Comprehensive control method for pressure position of hot continuous rolling rolled side guide plate

A comprehensive control and pressure control technology, applied in tension/pressure control, rolling mill control devices, metal rolling, etc., can solve the problems of short service life of the side guide plate, wear of the coiling side guide plate, scratches on the edge of the strip, etc. Achieve the effect of improving the stability of production operation, shortening the replacement cycle and reducing downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

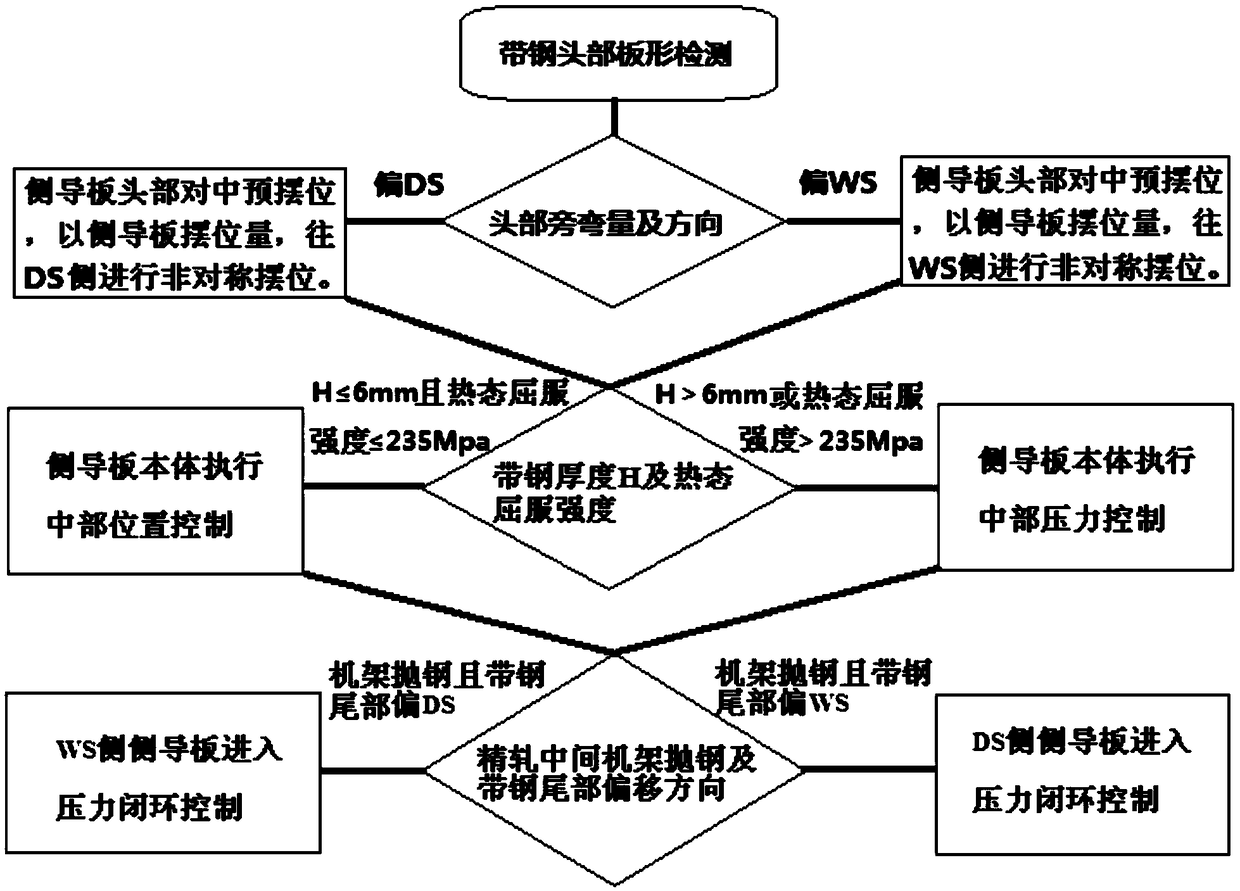

Method used

Image

Examples

Embodiment 1

[0081] In the embodiment of the present invention, a method for comprehensively controlling the pressure position of the coiling side guide plate of hot continuous rolling is applied to the production of cold-rolled plain steel with a finished product size of 3.5*1550mm (the yield strength in the hot state is about 150Mpa), and includes the following steps:

[0082] (1) Strip head shape detection:

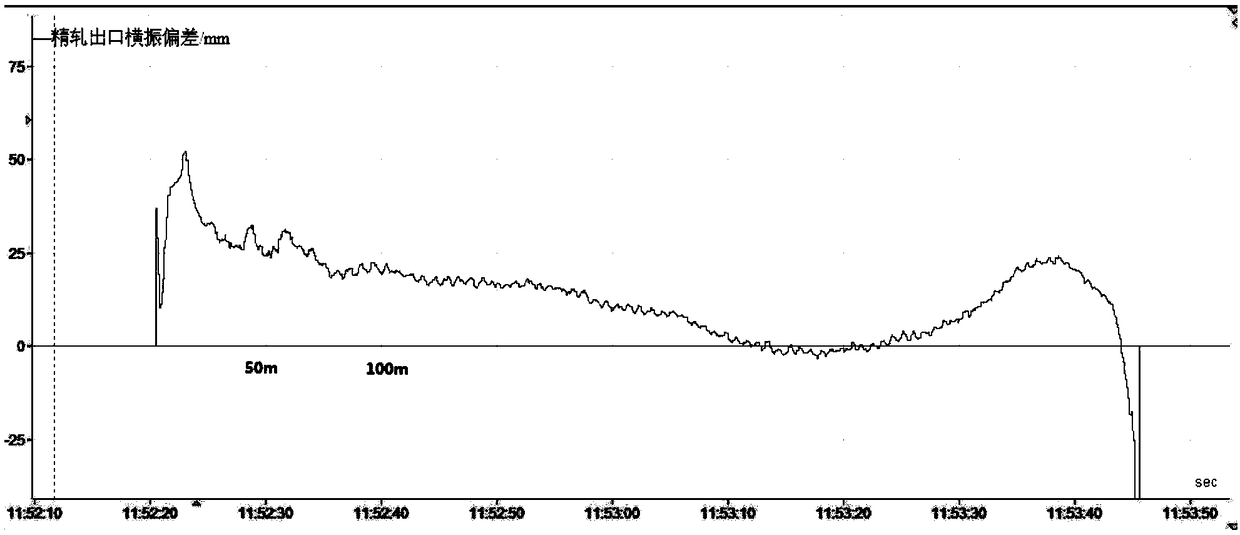

[0083] Detect the side bending of the strip head and the offset value of the strip body at the exit of the finishing mill. Specifically, the transverse vibration curve of the exit of the strip is obtained by using the exit width gauge of the exit of the strip. The exit of the strip of this type is The lateral vibration curve is as figure 2 shown;

[0084] According to the transverse vibration curve at the exit of finishing rolling, the maximum value Dev of the transverse vibration within 50m of the strip head can be calculated. max and the minimum Dev min , and within the range...

Embodiment 2

[0111] In an embodiment of the present invention, a method for comprehensively controlling the pressure position of the coiling side guide plate of hot continuous rolling is applied to the production of automobile frame steel with a finished product size of 8*1500mm (the yield strength in the hot state is about 355Mpa), and includes the following steps:

[0112] (1) Strip head shape detection:

[0113] The exit transverse vibration curve of this type of strip steel is as follows: Figure 4 As shown, according to the exit transverse vibration curve of the finishing rolling, the maximum value Dev of the transverse vibration within 50m of the strip head can be calculated max and the minimum Dev min , and within the range of 50m to 100m of strip steel (corresponding Figure 4 From 12:08:35 to 12:08:55) mean value of horizontal vibration Dev ave ; take Dev max -Dev ave with Dev min -Dev ave The larger difference in the middle value is taken as the side bending amount of the ...

Embodiment 3

[0131] In an embodiment of the present invention, a method for comprehensively controlling the pressure position of the coiling side guide plate in hot continuous rolling is applied to the production of wheel steel with a finished product size of 4*1300mm (the yield strength in the hot state is about 500Mpa), and includes the following steps:

[0132] (1) Strip head shape detection:

[0133] The exit transverse vibration curve of this type of strip steel is as follows: Image 6 As shown, according to the exit transverse vibration curve of the finishing rolling, the maximum value Dev of the transverse vibration within 50m of the strip head can be calculated max and the minimum Dev min , and within the range of 50m to 100m of strip steel (corresponding Image 6 From 11:58:40 to 11:58:53) the average value of the horizontal vibration Dev ave ; take Dev max -Dev ave with Dev min -Dev ave The larger difference in the middle value is taken as the side bending amount of the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com