Novel material distribution device and floor concrete casting construction method of novel material distribution device

A technology of a distributing device and a construction method, which is applied in the processing of building materials, construction, building structure, etc., can solve the problems of cumbersome repeated installation of pump pipes, damage to steel bars on the floor, and cumbersome cleaning of pump pipes, etc., so as to improve the construction of steel bars. Quality, solve pollution problems, solve the effect of cumbersome cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Relevant present invention is for reaching above-mentioned purpose of use and effect and the technical means adopted, presents preferred feasible embodiment, and cooperates as shown in the accompanying drawings, detailed description is as follows:

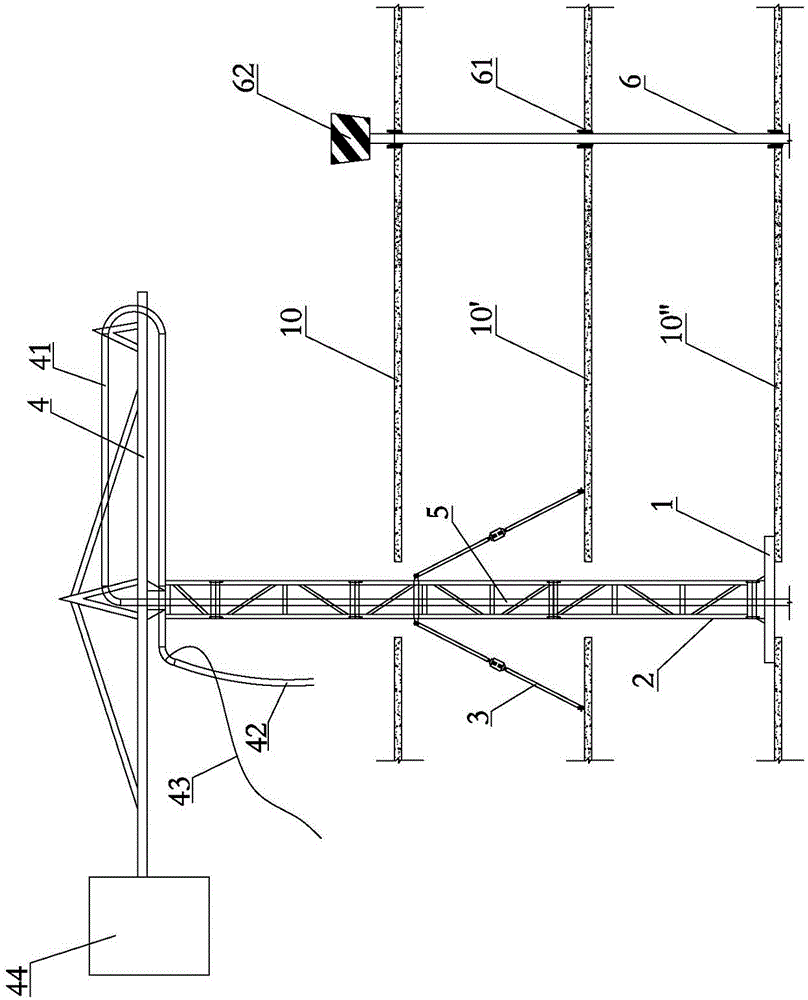

[0036] like figure 1 As shown, it is a working condition diagram of pouring floor concrete by the novel distribution device of the present invention. The present invention provides a new type of material distribution device, which mainly includes: a base section 1, a standard section 2, a diagonal brace 3, a distribution rod 4, a pump pipe 5 and a pump pipe circuit 6. Wherein, the foundation section 1 is installed and fixed on the second floor 10 "of the construction layer, and the standard section 2 is installed and fixed on the foundation section 1, and the standard section 2 passes through the next layer 10' of the construction layer and the construction layer successively. The hole reserved on layer 10, and the standard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com