Preparation method of non-rare earth MnAl permanent magnetic alloy

A permanent magnet alloy, rare earth-free technology, used in magnetic materials, magnetic objects, electrical components, etc., can solve the problems of low coercivity of MnAl permanent magnet alloys, difficulty in obtaining τ-MnAl phase, and limited application scope of alloys, etc. Achieve the effects of excellent machinability and corrosion resistance, simple production process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

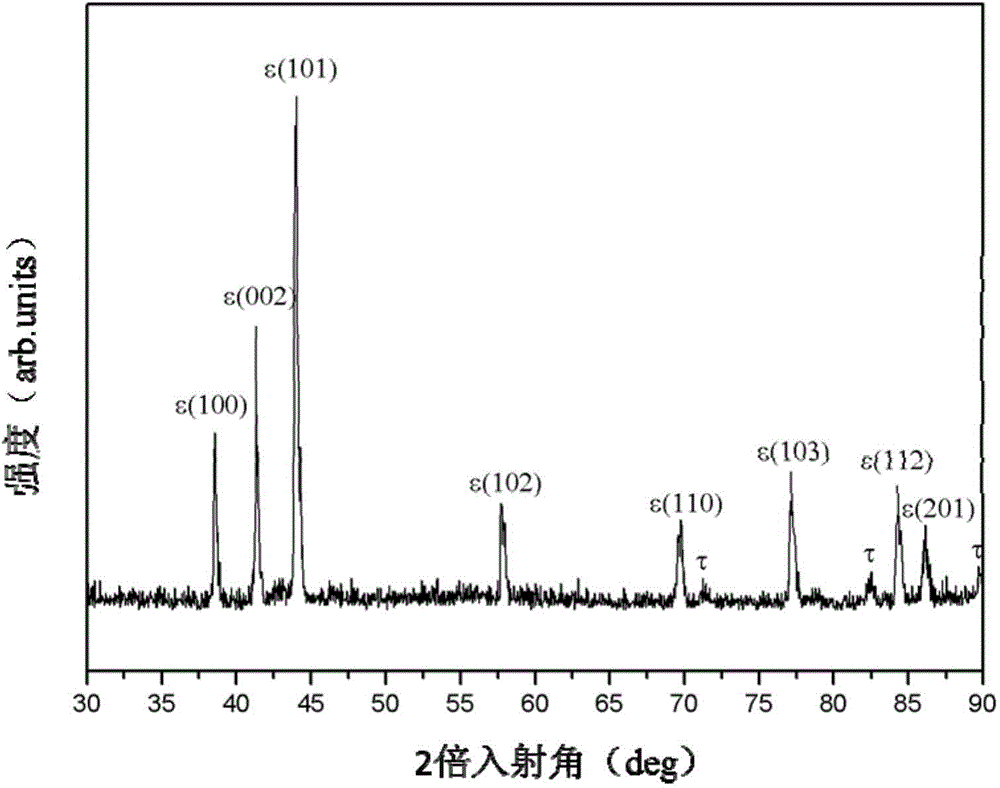

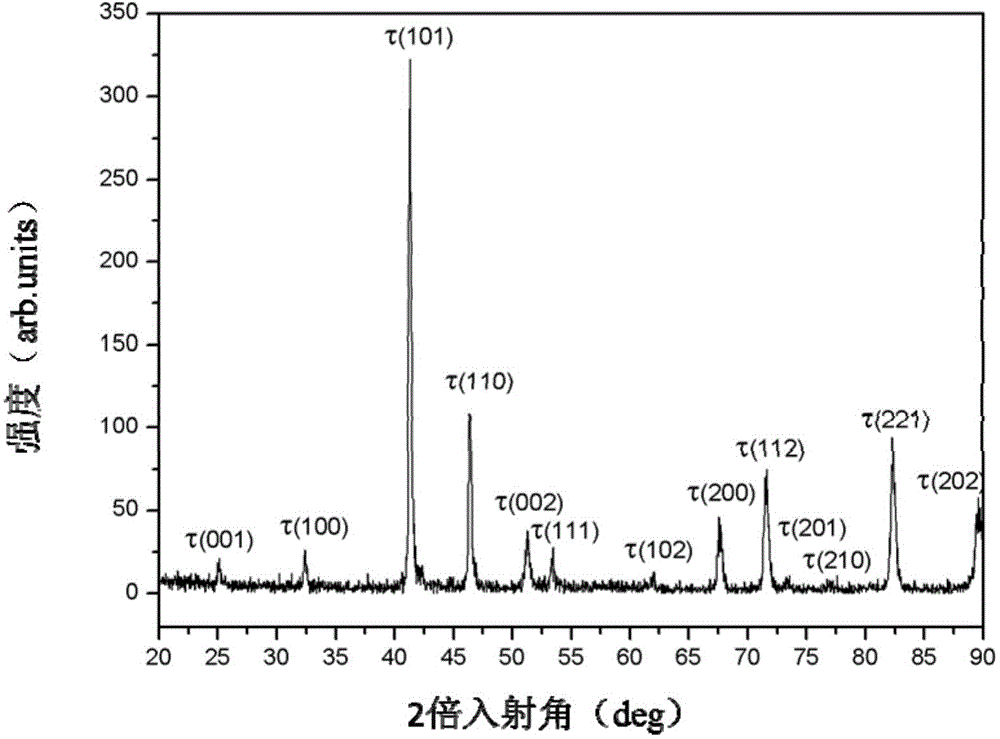

[0027] The pure manganese block and pure aluminum block with a purity of not less than 99.9% are formulated with an appropriate atomic percentage into Mn 55 Al 45 In the master alloy sample, since Mn is very volatile during smelting, in order to compensate for its volatilization during smelting, an additional 7 atomic percent of Mn was added to the batching, totaling 15 grams. Using a non-consumable vacuum electric arc furnace, under the protection of argon, put the master alloy raw materials with a good ratio into a water-cooled copper crucible, and then fill it with 99.99% argon as a protective atmosphere after vacuuming, and repeatedly smelt the alloy 4 times to obtain The as-cast master alloy with uniform composition; the smelted MnAl alloy ingot is broken, and the broken block alloy is put into acetone solution and alcohol solution for ultrasonic cleaning, and then it is taken out and dried naturally; MnAl is prepared by single-roller quick quenching method Alloy thin st...

Embodiment 2

[0030] The pure manganese block and pure aluminum block with a purity of not less than 99.9% are formulated with an appropriate atomic percentage into Mn 52 Al 48For the master alloy sample, since Mn is very volatile during smelting, in order to compensate for its volatilization during smelting, an additional 5 atomic percent of Mn was added during the batching, totaling 15 grams. Using a non-consumable vacuum electric arc furnace, put the proportioned master alloy raw materials into a water-cooled copper crucible under the protection of argon, and repeatedly smelt the alloy 4 times to obtain a cast master alloy with uniform composition; The alloy ingot is broken, and the broken block alloy is put into acetone solution and alcohol solution for ultrasonic cleaning, taken out and dried naturally; the MnAl alloy thin strip is prepared by single-roll quick quenching method, and the cleaned block alloy is put into In the quartz tube of the quenching tape-making equipment, the cham...

Embodiment 3

[0033] The pure manganese block and pure aluminum block with a purity of not less than 99.9% are formulated with an appropriate atomic percentage into Mn 58 Al 42 For the master alloy sample, since Mn is very volatile during smelting, in order to compensate for its volatilization during smelting, an additional 9 atomic percent of Mn was added to the ingredients, totaling 15 grams. Using a non-consumable vacuum electric arc furnace, put the proportioned master alloy raw materials into a water-cooled copper crucible under the protection of argon, and repeatedly smelt the alloy 4 times to obtain a cast master alloy with uniform composition; The alloy ingot is broken, and the broken block alloy is put into acetone solution and alcohol solution for ultrasonic cleaning, taken out and dried naturally; the MnAl alloy thin strip is prepared by single-roll quick quenching method, and the cleaned block alloy is put into In the quartz tube of the quenching tape-making equipment, the cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com