Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Improve permanent magnet performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Permanent Magnet Machine

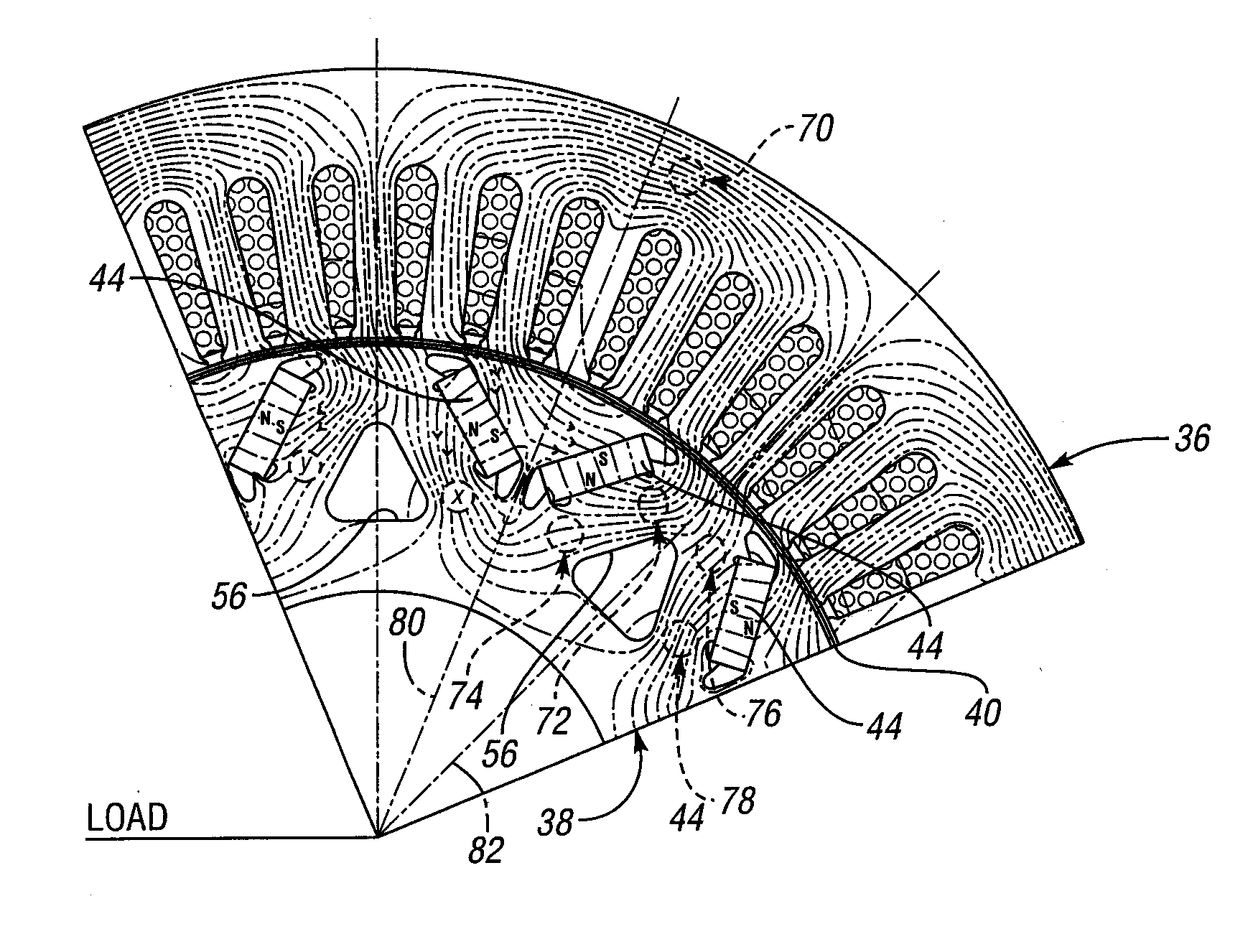

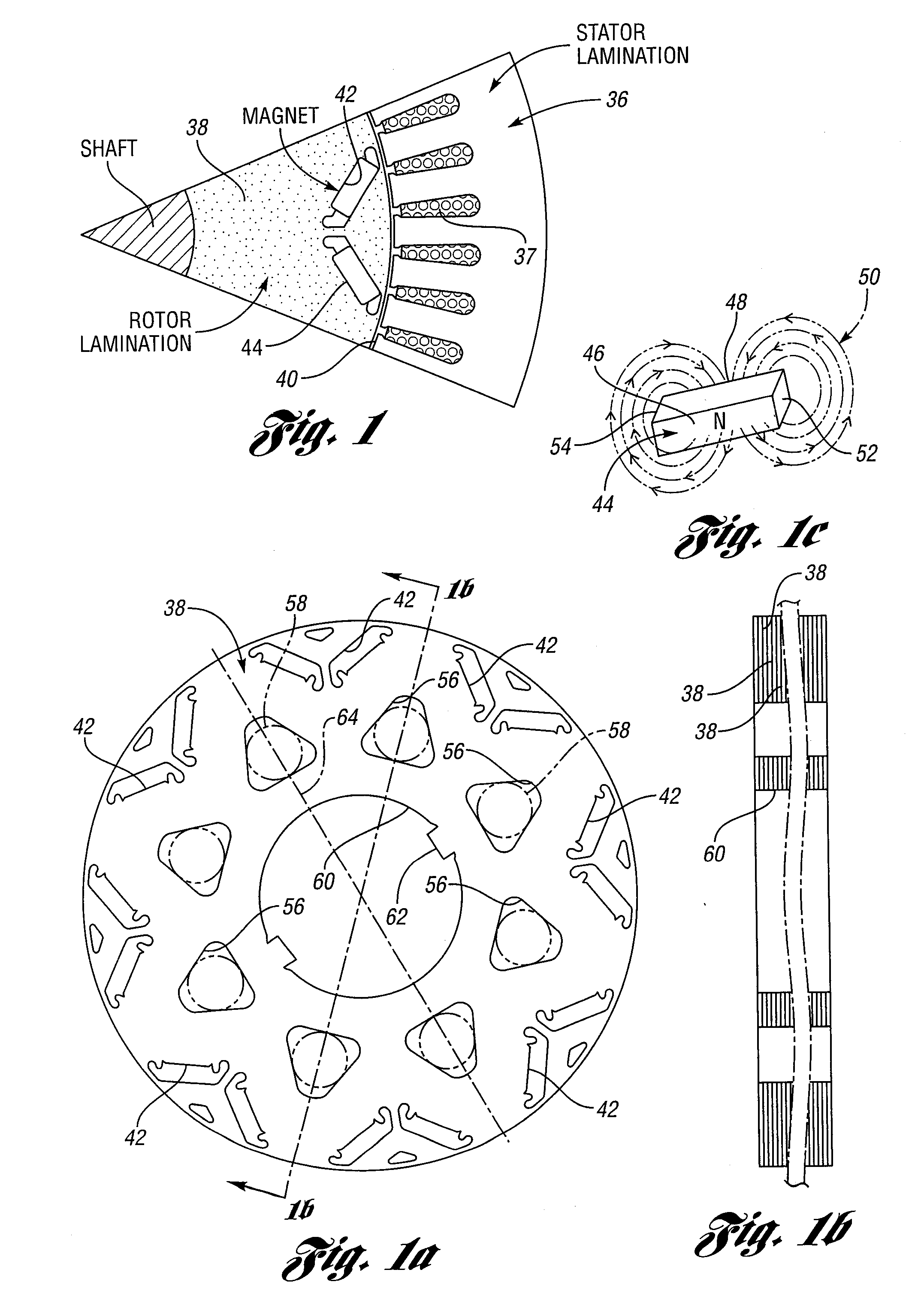

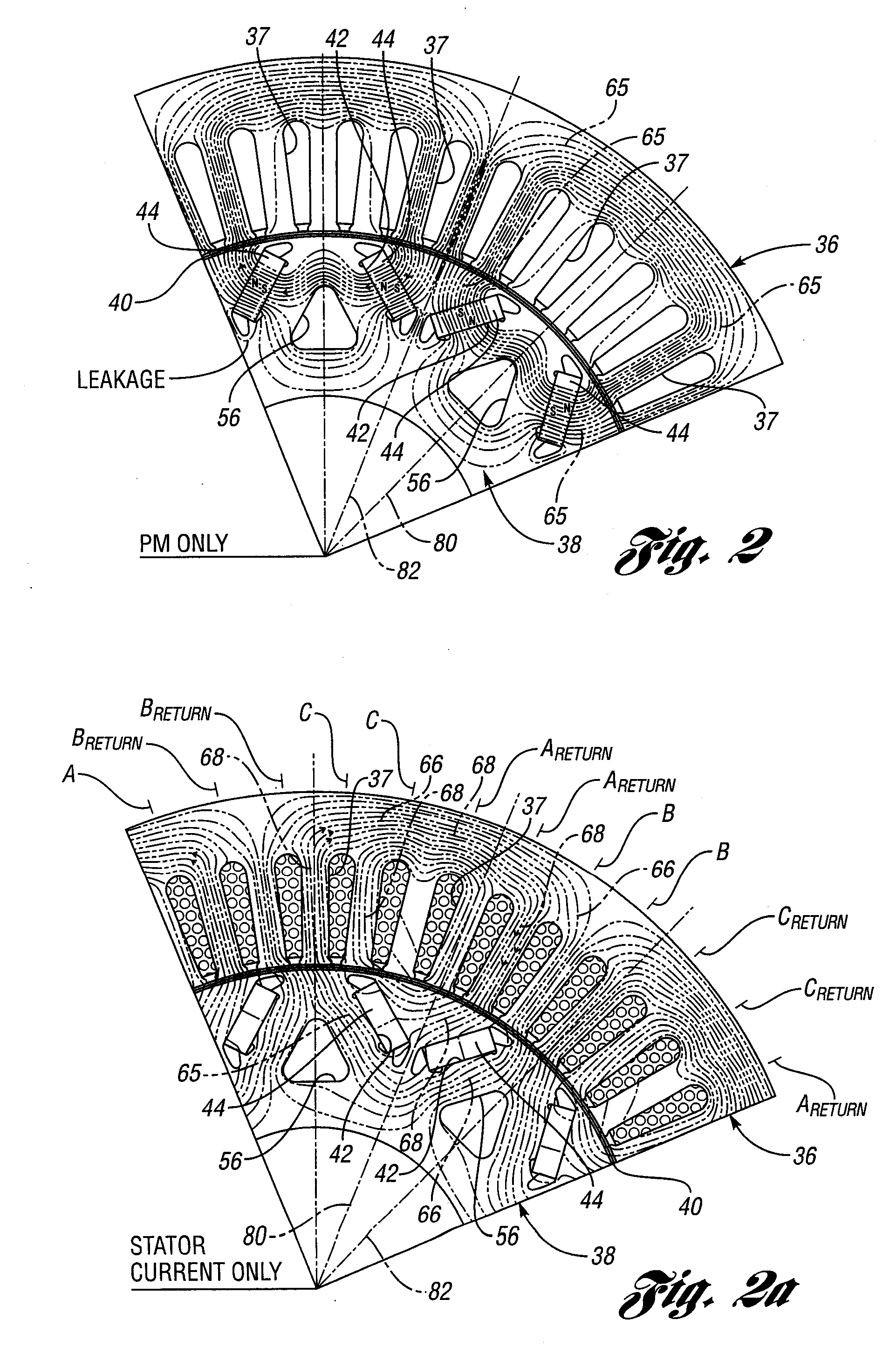

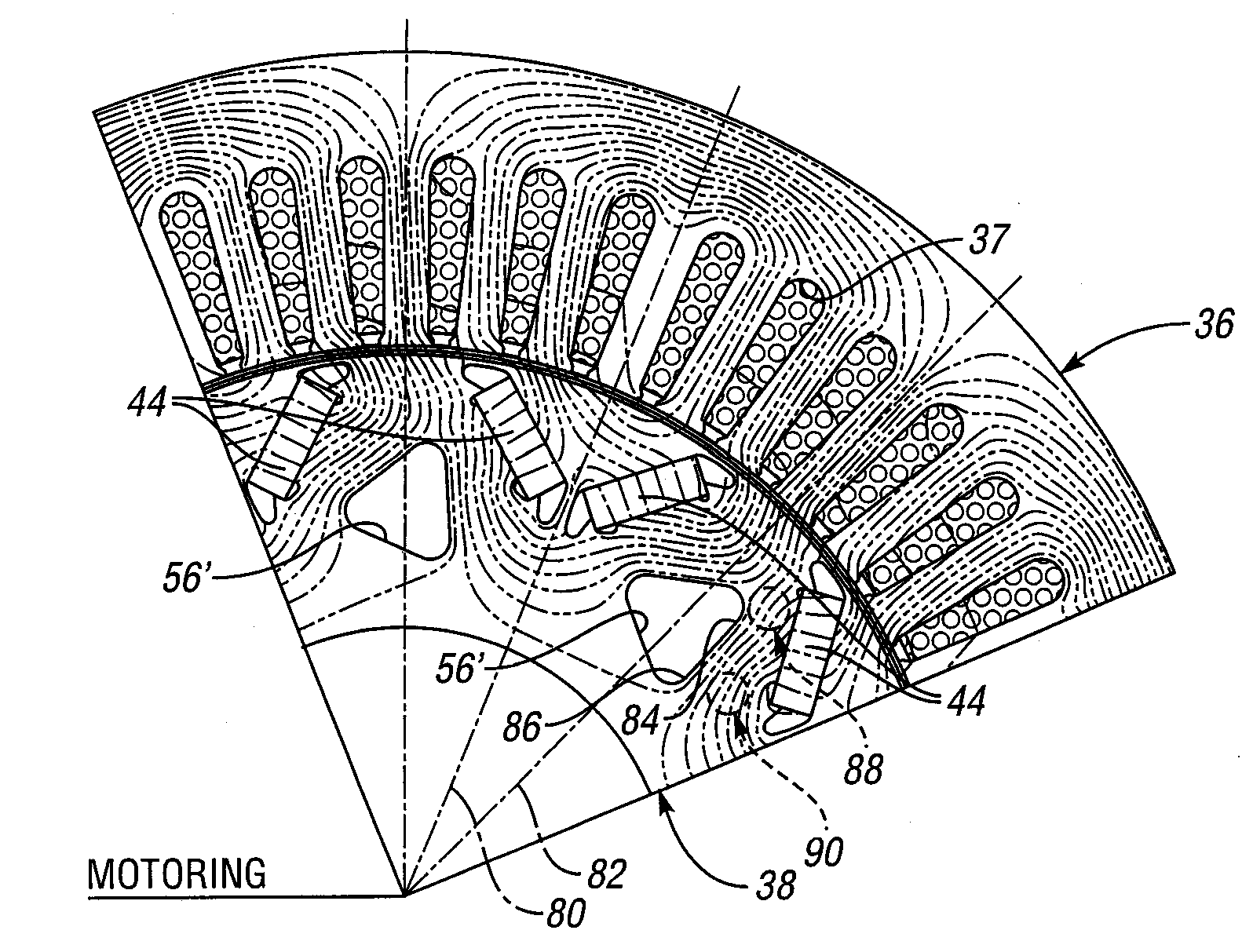

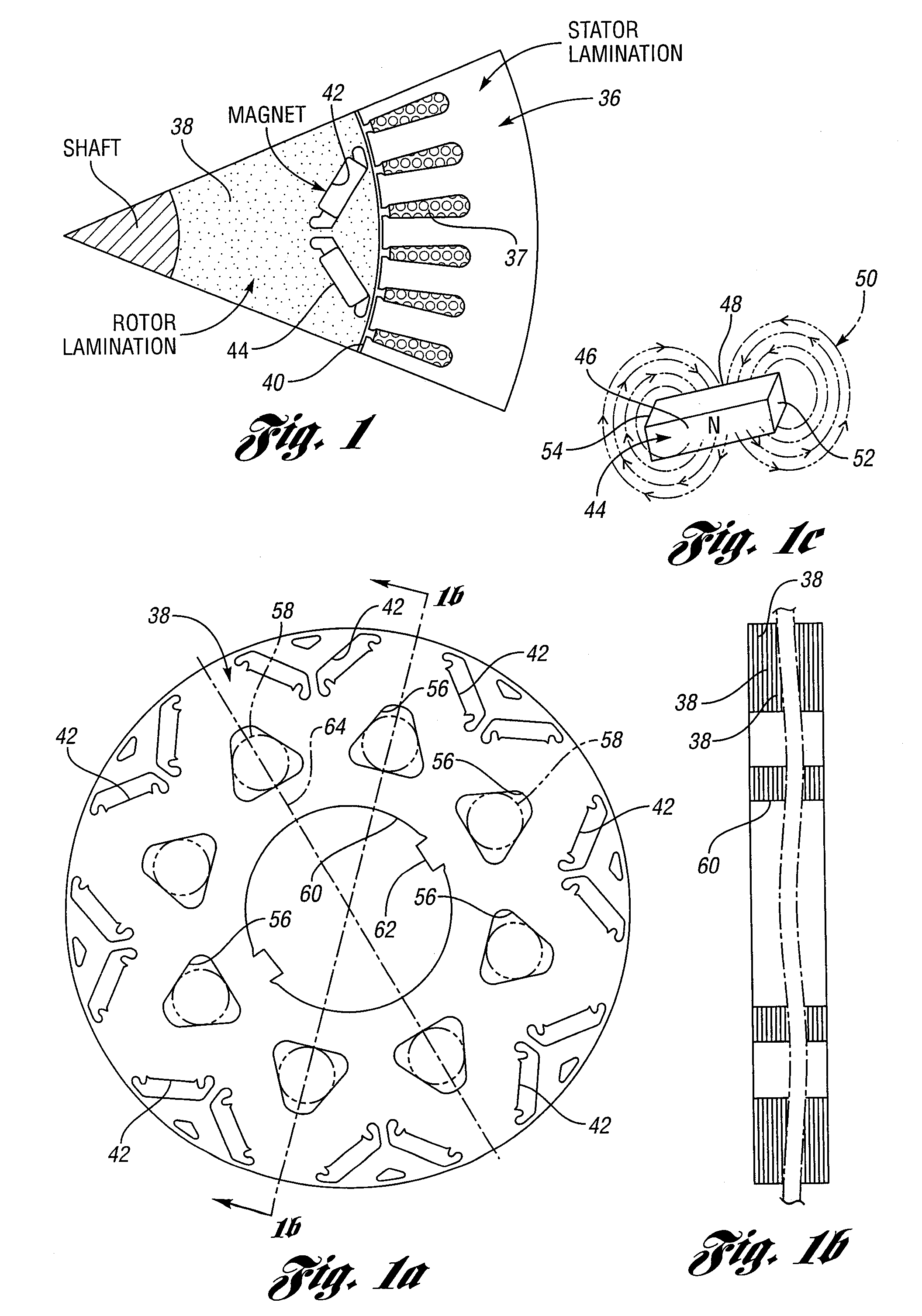

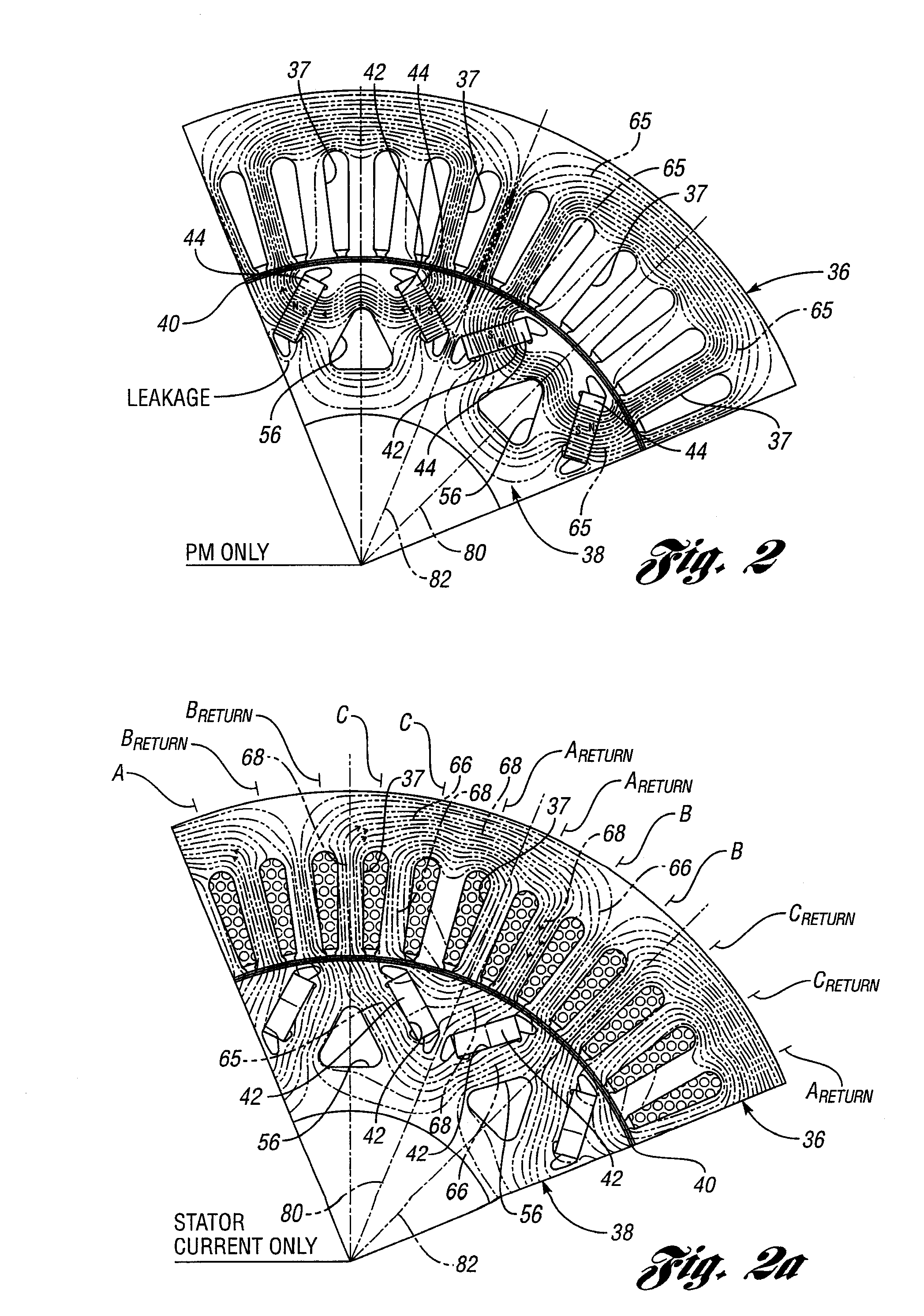

ActiveUS20090045688A1Improve performanceLower performance requirementsPropulsion by batteries/cellsVehicular energy storageElectric machineDistribution pattern

A permanent magnet electric machine with optimum motoring efficiency is disclosed. It is adapted for use in a hybrid electric vehicle powertrain. An asymmetric magnetic flux distribution pattern in the rotor of the machine is established to improve operating efficiency of the machine when it is in a motoring mode.

Owner:FORD GLOBAL TECH LLC

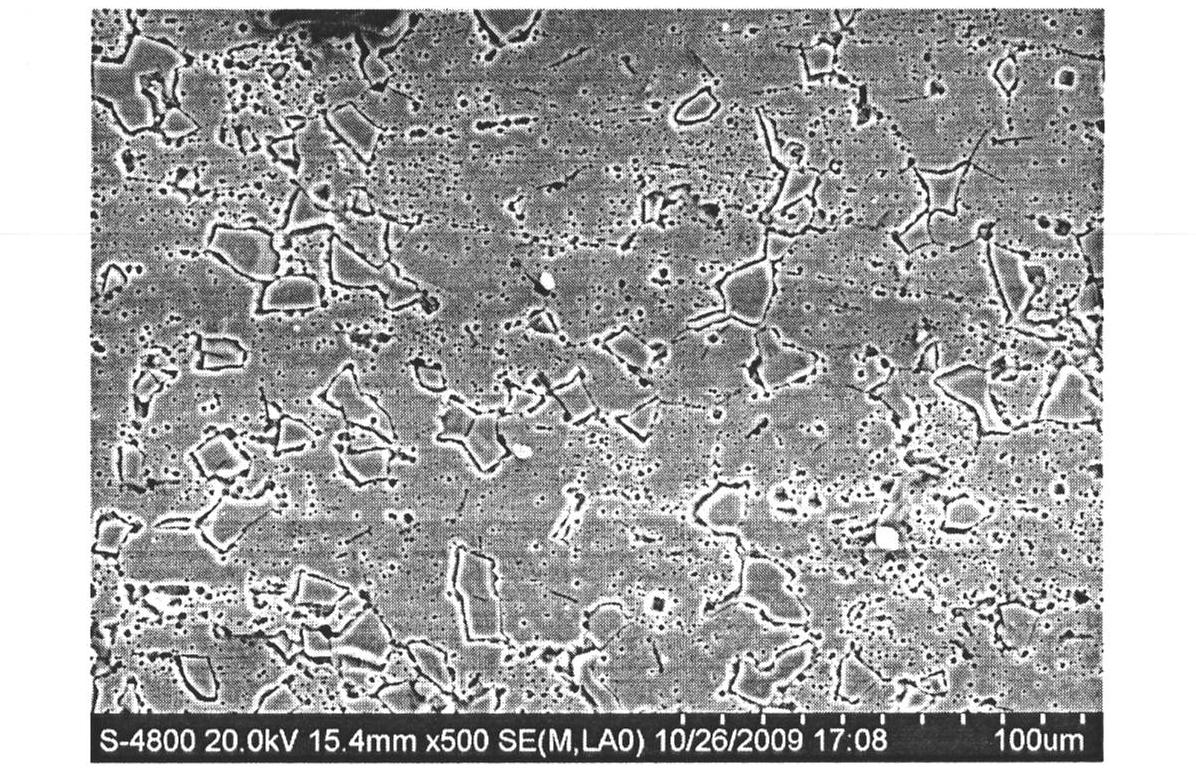

Iron base rare earth alloy powder and compound comprising iron base rare earth alloy powder and permanent magnet using the same

InactiveUS20040079449A1Improve liquidityImprove permanent magnet performanceInorganic material magnetismRare earthAlloy

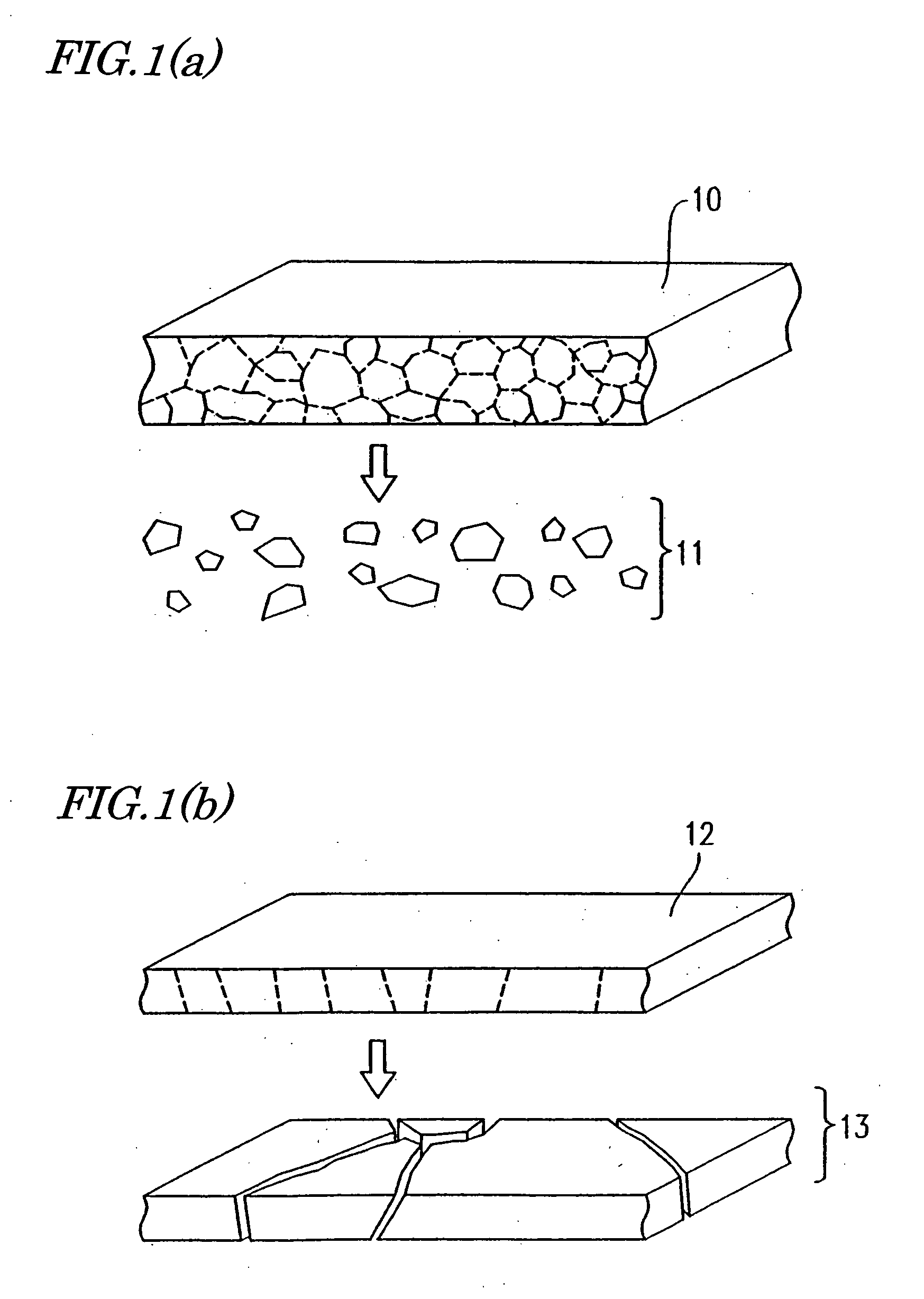

An iron-based rare-earth alloy powder includes: a first iron-based rare-earth alloy powder, which has a mean particle size of 10 mum to 70 mum and of which the powder particles have aspect ratios of 0.4 to 1.0; and a second iron-based rare-earth alloy powder, which has a mean particle size of 70 mum to 300 mum and of which the powder particles have aspect ratios of less than 0.3. The first and second iron-based rare-earth alloy powders are mixed at a volume ratio of 1:49 to 4:1. In this manner, an iron-based rare-earth alloy powder with increased flowability and a compound to make a magnet are provided.

Owner:SUMITOMO SPECIAL METAL CO LTD

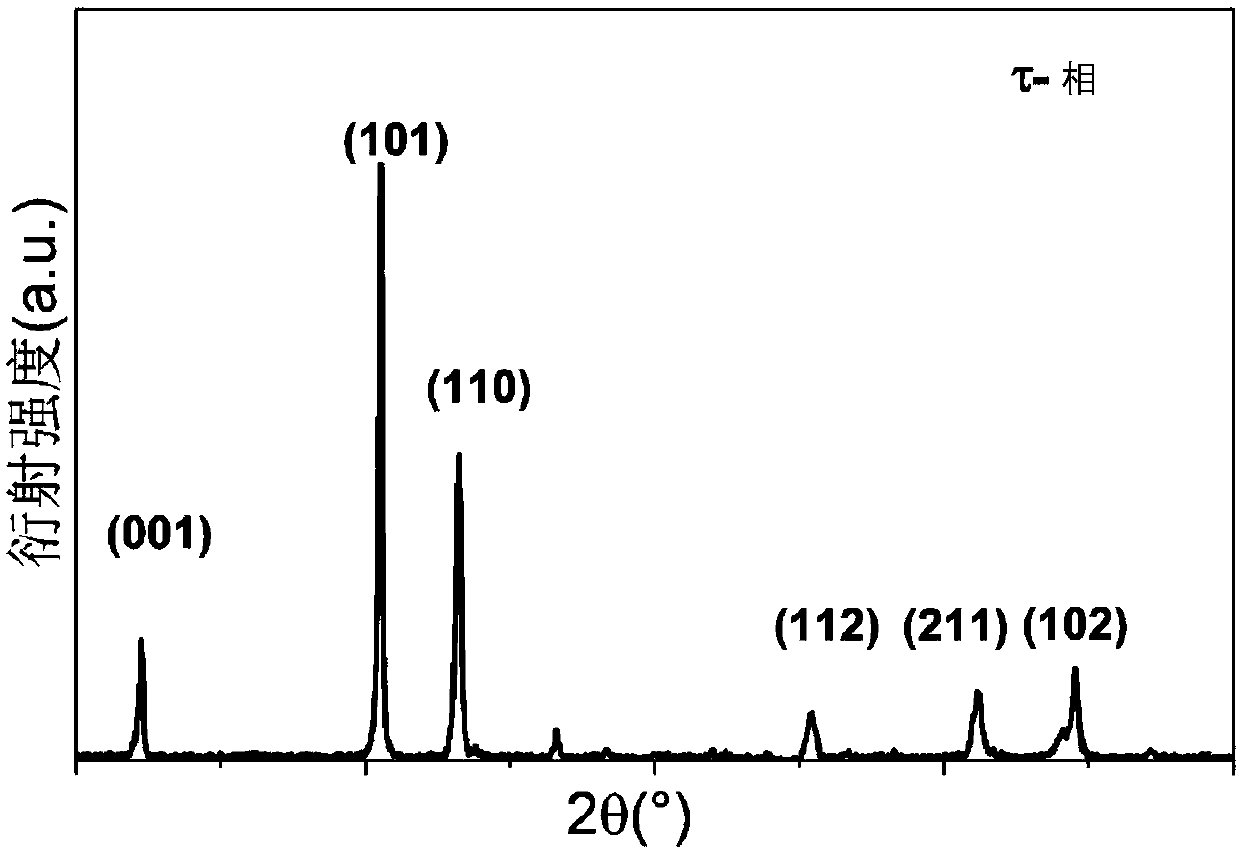

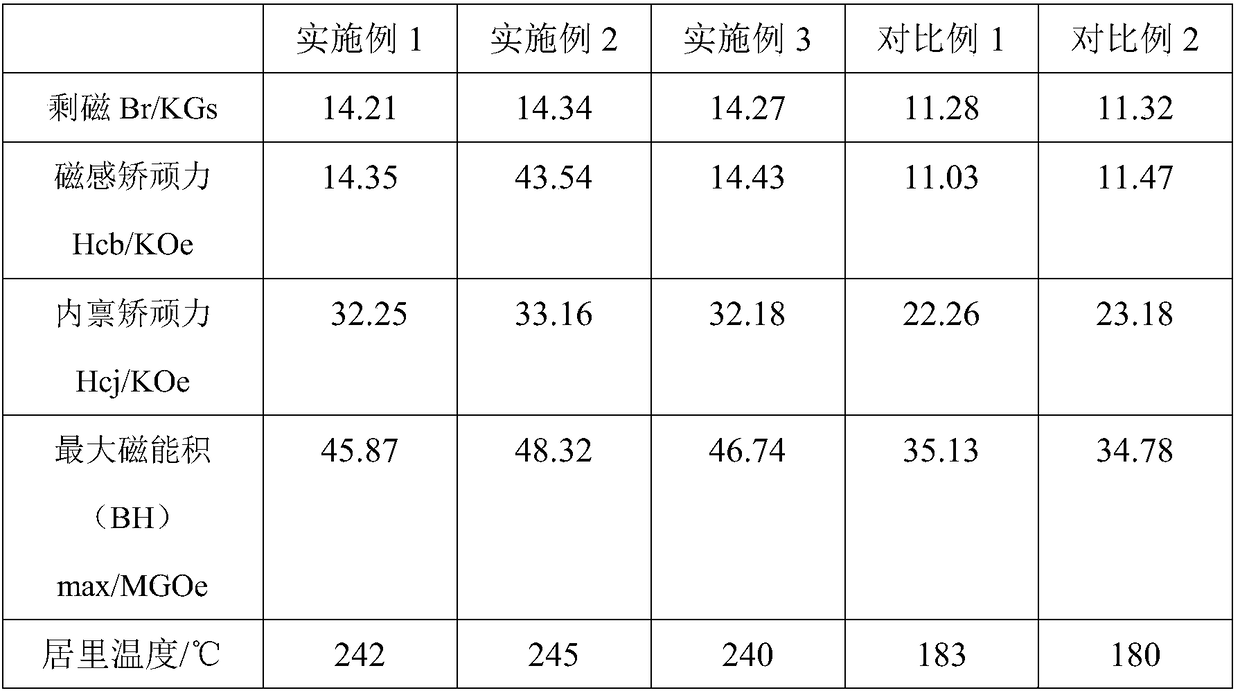

Preparation method of non-rare earth MnAl permanent magnetic alloy

InactiveCN104593625AEasy to processAccelerated corrosionMagnetic materialsElectric arc furnaceRare earth

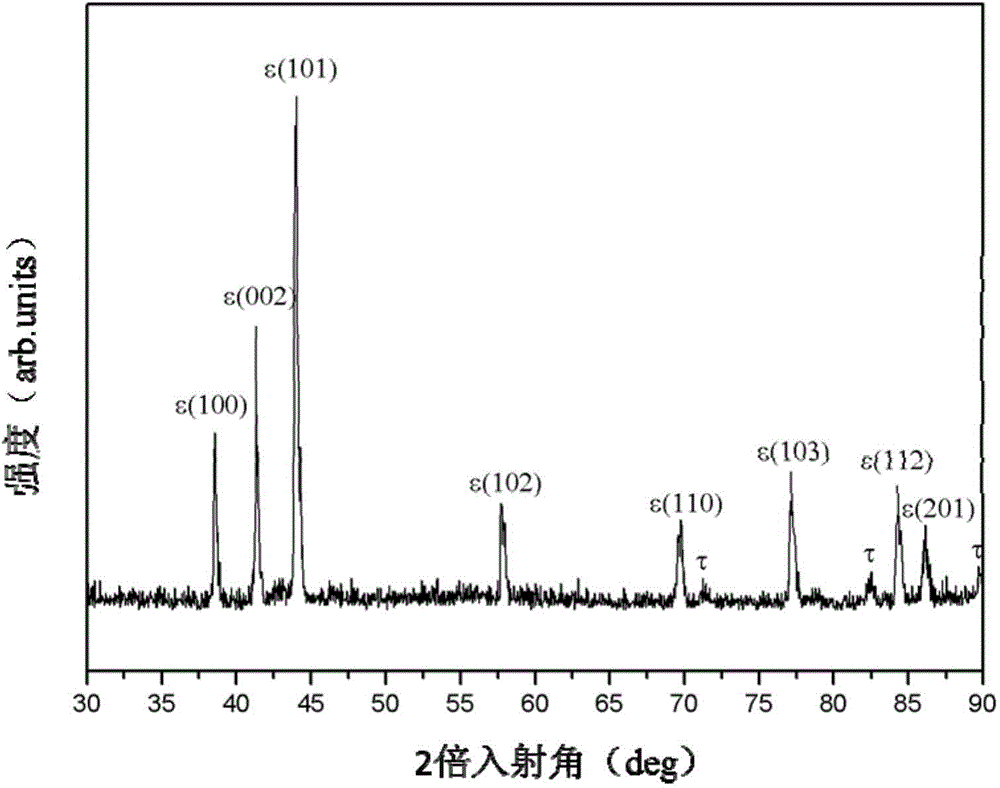

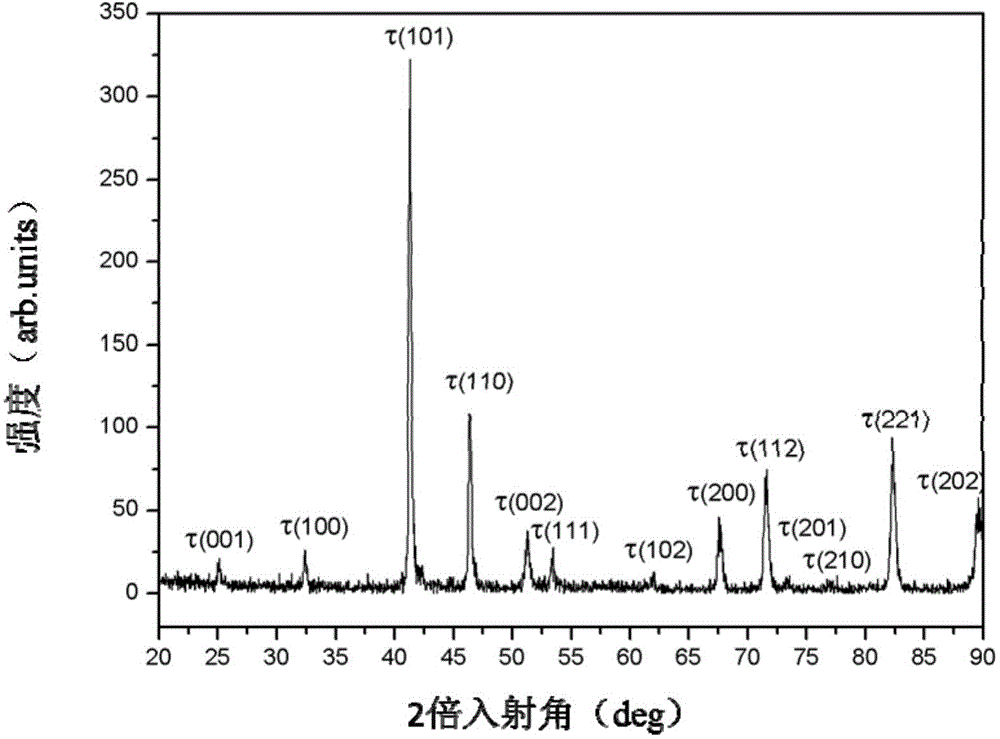

The invention relates to a preparation method of a non-rare earth MnAl permanent magnetic alloy. The preparation method comprises the following steps: (1) preparing the compositions of a master alloy sample: preparing master alloy raw materials with Mn60-xAl40+x as a nominal composition according to the atom percentage, wherein x is equal to 0-10; (2) smelting the master alloy: adopting a non-self-consumable electric arc furnace, putting the prepared master alloy raw materials into a water cooling copper crucible, and repeatedly smelting the alloy for 3-5 times to obtain a MnAl alloy ingot with uniform compositions; (3) preparing an MnAl alloy ribbon by the MnAl alloy ingot by adopting a single-roller rapid quenching method; (4) carrying out vacuum heat treatment: carrying out vacuum heat treatment on the MnAl alloy ribbon obtained in the third step to obtain a tau-phase MnAl alloy; and (5) mechanical ball milling: ball milling the tau-phase MnAl alloy obtained in the fourth step to obtain tau-phase MnAl alloy powder, namely the non-rare earth MnAl permanent magnetic alloy with high coercivity. Compared with the prior art, according to the preparation method disclosed by the invention, the cost is low, the preparation process is simple, and the obtained MnAl permanent magnetic alloy is good in permanent magnetic property and high in coercivity.

Owner:TONGJI UNIV

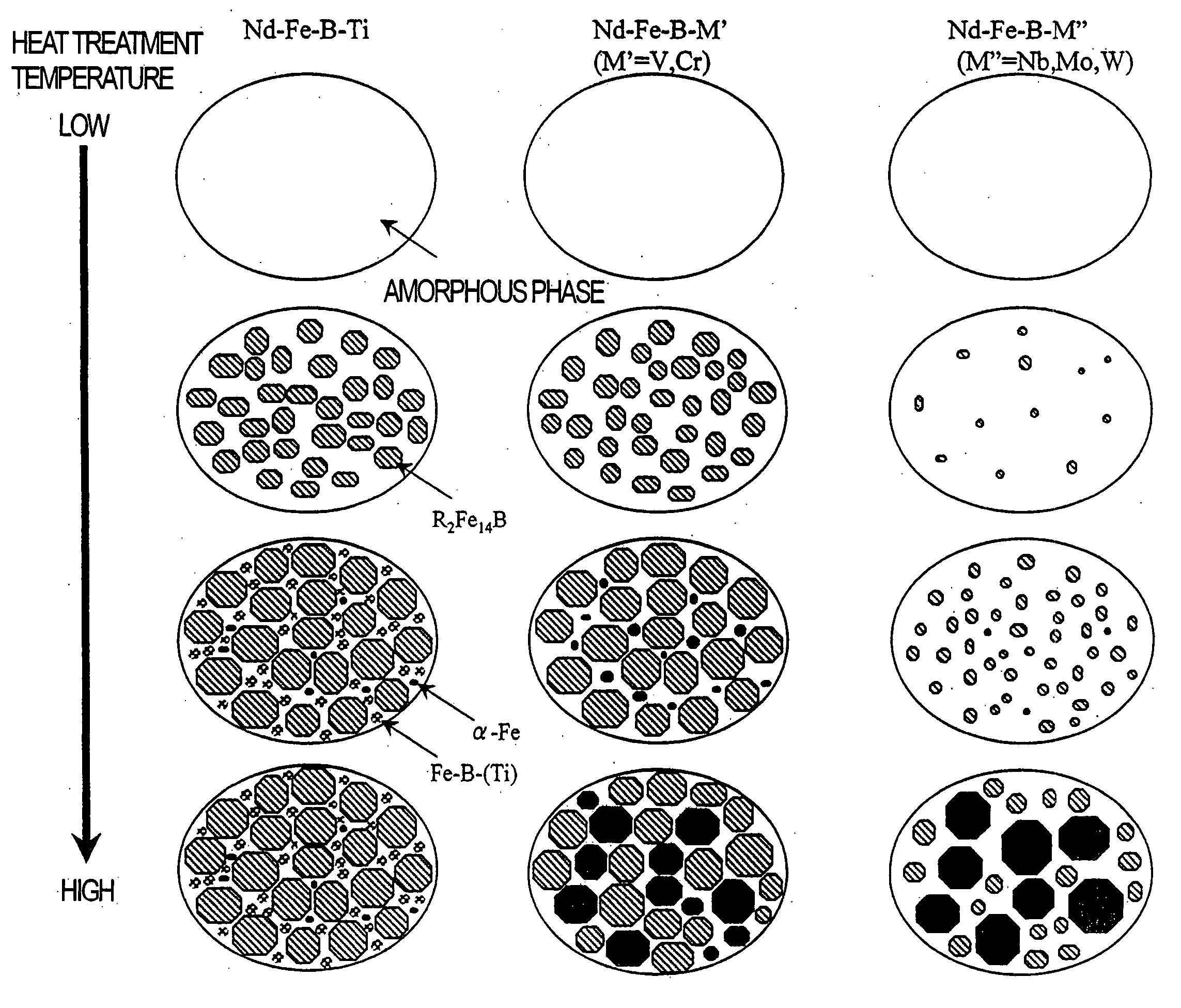

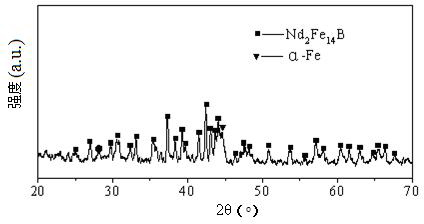

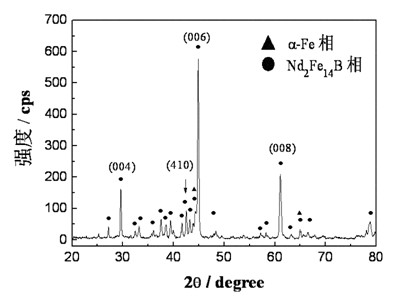

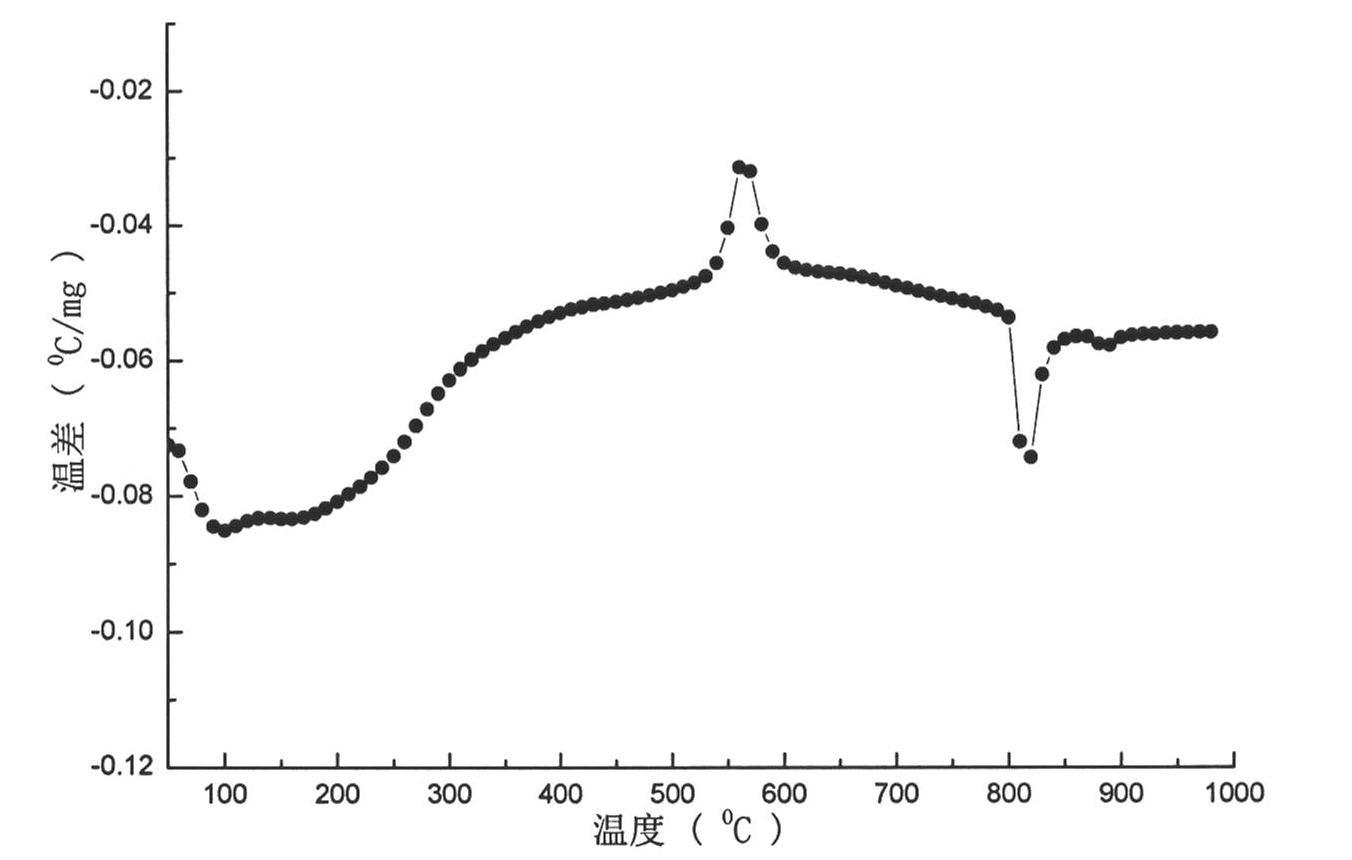

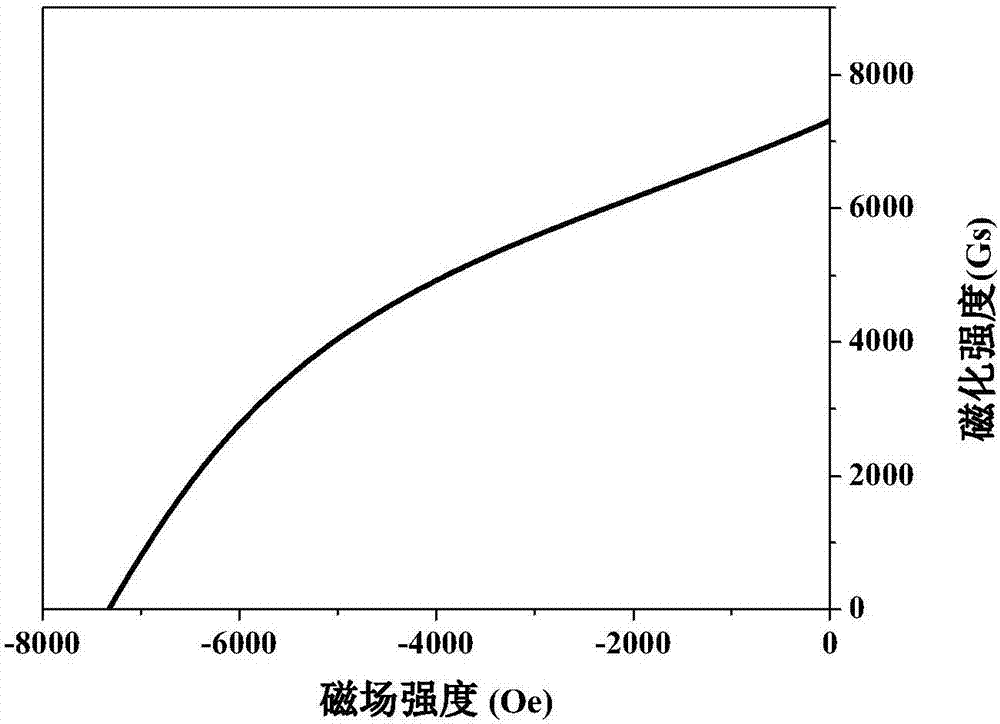

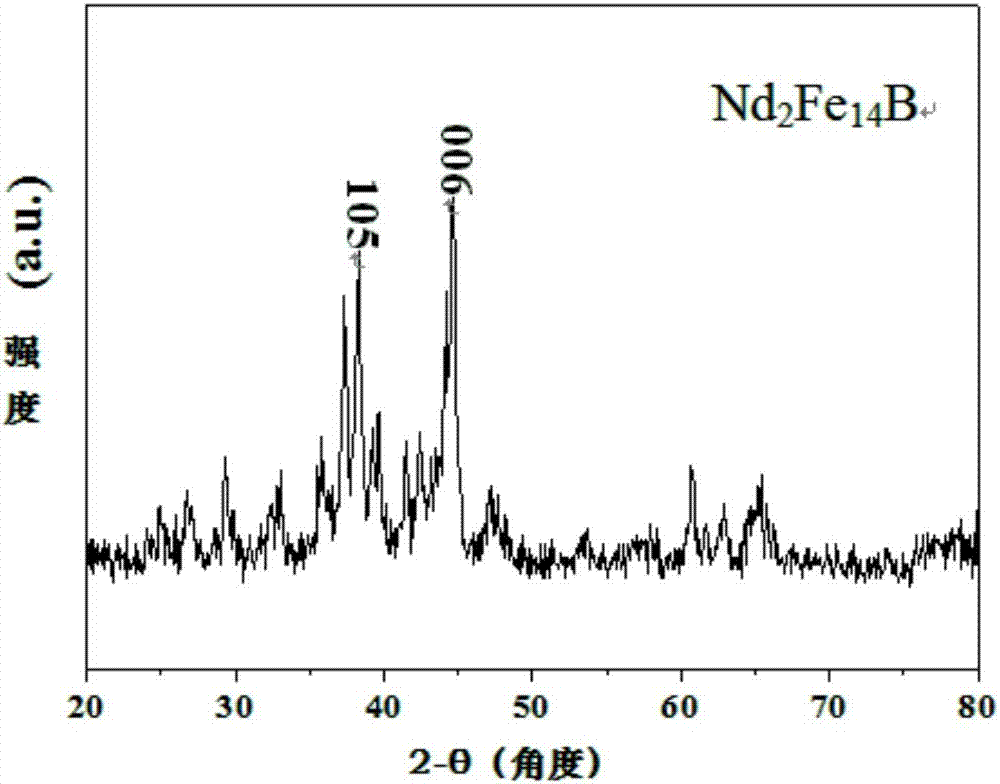

A kind of preparation method of nanocrystalline rare earth permanent magnetic alloy powder

ActiveCN102274974AImprove permanent magnet performanceStrong magnetismInorganic material magnetismThermal treatmentHeat treated

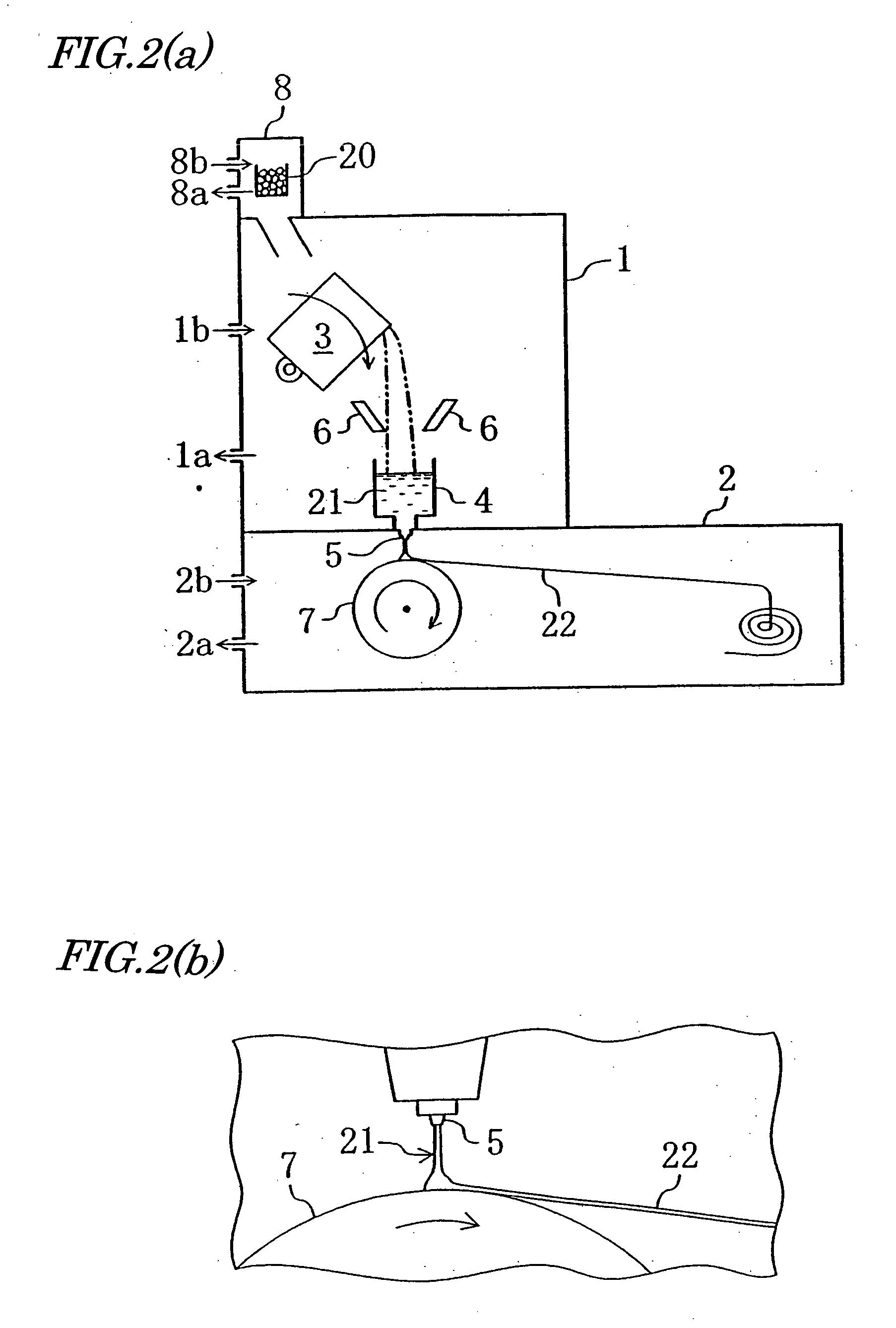

The invention belongs to the technical field of the rare-earth permanent magnet material, specifically relating to a method for preparing a nanocrystalline rare-earth permanent magnet alloy powder. The method comprises the following steps of: subjecting a rare-earth alloy to a vacuum smelting step, a vacuum quick quenching step, a crushing and sieving step and a thermal treatment step in this order, wherein the thermal treatment step is microwave heating treatment, the temperature of the thermal treatment is 600-700 DEG C, and the time for the thermal treatment is 1-15 min. The grain size of the nanocrystalline rare-earth permanent magnet alloy powder prepared by the method is 10-30 nm; and the magnetic energy product (BH) m of the magnetic powder reaches up to 120-180 kJ / m3; therefore, the powder has more excellent magnetic performance in contrast with the rare-earth permanent magnet alloy powder prepared by the traditional quick quenching technology which has the magnetic energy product (BH) m within a range of 100-140 kJ / m3.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

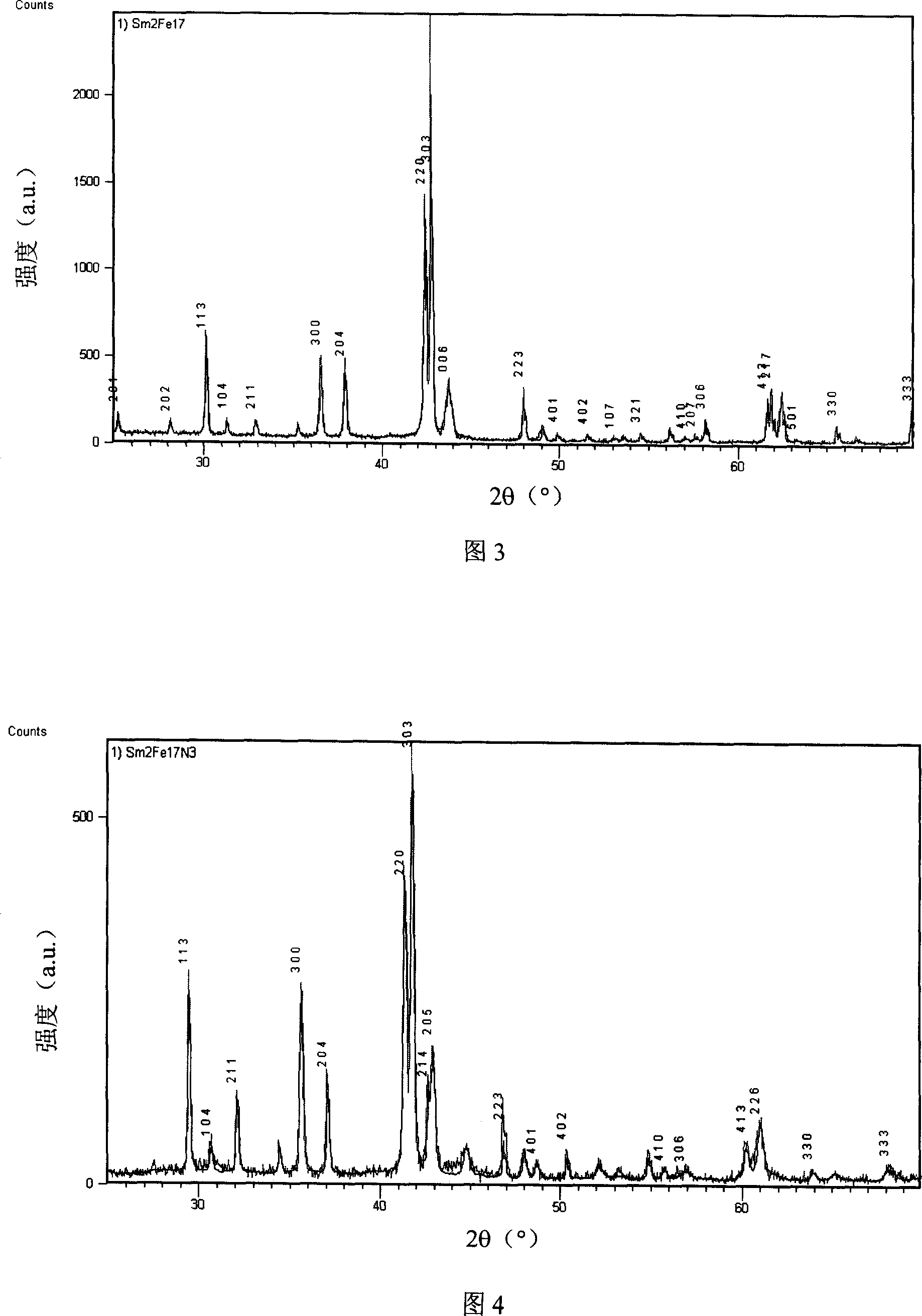

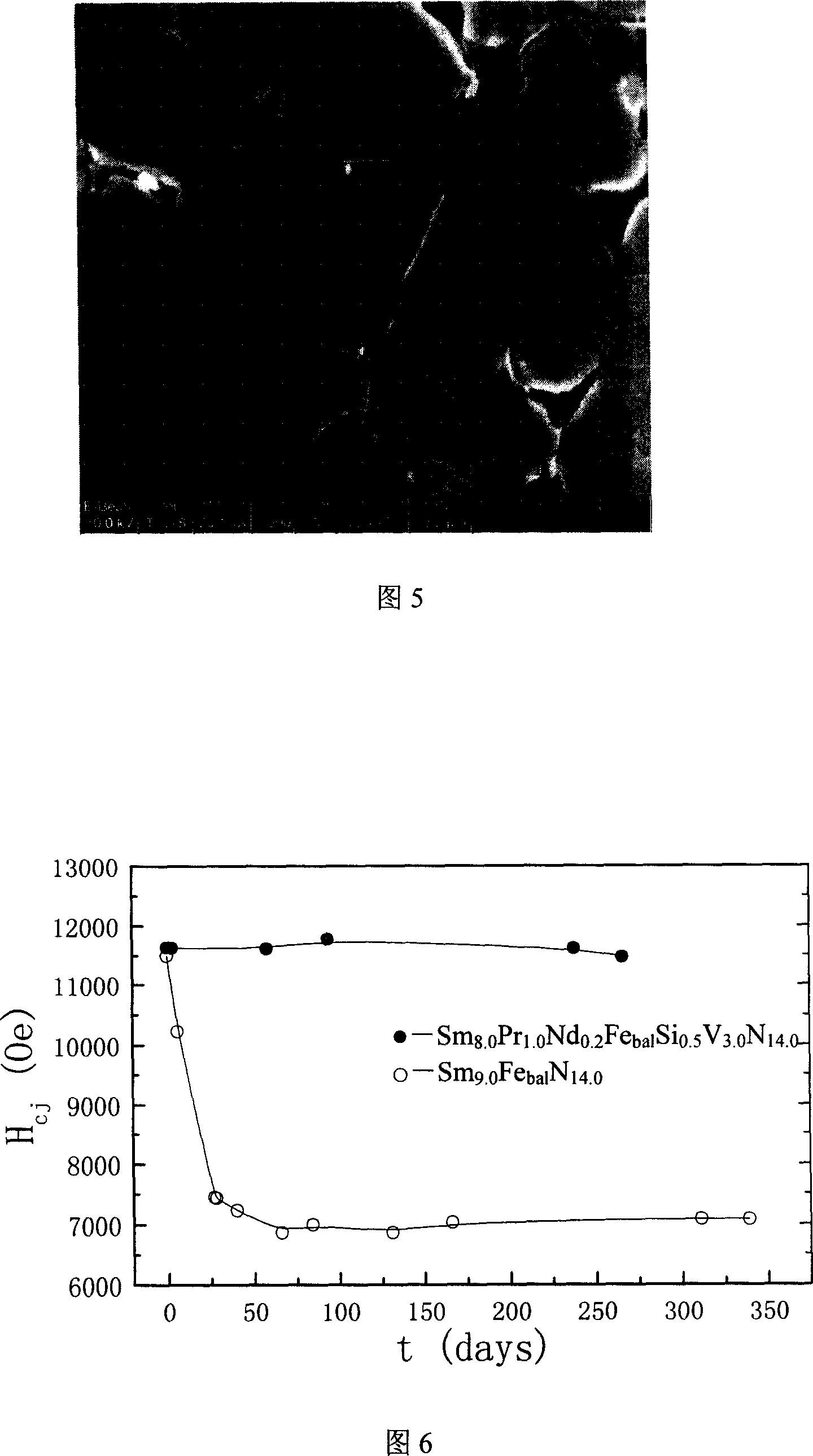

Anisotropic rare-earth permanent magnet material and its magnetic powder and magnet mfg. method

ActiveCN1937110AInhibitionUniphasic goodTransportation and packagingMetal-working apparatusRare-earth elementMetallurgy

Possessing Th2Zn17 type crystal structure, the disclosed material of anisotropic rare earth permanent magnet with its components can be expressed as (Sm1-alphaRalpha)xFe100-x-y-zMyIz, where R as Pr or combination between Pr or other rare earth elements, 0.01<= alpha <=0.30, M selected from Si, Ti, V, Cr, Mn, Co, Ni, Cu, Zn, Nb, Mo, Al, and Zr, I as N only or combination between N and C, 7<=x<=12,0.01<=y<=8.0,6<=z<=14.4. Using the specific technique produces magnetic powder of single crystal grain in sheet form with average grain size as 1-3 micro. The magnetic powder possesses anisotropy of magnetocrystalline under action of external magnetic field as well as rolling anisotropy and stress anisotropy. Based on three kinds of anisotropy, the invention discloses method for preparing high performance flexible rubber magnet with rolling anisotropy.

Owner:NINGXIA MAGVALLEY NOVEL MATERIALS TECH CO LTD

Permanent magnet machine

ActiveUS7791236B2Improve electromagnetic performanceImprove permanent magnet performancePropulsion by batteries/cellsVehicular energy storageElectric machineDistribution pattern

Owner:FORD GLOBAL TECH LLC

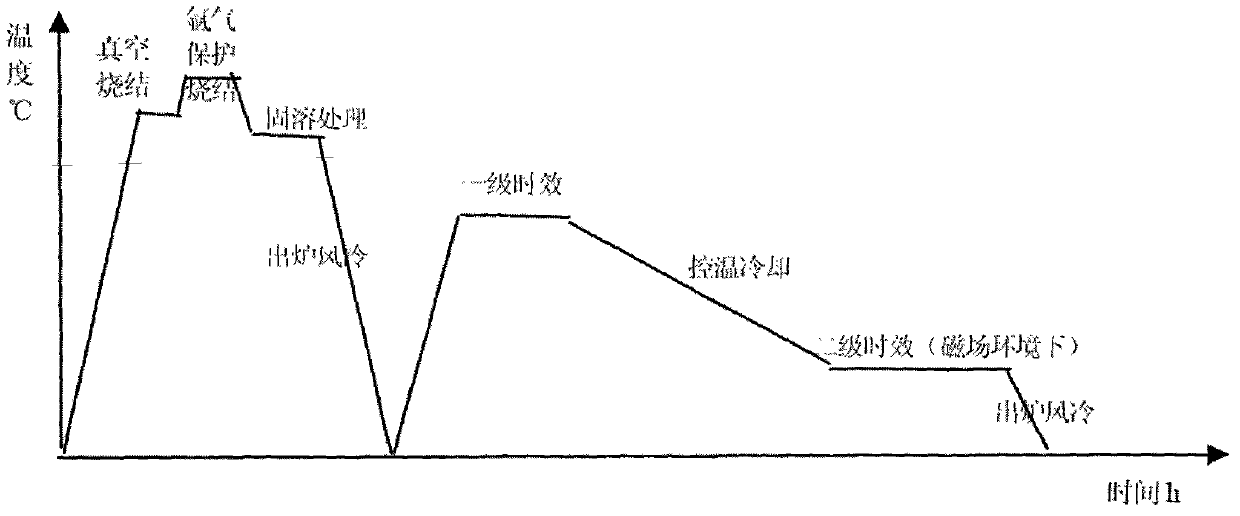

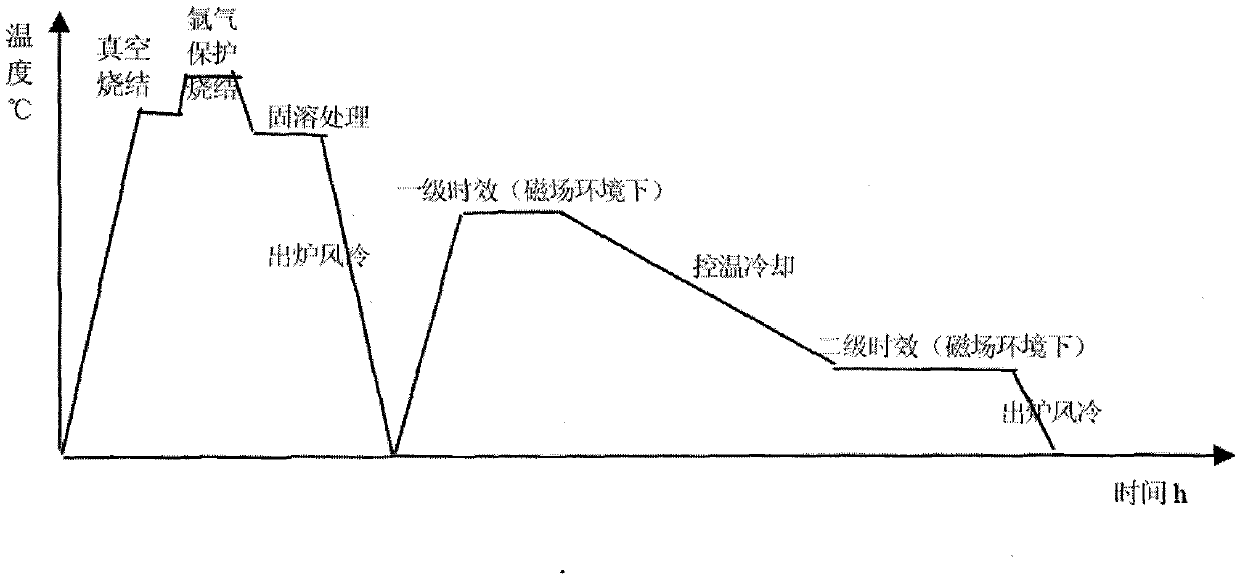

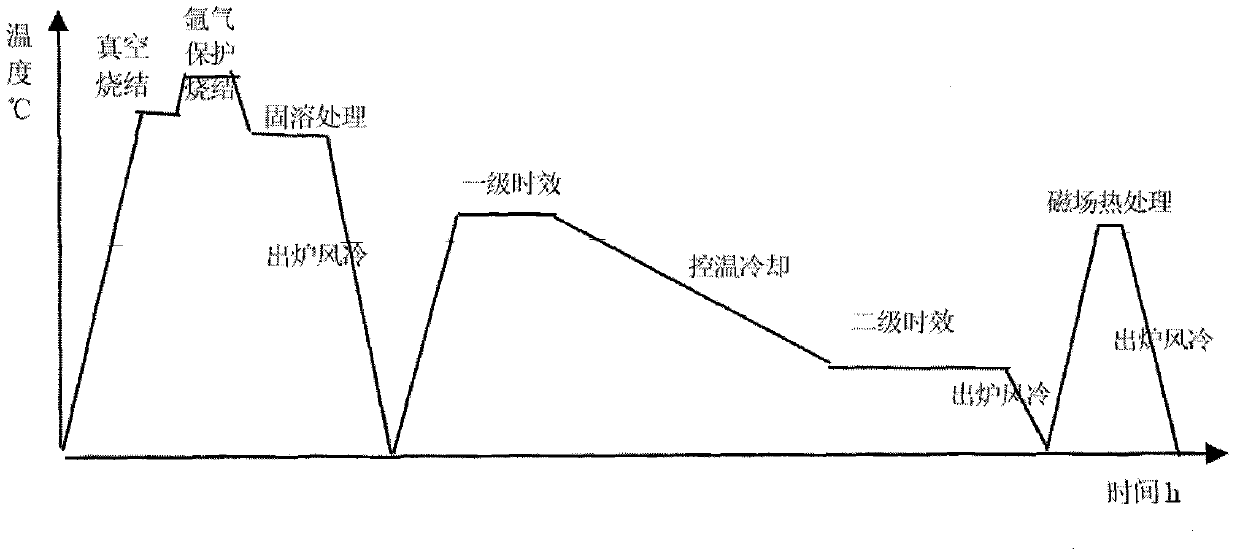

Method for preparing high performance SmCo permanent magnet material

InactiveCN102766835AImprove permanent magnet performanceImprove remanenceMagnetic materialsCompression moldingRare earth

The invention relates to a method for preparing a high performance SmCo permanent magnet material and belongs to the field of preparation of rare earth permanent magnet materials. The method includes that Sm (Col-u-v-wCuuFevZrw) z is used for preparing the SmCo permanent magnet material through processes of smelting, milling, compression molding, sintering, solid solution, magnetic field aging treatment, magnetic field post-heat treatment and the like. The permanent magnet material obtained after the magnetic field aging treatment or the magnetic field post-heat treatment can induce magnetic uniaxial anisotropy in the filed, the orientation degree is increased, so that the magnetic performance of the SmCo permanent magnet material is improved substantially.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

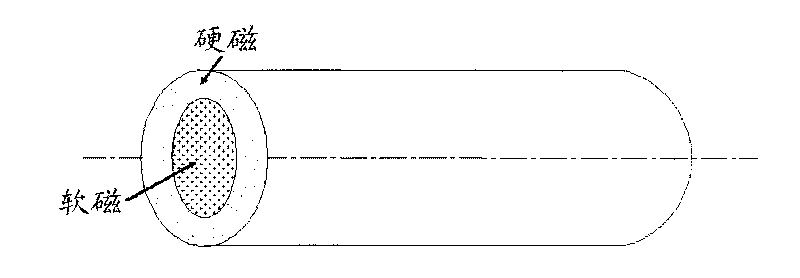

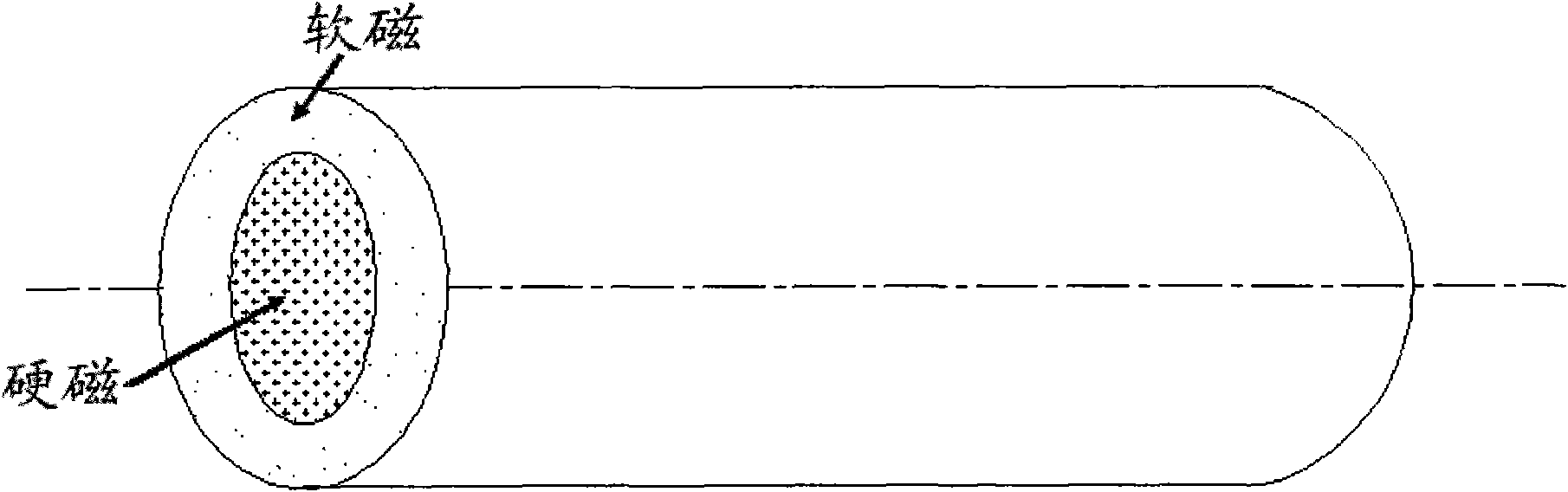

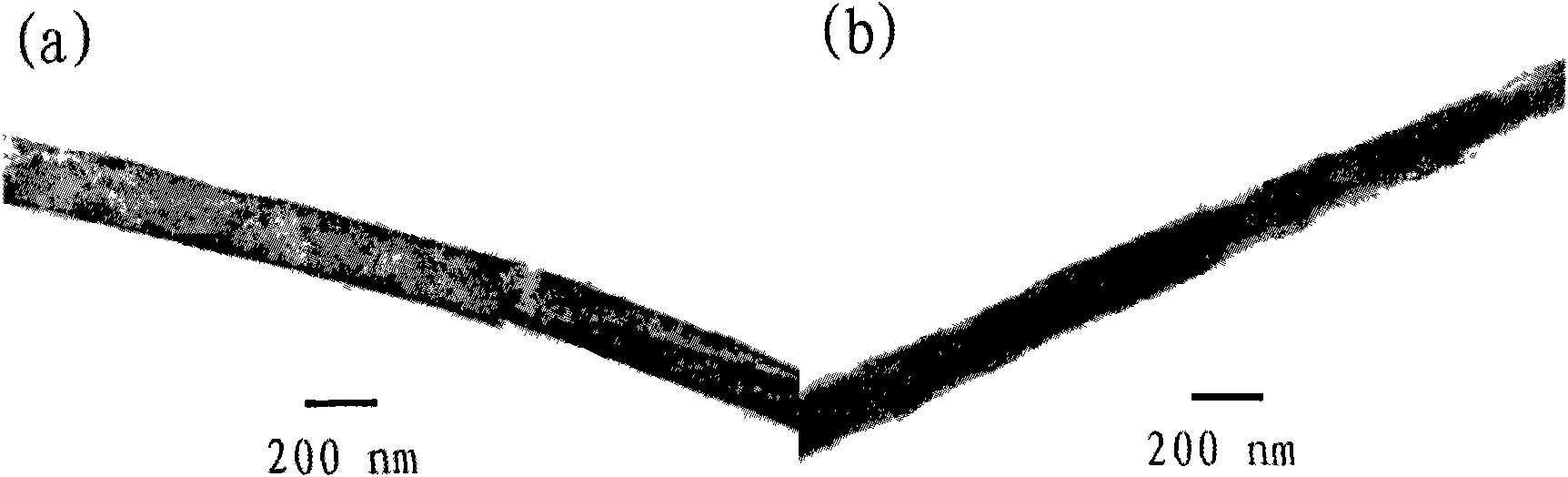

One-dimensional permanent magnetic nano-material, in which hard magnetic tubes are coated with soft magnetic wires and preparation method thereof

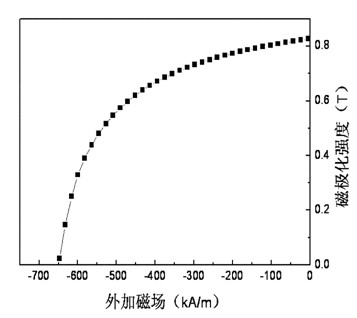

InactiveCN101692364AImprove permanent magnet performanceInorganic material magnetismMagnetic phaseElectrochemistry

The invention provides a one-dimensional permanent magnetic nano-material, in which hard magnetic tubes are coated with soft magnetic wires and a preparation method thereof. The material has a composite structure that hard magnetic nano-tubes prepared from hard magnetic phase FePt or CoPt alloy are coated with soft magnetic nano-wires prepared from soft magnetic phase pure metals including Fe, Co and Ni or binary and ternary alloy, wherein, the diameter of the one-dimensional permanent magnetic nano-material is 10nm to 220nm; the diameter of the soft magnetic phase nano-wires is 4nm to 60nm; and the wall thickness of the hard magnetic phase nano-tubes is 3nm to 80nm. The preparation method of the material comprises the following steps: firstly, preparing the hard magnetic alloy nano-tubes in a porous anodic alumina template by using the template wetting method; and then, growing the soft magnetic nano-wires in the nano-tubes by using the electrochemical deposition method. The invention has the advantages that the size of the one-dimensional permanent magnetic nano-material is controllable and the preparation method is simple.

Owner:CENT IRON & STEEL RES INST

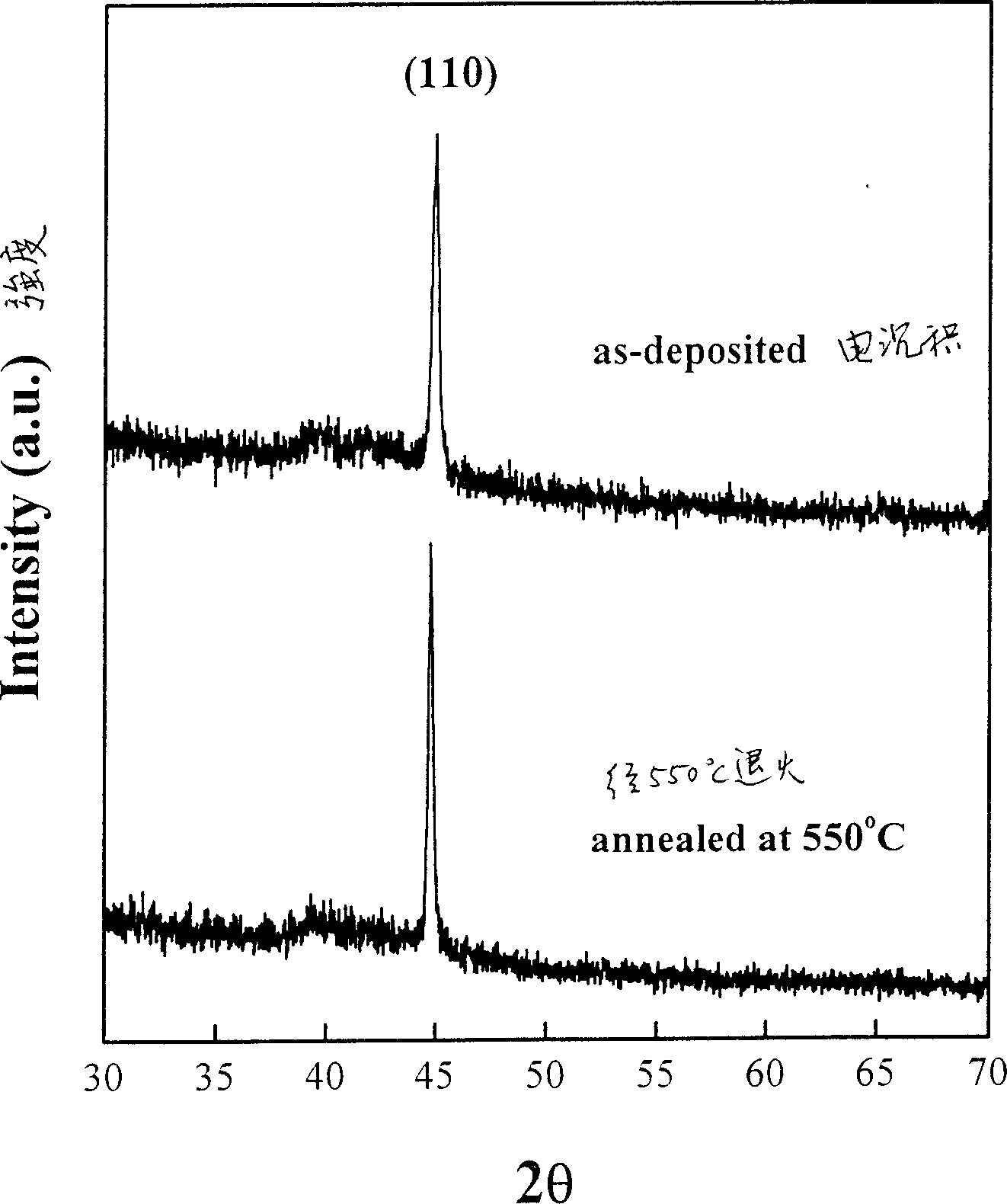

Iron-cobalt alloy nano linear array permanent-magnetic film material and its preparation

InactiveCN1529330AImprove permanent magnet performanceHigh curie temperatureInorganic material magnetismMagnetic film to substrate applicationFerrocobaltElectrochemical anodization

In the invention, pore templet in Nano alumina is prepared by method of electrochemic anode oxidation, and nano line array of ferrocobalt is prepared by method of electrochemic deposition. Diameter of line array of ferrocobalt is in 10nm-50nm, constituent of ferrocobalt is as CoxFe1-x , 20 more than or equal to 20 and less than or equal to 0.60. low temperature annealing of Nano line array of ferrocobalt obtained from electrochemic deposition obtains thin film material of permanent magnetism, performances of which are best when content of cobalt is 30%-40%, and diameter of Nano line is as 10nm-22nm.

Owner:NANJING UNIV

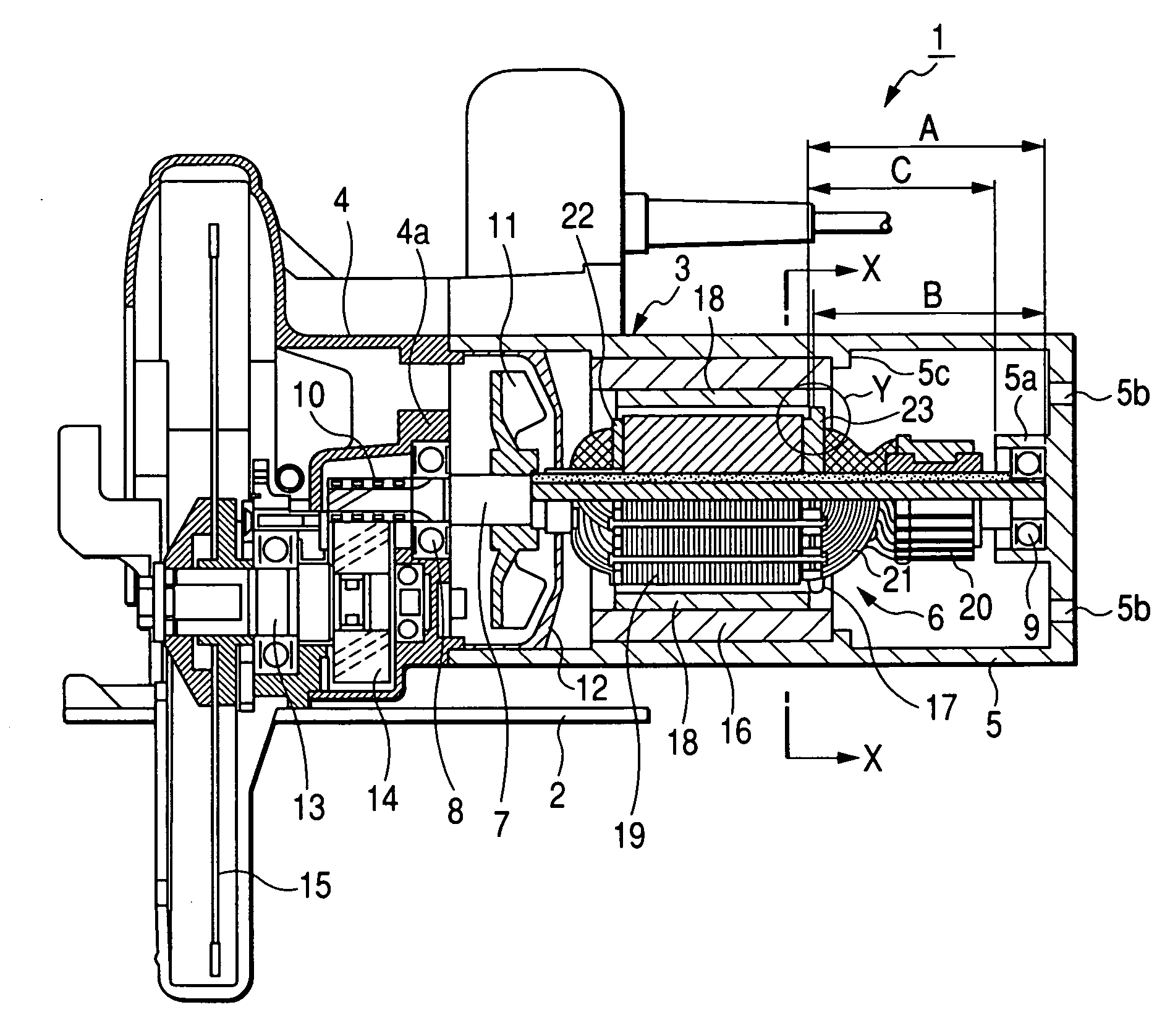

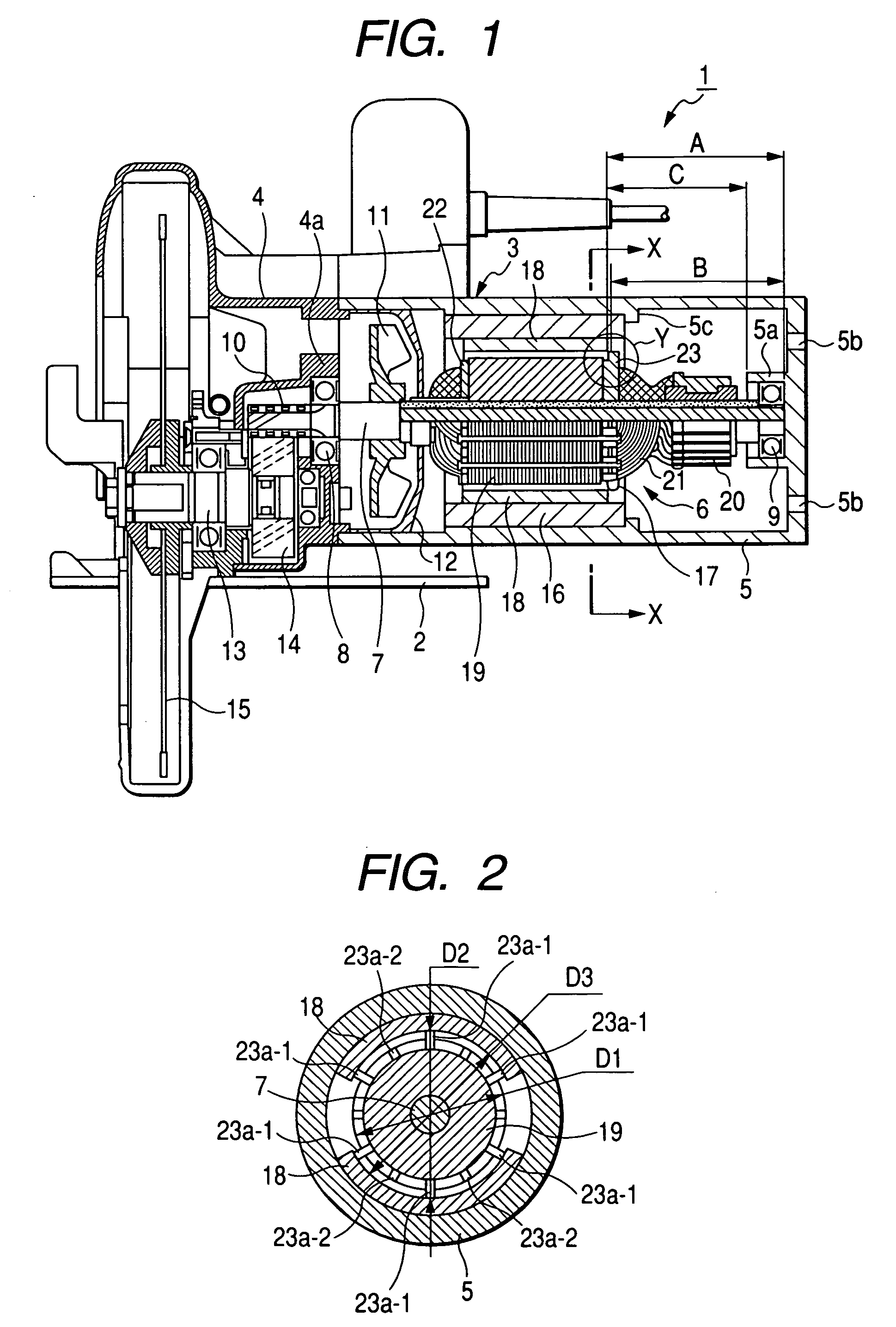

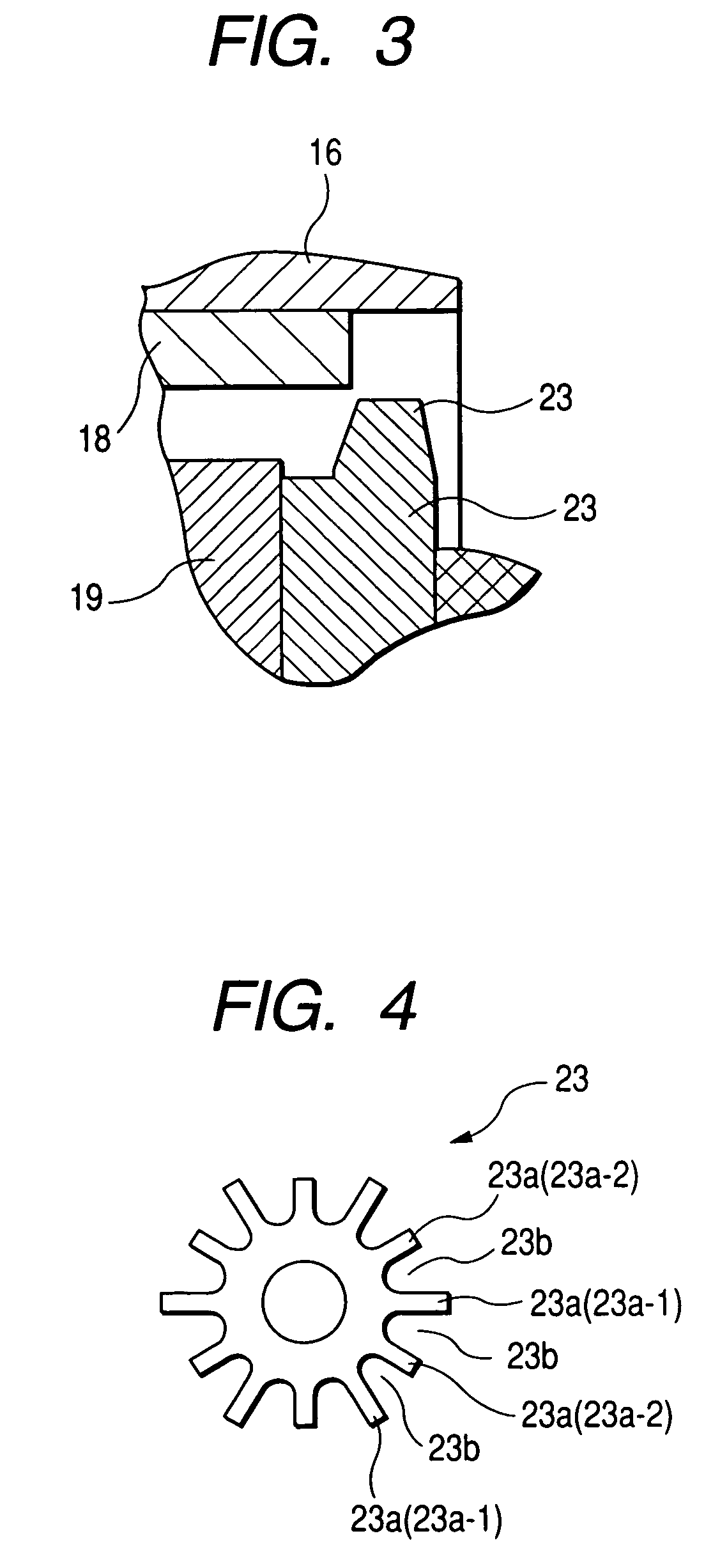

Electrical tool

InactiveUS20060250044A1Smoothly inserted into housingImprove machinabilityMetal sawing devicesMagnetic circuit rotating partsMan-hourCircular saw

To provide an electrical tool in which a permanent magnet motor can be smoothly mounted without requiring excess working power and man-hour. In the portable electrical circular saw (electrical tool) in which a commutator motor (permanent magnet motor) is mounted in a motor case (housing) which is integrally formed in a tube shape, the commutator motor includes a stator fixed to an inner circumferential surface of the motor case and a rotor which is rotatably disposed in the stator, and a plate having a plurality of protrusions is disposed on at least one of the both axial ends of a rotor core of the rotor, an outer diameter of at least two protrusions of the plate is larger than an outer diameter of the rotor core and smaller than an inner diameter of the stator.

Owner:HITACHI KOKI CO LTD

Method for preparing anisotropic nanocrystalline rare-earth permanent magnet block material

InactiveCN102543341AHigh densityImprove permanent magnet performanceInorganic material magnetismInductances/transformers/magnets manufactureRare earthElectric field

The invention discloses a method for preparing an anisotropic nanocrystalline rare-earth permanent magnet block material, which includes: firstly, preparing an alloy ingot by the vacuum smelting process; secondly, melting the alloy ingot and injecting an external direct-current electric field to the melt to realize direct-current inoculation process; thirdly, preparing an anisotropic nanocrystalline rare-earth permanent magnet material by the rapid copper mould solidification process under action of an external direct-current magnetic field; and finally processing the material in heat properly according to specific conditions. The anisotropic nanocrystalline rare-earth permanent magnet block material prepared by the method has the advantages of evident magnetic anisotropy, high density and fine comprehensive permanent magnetic performance. The method is simple in procedure, convenient in operation and low in processing consumption.

Owner:FUZHOU UNIV

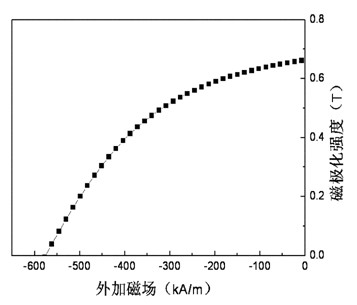

Hard magnetic linear nano coaxial cable wrapped by soft magnetic tube and preparation method thereof

InactiveCN101667480AImprove permanent magnet performanceIndividual molecule manipulationInorganic material magnetismMagnetic phaseElectrochemistry

The invention relates to a hard magnetic linear nano coaxial cable wrapped by a soft magnetic tube and a preparation method thereof, belonging to the technical field of nana materials preparation. Thecoaxial cable is in a double-layer coaxial composite structure and comprises an internal linear nano magnetic core and an external tubular material, wherein the internal linear magnetic core consistsof FePt, CoPt or FeCoPt one-dimensional hard magnetic phase nano wire which is externally wrapped by Fe, Co Ni metal or alloy soft magnetic nano tube to form a FeCoNi / FeCoPt interchange spring nano coaxial cable. The preparation method comprises the following steps: firstly, preparing a soft magnetic alloy nano tube in a porous anode alumina template by adopting a template wetting method; and secondly, growing the nano wire in the nano tube by adopting an electrochemical deposition method. The invention has the advantages that the nano permanent magnet material in the true sense is obtained,and the preparation method is simple.

Owner:CENT IRON & STEEL RES INST

Compound permanent magnetic powder and method for preparing same

InactiveCN101572143AUse to avoidReduce manufacturing costInorganic material magnetismMagnetic exchangeMass ratio

The invention provides a compound permanent magnetic powder with good permanent magnetic performance. The compound permanent magnetic powder has the advantages of common raw materials, low production cost and good magnetic exchange capability. The invention also provides a method for preparing the compound permanent magnetic powder, and the method is short in production period and low in production cost, and the compound permanent magnetic powder prepared by the method has good performance. The compound permanent magnetic powder is compounded by rare earth permanent magnetic alloy and iron based soft magnetic alloy, wherein the rare earth permanent magnetic alloy comprises the following components by weight: 23 to 27 percent of Nd, 1 to 3 percent of La, 1 to 1.5 percent of B, and the balancing of Fe; the iron based soft magnetic alloy comprises the following components by weight: 2 to 5 percent of Al, 5 to 8 percent of Si, 0.2 to 0.4 percent of Cu, 0.5 to 1 percent of Zr, 3 to 5 percent of B, 0.05 to 0.1 percent of Pr, 0.05 to 0.1 percent of P, and the balance of Fe; and the mass ratio of the rare earth permanent magnetic alloy to the iron based soft magnetic alloy in the compound permanent magnetic powder is 5-7:1.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Method for preparing high-performance biphase rare-earth permanent magnet material using hydrogenation heat treatment process

InactiveCN1545107AFine nanostructureRegular nanostructureInductances/transformers/magnets manufactureMagnetic materialsAdhesion processHydrogen

The invention discloses a preparing method of high-performance double-phase, rare-earth, permanent magnetic material by hydrogenation thermal treatment. Firstly, it adopts vacuum welting method to prepare alloy; secondly, adopts fast quenching method or mechanical alloying method to prepare prealloy powder; then, places the prealloy powder in a hydrogen processing device, vacuumize the device and charges in hydrogen for hydrogen absorption and dehydrogenation reactions at 600-1000 deg.C; and finally, adopts adhesion process, cold press process, and thermal press or thermal stress process to prepare an alloyed magnet. It has better synthetic permanent magnetic performance, and its producing device and process are simple, and the consumption of process is low.

Owner:ZHEJIANG UNIV

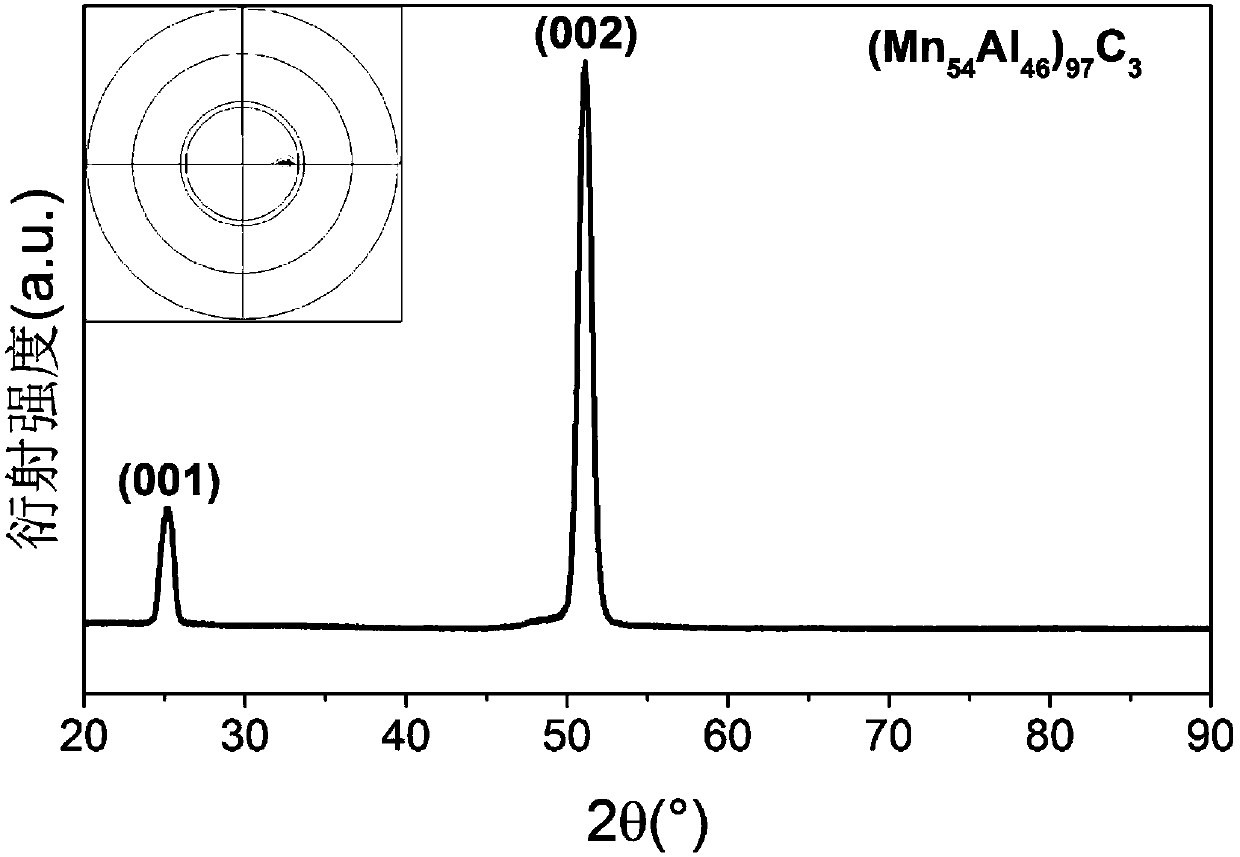

Mn-Al-CNTs type alloy as well as preparation method and application method thereof

InactiveCN101775562AStrong adsorptionImprove magnetic propertiesInductances/transformers/magnets manufactureAfter treatmentMagnet

The invention discloses an Mn-Al-CNTs type alloy as well as a preparation method and an application method thereof, relating to a manganese-based alloy. The components of the Mn-Al-CNTs type alloy based on atomic percentage are as follows: Mn50+xAl50-y(CNTs)y-x, wherein the limited ranges of x and y are as follows: x is not less than 1 and not more than 3, y is not less than 4 and not more than 5, and y-x is not less than 1 and not more than 3; the preparation method of the Mn-Al-CNTs type alloy comprises the following steps of: preparing cast alloys after raw materials preparation, melting and smelting, and then preparing final Mn-Al-CNTs type alloy products after treatments of solution and annealing; and the application method of the Mn-Al-CNTs type alloy is as follows: preparing the Mn-Al-CNTs type cast alloy into an annealing Mn50+xAl50-y(CNTs)y-x type alloy thin strip magnet. The invention further improves the magnetization intensity and the coercive force of the Mn-Al type alloy so as to further improve the permanent magnetism performance and the machining property of the Mn-Al type alloy materials.

Owner:HEBEI UNIV OF TECH

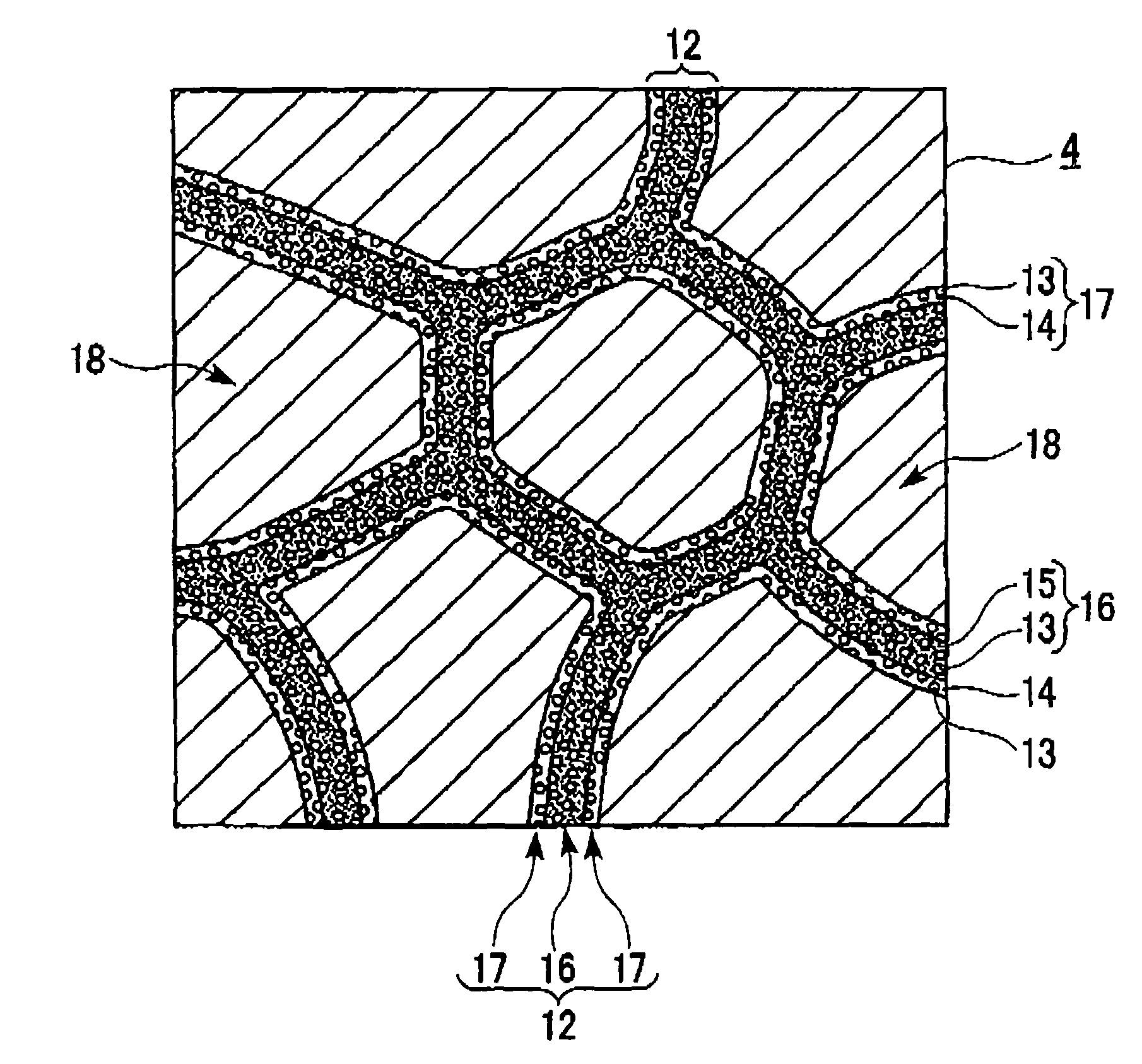

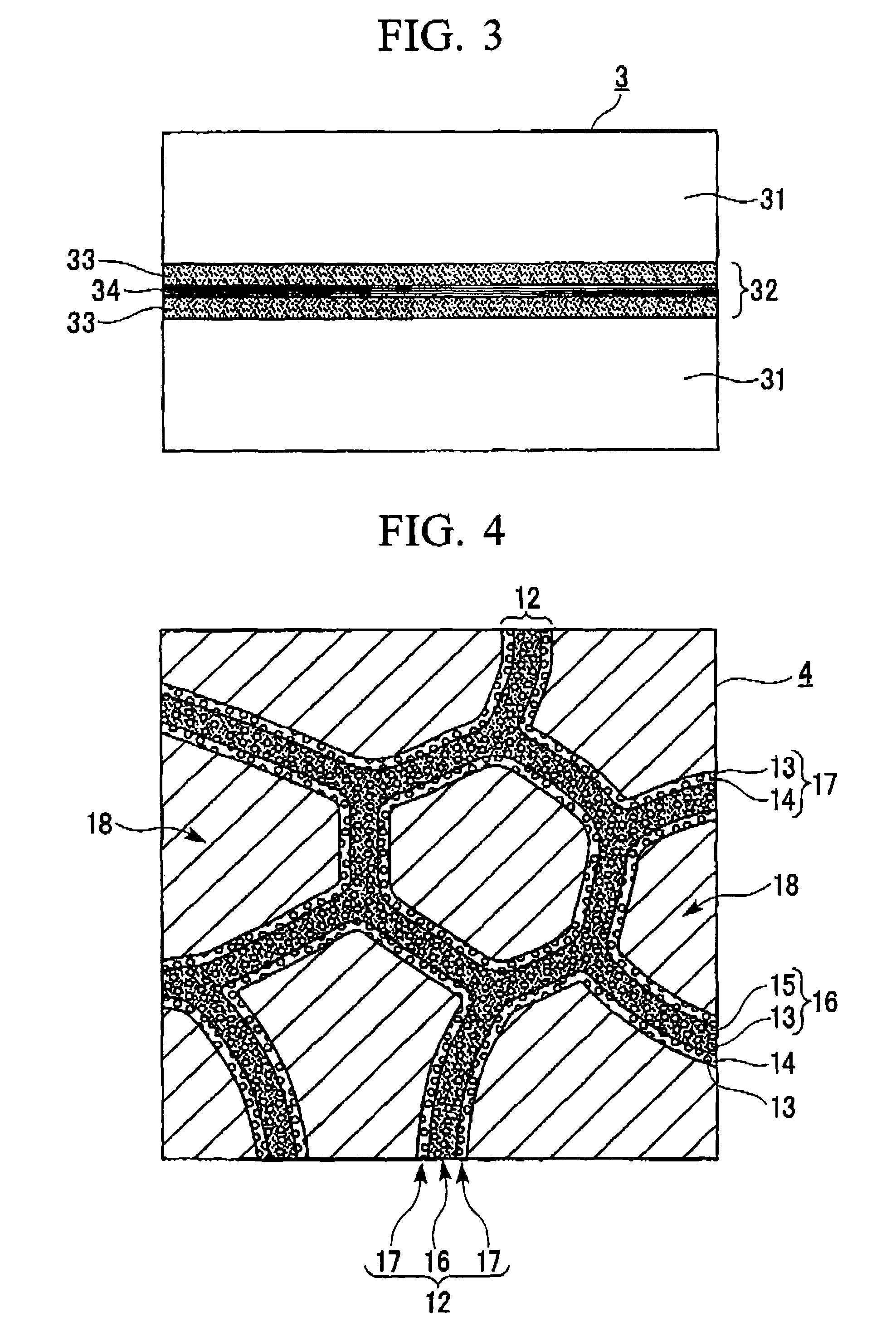

Rare earth magnet having high strength and high electrical resistance

InactiveUS7919200B2High bonding strengthHigh strengthThin magnetic filmsInductances/transformers/magnets manufactureHigh intensityRare-earth magnet

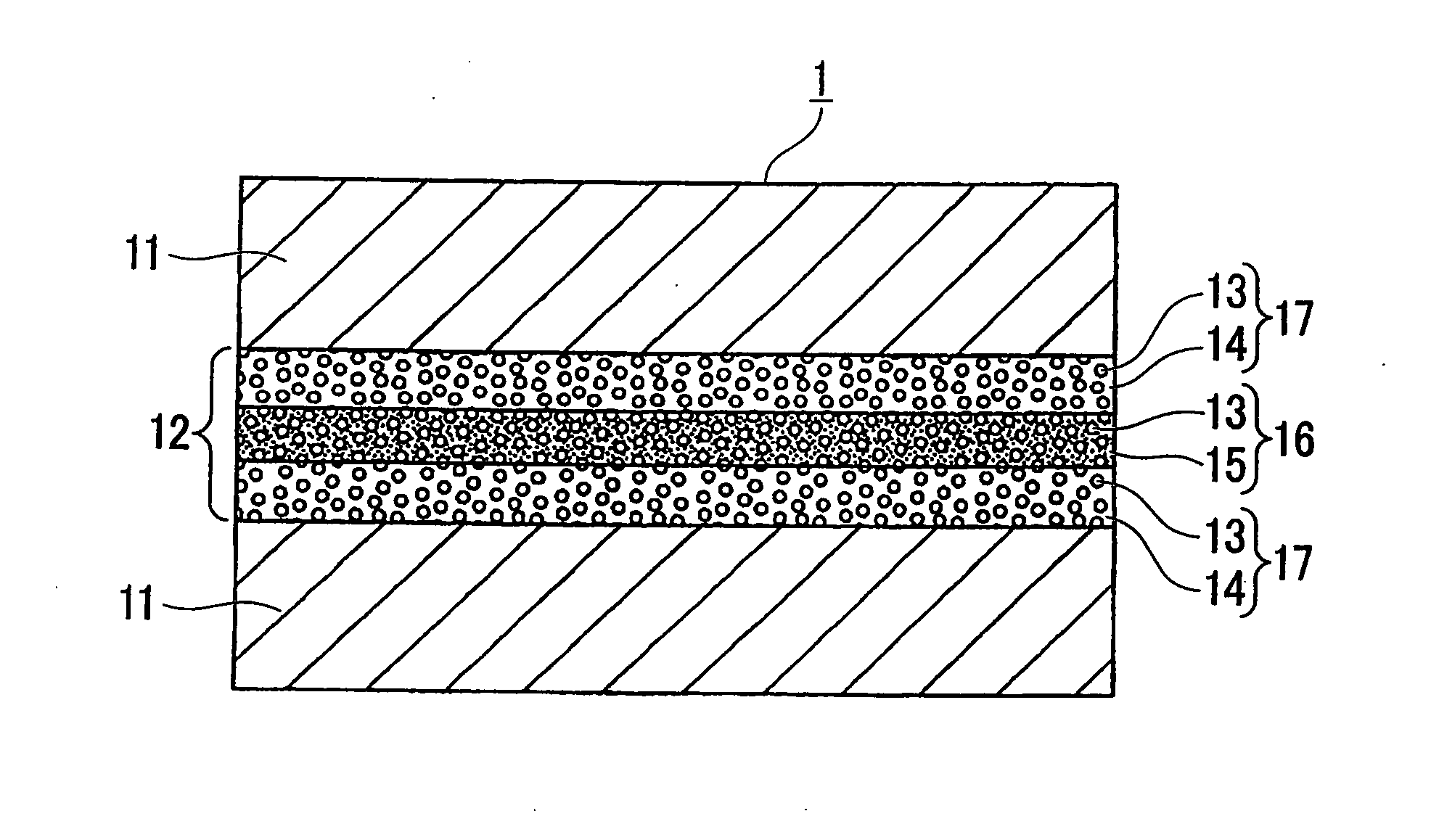

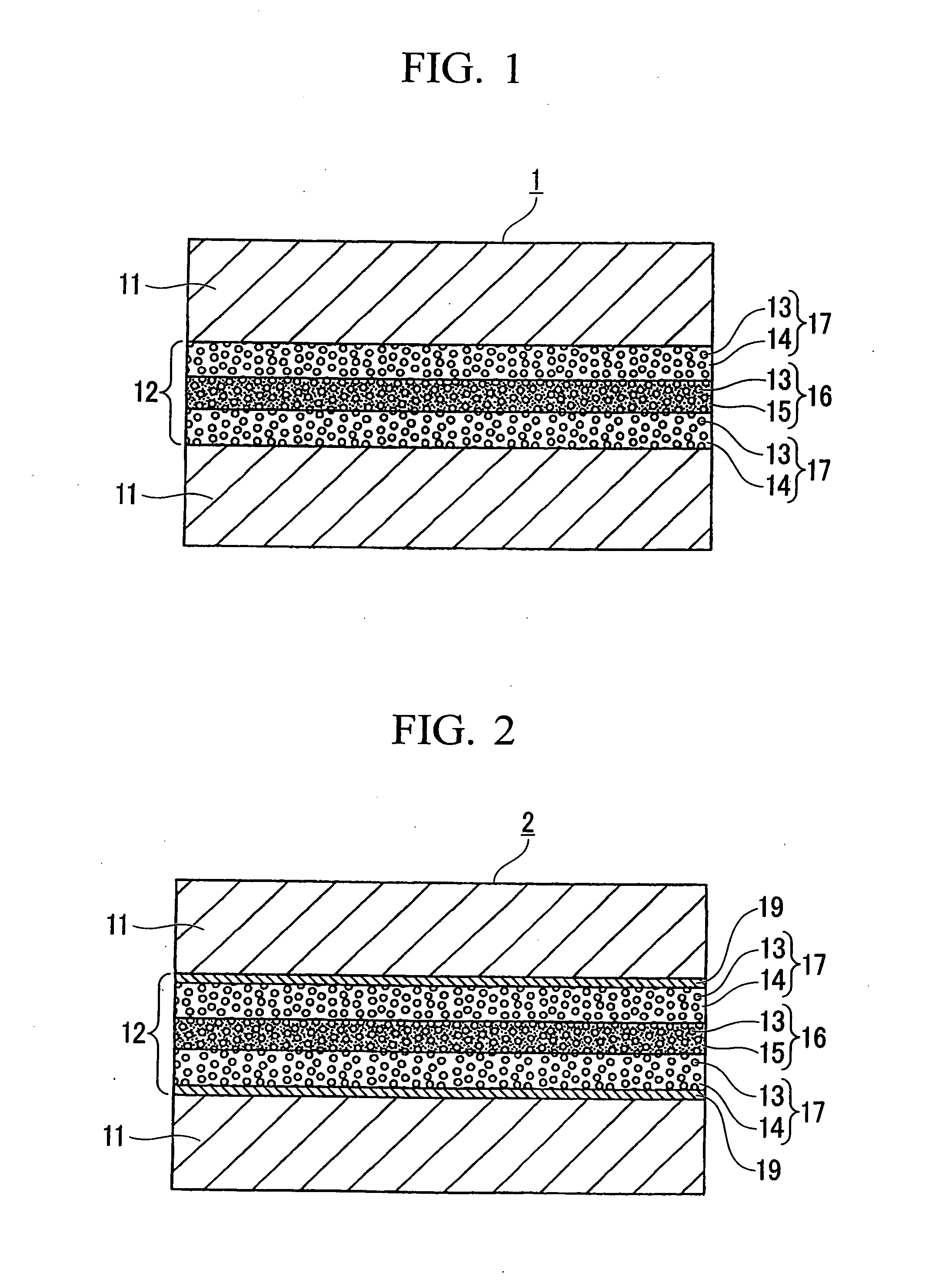

This rare earth magnet having high strength and high electrical resistance has a structure including an R—Fe—B-based rare earth magnet particles 18 which are enclosed with a high strength and high electrical resistance composite layer 12. The high strength and high electrical resistance composite layer 12 is constituted from a glass-based layer 16 that has a structure comprising a glass phase or R oxide particles 13 dispersed in glass phase, and R oxide particle-based mixture layers 17 that are formed on both sides of the glass-based layer 16 and contain an R-rich alloy phase 14 which contains 50 atomic % or more of R in the grain boundary of the R oxide particles.

Owner:NISSAN MOTOR CO LTD

High-performance dual-phase permaneng-magnet rare-earth material and its preparing process

InactiveCN1165055CImprove coercive forceImprove permanent magnet performanceInorganic material magnetismRare-earth elementMetallurgy

This invention discloses a high performance two-phase rare-earth permanent-magnet material and its preparation method. The said material contains rare-earth elements 6.2-12.0at%, nitrogen 0.5-4.5at%, metalloid elements 2.5-6.0at% with B as the main factor and the remaining transition metal mainly with FE. The preparation method is first to prepare alloy by vacuum fusing then to prepare alloy powder by adopting quick quench or mechanical alloying combined with suitable heat processing techniques, finally to adhere, cold and hot press or warm distortion to prepare alloy magnet. The magnet powder and magnet has preferable comprehensive performance of permanent magnet with higher working temp. and anti-corrosion and less content of rare earths.

Owner:ZHEJIANG UNIV

Shielding shell of low frequency transformer

InactiveCN101794659AImprove permanent magnet performanceLow costMagnetic paintsMagnetic/electric field screeningTransformerAcrylic acid

The invention provides a shielding shell of a low frequency transformer, wherein a shielding casing is arranged outside the transformer, the casing is made of nonmetal material or cheap metal material; the inner surface and outer surface of the casing are separately coated with a shielding coating; the main component of the coating is rare earth alloy powder, and the coating also contains titanate coupling agent, nonionic high molecular glucan used as surface modifier of iron powder, anionic high molecular sodium alginate used as diluent of iron powder and thermoplastic acrylic acid resin used as adhesive, and the prepared fine powder coating is coated on the inner and outer surfaces of the shielding casing. The significant effect of the invention is to install the shielding protective casing on the low frequency transformer; in order to save cost, cheap material can be used to prepare the shielding casing; and some magnetic materials are coated on the inner and outer surfaces of the casing, and the adopted rare earth alloy powder not only has good permanent magnetism, but also saves the cost.

Owner:蔡建林

Rare earth magnet having high strength and high electrical resistance

InactiveUS20110128106A1High bonding strengthHigh strengthPermanent magnetsThin magnetic filmsRare-earth elementRare-earth magnet

Owner:NISSAN MOTOR CO LTD

Method and application for preparing magnetic Sm2Co17/Al-Ni-Co composite through spark plasma sintering

InactiveCN108723355APermanent magnet effect is goodFast sinteringTransportation and packagingMetal-working apparatusMagnetic powderWet grinding

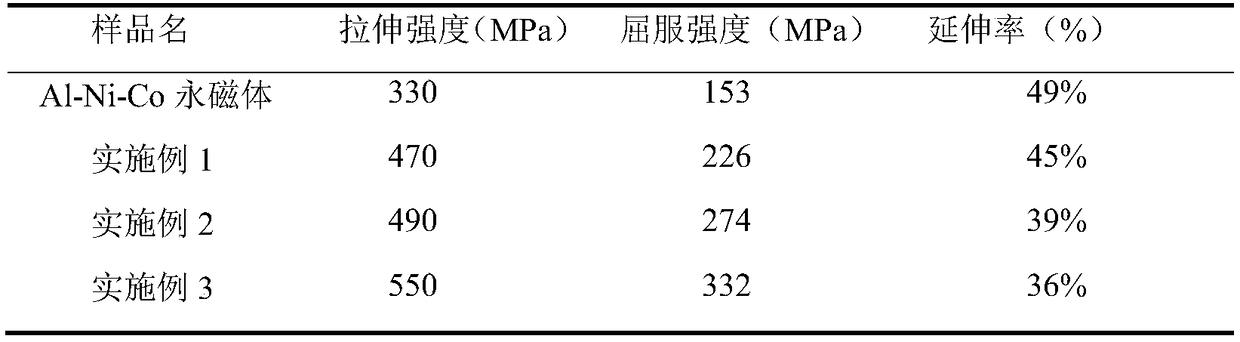

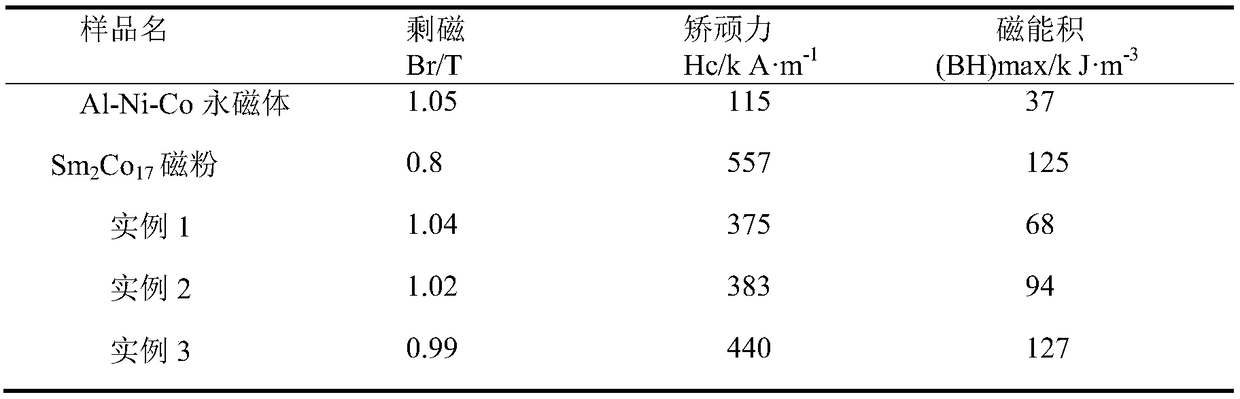

The invention belongs to the technical field of composite preparation, in particular to a method and application for preparing a magnetic Sm2Co17 / Al-Ni-Co composite through spark plasma sintering. Themethod for preparing the magnetic Sm2Co17 / Al-Ni-Co composite through spark plasma sintering specifically comprises the steps of mixing Sm2Co17 magnetic powder with aluminum powder, cobalt powder andnickel powder evenly, adding ethyl alcohol, conducting wet grinding in a ball grinding machine and conducting vacuum drying to obtain mixed powder; pressing and molding the mixed powder through cold isostatic pressing; putting an obtained composite billet into a graphite mold to conduct vacuum sintering in a spark plasma sintering furnace and cooling the composite billet to the indoor temperatureto obtain a Sm2Co17 / Al-Ni-Co composite after completion of sintering; and conducting magnetizing on the composite to obtain the magnetic Sm2Co17 / Al-Ni-Co composite. The magnetic Sm2Co17 / Al-Ni-Co composite obtained through the method has higher magnetism and better permanent magnetic effect. The composite is uniform and stable in structure has higher tensile strength and yield strength. The methodhas the advantages that the preparation process is simple, the controllability is high, sintering is fast and the sintering temperature is low and can be applied to production.

Owner:JIANGSU UNIV

Method for preparing anisotropy MnAlC single variant through uniaxial pressure constraint transformation

InactiveCN108281247AElimination of twinningAnisotropy hasInductances/transformers/magnets manufactureMagnetic materialsConstraint transformationMagnetization

The invention provides a method for preparing an anisotropy MnAlC magnetic single variant through uniaxial pressure constraint transformation and the MnAlC single variant prepared by the method. The method comprises the steps of carrying out smelting, rod casting and single crystal growth on MnAlC raw materials to form a MnAlC-epsilon phase single crystal; and annealing the MnAlC-epsilon phase single crystal for 3-10 min under uniaxial pressure of 250-350MPa and temperature of 580-680 degrees centigrade, thereby preparing a MnAlC-tau phase single variant. The MnAlC-tau phase single variant prepared by the method has saturation magnetization intensity exceeding 100emu / g and complete anisotropy, and an equivalent magnetocrystalline anisotropy field is greater than 4T. The method and the MnAlC single variant have the advantages that (1), bicrystals in alloy can be effectively eliminated, the single variant organization is realized, the material has anisotropy, and the relatively good permanent magnet performance is obtained; (2), the technology is simple, and bad influences of produced microdefects and precipitated equilibrium phases on the magnetic performance can be completely avoided.

Owner:BEIHANG UNIV

Method for preparing biphase rare-earth permanent magnet material using hydrogenation heat treatment process

InactiveCN1242427CFine nanostructureRegular nanostructureInductances/transformers/magnets manufactureMagnetic materialsAdhesion processHydrogen

Owner:ZHEJIANG UNIV

High resistivity fully compacted permanent magnet material and preparation method thereof

ActiveCN108242304AWide variety of sourcesCost advantageInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementRare earth

The invention discloses a rare earth permanent magnet material which comprises alloy powder, the primary component of which is RFeMB, wherein R contains Nd or PrNd, and M is one or more of Co, Ga, Aland Cu. The rare earth permanent magnet material also comprises oxyfluoride powder, the component of which is CaRE2[CO3]F2, wherein RE is selected from one or more of Ce, La and Nd. In addition, the invention also discloses a method for preparing the rare earth permanent magnet material. Synchysite which is wide in source and lower in cost is combined with rare earth elements, so that the resistivity of the fully compacted magnet is improved obviously, and the thermal processing performance of the magnet is reduced greatly, and therefore, the eddy-current loss is reduced effectively.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Neodymium-iron-boron magnetic material and preparation method

ActiveCN109326404AImprove permanent magnet performanceImprove magnetismInductances/transformers/magnets manufactureMagnetic materialsNiobiumGallium

The invention belongs to the field of magnetic materials and particularly relates to a neodymium-iron-boron magnetic material and a preparation method. The neodymium-iron-boron magnetic material comprises, by weight, 29-33 parts of praseodymium-neodymium alloy, 3-6 parts of dysprosium-iron alloy, 3-7 parts of boron-iron alloy, 0.6-0.8 part of niobium-iron alloy, 5-8 parts of yttrium-iron alloy, 1.0-2.5 parts of nano silica, 0.1-0.3 part of gallium, 0.5-1 part of aluminium oxide, 1-2 parts of an antioxidant and the balance iron. The obtained neodymium-iron-boron magnetic material has the advantages that by adding the nano silica and the niobium-iron alloy into the neodymium-iron-boron magnetic material and adopting the praseodymium-neodymium alloy as a main component, the Curie temperatureis remarkably increased, the coercive force of the neodymium-iron-boron magnetic material is increased, and the application value of the neodymium-iron-boron magnetic material is increased.

Owner:徐州永丰磁业有限公司

Preparation method of antiseptic manganese, bismuth and aluminum permanent-magnet material

InactiveCN107833724AStable permanent magnet performanceShort curing timeInductances/transformers/magnets manufactureMagnetic materialsSurface finishingBismuth

The invention discloses a preparation method of an antiseptic manganese, bismuth and aluminum permanent-magnet material. The permanent-magnet material prepared by adopting the method has excellent andstable permanent-magnet properties and can be obtained through the simple and easy preparation method. Chemical curing and photocuring are integrated, curing time is shortened, the cutting speed of the magnetic material is improved, accordingly the forming rate of prepared parts is improved, and the preparation efficiency of the magnetic material is improved. The manganese, bismuth and aluminum permanent-magnet material is also subjected to surface treatment so that the manganese, bismuth and aluminum permanent-magnet material can have the advantages of excellent corrosion resistance, ultra-low magnetism, impact resistance and the like.

Owner:SUZHOU NANER MATERIAL TECH CO LTD

Preparation method of manganese-bismuth permanent magnet with ceramic protection layer

InactiveCN108878091AImprove permanent magnet performanceStable permanent magnet performanceMolten spray coatingConductive/insulating/magnetic material on magnetic film applicationComposite ceramicProtection layer

The invention discloses a preparation method of a manganese-bismuth permanent magnet with a ceramic protection layer. The permanent magnet material prepared by the method has excellent performance andstable permanent magnet performance and can be obtained through a simple and feasible preparation method; according to the method, the connection firmness between a magnet matrix and an Al2O3-NiO composite ceramic layer can be ensured; bubble forming and falling off of the Al2O3-NiO composite ceramic layer do not occur easily; and meanwhile, the Al2O3-NiO composite ceramic layer is prepared by adopting a plasma spraying technology, so that high-quality protection on the surface of the magnet can be realized.

Owner:苏州诺弘添恒材料科技有限公司

Nanocrystalline misch metal permanent magnet and preparation method and application thereof

InactiveCN108364740ASimple processImprove protectionInorganic material magnetismInductances/transformers/magnets manufactureMisch metalRare earth

The invention provides a nanocrystalline misch metal permanent magnet and a preparation method and application thereof. A chemical formula of the permanent magnet is MMCo5, wherein MM is a misch metalalloy extracted from co-associated and primary light rare earth ores in the process of purification, containing impurities and having natural element proportion. A main phase of a permanent magnet material has a hexagonal structure of CaCu5 type. The intrinsic coercive force Hcj of the permanent magnetic material is greater than or equal to 4kOe, the residual magnet Br is greater than or equal to3kGs, and the maximum magnetic energy product (BH) Max is greater than or equal to 5MGOe. Co-associated and primary misch metal raw materials which are not subject to rare earth purification treatment are adopted to prepare a cobalt-based permanent magnet, and the permanent magnet is applied to a special environment. Therefore, a raw material process is simple, energy and resource consumption islow, the prices is low, and environmental protection and balanced utilization of rare earth resources are facilitated. The nanocrystalline MMCo5 permanent magnet has good magnetic property, heat stability, corrosion resistance properties and mechanical property.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

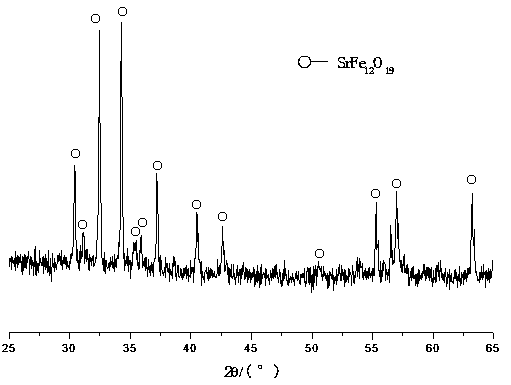

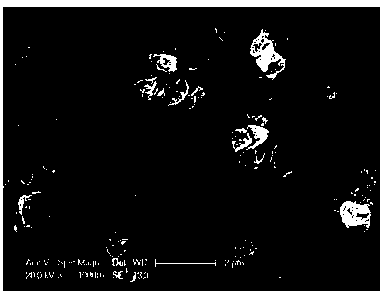

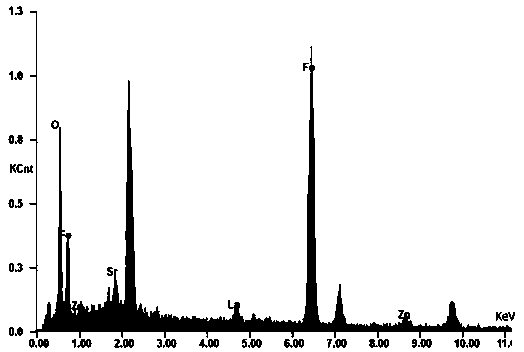

La-Zn co-doping permanent magnetic strontium ferrite material powder and preparation method thereof

The invention relates to La-Zn co-doping permanent magnetic strontium ferrite material powder and a preparation method thereof. According to the technical scheme, strontium carbonate, iron scale, lanthanum oxide and zinc oxide are mixed to obtain a mixture, wherein the molar ratio of SrCO3:Fe2O3:La2O3:ZnO is (0.6-0.9):(5.85-5.98):(0.05-0.20):(0.06-0.30); and then, 0.1-0.5wt% of dispersing agent and 90-110wt% of water are added to the mixture to prepare the slurry; then the slurry is wet milled in a steel ball-milling tank according to the mass ratio of the steel balls to the mixture being (7.5-10):1 till the granularity is 0.6-0.9mu m; and then the ball-milled slurry is put into a rotary kiln, heat insulation is carried out for 120-240 minutes under the condition of 1000-1350 DEG C, and the sully is cooled along with the kiln, thereby obtaining the La-Zn co-doping permanent magnetic strontium ferrite material powder. The preparation method is simple in process and low in cost; and the prepared La-Zn co-doping permanent magnetic strontium ferrite material powder has the coercive force of 160-320kA / m, residual magnetization of 215-300mT, saturation magnetization of 58-66emu / g, and excellent permanent magnetic performance.

Owner:WUHAN UNIV OF SCI & TECH

Manufacturing method of micro motor rotor

ActiveCN107344236ASimple internal structureUniform magnetic field distributionTransportation and packagingMetal-working apparatusPermanent magnet rotorAlcohol

The invention discloses a manufacturing method of a micro motor rotor. The manufacturing method is completed by procedures of pulverization, pressing of a green body, sintering, grinding machining and magnetization. In the pulverization process, H3BO3, camphor, alcohol, calcium stearate, silicon dioxide, Cr, Nb and Ti are added into fine magnetic powder, so that the internal structure of a magnetic pillar of a permanent magnet rotor is improved, the coercive force and the wear resistance of a magnetic body are improved, and a magnetic field in the magnetic pillar of the rotor is uniformly distributed; powder obtained by smashing of a coarse green body and the fine powder are mixed according to a ratio, so that powder for manufacturing a magnetic pillar of the motor rotor is finally manufactured, and the smoothness of the powder is improved; therefore, the uniformity of the internal structure of the magnetic pillar of the rotor is improved, and the uniformity of the distribution of the magnetic field in the magnetic pillar of the rotor is improved; during pressing of the green body, filling and cold pressing are repeatedly performed for three times, so that the structural uniformity and the intensity of the magnetic pillar of the rotor are enhanced, and the permanent magnet performance of the magnetic pillar of the rotor is improved; and by pre-magnetization, grinding machining and then magnetization for enhancing magnetization during pressing of the green body, the permanent magnet performance of the rotor is improved.

Owner:XUZHOU MINGRUN MAGNETIC MATERIAL CO LTD

Preparation method of anisotropic nanocrystalline ndfeb dense permanent magnet

ActiveCN106486281BImprove c-axis orientationImprove coercive forceInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementThermal deformation

The invention discloses a preparation method of an anisotropic nanocrystal NdFeB compact permanent magnet. The method comprises the steps of firstly preparing alloy powder according to the molar ratio of Nd11.5Fe81.5Zr1B6, adding 1.5%-2% of zinc powder to the Nd11.5Fe81.5Zr1B6 alloy powder, and mixing the zinc powder and the Nd11.5Fe81.5Zr1B6 alloy powder evenly and then carrying out hot-pressing on the mixed powder to form a compact block; and carrying out thermal deformation on the compact block, completing deformation when the deformation quantity of thermal deformation reaches 65%-70% to obtain the anisotropic nanocrystal NdFeB compact permanent magnet. An alloy element Zr is added, an amorphous Nd11.5Fe81.5Zr1B6 strip is prepared by adopting a magnetic levitation melting technology and a vacuum melt spinning technology, and is mixed with a proper amount of nano Zn powder, so that the anisotropic nanocrystal NdFeB magnet is prepared by adopting a thermal deformation technology; c-axis orientation of the NdFeB alloy is improved; the prepared anisotropic nanocrystal NdFeB compact magnet contains scarce rare earth, has relatively high coercivity and excellent overall permanent magnet performance and does not contain a heavy rare earth element and a strategic element Co; and the used raw materials are low in cost.

Owner:重庆文童机电有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com