Nanometer silicon dioxide aerogel glass fiber light felt and preparing method thereof

A technology of nano-silica and silica, which is applied in the field of glass fiber lightweight felt and its preparation, can solve the problems of high equipment requirements, high airgel content, and insufficient flexibility, and achieve excellent sound-absorbing performance and prolong service time , the effect of flexibility reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

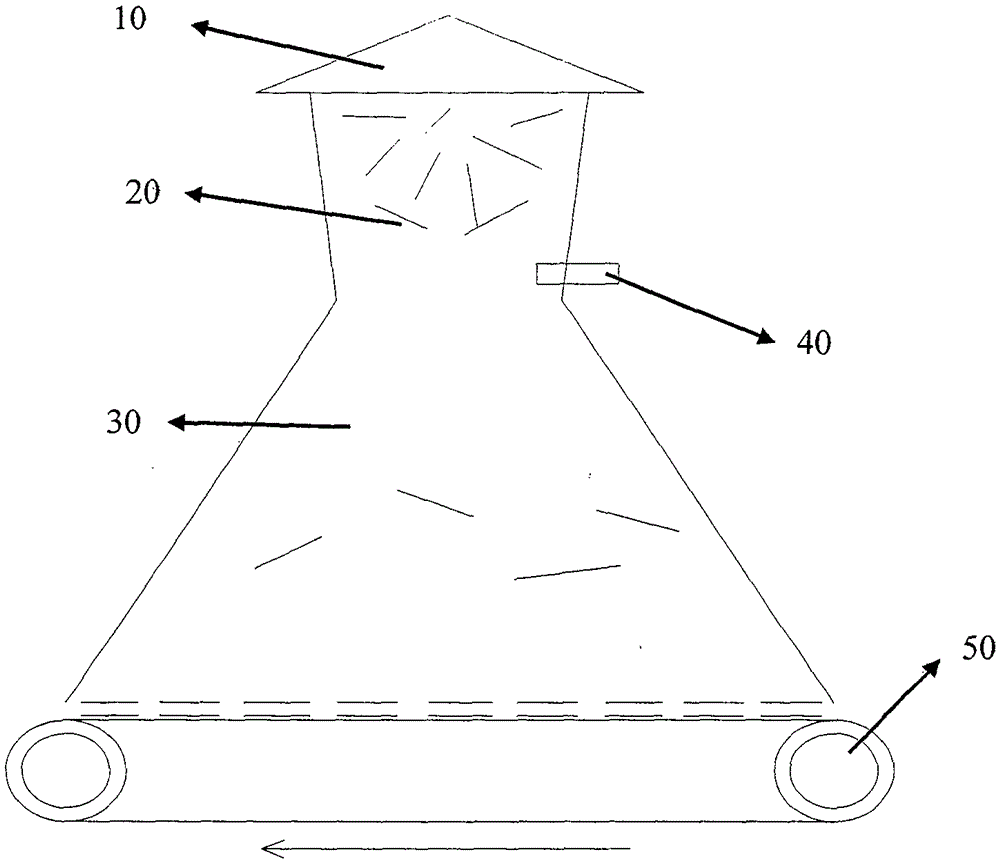

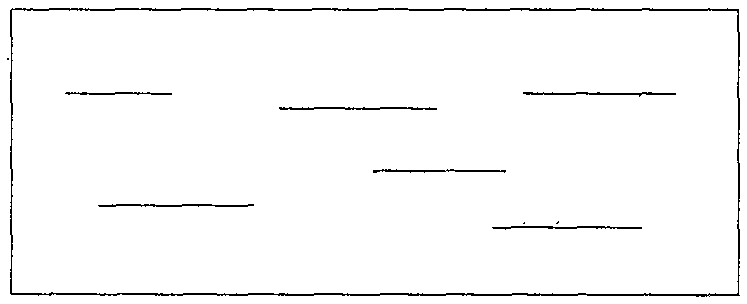

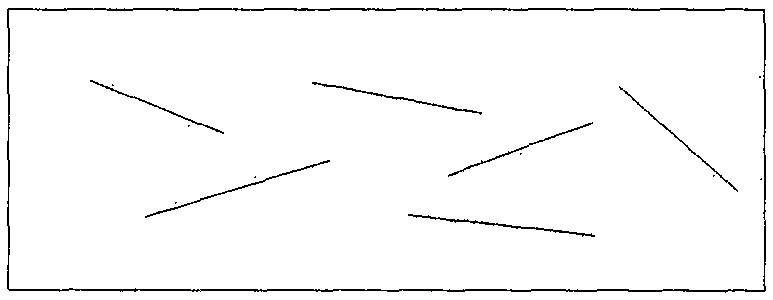

[0024] refer to figure 1 , is a device diagram for preparing nano-silica airgel glass fiber lightweight felt, 10 is the inlet section of the Venturi tube, 20 is the contraction section, 30 is the diffusion section, 40 is the air inlet, and 50 is the conveyor belt, figure 2 It is a cross-sectional view of silica airgel lightweight sound-insulating and heat-insulating glass fiber felt, image 3 It is the surface diagram of silica airgel lightweight sound-insulating and heat-insulating glass fiber felt, and its preparation includes the following steps:

[0025] (1) Spray the glass fiber filaments from the top of the Venturi tube, the flow rate is 100 kg per hour, the glass fiber filaments fall in the Venturi tube, the length of the Venturi tube is 3 meters, and the ratio of the upper and lower apertures is 1:3;

[0026] (2) an air inlet is set at the constriction section of the Venturi tube, sprays into the silica airgel particle from the air inlet, flow rate is 0.1 kilogram pe...

Embodiment 2

[0033] refer to figure 1 , is a device diagram for preparing nano-silica airgel glass fiber lightweight felt, 10 is the inlet section of the Venturi tube, 20 is the contraction section, 30 is the diffusion section, 40 is the air inlet, and 50 is the conveyor belt, figure 2 It is a cross-sectional view of silica airgel lightweight sound-insulating and heat-insulating glass fiber felt, image 3 It is the surface diagram of silica airgel lightweight sound-insulating and heat-insulating glass fiber felt, and its preparation includes the following steps:

[0034] (1) Spray glass fiber filaments from the top of the Venturi tube, the flow rate is 300 kg per hour, the glass fiber filaments fall in the Venturi tube, the length of the Venturi tube is 5 meters, and the ratio of the upper and lower apertures is 1:5;

[0035](2) An air inlet is set at the constriction section of the Venturi tube, sprays into the silica airgel particle from the air inlet, the flow rate is 0.5 kilogram per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com