Compact ferroelastic dual rare earth tantalate solid solution high-temperature ceramic and preparation method thereof

A high-temperature ceramic and double rare earth technology, applied in the field of high-temperature thermal barrier coating materials, can solve the problems of low operating temperature, low thermal expansion coefficient, and high thermal conductivity of YSZ, and achieve high-temperature phase stability, high purity, and improved fracture toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

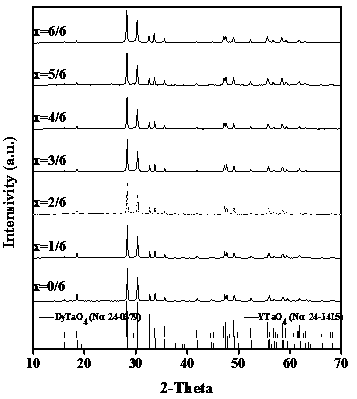

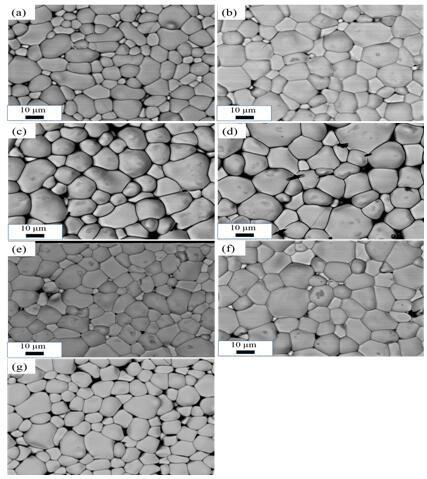

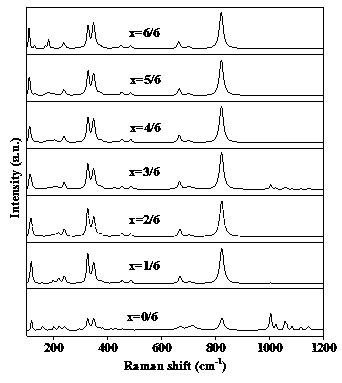

[0026] A method for preparing dense ferroelastic double rare earth tantalate solid solution high-temperature ceramics, the specific steps are:

[0027] (1) According to double rare earth tantalate (Y 1-x Dy x )TaO 4 (x=1 / 6) The stoichiometric ratio of solid solution ceramics weighs the rare earth oxide (Y 2 o 3 , Dy 2 o 3 ) and tantalum pentoxide (Ta 2 o 5 ), and then the materials rare earth oxide and tantalum pentoxide were ball milled and mixed to obtain mixed powder A. The mass ratio of material to balls was 4:1, the milling speed was 300 r / min, and the milling time was 24 h.

[0028] (2) The mixed powder A in step (1) was dried by rotary evaporation, the evaporation temperature was 50 ̊C, and the evaporation time was 1h.

[0029] (3) Pass the mixed powder A obtained in step (2) through a 300-mesh sieve and place it in a mold to compact it into a rough embryo, with a pressure of 6 MPa and a holding time of 3 min.

[0030] (4) Press the rough embryo obtained in st...

Embodiment 2

[0034] A method for preparing dense ferroelastic double rare earth tantalate solid solution high-temperature ceramics, the specific steps are:

[0035] (1) According to double rare earth tantalate (Y 1-x Dy x )TaO 4 (x=2 / 6) The stoichiometric ratio of solid solution ceramics weighs the rare earth oxide (Y 2 o 3 , Dy 2 o 3 ) and tantalum pentoxide (Ta 2 o 5 ), and then the materials rare earth oxide and tantalum pentoxide were ball milled and mixed to obtain mixed powder A. The mass ratio of material to balls was 4:1, the milling speed was 300 r / min, and the milling time was 24 h.

[0036] (2) The mixed powder A in step (1) was dried by rotary evaporation, the evaporation temperature was 50 ̊C, and the evaporation time was 1h.

[0037] (3) Pass the mixed powder A obtained in step (2) through a 300-mesh sieve and place it in a mold to compact it into a rough embryo, with a pressure of 6 MPa and a holding time of 3 min.

[0038] (4) Press the rough embryo obtained in st...

Embodiment 3

[0042] A method for preparing dense ferroelastic double rare earth tantalate solid solution high-temperature ceramics, the specific steps are:

[0043] (1) According to double rare earth tantalate (Y 1-x Dy x )TaO 4 (x=3 / 6) The stoichiometric ratio of solid solution ceramics weighs the rare earth oxide (Y 2 o 3 , Dy 2 o 3 ) and tantalum pentoxide (Ta 2 o 5 ), and then the materials rare earth oxide and tantalum pentoxide were ball milled and mixed to obtain mixed powder A. The mass ratio of material to balls was 4:1, the milling speed was 300 r / min, and the milling time was 24 h.

[0044] (2) The mixed powder A in step (1) was dried by rotary evaporation, the evaporation temperature was 50 ̊C, and the evaporation time was 1h.

[0045] (3) Pass the mixed powder A obtained in step (2) through a 300-mesh sieve and place it in a mold to compact it into a rough embryo, with a pressure of 6 MPa and a holding time of 3 min.

[0046] (4) Press the rough embryo obtained in st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com