Damping and noise-reducing wheel for rail transportation

A rail transit and noise reduction technology, applied in the field of rail transit, can solve problems such as large stress concentration and affect the safety of rubber materials, and achieve the effects of reducing stress concentration, facilitating heat dissipation, and reducing performance dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

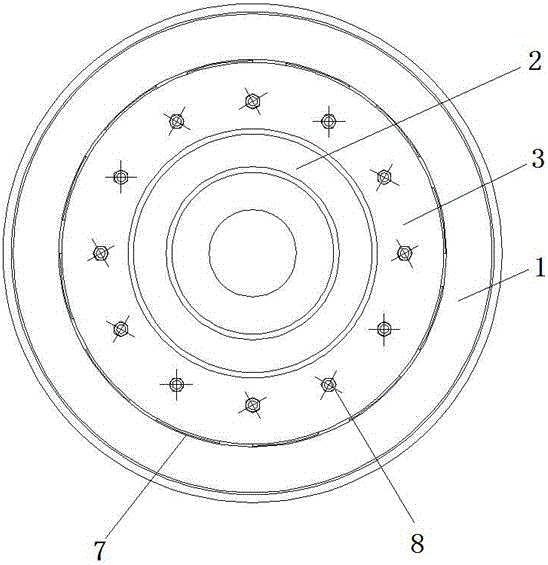

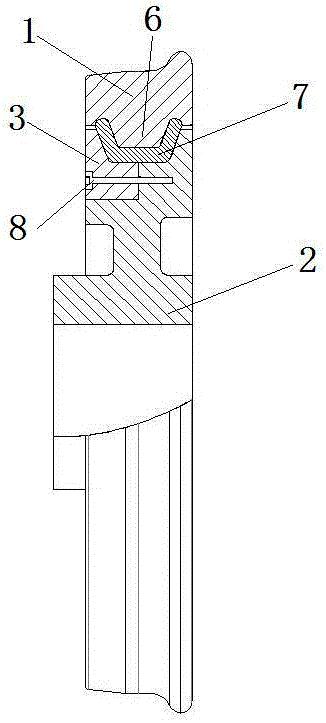

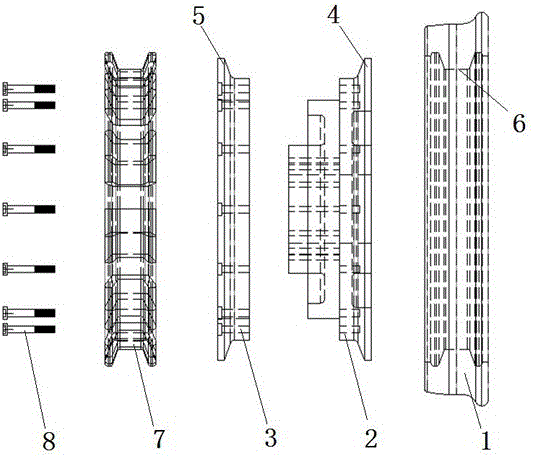

[0021] The present invention will be further explained below in conjunction with the drawings, such as figure 1 , figure 2 with image 3 The shown rail transit vibration and noise reduction wheel includes a wheel hub 1, a wheel center 2 and a pressure ring 3;

[0022] The outer edge of the wheel center 2 is provided with a wheel center shoulder 4, the outer edge of the pressure ring 3 is provided with a crushing shoulder 5, and the pressure ring 3 is pressed on one side of the wheel center 2 and fixed by threads. 4 and the crushing shoulder 5 constitute a circular U-shaped space;

[0023] A hub 1 is sheathed on the wheel center 2 and the pressure ring 3, and an annular convex body 6 is arranged at the center of the inner circular end surface of the hub 1, and an annular closed U-shaped groove is formed between the convex body 6 and the U-shaped space;

[0024] A plurality of U-shaped rubber bodies 7 are uniformly distributed in the U-shaped groove at equal intervals. The U-shaped ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com