Ultrahigh-temperature corrosion-resistant composite material and preparation method thereof

A composite material and corrosion-resistant technology, which is applied in the field of composite materials, can solve the problems of easy oxidation and corrosion thermal conductivity, etc., and achieve the effects of enhanced oxidation resistance, low thermal conductivity, and reduced surface temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] An ultra-high temperature corrosion-resistant composite material, including a C / C composite material substrate, on which an adhesive layer and a ceramic layer are deposited sequentially, the composition of the adhesive layer in Example 1 is NiCrAlY, and the ceramic layer The composition is YTaO 4 .

[0026] Rare earth tantalate (RETaO 4 ) or niobate (RENbO 4 ) preparation method, comprising the following steps:

[0027] Step 1: Put the RE 2 o 3 、 Ta 2 o 5 or Nb 2 o 5 According to the molar ratio of 1:1, it is added into a ball mill for ball milling. The rotating speed of the ball mill is 300r / min. After the ball milling, it is dried and sieved to obtain powder A.

[0028] Step 2: The powder A after drying and sieving in step 1 is prepared by high-temperature solid-state reaction method to obtain component RETaO 4 / RENbO 4 powder B, the reaction temperature is 1700° C., and the reaction time is 10 h; and the powder B is sieved with a 300-mesh sieve.

[0029] ...

Embodiment 2~17

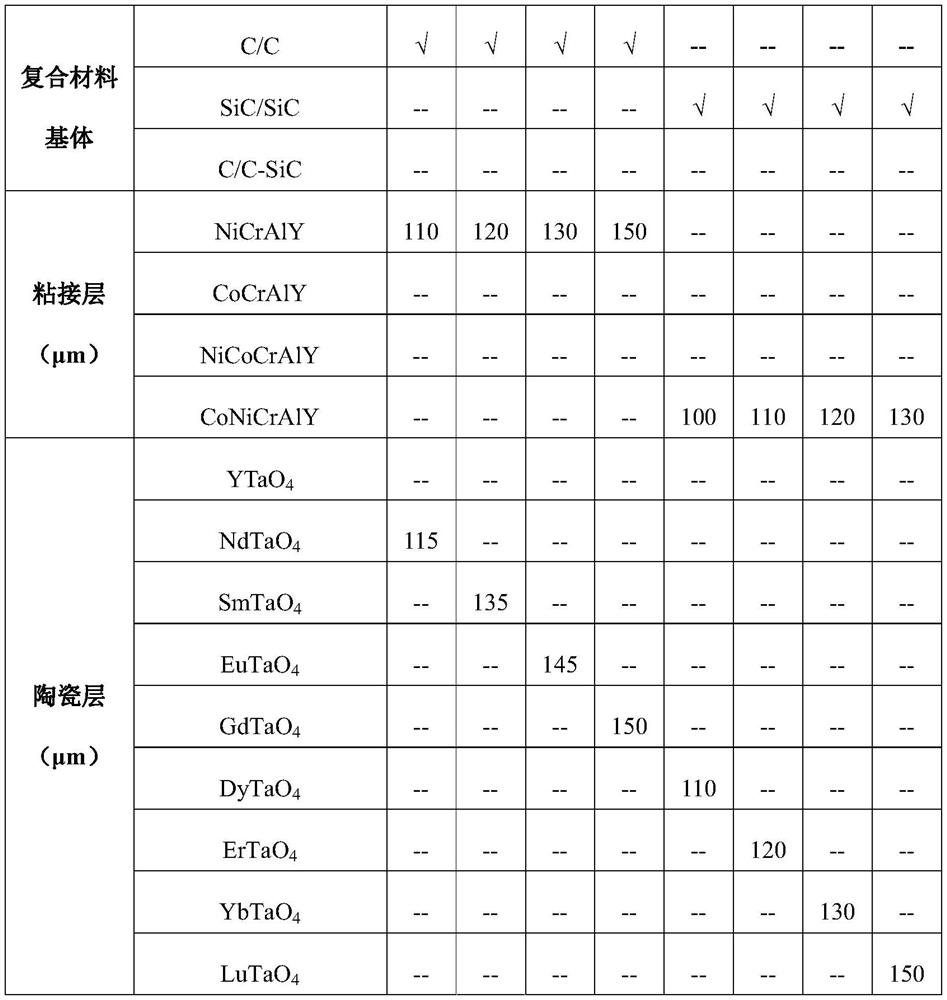

[0035] The difference from Example 1 is that the composition or thickness of the composite material substrate and each coating layer is different, as shown in Tables 1-2 below for details.

[0036] Table 1 is the composition and thickness table of each coating of embodiment 2~9 ("--" means not containing in the table)

[0037]

[0038]

[0039] Table 2 is the composition and thickness table of each coating of embodiment 10~17 ("--" means not containing in the table)

[0040]

[0041]

Embodiment 18

[0043] The difference from Example 1 is that the composition of the ceramic layer includes YTaO 4 and SmTaO 4 , and the proportioning of the two powders is that the respective volume fractions are 50% respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com