Cold extrusion strengthening method for assembling hole of CFRP composite material laminate

A composite material layer and assembly hole technology, which is applied in the direction of chemical instruments and methods, lamination, and lamination auxiliary operations, can solve the problems that the assembly holes of CFRP composite laminates have not attracted widespread attention, the fatigue performance of CFRP composite components is reduced, Affect aircraft durability design and other issues to achieve the effect of improving notch sensitivity, helping maintenance, and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In the detailed description of the following embodiments, the detailed embodiments and the specific operation process are given on the premise of the technical solution of the present invention, but the protection scope of the present invention is not limited to the following embodiments.

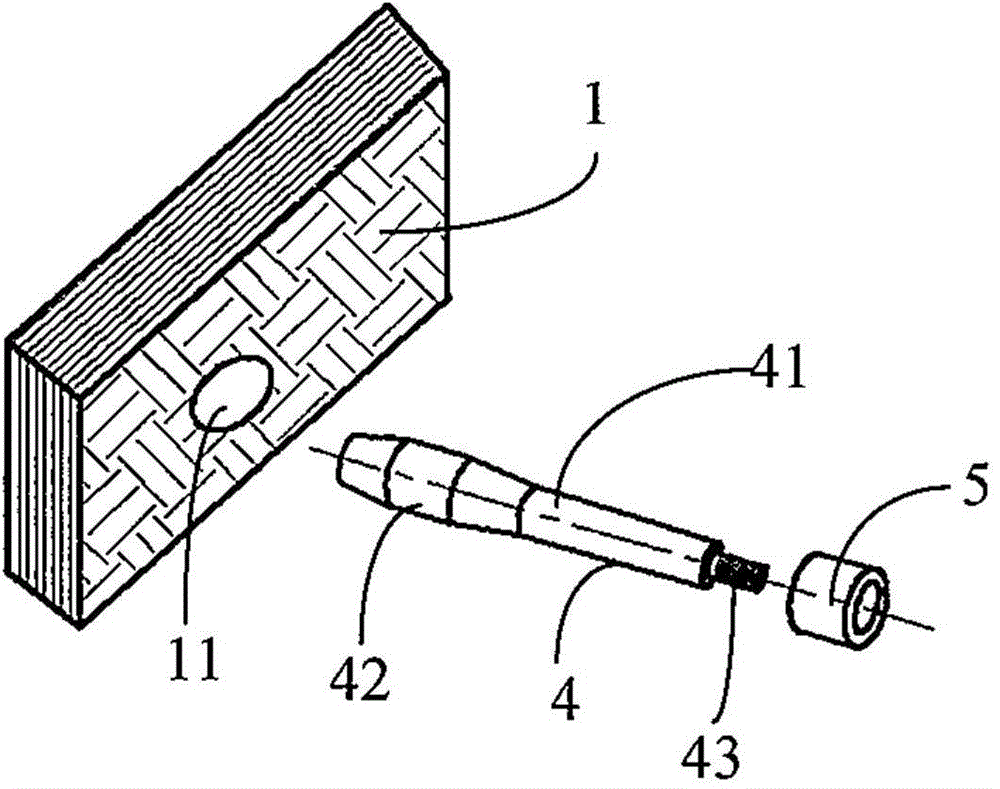

[0034] Combine below Figure 1 to Figure 7 The technical scheme of the present invention is further described. Figure 1 to Figure 7 The operation process of the cold extrusion strengthening method of the assembly hole of the CFRP composite laminate according to an embodiment of the present invention is illustrated in sequence, and the specific operation is as follows:

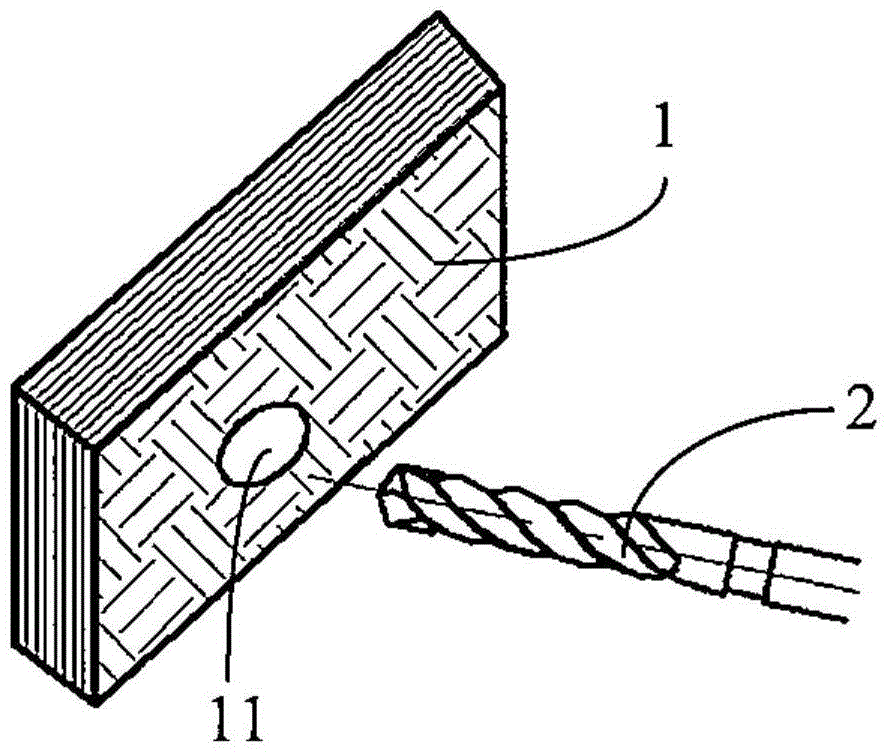

[0035] Step 1: Use, for example, a cemented carbide drill bit 2 to drill the CFRP composite laminate 1 to ensure that there is no delamination of the composite laminate at the entrance and exit of the assembly hole 11, such as figure 1 shown;

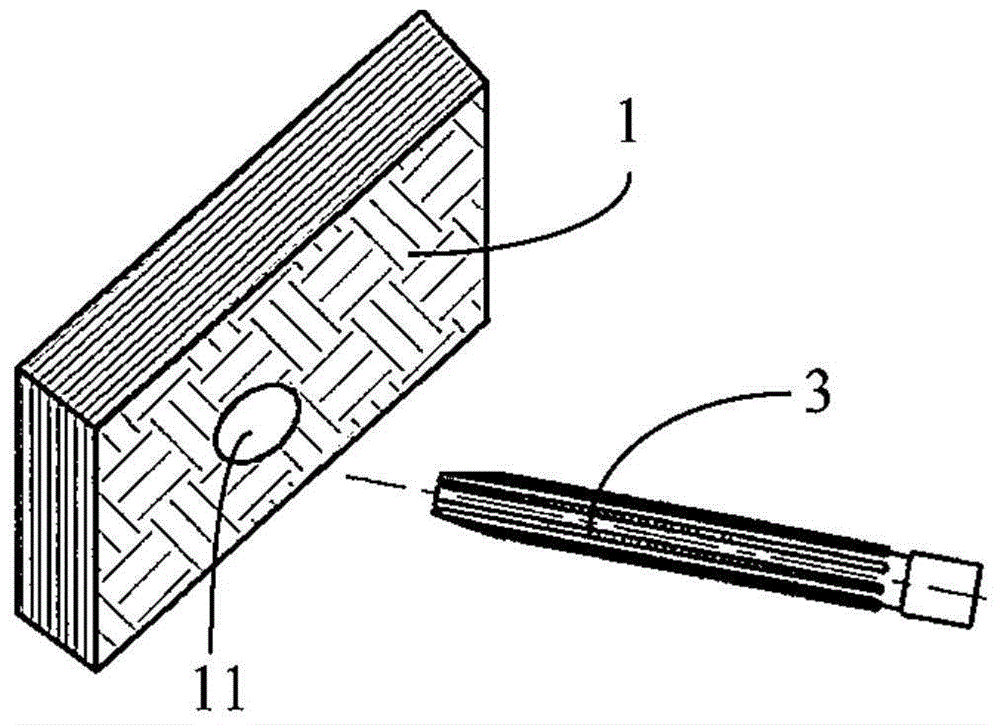

[0036] Step 2: Use the reamer 3 to ream the assembly hole 11 drilled in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com