Method for improving low temperature impact toughness of 40CrNiMoA material

A low-temperature impact toughness and low-temperature technology, applied in the field of cryogenic treatment and heat treatment, can solve the problems of adverse effects of 40CrNiMoA material design and application, lack of data and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Cool the 40CrNiMoA material after vacuum oil quenching and vacuum high-temperature tempering to -80°C at a rate of 2°C / min, and keep it warm for 0.5h;

[0016] Then continue to cool down to -180°C at a rate of 2°C / min, and hold for 3 hours; then heat the 40CrNiMoA material to 160°C at a heating rate of 2°C / min, and hold for 2 hours; cool with the furnace after the low-temperature tempering process.

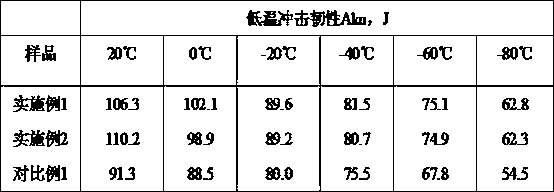

[0017] The treated 40CrNiMoA material was tested for low-temperature impact performance at different temperatures. The test method used was the national standard GB / T 229-2007 "Metallic Materials Charpy Pendulum Impact Test Method". The test results are shown in Table 1.

Embodiment 2

[0019] Cool the 40CrNiMoA material (the material is the same as in Example 1) after vacuum oil quenching and vacuum high-temperature tempering to -85°C at a rate of 3°C / min, and keep it for 1h; then continue to cool down to -180°C at a rate of 3°C / min ℃, holding for 2h; then heating the 40CrNiMoA material to 170°C at a heating rate of 3°C / min, holding for 2h; cooling with the furnace after the low-temperature tempering process.

[0020] The treated 40CrNiMoA was tested for low-temperature impact performance at different temperatures. The test methods used were all based on the national standard GB / T 229-2007 "Metallic Materials Charpy Pendulum Impact Test Method". The test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com