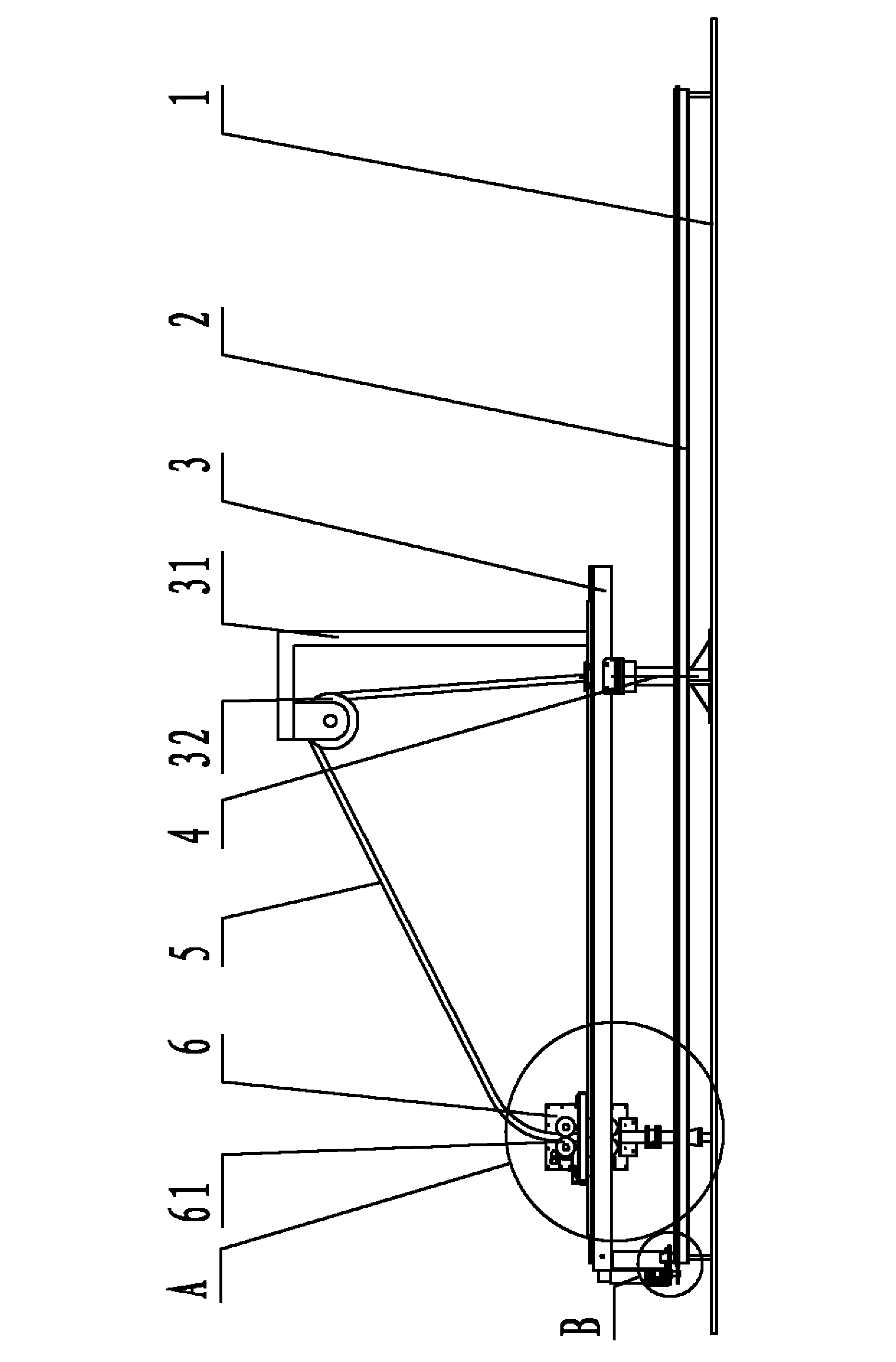

Cleaning machine for heat exchange pipe of evaporator

A technology of heat exchange tubes and washing machines, which is applied in the direction of washing, cleaning heat transfer devices, lighting and heating equipment, etc., can solve the problems of poor safety and high labor intensity of operation, and achieve safe use, low labor intensity and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

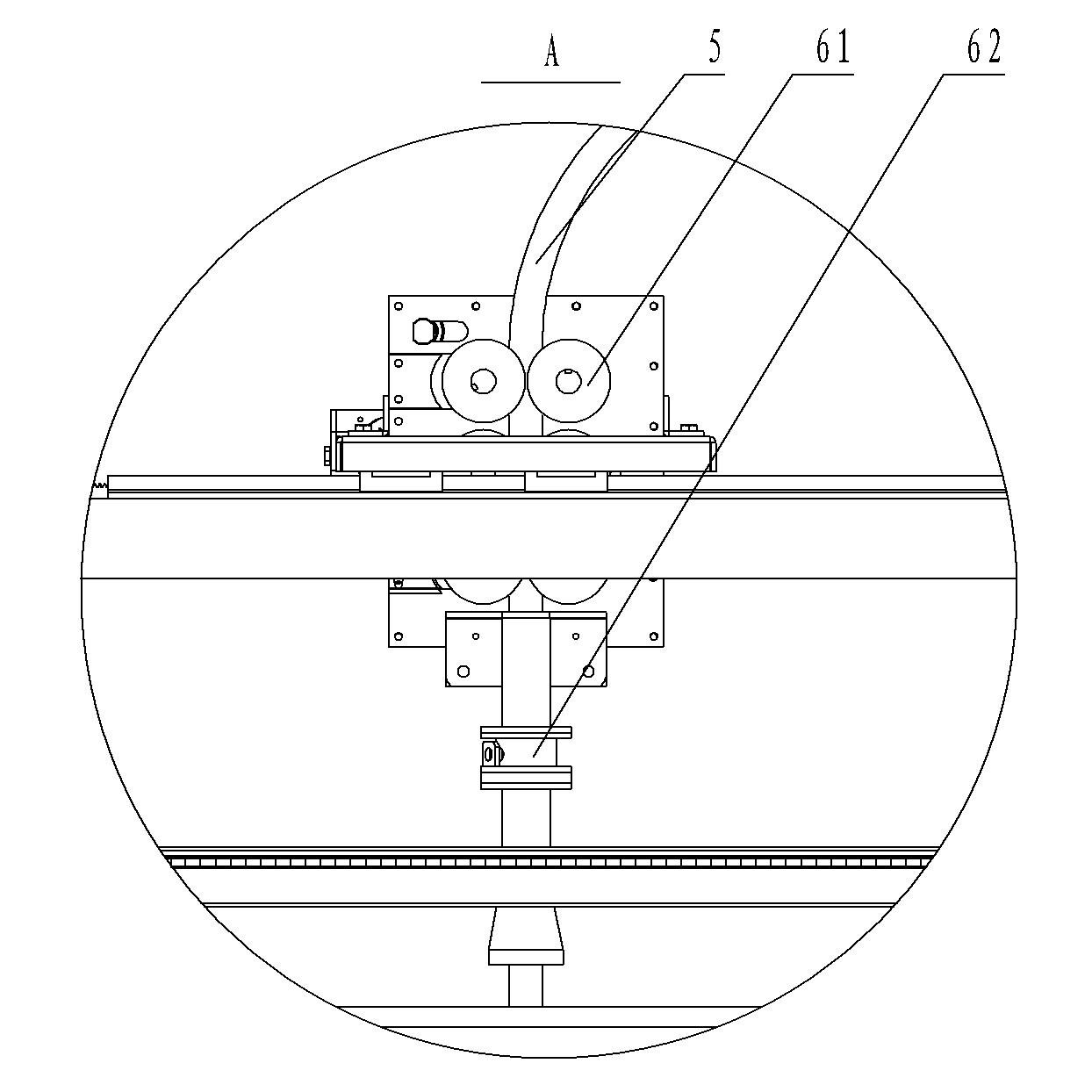

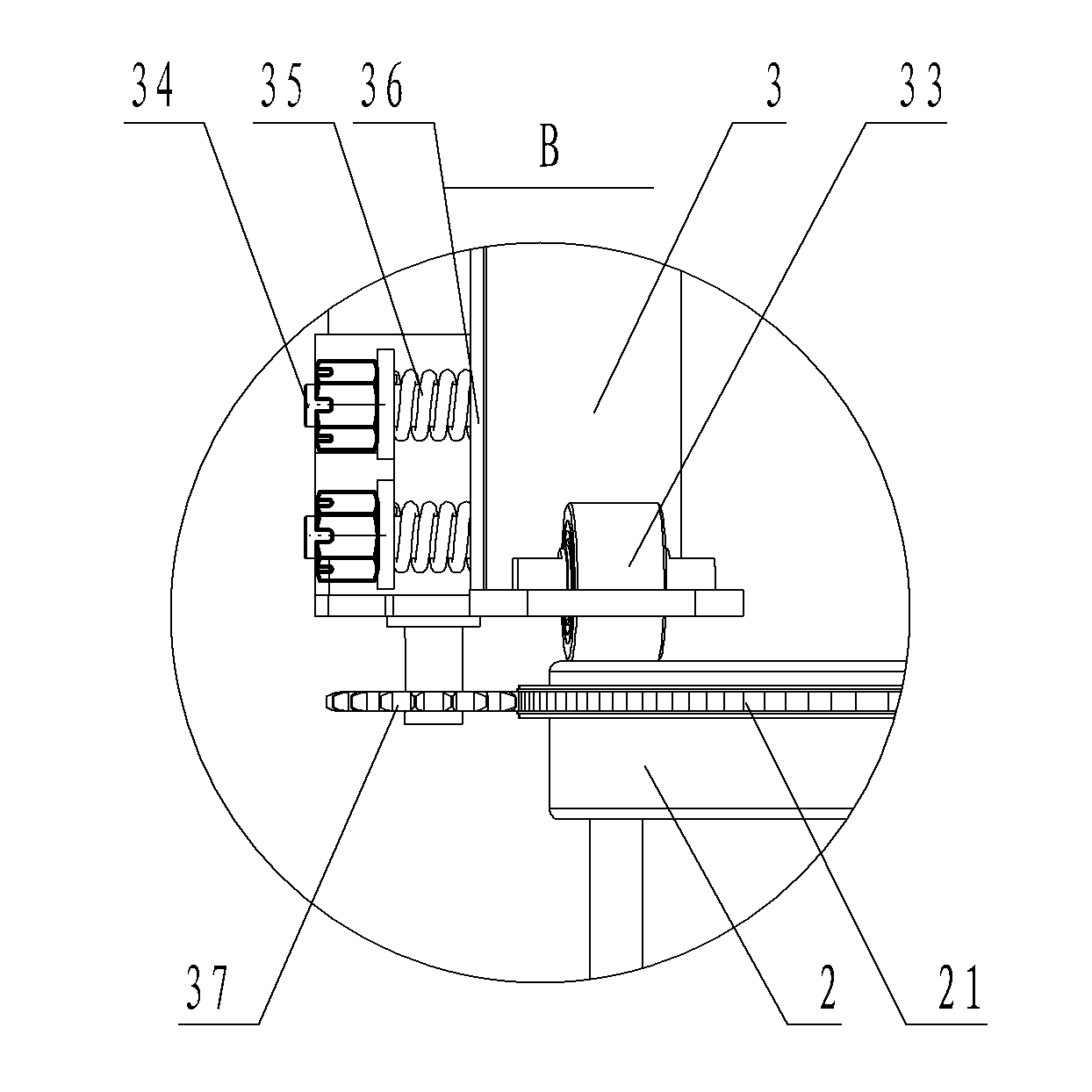

Method used

Image

Examples

Embodiment 2

[0027] Embodiment two: in Figure 1 to Figure 7 In the first embodiment, the rack of the head drive device can be replaced by a chain, the gear of the head drive device can be replaced by a sprocket, and other parts remain the same as the first embodiment.

Embodiment 3

[0028] Embodiment three: in Figure 1 to Figure 7 On the basis of the first embodiment, the machine head driving device composed of a screw mandrel connected by the machine head power machine installed on the frame and a screw nut fixedly connected with the cleaning machine head installed on the screw mandrel replaces the above-mentioned The other parts of the machine head driving device of the first embodiment remain the same as those of the first embodiment.

Embodiment 4

[0029] Embodiment four: in Figure 1 to Figure 7 On the basis of Embodiment 1, the chain in Embodiment 1 is replaced by the rack fixedly connected on the circular track, and the gear installed on the output shaft of the reducer of the frame power machine is replaced by gears, and other parts remain the same as Embodiment 1. same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com