Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

100results about How to "Improve squareness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

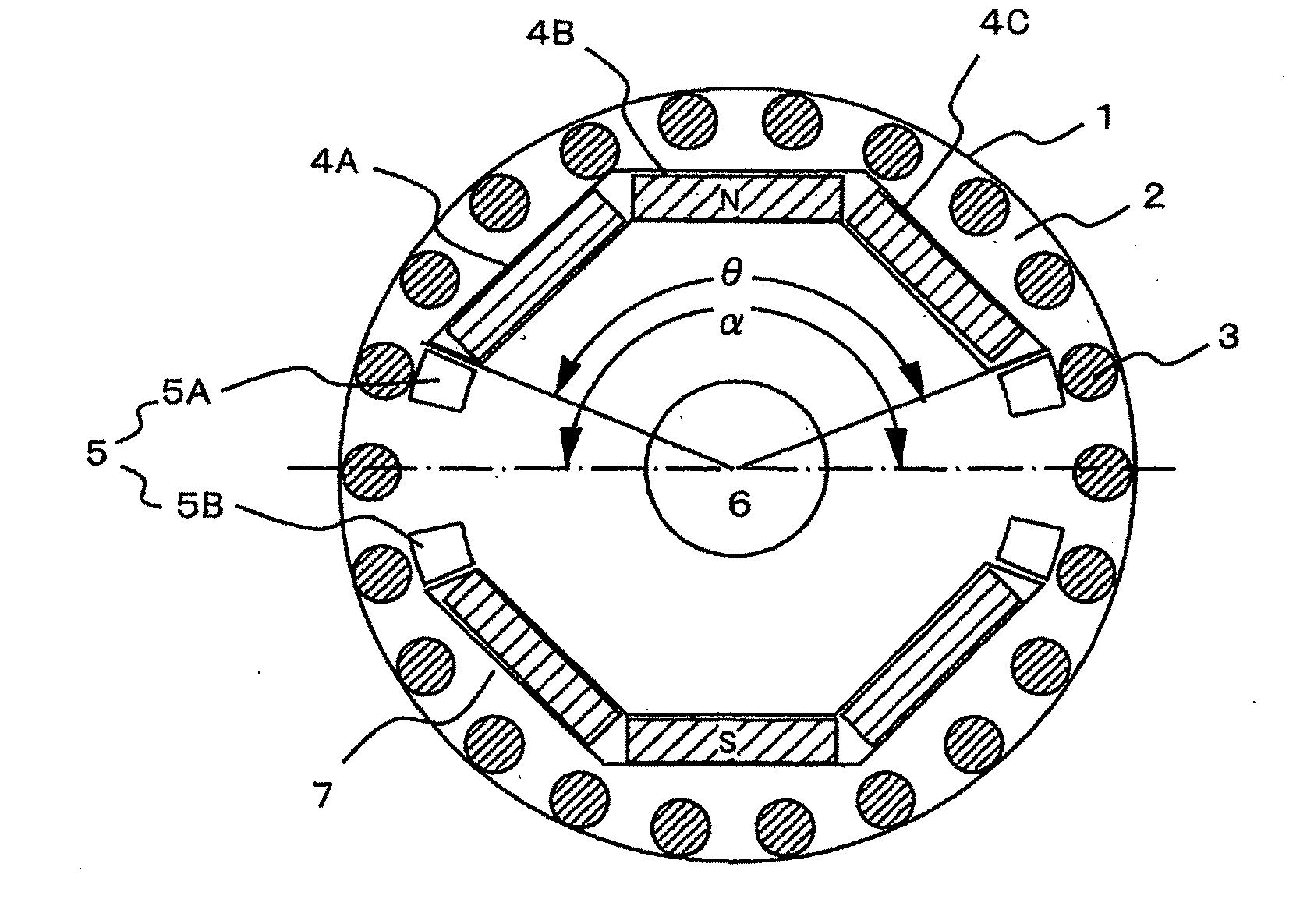

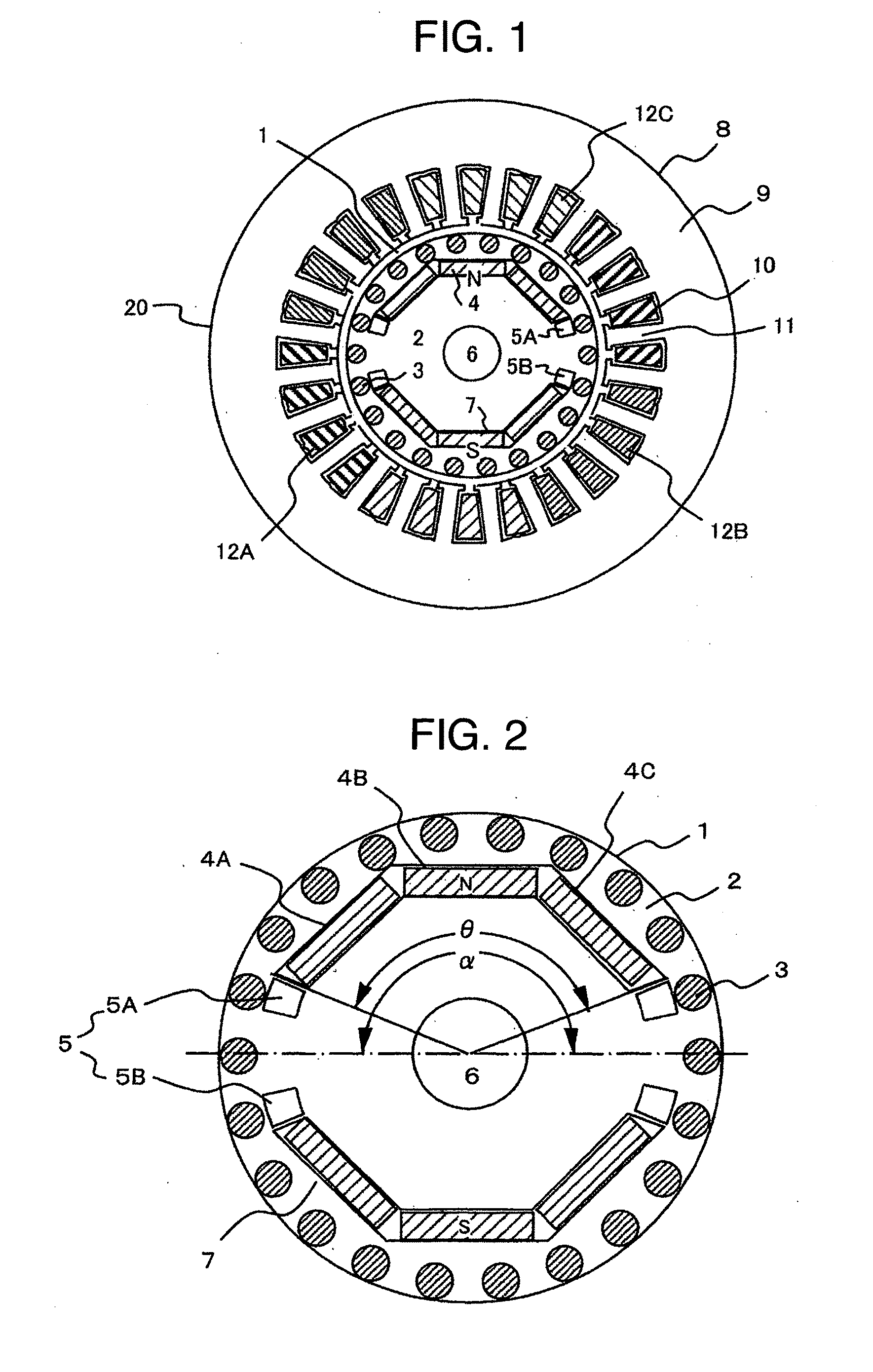

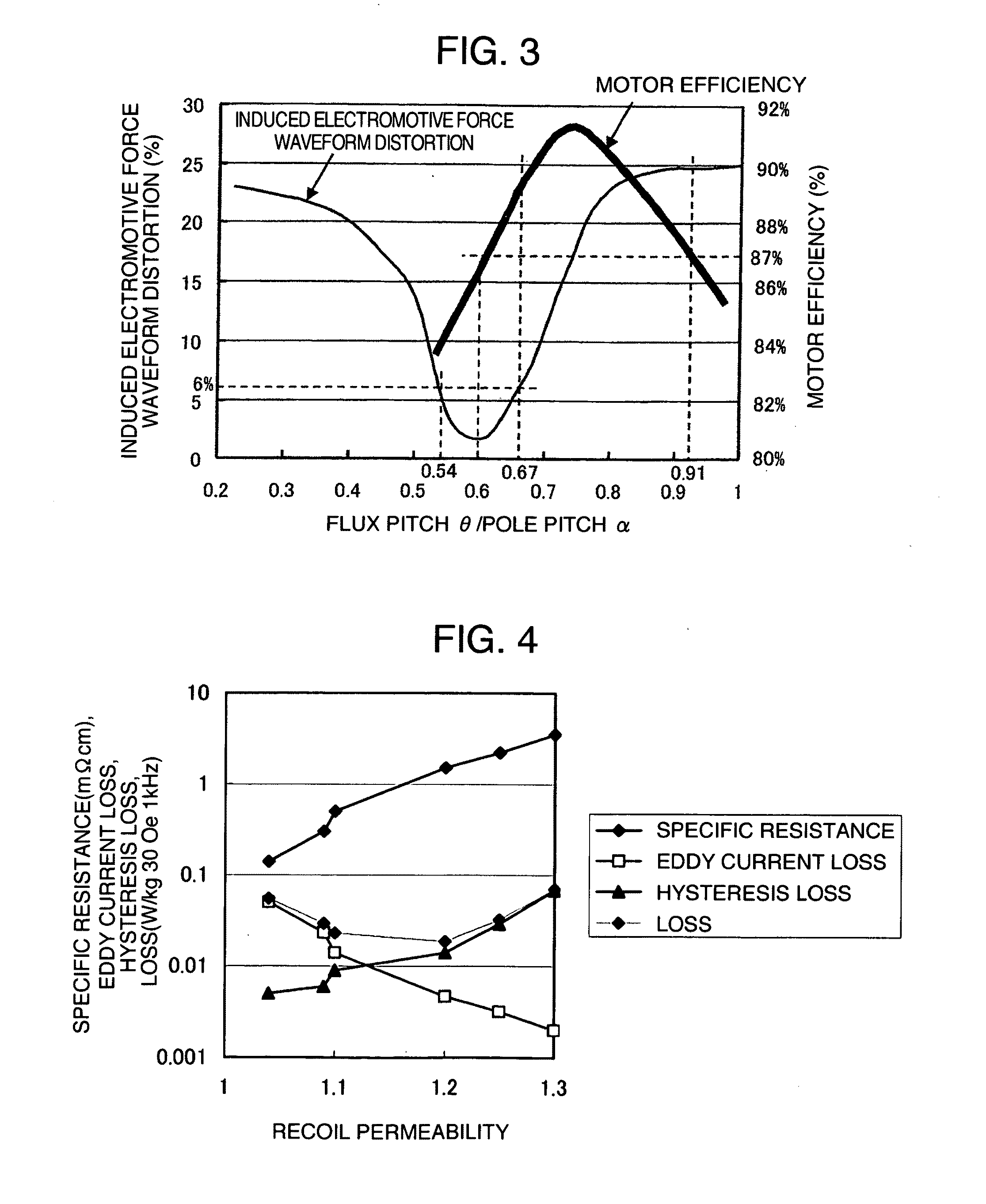

Self starting permanent magnet synchronous motor

InactiveUS20090200885A1Increase resistanceImprove the immunityTransportation and packagingMetal-working apparatusMagnetizationPermanent magnet synchronous motor

The present invention provides a permanent magnet that a fluorine compound is formed on the surfaces of Fe-based magnetic particles, and a recoil permeability is determined in a range of 1.05 to 1.30 by controlling an iron concentration in the fluorine compound to a range of 1 to 50% to reduce a loss due to magnetization rotation, thereby remedying reduction of a residual magnetic flux density and degradation of steady-state characteristics.

Owner:HITACHI LTD

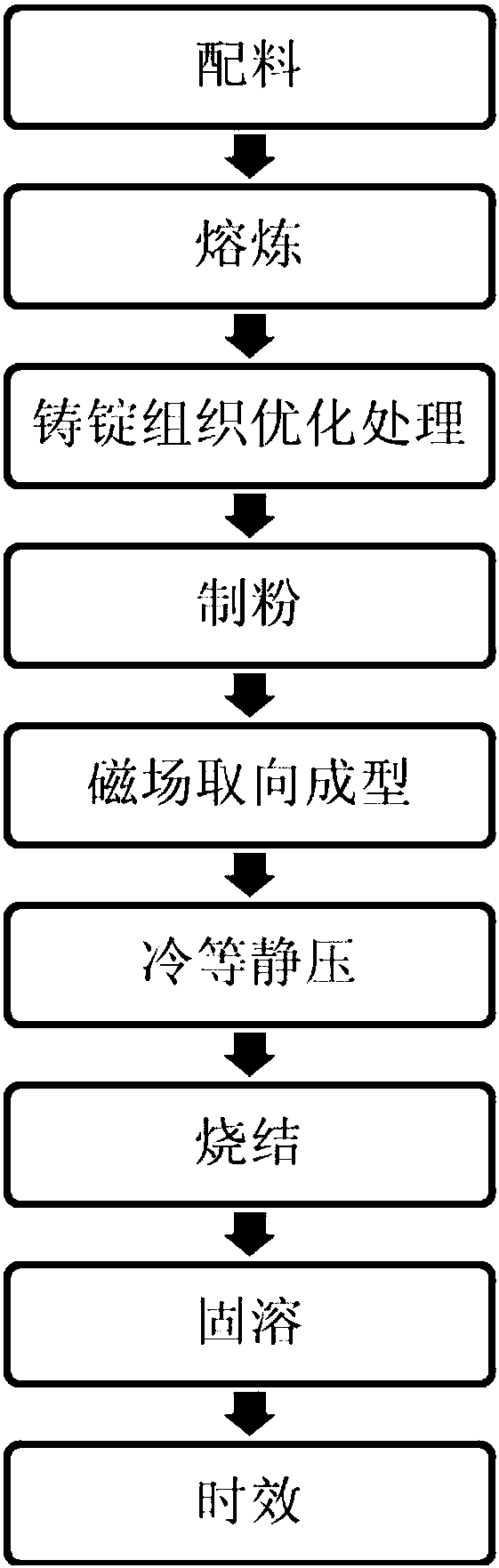

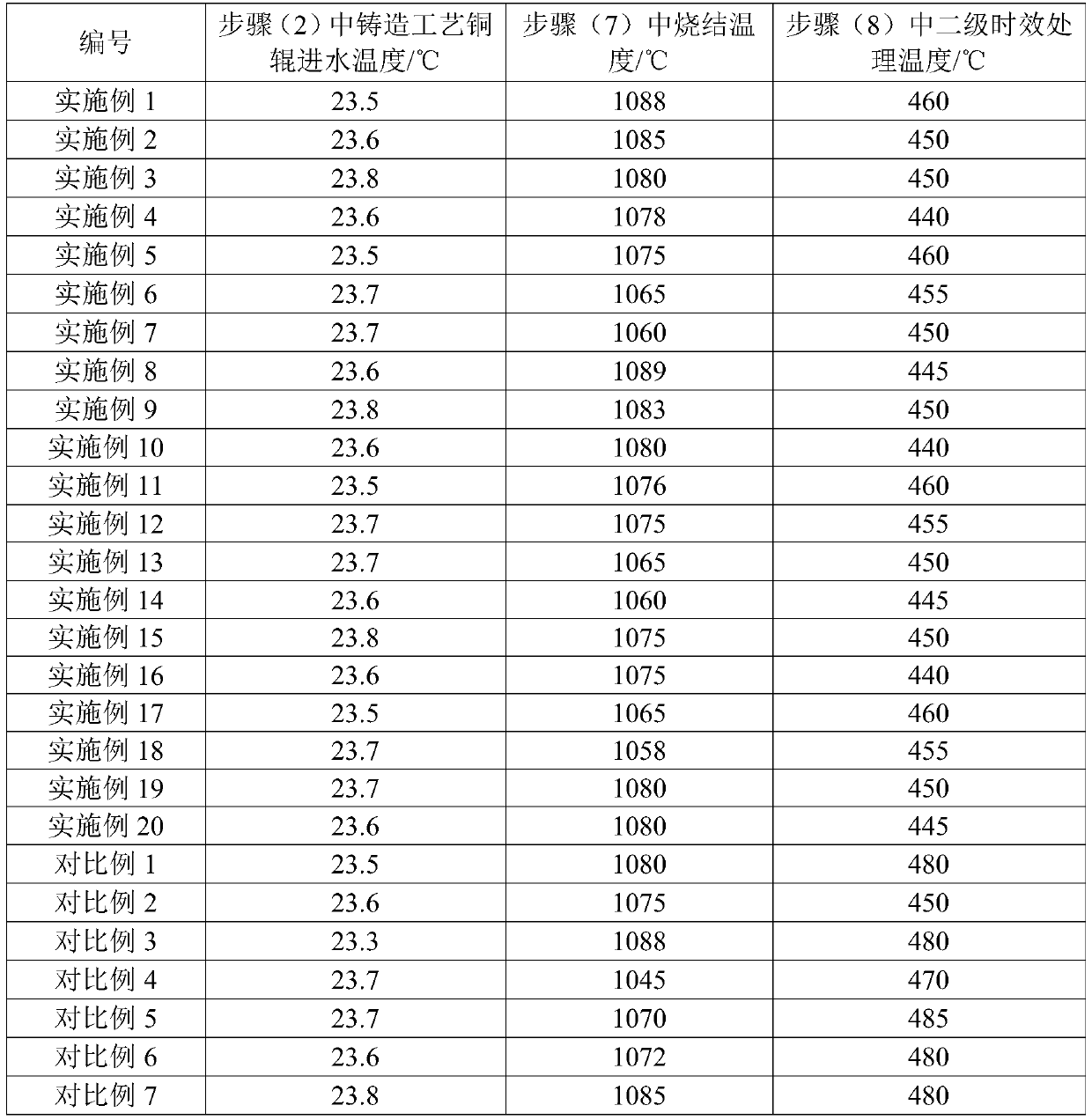

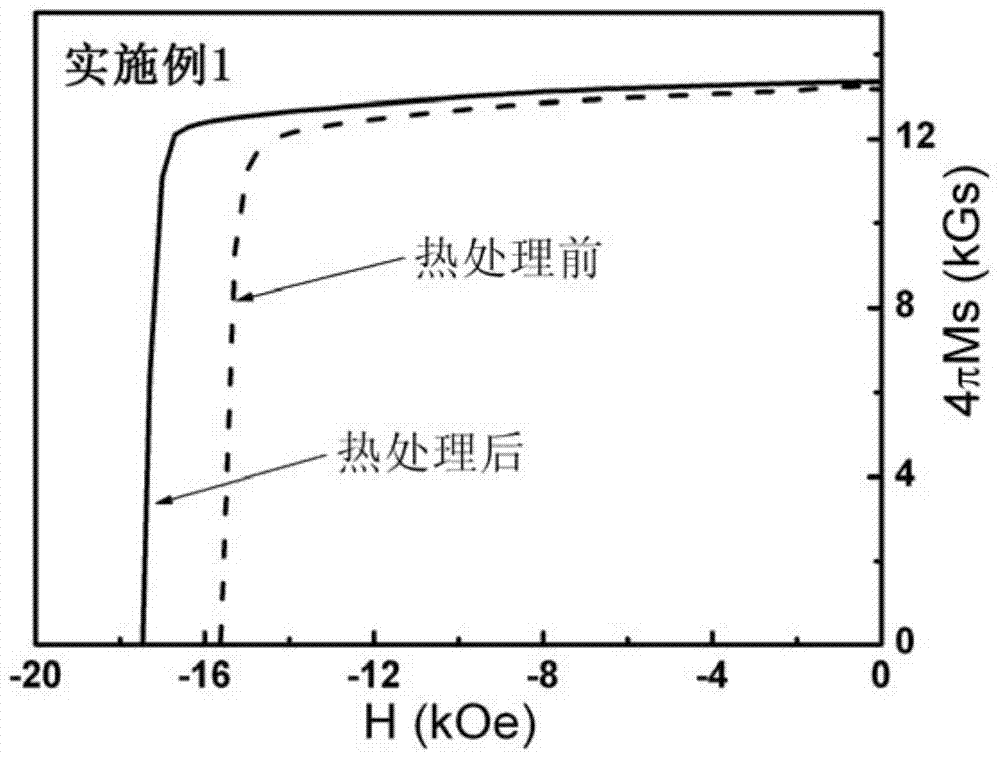

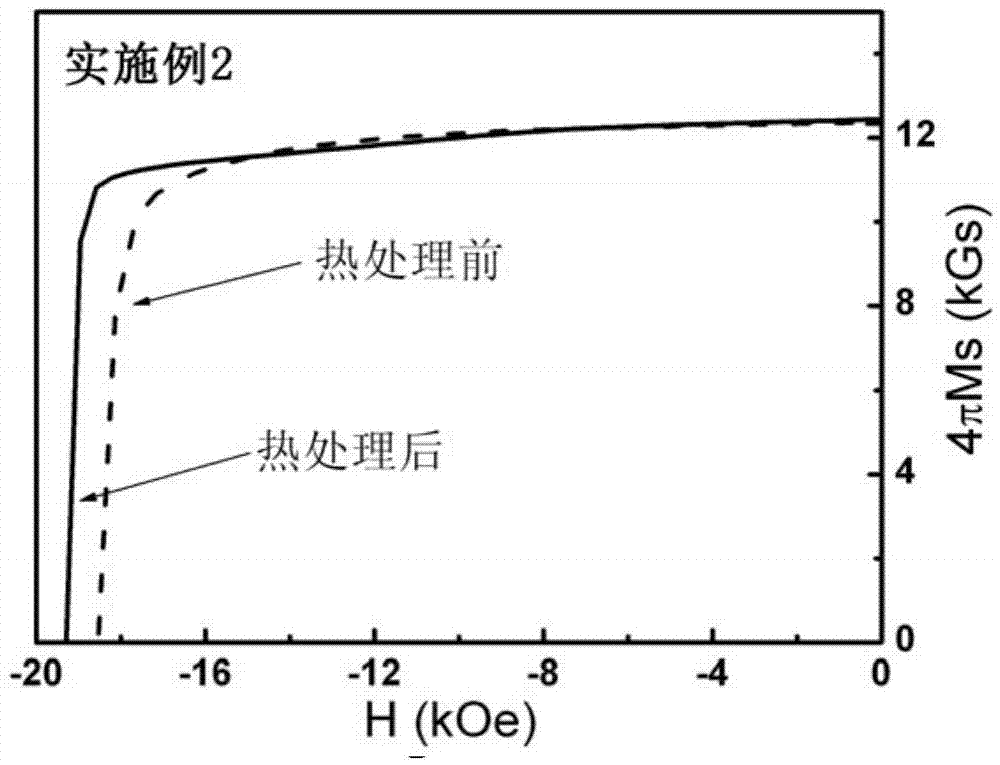

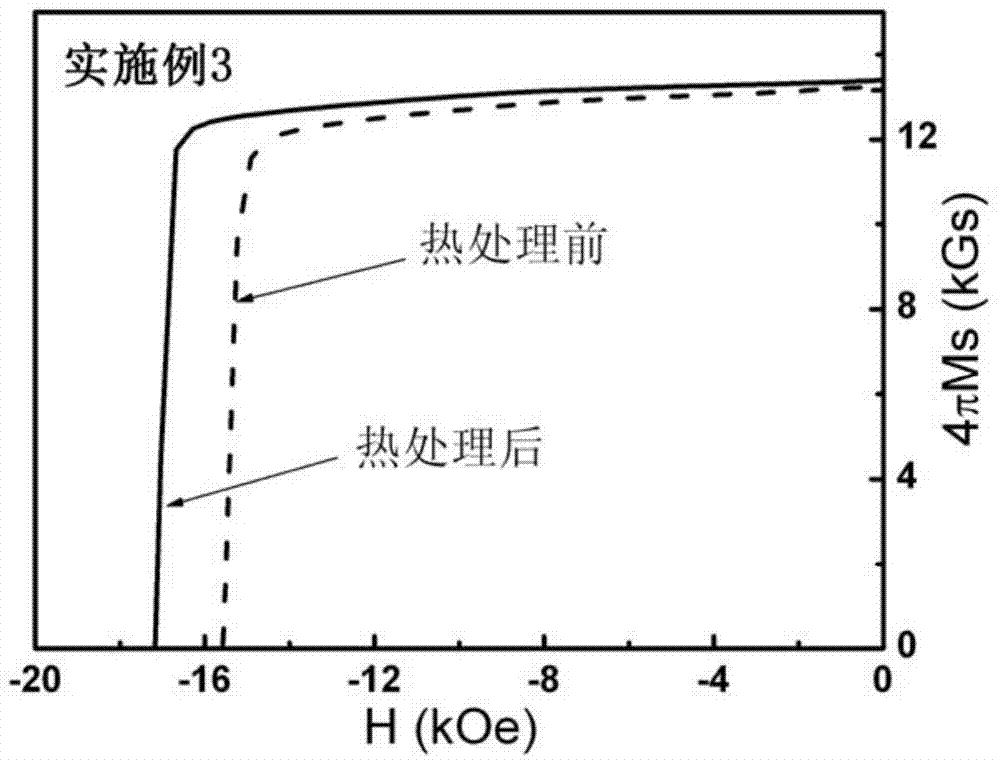

High-temperature high-coercivity samarium-cobalt permanent magnet material and preparation method thereof

ActiveCN108039258ALarge-scale industrial productionPromote growthInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementIngot

The invention provides a high-temperature high-coercivity samarium-cobalt permanent magnet material and a preparation method thereof. The permanent magnet material is Sm(Co1-u-v-wFeuCuvZrw)z, whereinu ranges from 0.09-0.18, v ranges from 0.05-0.10, w ranges from 0.02-0.04 and z ranges from 6.9-7.8. The preparation method includes the steps that the rare earth element Sm with the purity of 99.95%,Co with the purity of 99.98%, Cu with the purity of 99.99%, Fe with the purity of 99.9% and Zr with the purity of 99.9% are evenly mixed and smelted into an alloy ingot, and the ingot is subjected tostructure optimization treatment; micron-sized alloy powder is prepared by using the powder metallurgy technology, then orientation forming, high-temperature sintering, solid solution and aging treatment are conducted, and the samarium-cobalt permanent magnetic alloy is prepared. According to the method, the proportion of a TbCu7 structure is effectively improved, and a samarium-cobalt permanentmagnet free of a Zr6(FeCo)23 phase and uniform in structure is prepared, has high coercivity, high magnetic energy and other excellent properties at ultra-high temperature and can be suitable for ultra-high-temperature environments with the temperature of 550 DEG C or above.

Owner:BEIHANG UNIV

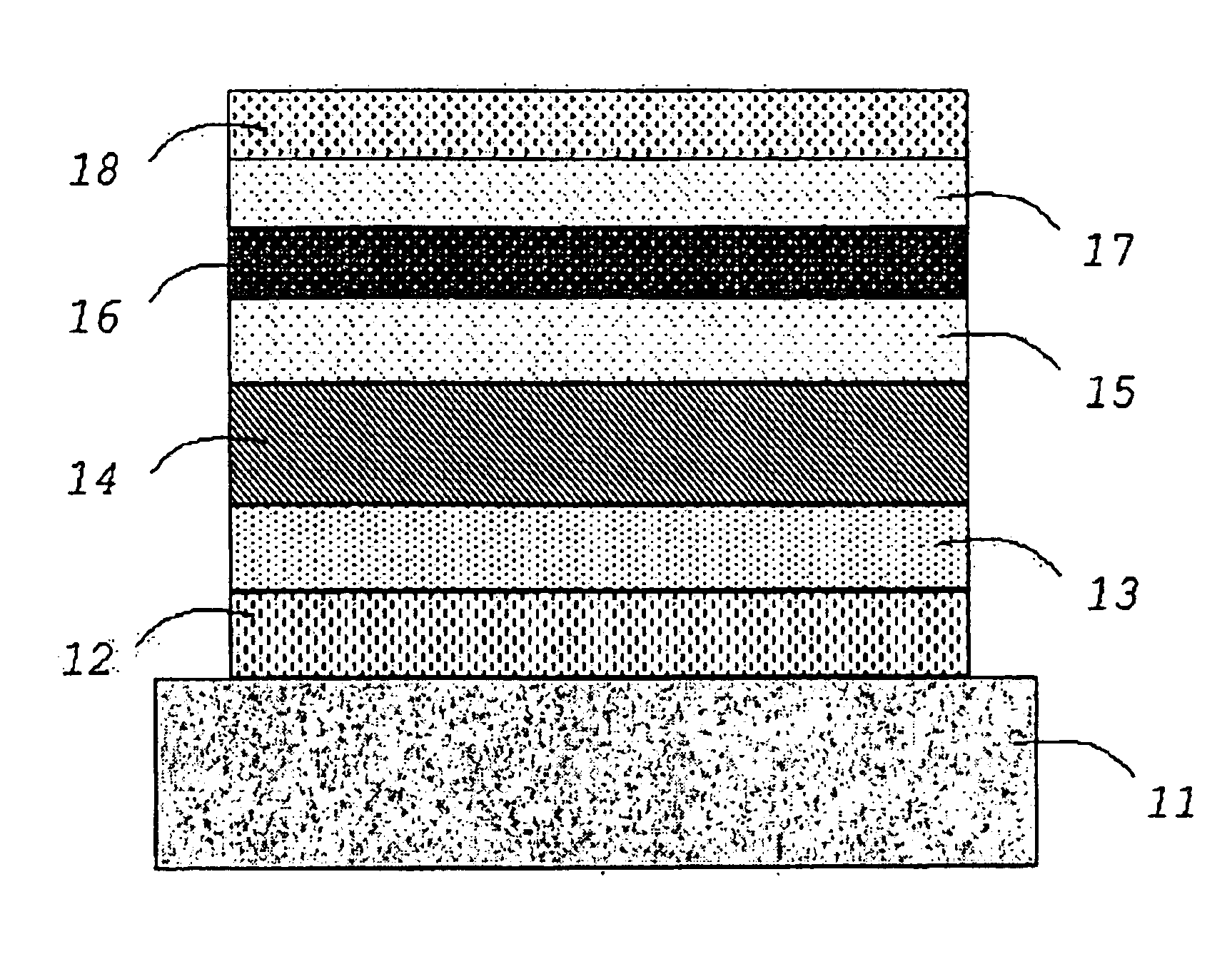

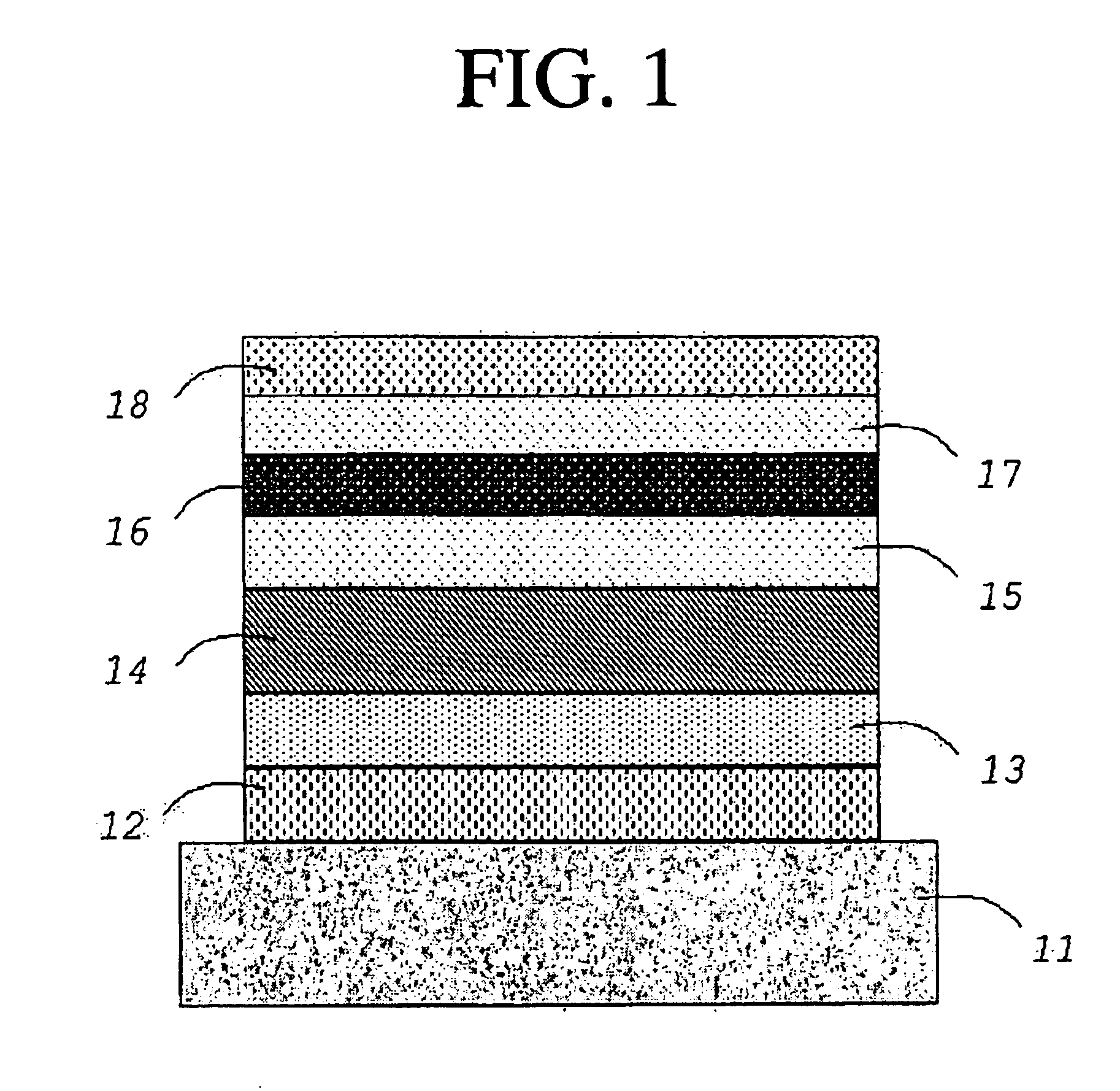

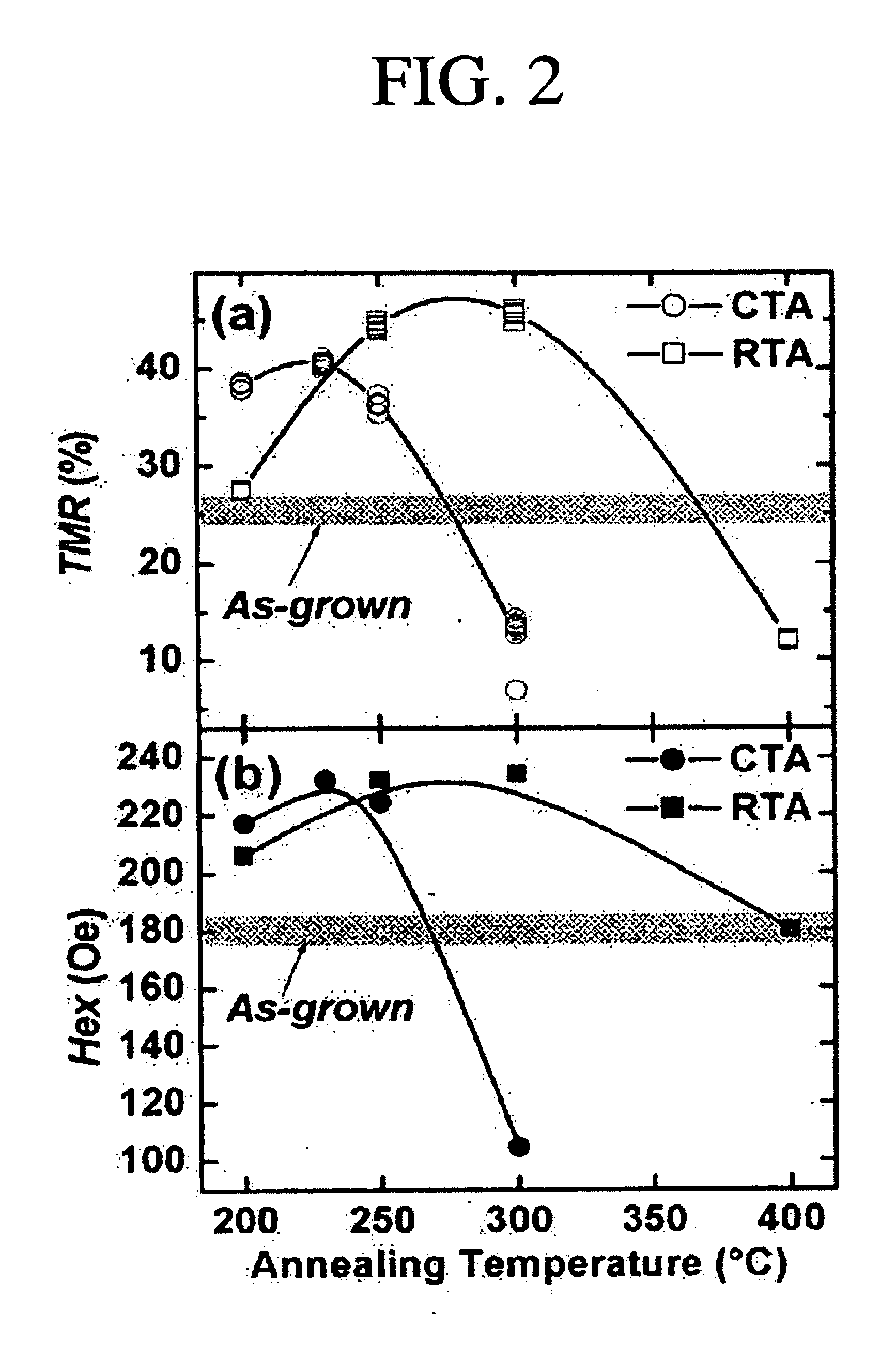

Magnetic tunneling junction and fabrication method thereof

InactiveUS6848169B2Increasing TMR ratioRaise the ratioNanostructure applicationNanomagnetismMagnetic reluctanceOxygen

A fabrication method of a magnetic tunnel junction includes the steps of: forming a magnetic tunnel junction constructed having a first magnetic layer, a tunnel barrier formed at an upper surface of the first magnetic layer and a second magnetic layer formed at an upper surface of the tunnel barrier; and thermally treating the junction rapidly for 5 seconds˜10 minutes at a temperature of 200˜600° C. to re-distribute oxygens in the tunnel barrier and make the interface between the tunnel barrier and the magnetic layer to be even. The tunneling magnetoresistance and thermal stability of the magnetic tunnel junction can be improved through the rapid thermal annealing.

Owner:KOREA INST OF SCI & TECH

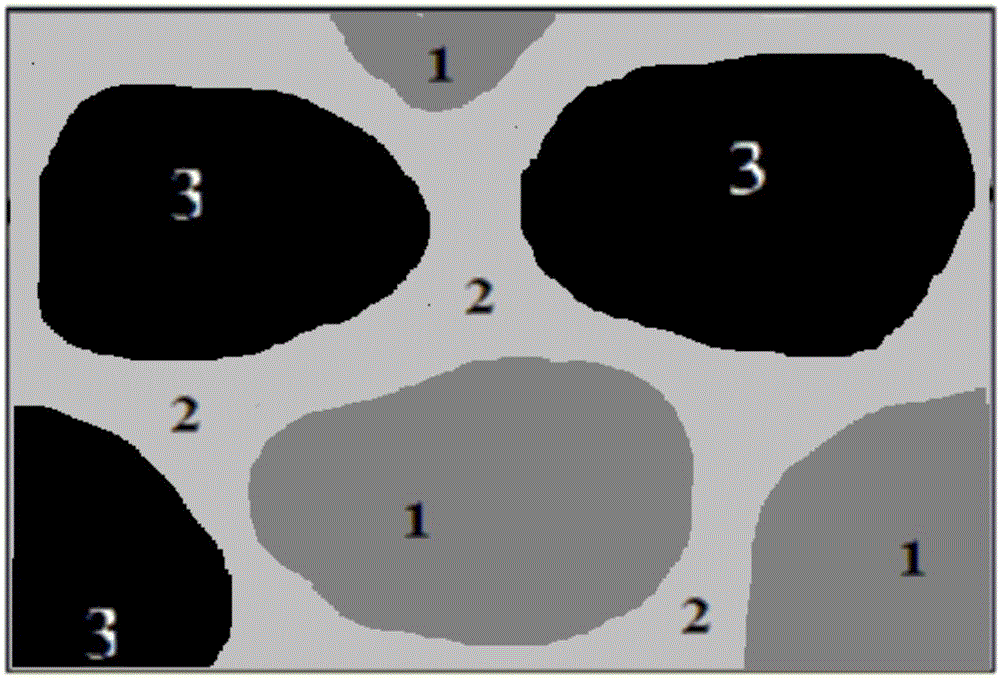

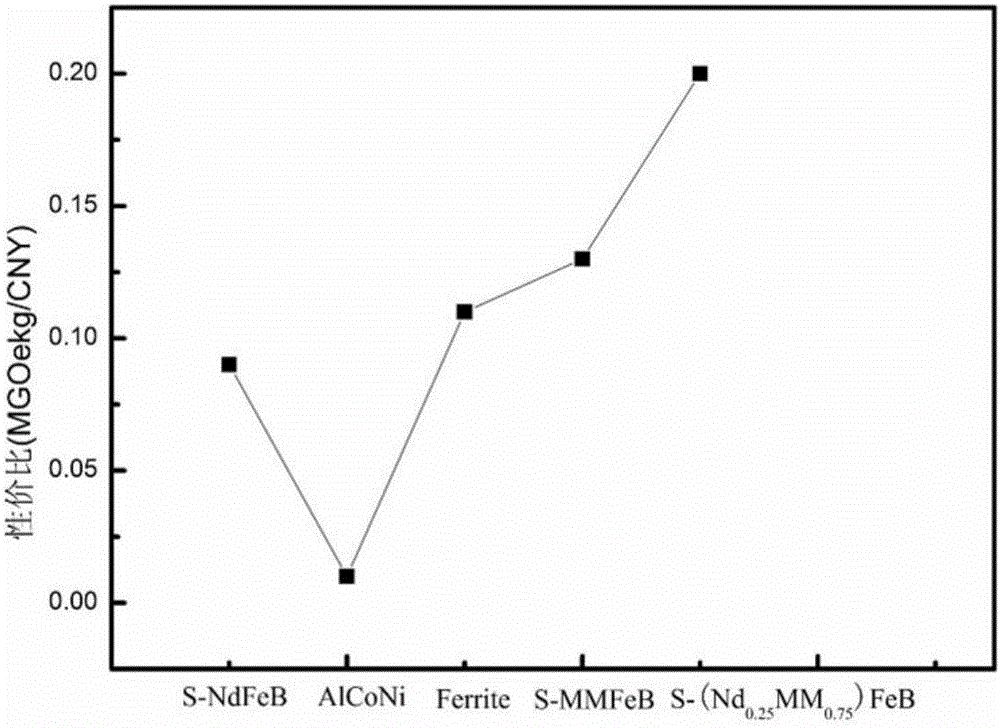

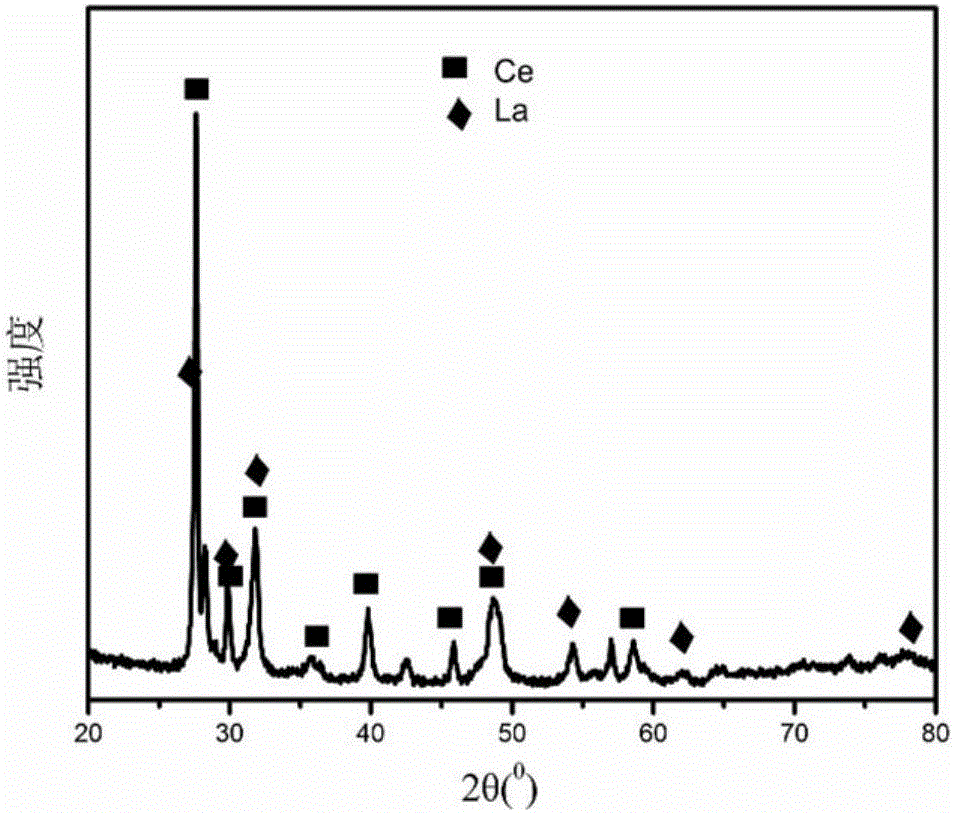

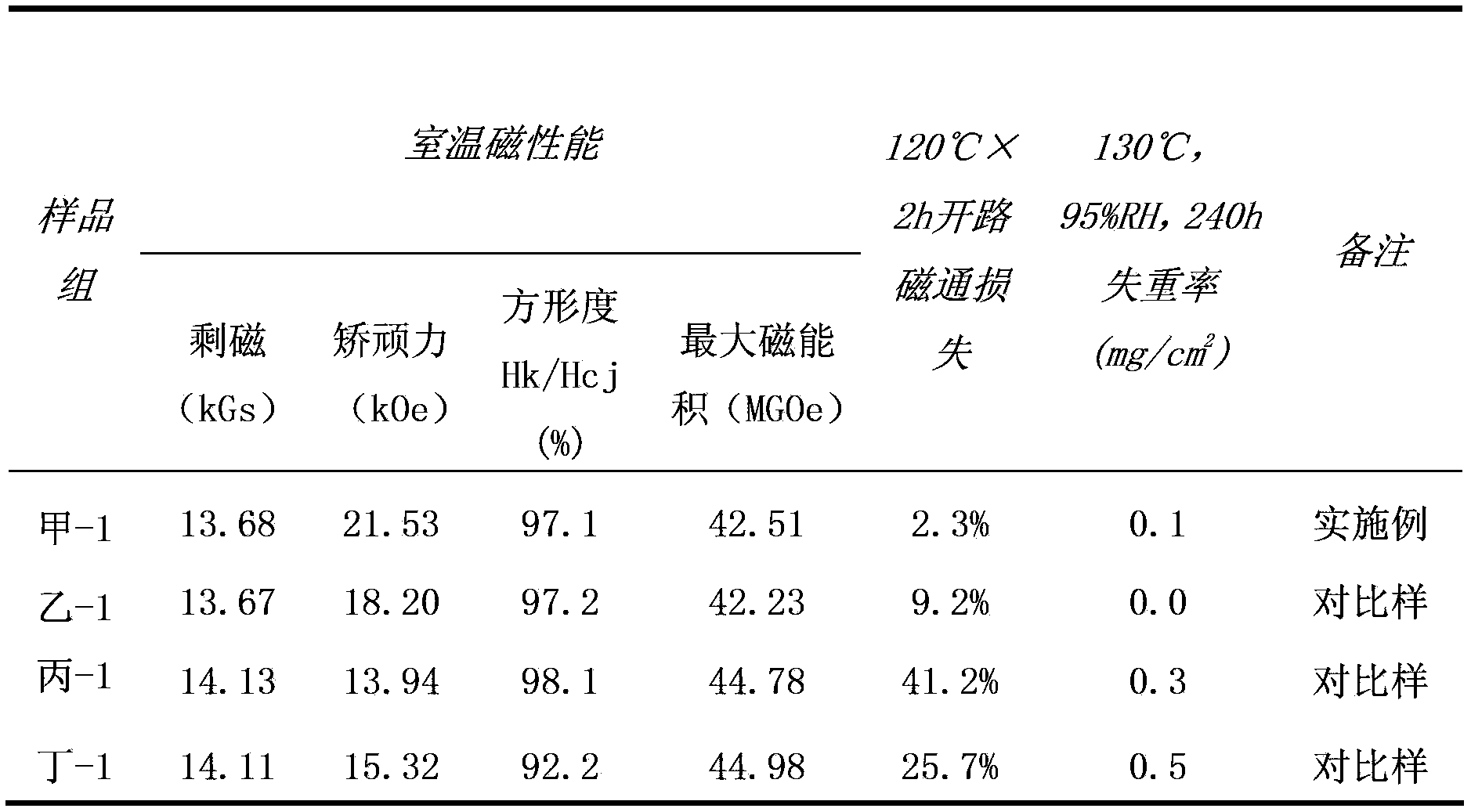

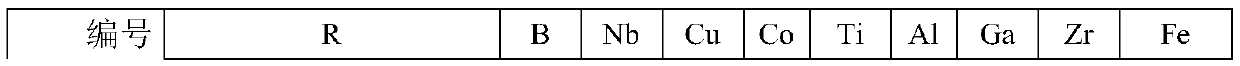

Double-hard magnetic main phase mixed rare-earth permanent magnet and preparation method thereof

ActiveCN106128674ANo wasteNo pollution in the processInductances/transformers/magnets manufactureMagnetic materialsChemical compositionCerium

The invention relates to a double-hard magnetic main phase mixed rare-earth permanent magnet and a preparation method thereof. The permanent magnet comprises double hard magnetic main phases and a rear-earth-rich phase, wherein the double hard magnetic main phases are MM<2>Fe<14>B and (PrNd)<2>Fe<14>B respectively; the permanent magnet is prepared from the following chemical component in percentage by mass: [MM<x1>(PrNd)<1-x1>]<x>Fe<100-x-y-z>B<y>TM<z>; x is smaller than or equal to 31 and greater than or equal to 27; x1 is smaller than or equal to 1 and greater than or equal to 0; y is smaller than or equal to 1 and greater than or equal to 0.9; z is smaller than or equal to 1.5 and greater than 0; TM is a composition of more of the elements Al, Cu, Co, Nb, Ga, Tb and Zr; and MM is a mixed rare-earth alloy which is directly separated from raw ore and contains La, Ce, Pr and Nd. The anisotropic sintered mixed rare-earth permanent magnet with high cost performance within a range of 10-48MGOe can be prepared by adjusting the content of PrNd. A basic rare-earth raw material used by the permanent magnet is cheap mixed rare earth, so that a separation and purification technology for the rare earth can be reduced, efficient utilization of lanthanum-cerium rare earth is achieved and the double-hard magnetic main phase mixed rare-earth permanent magnet meets the requirements of low carbon economy on green production technology innovation of a rare-earth permanent magnet product.

Owner:CENT IRON & STEEL RES INST

Rare-earth permanent magnet and preparation method thereof

ActiveCN104051101ALower activation energyEasy to spreadPermanent magnetsInductances/transformers/magnets manufactureRare-earth elementPowder method

The invention discloses a rare-earth permanent magnet. The rare-earth permanent magnet mainly comprises the following components in percentage by atom: 12.1-16.2 percent of R, 0-3.4 percent of M1, 0-7.2 percent of M2, 5.1-7.4 percent of B and the balance of T, wherein the R is at least one of rear-earth elements including Y and Sc, and at least contains Nd; the M1 is at least one of Nb, Ti, Zr, V, Cr, Mo and Mn; the M2 is at least one of Al, Cu, Zn, Ga, In, Ge and Sn; the T is Fe or Fe and Co. A preparation method of the rare-earth permanent magnet comprises the processes of preparation of a magnet blank, coating, thermal treatment, and ageing, wherein the magnet blank is prepared by using a double-alloy method or a composite powder method. According to the magnet prepared by using the method, the coercive force, the temperature resistance and the corrosion resistance of a larger-size magnet can be improved, and the residual magnetism and the squareness of the magnet are not reduced.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

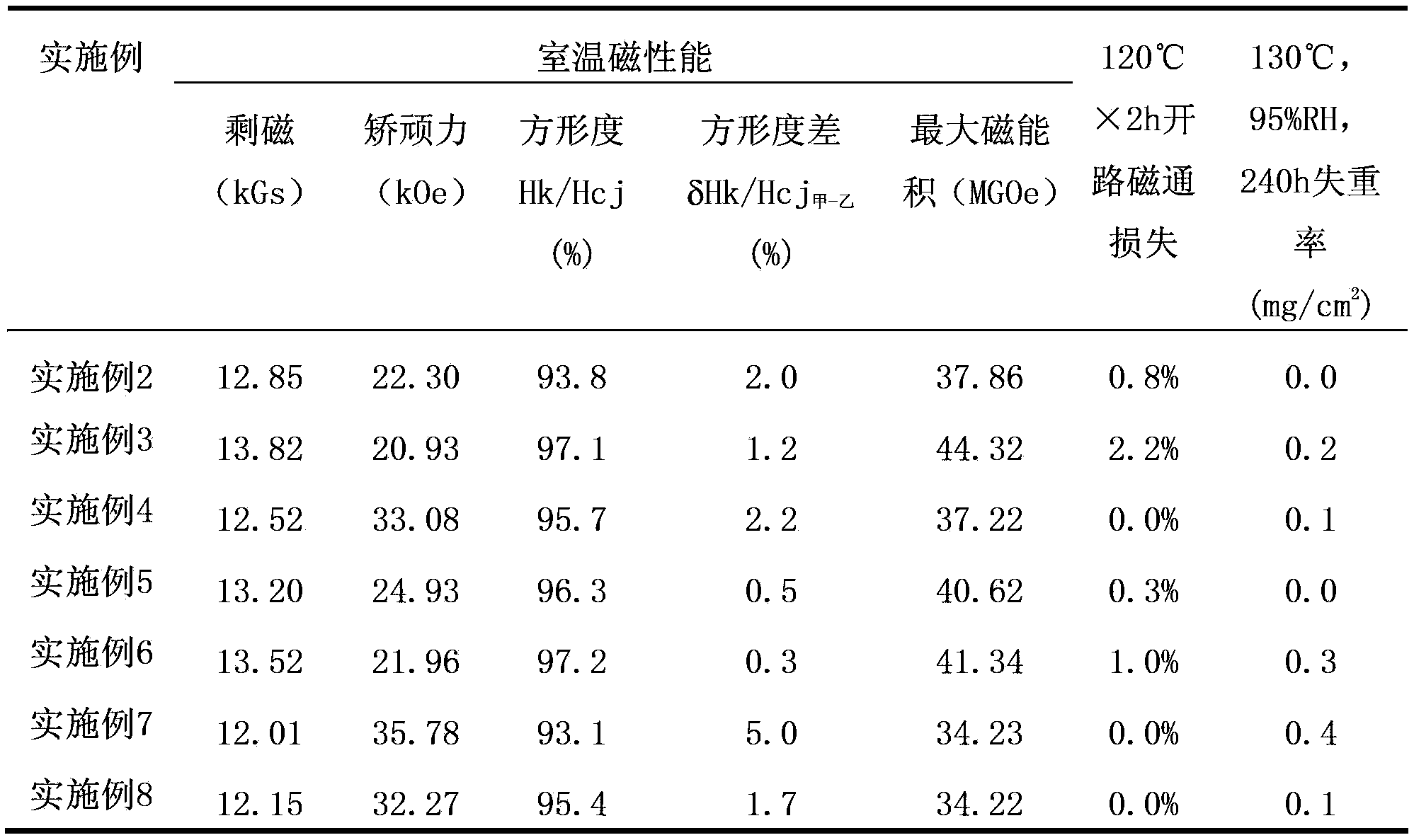

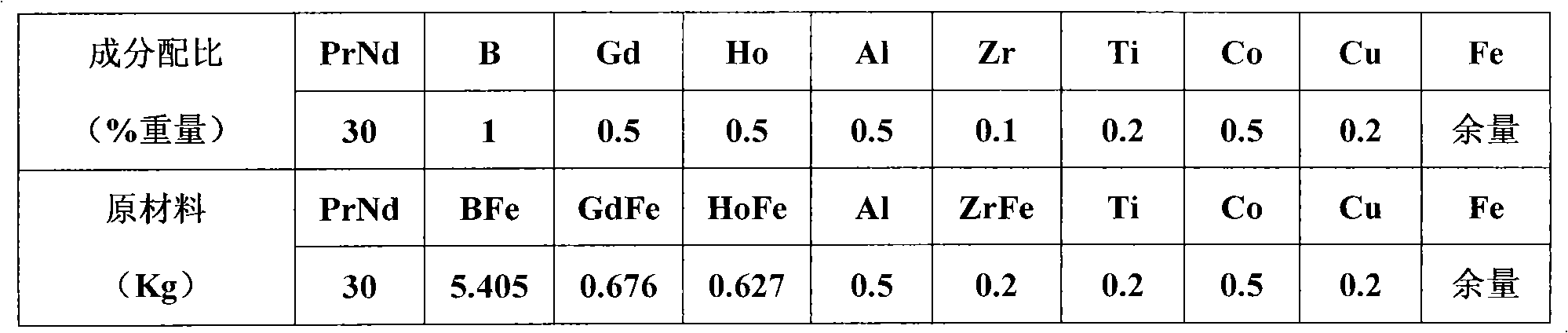

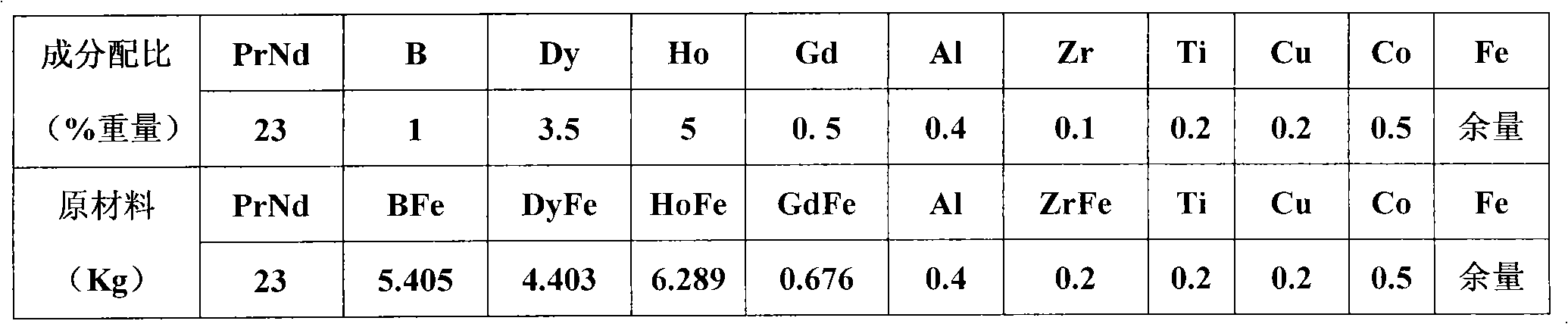

Medium-to-high grade neodymium-iron-boron magnet with composite addition of gadolinium and holmium

InactiveCN101552062AAlleviate shortagesPowder speed increasedInductances/transformers/magnets manufactureMagnetic materialsCobaltImpurity

The invention discloses a medium-to-high grade neodymium-iron-boron magnet with composite addition of gadolinium and holmium, which is composed of the following components by weight percentage: 20 percent-33 percent of praseodymium-neodymium alloy, 0.5 percent-10 percent of gadolinium, 0.5 percent-10 percent of holmium, 0.9 percent-1.2 percent of boron, 0.1 percent-0.8 percent of aluminum, 0.1 percent-0.5 percent of copper, 0.1 percent-0.5 percent of zirconium, 0.1 percent-0.5 percent of titanium, 0 percent-10 percent of dysprosium, 0 percent-3.0 percent of cobalt and the balance of iron and a small amount of inevitable impurities in materials. The medium-to-high grade neodymium-iron-boron magnet with composite addition of gadolinium and holmium has high corrosion resistance, square degree and magnetic energy product; furthermore, the powder discharging speed of the powder production procedure in the preparation process is fast, thereby shortening the production cycle, improving the magnetic performances of the magnet and enhancing the enterprise competitiveness.

Owner:宁波同创强磁材料有限公司

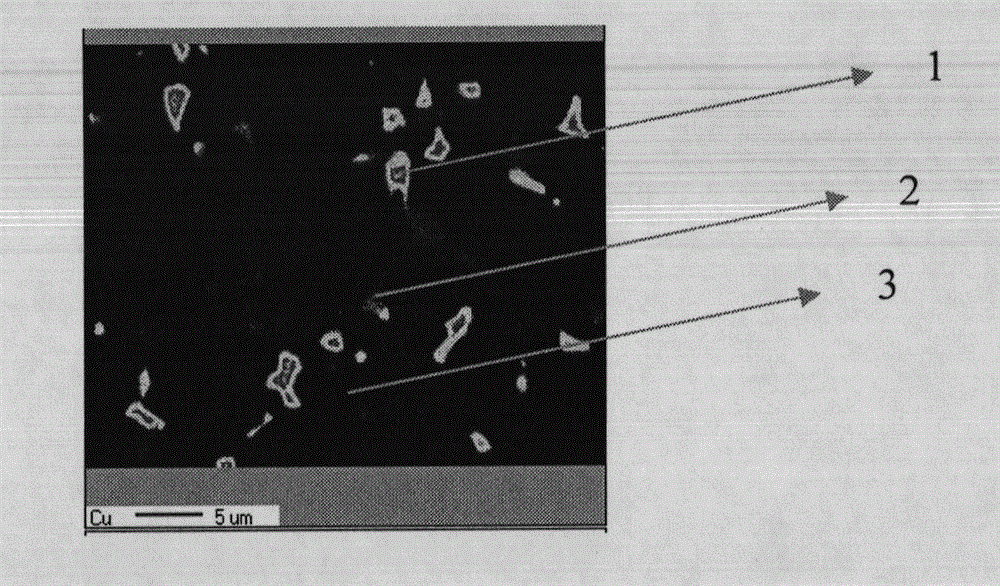

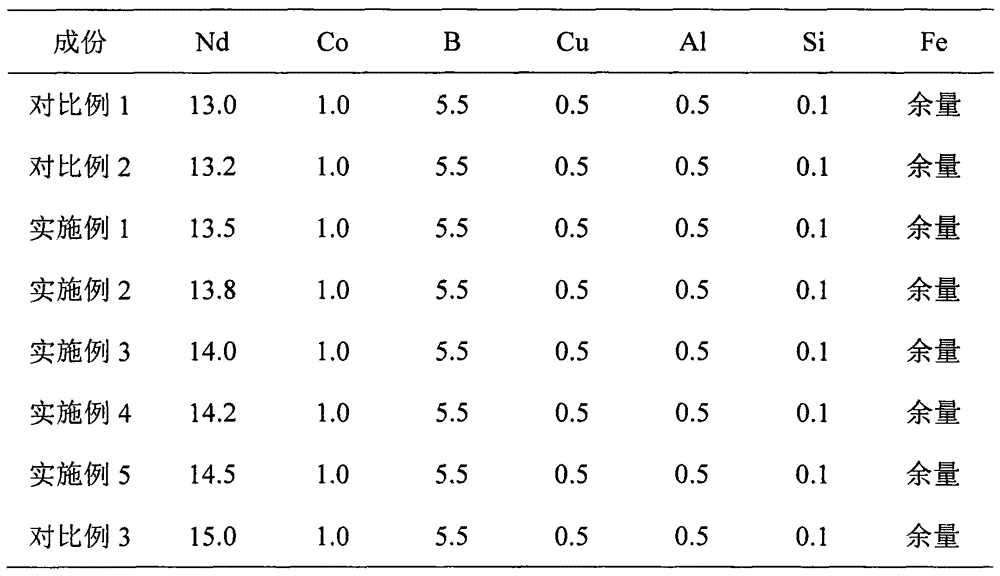

Low-B rare earth magnet

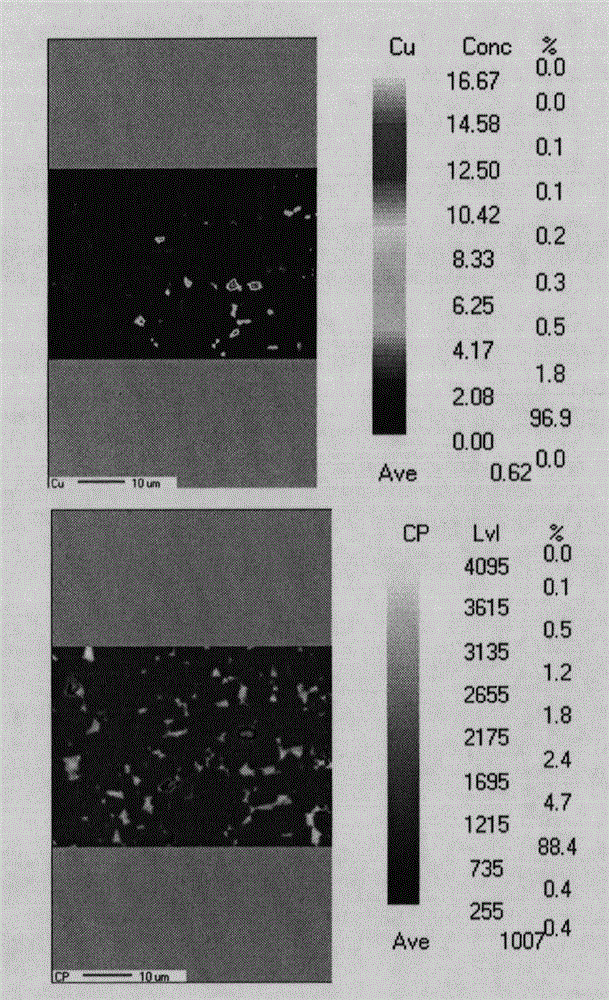

InactiveCN104674115AImprove squarenessImprove heat resistanceFurnace typesMagnetic materialsRare-earth elementMagnetic effect

Disclosed is a low-B rare earth magnet. The rare earth magnet contains a main phase of R2T14B, and comprises the following raw material components: 13.5 at%-14.5 at% of R, 5.2 at%-5.8 at% of B, 0.3 at%-0.8 at% of Cu, 0.3 at%-3 at% of Co, and the balance being T and inevitable impurities, the R being at least one rare earth element comprising Nd, and the T being an element mainly comprising Fe. 0.3-0.8 at% of Cu and an appropriate amount of Co are added to the rare earth magnet by compositing, so that three Cu-rich phases are formed in the grain boundary, and the magnetic effect of the three Cu-rich phases existing in the grain boundary and the solving of the problem of insufficient B in the grain boundary can obviously improve the squareness and heat-resistance of the magnet.

Owner:XIAMEN TUNGSTEN CO LTD

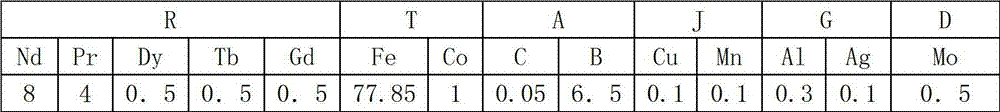

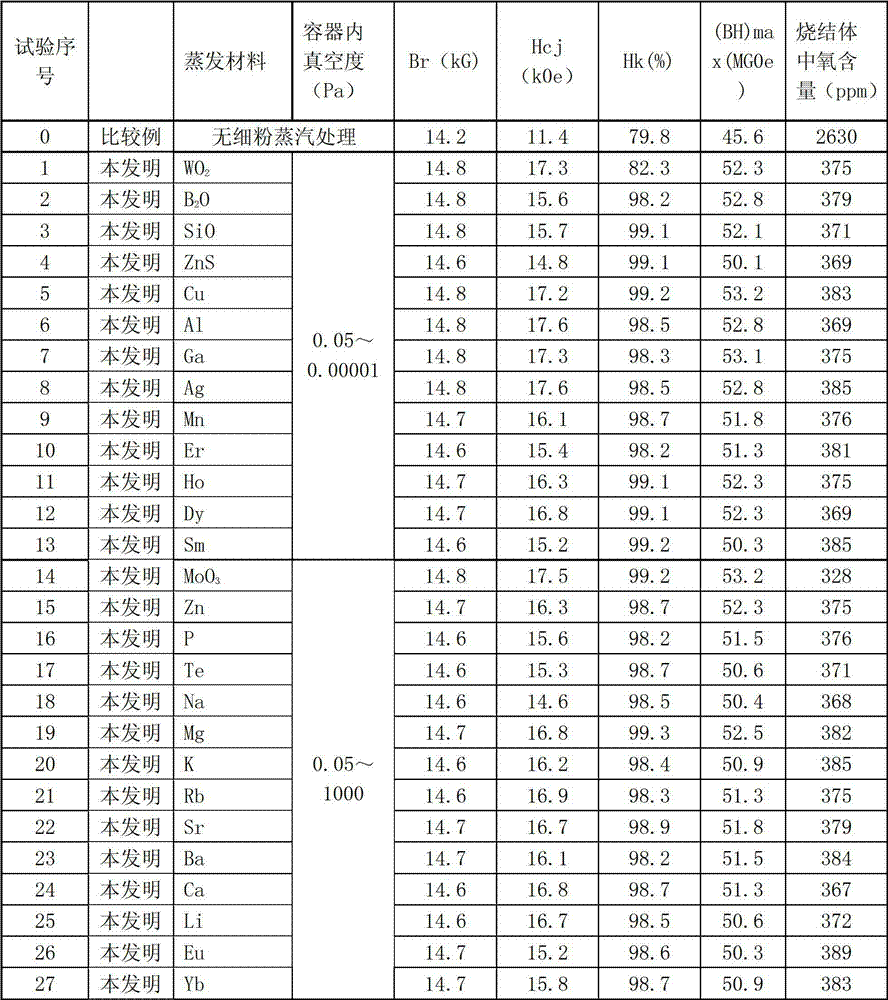

Method for manufacturing sintered Nd-Fe-B magnet on basis of vapor deposition heat treatment for fine powder

ActiveCN103050268ASuitable processing temperatureImprove coercive forceTransportation and packagingMetal-working apparatusEvaporationAlloy

The invention discloses a method for manufacturing a sintered Nd-Fe-B magnet on the basis of vapor deposition heat treatment for fine powder. The method includes a working procedure for manufacturing and sintering the sintered Nd-Fe-B magnet with the oxygen content lower than 2500ppm. The working procedure includes smelting neodymium, iron and boron to obtain alloy, coarsely grinding the alloy, then manufacturing the coarsely ground alloy into the fine powder by means of micro-grinding, and performing vapor deposition treatment for the fine powder obtained by means of micro-grinding and evaporation materials at the temperature of 100-1000 DEG C for a period longer than 1 minute and shorter than 24 hours; and forming a magnet by a magnetic field forming process, and sintering the magnet in a vacuum or inert-gas environment at the temperature of 900-1140 DEG C. The method has the advantages that the sinter characteristic of the powder is changed dramatically owing to an additional vapor heat treatment procedure for the fine powder, and the purpose of manufacturing the magnet with high coercive force, rectangularity and heat resistance is achieved.

Owner:FUJIAN CHANGTING GOLDEN DRAGON RARE EARTH CO LTD

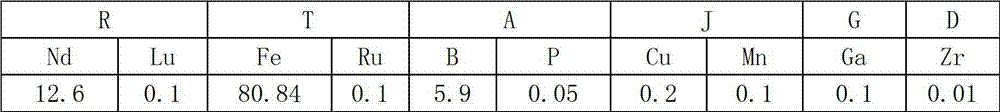

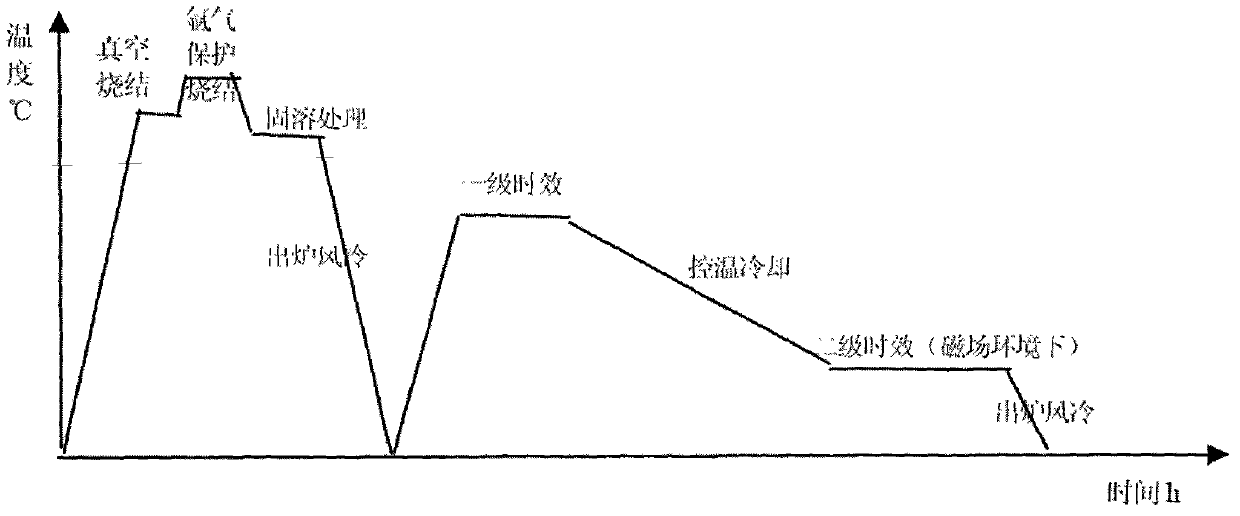

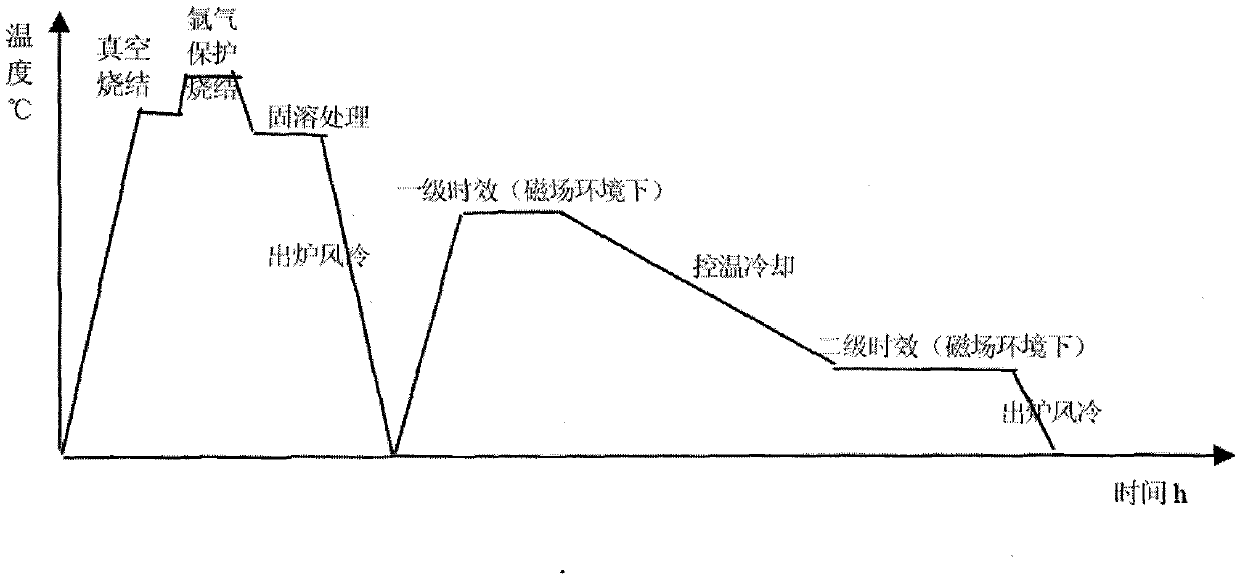

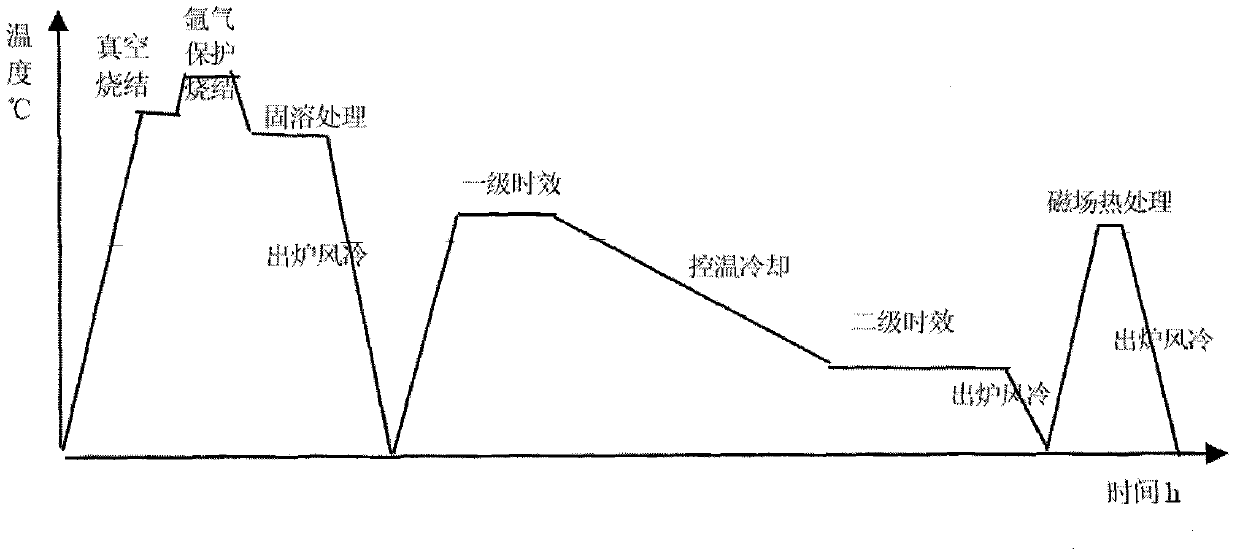

Method for preparing high performance SmCo permanent magnet material

InactiveCN102766835AImprove permanent magnet performanceImprove remanenceMagnetic materialsCompression moldingRare earth

The invention relates to a method for preparing a high performance SmCo permanent magnet material and belongs to the field of preparation of rare earth permanent magnet materials. The method includes that Sm (Col-u-v-wCuuFevZrw) z is used for preparing the SmCo permanent magnet material through processes of smelting, milling, compression molding, sintering, solid solution, magnetic field aging treatment, magnetic field post-heat treatment and the like. The permanent magnet material obtained after the magnetic field aging treatment or the magnetic field post-heat treatment can induce magnetic uniaxial anisotropy in the filed, the orientation degree is increased, so that the magnetic performance of the SmCo permanent magnet material is improved substantially.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

NdFeB (neodymium iron boron) magnetic material with ultrafine powder and preparation method thereof

InactiveCN103151132AInhibit growthGuaranteed uniformityInorganic material magnetismChemical reactionGrain boundary

The invention discloses a NdFeB (neodymium iron boron) magnetic material with ultrafine powder and a preparation method thereof. The ultrafine powder generated through air-current mill is added into normal magnetic powder which comprises certain amount of Pr-Nd-Dy, mixed rare earth (La-Ce), B, Al, Cu and the balance of Fe to prepare the NdFeB product. Proper addition can enrich rare earth phase; the product is prevented from being oxidized because of over low total amount of rear earth; a crystal boundary is strengthened, and the coercivity is improved; and NdFeB crystalline grains are prevented from being grown in a sintering process, the uniformity of the grains in the product is guaranteed, and the squareness of the product is improved. The granularity of the ultrafine powder is less than 2 mu m, the grains are large in specific surface area and few in defects, so that the surface activity is high, chemical reaction speed is high, the solubility is high, particularly the coercivity is very high, the sintering temperature of a magnetic body is reduced, and the coercivity is increased.

Owner:辽宁恒德磁业有限公司

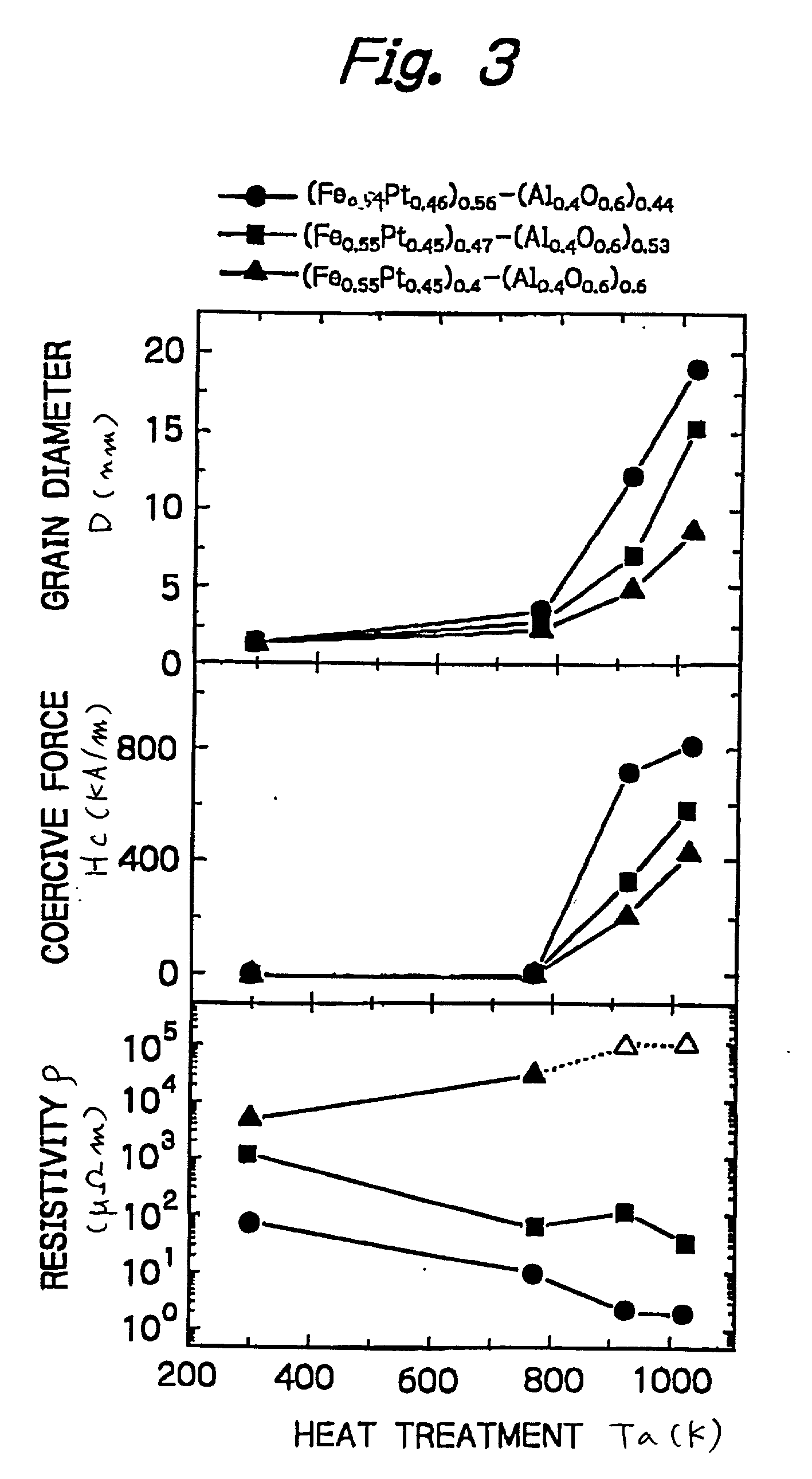

Nanogranular thin film and magnetic recording media

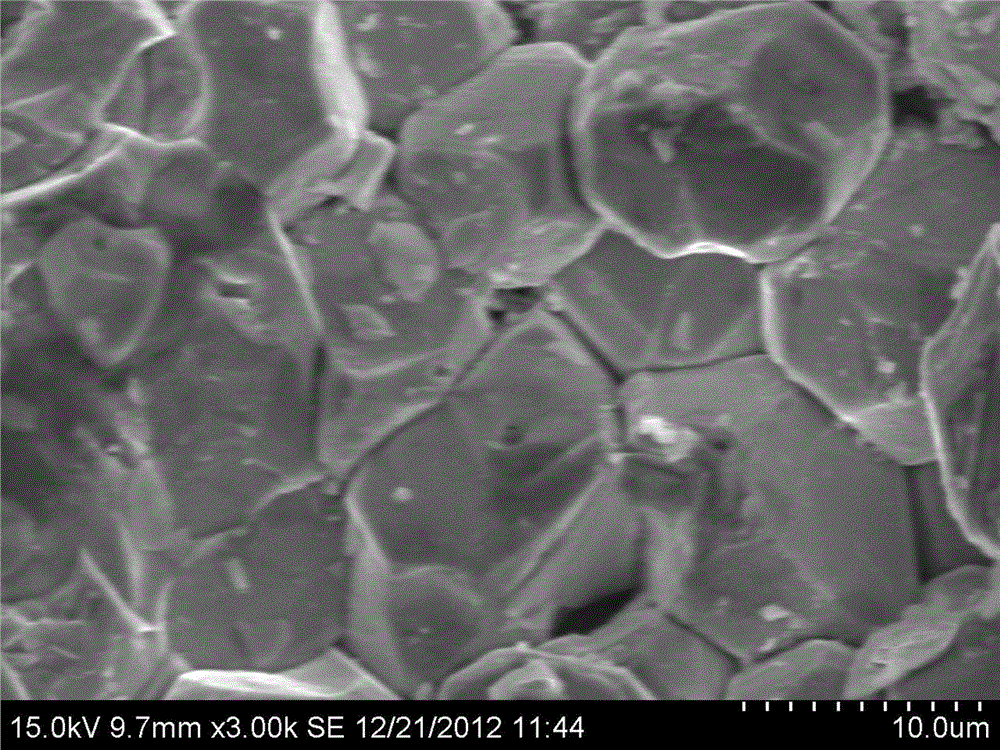

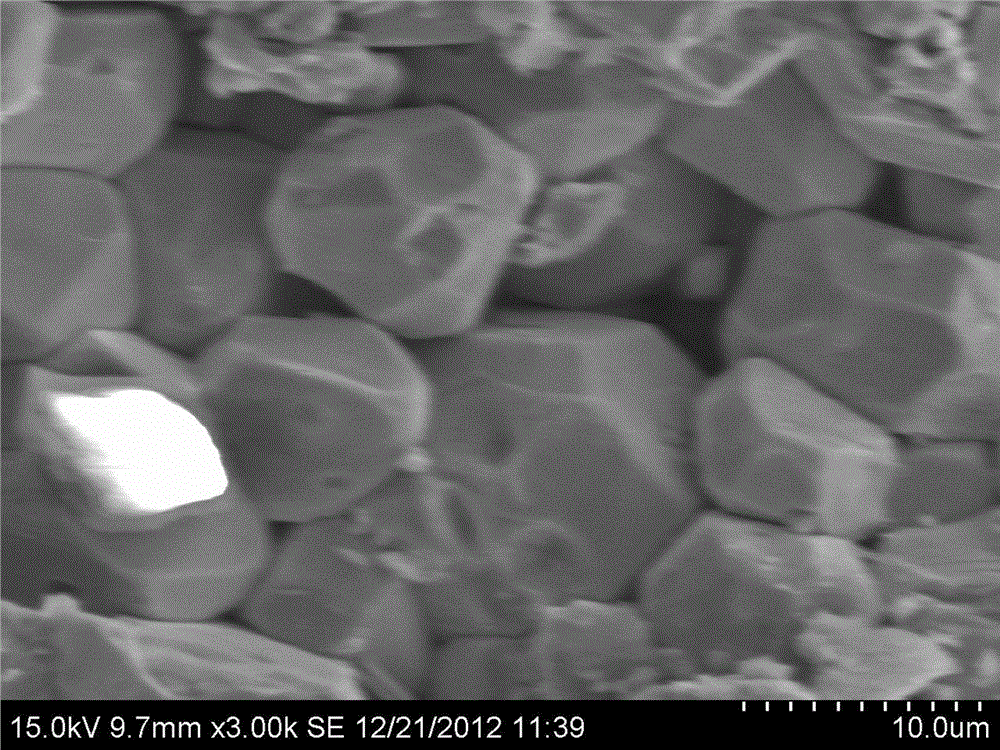

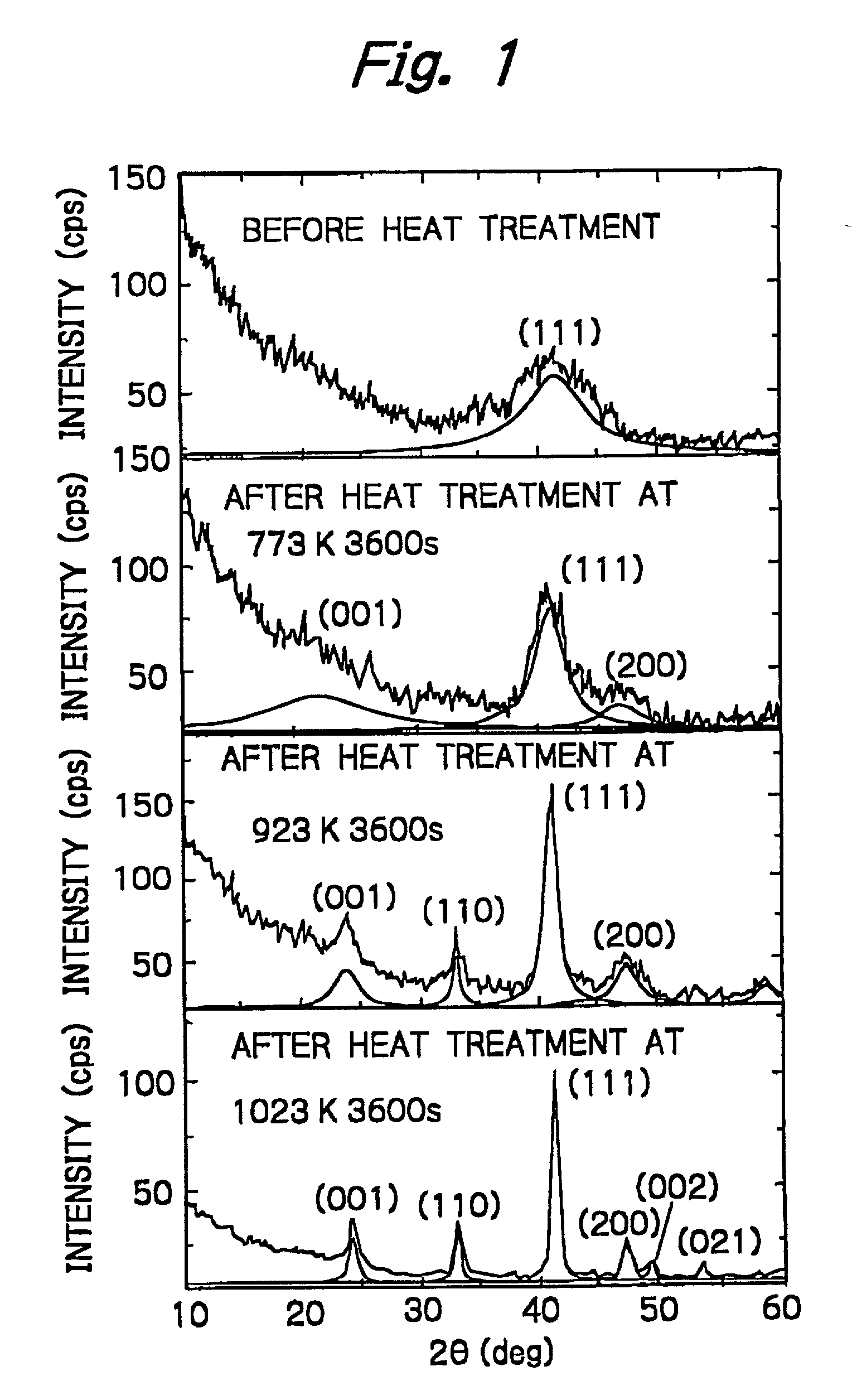

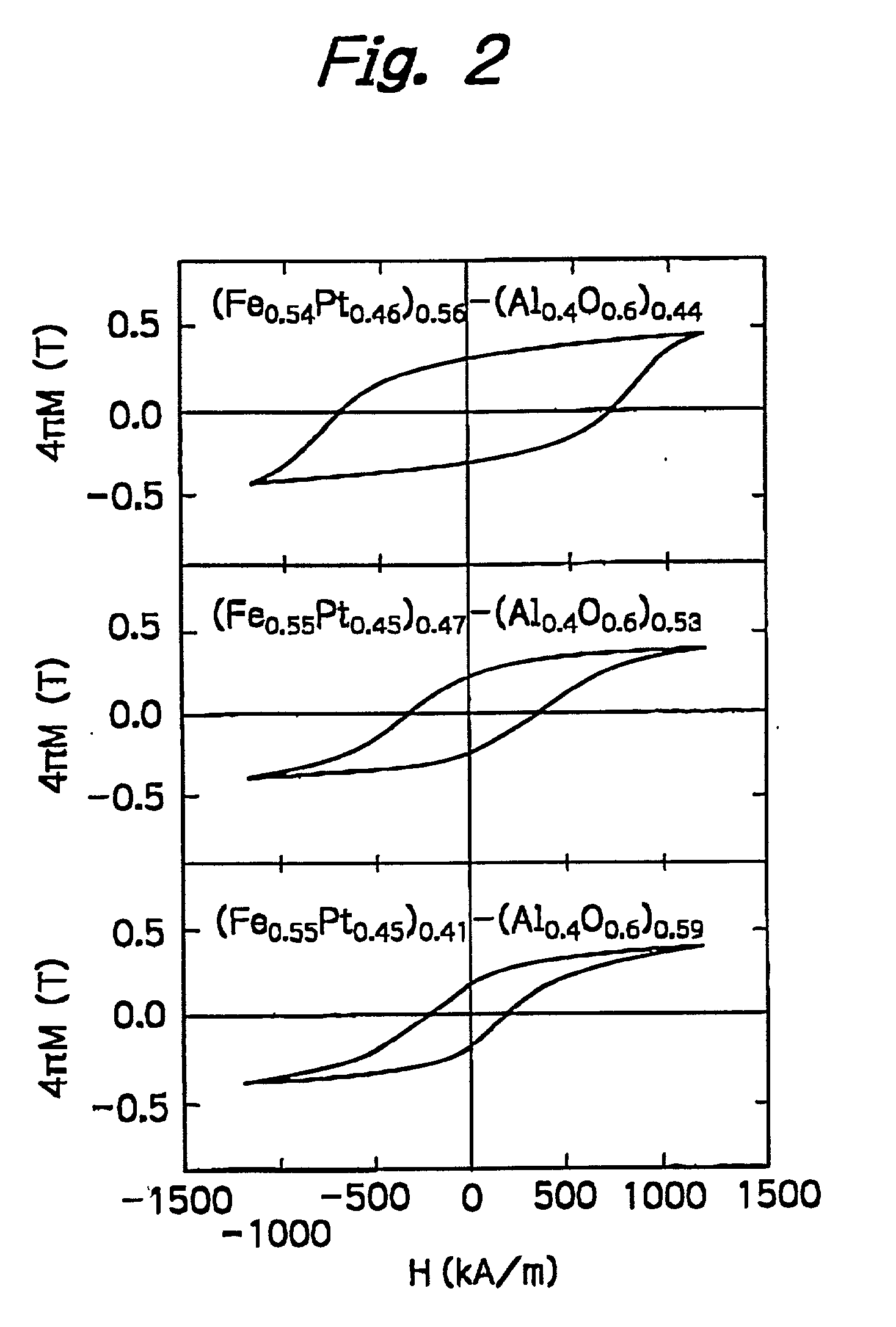

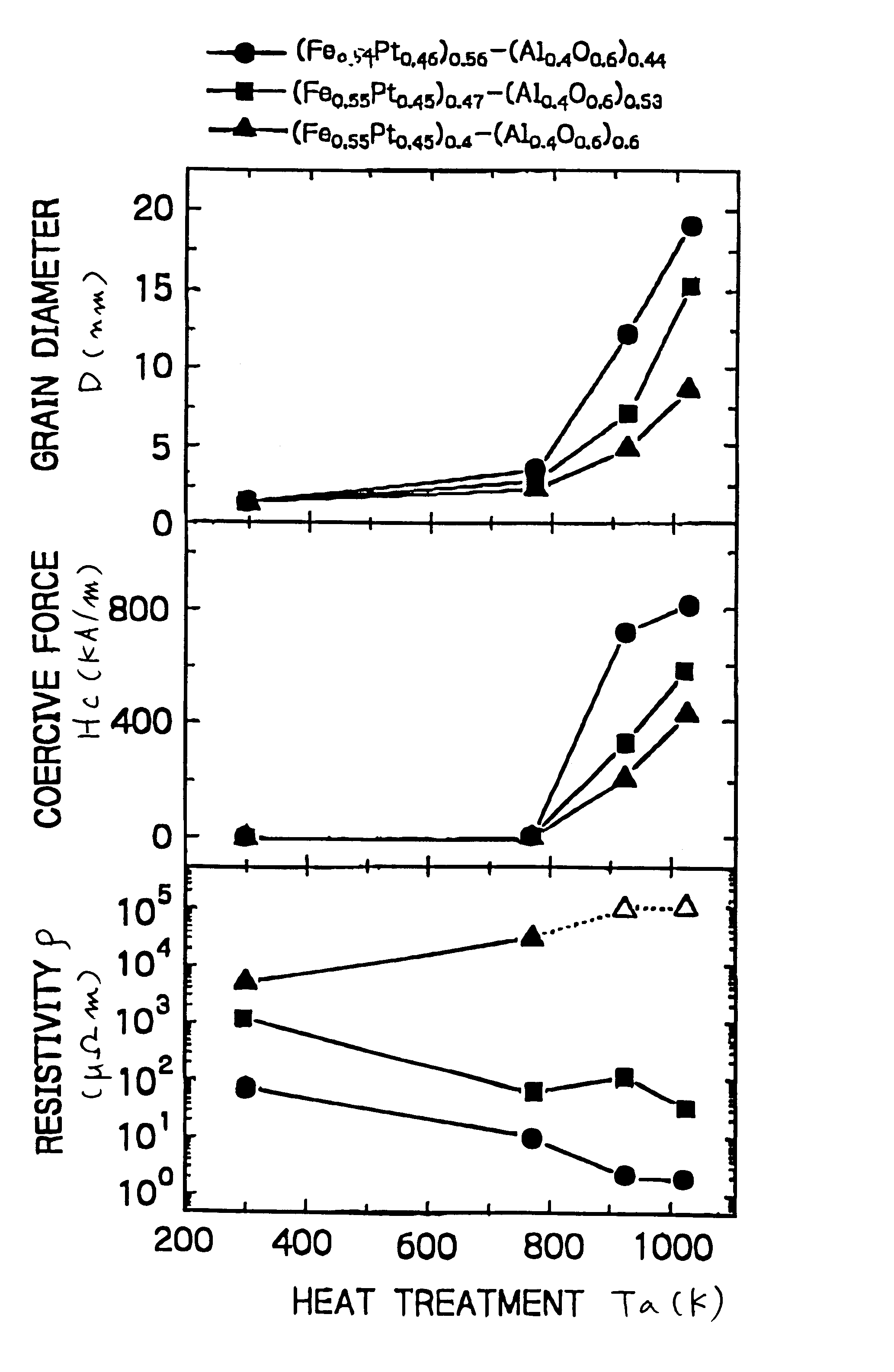

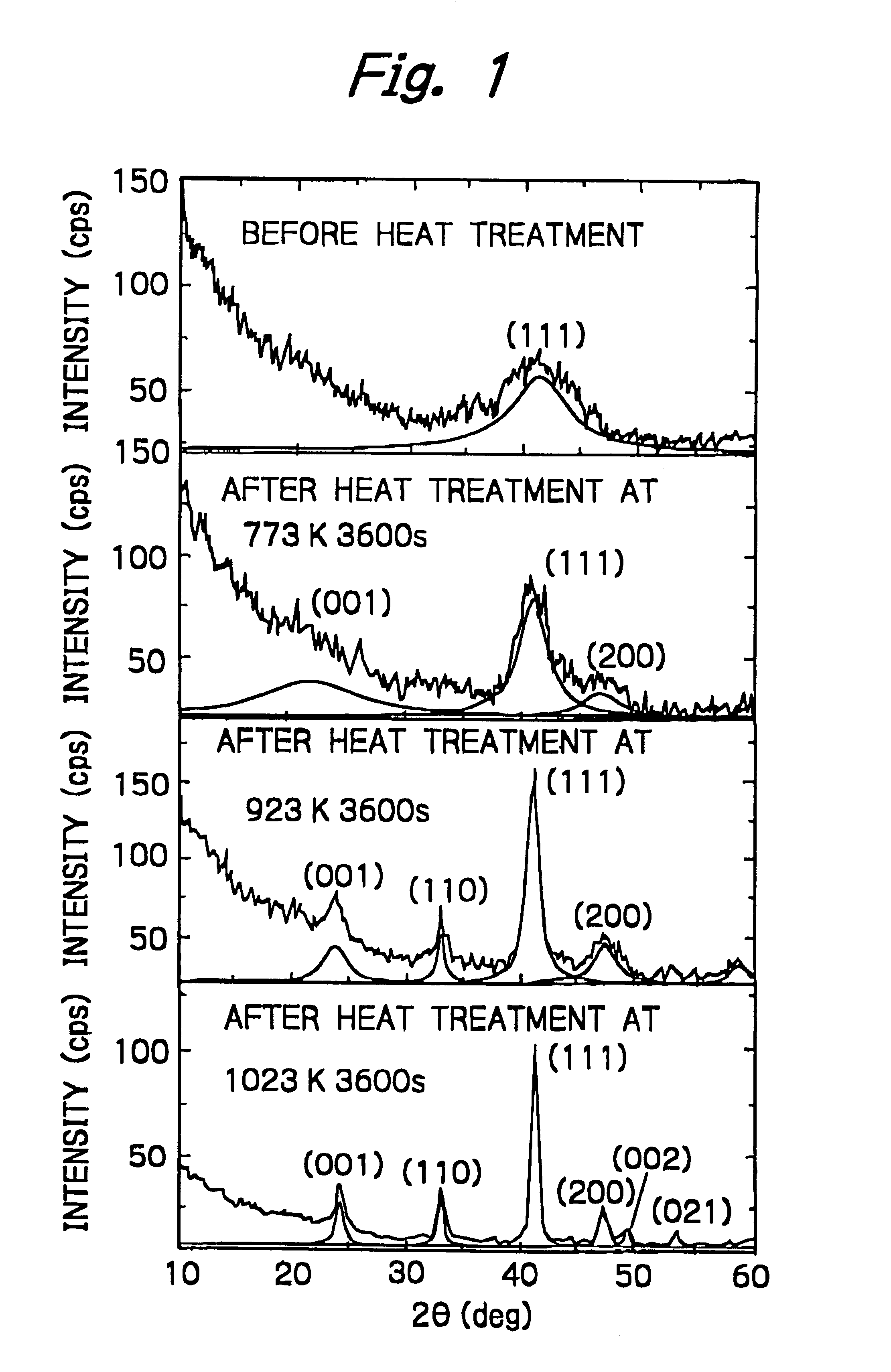

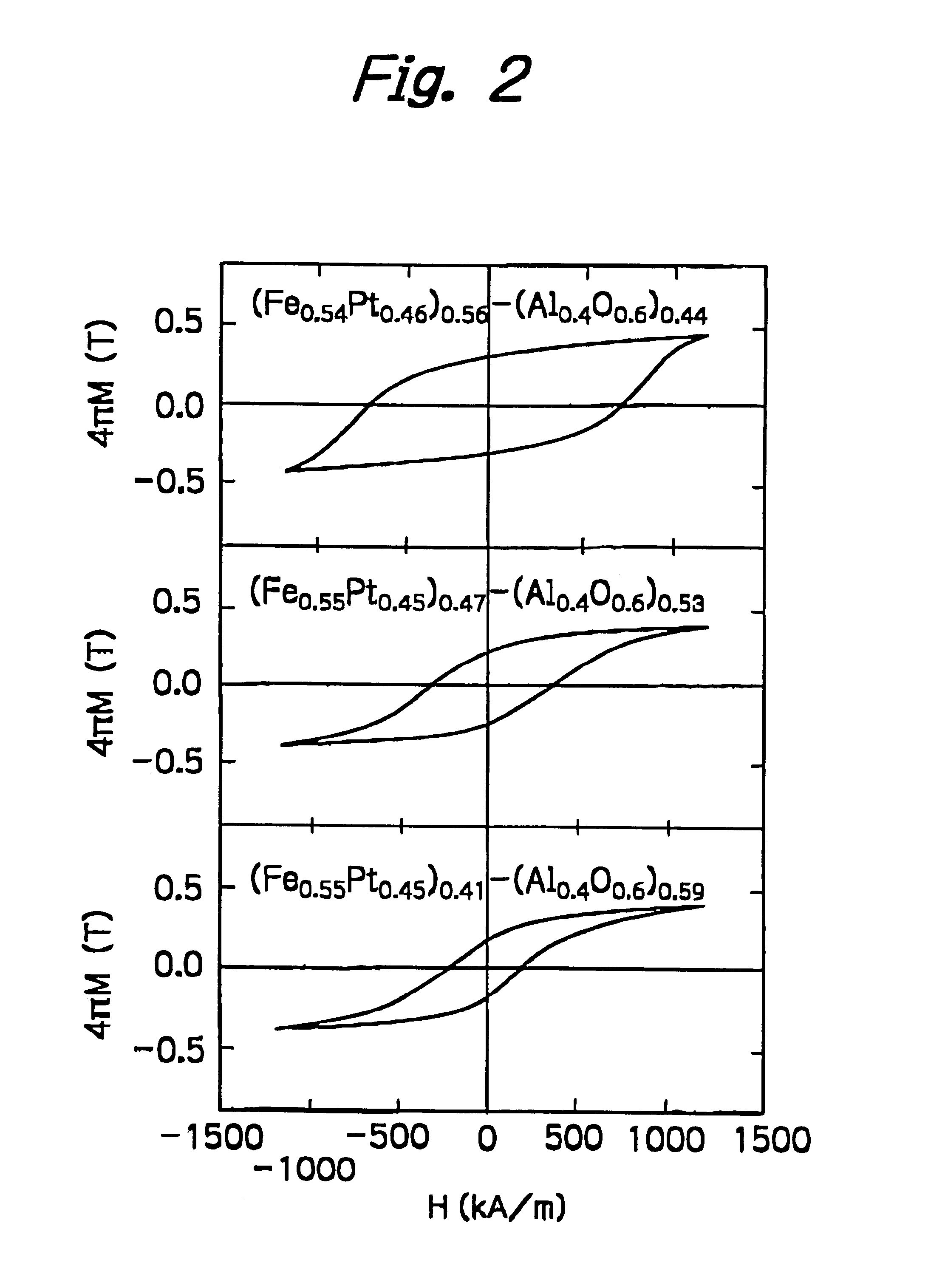

InactiveUS20010036563A1Improve thermal stabilityReduce noiseNanomagnetismMaterials with cobaltNanometreOptoelectronics

A nanogranular thin film consisting of nonmagnetic matrix and ferromagnetic fine particles in nano scale is improved to enhance the thermal stability and the S / N ratio. The ferromagnetic fine particles consist of (FeaCo1-a)1-xPtx, (0.3<=x<=0.7, 0.1<=x<=1), (FeaCo1-a)1-xPdx, (0.3<=x<=0.7, 0.1<=x<=1) or (FeaCo1-a)1-x(PtbPd1-b)x, (0.3<=x<=0.7, 0.1<=x<=1, and 0<b<1).

Owner:FOUND THE RES INST FOR ELECRTRIC & MAGNETIC MATERIALS THE

NdFeB magnet and preparation method thereof

ActiveCN104064301ARefine the grain sizeRaise the sintering temperaturePermanent magnetsInductances/transformers/magnets manufactureIngotCopper

The invention provides an NdFeB magnet which comprises, by mass, 29% to 33% of Pr-Nd, 0.97% to 1.5% of B, 0.4% to 0.6% of Dy, 0.2% to 0.8% of Al, 0.6% to 0.8% of Co, 0.01% to 0.5% of Cu, 0.01% to 0.2% of Zr and the balance Fe. The invention further discloses a preparation method of the NdFeB magnet. The method includes the steps that firstly, Pr-Nd alloy, Zr-Fe alloy, B-Fe alloy, Dy-Fe alloy, aluminum, cobalt, copper and iron are molten to prepare an NdFeB cast ingot; secondly, the obtained NdFeB cast ingot is milled into NdFeB powder; finally, the NdFeB powder is sintered into the NdFeB magnet. The NdFeB magnet prepared through the method has a more refined magnet grain size and higher magnet stability.

Owner:BEIJING JINGCI ELECTRIC TECH CO LTD

Nanogranular thin film and magnetic recording media

InactiveUS6623857B2Improve thermal stabilityReduce noiseNanomagnetismMaterials with cobaltNanoparticleOptoelectronics

A nanogranular thin film consisting of nonmagnetic matrix and ferromagnetic fine particles in nano scale is improved to enhance the thermal stability and the S / N ratio. The ferromagnetic fine particles consist of (FeaCo1-a)1-xPtx, (0.3<=x<=0.7, 0.1<=a<=1), (FeaCo1-a)1-xPdx, (0.3<=x<=0.7, 0.1<=a<=1) or (FeaCo1-a) 1-x(PtbPd1-b)x, (0.3<=x<=0.7, 0.1<=a<=1, and 0<b<1).

Owner:FOUND THE RES INST FOR ELECRTRIC & MAGNETIC MATERIALS THE

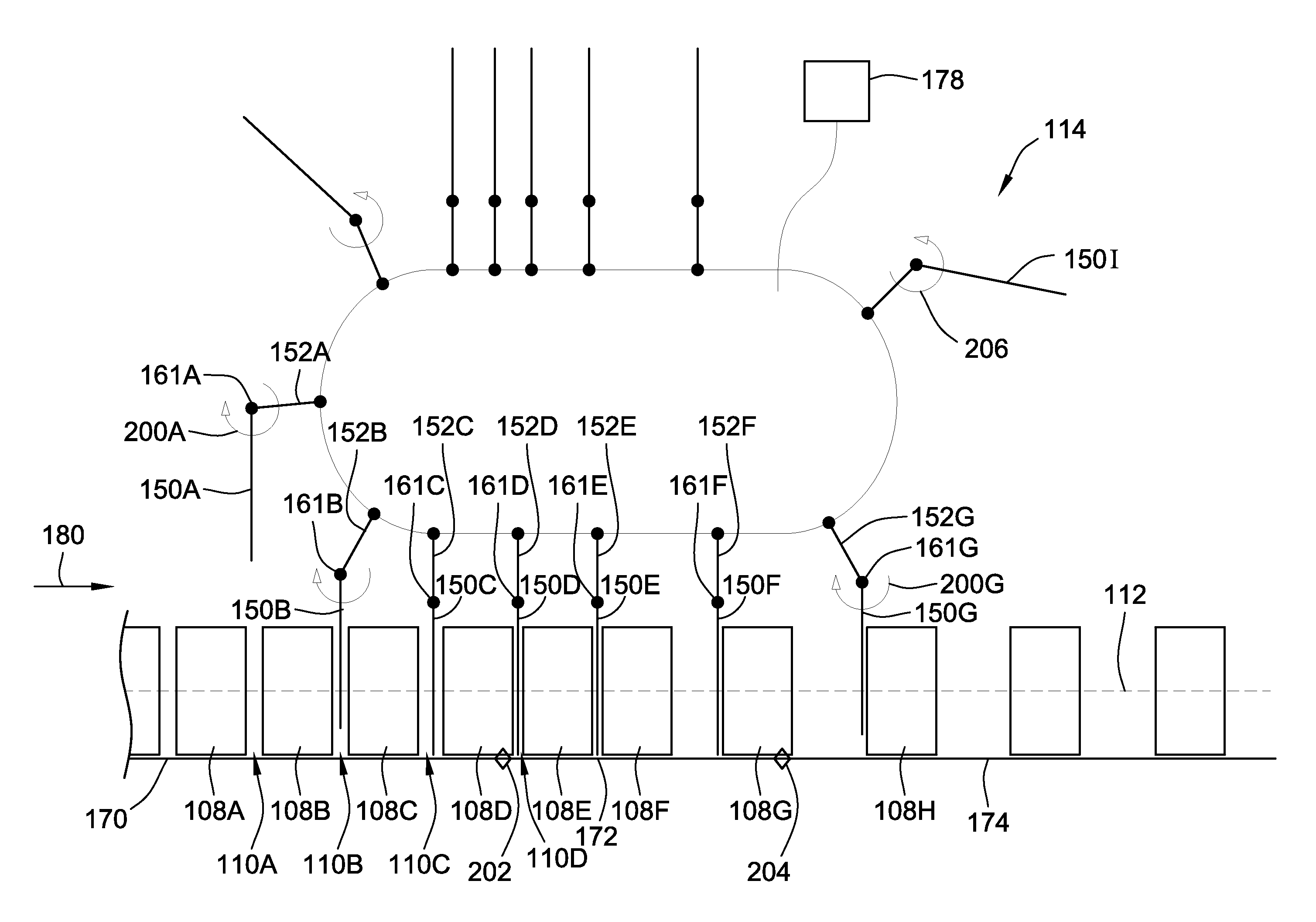

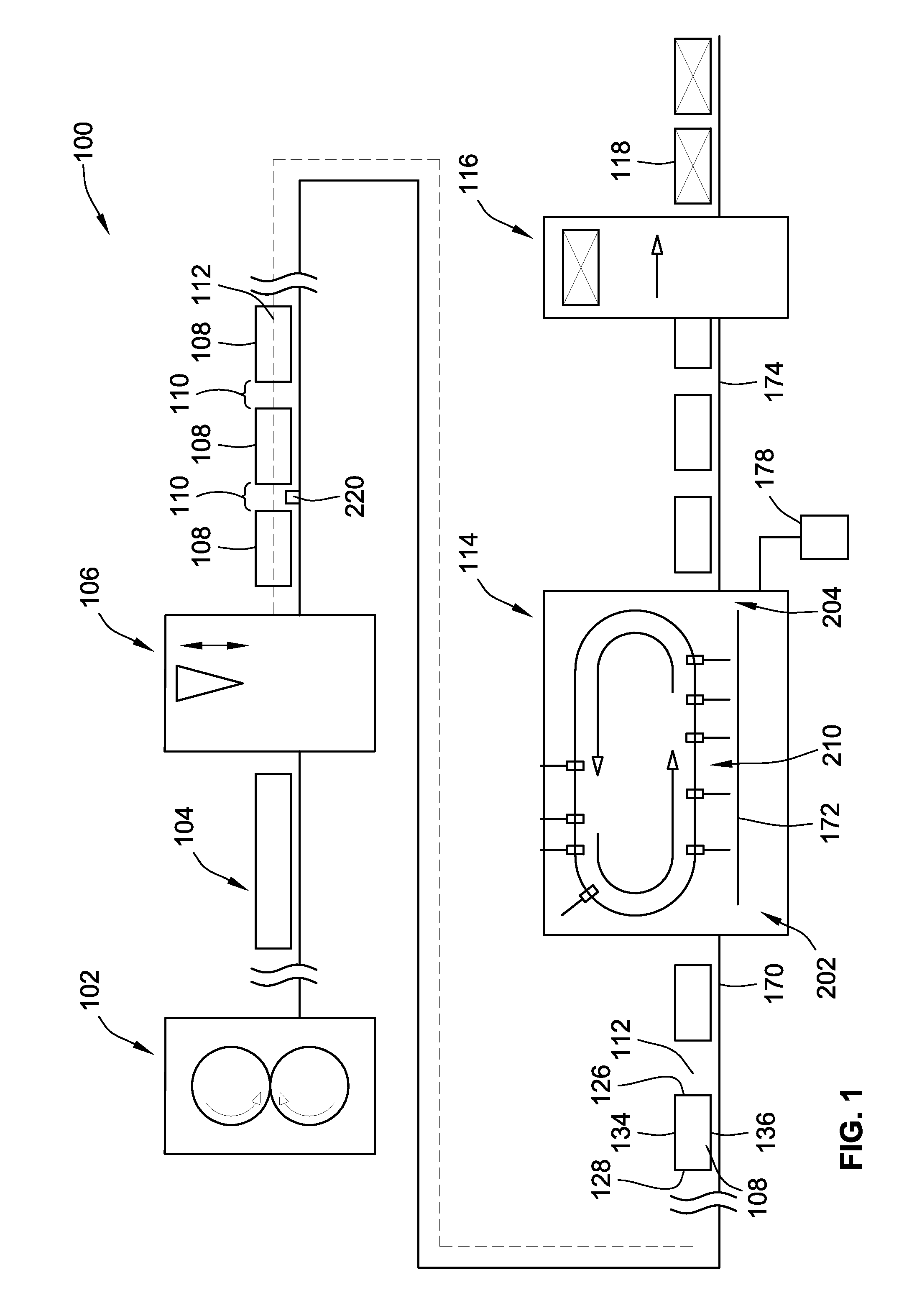

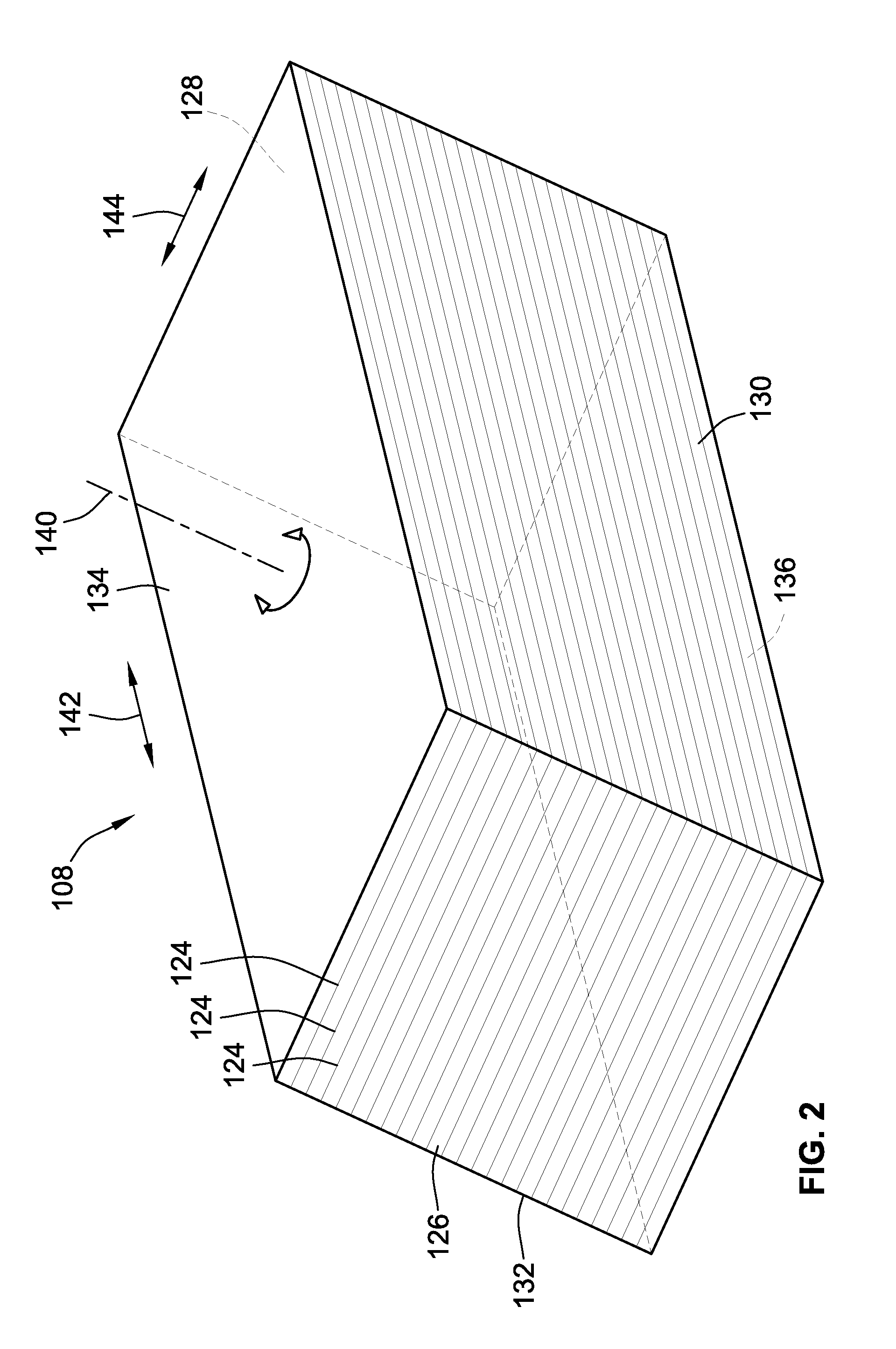

Pack alignment apparatus and methods using linear motor

InactiveUS20150078876A1Increase the number ofReduce in quantityLoadersNon-mechanical conveyorsPosition toleranceLinear motor

A system for forming and wrapping a plurality of stacks of sheet-like product is provided. The system includes a stack aligner for squaring up leading and trailing ends of the stack as well as sides of the stacks is provided. The stack aligner is also configured for controlling the position of the stacks along the stack travel path such that the stacks exit the stack aligner with tight positional tolerances for being fed to the stack wrapping arrangement.

Owner:C G BRETTING MFG

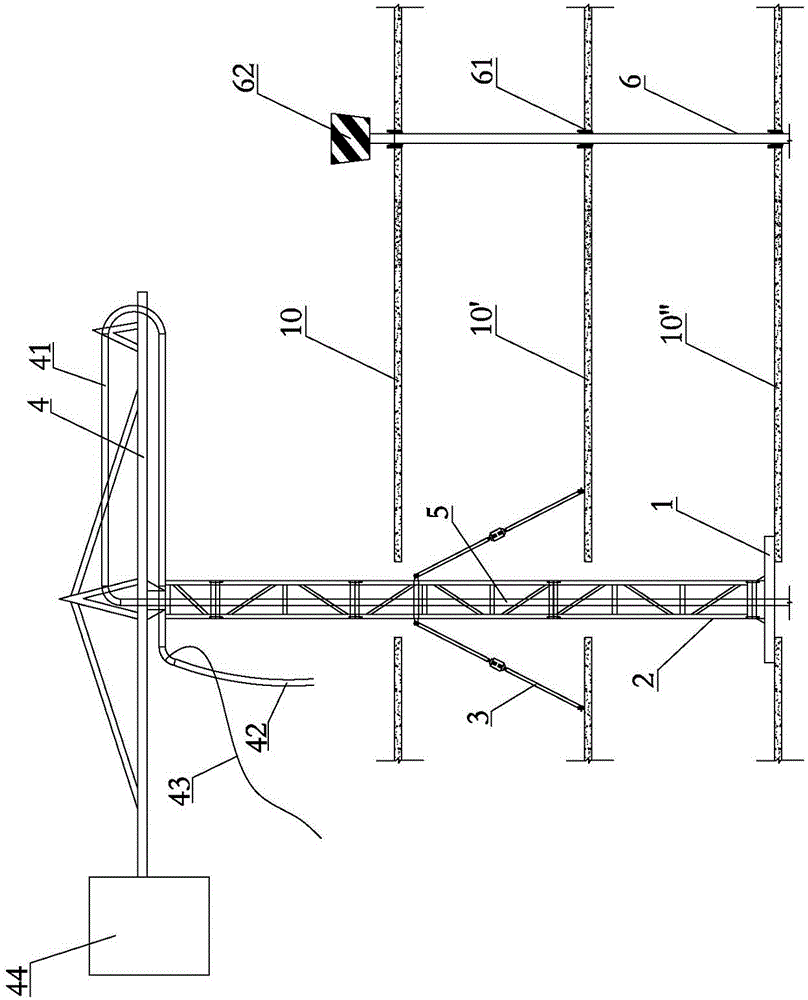

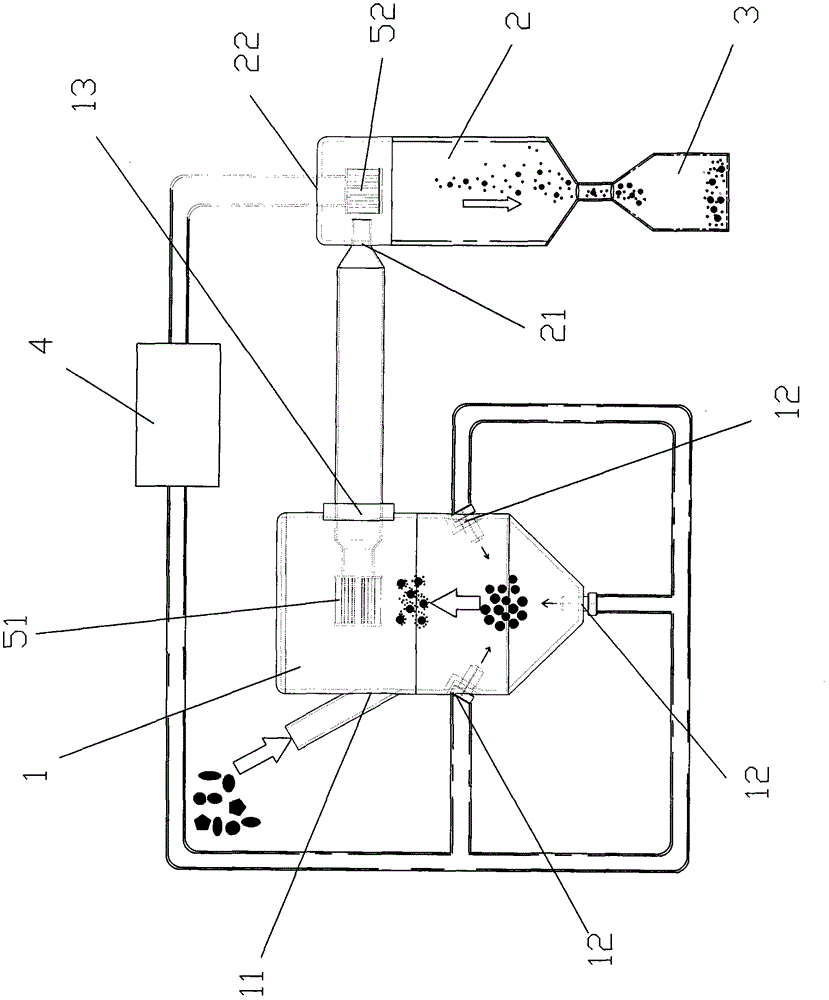

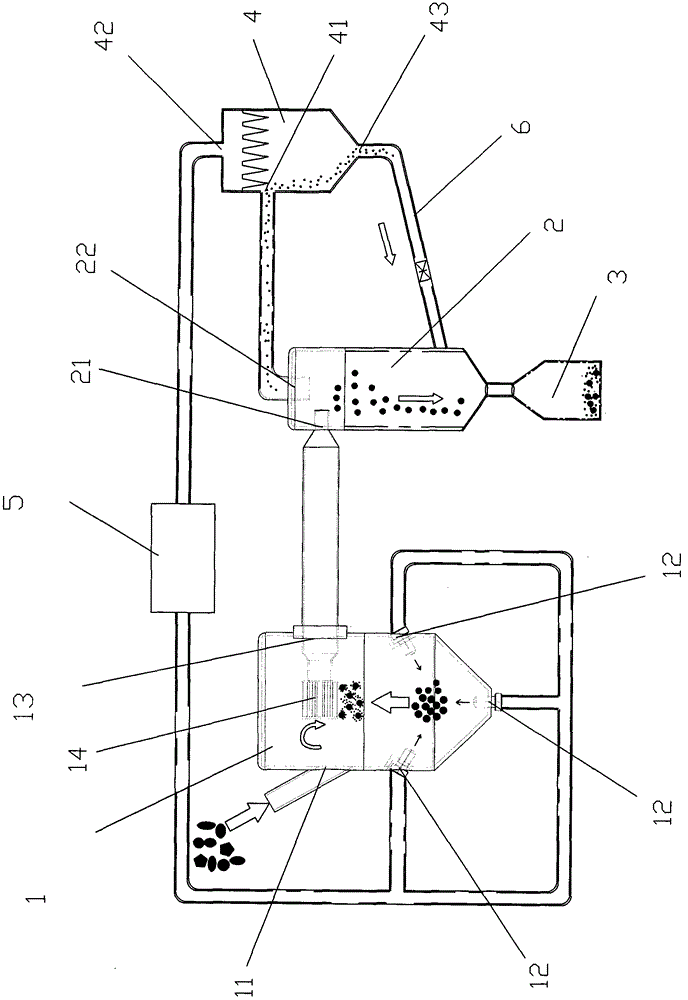

Novel material distribution device and floor concrete casting construction method of novel material distribution device

InactiveCN104975719ASolve the impact of cumbersome installation workSolve cleaningBuilding material handlingMaterial distributionRebar

The invention provides a novel material distribution device and a floor concrete casting construction method of the novel material distribution device, wherein the novel material distribution device mainly comprises a foundation section, a standard section, a material distribution rod, a pump pipe and a pump pipe loop, wherein the foundation section is fixed on the lower two layers of a construction layer; the standard section is fixed on the standard section; the standard section sequentially passes through holes reserved in the lower layer of the construction layer and the construction layer but is not in contact with the holes; the material distribution rod is fixed above the standard section; the pump pipe is connected with one end of the material distribution pipe arranged on the material distribution rod; the other end of the material distribution pipe is connected with a hose used for concrete casting; the pump pipe loop is specially used for cleaning a material distribution machine; and waste water can be directly conveyed into a collecting device arranged on the ground. The novel material distribution device and the floor concrete casting construction method of the concrete casting construction method can solve the following technical problems that the problem of damage of a conventional floor concrete cast pump pipe to floor steel bars is solved; the problem of influence of the vibration of the conventional floor concrete cast pump pipe on a formwork support frame system and a formwork system is solved; and the problems of pollution and cleaning complexity of the conventional floor concrete cast pump pipe are solved.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

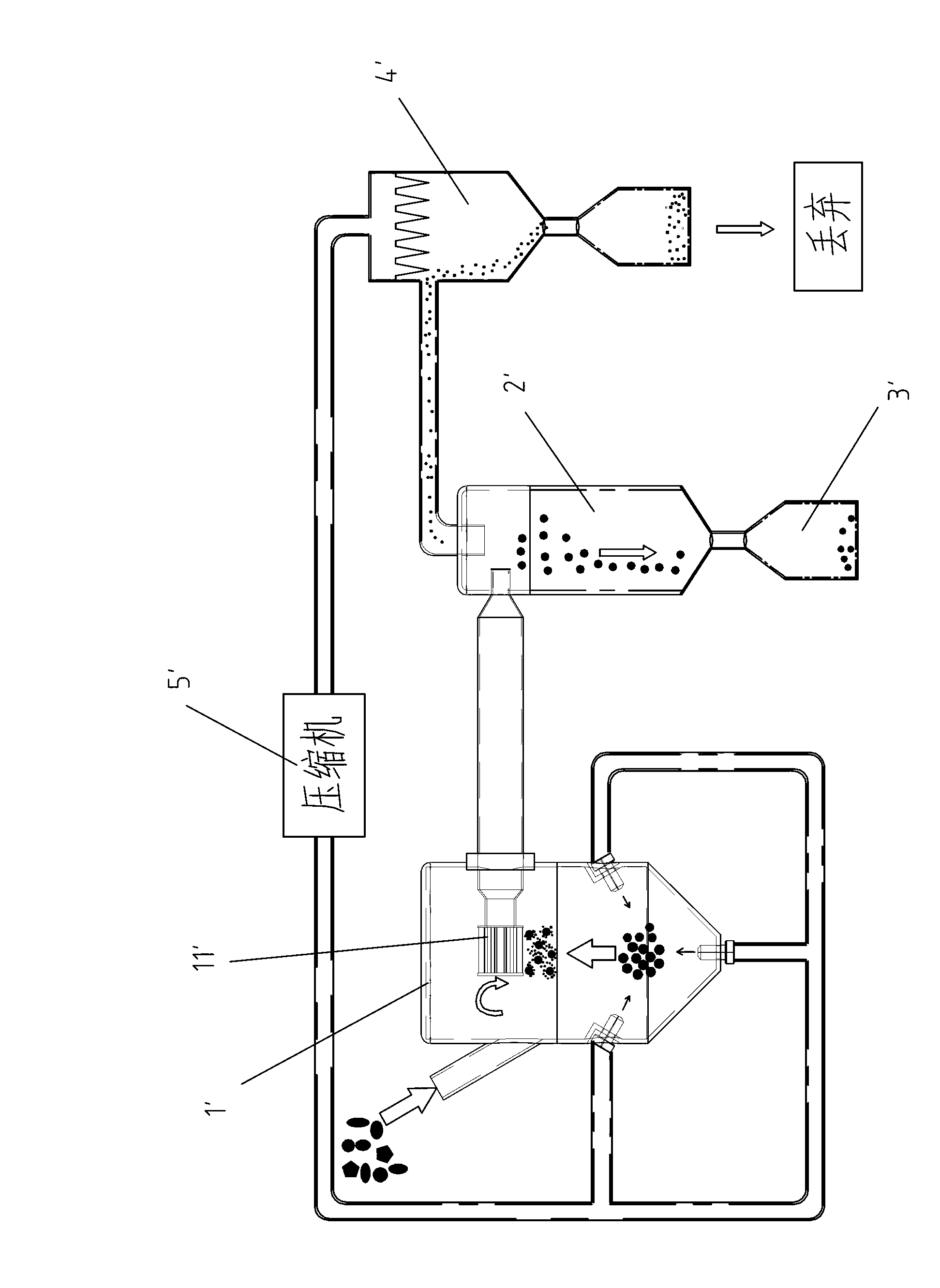

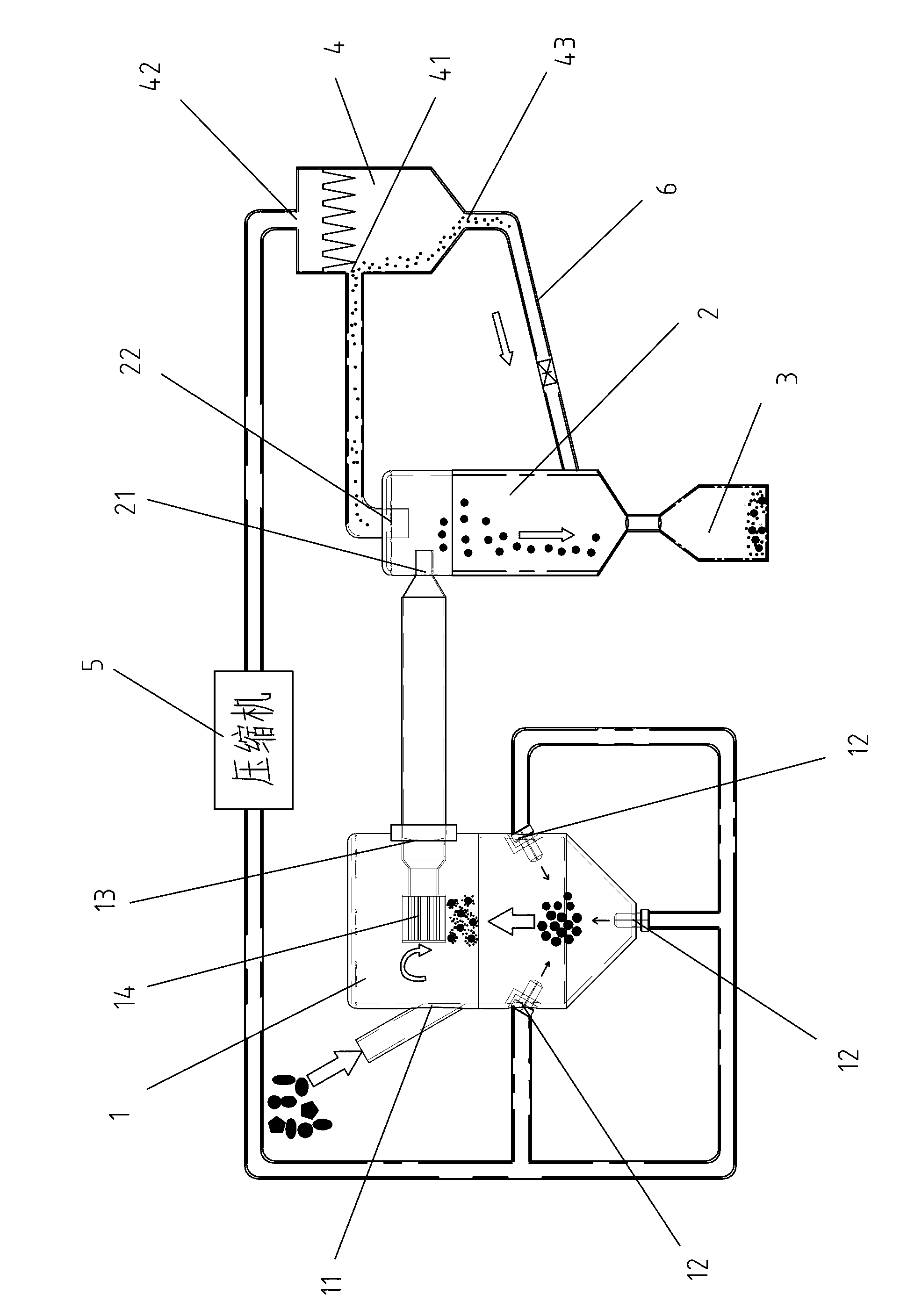

Alloy powder for rare-earth magnet, methods for manufacturing alloy powder and rare-earth magnet and powder manufacturing device

ActiveCN103817335ALow coercivityImprove coercive forceInductances/transformers/magnets manufactureMagnetic materialsAbnormal grain growthMicrometer

The invention discloses alloy powder for a rare-earth magnet, methods for manufacturing the alloy powder and the rare-earth magnet and a powder manufacturing device. The method for manufacturing the alloy powder includes acquiring all powder with the grain size smaller than 50 micrometers in working procedures for finely crushing at least one type of alloy for the rare-earth magnet and at least one type of alloy coarse powder for the rare-earth magnet by the aid of high-speed inert gas flow with the oxygen content lower than 1000ppm. By the aid of the alloy powder, the methods and the powder manufacturing device, ultrafine powder with the grain size smaller than 1 micrometer does not need to be separated from crushed powder which is transmitted from a crushing device and has a low oxygen content, the oxygen content of atmosphere of the crushing device is reduced and is lower than 1000ppm when the crushing device is used for crushing, and accordingly abnormal grain growth (AGG) can be prevented in a follow-up sintering procedure for acquiring a sintered magnet with a low oxygen content. The alloy powder, the methods and the powder manufacturing device have the advantages that working procedures can be simplified, and the manufacturing cost can be reduced.

Owner:FUJIAN CHANGJIANG GOLDEN DRAGON RARE EARTH CO LTD

Preparation method of sintered neodymium iron boron magnet free of heavy rare earth

InactiveCN108417376AImprove performancePerformance is not affectedInductances/transformers/magnets manufactureMagnetic materialsHydrogenRare earth

The invention discloses a preparation method of a sintered neodymium iron boron magnet free of heavy rare earth. The preparation method comprises the following steps of (a), configuring neodymium ironboron alloy and preparing a quick hardening sheet; (b), performing hydrogen demolish treatment on the quick hardening sheet to obtain rough powder; (c), adding a reagent to the rough powder, next performing grinding until the average grain diameter SMD is equal to 3.0-4.0[mu]m; (d), adding a reagent to the grinded powder, and performing re-grinding until the SMD is equal to 1.5-2.0[mu]m; (e), performing pressing and shaping in a magnetic field orientation condition, wherein the orientation magnetic field is 2.0-3.0T, and then carrying out an isostatic pressing mode to further enable the magnet to be sense; and (f), performing sintering on the green body obtained after isostatic pressing in a vacuum sintering furnace, performing cooling, and then carrying out first-stage aging tempering treatment and second-stage aging tempering treatment. According to the preparation method disclosed in the invention, in the air flow milling process, an additive is added and secondary grinding is performed, so that rough particles are reduced, and the mixed reagent can fully coat fine powder, powder oxidization is prevented, powder fluidity is improved, corrosion is eliminated, and powder consistency is improved.

Owner:NINGBO SONGKE MAGNETIC MATERIAL

Sintered Nd-Fe-B magnet manufacturing method and device

ActiveCN102842419ALess prone to growthSave rare earthPermanent magnetsInductances/transformers/magnets manufactureAbnormal grain growthRare earth

The invention discloses a sintered Nd-Fe-B magnet manufacturing method and device. The method comprises the following steps: in the manufacturing procedure of Nd-Fe-B system sintered magnet in which the oxygen content is below 2,500 ppm and in the crushing procedure under the condition that the oxygen content in inert gas is below 1,000 ppm, after the grading step, a mixing step is added to re-mix the originally separated ultrafine powder into finished crushed powder, and the originally separated ultrafine powder enters the follow-up processing procedure together with the finished crushed powder. By adopting the method, in the follow-up sintering procedure, AGG (Abnormal Grain Growth) can not be easily caused in the follow-up sintering procedure, besides, precious rare earth can be saved and extremely high pricing competitiveness is achieved through material conservation.

Owner:FUJIAN CHANGJIANG GOLDEN DRAGON RARE EARTH CO LTD

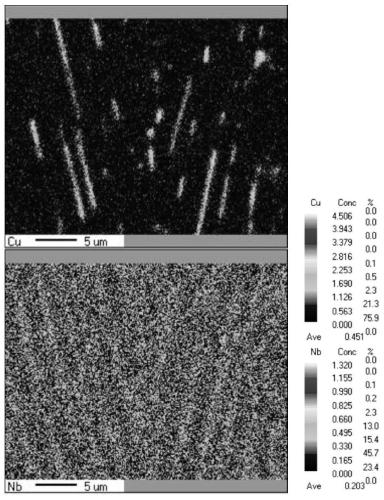

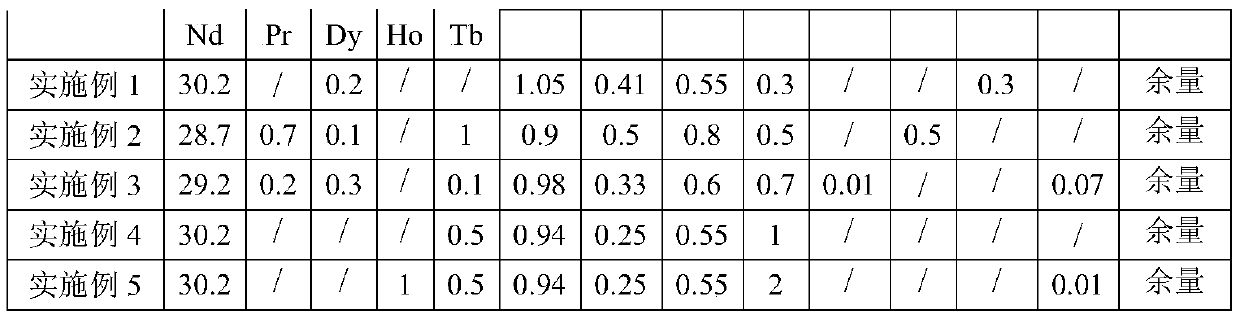

Neodymium-iron-boron permanent magnet material, and raw material composition, preparation method and application thereof

PendingCN111599562AImprove squarenessIncrease temperatureInductances/transformers/magnets manufactureMagnetic materialsHeat treatedNeodymium iron boron

The invention discloses a neodymium-iron-boron permanent magnet material, and a raw material composition and a preparation method thereof. The raw material composition for preparing the neodymium ironboron permanent magnet material comprises the following components: 0.25-0.5 mass percent of Nb and 0.55-0.8 mass percent of Cu. The squareness of the neodymium-iron-boron permanent magnet material prepared from the raw material composition is 99% or above. The absolute values of the temperature coefficients of Hcj at the temperature of 20-150 DEG C are all 0.422% or below; the heat treatment temperature zone is 470-510 DEG C; Br is greater than or equal to 14kGs, and the coercive force is greater than or equal to 25kOe.

Owner:FUJIAN CHANGJIANG GOLDEN DRAGON RARE EARTH CO LTD

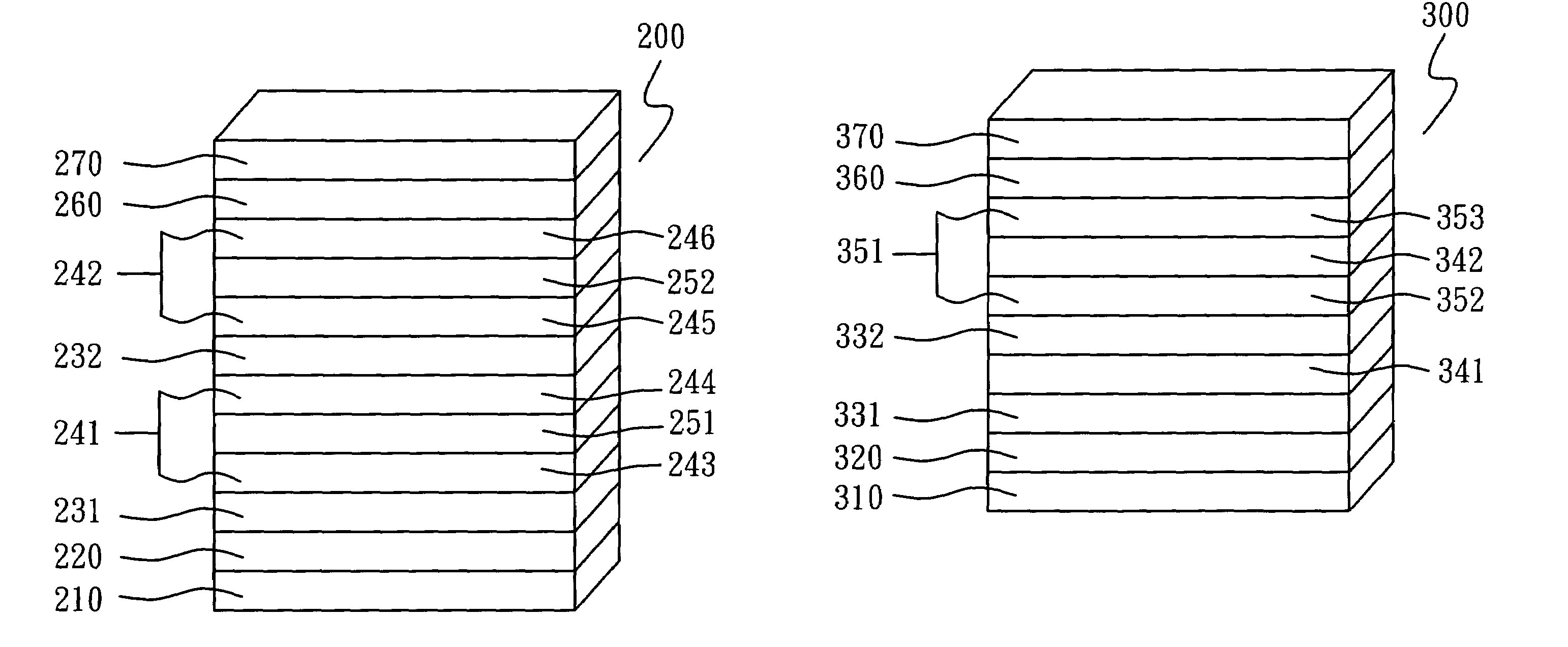

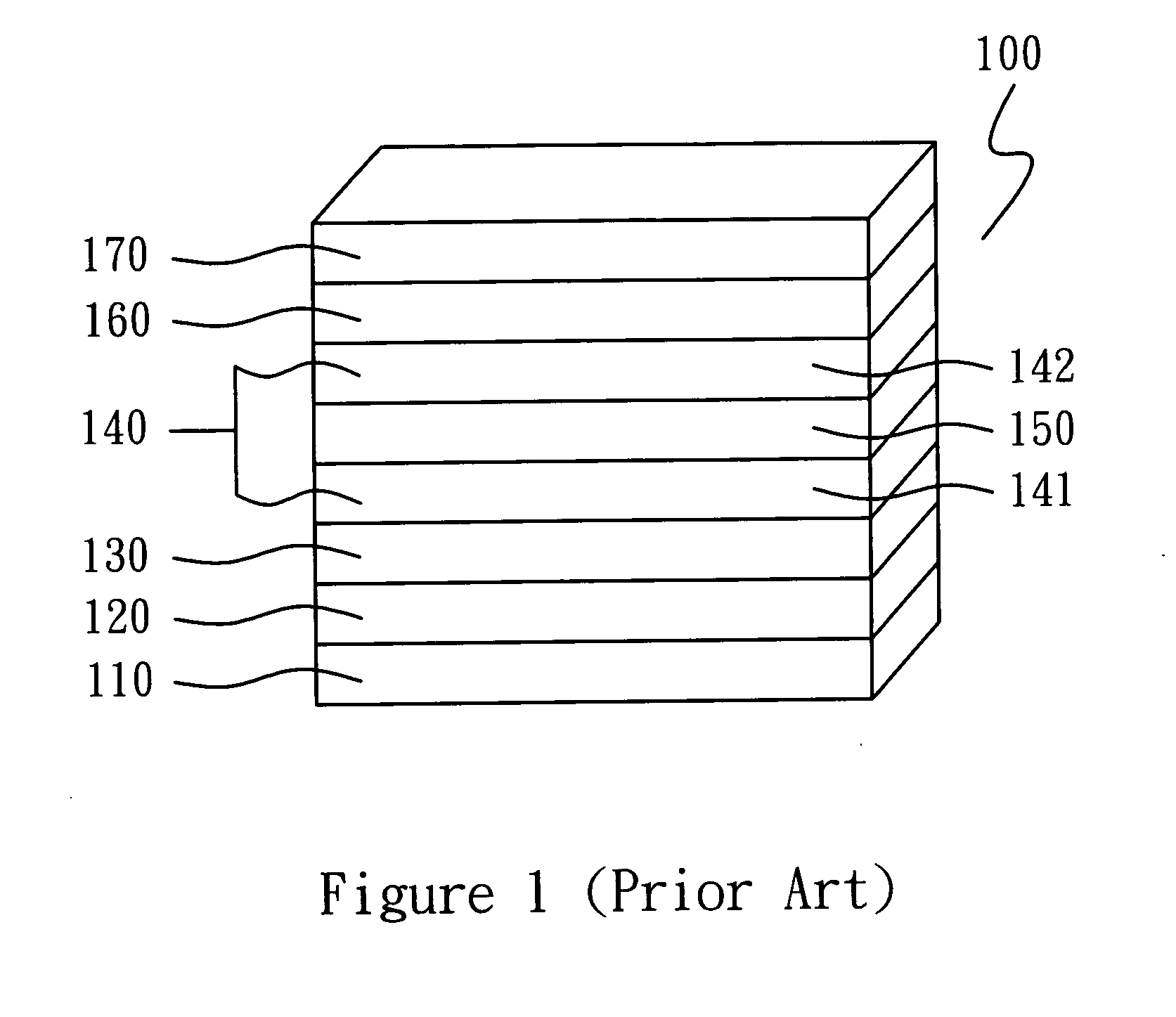

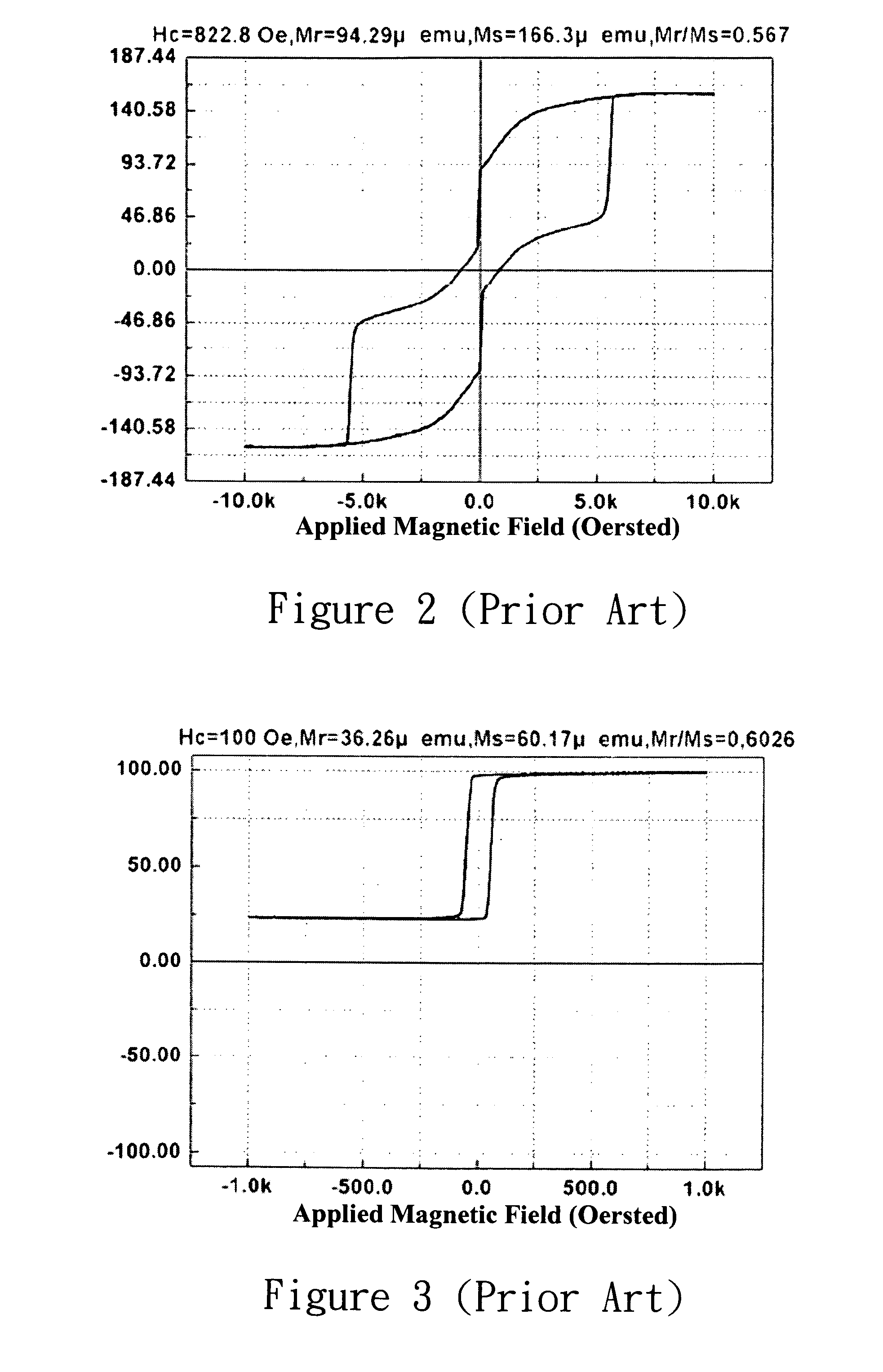

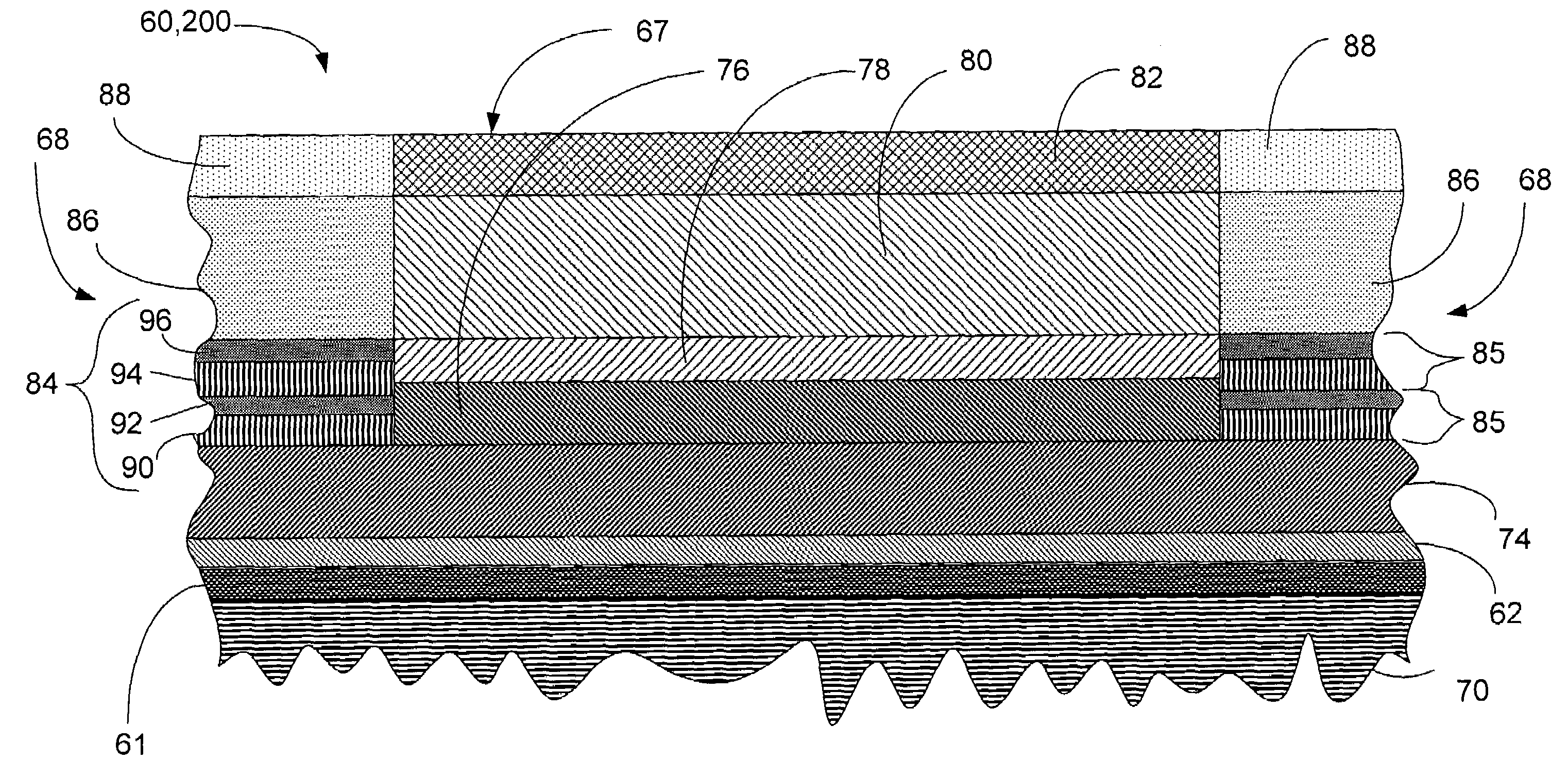

Magnetic tunneling junction structure for magnetic random access memory

InactiveUS20070215955A1Reduce coercive fieldImprove squarenessTransistorNanomagnetismHysteresisStatic random-access memory

A magnetic tunneling junction structure for magnetic random access memory is disclosed. A composite structure includes at least a pinning layer, a barrier layer, a ferromagnetic layer and a free layer, and the material of the pinning layer and the free layer are perpendicularly anisotropic ferrimagnetic. As the structures include of several barrier layers, free layers and ferrimagnetic layers, that lower coercivity and high squareness for the hysteresis curves can be obtained, and reduction of the coercivity of the free layer can be achieved.

Owner:NATIONAL YUNLIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

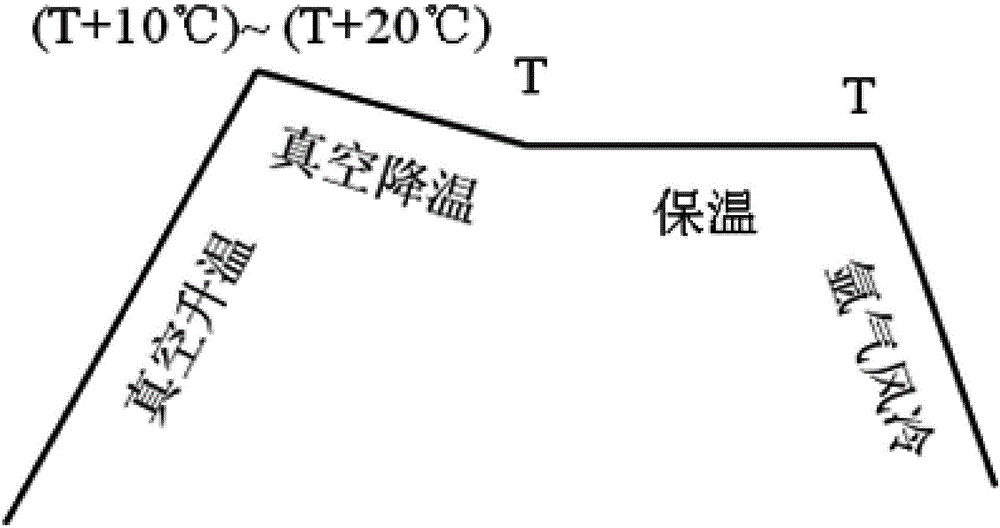

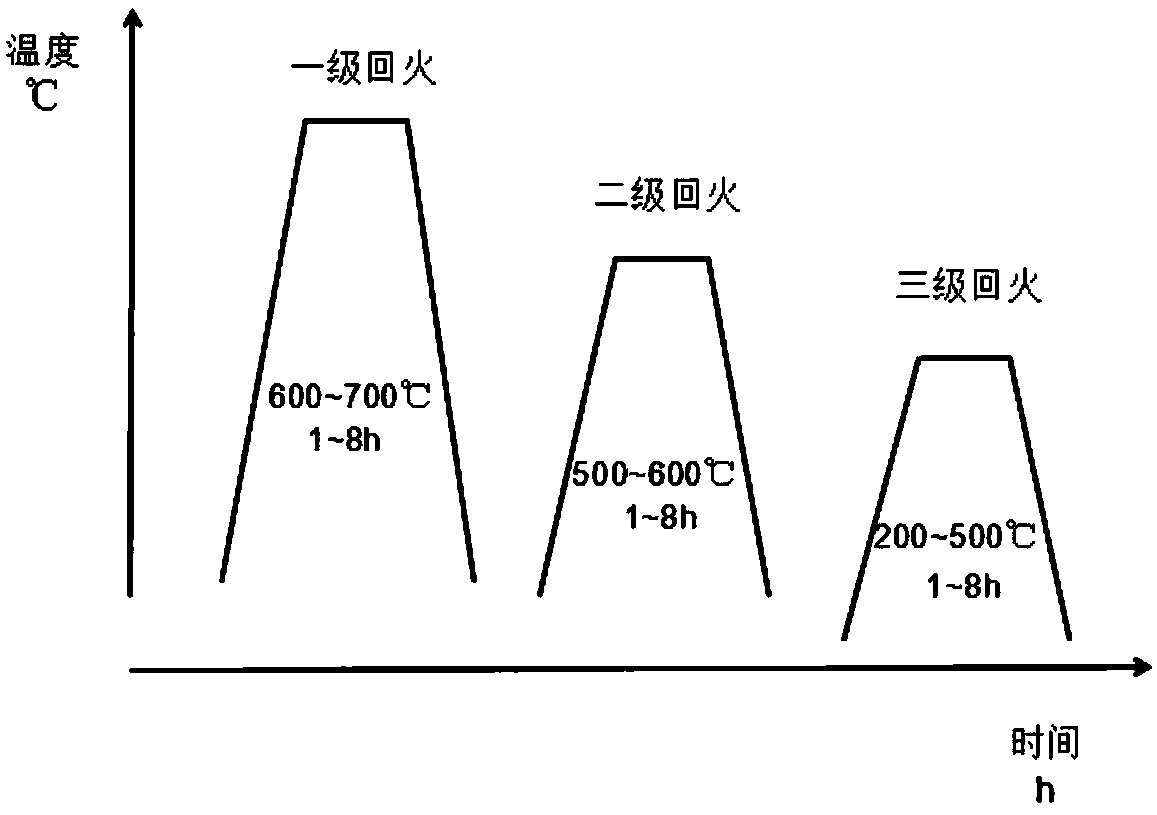

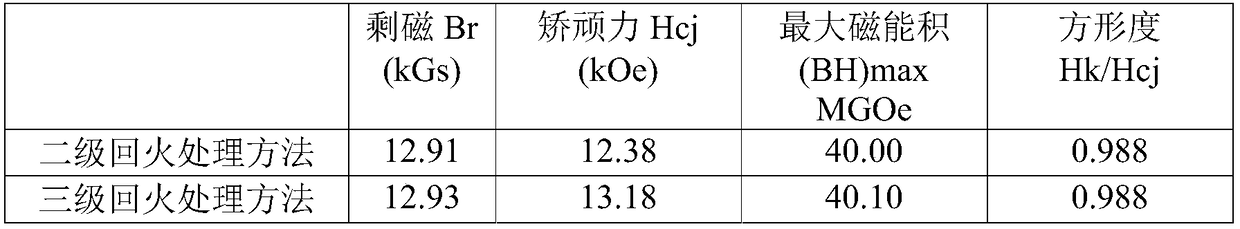

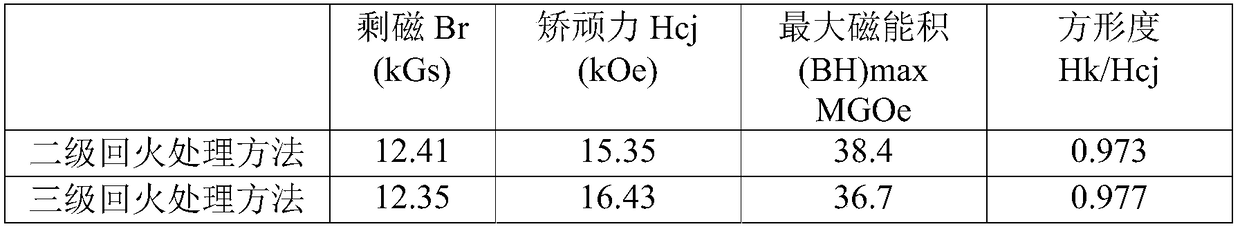

Tempering technology for NdFeB magnet

InactiveCN106158208AHigh densityImprove squarenessInductances/transformers/magnets manufactureMagnetic materialsSquare degreeThree stage

The invention provides a tempering technology for an NdFeB magnet. The tempering technology comprises steps as follows: firstly, under the condition of vacuum or protective gas, a sintered NdFeB magnet blank is subjected to primary heating and primary heat preservation, and a primary tempered intermediate is obtained after cooling; then, the primary tempered intermediate obtained in the step is tempered N times, and the NdFeB magnet is obtained; each tempering process is as follows: heating is performed firstly, cooling is performed, heat preservation is performed, and cooling is performed finally; the heat preservation temperature is T, and heat preservation temperatures of the tempering processes decrease sequentially; n is a natural number larger than or equal to 1. The technology starts from the tempering processes during preparation of the magnet, a technology of multistage tempering heat treatment is adopted, that is, a method adopting three-stage tempering after two-stage tempering is adopted, a multistage tempering method adopting four-stage tempering after two-stage tempering and three-stage tempering can be adopted, the coercivity can be effectively improved, and the density and square degree of the magnet can be improved.

Owner:京磁材料科技股份有限公司

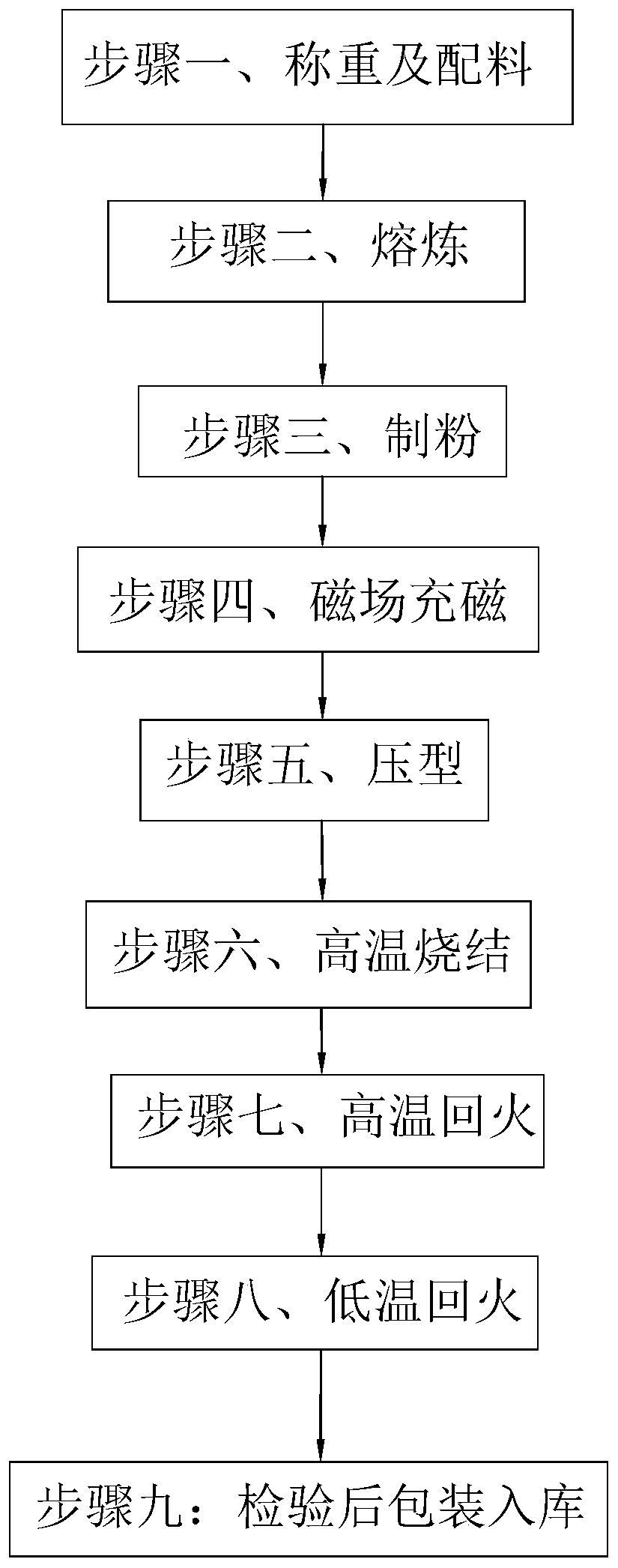

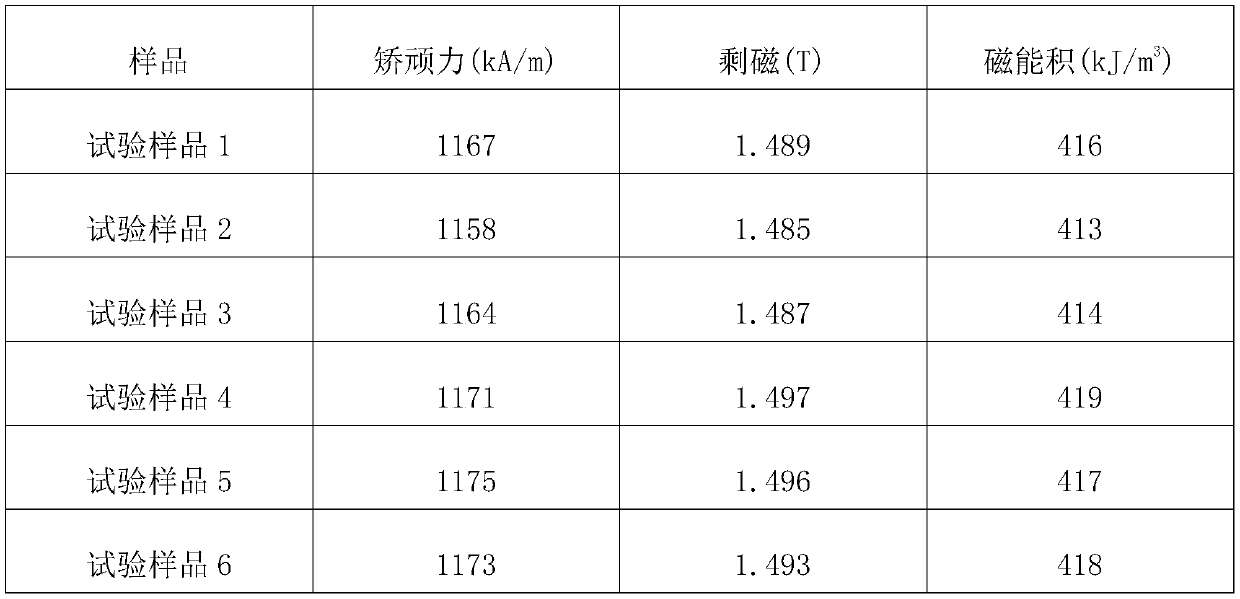

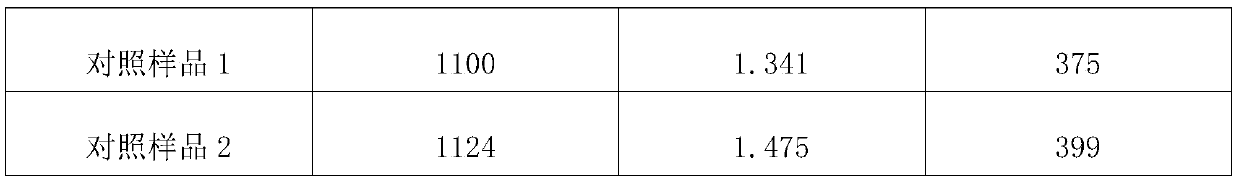

Neodymium iron boron permanent magnet material and preparation method thereof

InactiveCN110504077AImprove coercive forceImprove squarenessInductances/transformers/magnets manufactureMagnetic materialsTemperingNiobium

The invention discloses a neodymium iron boron permanent magnet material and a preparation method thereof, and belongs to the technical field of permanent magnet materials. The neodymium iron boron permanent magnet material is technically characterized by comprising the following components in percentage by weight: 30-45% of neodymium, 2-2.5% of niobium, 2.5-4.2% of cobalt, 0.15-0.2% of zinc, 0.2-0.5% of gallium, 2.5-4.8% of boron, 0.1-0.5% of tungsten, 2.5-4% of thulium oxide and the balance of iron. The preparation method of the neodymium iron boron permanent magnet material comprises the following steps: weighing and dosing, smelting, pulverizing, magnetic field magnetizing, briquetting, high-temperature sintering, high-temperature tempering, low-temperature tempering, inspection, packaging and warehousing. The coercive force of the neodymium iron boron permanent magnet material is effectively improved, so that the neodymium iron boron permanent magnet material has excellent performances of improving the square degree and improving the temperature stability.

Owner:宁波可可磁业股份有限公司

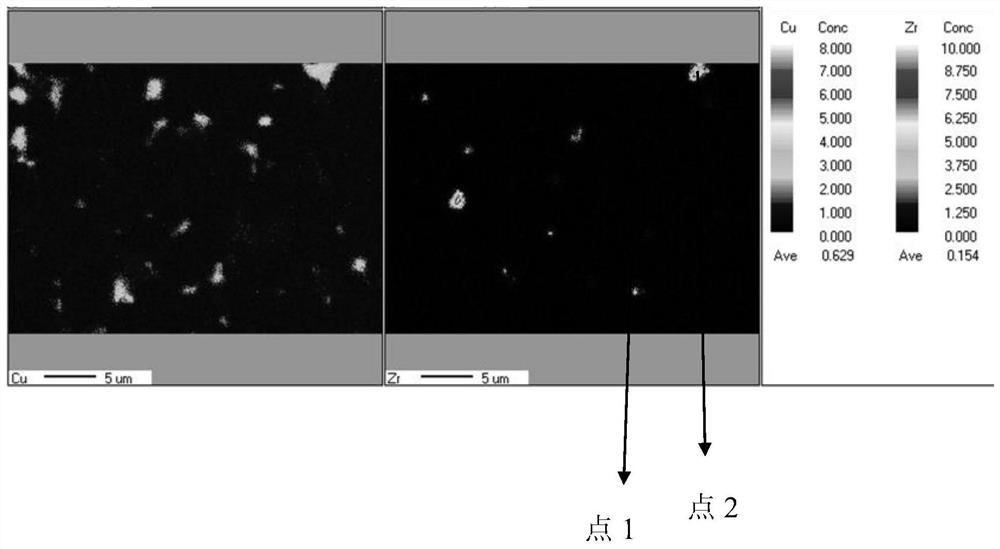

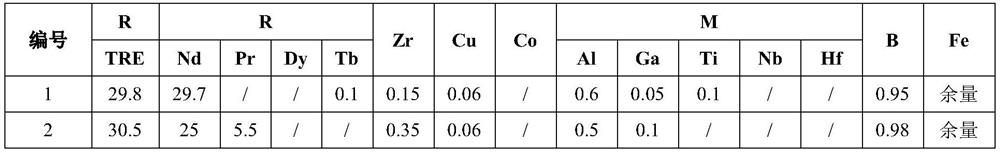

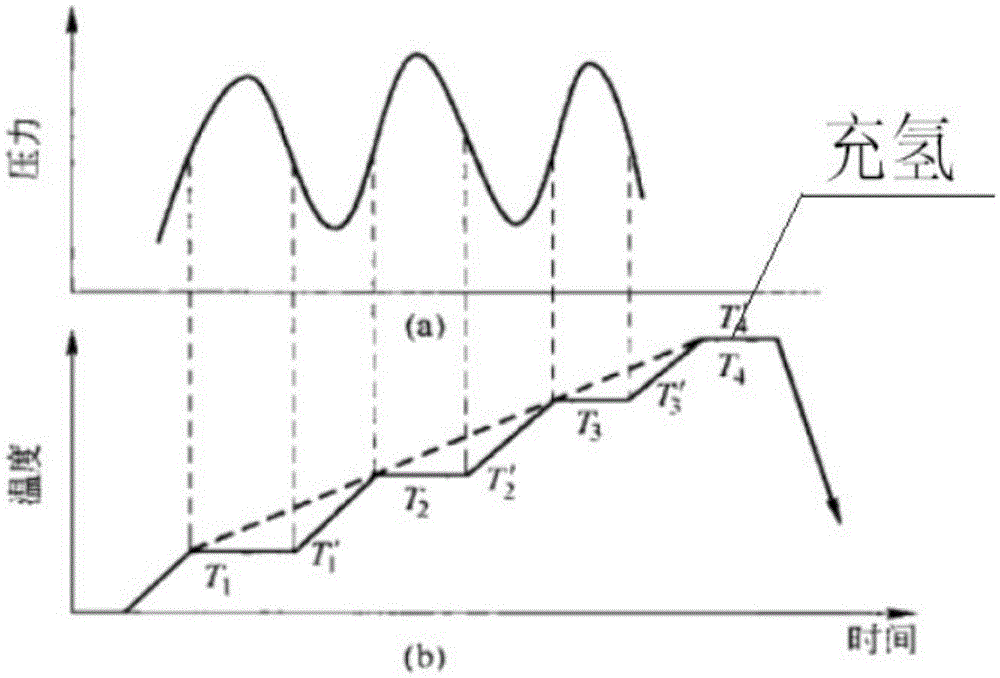

R-T-B series permanent magnet material, raw material composition and preparation method and application thereof

ActiveCN111613407AImprove coercive forceControl contentInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementMetallurgy

The invention discloses an R-T-B series permanent magnet material, a raw material composition and a preparation method and application thereof. The raw material composition of the R-T-B series permanent magnet material comprises the following components in percentage by mass: 29.5-32% of R which is a rare earth element at least containing Nd, whereinthe content of Pr is 0-17%; 0.15-0.50% Zr; 0-0.08% of Cu, wherein Cu is not 0 or 0.08; 0-0.3% of M, wherein M is one or more of Al, Ga, Ti, Nb, Hf, Si, Sn, Ge, Ag, Au, Bi and Mn; 0.95-1.05% of B; and 64-70% of Fe, wherein the percentage is the masspercentage accounting for the total mass of the raw material composition of the R-T-B series permanent magnet material, and the sum of the contents of all the components is 100%. The R-T-B series permanent magnet material has the advantages of being good in squareness, good in high-temperature performance and excellent in mechanical performance.

Owner:FUJIAN CHANGJIANG GOLDEN DRAGON RARE EARTH CO LTD

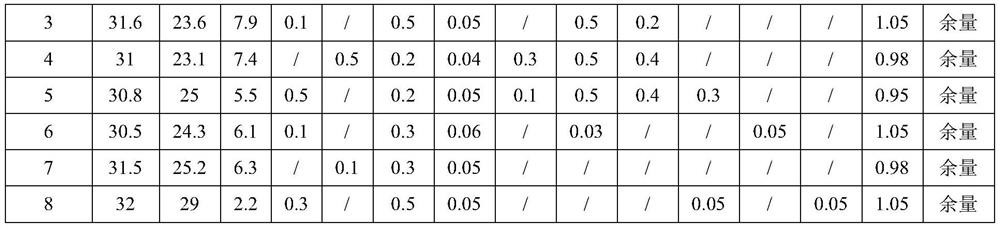

Sintering method for neodymium-iron-boron magnet

ActiveCN105551790AImprove remanence (Br)Avoid consumptionInorganic material magnetismInductances/transformers/magnets manufactureHydrogenRare earth

The invention provides a sintering method for a neodymium-iron-boron magnet. The method comprises the following steps: firstly, carrying out continuous warming or stepped warming on a green neodymium-iron-boron magnet body to reach a sintering temperature under a vacuum or protective gas condition, and obtaining a neodymium-iron-boron magnet intermediate; and carrying out constant-temperature firing on the neodymium-iron-boron magnet intermediate obtained in the previous step under a hydrogen condition, and obtaining a neodymium-iron-boron magnet blank. In a plurality of steps for preparing the neodymium-iron-boron magnet, hydrogen is filled into a system at a specific high-temperature sintering stage in the sintering process from the sintering method, so that a neodymium-rich phase in the blank material is uniform in distribution; a rare-earth phase is prevented from being consumed; a rare-earth phase oxide is avoided; rare earth does not need to add when a formula is designed; the cost is saved; the coercivity of a product is also improved; and the sintering method has very important significance for development of a neodymium-iron-boron magnet product.

Owner:廊坊京磁精密材料有限公司

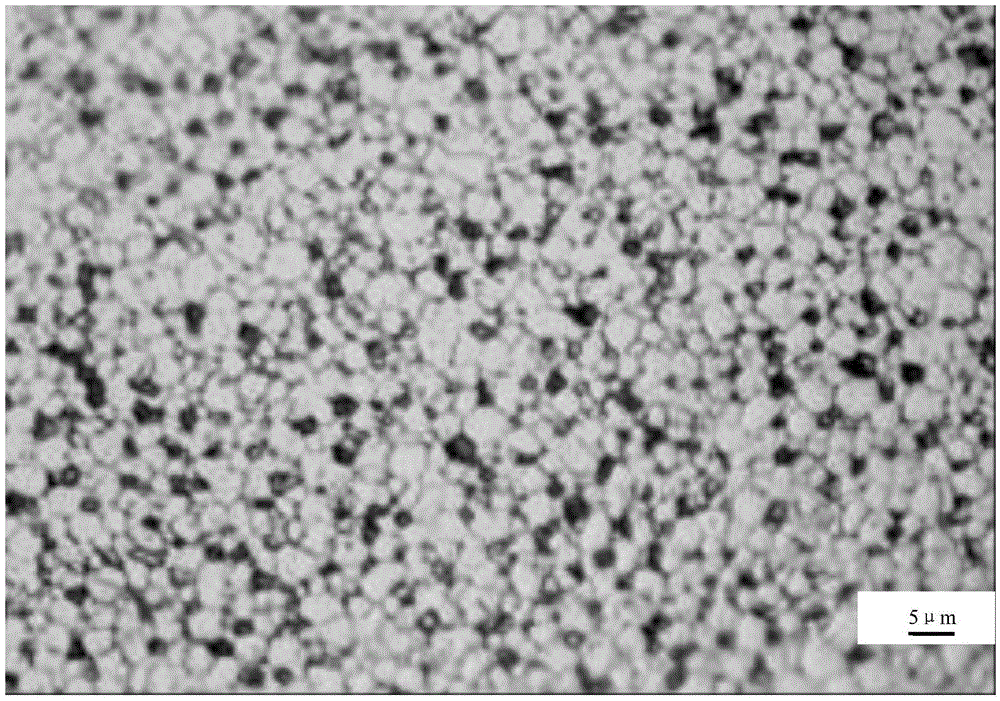

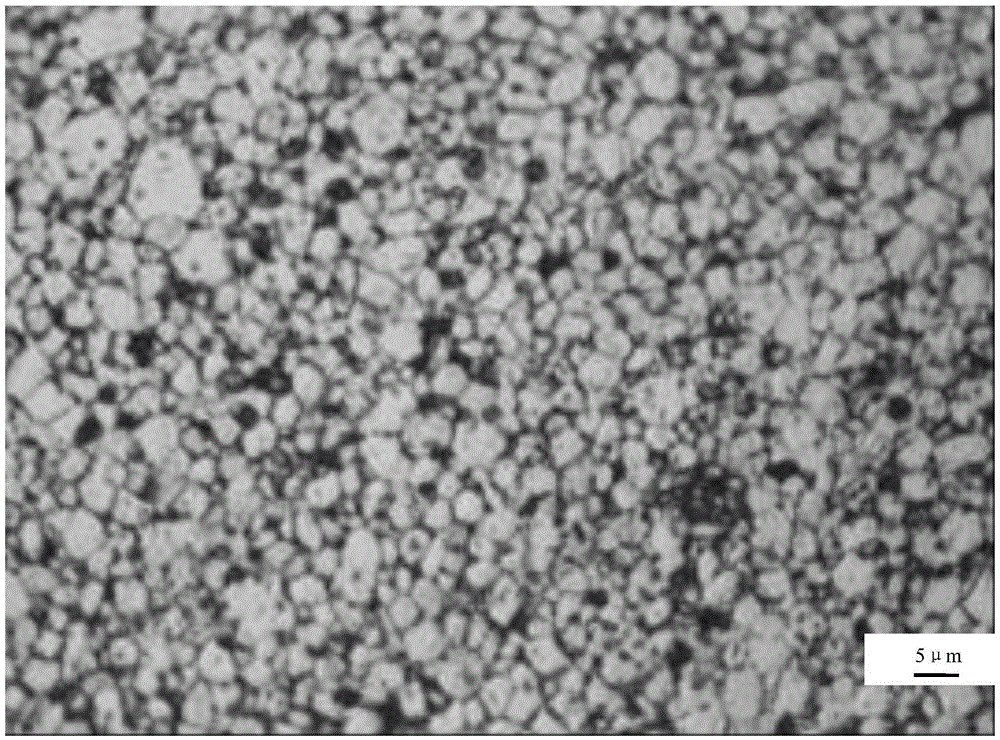

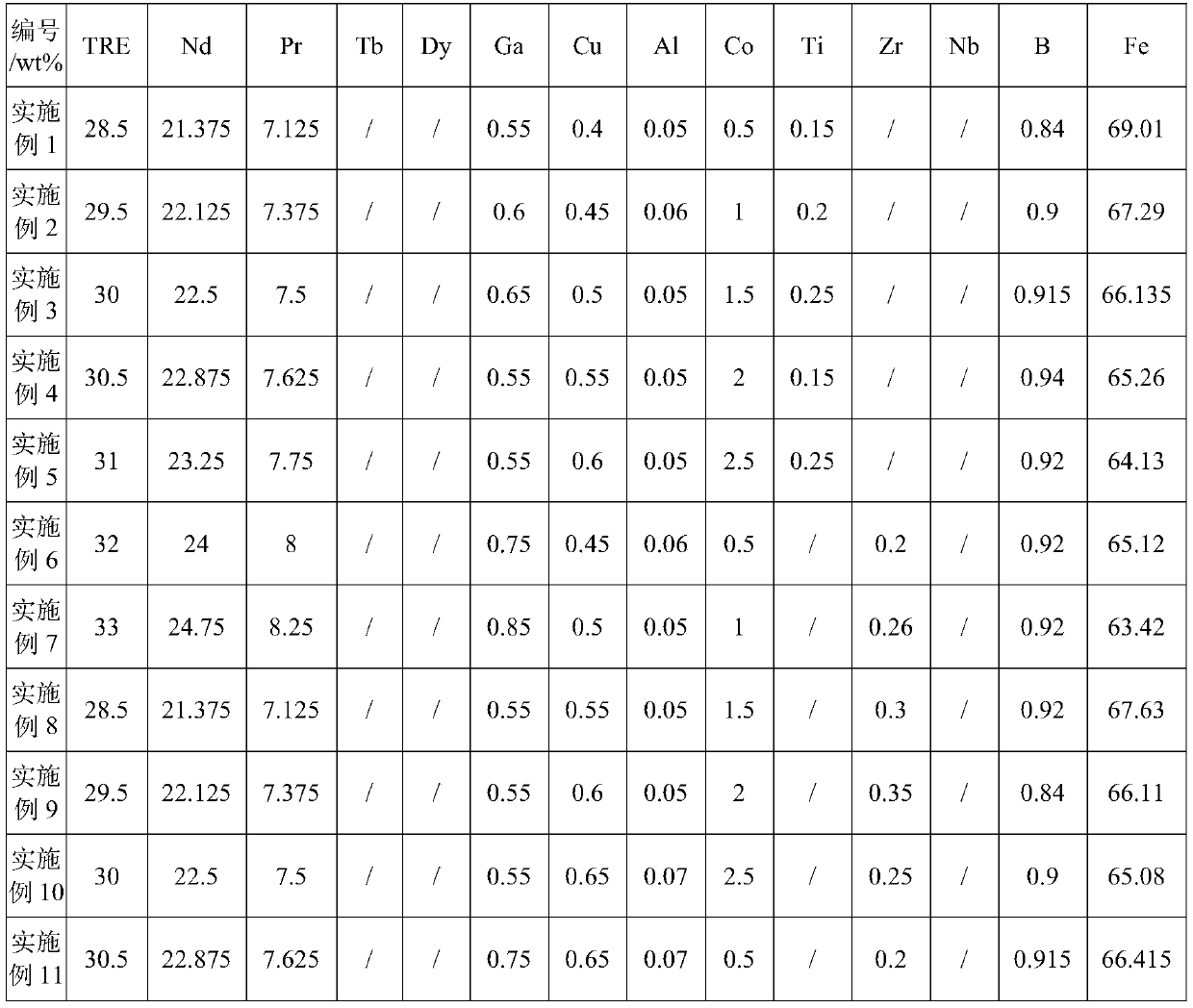

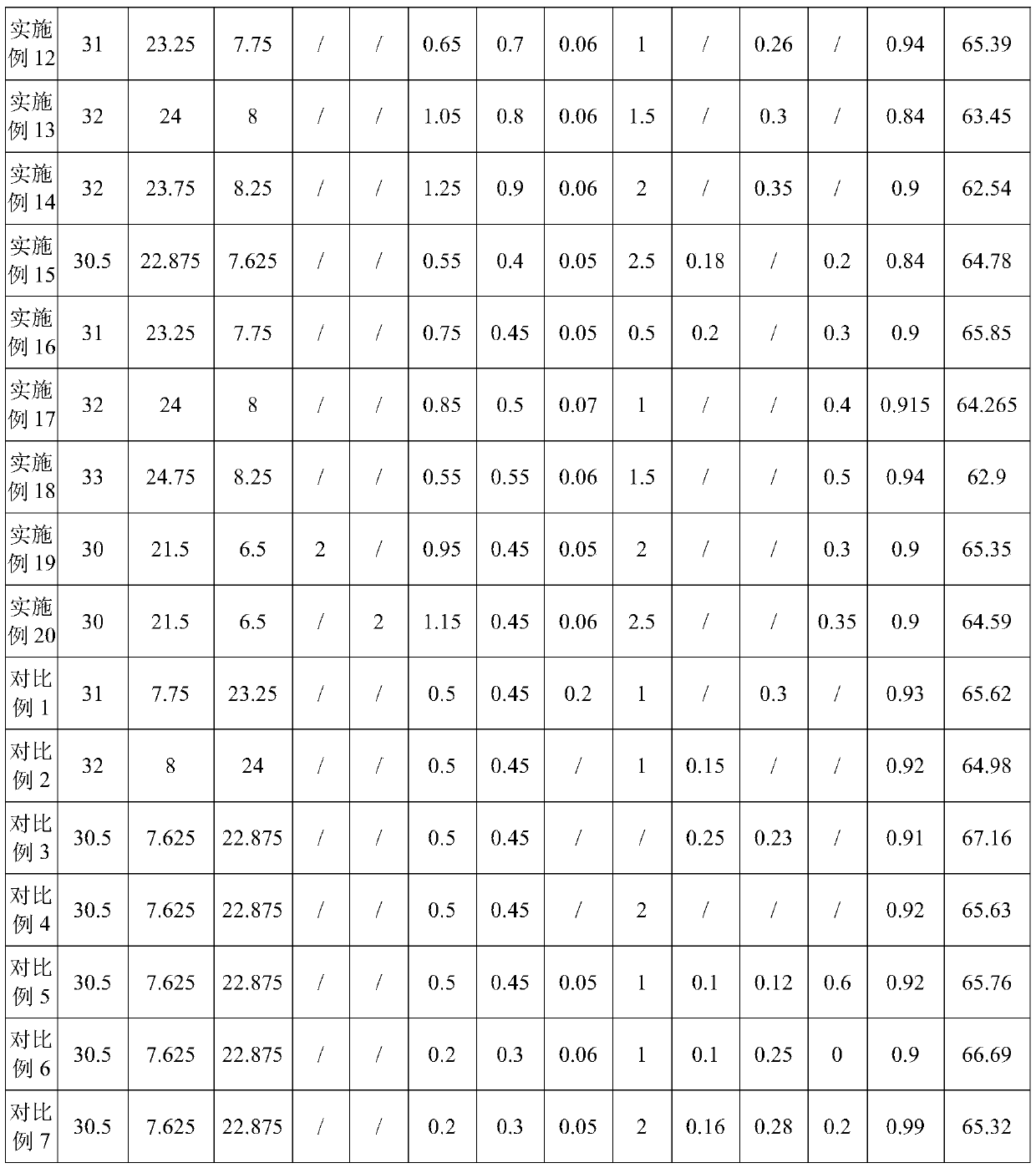

R-T-B series permanent magnet material and preparation method and application thereof

ActiveCN111243812AStrong magnetismImprove temperature stabilityInductances/transformers/magnets manufactureMagnetic materialsMetallurgyMagnet

The invention discloses an R-T-B series permanent magnet material and a preparation method and application thereof. The raw material composition of the R-T-B series permanent magnet material is prepared from the following components in percentage by mass: 28.5 to 33.0 percent of R; ga:>0.5%; cu: > = 0.4%; b: 0.84%-0.94% of the total weight of the raw materials; 0.05 to 0.07% of Al; co: < = 2.5% but not 0; 60 to 70 percent of Fe; n is one or more of Ti, Zr and Nb; when N contains Ti, the content of Ti is 0.15%-0.25%; when N contains Zr, the content of Zr is 0.2%-0.35%; when N contains Nb, the content of Nb is 0.2%-0.5%; wherein the percentage is the mass percentage of each component in the total mass of the raw material composition. The R-T-B series permanent magnet material disclosed by the invention is relatively good in magnetic performance, and the magnetic performance of the same batch of products is uniform.

Owner:FUJIAN CHANGJIANG GOLDEN DRAGON RARE EARTH CO LTD

Method for improving magnetic property of sintered neodymium-iron-boron permanent magnet

ActiveCN104766717AImprove microstructureGood orientationIncreasing energy efficiencyInductances/transformers/magnets manufactureHigh energyElectromagnetic field

Provided is a method for improving the magnetic performance of a sintered neodymium-iron-boron permanent magnet. According to the method, a sintered magnet undergoes inductive eddy current heating to turn a neodymium-rich phase thereof into a liquid phase, thus on the one hand, under the effect of an induced electromagnetic field, the flow of the neodymium-rich liquid phase can be intensified through electromagnetic stirring of induced eddy currents, so as to optimize the microstructure of the magnet; and on the other hand, main phase grains are more prone to rotate along the magnetic field direction of an induction coil, further increasing the degree of orientation of the magnet. Experiments prove that the coercive force of the sintered neodymium-iron-boron permanent magnet is somewhat improved, so does the squareness thereof. And meanwhile, both the remanence and the maximum magnetic energy product of the permanent magnet are also boosted. In addition, the method has the advantages of cleanliness without any pollution, high energy efficiency, great simplicity and practicability and so forth, and accordingly is highly promising in application.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Cerium-containing neodymium-iron-boron magnet and heat treatment processs and application thereof

ActiveCN109065312AGuaranteed Magnetic PropertiesLow costInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementThree stage

The invention provides a cerium-containing neodymium-iron-boron magnet and a heat treatment processs and application thereof. The cerium-containing neodymium-iron-boron magnet comprises that followingcomponent in parts by weight: 20-32 parts by weight of praseodymium-neodymium alloy (Pr-Nd), 3-11 parts by weight of cerium (Ce), 40.65 to 76.06 parts by weight of iron (Fe), wherein the percentage content of heavy rare earth elements in the cerium-containing neodymium-iron-boron magnet is low than 3 percent, and the cerium-containing neodymium-iron-boron magnet does not contain low melting pointrare earth liquid phase alloy. The heat treatment process comprises a three-stage tempering treatment. The cerium-containing neodymium-iron-boron magnet can be used for preparing motors, the cerium-containing NdFeB magnet has excellent performance.

Owner:SHANGHAI JIAO TONG UNIV +2

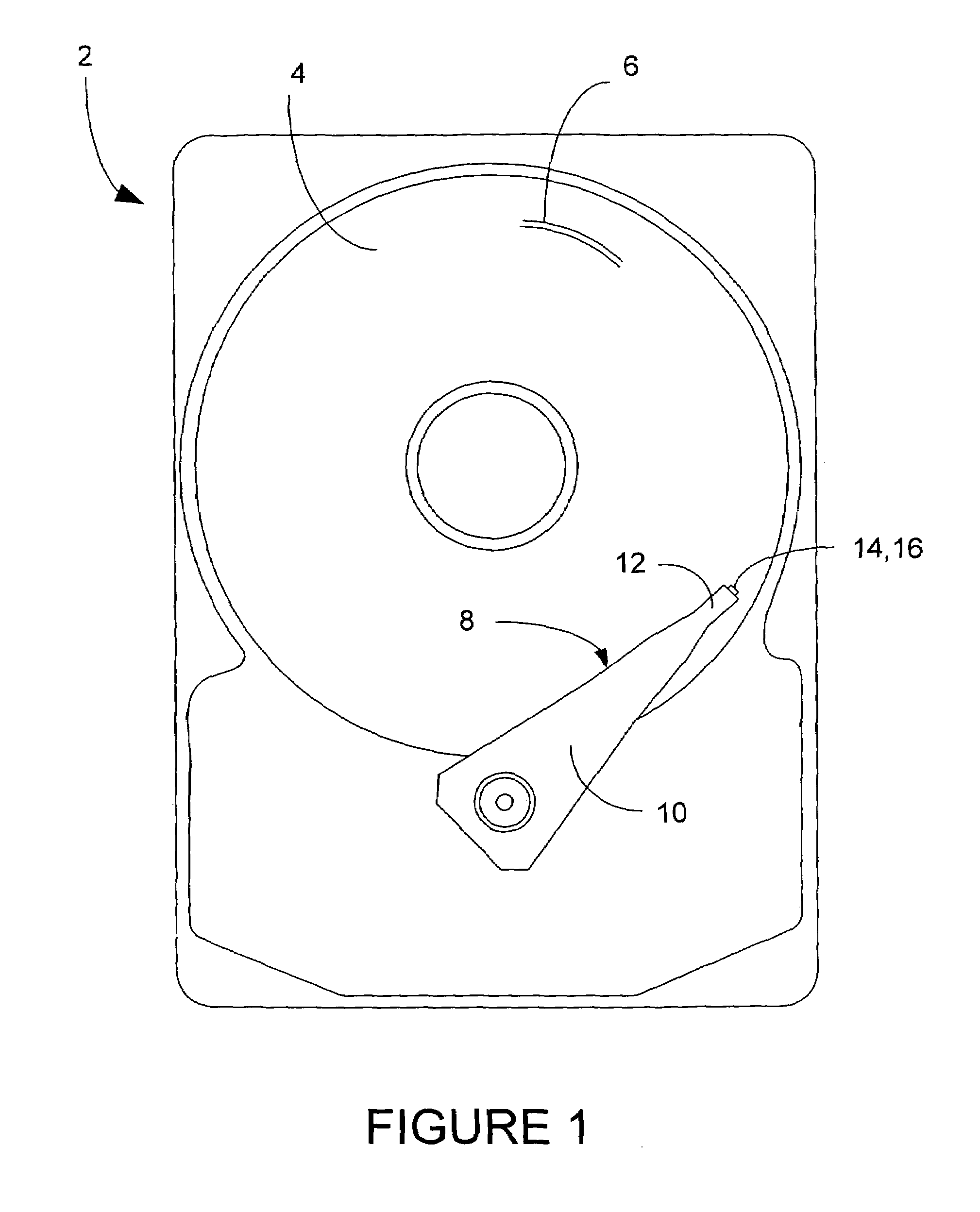

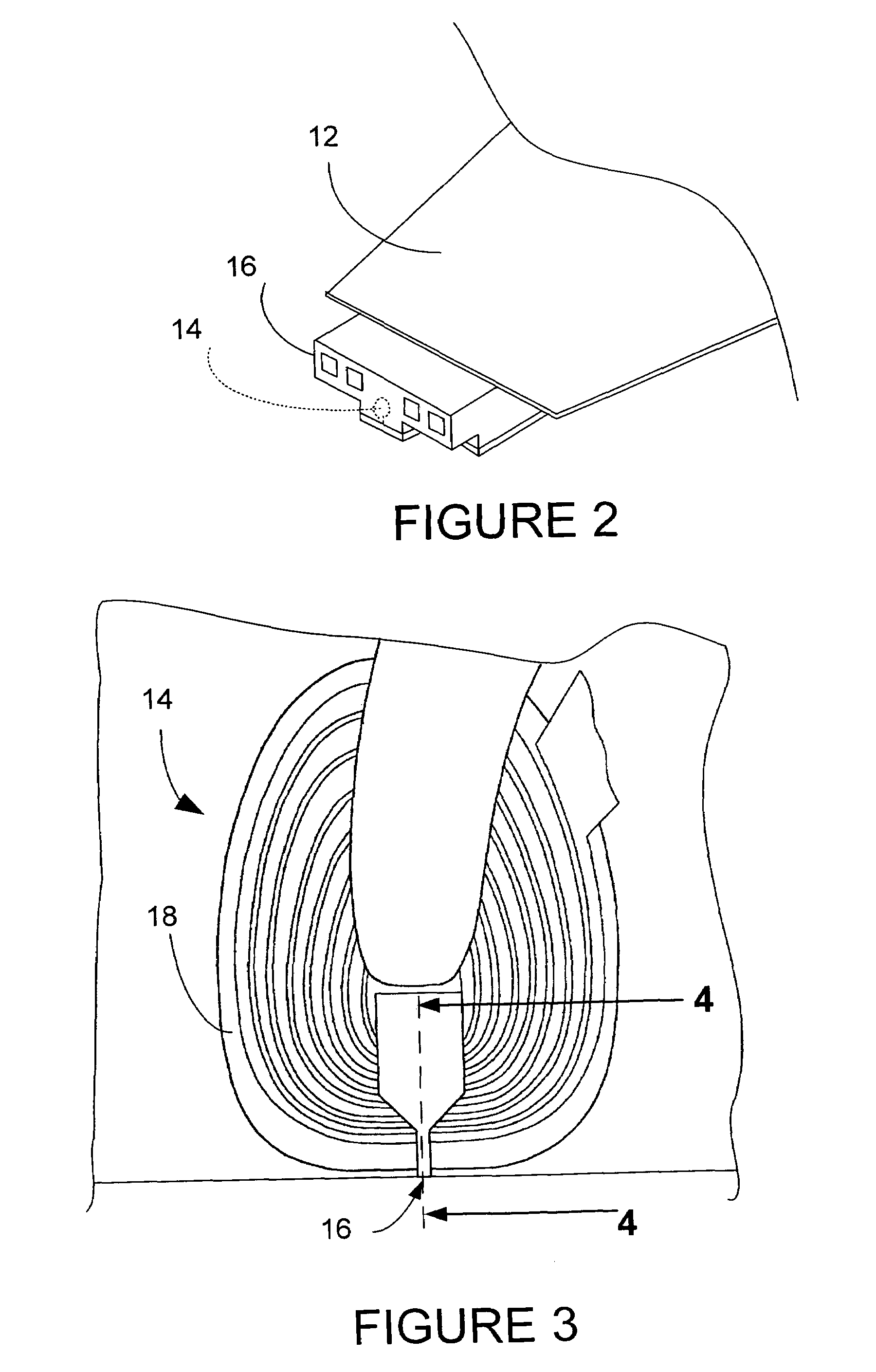

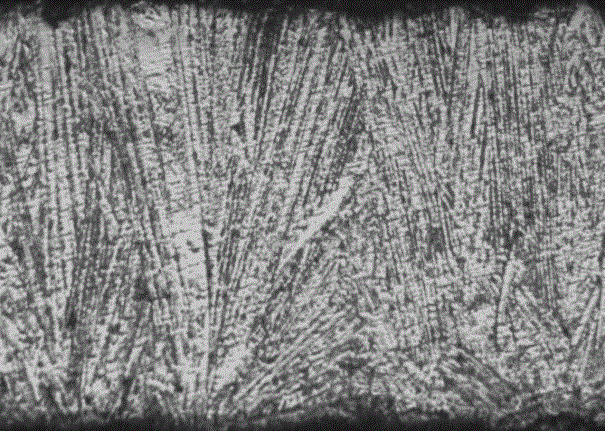

Seedlayer for high hard bias layer coercivity

InactiveUS7433163B2Increase in coercivityNot easy to layerNanomagnetismMagnetic measurementsOptoelectronicsBi layered

A seedlayer structure for a high coercivity hard bias layer is disclosed, having at least one bi-layer seedlayer, including a CrMo layer, and a W layer fabricated on the CrMo layer. A hard bias layer is fabricated on the bi-layer seedlayer. Preferably, the seedlayer structure includes two bi-layer seedlayers, which including a first CrMo layer, a first W layer fabricated on the first CrMo layer, a second CrMo layer fabricated on the first W layer, and a second W layer fabricated on the second CrMo layer. Also disclosed is a high coercivity hard bias stack structure, a magnetic read head for a disk drive having a high coercivity hard bias stack structure and a method for fabricating a coercivity hard bias layer for a magnetic read head.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Method for making high-square-degree sintered NdFeB permanent magnets with cerium, titanium, cobalt and zirconium compound additive

InactiveCN104821226AImprove squarenessHigh densityInductances/transformers/magnets manufactureMagnetic materialsHydrogenCerium

The invention discloses a method for making high-square-degree sintered NdFeB permanent magnets with a cerium, titanium, cobalt and zirconium compound additive. The method comprises the steps that raw materials are prepared with 27.0% to 29.0% of Nd, 2.5% to 4.0% of Ce, 63.5% to 67.5% of Fe, 1.0% to 1.2% of B, 0.5% to 1.0% of Nb, 1.0% to 3.0% of Co, 0.1% to 0.3% of Zr, 10.5% to 1.0% of A, 0.1% to 0.3% of Cu, and 0.1% to 0.3% of Ti, the raw materials are smelted under the temperature of 1380 DEG with a vacuum induction rapid-hardening casting strip furnace, smelted alloy liquid is processed through electromagnetic stirring to be uniform, and is poured to a rotating water-cooling copper stick, and the alloy liquid is rapidly cooled to form alloy slices with the thickness ranging from 0.2 mm to 0.5 mm; NdFeB alloy slices are broken into NdFeB alloy particles with the length ranging from 120 microns to 200 microns with a hydrogen breaking furnace; the particles are further broken into NdFeB alloy powder with the length ranging from 3.0 microns to 4.5 microns by an air-current mill; the powder is formed in a forming press, and is further densified through isostatic cool pressing; formed initial blanks are sintered, and sintered permanent magnets are finally obtained. With the method for making high-square-degree sintered NdFeB permanent magnets with the cerium, titanium, cobalt and zirconium compound additive, the squre degree of the permanent magnets can be improved, and the production cost can be greatly reduced.

Owner:安徽万磁电子股份有限公司

Preparation method of neodymium-iron-boron alloy sheet

InactiveCN106098283AImprove stabilityGood repeatabilityInductances/transformers/magnets manufactureMagnetic materialsRemanenceAlloy

The invention provides a preparation method of a neodymium-iron-boron alloy sheet. The preparation method comprises the steps of loading, vacuumizing, filling with argon, melting, refining, insulating heat at a high temperature for deslagging, reducing temperature, casting, cooling and tapping. The obtained alloy sheet has a thickness of 0.2 to 0.4mm, a ratio higher than 98 percent and oxygen content lower than 60ppm; it can be seen from a section metallographic diagram that a proportion of fine grains is less, the penetrability of columnar crystal is good, intrinsic coercivity and squareness of a produced magnet are greatly increased while better remanence and magnetic energy product are kept, and the overall performance is better. Meanwhile, according to the preparation method of the neodymium-iron-boron alloy sheet, contents of various components in a product are small in deviation from design proportions, and the product is good in stability, perfect in repeatability and suitable for large-scale production.

Owner:GANZHOU FORTUNE ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com