Double-hard magnetic main phase mixed rare-earth permanent magnet and preparation method thereof

A dual-hard magnetic main phase and mixed rare earth technology is applied in the fields of magnetic objects, inductors/transformers/magnets, magnetic materials, etc. It can solve the problems of non-use and cost increase, and achieve environmental protection, wide sources, and short refining process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

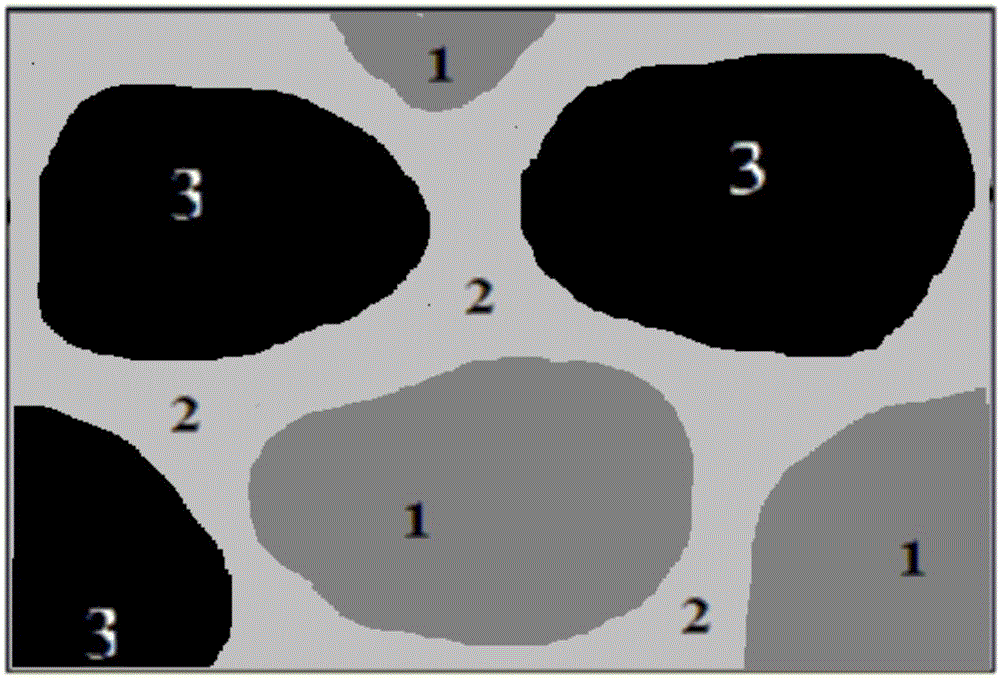

Image

Examples

preparation example Construction

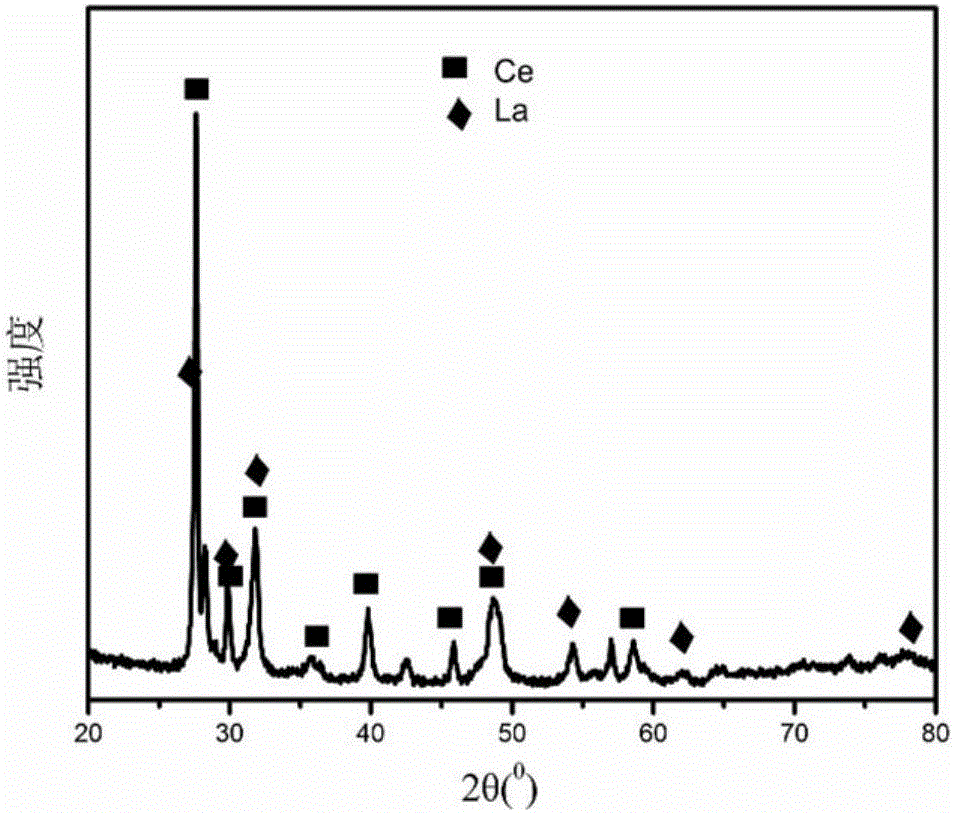

[0073] A kind of mixed rare earth permanent magnet and the steps of preparation method thereof are as follows:

[0074] Step 1: Ingredients. The preparation process mode is different, the alloy batching mode of application example is different, the chemical formula of alloy and detailed raw material ratio are as follows:

[0075] Table 4 Ingredients and Materials

[0076]

[0077]

[0078] Polish off the oxidized skin of each raw material to reveal the metallic luster, then weigh the raw materials required for each component, and use them immediately after batching.

[0079] Step 2: melting and preparing quick-setting tablets.

[0080] MM 31 Fe bal B 0.97 tm 1.5 The main phase alloy quick-setting sheet is alloy ①;

[0081] (PrNd) 27 Fe bal BB 0.97 tm 0.5 The other main phase alloy quick-setting sheet is alloy ②;

[0082] chemical formula [MM 0.2 (PrNd) 0.8 ] 30 Fe bal BB 0.97 tm 1.3 For alloy ③;

[0083] chemical formula [MM 0.4 (PrNd) 0.6 ] 30 Fe ...

Embodiment 2

[0089] Embodiment 2 is a control group, what used is double alloy method, prepares alloy 3., alloy 4. and alloy 5. with this process;

[0090] The condition of jet milling is that the sorting speed is 4800r / min, and the oxygen content is about 48ppm. The final prepared magnetic powder is measured three times with an average particle size analyzer, and the average value is 3μm.

[0091] Step 5: Shaping. Using vertical molding technology under pulsed magnetic field, with N 2 Oxygen is continuously exhausted from the counter-pressure cavity. When the oxygen content is less than 300ppm, the pulsed magnetic field is oriented at 2T, the pressure is 5-10MPa and the compaction density is 3-3.9g / cm 3 , into a vacuum bag, but it needs to be further compacted by cold isostatic pressing above 280MPa. The green density after compaction is 4~6g / cm 3 .

[0092] Step 6: Sintering and tempering treatment. Put the green body into the vacuum sintered furnace tube quickly, use Ar gas to clea...

Embodiment 1

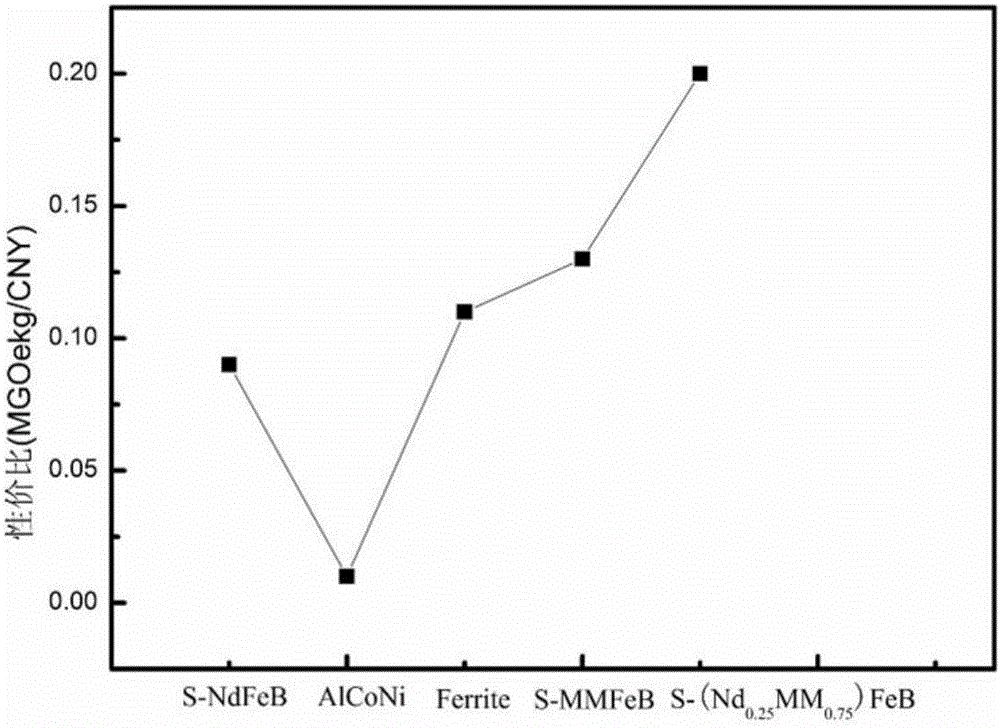

[0094] Example 1 uses the double hard magnetic main phase method to prepare a magnet. Under the same preparation cost, the magnetic performance is the highest, showing the superiority of this method. Only such cost-effective sintered mixed rare earth permanent magnets can be favored by customers and finally win the market.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Remanence | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com