Preparation method of in-situ synthesized aluminum oxide-aluminum nitride synergetic graphene enhanced aluminum-based composite material

A technology for strengthening aluminum-based and composite materials, applied in the direction of graphene, chemical instruments and methods, carbon compounds, etc., can solve the problem of large brittleness and equality, and achieve the effects of improving plasticity, avoiding agglomeration, and promoting uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

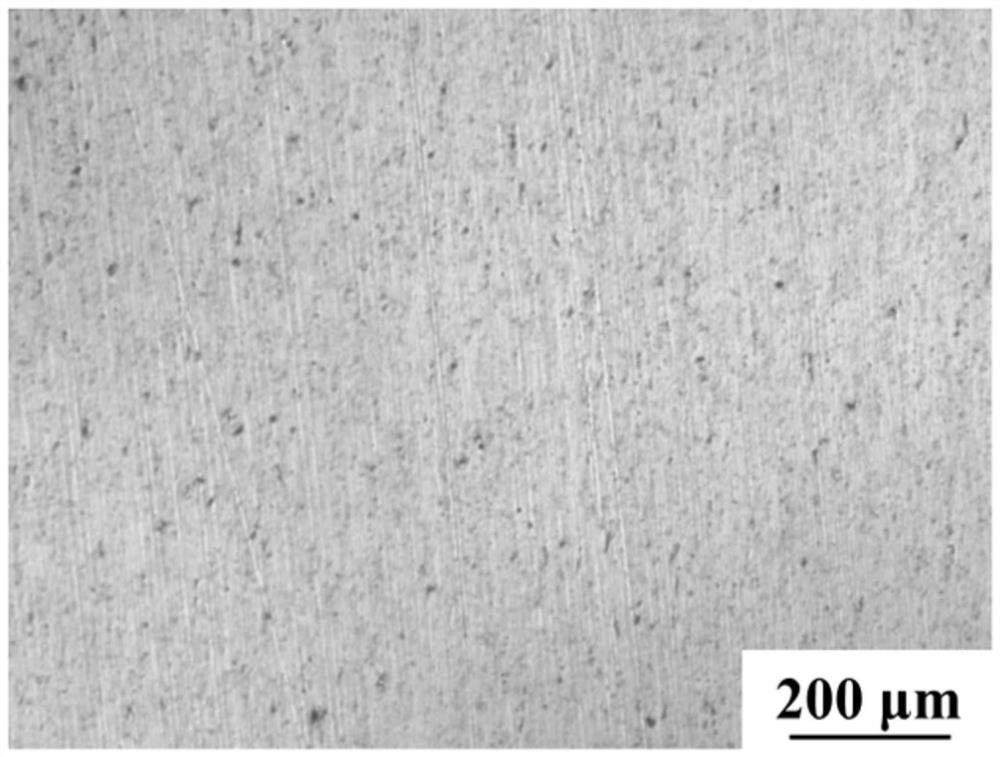

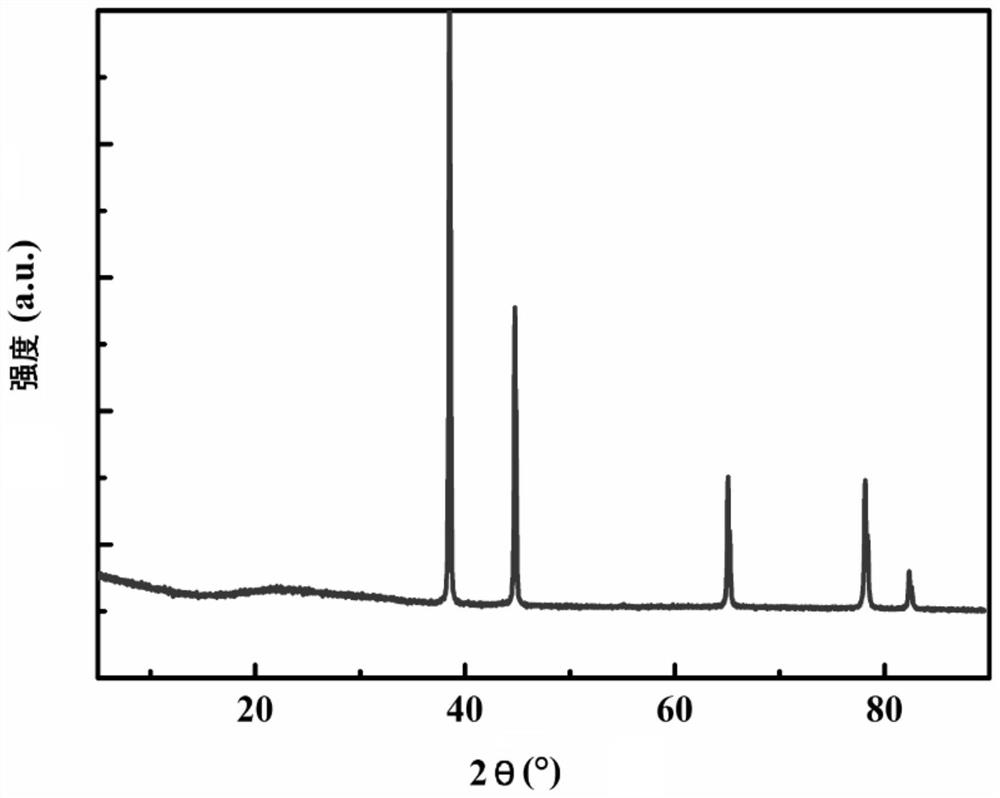

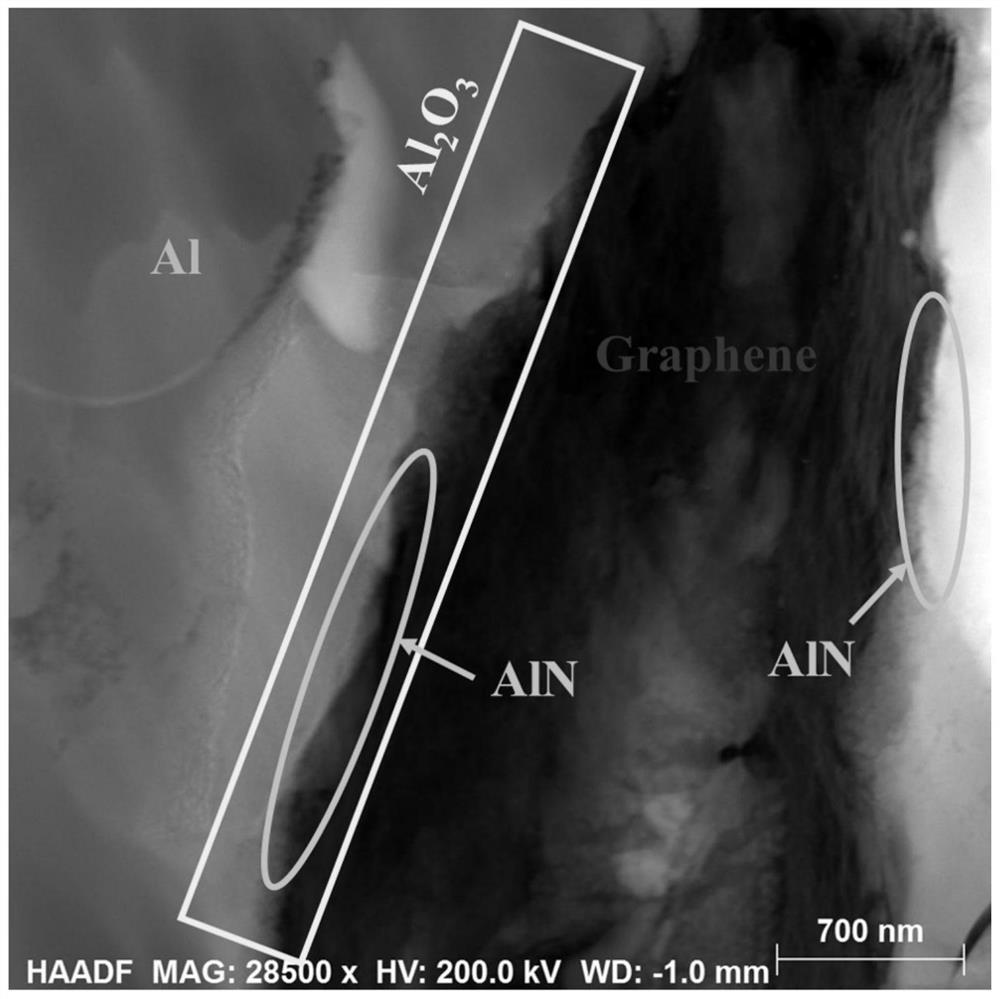

[0029] Specific embodiment one: In this embodiment, the preparation method of in-situ self-generated alumina-aluminum nitride synergistic graphene-reinforced aluminum matrix composite material is carried out according to the following steps:

[0030] 1. Weighing

[0031] Weighing 0.3% to 4% of graphene and the rest of the aluminum metal powder as raw materials by mass fraction; weighing the aluminum alloy block, the weight ratio of the aluminum alloy block to the aluminum metal powder is (3 to 10): 1;

[0032] 2. Graphene dispersion and prefabricated block forming

[0033] Mix the graphene and aluminum metal powder weighed in step 1 and perform ball milling, disperse the mixed powder obtained after ball milling into an aqueous ethanol solution, add a dispersant and stir, then filter and dry in sequence to obtain a graphene-aluminum mixed powder , and then the graphene-aluminum mixed powder is packed into a cold-pressing mold for cold pressing to obtain a graphene / aluminum pre...

specific Embodiment approach 2

[0046] Embodiment 2: This embodiment differs from Embodiment 1 in that the graphene described in step 1 is few-layer graphene, with an average sheet diameter of 200 nm-20 μm and an average thickness of 0.3-30 nm.

specific Embodiment approach 3

[0047] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the dispersant described in step two is polyethylene glycol (polymerization degree is 100~1000), polyvinyl alcohol (polymerization degree is 100~1000) , sodium dodecylbenzenesulfonate, cetyltrimethylammonium bromide, ammonia water or polydimethylsiloxane (polymerization degree 100-500), etc.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com