Method for preparing high-temperature alloy cutting tool coating in ion source enhanced arc ion plating mode

A technology of arc ion plating and high-temperature alloys, which is applied in ion implantation plating, metal material coating technology, coating, etc., can solve the problems of poor surface roughness, affecting the cutting performance and service life of coating tools, and achieve the goal of coating Effects of layer bonding strength improvement, wear resistance and oxidation resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

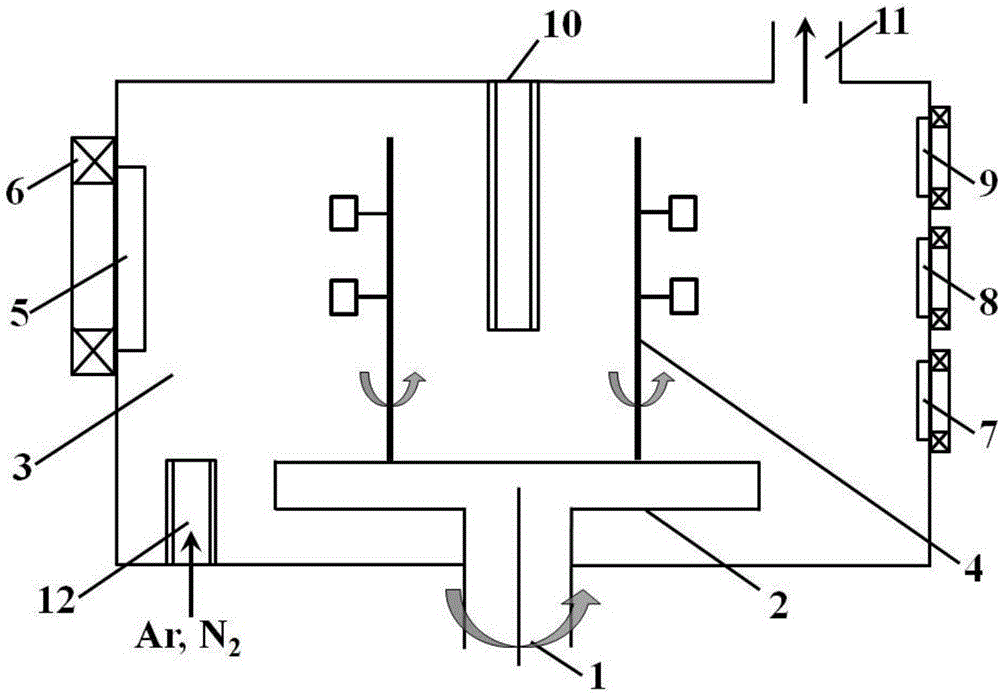

[0026] During research, the applicant found that introducing a gas ion source into the traditional arc ion plating method and using high-energy gas discharge to etch the surface of the workpiece can significantly improve its bonding force. At the same time, using the enhanced bombardment synergistic effect of the ion source, the plasma density in the vacuum chamber and the ionization effect of the reaction gas are improved, and the microscopic particles of the coating are significantly refined, which can greatly improve the dense structure and oxidation resistance of the coating. Therefore, if it is used to prepare tool coatings, it is expected to well meet the severe cutting conditions and use effects of aviation superalloy tools.

[0027] This embodiment provides a method for preparing a superalloy cutting tool coating by ion source-enhanced arc ion plating, in which a wear-resistant and oxidation-resistant CrAlN coating is prepared on the surface of a cemented carbide tool. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| anti-oxidation temperature | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com