high-performance ceramic reinforced iron-based composite material and a preparation method thereof, and belongs to the technical field of composite materials. The compositematerial comprises an iron matrix and a three-dimensional network-shaped ZTA ceramic. The three-dimensional network-shaped ZTA ceramic is a three-dimensional network-shaped ZTA ceramic with a macroscopic size, and the iron matrix penetrates through the three-dimensional network-shaped ZTA ceramic and coats the surface of the three-dimensional network-shaped ZTA ceramic. The preparation method comprises the following steps of sintering zirconium oxide and aluminum oxide ceramic mixed powder slurry through a template replication method to obtain the three-dimensional network-shaped ZTA ceramic;casting and infiltrating molten iron into the three-dimensional network-shaped ZTA ceramic to obtain the three-dimensional network-shaped ZTA ceramic reinforced iron-based composite material. The composite material has the advantages of excellent shock resistance, impact resistance and wear resistance under various severe working conditions.

Owner:CENT SOUTH UNIV

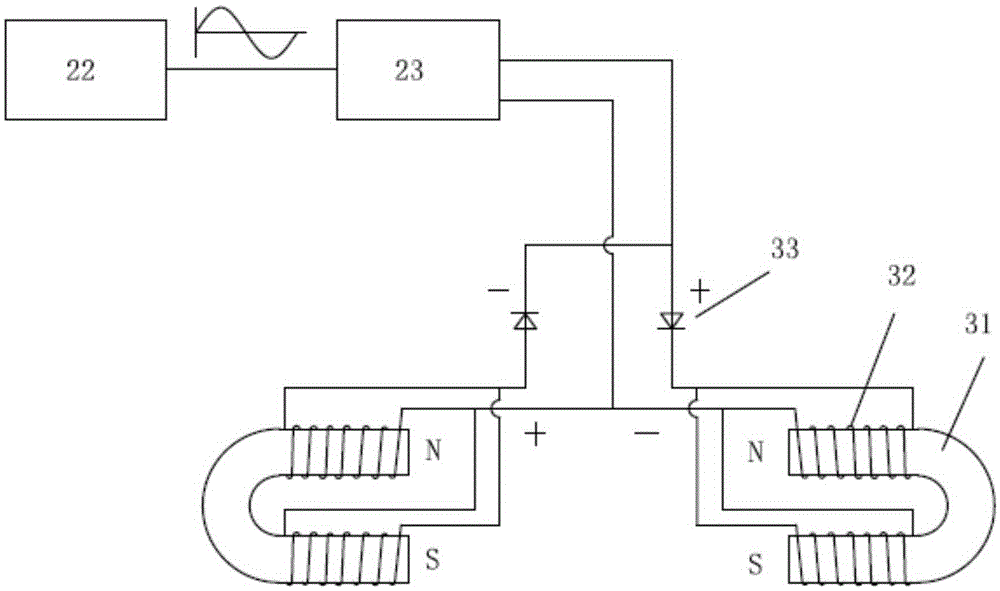

Electromagnetic harmonic wave exciting device for high-speed rotating impeller

ActiveCN105258886ADoes not affect vacuumImprove securityVibration testingImpellerAudio power amplifier

The invention discloses an electromagnetic harmonic wave exciting device for a high-speed rotating impeller. The electromagnetic harmonic wave exciting device comprises electromagnets, coils, installation boxes, electromagnetic exciter supports, power amplifiers and a signal generator. A sinusoidal signal is generated by use of the signal generator, passes through the power amplifiers and is then transmitted to electromagnetic exciters via a rectifier diode, and a sinusoidal excitation force is applied to the rotating impeller. A pair of electromagnetic exciters constitute a group and are symmetrically arranged at front and back of the impeller. A plurality of electromagnetic exciters are arranged along the circumference of the impeller and form circumferential sinusoidal excitation to the high-speed rotating impeller. The invention solves the problems of over temperature and insufficient excitation force due to that a conventional rotating impeller adopts a gas excitation manner, can meet sinusoidal excitation requirements of the impeller in a vibration test of the high-speed rotating impeller, and can adjust the amplitude of the sinusoidal excitation force.

Owner:XIAN THERMAL POWER RES INST CO LTD

Ultrahigh-temperature corrosion-resistant composite material and preparation method thereof

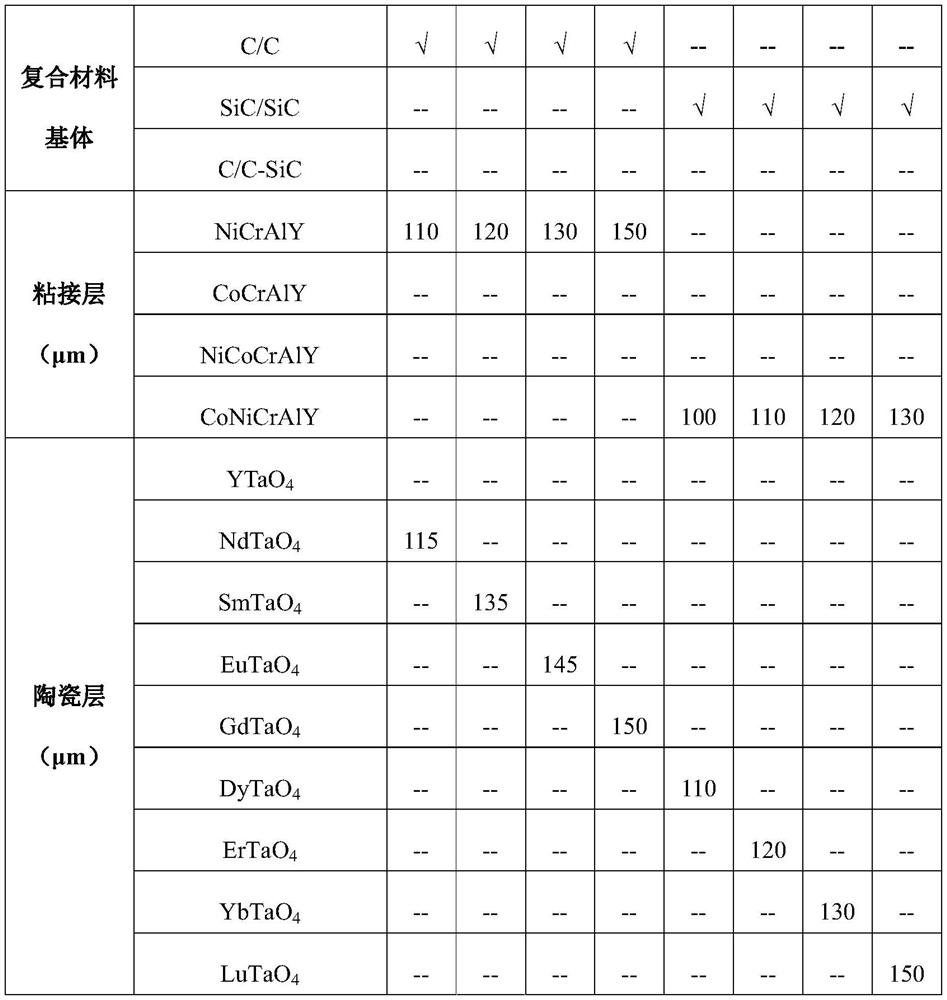

The invention relates to the technical field of composite materials, and discloses an ultrahigh-temperature corrosion-resistant composite material and a preparation method thereof. The composite material comprises a composite material base body, a bonding layer and a ceramic layer are sequentially deposited on the composite material base body, and the ceramic layer is formed by mixing one or two of rare earth tantalate (RETaO4) and rare earth niobate (RENbO4) in proportion. The prepared composite material can adapt to various severe corrosion environments, the service time of the C / C, SiC / SiC,C / C-SiC and other composite materials can be effectively prolonged, material and energy waste caused by corrosion is greatly reduced, and economic benefits are generated.

Owner:KUNMING UNIV OF SCI & TECH +1

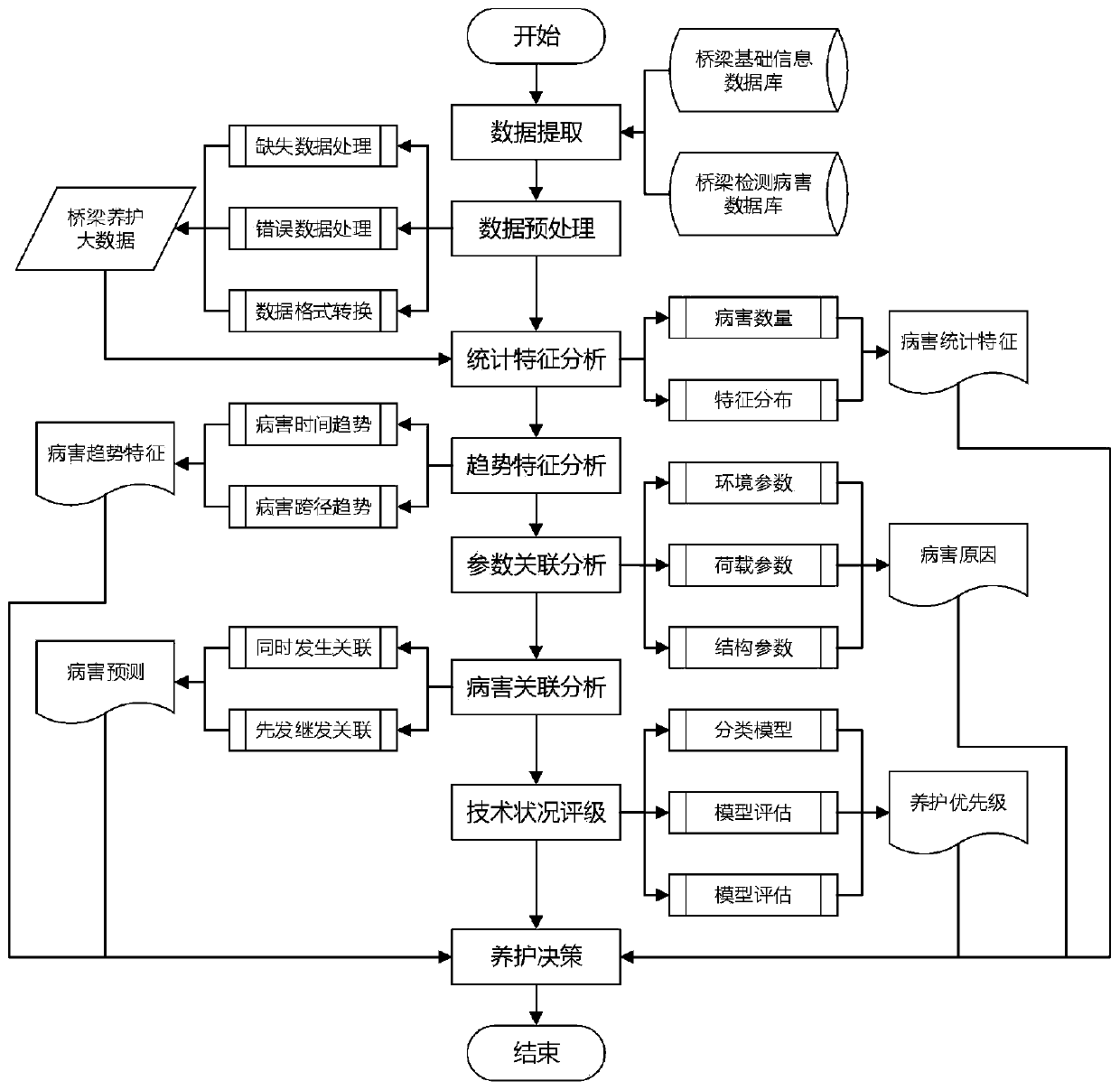

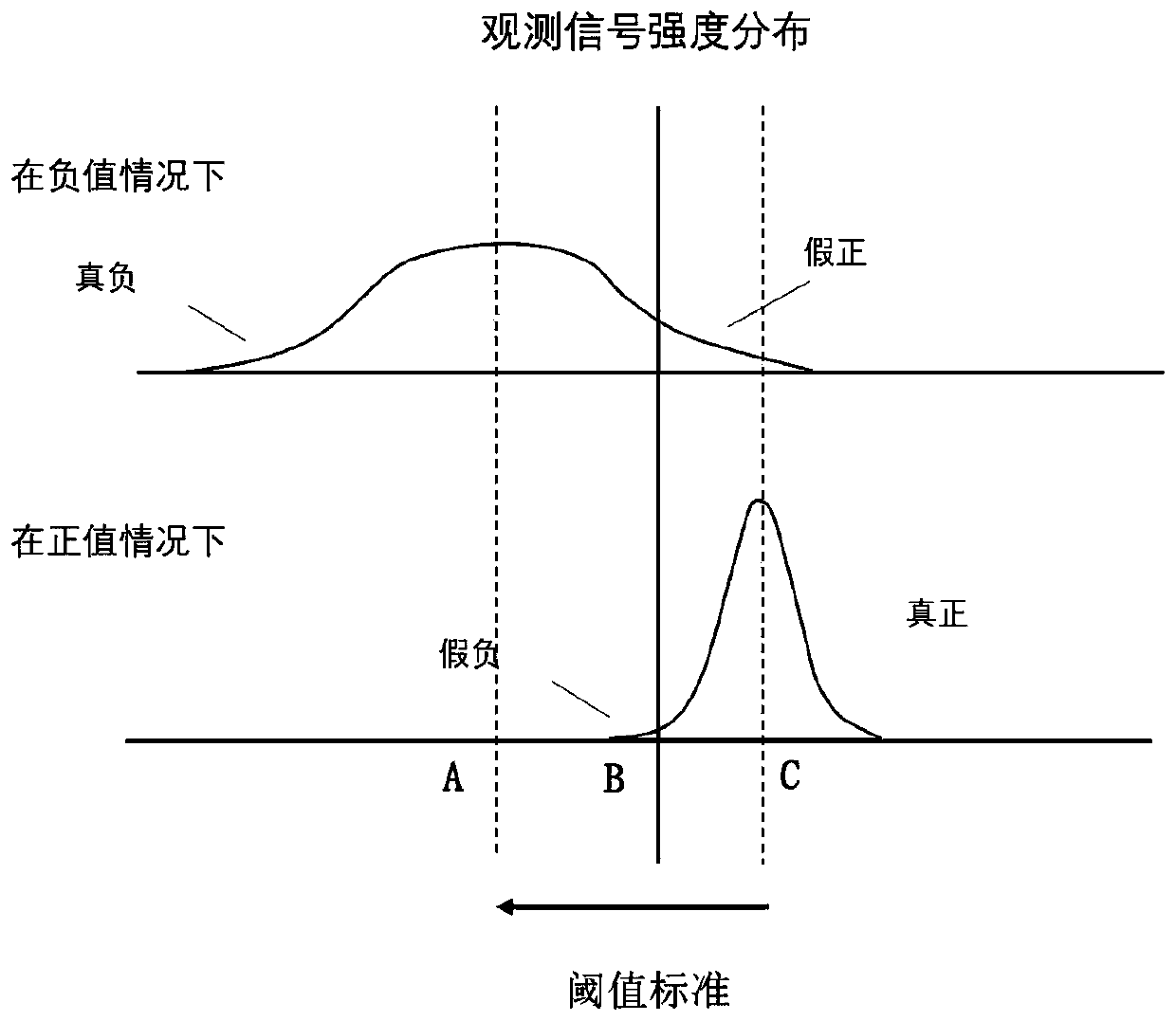

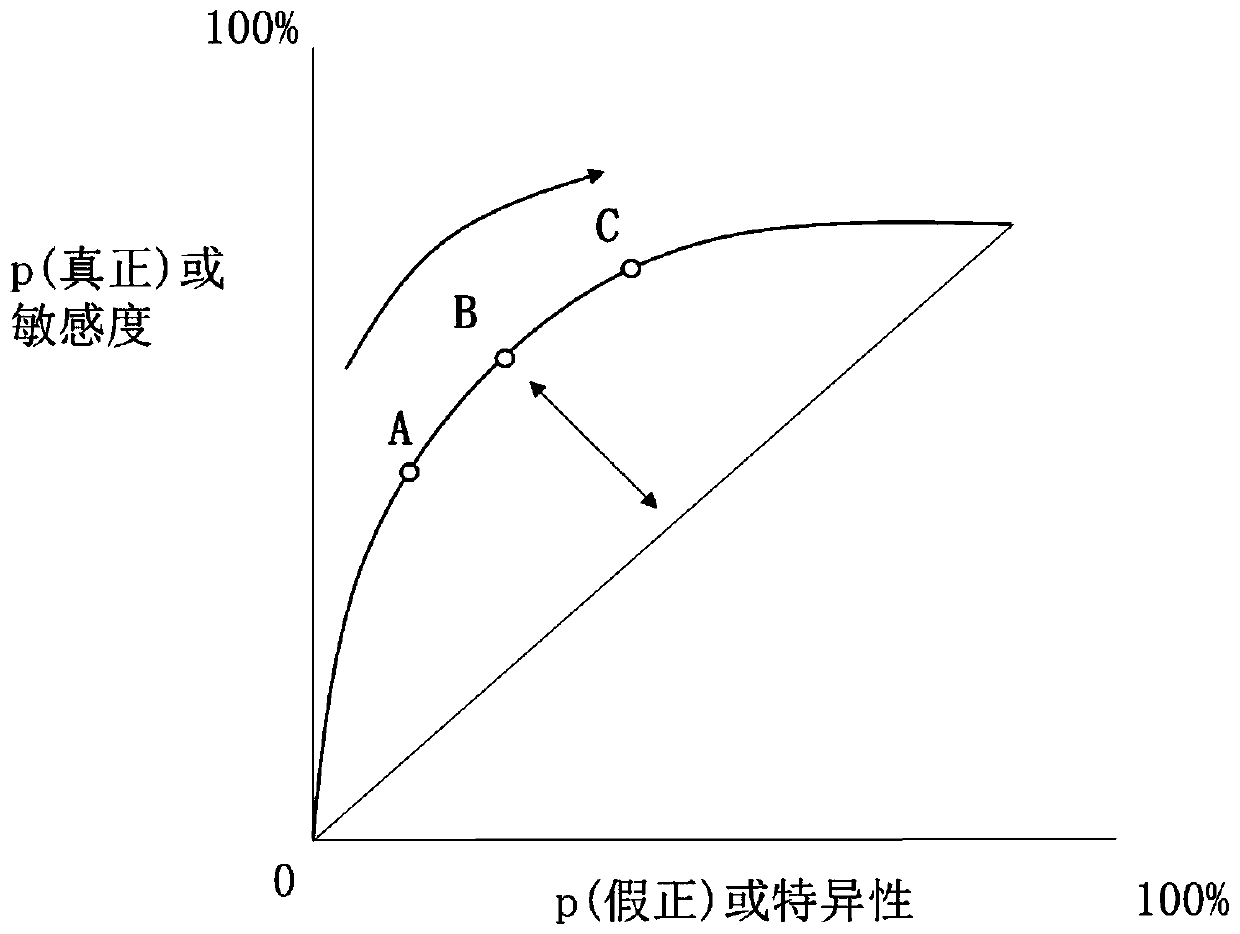

Bridge disease big data analysis method

PendingCN111310275AReduce the occurrence of serious secondary diseasesDelay performance degradationGeometric CADCharacter and pattern recognitionPreventive maintenanceData science

The invention discloses a bridge disease big data analysis method, which relates to the field of bridge maintenance and comprises the steps of preprocessing bridge maintenance big data, screening characteristic data, analyzing trend characteristics, finding out parameter association, analyzing disease association, grading technical conditions and the like. According to the invention, statistical characteristics and trends of bridge diseases are quantitatively described; according to the method, the disease influence factors and the first-occurrence and second-occurrence incidence relation between diseases are found out and used for guiding, controlling and preventing bridge diseases, bridge structure performance degradation is delayed through preventive maintenance, maintenance and replacement projects with high cost consumption are reduced, and therefore the bridge service time is prolonged, and the maintenance expenditure is saved.

Owner:NANJING ZHIXING INFORMATION TECH CO LTD +1

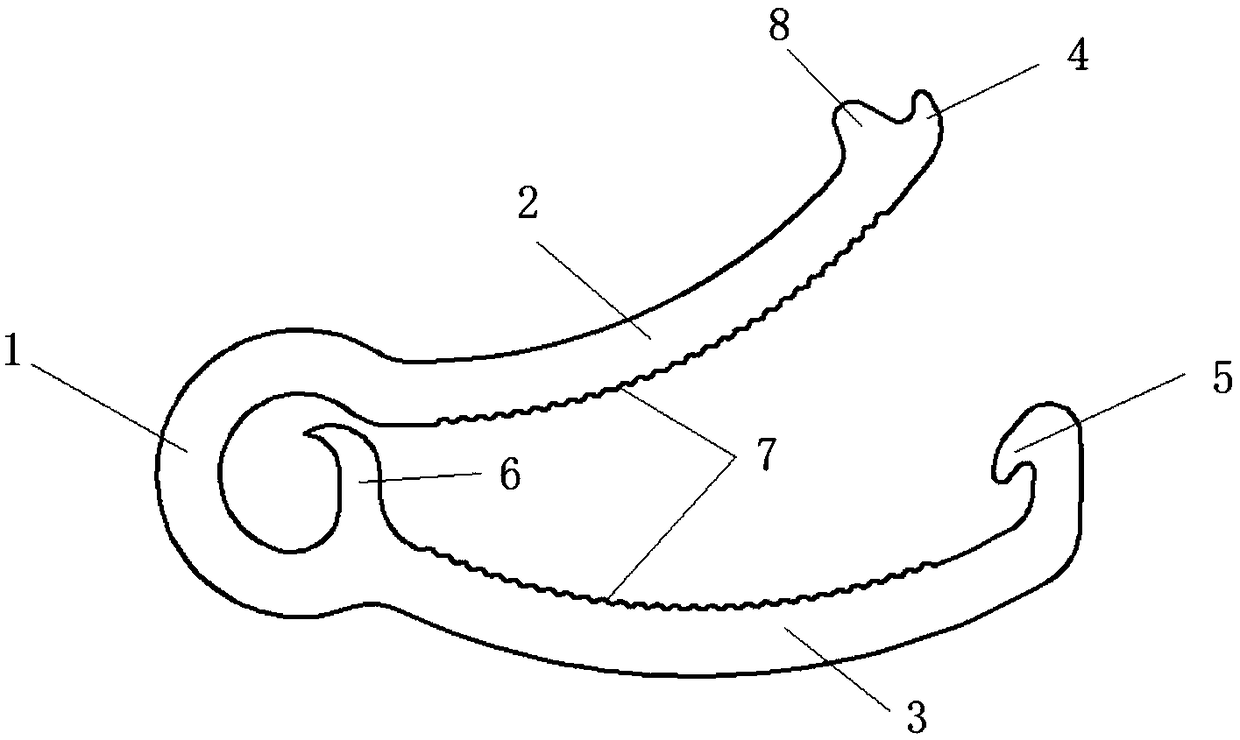

Degradable zinc alloy peritoneoscope hemostatic clip and preparing method thereof

Disclosed are a degradable zinc alloy peritoneoscope hemostatic clip and a preparing method thereof. The degradable zinc alloy peritoneoscope hemostatic clip is made of a zinc alloy. As for the components of the zinc alloy, an alloy element Mg is added into a pure zinc matrix. The degradable zinc alloy peritoneoscope hemostatic clip has the advantages that by introducing an arc structure and additionally arranging a lock catch, anti-slide insections and a limiting protrusion, stress concentration after the metal hemostatic clip is closed is effectively improved, meanwhile the clamping propertyof the hemostatic clip is effectively improved, and the risk of sliding off of the hemostatic clip after an operation is reduced; zinc is a necessary element of the human body, the good biocompatibility and absorbability are achieved by using the hemostatic clip prepared through the zinc alloy, and meanwhile, the service time of the hemostatic clip is increased obviously through the appropriate degradation in vivo characteristic of the hemostatic clip; the hemostatic clip is simple and easy in structure and simple in preparation technology, and the preparation cost is reduced effectively; andthe designed and prepared hemostatic clip fully meets the clinical use requirement.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

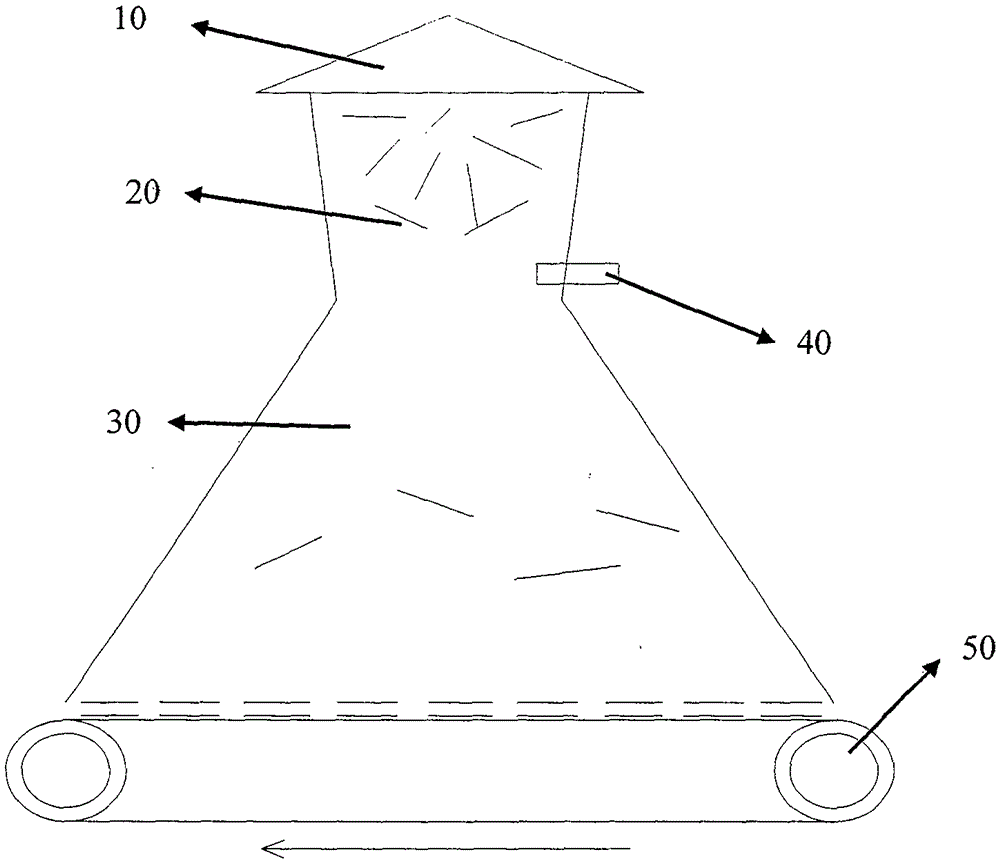

Nanometer silicon dioxide aerogel glass fiber light felt and preparing method thereof

The invention discloses nanometer silicon dioxide aerogel glass fiber light felt and a preparing method thereof. The glass fiber light felt is characterized by being formed by horizontally arranging glass fibers with silicon dioxide aerogel particles adhering to the surfaces uniformly. No glass fibers penetrate through the felt in the thickness direction. The diameter of each glass fiber is 1-4 micrometers, the length of each glass fiber is 5-30 millimeters, and the particle size of each silicon dioxide aeraogel particle is 10-100 nanometers. By means of the venturi effect, the silicon dioxide aerogel particles are adsorbed to the surfaces of the glass fibers uniformly, the thickness of a silicon dioxide aerogel adhesion layer on the surface of each glass fiber is 50-500 nanometers, the proportion of the uncovered portion of the surface of each fiber is 5-10%, the weight ratio of the silicon dioxide aerogel particles in the felt is 0.1-1%, the volume weight of the felt is 5-20 kilograms per cubic metre, the compression resilience of the felt is 20-30%, the porosity of the felt is 70-90%, and the heat conductivity coefficient of the nanometer silicon dioxide aerogel glass fiber light felt is 0.008-0.015 W / m.K.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Mullite brick with fiber toughening and preparation method thereof

The invention relates to a mullite brick with fiber toughening and a preparation method thereof. The mullite brick is prepared from the following raw materials in percentage by mass: 25%-35% of fusedmullite with a particle size of 3-5 mm; 10%-25% of sintered mullite with a particle size of 1-3 mm; 10%-20% of andalusite with a particle size of 1-3 mm; 5%-15% of sintered mullite with the particle size of 0-1 mm, 10%-20% of sintered mullite powder with the particle size of -200 meshes, 5%-10% of white corundum with the particle size of + 350 to -250 meshes, 4%-6% of aluminum oxide micro powder with the particle size of 5-6 microns and 4%-6% of ball clay with the particle size of -200 meshes. According to the preparation method, a mullite sol precursor which accounts for 4-6% of the total weight of the raw materials is added, the mullite brick provided by the invention has very high impact resistance, can effectively improve the thermal shock resistance of a fired brick, and prevents thefired brick from cracking and peeling off, thereby prolonging the service time and prolonging the service life of a lining.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Anti-cavitation corrosion-resistant metal-ceramic matrix composite material and preparation method thereof

ActiveCN114214555AReduce process stepsReduce processing costsMetallic materialsCeramic matrix composite

The invention discloses a preparation method of an anti-cavitation corrosion-resistant metal-ceramic matrix composite material. The preparation method comprises the following steps: (1) preparing a composite prefabricated part by taking a metal material, a ceramic material and a rare earth material as raw materials; in the composite prefabricated part, the volume ratio of the metal phase to the ceramic phase is (5-95): (95-5); the addition amount of the rare earth material is 0.1-10% of the total mass of the metal material and the ceramic material; and (2) carrying out laser remelting treatment on the composite prefabricated part prepared in the step (1). Due to introduction of the rare earth material, the melting point of the metal-ceramic matrix composite material is reduced, meanwhile, the laser absorptivity of the material is improved, and the cavitation erosion resistance and corrosion resistance of the metal-ceramic matrix composite material are improved. In addition, the metal material, the ceramic and the rare earth material can play a synergistic role in the cavitation erosion-corrosion environment, so that the prepared metal-ceramic based composite material has excellent cavitation erosion resistance and corrosion resistance.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

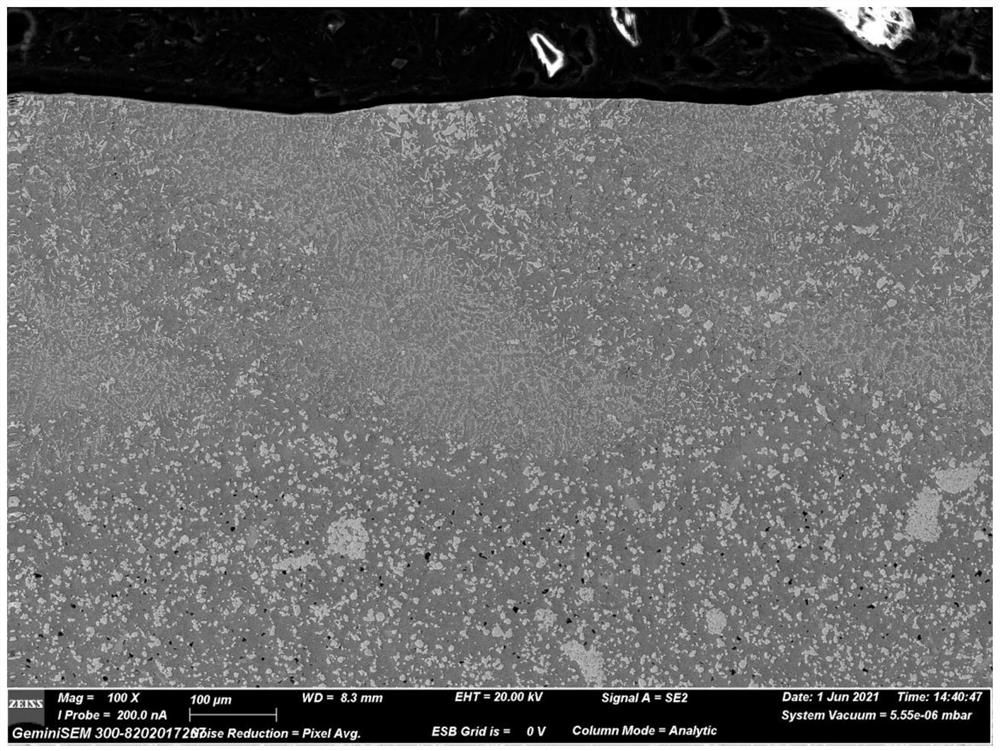

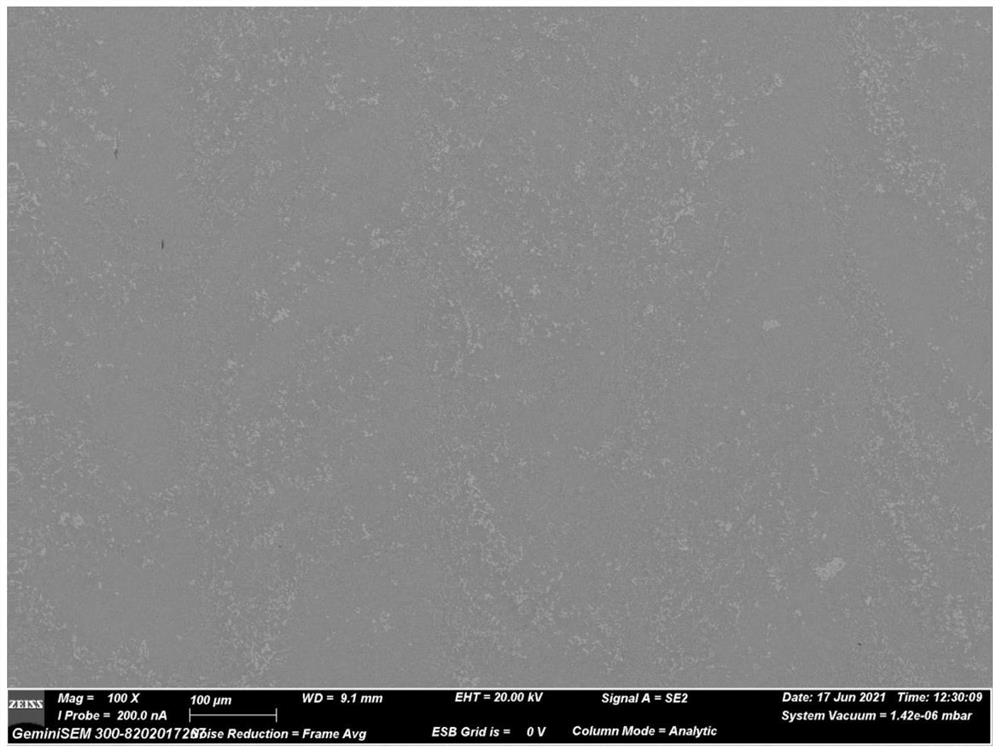

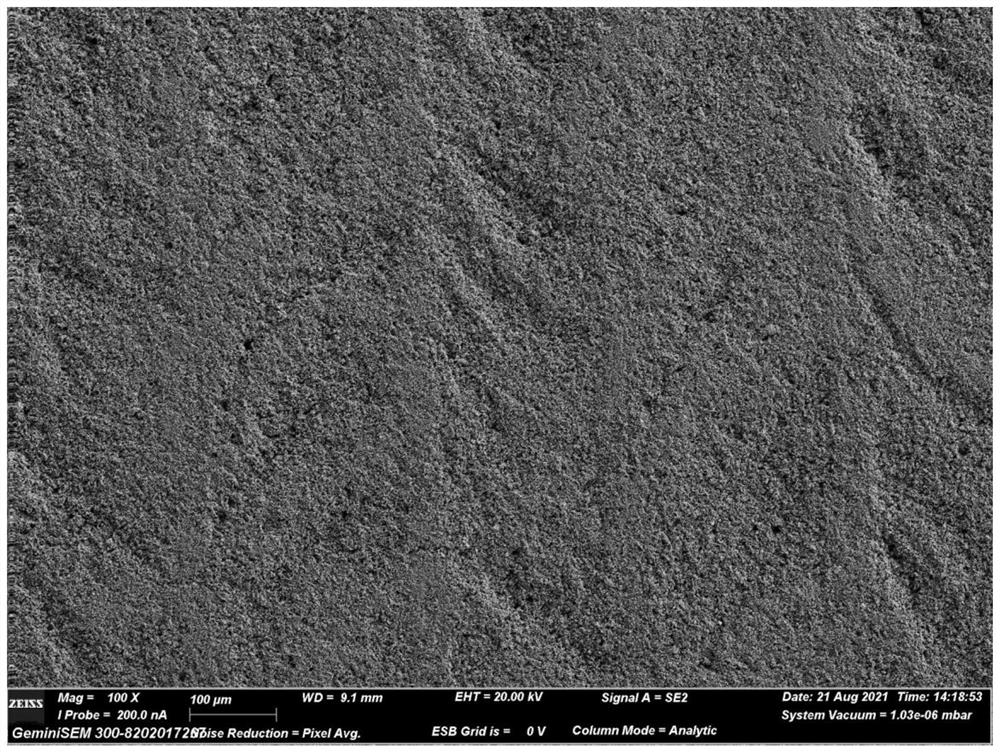

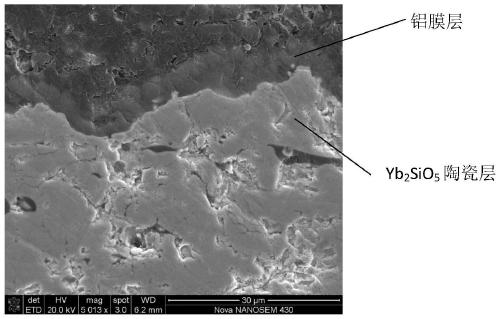

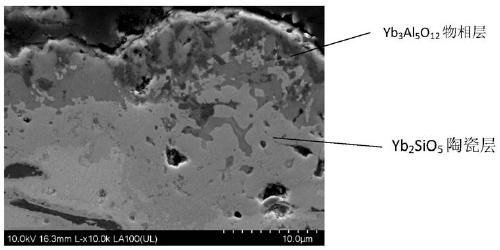

Environmental barrier coating and coating method and application thereof

ActiveCN110284097AImprove service performanceExtend service timeMolten spray coatingVacuum evaporation coatingAluminateCoated surface

The invention relates to the technical field of ceramic coating surface treatment and discloses an coating method of an environmental barrier coating. The method includes the steps that the surface of a rare earth silicate ceramic layer is coated with an aluminum film layer; and the aluminum film layer is subjected to thermal treatment, so that a rare earth aluminate phase is formed at least in pores of one surface, facing the aluminum film layer, of the rare earth silicate ceramic layer. By means of the method, the aluminum film layer is disposed on the surface of the rare earth silicate, then thermal treatment is performed, thus molten aluminum enters the pores of the surface of the rare earth silicate ceramic layer to fill the pores, the molten aluminum has a reaction with rare earth oxide and silicon dioxide which are generated by decomposing the rare earth silicate ceramic layer under the thermal environment so that rare earth aluminate which is more compact and water-resistant can be generated, the service properties of the environmental barrier coating are effectively improved, and the service life of the environmental barrier coating is prolonged. The environmental barrier coating prepared by the method is further disclosed and is good in service property and long in service life.

Owner:GUANGDONG INST OF NEW MATERIALS

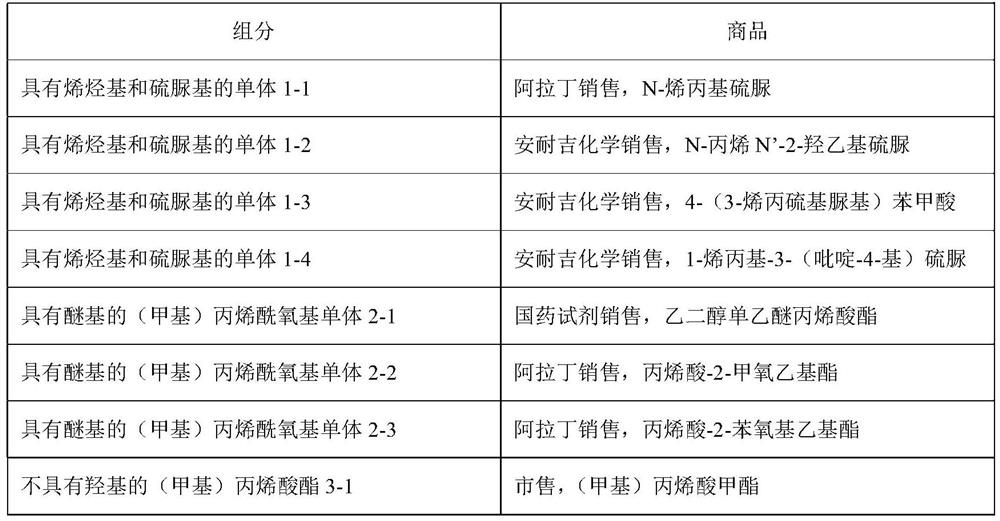

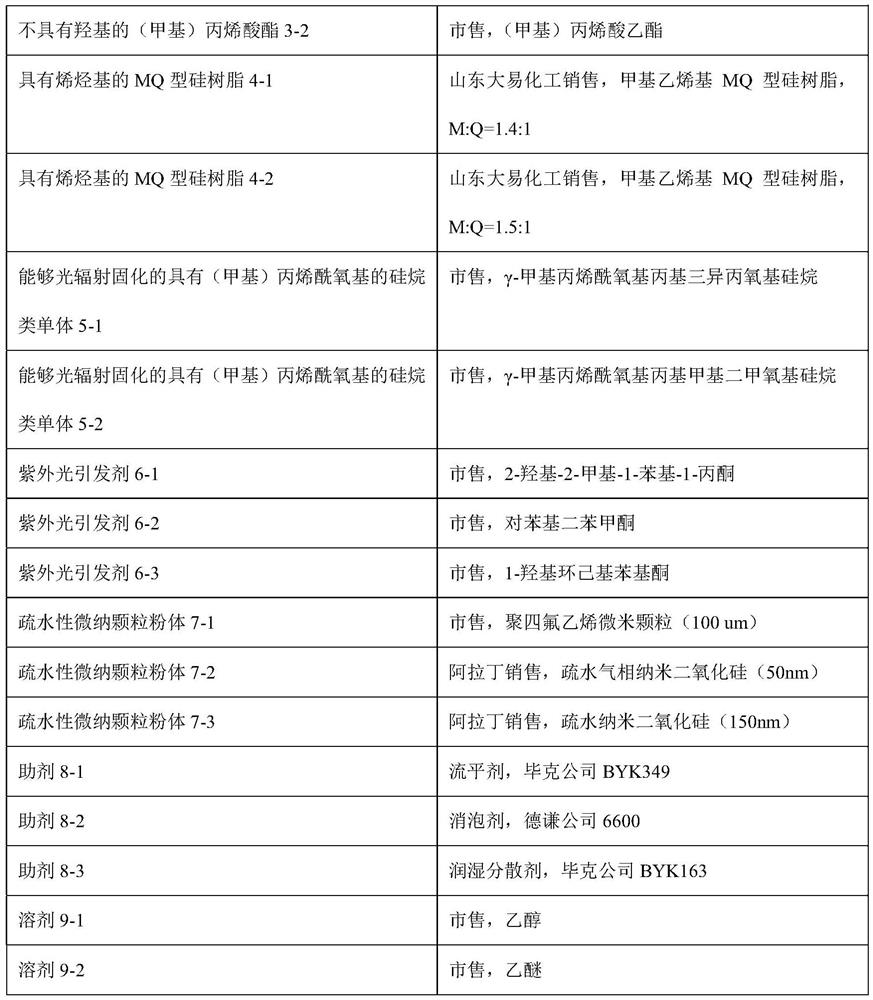

Underwater high-adhesion organosilicone marine antifouling paint and cured coating and preparation method thereof

ActiveCN113736364ASimple production processExtend service timeAntifouling/underwater paintsPaints with biocidesThioureaEther

The invention discloses an underwater high-adhesion organosilicone marine antifouling paint and a cured coating and a preparation method thereof. The coating subjected to ultraviolet curing shows an excellent hydrophobic effect on a seawater contact interface, and the hydrophobic effect is kept for a long time; the coating can be firmly bonded on a base material or epoxy intermediate paint contact interface by virtue of Van der Waals force and hydrogen bonds between thiourea groups and ether groups, and meanwhile, the synergistic effect of hydrophobic interaction and weak hydrogen bonds can ensure that the coating keeps a good bonding effect in a long-term underwater environment; and the coating can be widely applied to ocean ships, offshore oil drilling platforms, deep sea detection equipment, underwater long-term use equipment and the like, and is particularly suitable for facilities immersed in a seawater environment for a long time.

Owner:ZHEJIANG YUTONG NEW MATERIAL

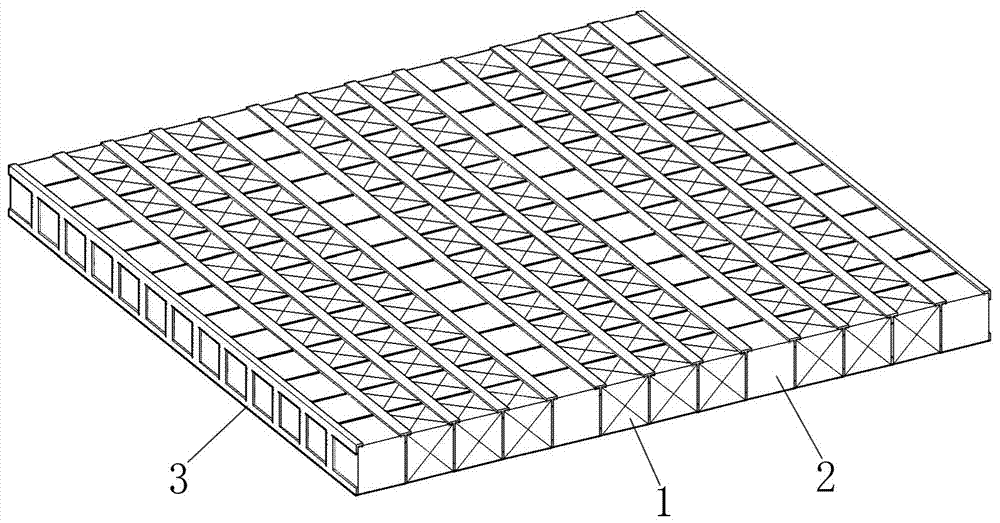

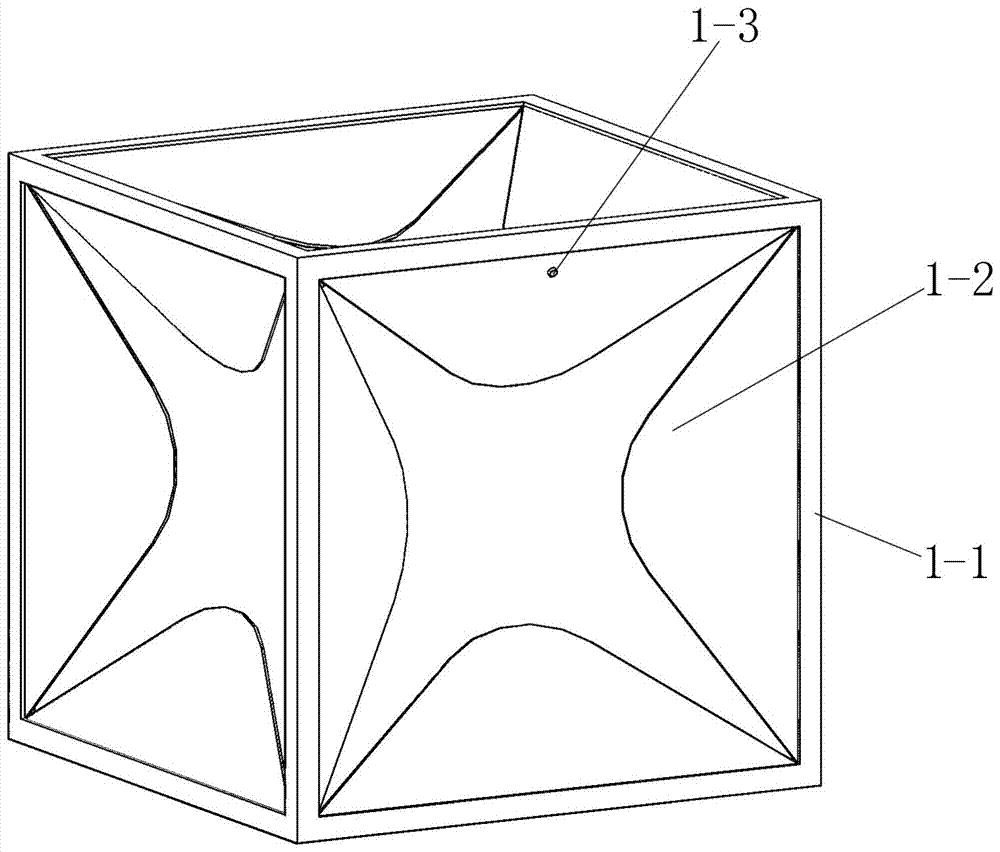

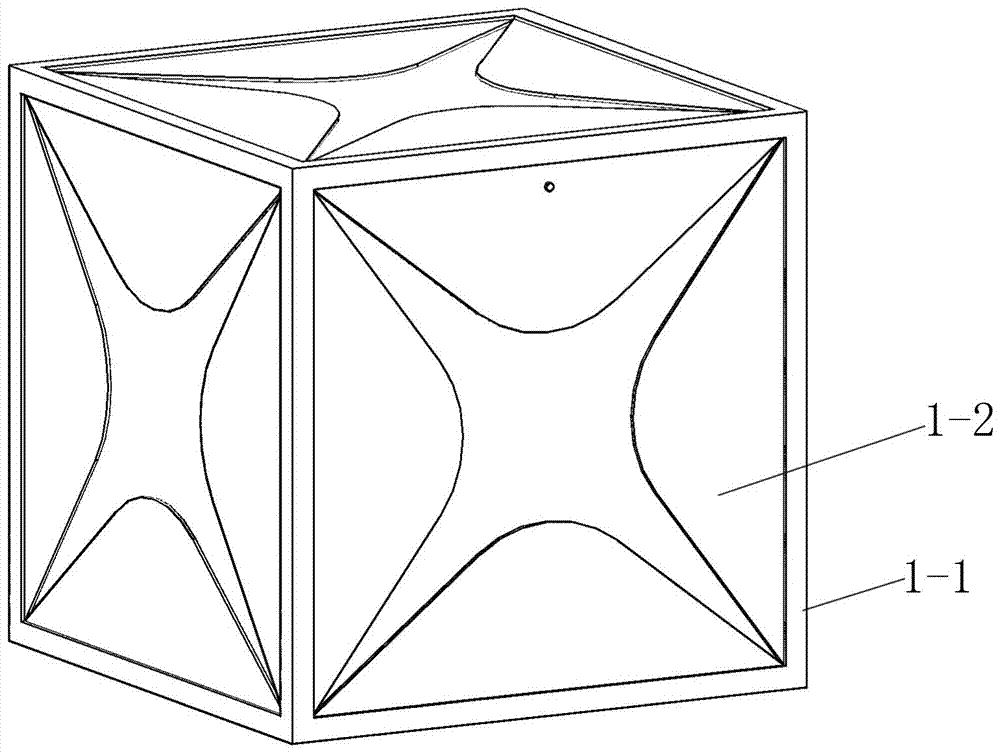

Modular aerostatic island

ActiveCN107089315AExtend service timeImprove reliabilityRigid airshipsGas-bag arrangementsButt jointAerostatics

The invention relates to a modular aerostatic island and belongs to the technical field of aerostatics. The problem existing in an existing aerostat is solved. The modular aerostatic island comprises constant lift material units, lift balancing control units and gridding frameworks. The multiple constant lift material units and the multiple lift balancing control units are fixedly connected through the gridding frameworks. All units can achieve industrialized, standardized and large-scale production and have large advantages in product quality control and cost control. According to different service actual needs, the needed unit number can be calculated according to the working condition and the size of the needed aerostatic island, so that the material units are formed through customization and assembly, in this way, arraying and emergency response efficiency can be improved through large-scale production, the units can be replaced and repaired through adjusting the working height, and aloft butt joint between islands can also be achieved, and aerostatic island durable aerostation stationing in a real meaning is achieved. The modular aerostatic island is used for durable aerostation stationing.

Owner:HARBIN INST OF TECH

Phenolic resin based friction material for ultrasonic motors and preparation method thereof

InactiveCN106566471AImprove carrying capacityImprove wear resistanceOther chemical processesAluminum silicateElectric machinery

The invention discloses a phenolic resin based friction material for ultrasonic motors. The phenolic resin based friction material is prepared from the following components by mass percentage: 55-70% of phenolic resin; 10-20% of aramid fiber; 10-20% of aluminum silicate; 0-10% of copper powder; and 0-10% of graphite. The invention also discloses a preparation method of the material. The method includes: subjecting uniformly mixed materials to hot press molding, then slicing the hot press molded material and applying the obtained material to ultrasonic motors. The friction material prepared by the method has good comprehensive performance, can meet the use requirements of ultrasonic motors under the harsh environments of a wide temperature range, ultralong service life requirement, and large load, etc., and broadens the application requirements of ultrasonic motors in aerospace, precise instruments and high-end equipment. Also the method is simple and reliable, and the prepared material has stable properties, therefore the phenolic resin based friction material is an ideal friction material for ultrasonic motors, and the method is a reliable preparation method.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

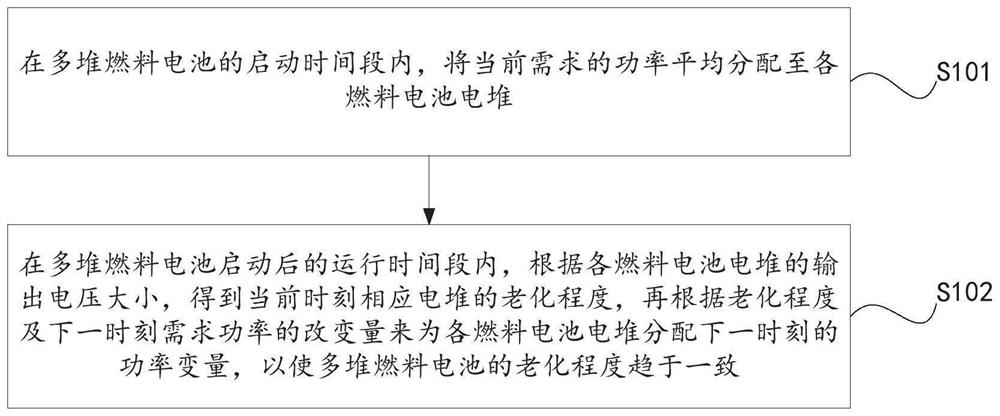

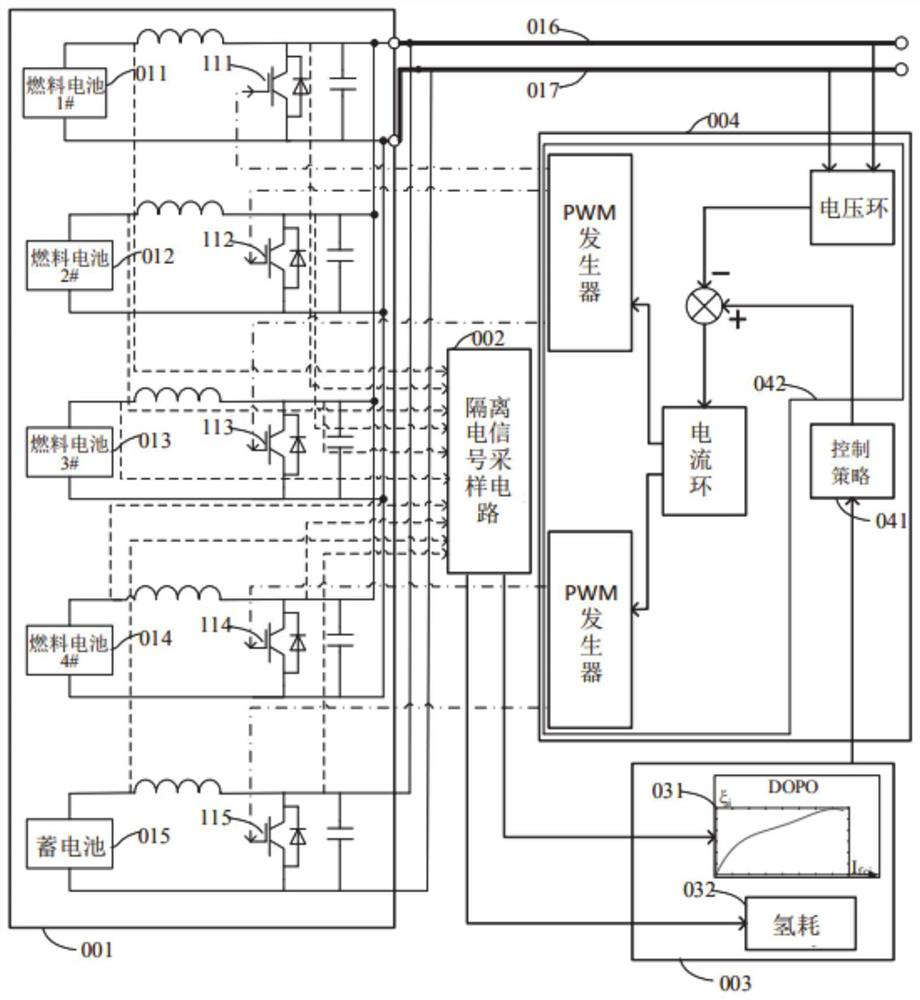

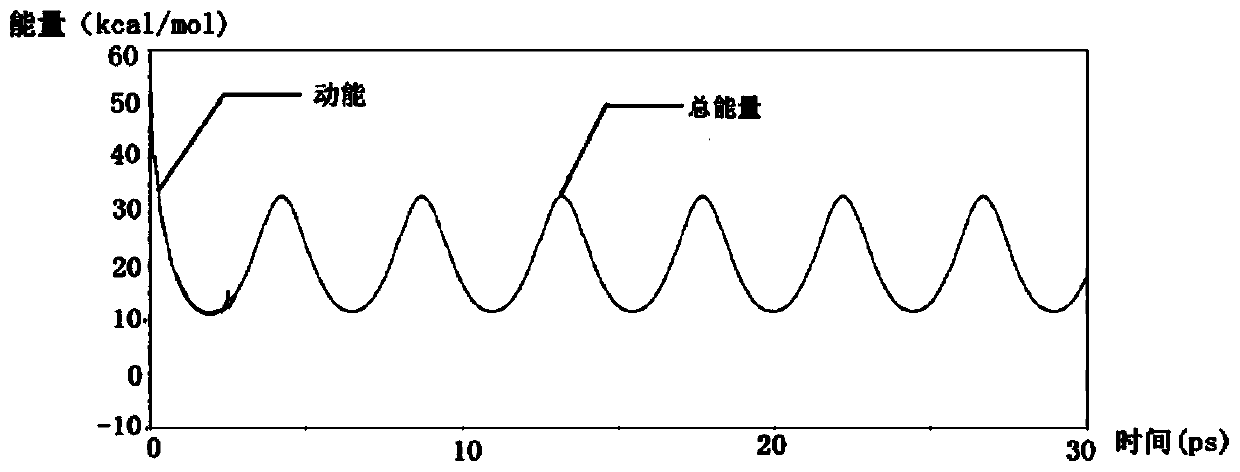

Multi-stack fuel cell control method, control device, system and vehicle

ActiveCN113173108AFix security issuesFix stability issuesBattery/fuel cell control arrangementTransportation hydrogen technologyFuel cellsControl theory

The invention belongs to the field of battery control, and provides a multi-stack fuel cell control method, a control device, a system and a vehicle. The control method comprises the following steps that in a starting time period of a multi-stack fuel cell, the currently required power is averagely distributed to each fuel cell stack; in an operation time period after the multi-stack fuel cell is started, the aging degree of the corresponding stack at the current moment is obtained according to the magnitude of the output voltage of each fuel cell stack, and then the power variable at the next moment is allocated to each fuel cell stack according to the aging degree and the variation of the required power at the next moment, so that, the aging degrees of the multiple stacks of fuel cells tend to be consistent.

Owner:CRRC QINGDAO SIFANG CO LTD

Method for designing low-entropy and safe high-speed milling cutter and high-speed milling cutter

ActiveCN103624308AAchieving Design Across ScalesSolve problems that cannot be described quantitativelyMilling cuttersSpecial data processing applicationsMilling cutterEngineering

The invention relates to a milling cutter designing method and a milling cutter, in particular relates to a method for designing a low-entropy and safe high-speed milling cutter and the high-speed milling cutter, and aims to solve the problems that the entropy cannot be controlled due to disordering of particle swarms of the milling cutter and the safety of the high-speed milling cutter is reduced. According to the characteristic that the disordering of the particle swarms of a high-speed milling cutter assembly is associated with the reducing of the safety, a safety reducing process is described by virtue of an entropy determination method; by virtue of an entropy model, a mesoscopic motion state is judged, and the safety reducing process is determined; by virtue of an entropy control method, a control variable for controlling the safety reducing process is revealed, and the disordering of the particle swarms can be effectively controlled; macroscopic and mesoscopic structure parameters are collaboratively designed by virtue of a low-entropy high-speed milling cutter safety designing method; the safety and stability of the low-entropy milling cutter are verified. The diameter of the milling cutter is 63mm, the number of tool teeth is 4, the tool teeth are unequally distributed, included angles between the teeth are 88 degrees, 89 degrees, 90 degrees and 93 degrees, the tooth root of a tool body is of a chamfer and transition circular arc structure, and a front blade installation angle is 2 degrees. The method is applied to milling cuter designing and high-speed milling.

Owner:HARBIN UNIV OF SCI & TECH

High-heat-conductivity long-life blast furnace hearth and brick lining building method

ActiveCN109055639AAlleviate brick lining crackingAchieving Overall LongevityBlast furnace detailsInternal formsHearthErosion

The invention discloses a high-heat-conductivity long-life blast furnace hearth and further provides a brick lining building method of the high-heat-conductivity long-life blast furnace hearth. The high-heat-conductivity long-life blast furnace hearth comprises a furnace shell, a cooling wall and brick linings which are arranged sequentially from outside to inside. On the lower portion of the hearth, the lower-middle portion of the hearth, the middle of the hearth, the upper-middle portion of the hearth and the upper portion of the hearth, the brick linings comprise small-block carbon bricks,carbon ramming material layers and large-block carbon bricks which are arranged sequentially; and at the top of the hearth, the brick linings are formed by building a plurality of small-block carbon bricks. According to the high-heat-conductivity long-life blast furnace hearth, cracking of the hearth brick linings due to thermal stress and erosion damage caused by harmful elements through cracks can be avoided, circulation erosion of molten iron can be further resisted effectively, thus the erosion damage to the hearth is relieved, and the service life of a blast furnace is prolonged.

Owner:武汉钢铁有限公司

Ceramic rotor spinning false twisting disc and ceramic processing method for inner surface of false twisting disc

InactiveCN104005125ANo impuritiesDense surfaceAnodisationContinuous wound-up machinesOxide ceramicChemical composition

The invention discloses a ceramic rotor spinning false twisting disc and a ceramic processing method for the inner surface of the false twisting disc and belongs to the field of spinning machinery equipment. The ceramic rotor spinning false twisting disc and the ceramic processing method for the inner surface of the false twisting disc are aimed to solve the problems of non-uniform surface coating distribution, poor quality and short service life of a traditional chrome plated false twisting disc and problems of high production cost and complex technique of a powder sintering ceramic false twisting disc. The inner surface of the ceramic rotor spinning false twisting disc is plated with a layer of ceramic film. The ceramic processing method for the inner surface of the false twisting disc includes that preparing an oxide ceramic layer at the surface of the false twisting disc, wherein the chemical ingredient of the generated ceramic layer is oxide which is same with the chemical ingredient of the false twisting disc produced through a ceramic powder pressing sintering technique; remelting and refining the ceramic layer, wherein the refined surface is uniform and wearable, and the service time of the false twisting disc on equipment is prolonged. The ceramic rotor spinning false twisting disc is suitable for spinning various materials.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com