Method for preparing high performance SmCo permanent magnet material

A permanent magnet material, high-performance technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problem of low performance, achieve the effect of improving remanence, improving permanent magnet performance, and improving market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The constant magnetic field environment is stabilized at 850°C for primary aging. Its specific process steps are as follows:

[0037] Remove the surface oxides of metal materials Sm, Co, Cu, Fe, Zr and break them into lumps suitable for smelting. Then press the ingredients in Table 1.

[0038] Table 1

[0039] components

SM

co

Fe

Cu

Zr

weight percentage (%)

24.5

49.5

14

9

3

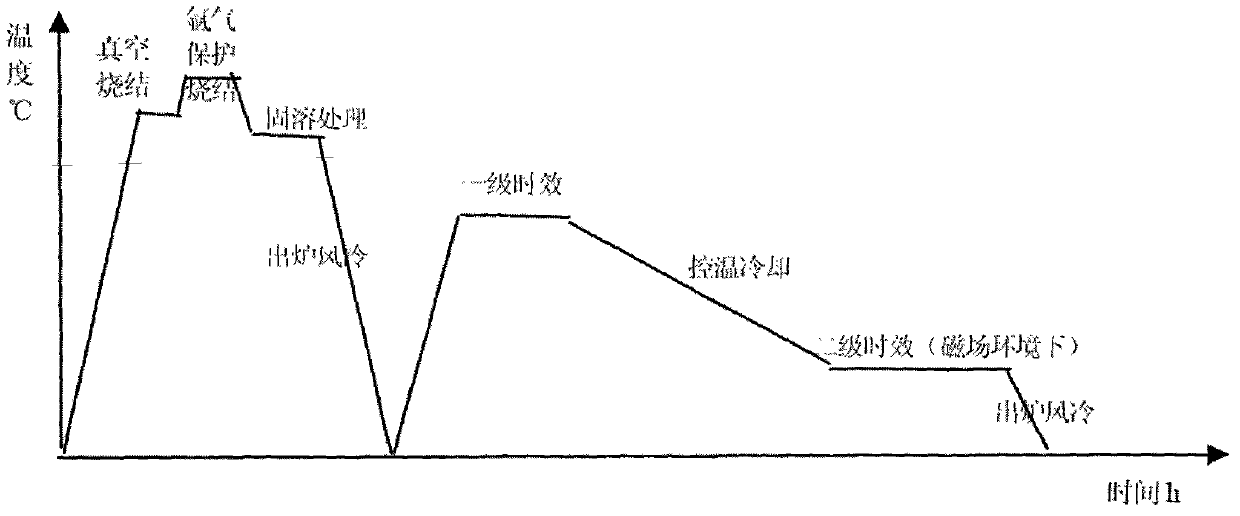

[0040] according to figure 1 The following process steps are carried out as shown: Put the prepared raw materials into a vacuum induction furnace for melting at 1325°C, turn the alloy over and melt it 4 times. Then the alloy ingot is coarsely crushed and passed through a 40-mesh sieve (0.45mm mesh), and the powder obtained through the 40-mesh pass is ball-milled with gasoline as a medium, and taken out after ball-milling to 4-8 μm. The powder is dried in the air, and then shaped under a vertical magnetic field greater t...

Embodiment 2

[0044] During the secondary aging at 450°C, the constant magnetic field environment was stabilized. Its specific process steps are as follows:

[0045] Remove the surface oxides of metal materials Sm, Co, Cu, Fe, Zr and break them into lumps suitable for smelting. Then press the ingredients in Table 2.

[0046] Table 2

[0047] components

SM

co

Fe

Cu

Zr

weight percentage (%)

23.5

48.5

16

10

2

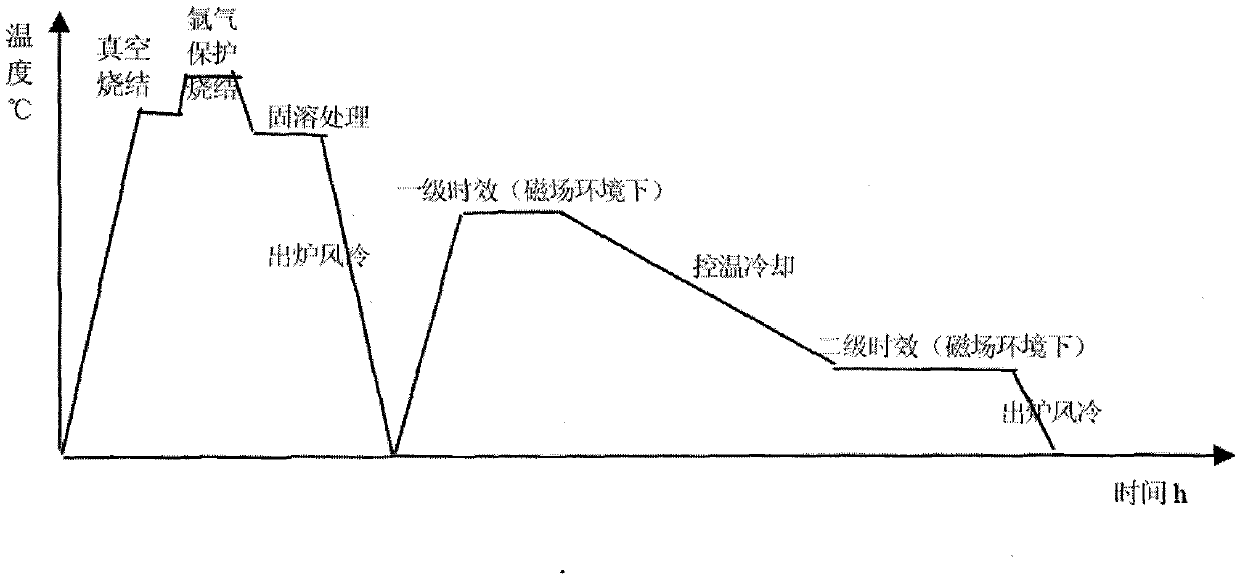

[0048] according to figure 2 The following process steps are carried out as shown: put the prepared raw materials into a vacuum induction furnace for melting at 1320°C, and turn the alloy over for 5 times of melting. Then the alloy ingot is coarsely crushed and passed through a 40-mesh sieve (0.45mm mesh), and the powder obtained through the 40-mesh pass is ball-milled with gasoline as a medium, and taken out after ball-milling to 4-8 μm. The powder is dried in the air, and then shaped under a vertical magn...

Embodiment 3

[0052] The constant magnetic field environment was added to both the primary aging at 850°C and the secondary aging at 450°C. Its specific process steps are as follows:

[0053] Remove the surface oxides of metal materials Sm, Co, Cu, Fe, Zr and break them into lumps suitable for smelting. Then press the ingredients in Table 3.

[0054] table 3

[0055] components

SM

co

Fe

Cu

Zr

weight percentage (%)

25.5

47.5

14

10

3

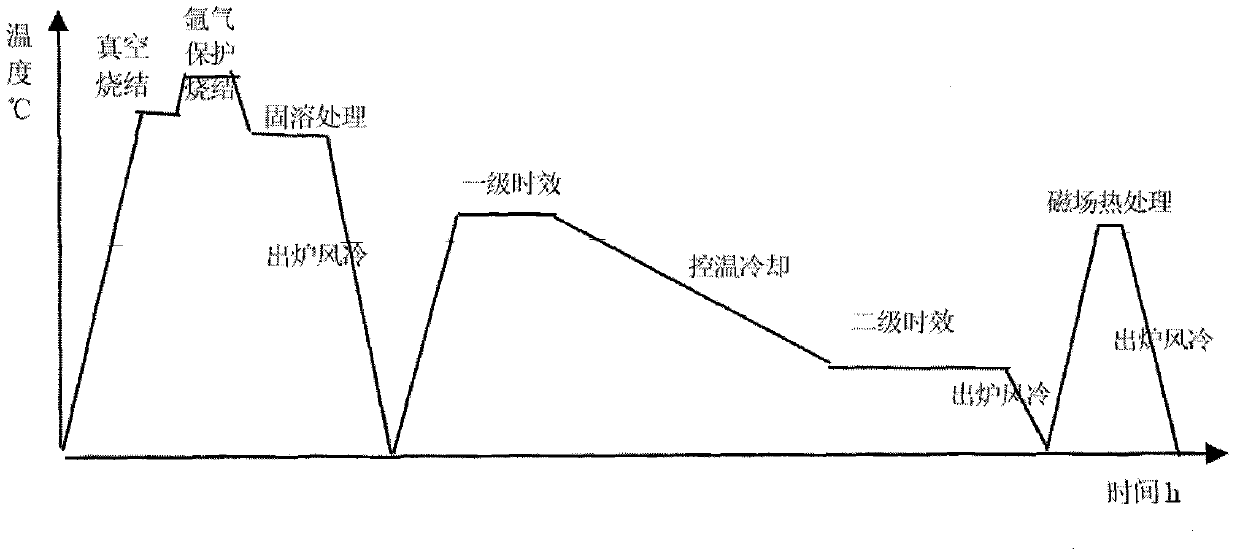

[0056] according to image 3 The following process steps are carried out as shown: Put the prepared raw materials into a vacuum induction furnace for melting at 1330°C, and turn the alloy over for 3 times. Then the alloy ingot is coarsely crushed and passed through a 40-mesh sieve (0.45mm mesh), and the powder obtained through the 40-mesh pass is ball-milled with gasoline as a medium, and taken out after ball-milling to 4-8 μm. The powder is dried in the air, and then shaped under a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic energy product | aaaaa | aaaaa |

| service temperature | aaaaa | aaaaa |

| magnetic energy product | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com