Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Reduce thermal mismatch stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Barrier coating system for refractory metal core

InactiveUS20070116972A1Improve adhesionReduce thermal mismatch stressLiquid surface applicatorsFoundry mouldsCoating systemNitride

A refractory metal core system for use in casting a product is provided. The refractory metal core system comprises a refractory metal core and a layer of aluminum nitride deposited on the refractory metal core, which layer of aluminum nitride acts as a bond coat. The system may further comprise a layer of alumina deposited on top of the aluminum nitride layer.

Owner:UNITED TECH CORP

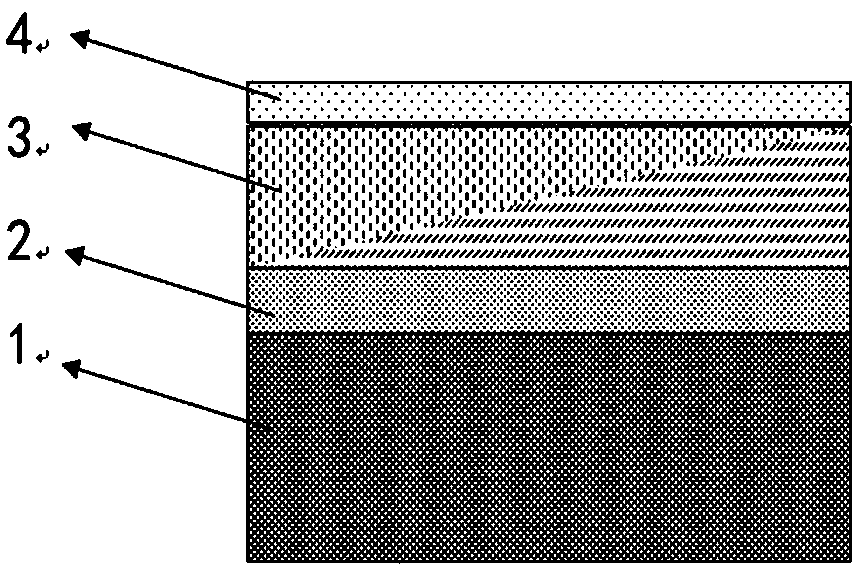

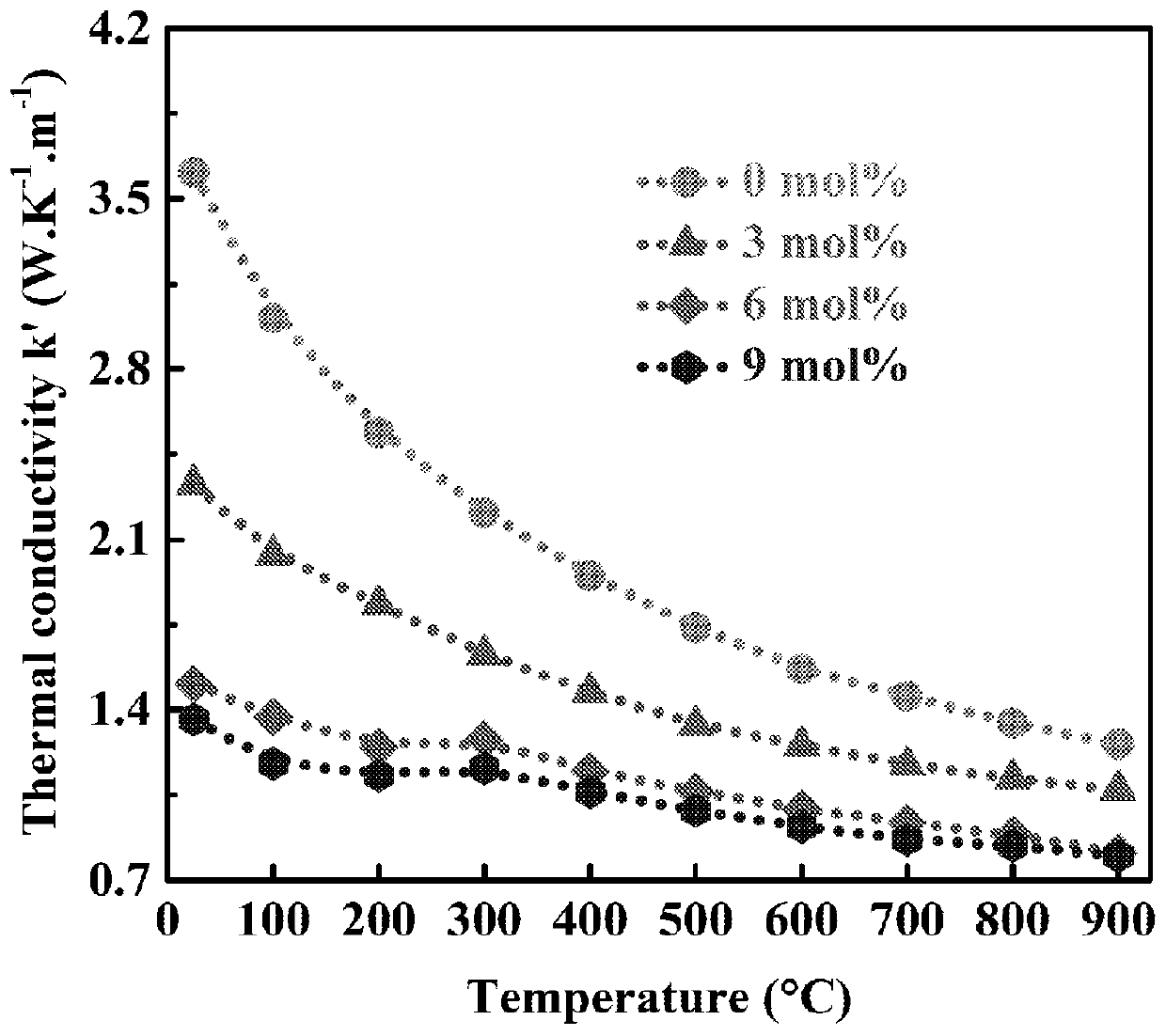

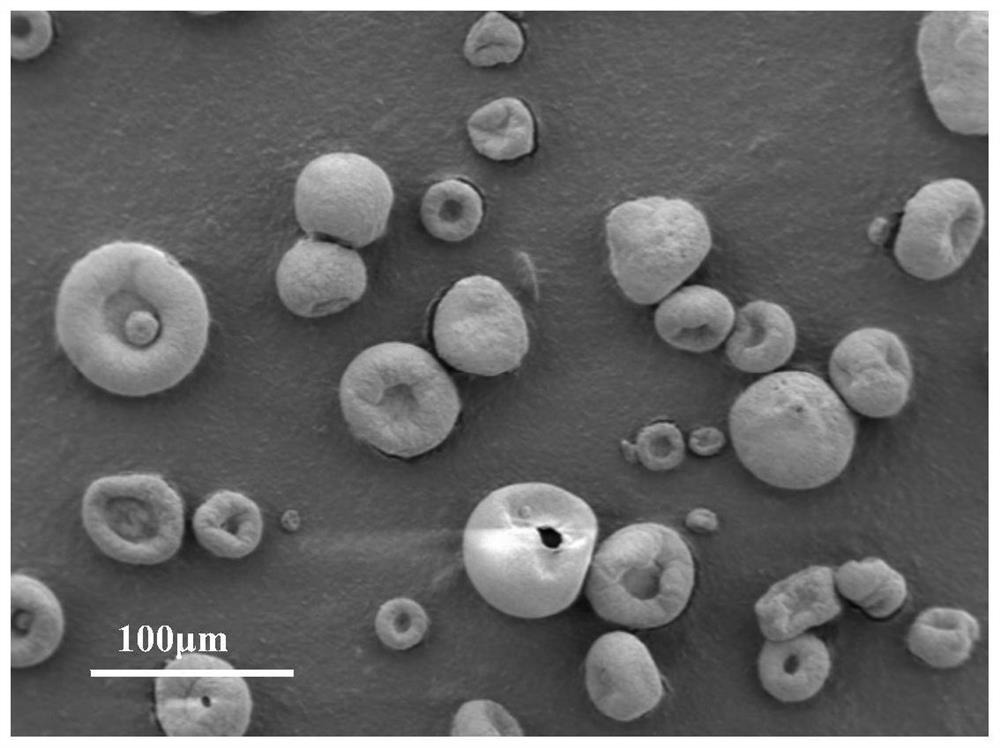

YSZ-rare earth zirconate thermal barrier coating of gradient structure and preparation method thereof

InactiveCN108441807AImprove thermal shock resistanceReduce thermal mismatch stressMolten spray coatingOxide ceramicRare earth

The invention provides an YSZ-rare earth zirconate thermal barrier coating of a gradient structure and a preparation method thereof. The coating material comprises an adhesive layer, an 8YSZ-rare earth zirconate gradient layer and a surface layer. The 8YSZ-rare earth zirconate material has relatively low conductivity, high-temperature sintering resistance and excellent resistance to heat shocks, and also can prevent oxygen from entering the adhesive layer on active service to alleviate oxidization of the adhesive layer to form TGO. The heat mismatching stress of the material can be reduced bymeans of an optimized design of the gradient structure, so that the heat stability of the whole material member is improved; the surface layer is a CMAS corrosion layer, so that the problem that an existing YSZ coating is corroded by CMAS can be alleviated. As Pd or a oxide ceramic layer is adopted, CMAS molten at a high temperature is not wet in the surface layer, and the rolling angle is small,and CMAS is hardly attached to the surface of the coating, so that CMAS corrosion is avoided.

Owner:FUZHOU UNIV

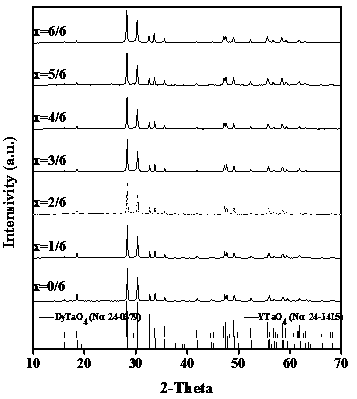

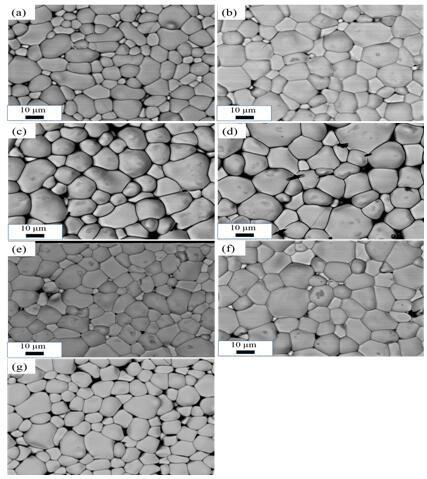

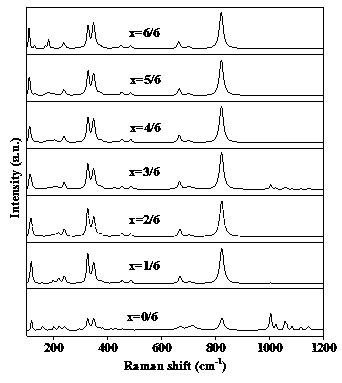

Compact ferroelastic dual rare earth tantalate solid solution high-temperature ceramic and preparation method thereof

The invention discloses compact ferroelastic dual rare earth tantalate solid solution high-temperature ceramic and a preparation method thereof, and belongs to the technical field of high temperatureresistant material of thermal barrier ceramic coating. The structural formula is (Y1-xDyx)TaO4 (x=0.1-0.9). Previously dried rare earth oxides (Y2O3, Dy2O3) and tantalum pentoxide (Ta2O5) are weighedaccording to the stoichiometric ratio required. Then, the materials are ball milled with ethanol as a solvent to obtain mixed powder A; the mixed powder A is sieved and compacted in a mold, and then ablank undergoes isostatic cool pressing to prepare a compact blank; and finally, the compact blank undergoes pressureless sintering to obtain the compact dual rare earth tantalate solid solution high-temperature ceramic. The dual rare earth tantalate solid solution high-temperature ceramic prepared by the method has characteristics of high process purity, low impurity content, high compactness, uniform grain size, low heat conductivity, large coefficient of thermal expansion, good toughness and the like.

Owner:KUNMING UNIV OF SCI & TECH

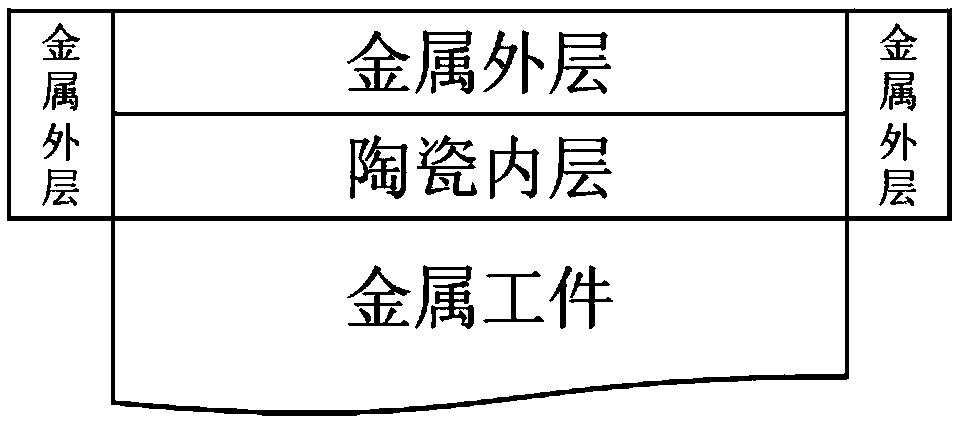

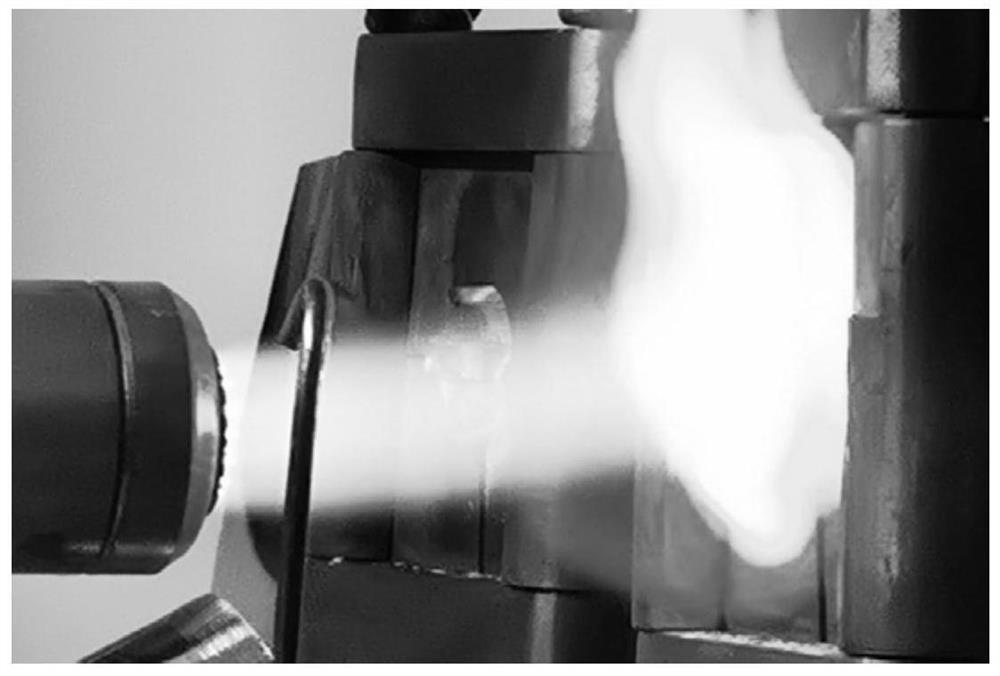

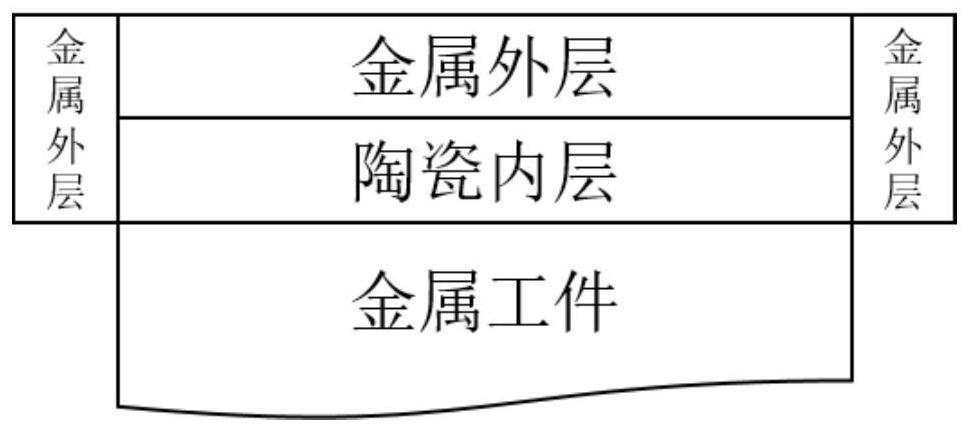

Metal workpiece double layer coating suitable for high temperature environment and manufacturing method thereof

The invention discloses a metal workpiece double layer coating suitable for high temperature environment and a manufacturing method thereof. The manufacturing method of the metal workpiece double layer coating suitable for the high temperature environment includes the following steps of 1) pretreatment: degreasing the surface of a metal workpiece, sandblasting roughening and cleaning; 2) spraying:preheating the pretreated metal workpiece, adopting an atmospheric plasma spraying device for spraying, first spraying a ceramic inner layer on the surface of the metal workpiece, then heating and spraying a metal outer layer and then spraying a metal layer on the side of an obtained coating; 3) heat treatment: conducting vacuum heat treatment on the sprayed metal workpiece and conducting gas quenching. According to the manufacturing method, the metal layer is sprayed on the ceramic layer. On one hand, the high cost of ceramic precision machining is reduced; on the other hand, various corrosion-resistant or wear-resistant alloy materials can be applied. In addition, the melting point of metal is lower than that of the ceramic, and the mechanical properties of the coating can be changed bythe heat treatment process.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV +1

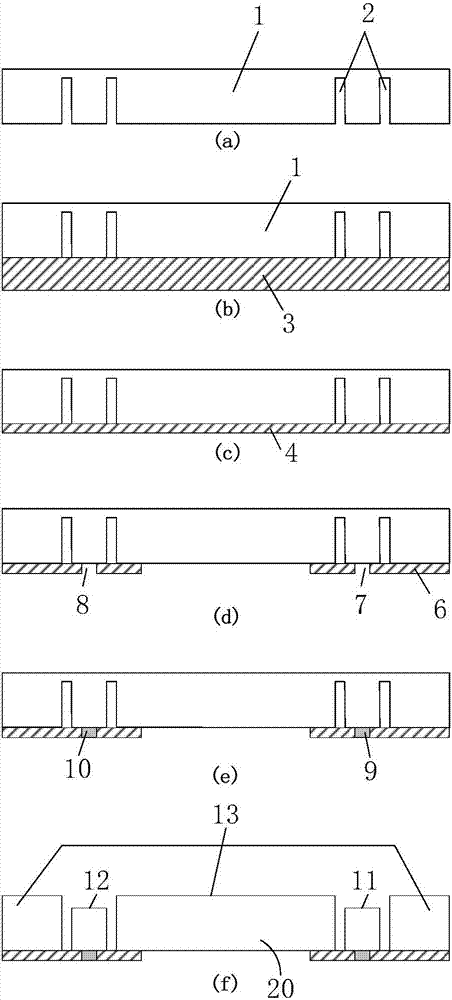

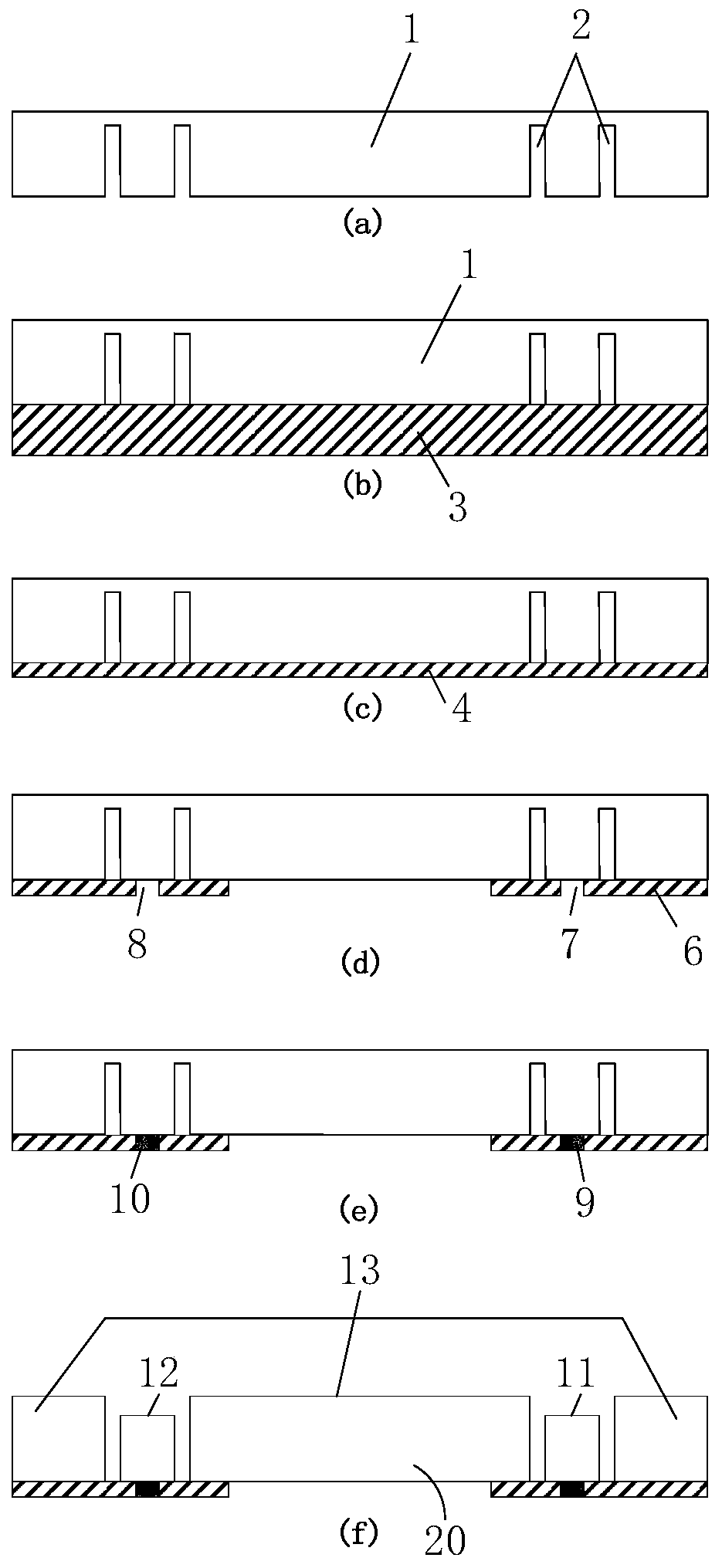

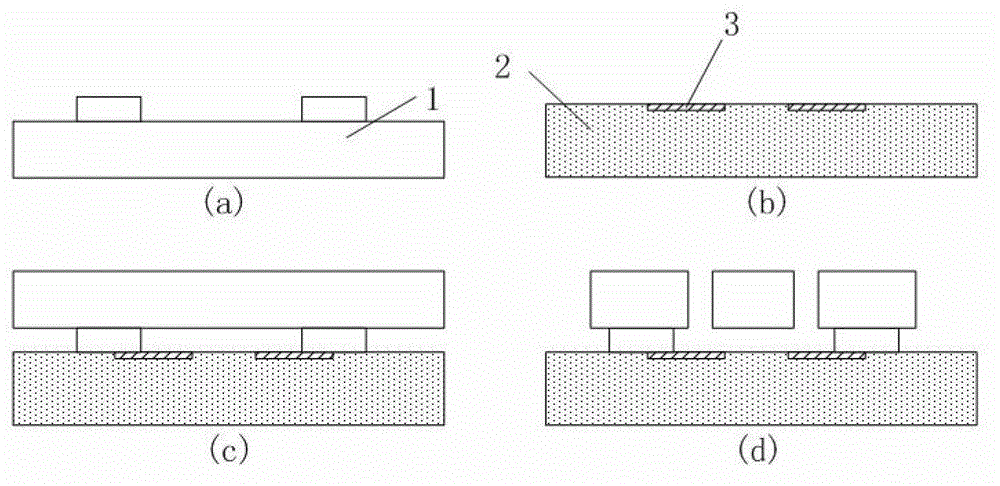

Full-silicon MEMS wafer-level vacuum packaging method based on anode bonding

ActiveCN107963609AReduce processing difficultyImprove yieldDecorative surface effectsChemical vapor deposition coatingSignal-to-noise ratio (imaging)Bonding process

The invention discloses a full-silicon MEMS wafer-level vacuum packaging method based on anode bonding; two-time anode bonding is adopted in the MEMS wafer-level vacuum packaging process to realize mechanical and electric signal connection among a cover plate, an MEMS device structure and a substrate and form a pressure controllable MEMS sealing cavity; compared with the existing full-silicon bonding process based on silicon-silicon solder bonding and silicon-silicon fusion bonding, the method in the invention is low in process difficulty and high in rate of finished products; the cover plateglass sheet is thinned to 10-50 microns and the substrate glass sheet is thinned to 10 -50 microns; the thickness of the dielectric layer of the existing full-silicon bonding process is not more than3 microns to the maximum; the thinner dielectric layer is, the larger the introduced parasitic capacitance is; hence, the parasitic capacitance introduced by the method in the invention is small, so that the signal-to-noise ratio output by the MEMS device is improved.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

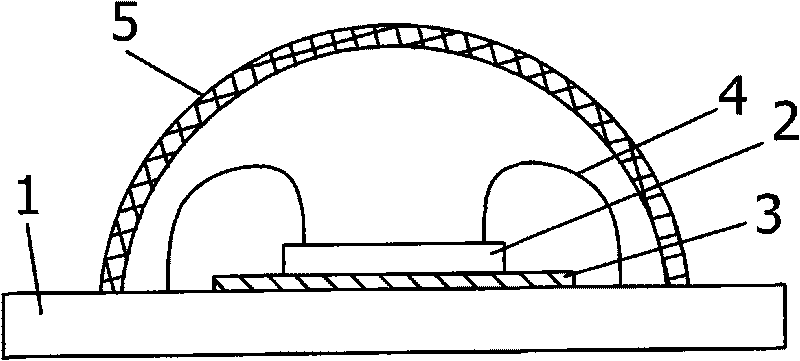

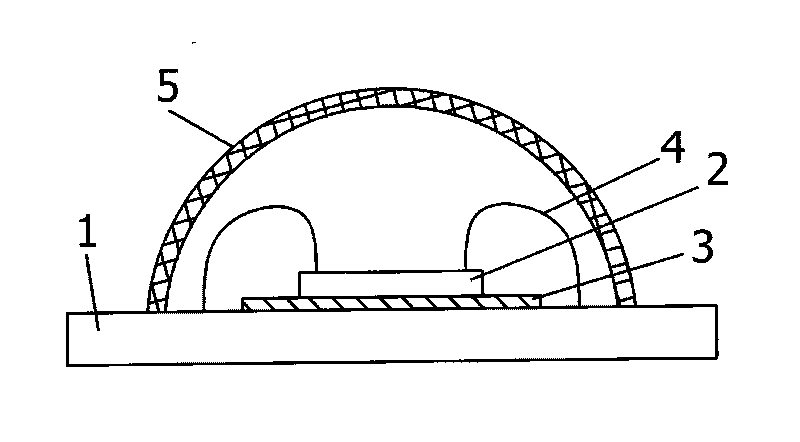

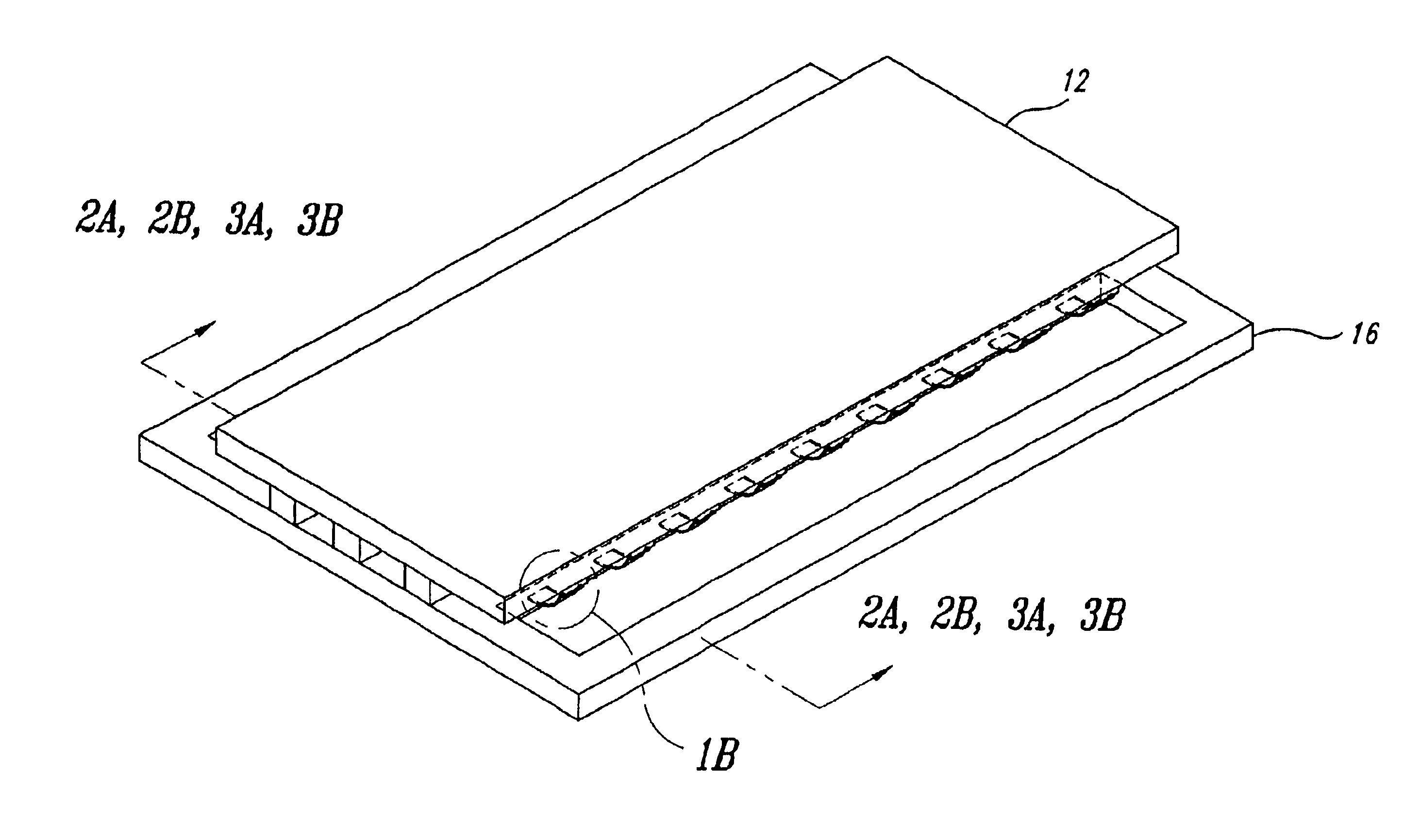

High-power LED lamp effectively lowering packaging thermal resistance

InactiveCN101696779AGuaranteed efficacyGuaranteed service lifePoint-like light sourceSemiconductor/solid-state device detailsHeat conductingMicrometer

The technical problem provides a high-power LED lamp effectively lowering packaging thermal resistance, which has a novel structure, and lowers thermal mismatching stress without greatly increasing the heat sink thickness. The technical scheme is that: the high-power LED lamp effectively lowering the packaging thermal resistance comprises a metallic base, an LED chip packaged on the metallic base, a metallic conductor and a packaging colloid, wherein a heat sink buffer layer, used for buffering the thermal mismatching stress between the LED chip and the metallic base, is arranged between the metallic base and the LED chip; the heat sink buffer layer is an FeNi alloy layer electroplated on the metallic base, and the FeNi alloy layer is between 2 and 5 micrometers in thickness; the LED chip and the heat sink buffer layer are connected in a mode of eutectic welding; the Ni content in the FeNi alloy layer is 36 percent; and the metallic base 1 is made of copper materials with better heat-conducting property. The high-power LED lamp effectively lowering the packaging thermal resistance has a novel structure, and effectively lowers the thermal mismatching stress so as to ensure the efficacy and service life of the high-power LED lamp.

Owner:DONGGUAN KINGSUN OPTOELECTRONIC CO LTD

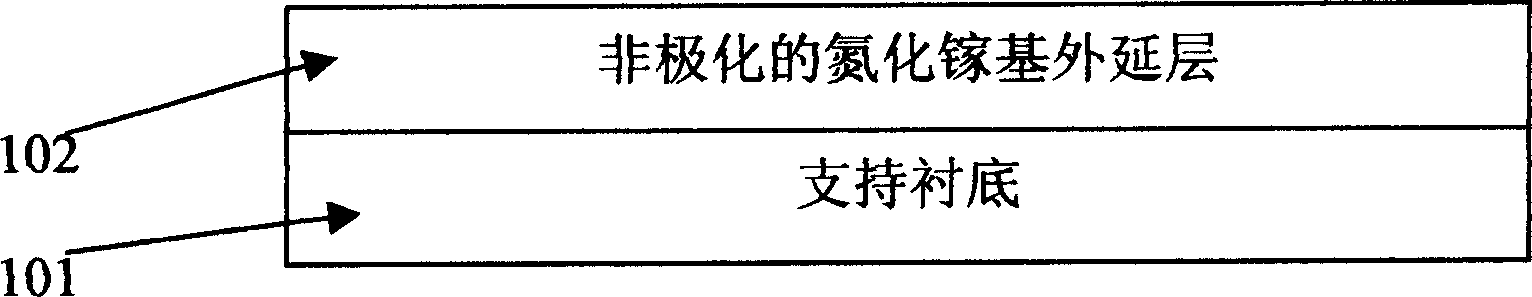

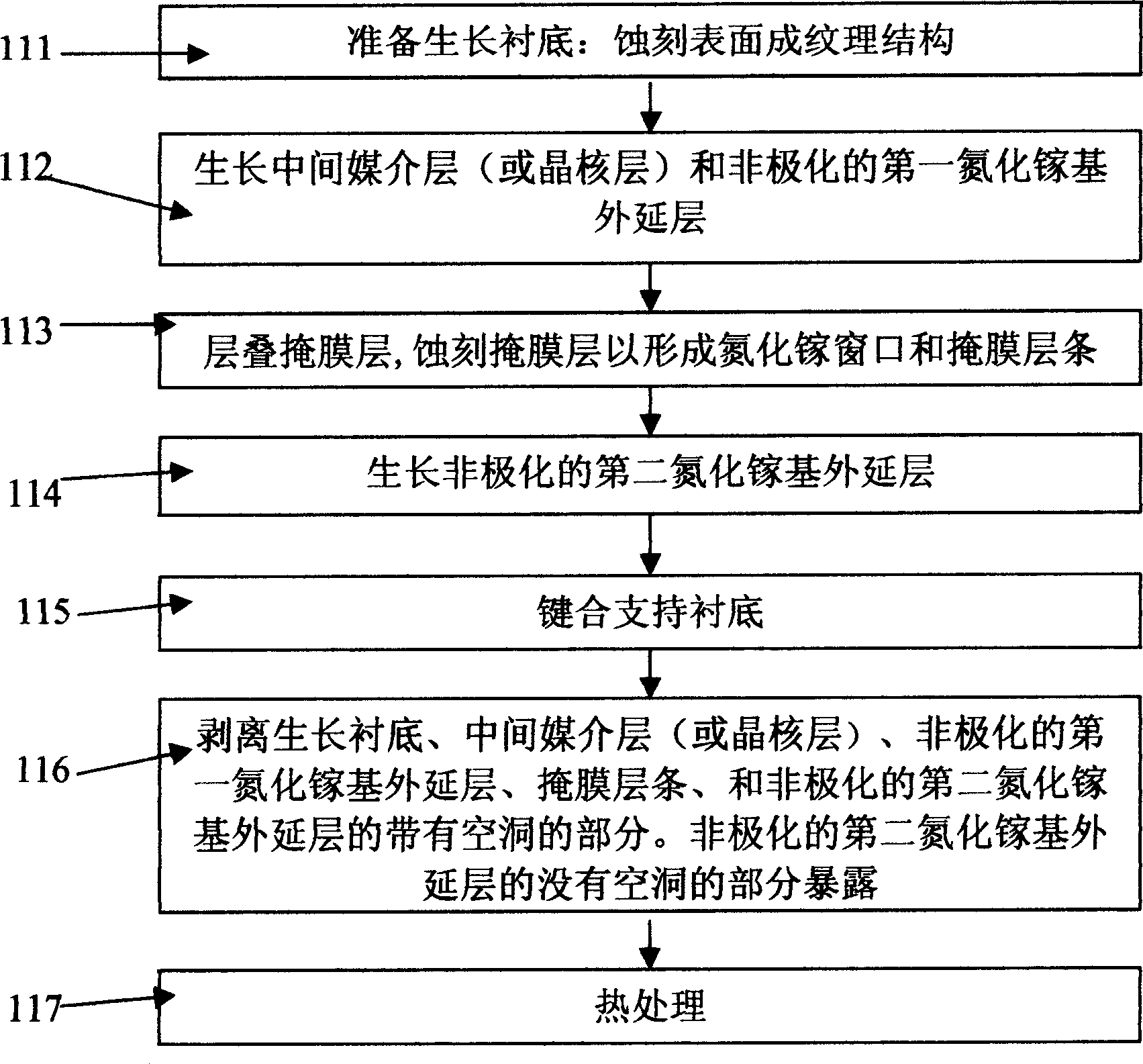

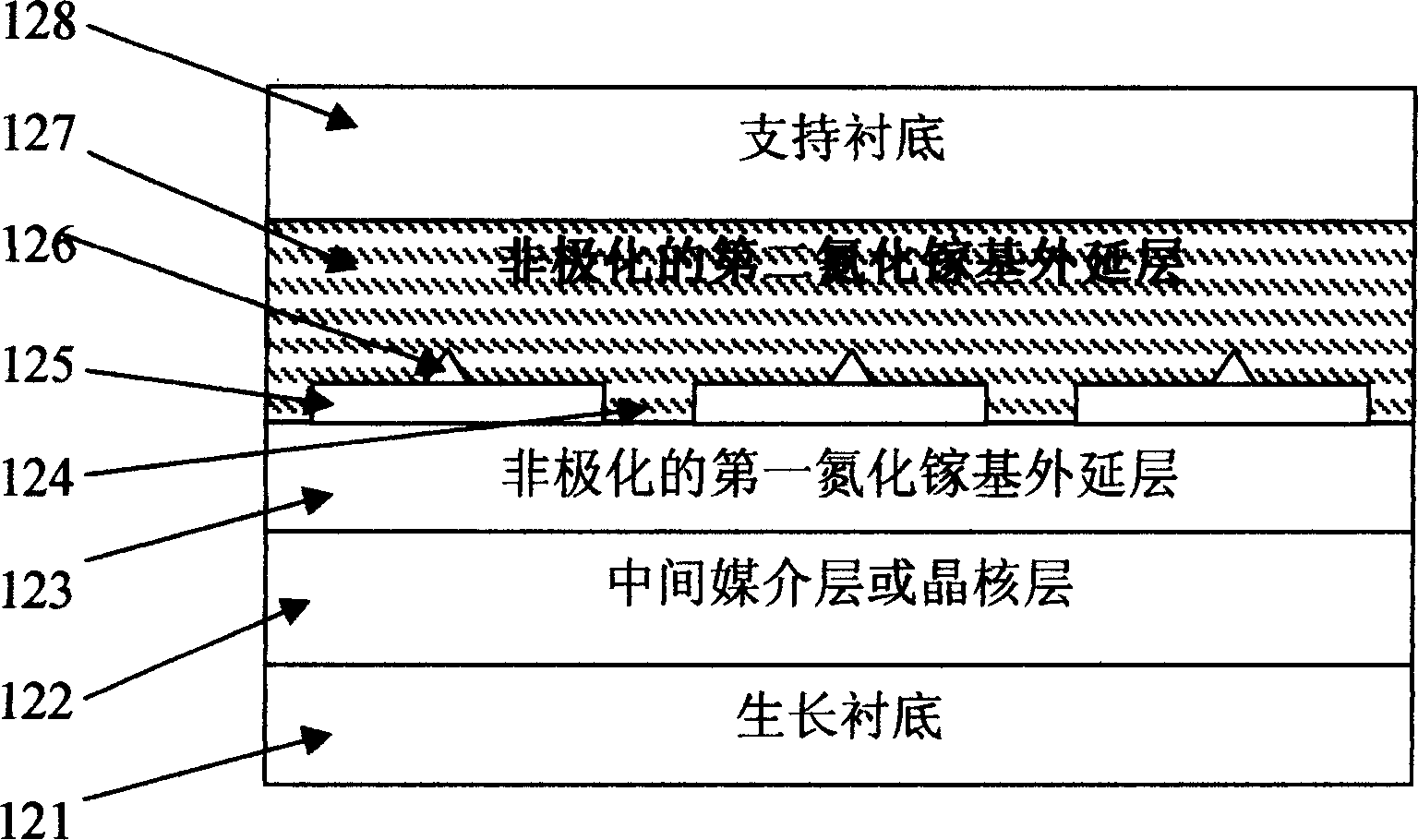

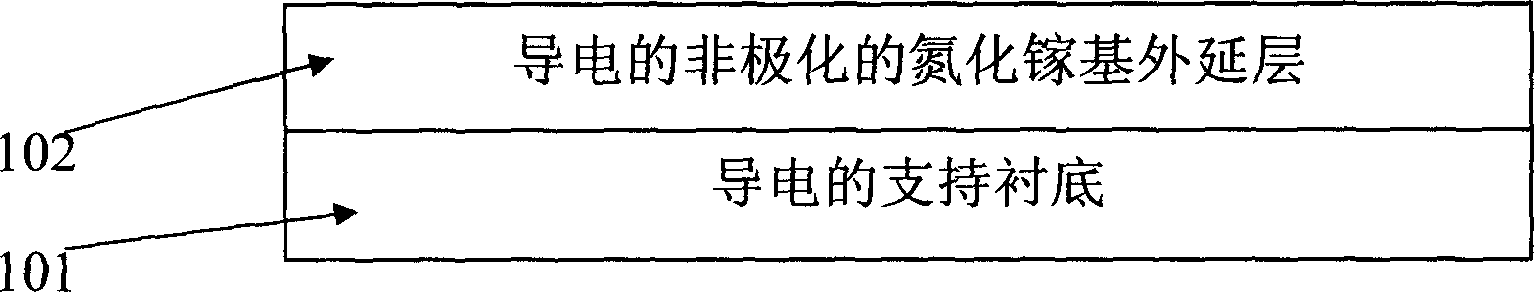

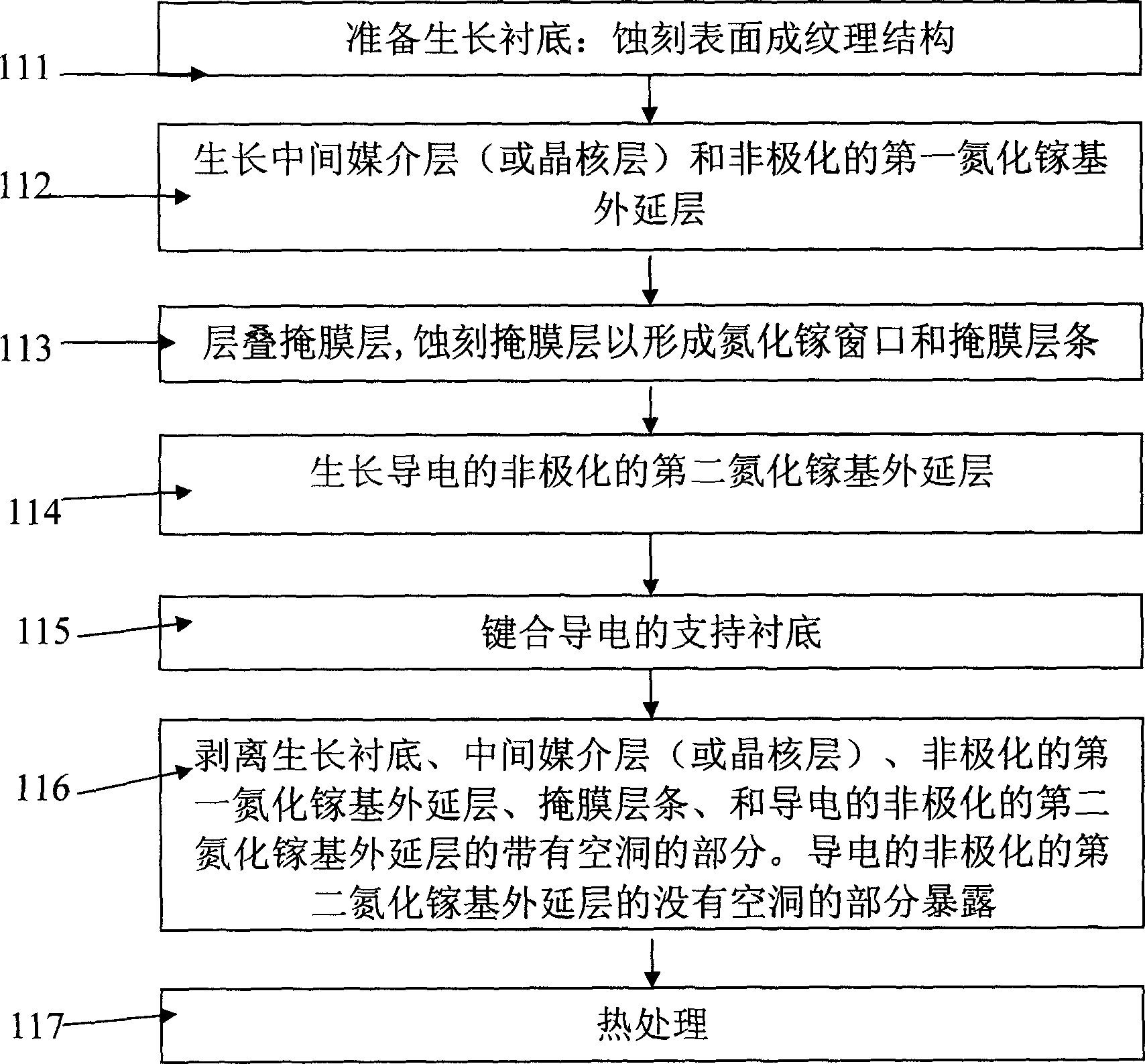

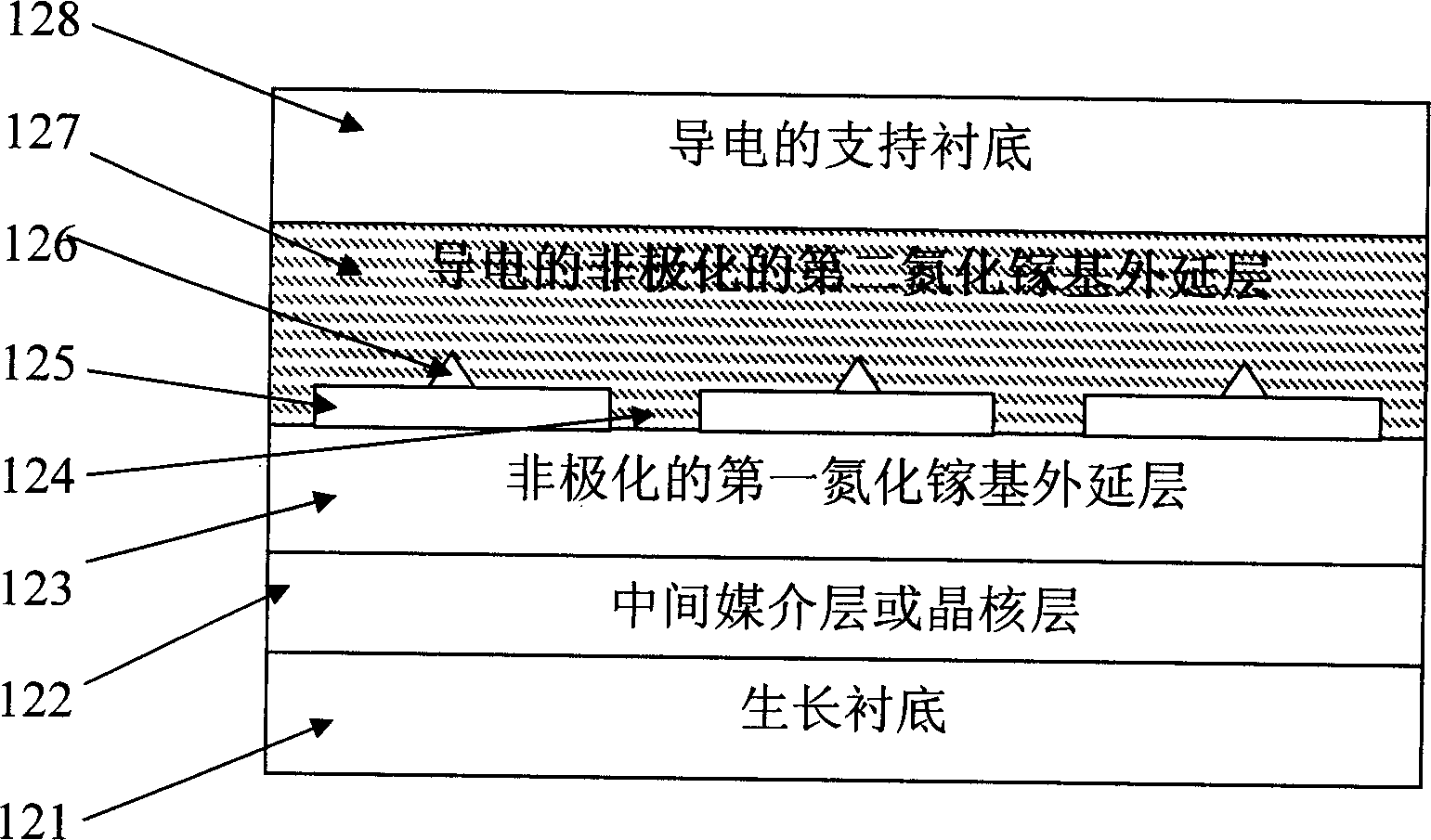

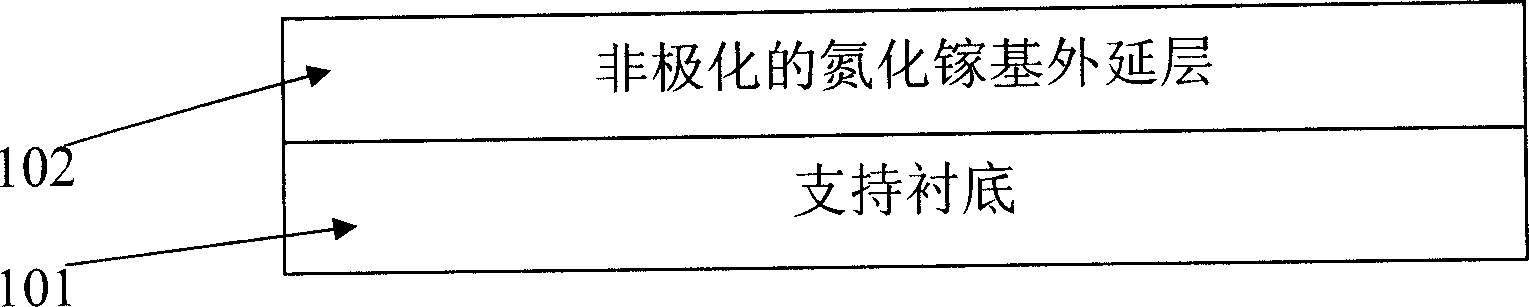

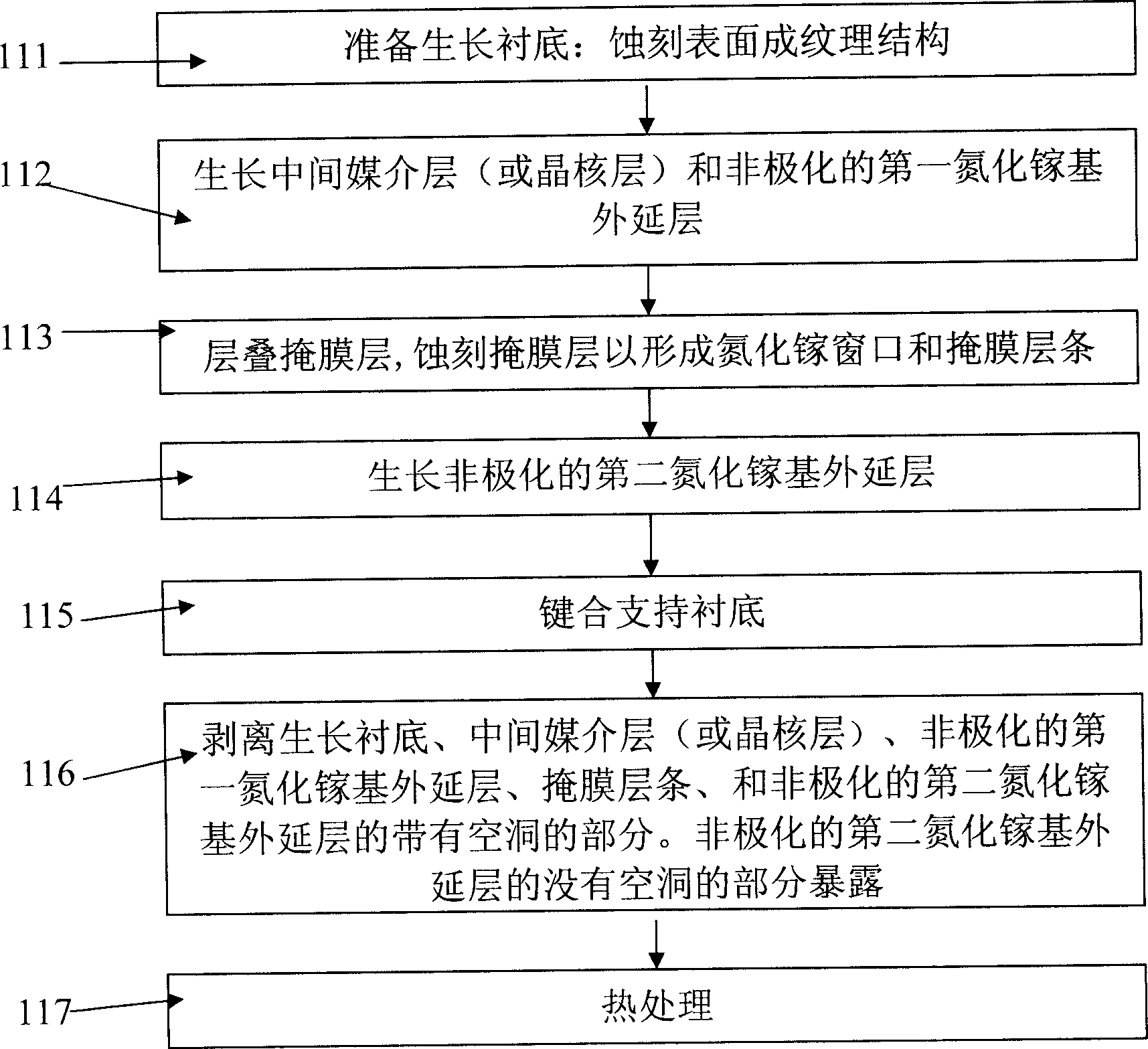

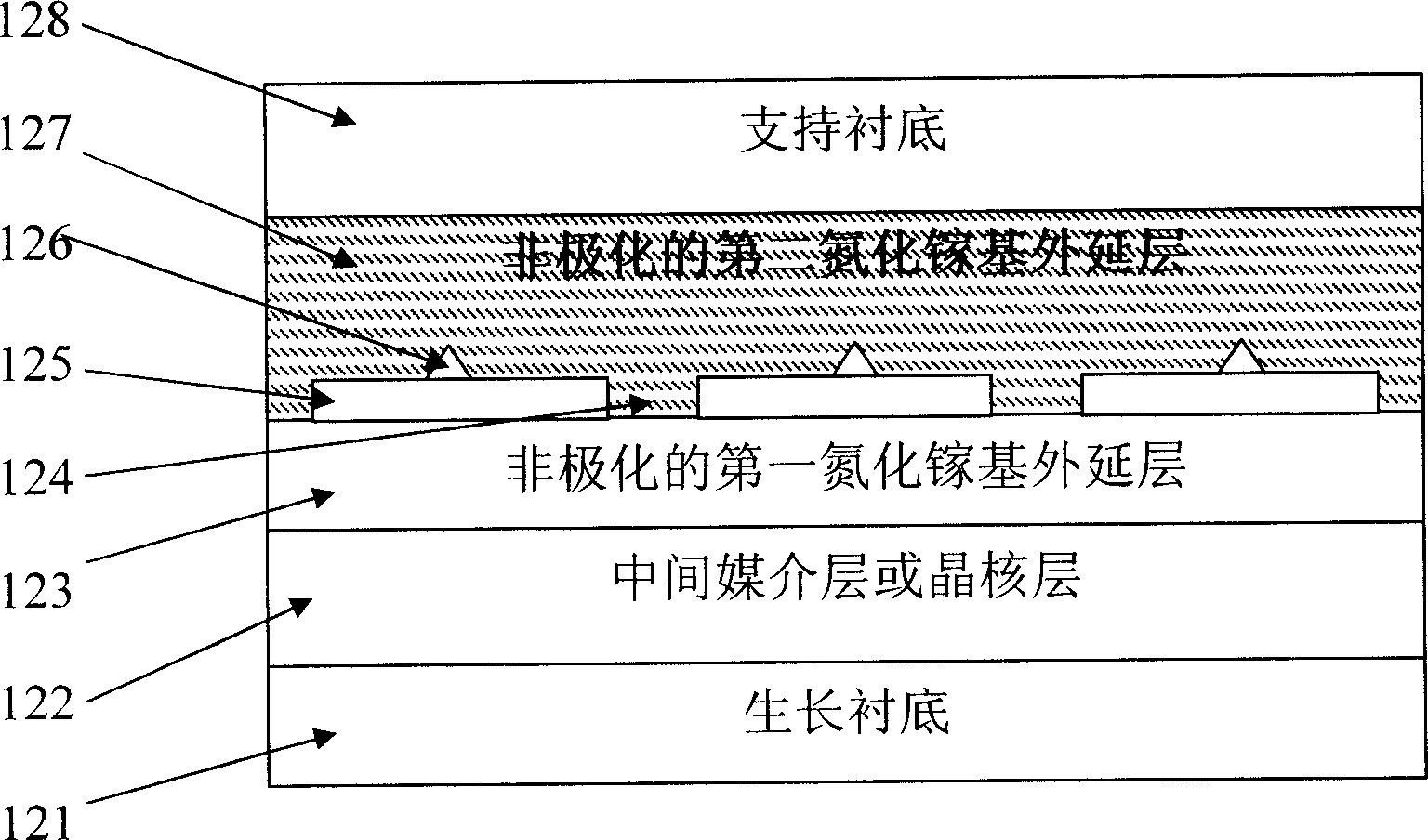

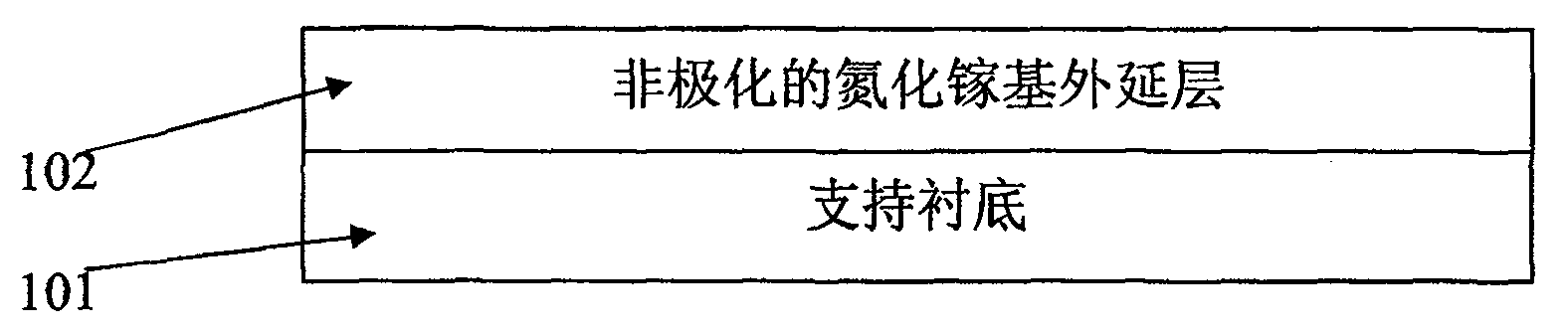

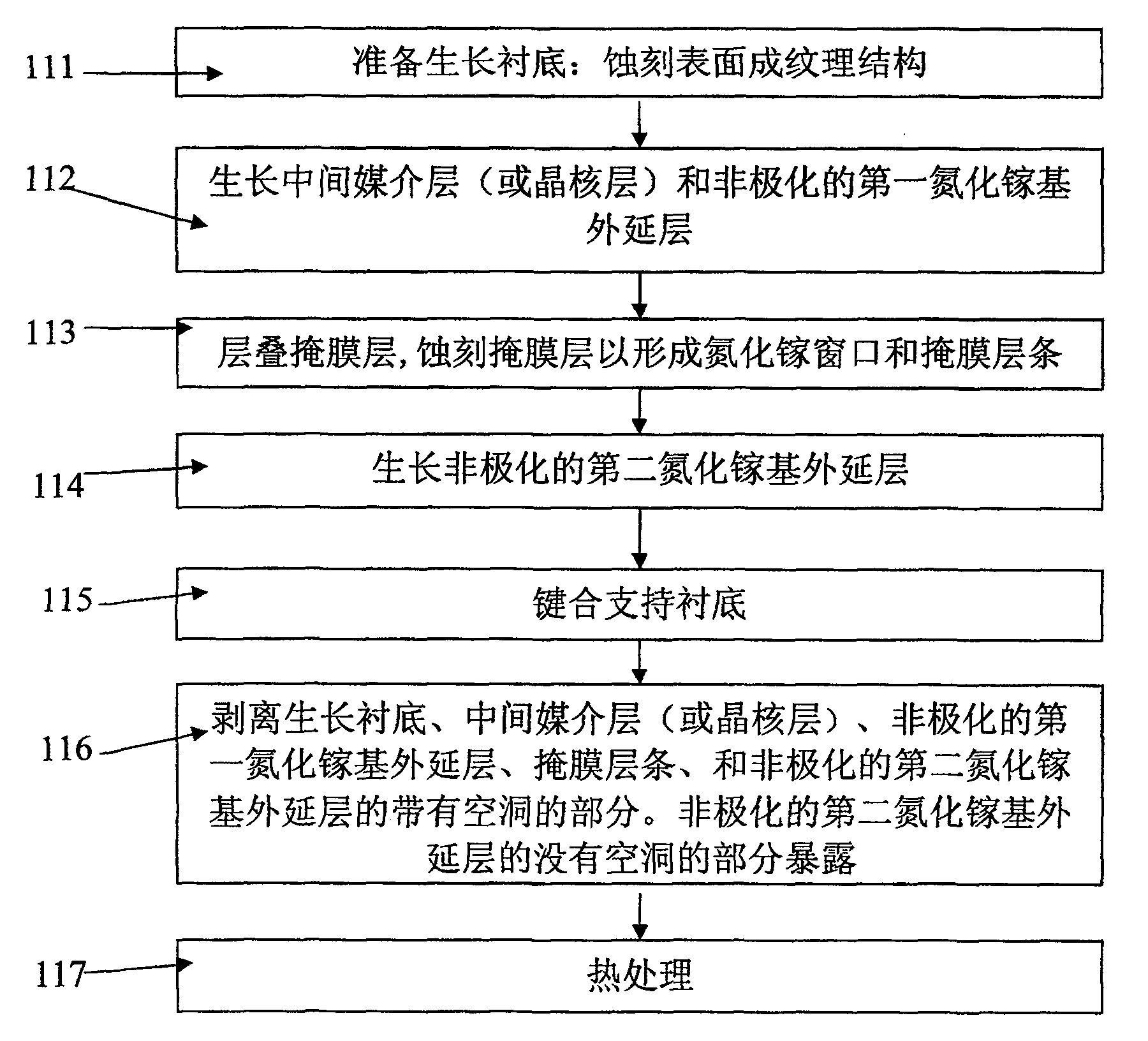

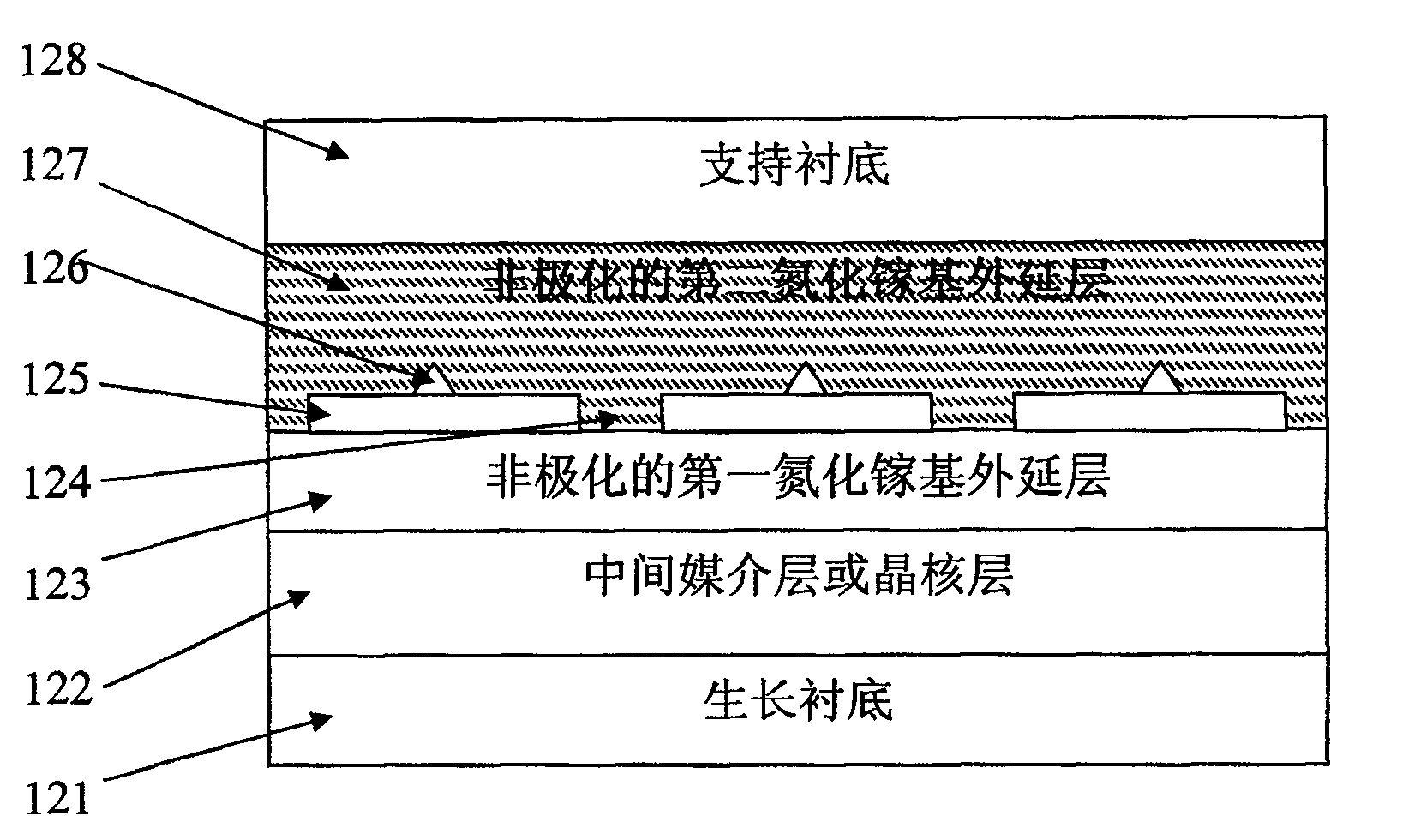

Non-polarized composite gallium nitride substrate lining and production method

InactiveCN1851943AImprove heat transfer efficiencyQuality improvementSemiconductor/solid-state device manufacturingSemiconductor devicesGallium nitrideOhm

This invention discloses a method for producing a non-polar compound GaN base substrate, in which, the structure of the substrate is reflection / ohm / stress buffer layer laminated between a support substrate and non-polar GaN base epitaxial layer, the method includes: growing an intermediate layer( or a germ layer) and a non-polar first GaN base epitaxial layer orderly on the substrate, laminating a mask layer, etching the mask layer to form a GaN window and mask layer strips, growing a non-polar second GaN base epitaxial layer, laminating the reflection / ohm / stress buffer layer, bonding the support substrate, peeling off the growing substrate, the intermediate layer, the non-polar first GaN base epitaxial layer, the mask layer strips and the cavity part in the non-polar second GaN base epitaxial layer and exposing the part without cavities to be heat-processed.

Owner:金芃 +1

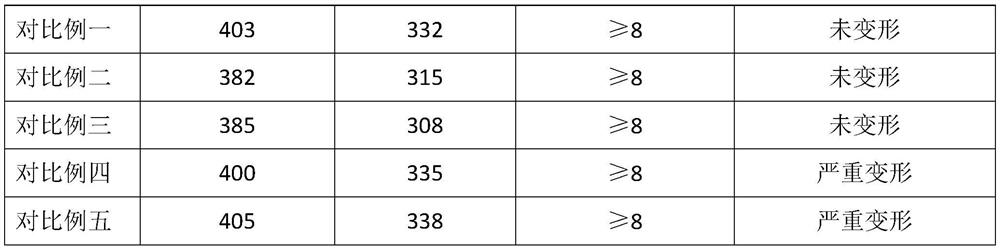

Multi-layer structure self-repairing thermal barrier coating layer and preparation method thereof

InactiveCN109778102AImprove insulation performanceReduce thermal mismatch stressMolten spray coatingChemical compositionAlloy substrate

The invention relates to a multi-layer structure self-repairing thermal barrier coating layer and a preparation method thereof. The multi-layer structure self-repairing thermal barrier coating layer comprises a bottom layer, a middle layer and a ceramic layer which are sequentially formed on a high-temperature alloy substrate; the chemical formula of the bottom layer is MCrAlY, wherein M is Co and / or Ni; the chemical composition of the middle layer is (1-y)TiC + xAl2O3+(y-x)YSZ, wherein y is larger than or equal to 0.65 and smaller than or equal to 0.85, and x is larger than or equal to 0.05 and smaller than or equal to 0.15; and the ceramic layer is a YSZ based coating layer.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

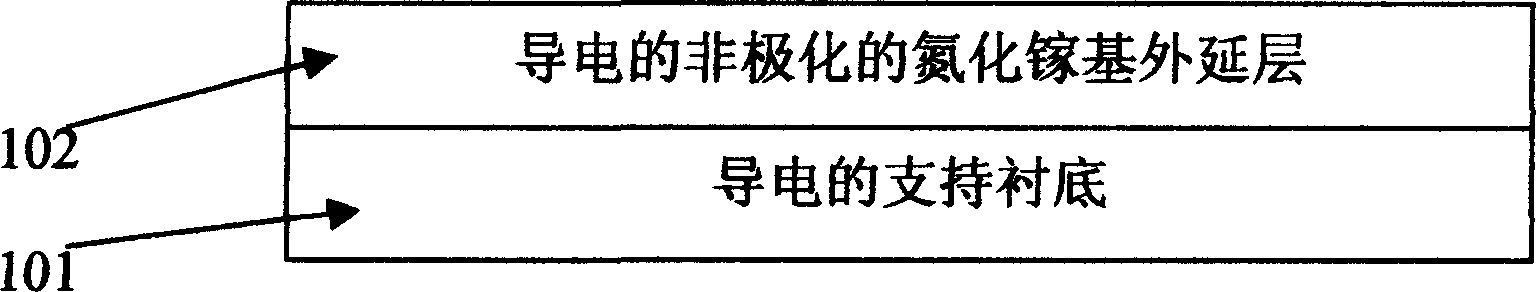

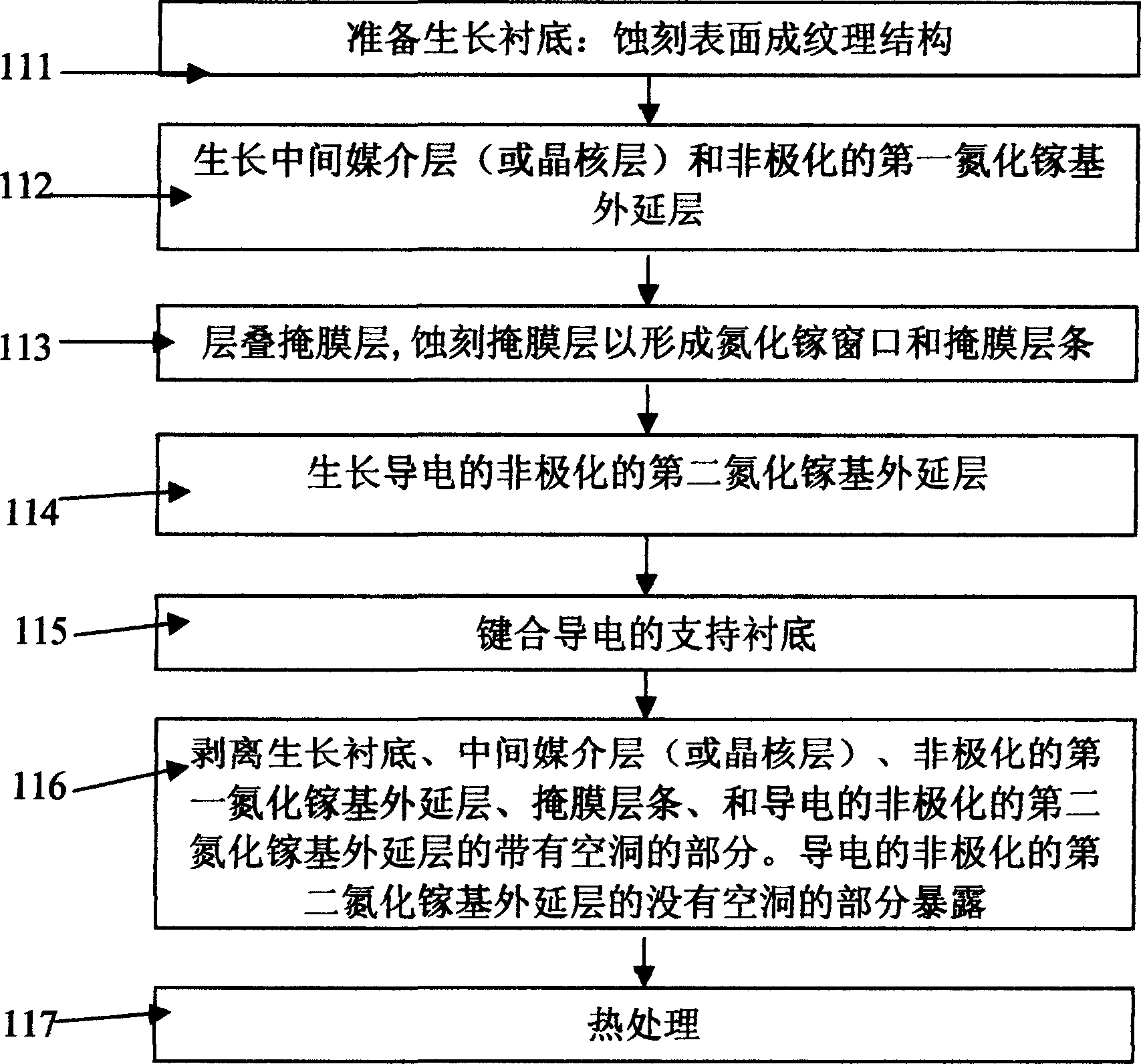

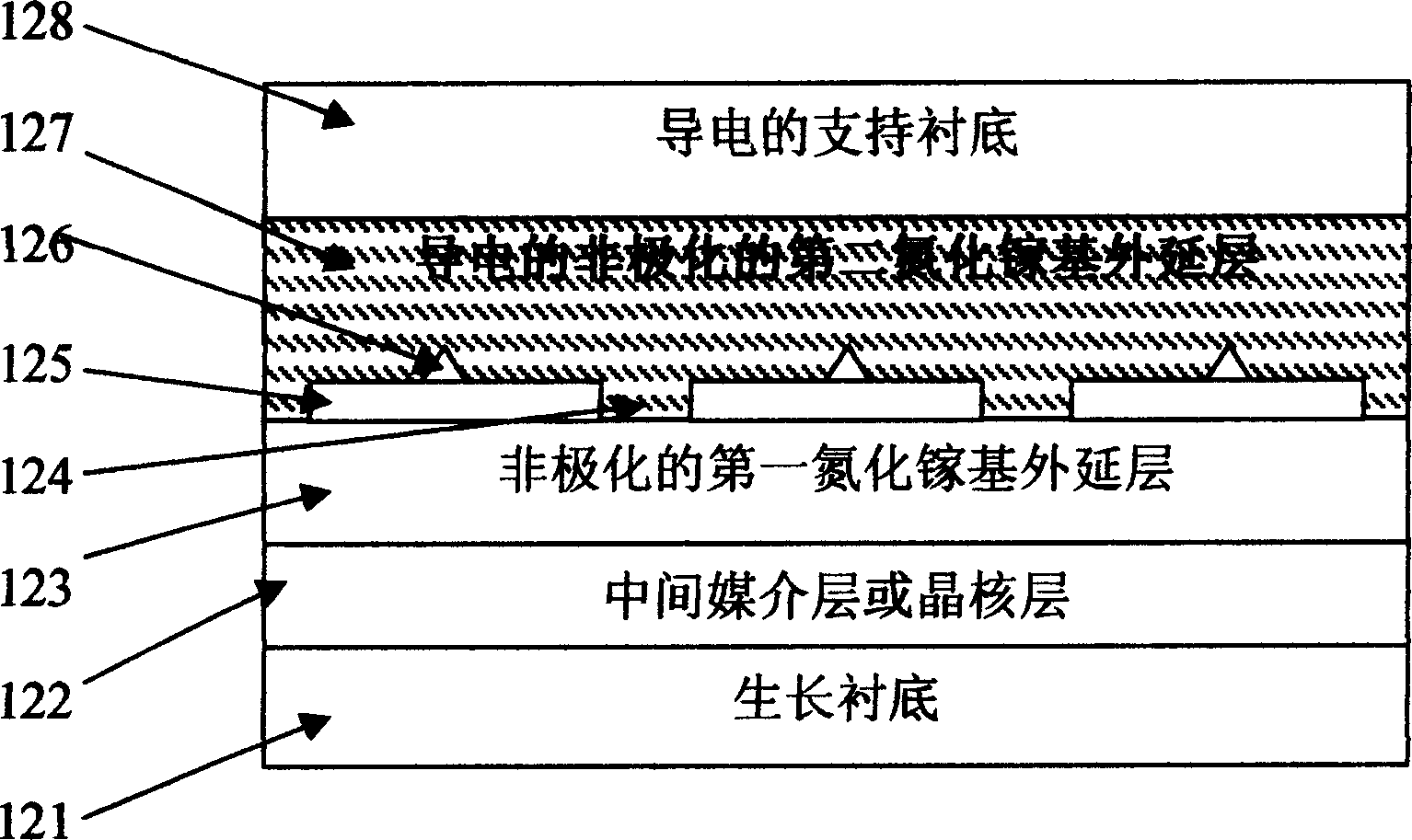

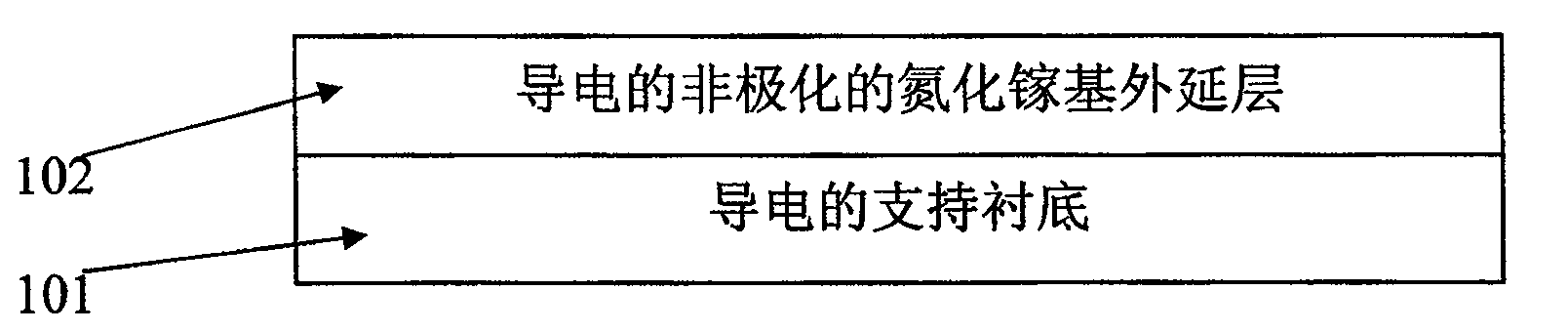

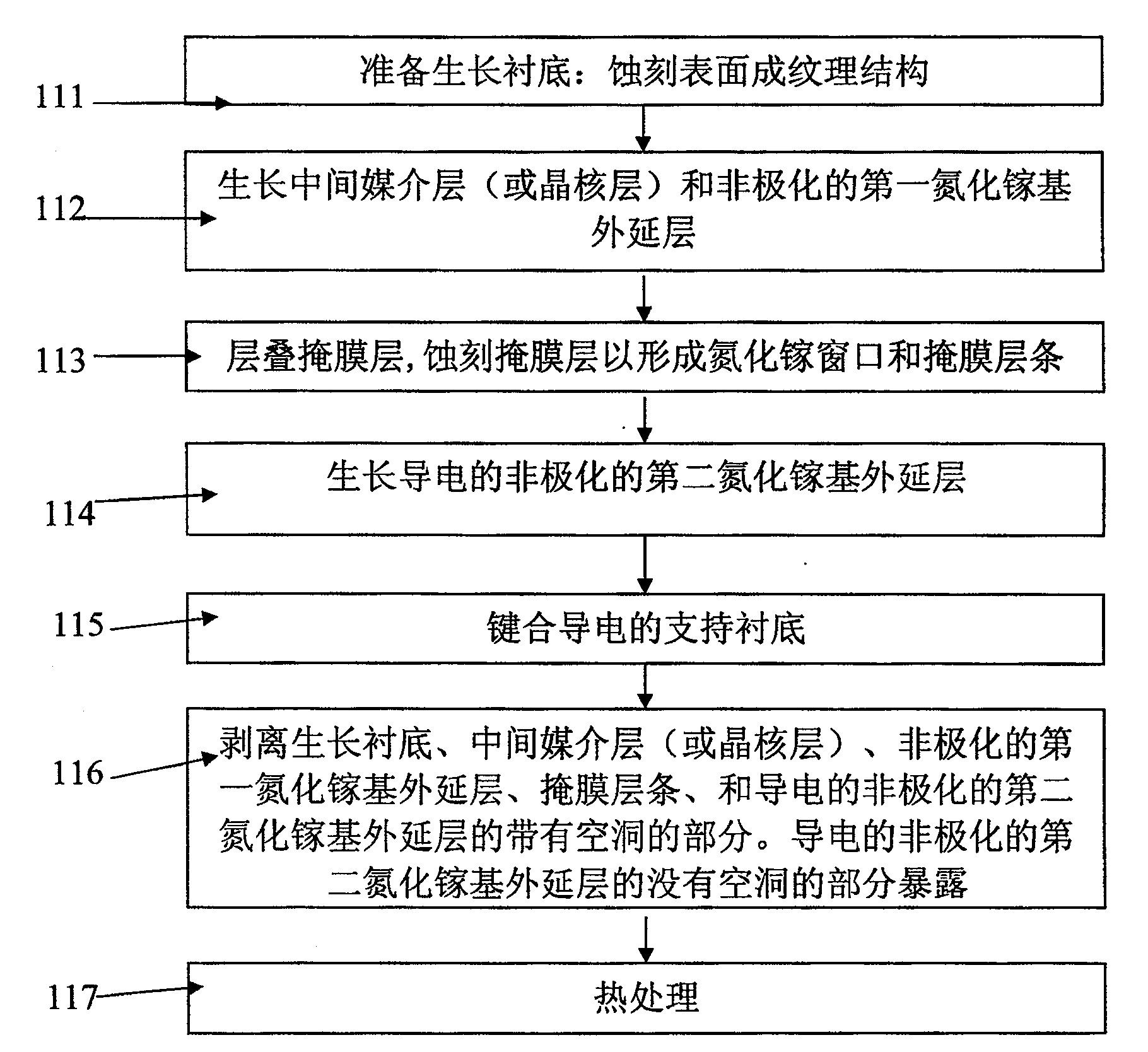

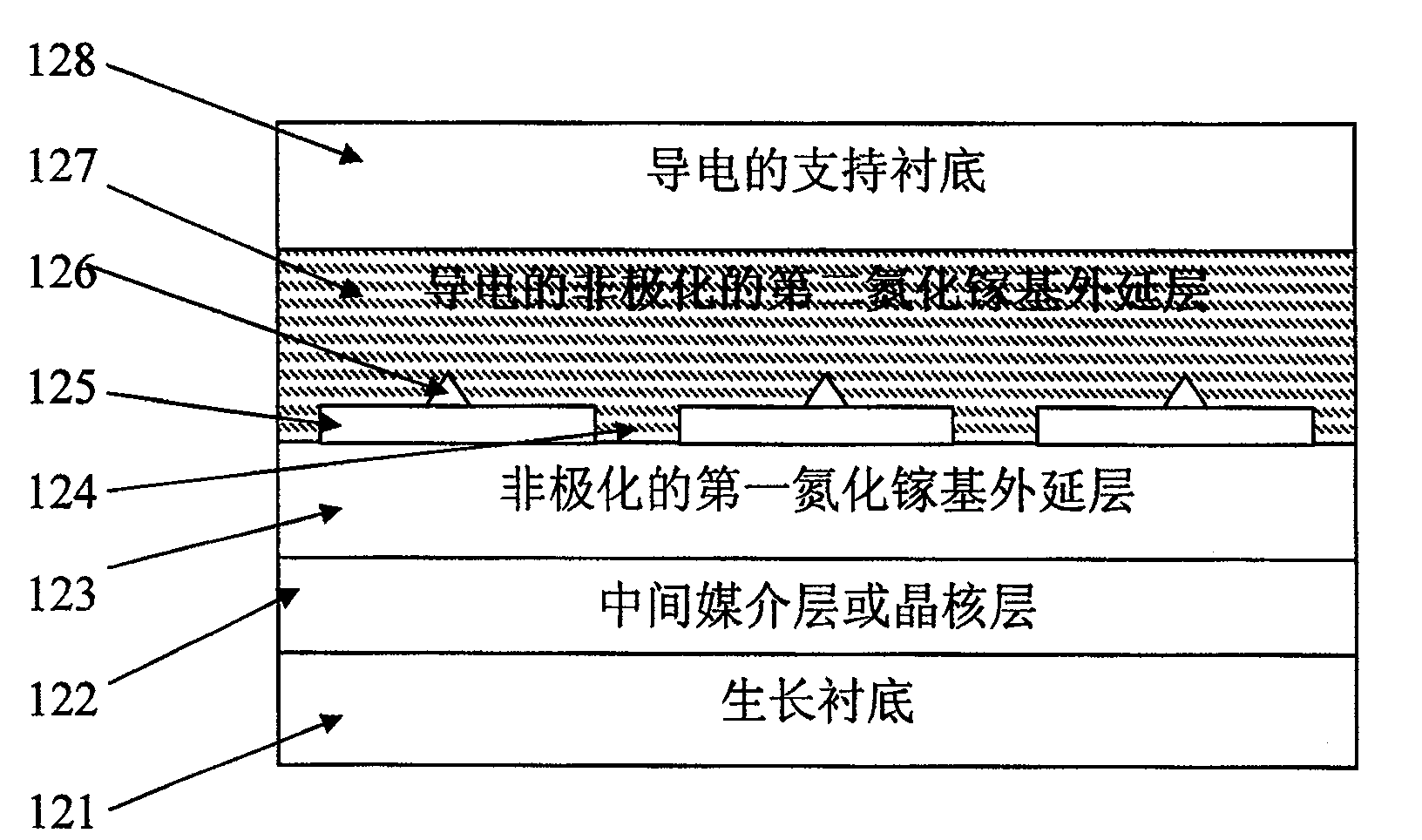

Conductive non-polarized composite gallium nitride substrate lining and production method

InactiveCN1851944AQuality improvementImprove heat transfer efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesGallium nitrideMaterials science

This invention discloses a conductive non-polar compound GaN substrate and a production method, in which, the conductive reflection / ohm / stress buffer layer is laminated between the conductive support substrate and the non-polar GaN epitaxial layer, the production method includes: growing an intermediate layer(or germ layer) and a non-polar first GaN epitaxial layer orderly on the growing substrate, laminating a mask layer, etching the mask layer to form a GaN window and mask layer strips, growing a conductive second GaN epitaial layer, laminating the conductive reflection / ohm / stress buffer layer, bonding the support substrate, peeling off the growing substrate, the intermediate layer, the first epitaxial layer, the mask layer and the second epitaxial layer with cavities to be heat-processed.

Owner:金芃 +1

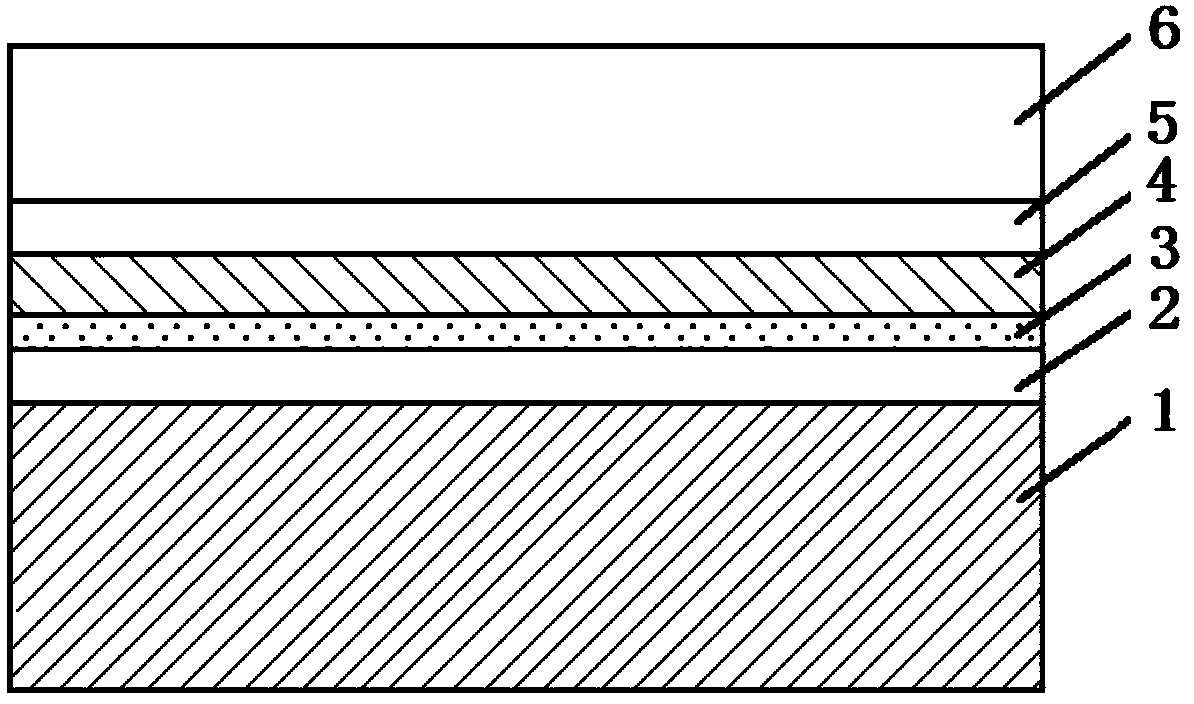

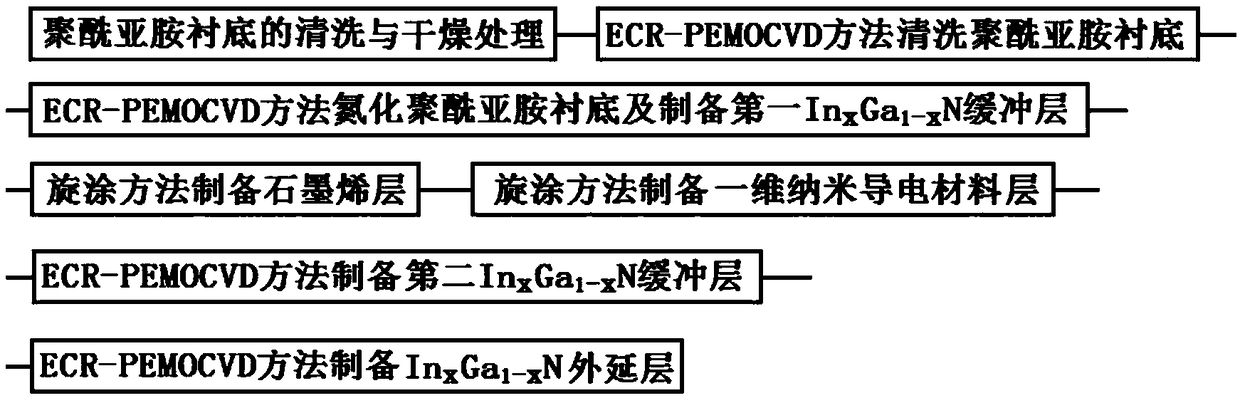

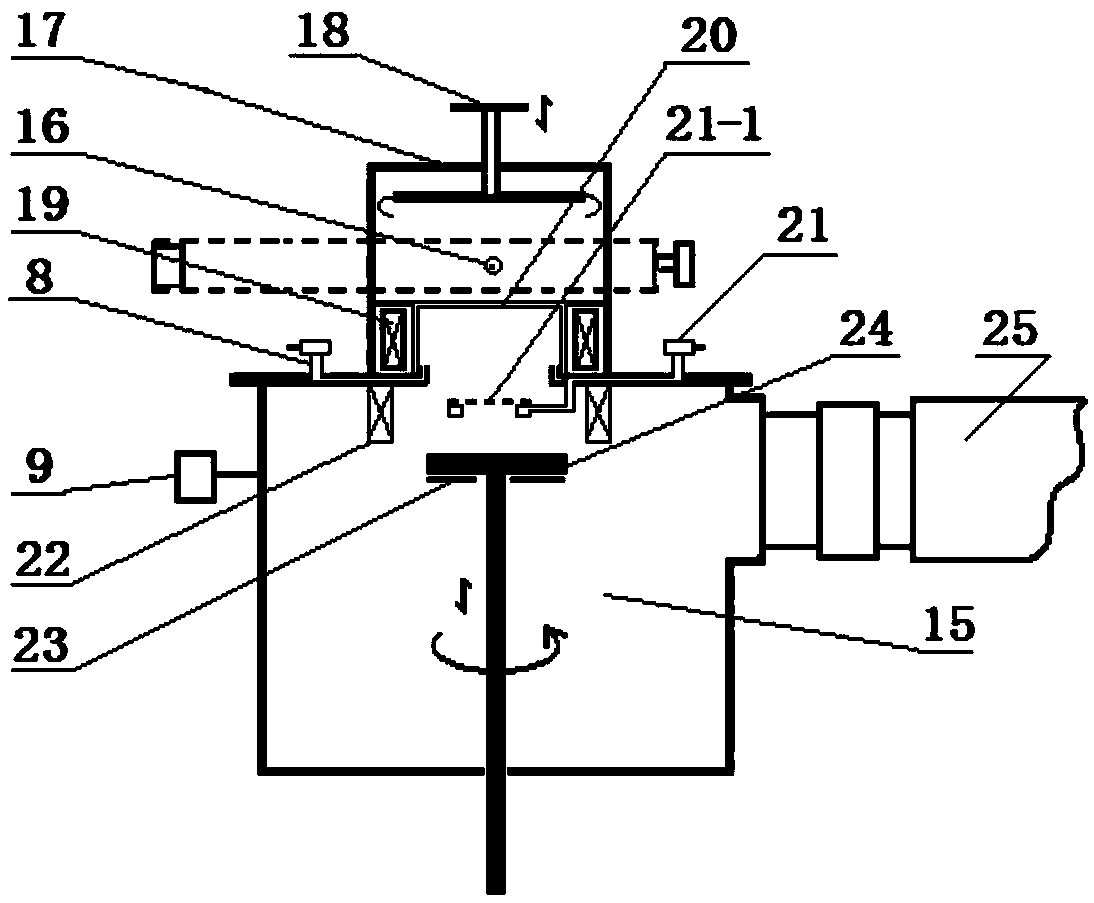

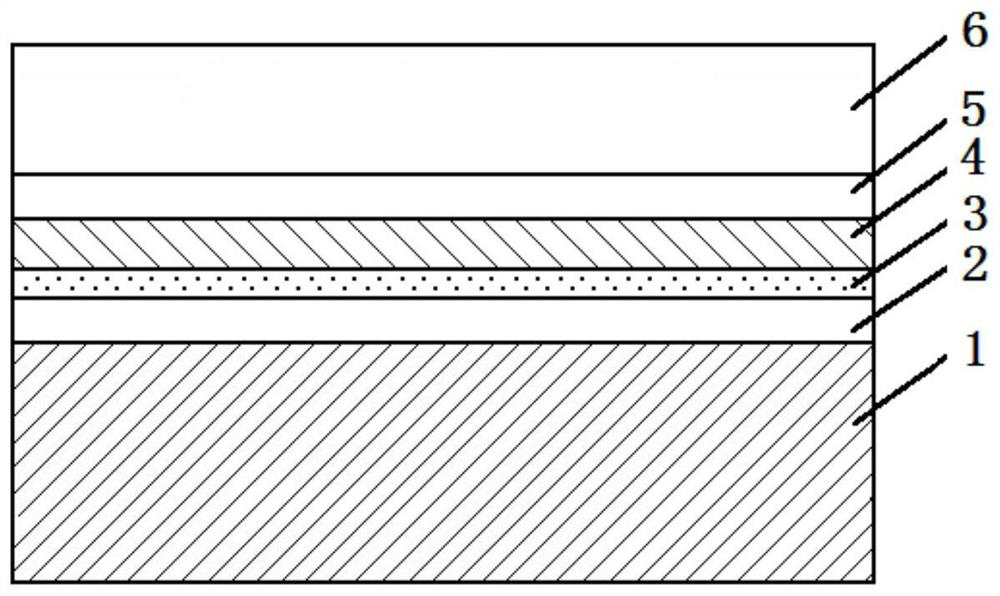

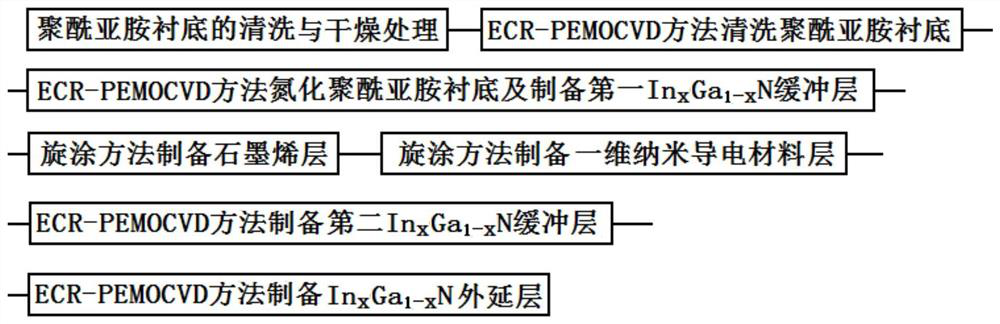

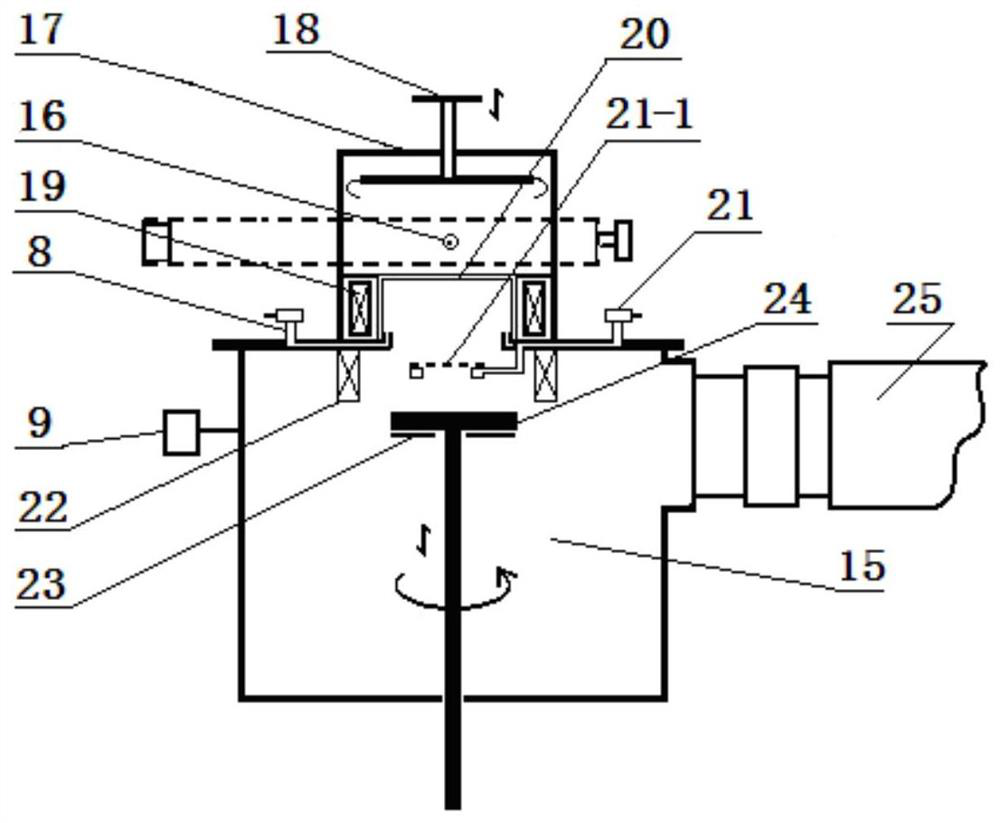

Indium gallium nitride thin film on flexible transparent polyimide substrate and preparation method of indium gallium nitride thin film

ActiveCN108831823AReduce thermal mismatch stressPrevent volatilizationSemiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseConductive materials

The invention belongs to the technical field of manufacturing of group-III nitride thin films and devices and provides an indium gallium nitride thin film on a flexible transparent polyimide substrateand a preparation method of the indium gallium nitride thin film. Polyimide is taken as a substrate and a first In<x>Ga<1-x>N buffer layer, a graphene layer, a one-dimensional nano-conductive material layer, a second In<x>Ga<1-x>N buffer layer and an In<x>Ga<1-x>N epitaxial layer are sequentially prepared on one side surface of the polyimide substrate from inside to outside, wherein the first In<x>Ga<1-x>N buffer layer, the second In<x>Ga<1-x>N buffer layer and the In<x>Ga<1-x>N epitaxial layer all are prepared by using an electron cyclotron resonance-plasma enhanced metal organic chemical vapor deposition method at low temperature; and the graphene layer and the one-dimensional nano-conductive material layer are prepared by using a spin coating method, so that the prepared high-quality In<x>Ga<1-x>N thin film can be used for preparing flexible transparent devices, such as an indium gallium nitride-based solar cell and a thin-film transistor and has a broad application prospect.

Owner:DALIAN UNIV OF TECH

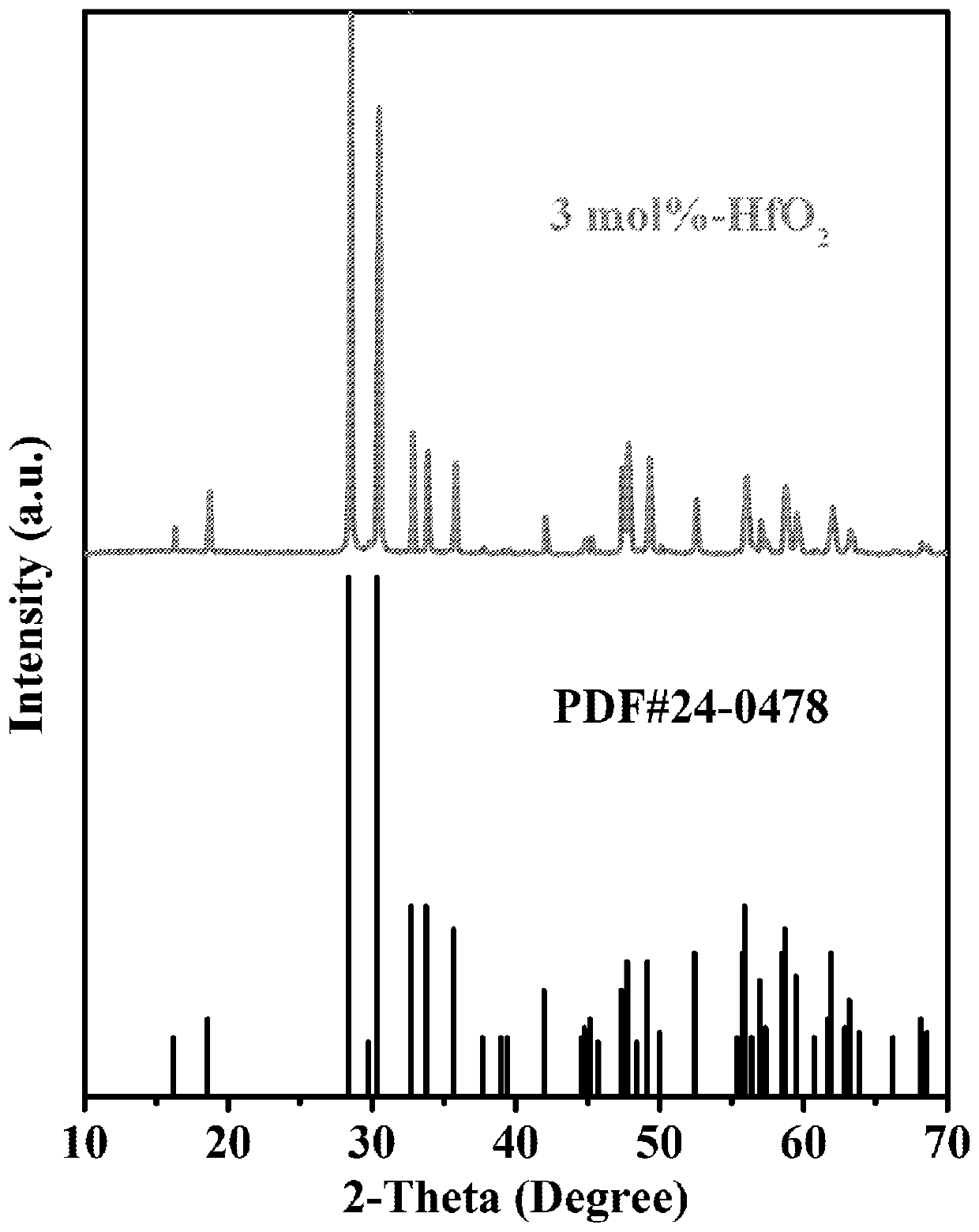

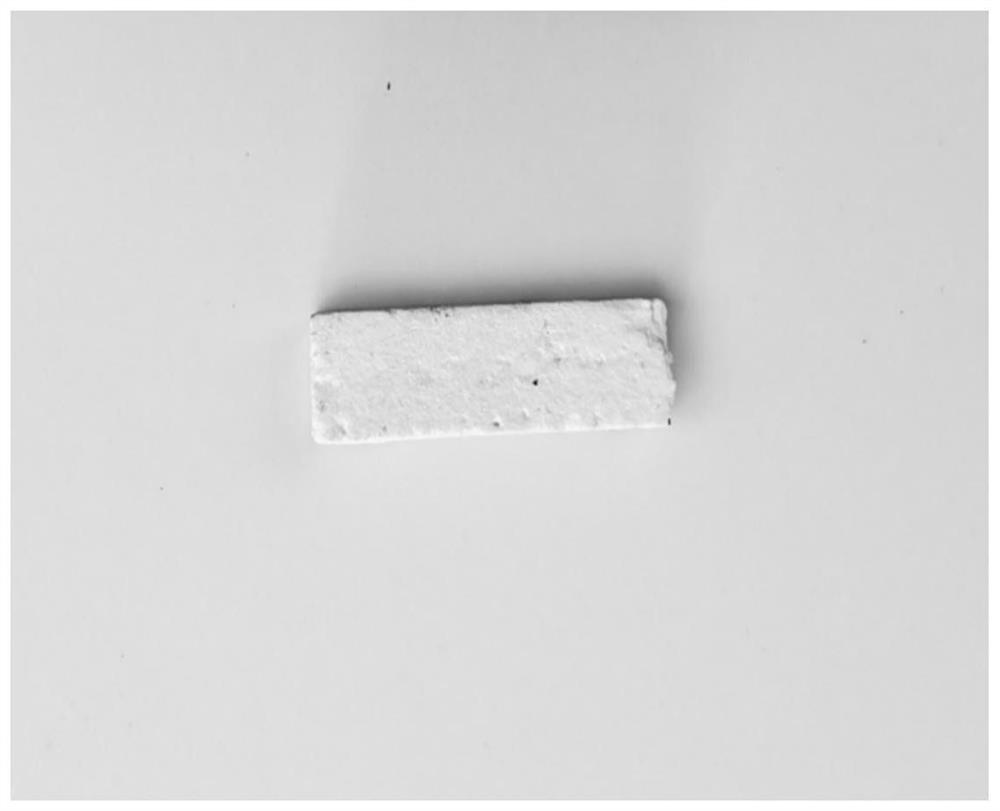

Porous tantalite ceramic and preparation method thereof

The invention relates to the technical field of thermal barrier coatings, in particular to a porous tantalite ceramic. The ceramic is prepared by sintering RE2O3 powder, Ta2O5 powder and HfO2 powder,the molar ratio of RE: Ta: Hf in the ceramic is 1:1: x, wherein the x is larger than 0 and smaller than 0.1; the ceramic is of a porous structure, and the porosity is larger than 0.2. The preparationmethod of the ceramic comprises the following steps of: weighing the RE2O3 powder, the Ta2O5 powder and the HfO2 powder, wherein the molar ratio of RE: Ta: Hf is 1:1:x, adding a solvent, mixing, and grinding by using a grinding machine to obtain powder A; drying the powder A, and sieving for the first time to obtain powder B; placing the powder B in a mold, compacting, and pre-sintering to obtaina block C; cooling the block C to room temperature, grinding by using the grinding machine, and sieving for the second time to obtain powder D; and sintering the powder D to obtain the porous tantalite ceramic. The porous tantalite ceramic prepared by adopting the technical scheme has the advantages of high porosity, low thermal conductivity at high temperature and good heat insulation performance.

Owner:陕西天璇涂层科技有限公司

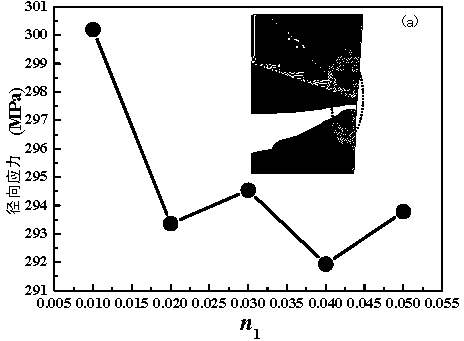

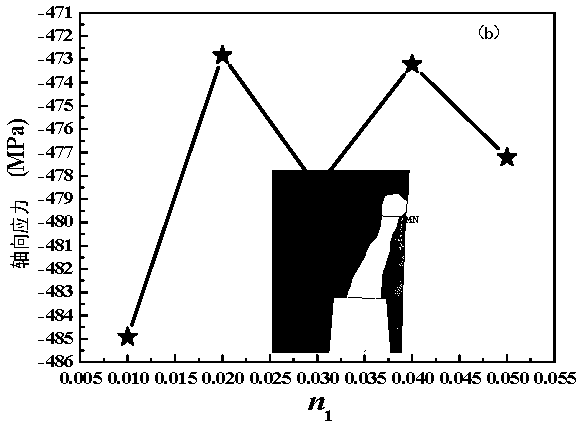

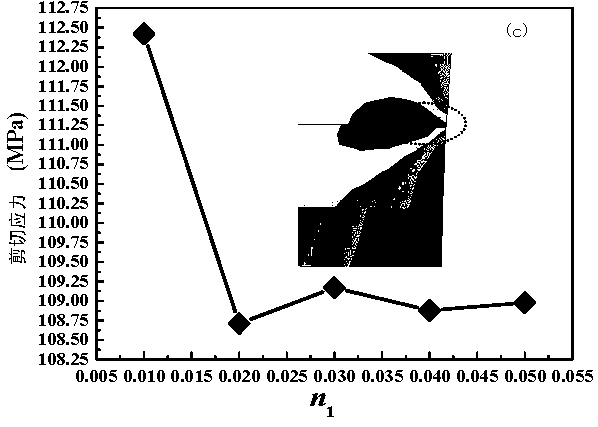

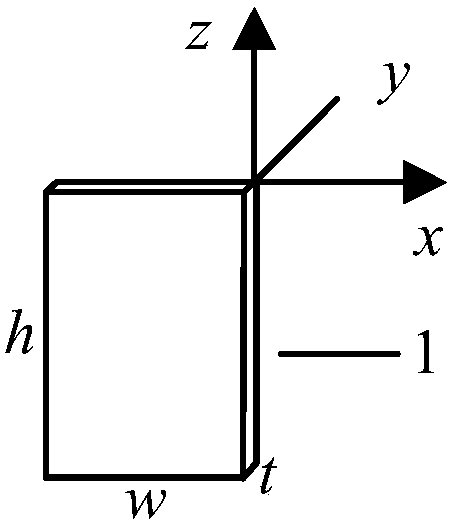

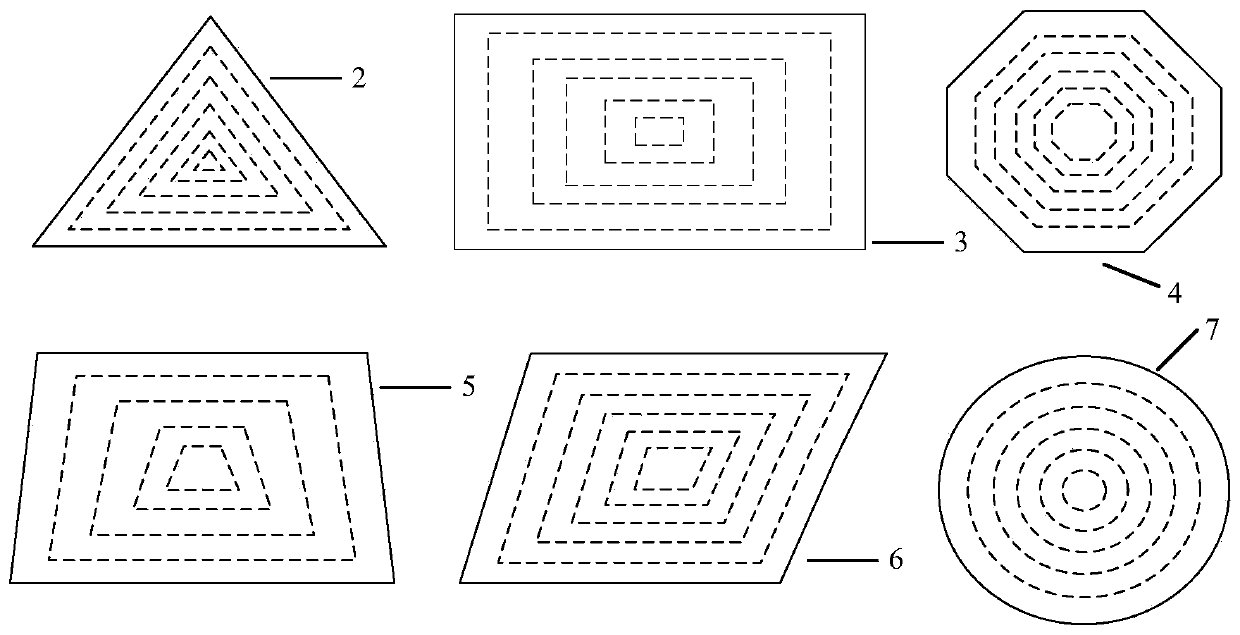

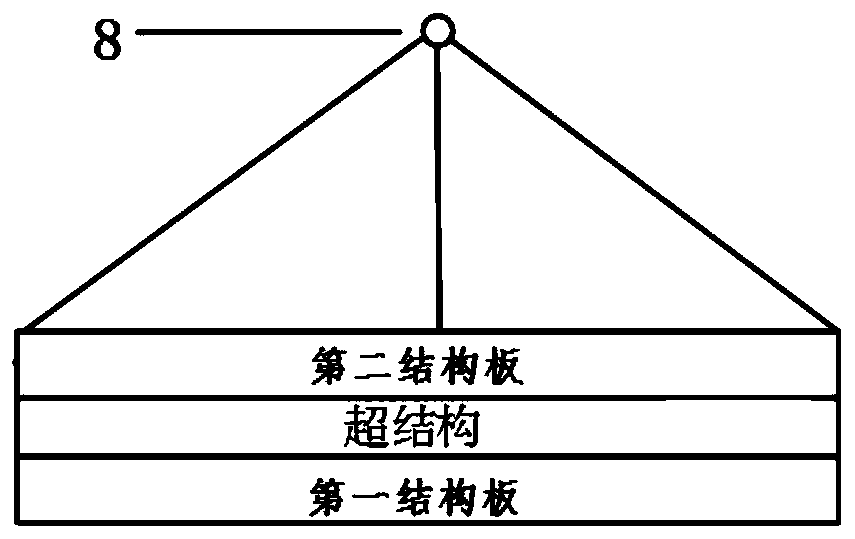

Superstructure with high resonant frequency and thermal mismatch zero warping and determination method thereof

ActiveCN110298064AMeet the requirements of the first-order natural frequencyReduce thermal mismatch stressGeometric CADDesign optimisation/simulationIn planeResonance

The invention relates to a superstructure with high resonant frequency and thermal mismatch zero warping and a determination method thereof. The superstructure is used for connection of heterostructures and comprises a multistage microstructure, wherein each stage of microstructure comprises a plurality of microstructure units; the multi-stage microstructures are distributed from outside to inside, and an envelope line formed by each stage of microstructures with self-similar characteristics in the plane and an in-plane contour line of the heterostructure have a geometric similar relationship.Based on the super-structure provided by the invention, the buckling deformation during temperature change is close to zero, and the super-structure has the characteristic of high first-order resonant frequency and meets the use requirements of on-orbit dimensional stability and high emission rigidity of a spacecraft structure.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

SiC-based composite material with high-temperature ceramic coating YSZ-RETaO4 and preparation method of SiC-based composite material

The invention relates to the technical field of composite materials, and particularly discloses a SiC-based composite material with a high-temperature ceramic coating YSZ-RETaO4 and a preparation method of the SiC-based composite material. The method comprises the following steps: aluminum oxide, aluminum hydroxide, aluminum dihydrogen phosphate and calcium oxide are weighed, ball-milled togetherwith absolute ethyl alcohol, uniformly mixed, dried and sieved; the SiC matrix in an alumina porcelain boat through the sieved powder, and high-temperature calcination is carried out to form a transition layer on the surface of the SiC matrix; YSZ and RETaO4 powder is sprayed to the surface of the transition layer through an atmospheric plasma spraying method, and the SiC composite material with the ceramic coating sprayed to the surface is formed. The thermal conductivity of the silicon carbide-based composite material prepared by the method is 0.67-0.82 W.m<-1>.K<-1>, and the silicon carbide-based composite material meets the use environment with the ultrahigh temperature of 2200-2500 DEG C or above.

Owner:KUNMING UNIV OF SCI & TECH +1

Electric non-polarized composite gallium nitride base substrate and production method

InactiveCN1845350AQuality improvementImprove heat transfer efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesGallium nitrideMedia layer

The disclosed processing steps for a conductive non-polar composite GaN substrate comprise: on the growth substrate, growing middle medium layer (or crystal kernel) and the non-polar first GaN-based extension layer in turn; overlaying the mask layer to etch and form the GaN window and mask layer strip; growing the non-polar second GaN extension layer; overlaying the conductive reflection / ohm / stress buffer layer; bonding substrate; then, peeling the substrate, medium layer, the first extension layer, mask strip, and the part with hole on the second extension layer for thermal treatment.

Owner:INVENLUX OPTOELECTRONICS (CHINA) CO LTD

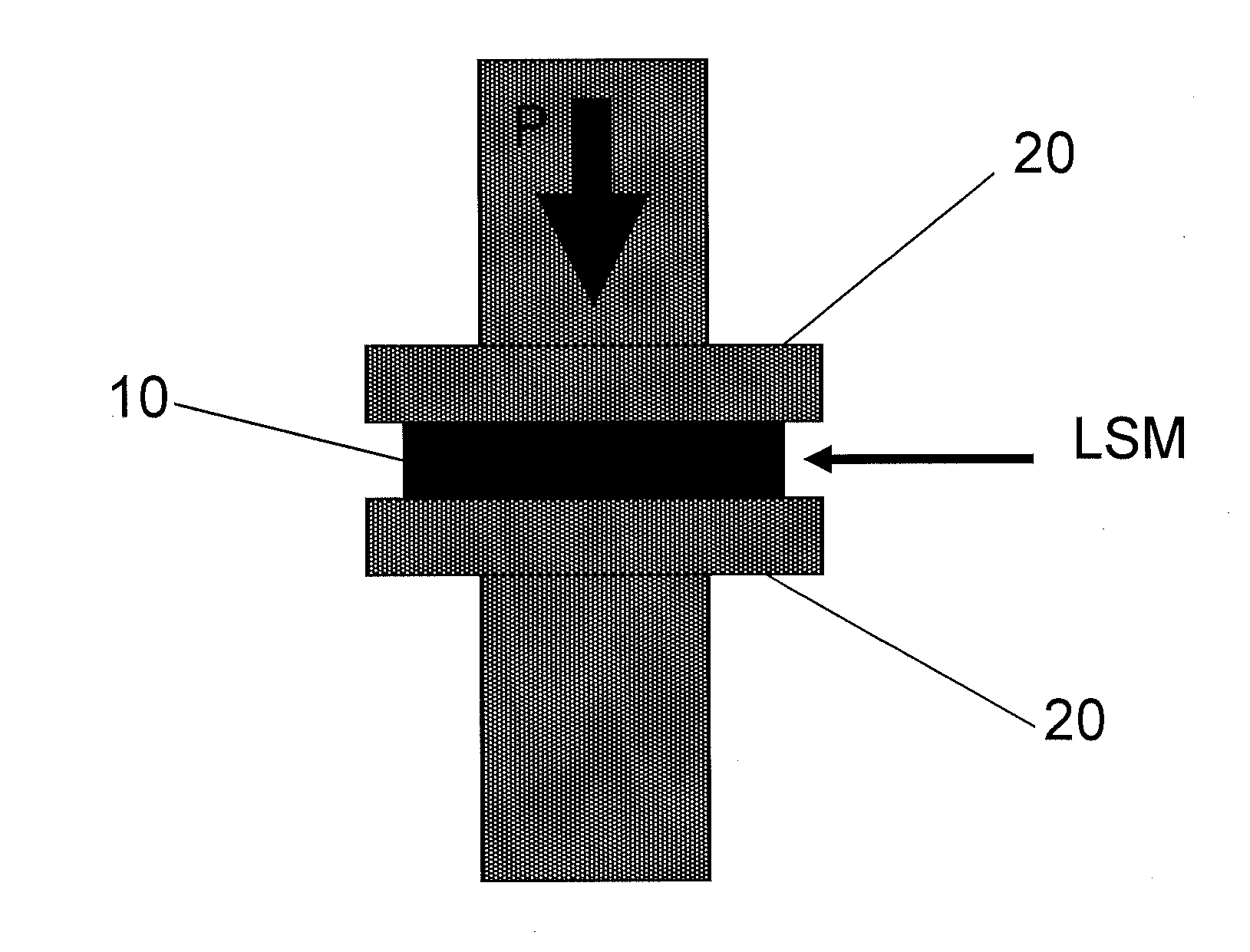

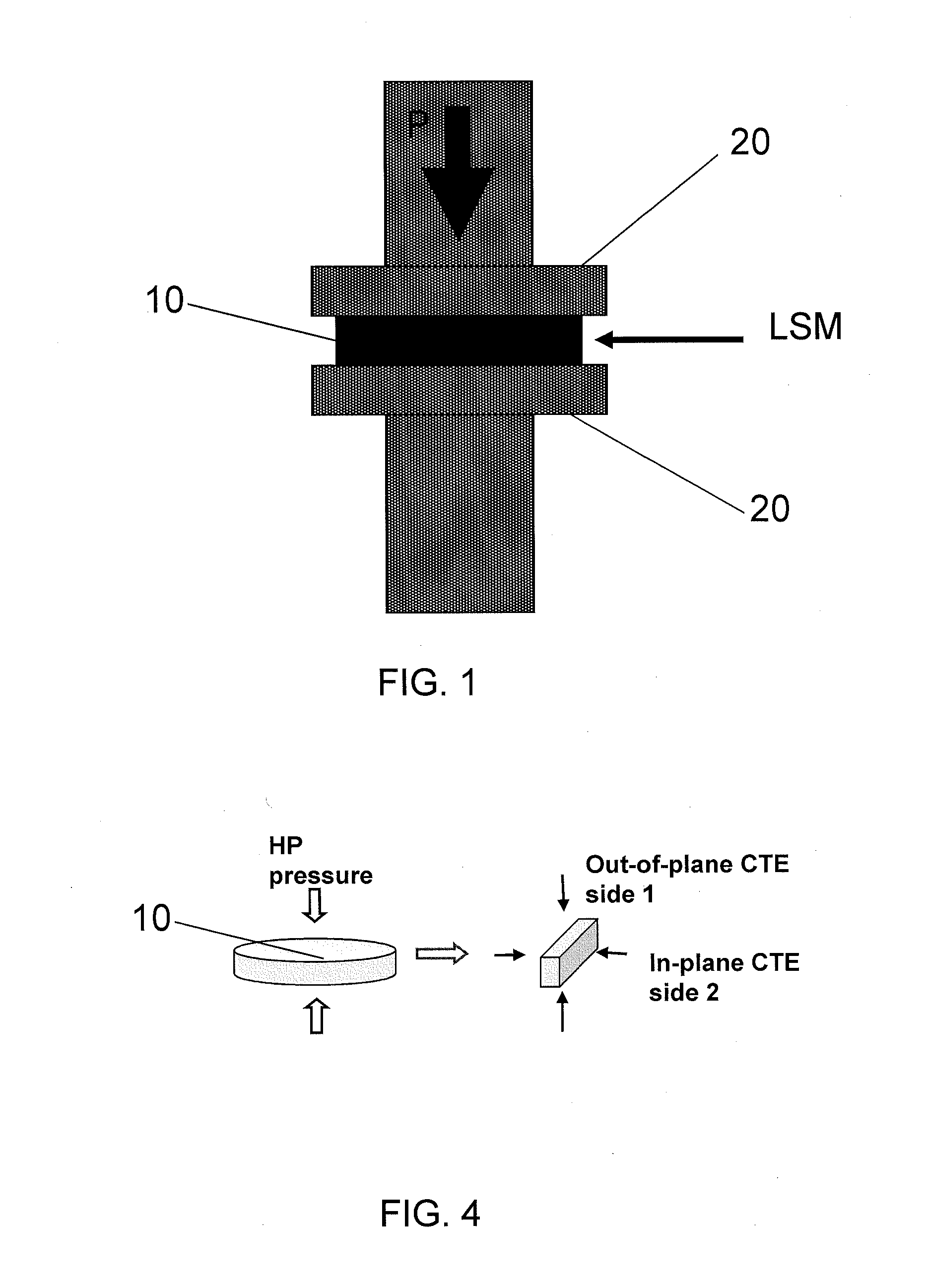

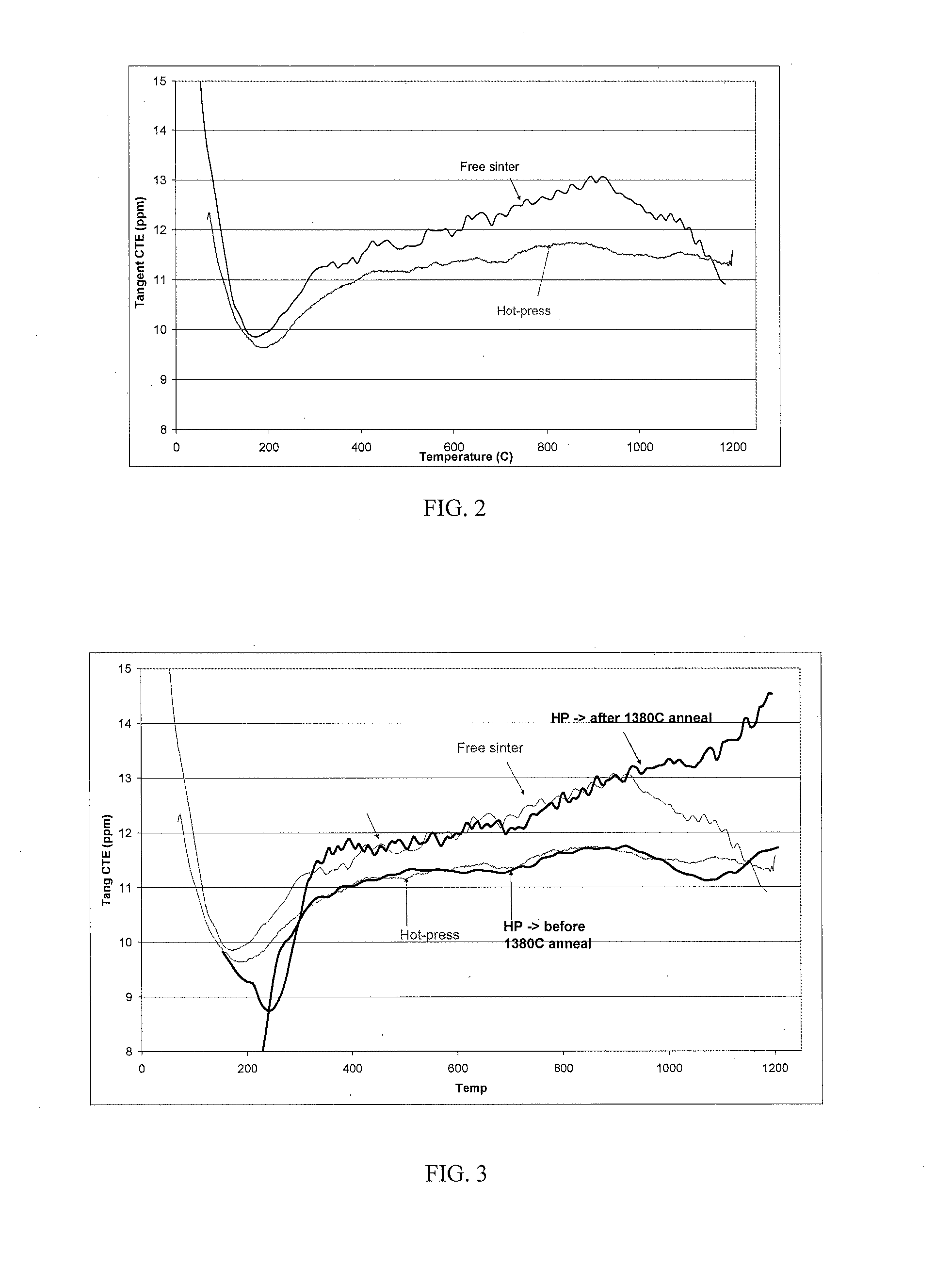

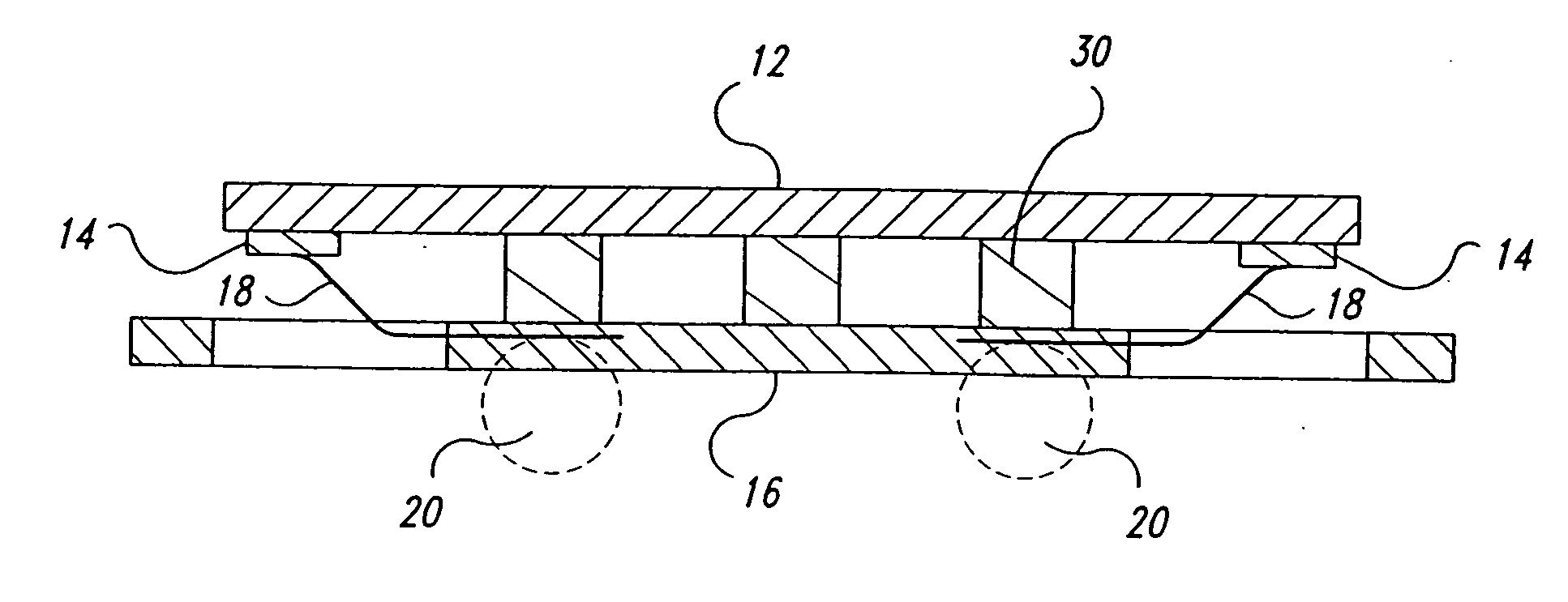

Anisotropic cte lsm for sofc cathode

InactiveUS20110158880A1Minimizing and significantly reducing failureReduce thermal mismatch stressCell electrodesCeramic shaping apparatusLanthanum strontium manganiteFuel cells

An anisotropic coefficient of thermal expansion (CTE) cathode of a solid oxide fuel cell (SOFC) is formed by placing a layer of perovskite powder between two platens, and sintering the layer while applying pressure to the platens, thereby forming the anisotropic CTE cathode. The perovskite can be lanthanum strontium manganite (LSM).

Owner:SAINT GOBAIN CERAMICS & PLASTICS INC

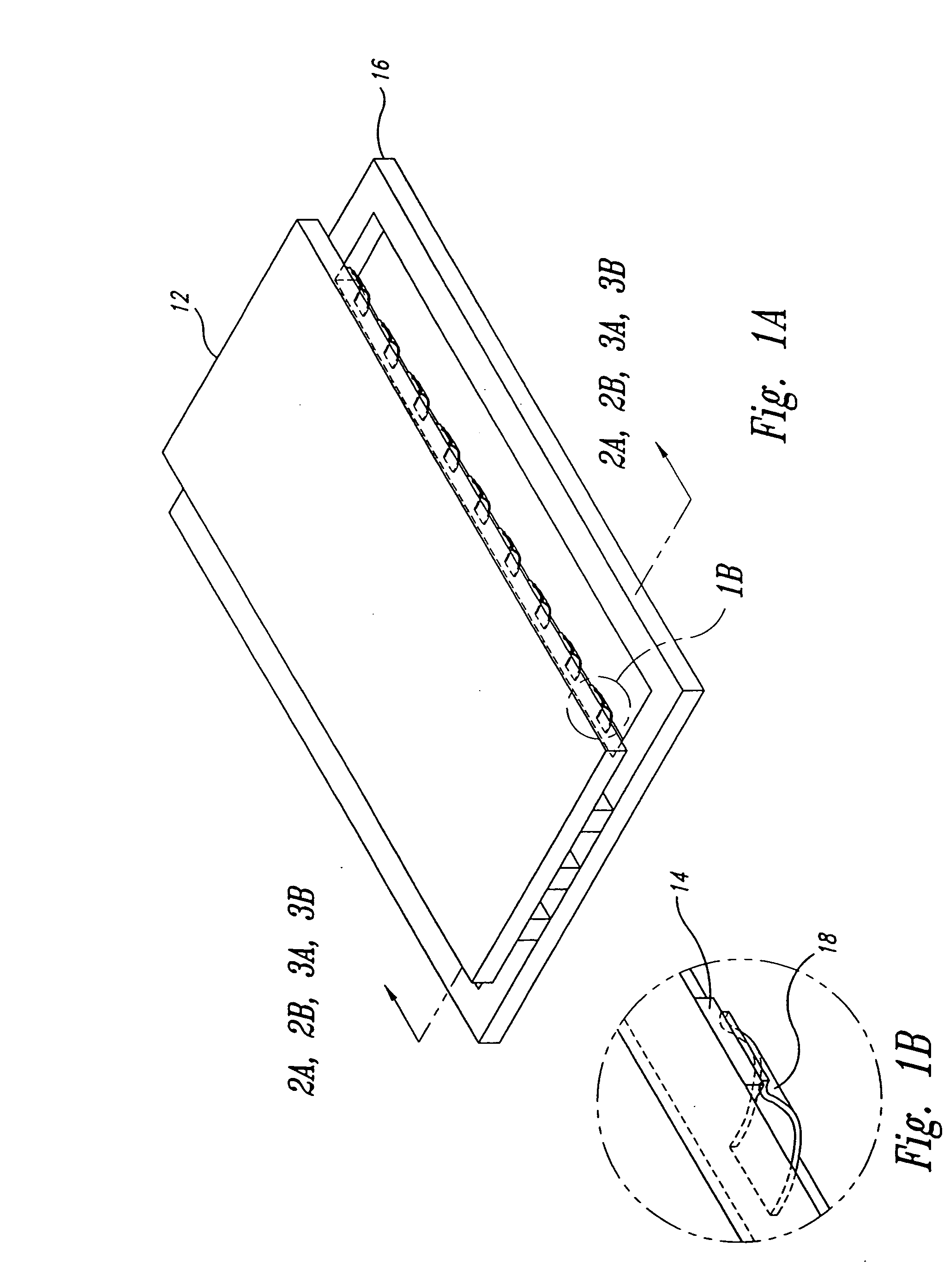

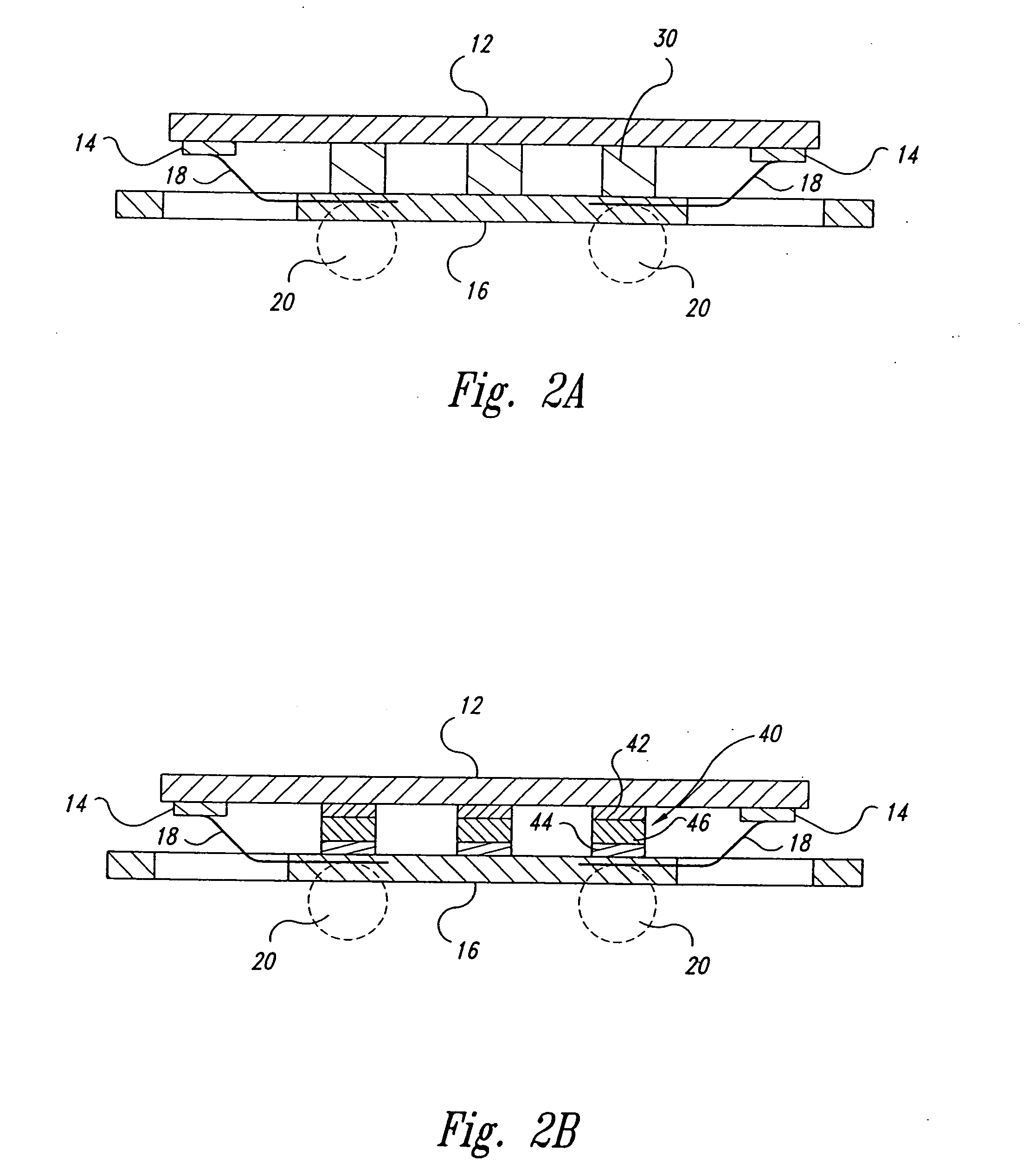

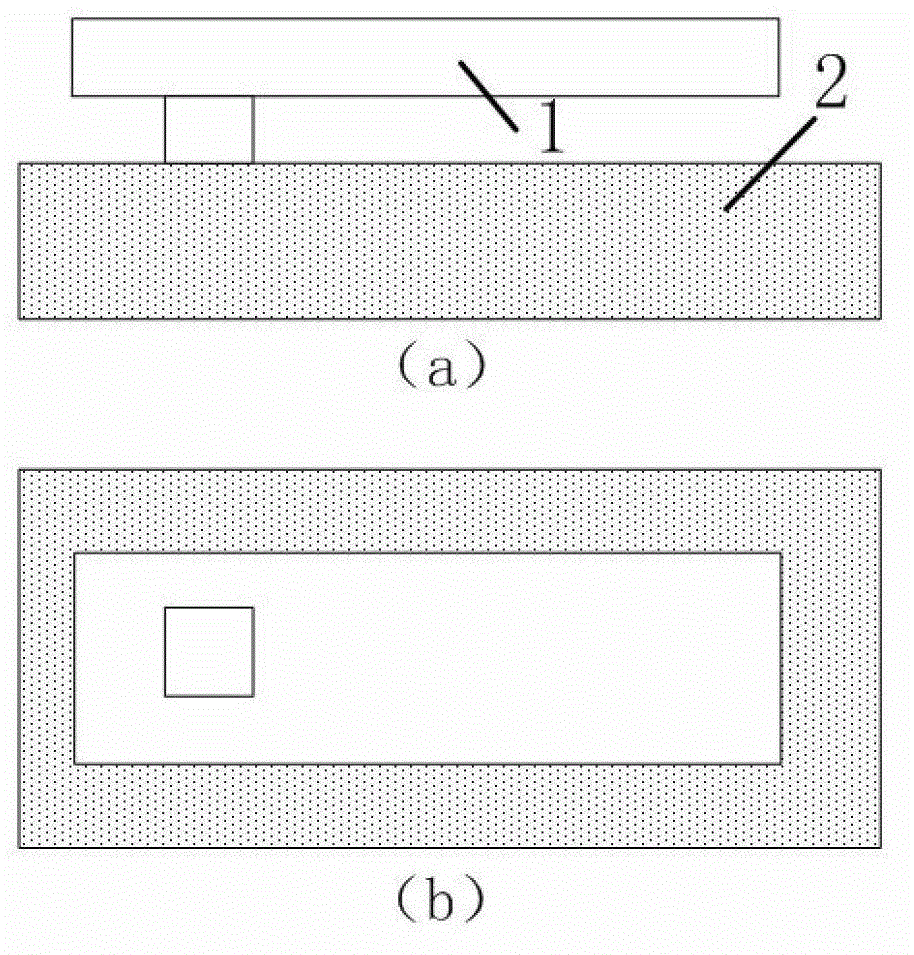

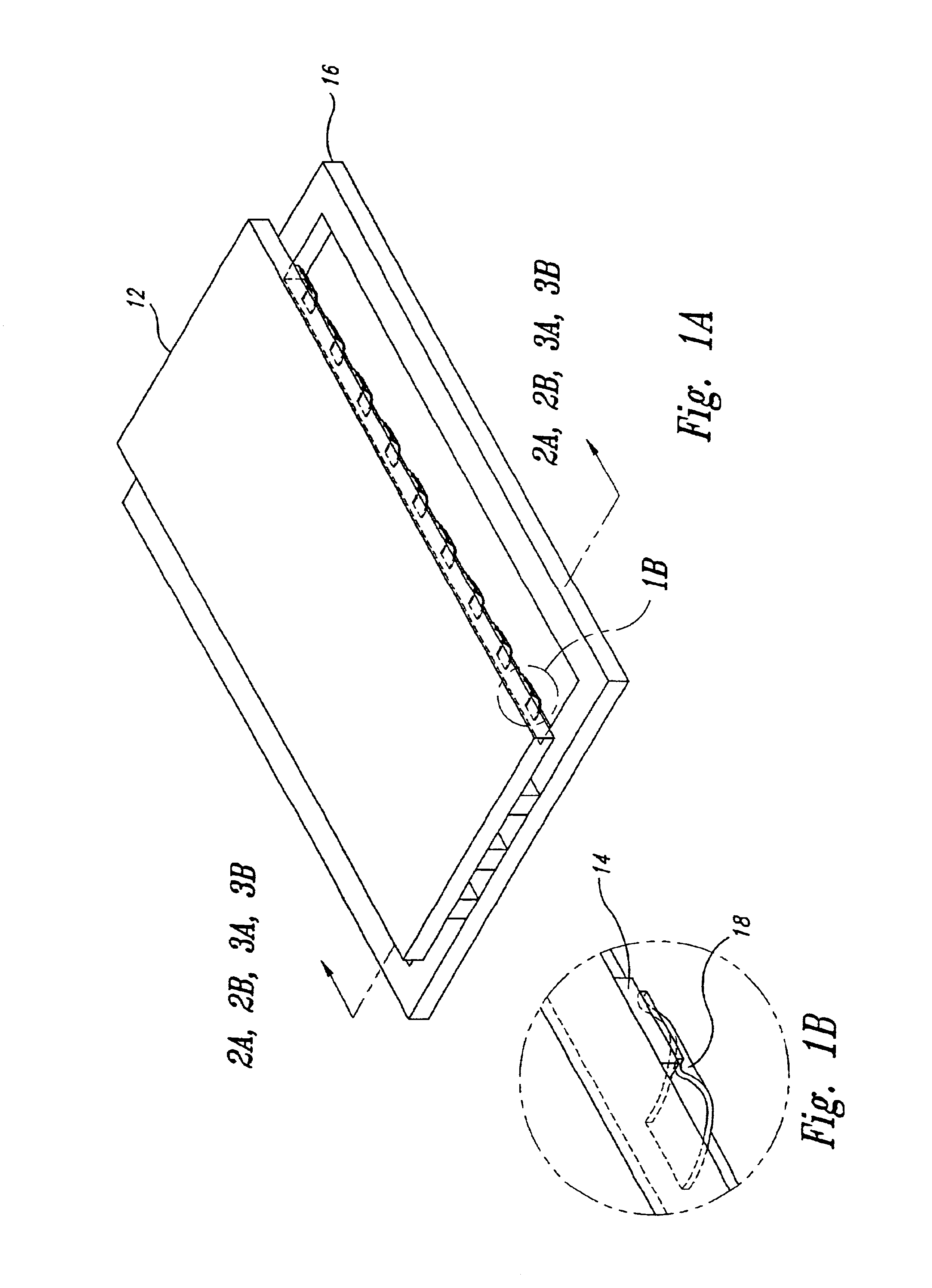

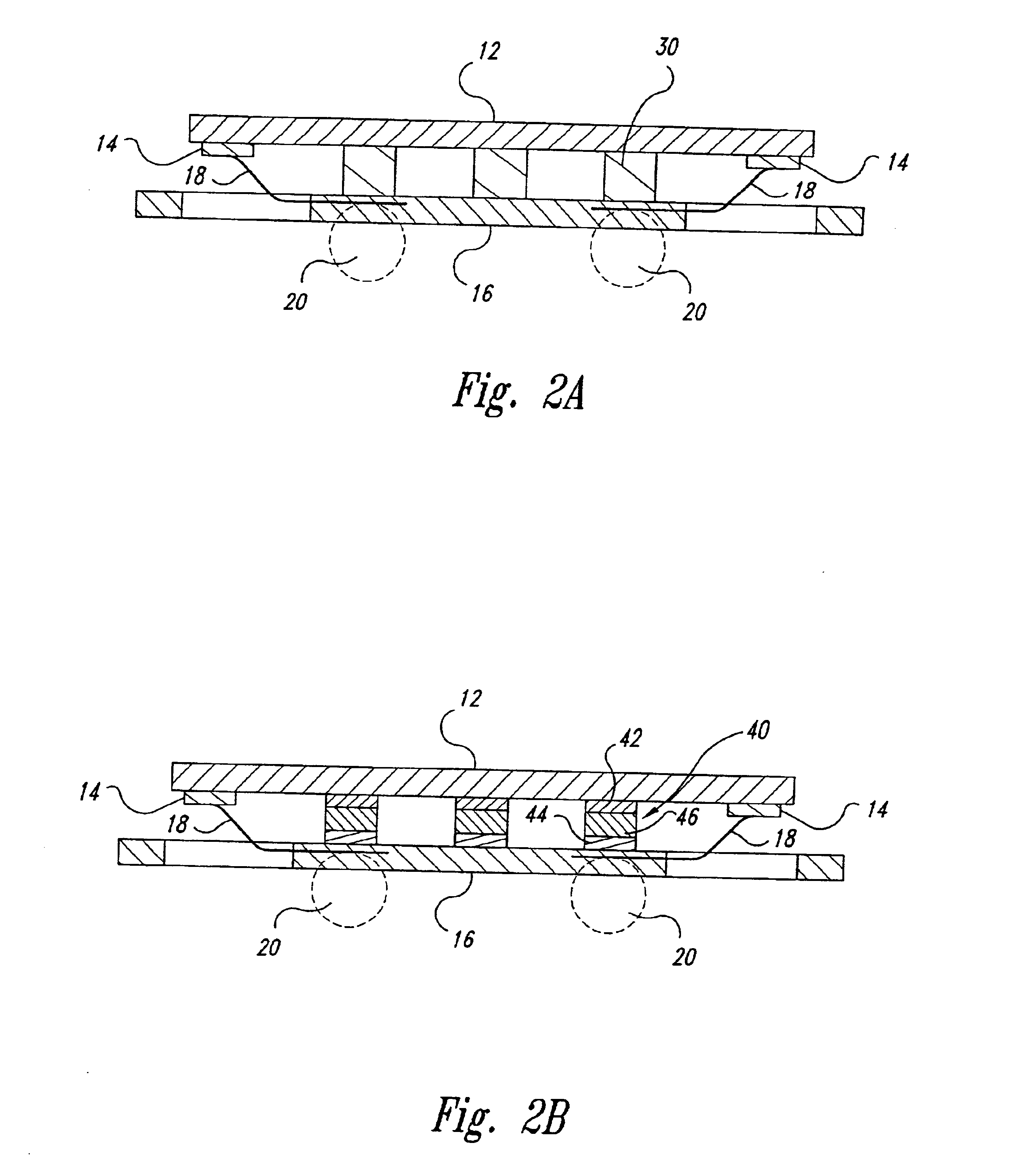

Method and structure for manufacturing improved yield semiconductor packaged devices

InactiveUS20050285279A1Reduce thermal mismatch stressImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesElastomerSemiconductor package

A semiconductor package structure for a ball grid array type package using a plurality of pieces of adhesive elastomer film to attach a semiconductor die to a substrate having conductive traces in order to alleviate thermal mismatch stress between the semiconductor die and the printed circuit board to which the packaged device is soldered, while maintaining the reliability of the packaged device itself.

Owner:ROUND ROCK RES LLC

A wafer-level vacuum packaging method for all-silicon mems based on anodic bonding

ActiveCN107963609BReduce processing difficultyImprove yieldDecorative surface effectsChemical vapor deposition coatingGlass chipSignal-to-noise ratio (imaging)

The invention discloses a full-silicon MEMS wafer-level vacuum packaging method based on anode bonding; two-time anode bonding is adopted in the MEMS wafer-level vacuum packaging process to realize mechanical and electric signal connection among a cover plate, an MEMS device structure and a substrate and form a pressure controllable MEMS sealing cavity; compared with the existing full-silicon bonding process based on silicon-silicon solder bonding and silicon-silicon fusion bonding, the method in the invention is low in process difficulty and high in rate of finished products; the cover plateglass sheet is thinned to 10-50 microns and the substrate glass sheet is thinned to 10 -50 microns; the thickness of the dielectric layer of the existing full-silicon bonding process is not more than3 microns to the maximum; the thinner dielectric layer is, the larger the introduced parasitic capacitance is; hence, the parasitic capacitance introduced by the method in the invention is small, so that the signal-to-noise ratio output by the MEMS device is improved.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

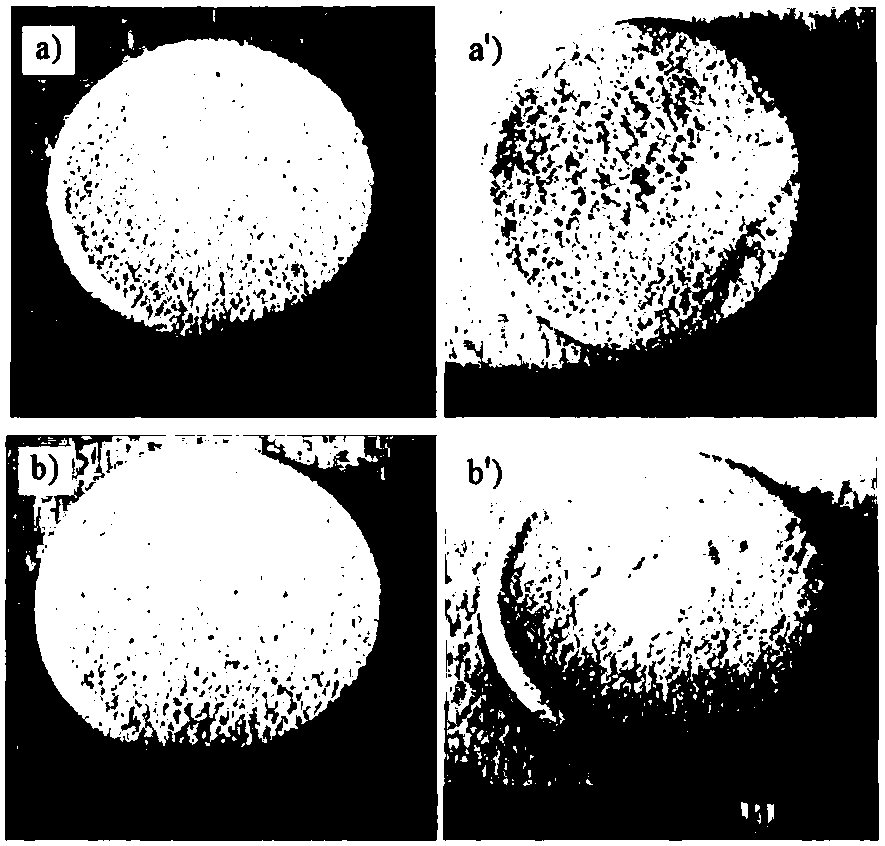

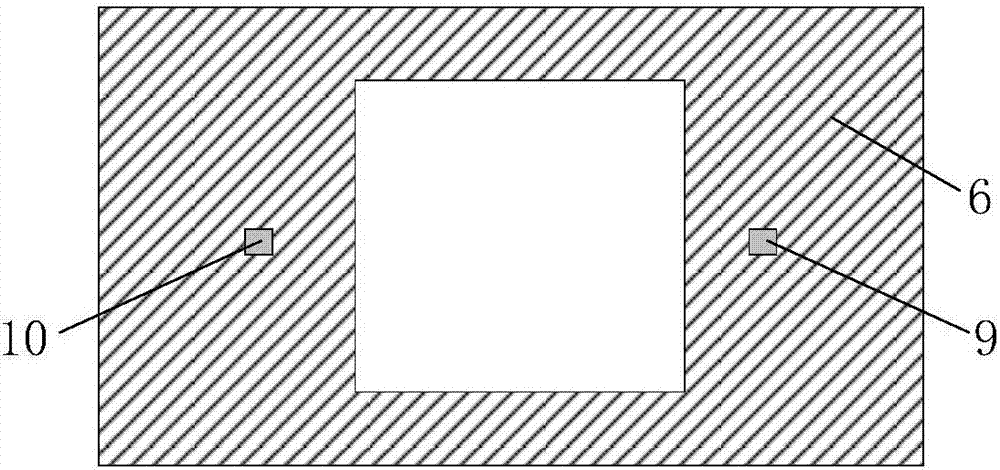

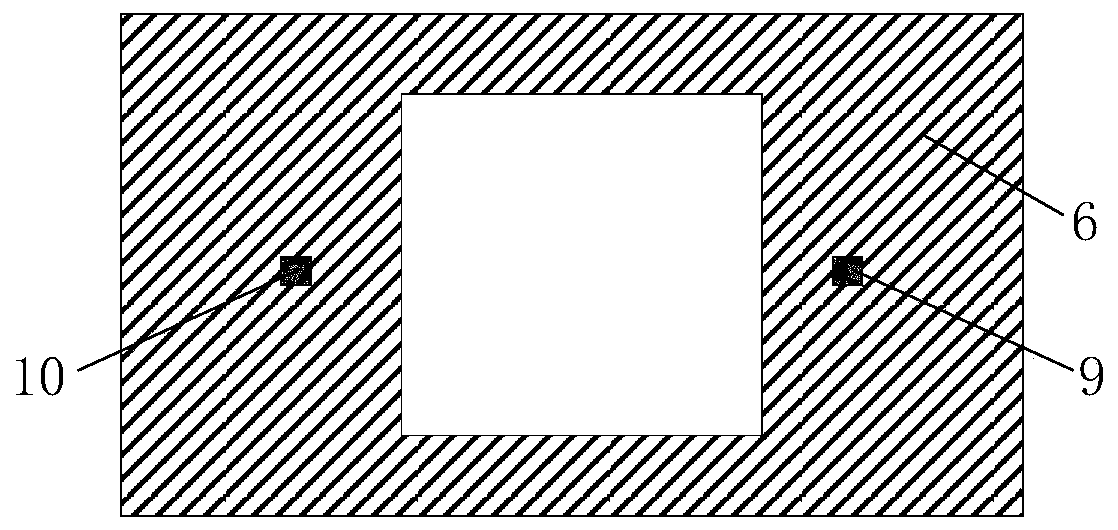

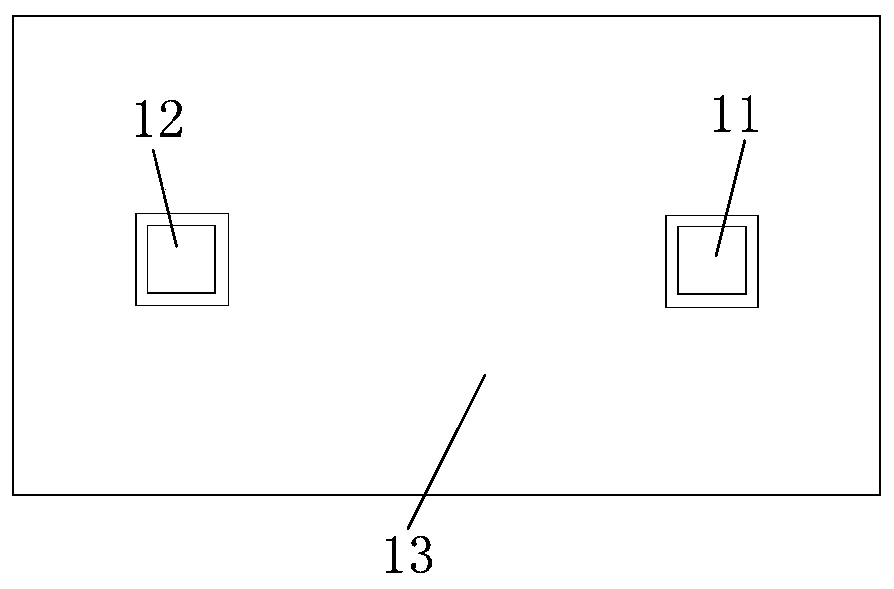

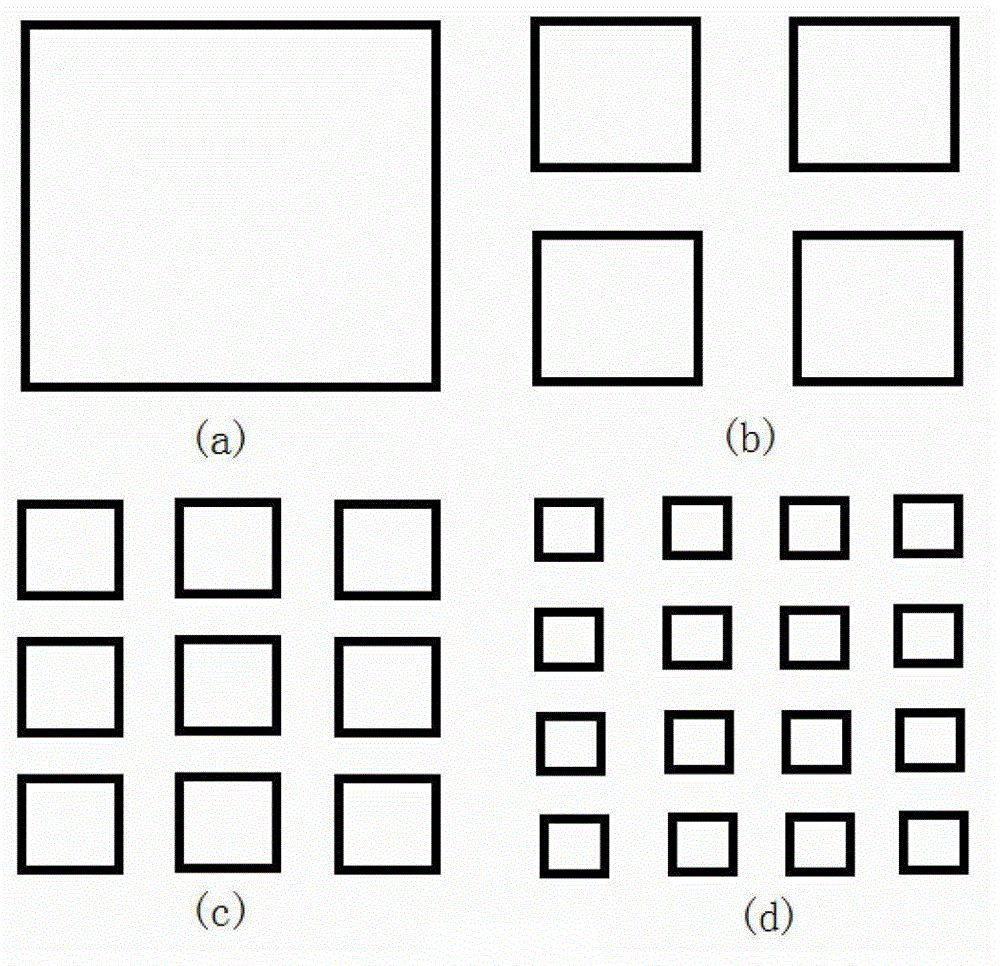

A method for enhancing the bonding strength of sog process microstructure

InactiveCN103011056BIncrease production costImprove processing yieldDecorative surface effectsChemical vapor deposition coatingUltimate tensile strengthAnchor point

The invention discloses a method for enhancing the bonding strength of an SOG (silicon on glass) process microstructure. According to the method, an operation of microstructure bonding is implemented by using a combined anchor point structure consisting of a plurality of anchor points. Preferably, the combined anchor point is in an array form. The number of the anchor points, through which the bonding strength of the combined anchor point structure is maximal, can be determined through a stretching or shear fracture test, and taken as the number of the anchor points in the combined anchor point. The size of gaps between the anchor points in the combined anchor point can be determined according to two factors including the minimum photoetching allowed spacing and the limited spacing for keeping the facilitation of stress release. The invention also provides an MEMS (micro-electromechanical system) device using the combined anchor point structure. According to the invention, the thermal mismatch stress caused in the technological process is reduced through a reasonable design on the distribution of the anchor points, so that the bonding strength of a microstructure manufactured based on an SOG process is enhanced, therefore, the technological rate of finished products can be significantly improved, and the reliability of the MEMS device manufactured based on the SOG process can be improved.

Owner:PEKING UNIV

Method and structure for manufacturing improved yield semiconductor packaged devices

InactiveUS6902956B2Improve reliabilityReduce thermal mismatch stressSemiconductor/solid-state device detailsSolid-state devicesElastomerSemiconductor package

A semiconductor package structure for a ball grid array type package using a plurality of pieces of adhesive elastomer film to attach a semiconductor die to a substrate having conductive traces in order to alleviate thermal mismatch stress between the semiconductor die and the printed circuit board to which the packaged device is soldered, while maintaining the reliability of the packaged device itself.

Owner:ROUND ROCK RES LLC

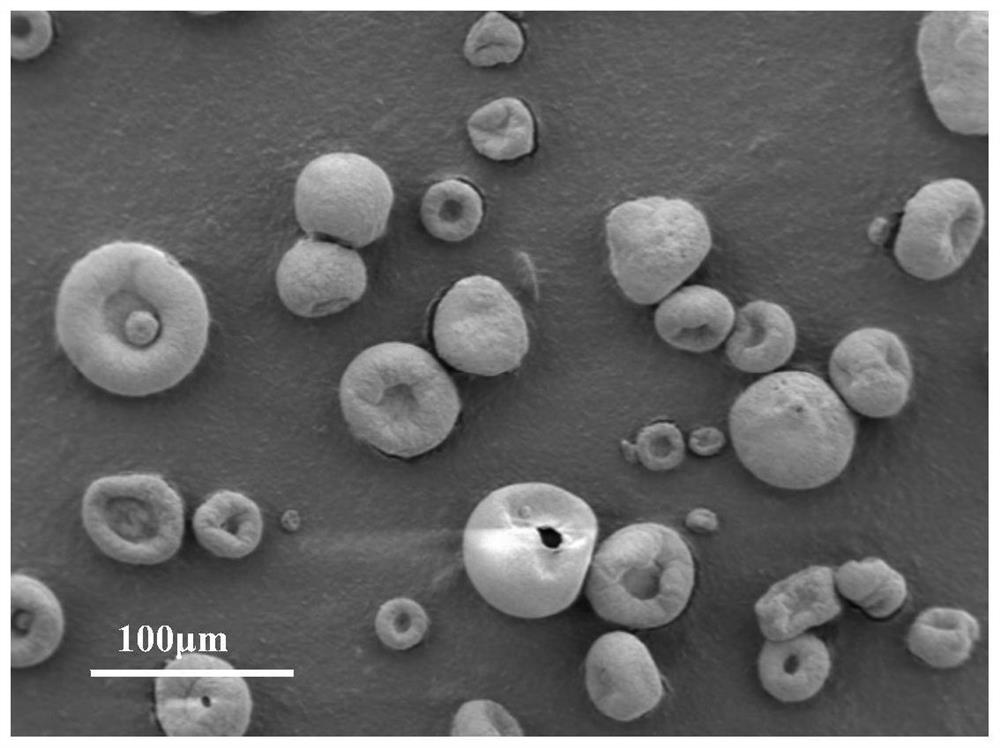

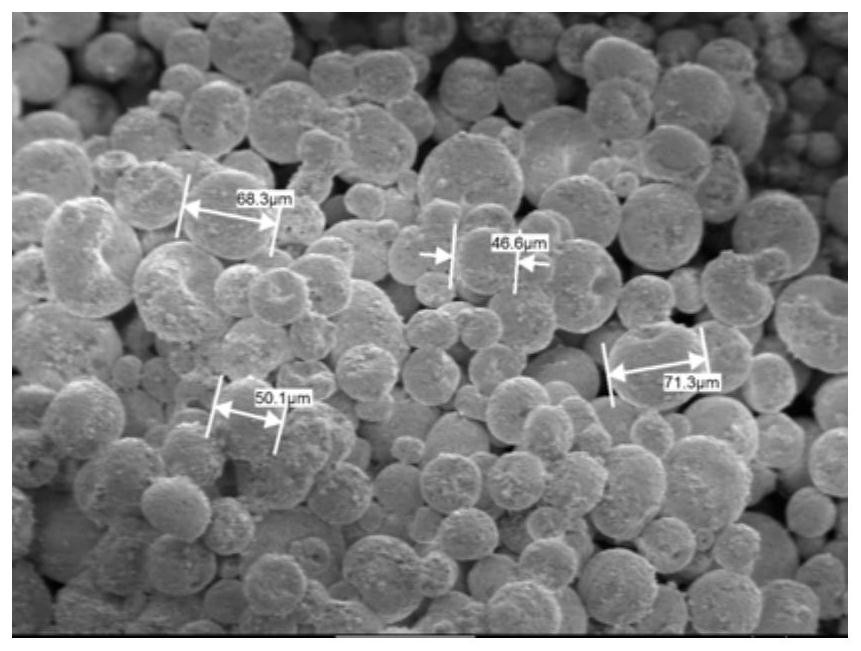

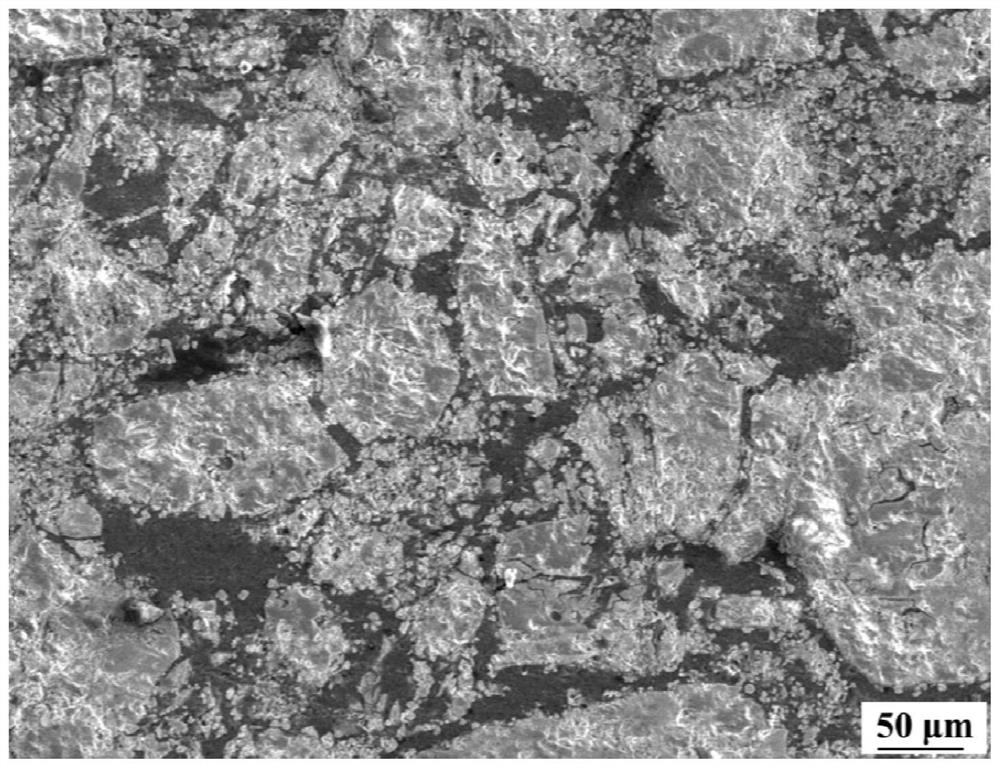

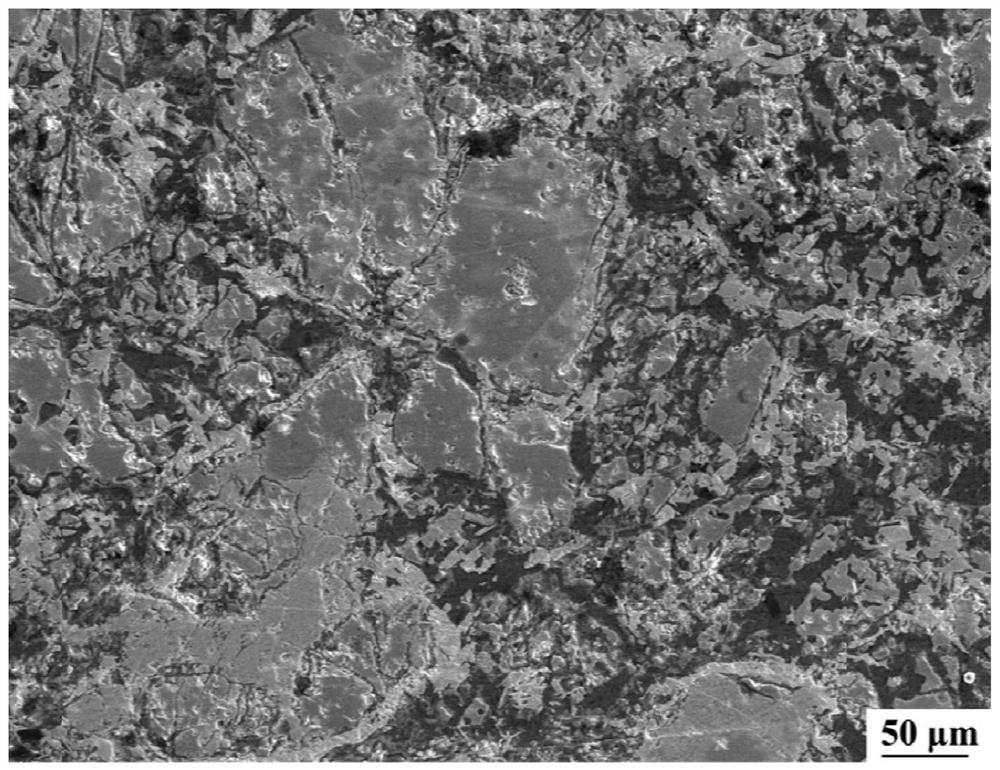

Aluminum-based composite material and semi-solid preparation method thereof

ActiveCN114836658AImprove surface active stateImprove the quenching methodIncreasing energy efficiencySemi solidSlurry

The invention discloses an aluminum-based composite material and a semi-solid preparation method thereof. The composite material comprises the following components in percentage by volume: 6-14% of ceramic particles and 86-94% of aluminum alloy. The preparation method comprises the steps of powder surface modification treatment, molten alloy liquid preparation, semi-solid slurry preparation, composite material blank preparation and composite material blank heat treatment. According to the method, the high-quality and low-cost composite material and the semi-solid near-net forming preparation thereof can be realized, the preparation of the high-quality aluminum-based composite material is realized through powder surface modification treatment, molten alloy liquid component design and a composite material heat treatment process, and the technological process is simple in flow, low in cost and high in yield.

Owner:福建祥鑫轻合金制造有限公司

High-temperature ceramic coating YSZ-RETAO 4 SIC base composite materials and their preparation methods

The invention relates to the technical field of composite materials, and specifically discloses a high-temperature ceramic coating YSZ-RETaO 4 The SiC-based composite material and its preparation method, weigh aluminum oxide, aluminum hydroxide, aluminum dihydrogen phosphate and calcium oxide, ball mill with absolute ethanol, mix evenly, dry and then sieve; pass the sieved powder SiC The substrate is embedded in an alumina ceramic boat and calcined at a high temperature to form a transition layer on the surface of the SiC substrate; YSZ and RETaO are coated by atmospheric plasma spraying 4 The powder is sprayed onto the surface of the transition layer to form a SiC composite material sprayed with a ceramic coating on the surface. The thermal conductivity of the silicon carbide-based composite material prepared in this patent is 0.67-0.82W·m ‑1 ·K ‑1 Between, to meet the use environment of ultra-high temperature 2200 ~ 2500 ℃.

Owner:KUNMING UNIV OF SCI & TECH +1

Non-polarized composite gallium nitride base substrate and production method

InactiveCN1845349AQuality improvementImprove heat transfer efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesGallium nitrideThermal treatment

The disclosed non-polar composite GaN-based substrate comprises overlays between the substrate and the GaN extension layer reflection / ohm / stress buffer layer. Wherein, the preparation method for the substrate comprises: on the growth substrate, growing middle medium layer (or crystal kernel) and the non-polar first GaN-based extension layer in turn; overlaying the mask layer; etching the mask to form the GaN window and mask layer strip; growing the non-polar second GaN extension layer; overlaying the reflection / ohm / stress buffer layer; bonding substrate; peeling the substrate, medium layer, the first extension layer, mask strip, and the part with hole on the second extension layer; exposing other part of the second extension layer for thermal treatment.

Owner:INVENLUX OPTOELECTRONICS (CHINA) CO LTD

C/C composite material with high-temperature ceramic coating layer MTaO4 and preparation method thereof

The invention relates to the technical field of composite materials, and particularly discloses a C / C composite material with a high-temperature ceramic coating layer MTaO4 and a preparation method thereof. The method comprises steps: weighing monocrystalline silicon, aluminum oxide and calcium oxide, carrying out ball milling together with absolute ethyl alcohol, uniformly mixing, drying, and screening; embedding a C / C composite matrix in an alumina porcelain boat by using screened powder, and carrying out high-temperature calcination to form a transition layer containing silicon carbide andaluminosilicate on the surface of the C / C composite matrix; and spraying MTaO4 powder to the surface of the transition layer by adopting an atmospheric plasma spraying method to form the C / C compositematerial of which the surface is sprayed with the MTaO4 ceramic coating layer. The C / C composite material obtained by adopting the method disclosed by the invention can resist the ultrahigh temperature of 2000 DEG C or above for 10-120 minutes, and keeps good oxidation resistance and ablation resistance.

Owner:KUNMING UNIV OF SCI & TECH +1

A kind of ysz-rare earth zirconate thermal barrier coating with gradient structure and its preparation method

InactiveCN108441807BImprove thermal shock resistanceReduce thermal mismatch stressMolten spray coatingOxide ceramicCoated surface

Owner:FUZHOU UNIV

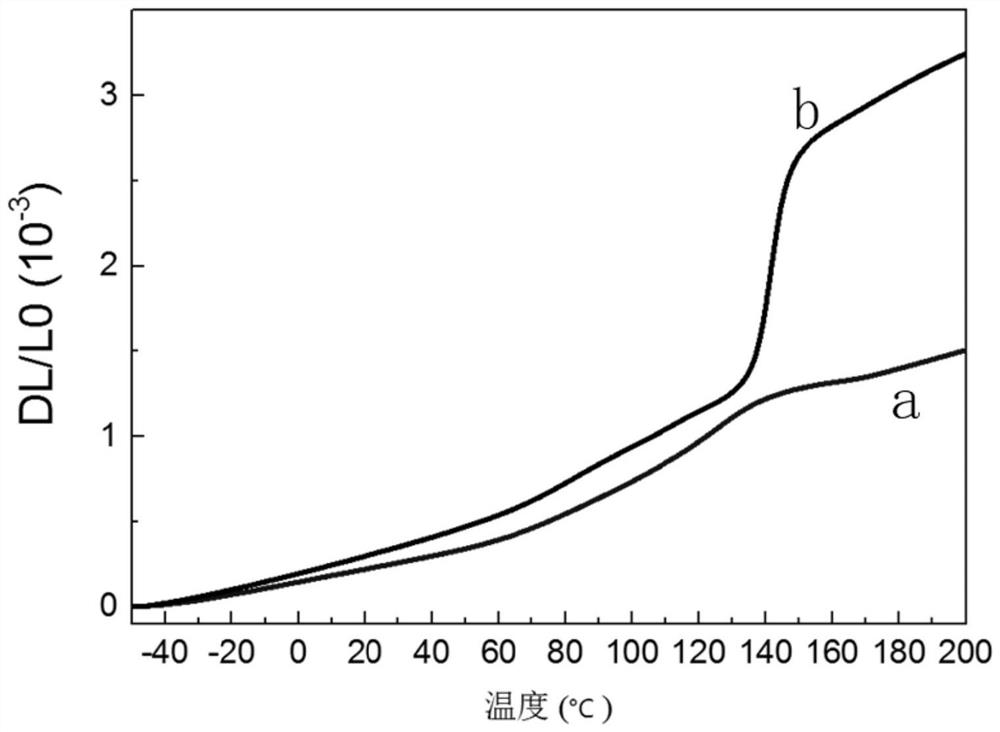

A kind of preparation method of low-expansion zirconium tungstate/aluminum composite material

ActiveCN114231784BReduce thermal mismatch stressSmall coefficient of thermal expansionThermal dilatationAluminium matrix

A preparation method of a low-expansion zirconium tungstate / aluminum composite material, relating to a low-expansion ZrW 2 O 8 / Al composite material preparation method. In order to solve the problem of excessive γ‑ZrW content in the zirconium tungstate / Al composite prepared by the existing method 2 O 8 This leads to the problem of a large thermal expansion coefficient of the composite material. Method: Weigh ZrW by volume fraction 2 O 8 powder and aluminum matrix; ZrW 2 O 8 The powder is placed in a molding die and pre-compressed, then sintered at high temperature and quenched to obtain ZrW 2 O 8 Preforms, impregnated with liquid aluminium. In the low-expansion zirconium tungstate / Al composite material prepared by the invention, the aluminum matrix and ZrW 2 O 8 The particles all have a continuous structure, which reduces the γ‑ZrW in the as-cast zirconium tungstate / Al composites 2 O 8 content. The internal stress is reduced by stress relief annealing treatment, thereby reducing the thermal expansion coefficient of zirconium tungstate / Al composites. The invention is suitable for preparing zirconium tungstate / aluminum composite material.

Owner:HARBIN INST OF TECH

Indium gallium nitride thin film on flexible transparent polyimide substrate and preparation method thereof

ActiveCN108831823BReduce thermal mismatch stressPrevent volatilizationSemiconductor/solid-state device manufacturingChemical vapor deposition coatingIndiumConductive materials

The invention belongs to the technical field of manufacturing of group-III nitride thin films and devices and provides an indium gallium nitride thin film on a flexible transparent polyimide substrateand a preparation method of the indium gallium nitride thin film. Polyimide is taken as a substrate and a first In<x>Ga<1-x>N buffer layer, a graphene layer, a one-dimensional nano-conductive material layer, a second In<x>Ga<1-x>N buffer layer and an In<x>Ga<1-x>N epitaxial layer are sequentially prepared on one side surface of the polyimide substrate from inside to outside, wherein the first In<x>Ga<1-x>N buffer layer, the second In<x>Ga<1-x>N buffer layer and the In<x>Ga<1-x>N epitaxial layer all are prepared by using an electron cyclotron resonance-plasma enhanced metal organic chemical vapor deposition method at low temperature; and the graphene layer and the one-dimensional nano-conductive material layer are prepared by using a spin coating method, so that the prepared high-quality In<x>Ga<1-x>N thin film can be used for preparing flexible transparent devices, such as an indium gallium nitride-based solar cell and a thin-film transistor and has a broad application prospect.

Owner:DALIAN UNIV OF TECH

Non-polarized composite gallium nitride base substrate and production method

InactiveCN100547816CQuality improvementReduce defectsSemiconductor/solid-state device manufacturingSemiconductor devicesGallium nitrideMedia layer

Owner:INVENLUX OPTOELECTRONICS (CHINA) CO LTD

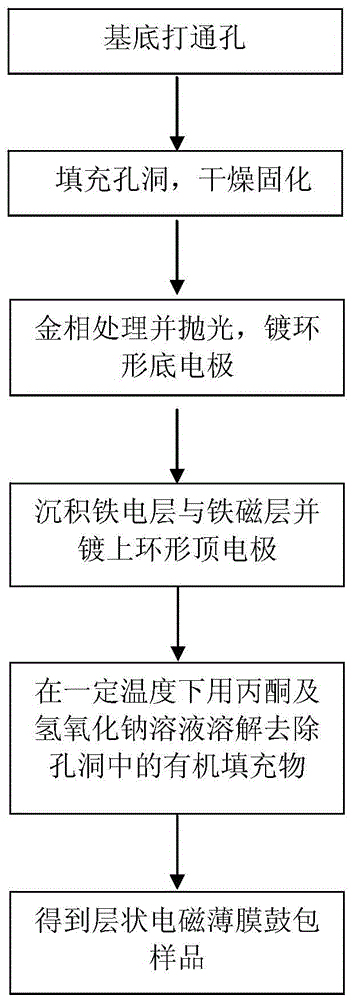

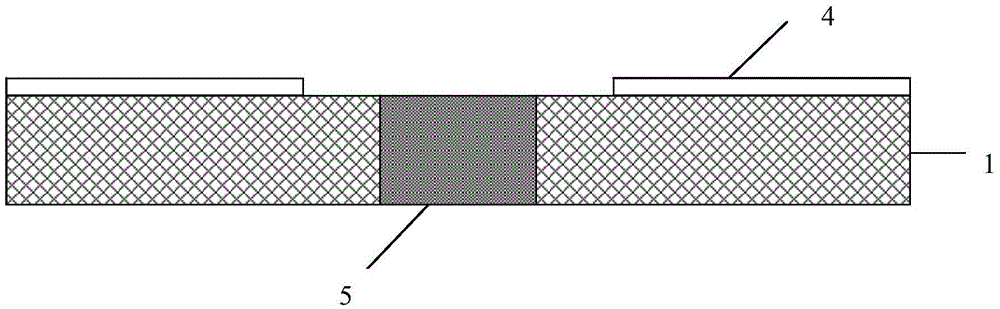

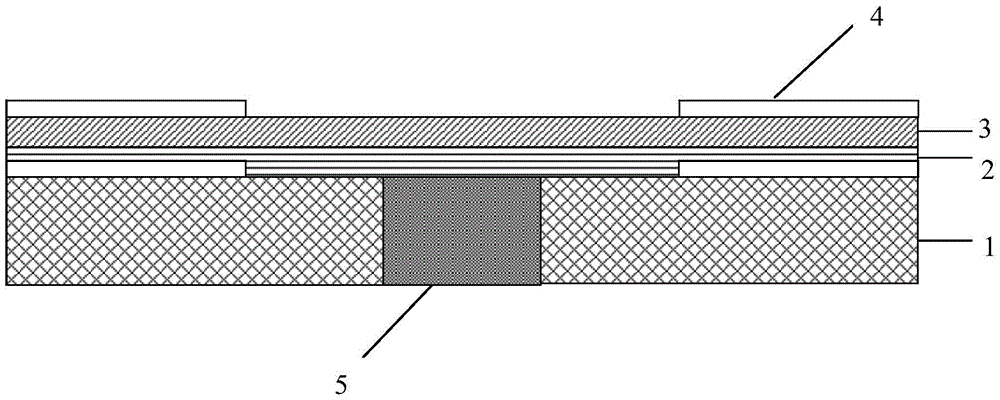

A kind of preparation method of bulge sample of layered electromagnetic thin film material

ActiveCN103762307BMeet the requirements of different annealing temperaturesHigh affinityGalvano-magnetic device manufacture/treatmentFerroelectric thin filmsMixed materials

Owner:湖南新生代新材料科技有限公司

Electric non-polarized composite gallium nitride base substrate and production method

InactiveCN100547817CQuality improvementReduce defectsSemiconductor/solid-state device manufacturingSemiconductor devicesGallium nitrideThermal treatment

The disclosed processing steps for a conductive non-polar composite GaN substrate comprise: on the growth substrate, growing middle medium layer (or crystal kernel) and the non-polar first GaN-based extension layer in turn; overlaying the mask layer to etch and form the GaN window and mask layer strip; growing the non-polar second GaN extension layer; overlaying the conductive reflection / ohm / stress buffer layer; bonding substrate; then, peeling the substrate, medium layer, the first extension layer, mask strip, and the part with hole on the second extension layer for thermal treatment.

Owner:INVENLUX OPTOELECTRONICS (CHINA) CO LTD

A double-layer coating for metal workpieces suitable for high-temperature environments and its manufacturing method

The invention discloses a metal workpiece double layer coating suitable for high temperature environment and a manufacturing method thereof. The manufacturing method of the metal workpiece double layer coating suitable for the high temperature environment includes the following steps of 1) pretreatment: degreasing the surface of a metal workpiece, sandblasting roughening and cleaning; 2) spraying:preheating the pretreated metal workpiece, adopting an atmospheric plasma spraying device for spraying, first spraying a ceramic inner layer on the surface of the metal workpiece, then heating and spraying a metal outer layer and then spraying a metal layer on the side of an obtained coating; 3) heat treatment: conducting vacuum heat treatment on the sprayed metal workpiece and conducting gas quenching. According to the manufacturing method, the metal layer is sprayed on the ceramic layer. On one hand, the high cost of ceramic precision machining is reduced; on the other hand, various corrosion-resistant or wear-resistant alloy materials can be applied. In addition, the melting point of metal is lower than that of the ceramic, and the mechanical properties of the coating can be changed bythe heat treatment process.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com