Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

139results about How to "Meet wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-abrasion resistant ultraviolet light solidifying fingerprint resistant coating

InactiveCN101701129AGood hardness and wear resistanceMeet wear resistancePolyurea/polyurethane coatingsSolventFingerprint

The invention relates to a light solidifying high-abrasion resistant fingerprint resistant coating which is used for the surfaces of plastic shells of portable electronic products, such as mobile phones, MP3, digital cameras, handheld computers, and the like and comprises the following components: 10-35 percent of high-functionality urethane acrylate, 5-25 percent of bifunctional urethane acrylate, 0.01-20 percent of acrylic ester monomer, 5-20 percent of high-functionality acrylic ester, 5-40 percent of fluorin-contained acrylic ester, 0.01-10 percent of nano inorganic powder filler, 1-5 percent of light initiating agent, 0.01-5 percent of auxiliary agent and 5-30 percent of solvent. The invention improves the fingerprint resistant capability of a coating film by the enrichment and microphase separation of a fluorin-contained group added into the coating on the surface of a coating surface, provides excellent abrasion resistance and hardness by using the polyurethane structure in the coating and the added nano abrasion resistant filler and meets the requirements of abrasion resistance, scratch resistance and fingerprint resistance of the portable electronic products.

Owner:武汉嘉特利佰联创科技有限公司

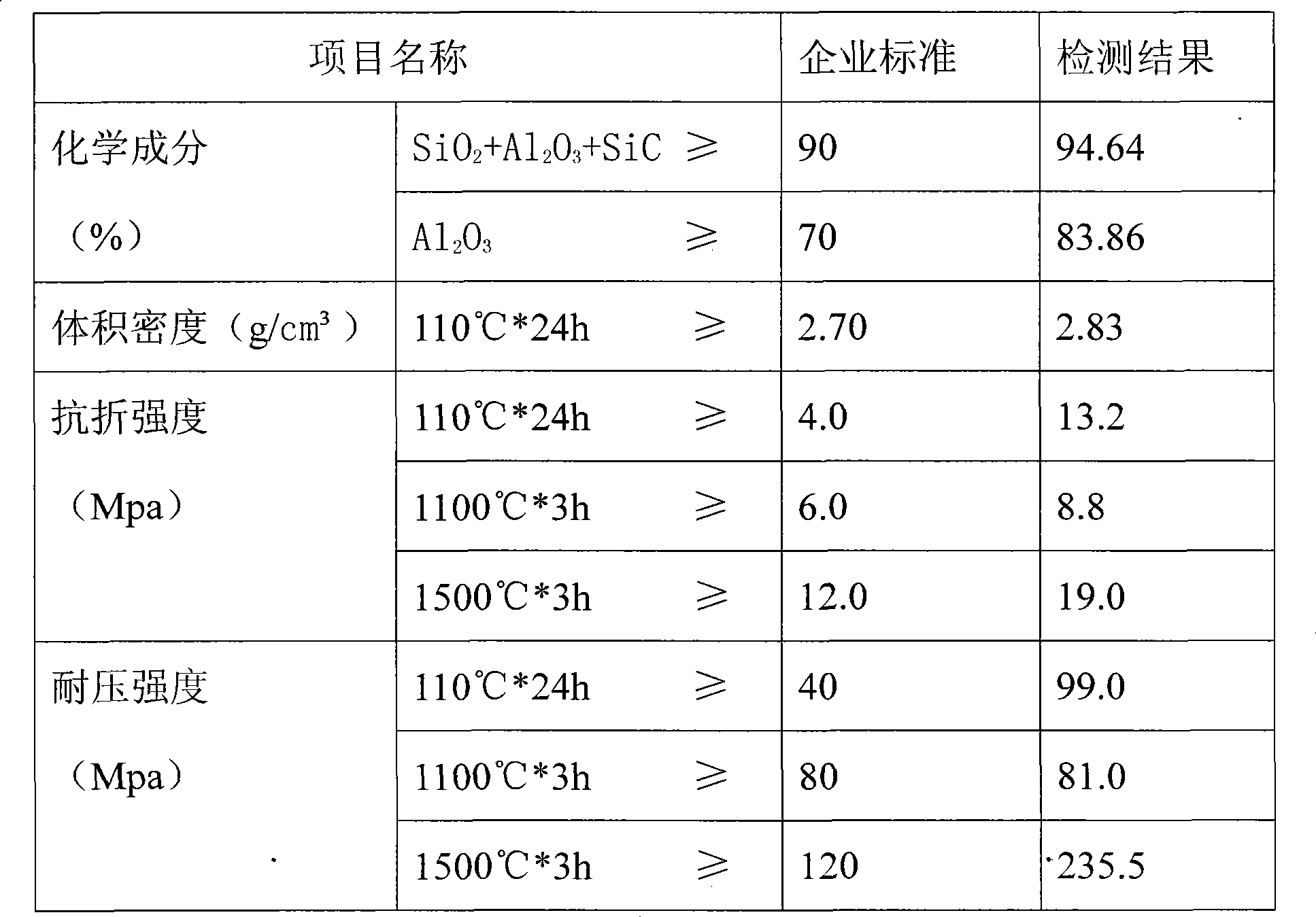

Corundum-mullite self-flow refractory castable

The invention discloses a corundum mullite artesian fireproof casting material, which comprises 30-35% of plate-shaped corundum, 5-8% of carborundum powder material, 4-5% of pure calcium aluminate cement, 35-45% of mullite, 10-15% of alpha-Al2O3 micropowder and 3-5% of bonite by mass percentage. The casting material is characterized by good fluidity, good resistance to thermal shock, low porosity rate of entity after casting, good chemical resistance, high intensity and long service life.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

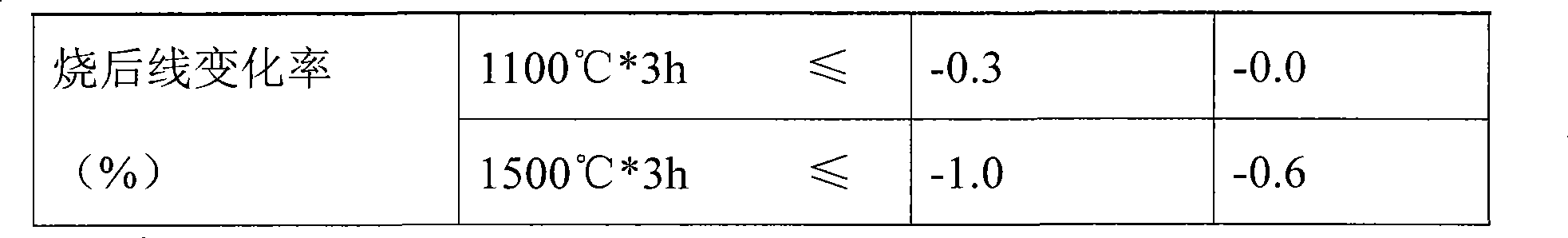

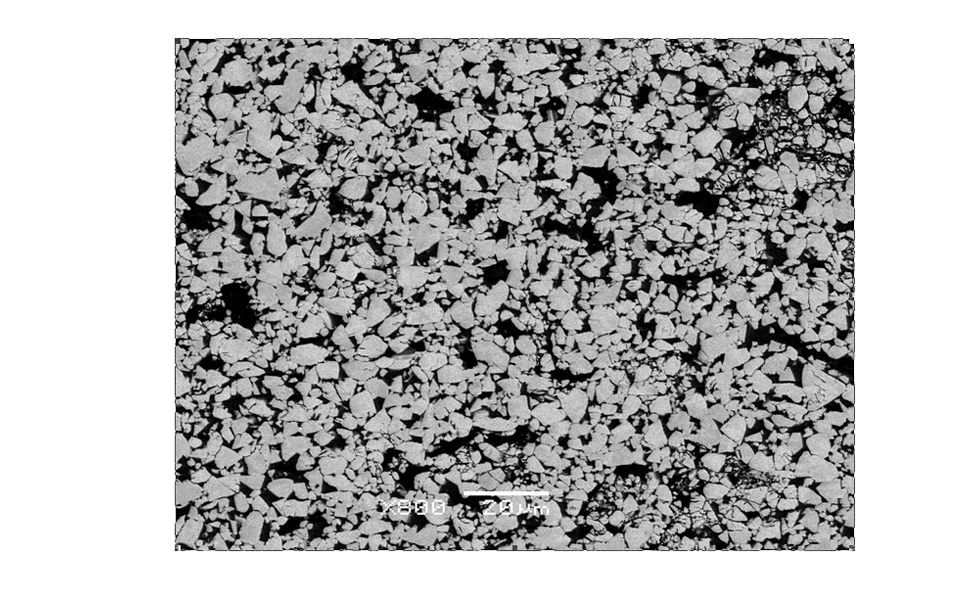

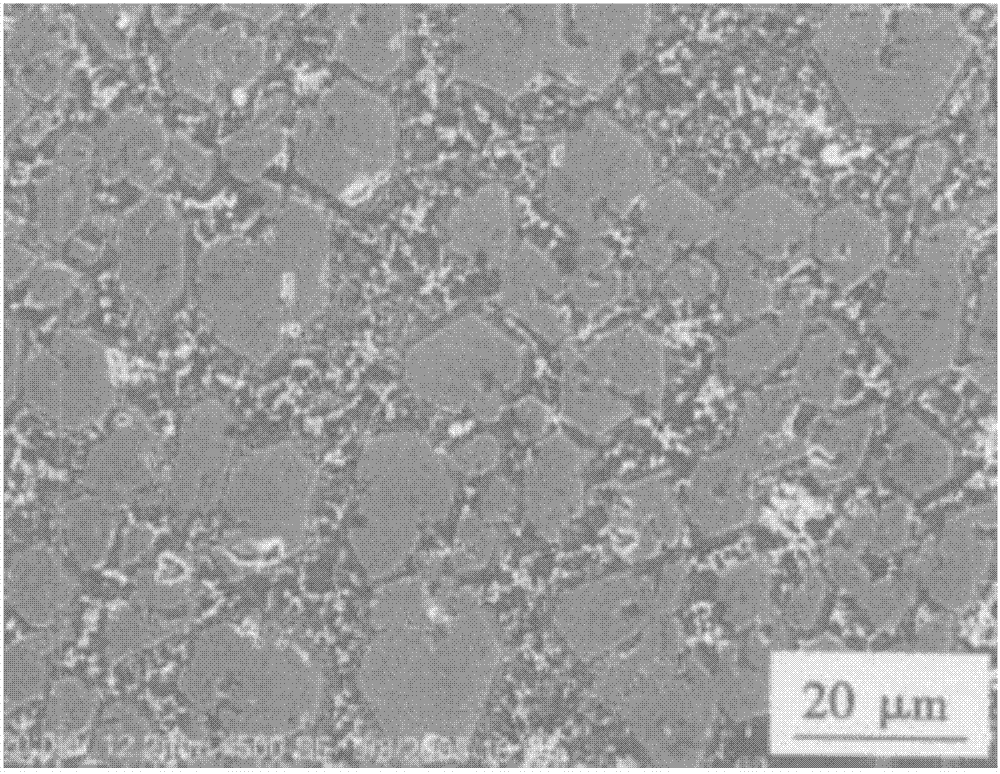

Hard alloy using iron-aluminum intermetallic compound as bonding phase and preparation method thereof

ActiveCN101985718AUniform tissue structureGood mechanical properties at room temperatureIron powderAlloy

The invention discloses a hard alloy using an iron-aluminum intermetallic compound as a bonding phase and a preparation method thereof. The hard phase is carbide, and the bonding phase is 10 to 40 volume percent of FeAl or Fe3Al. The preparation method comprises the following steps of: ball-milling and mixing 1.69 to 19.09 mass percent or 1.31 to 13.75 mass percent of pre-alloying powder of Fe2Al5, 2.10 to 23.78 mass percent or 3.23 to 33.81 mass percent of iron powder and the balance of carbide powder based on the component of FeAl or Fe3Al for 18 to 36 hours, preparing the obtained ball-milling mixture into uniform mixture powder by spray drying, pressing the mixture powder to form a blank, preserving the heat for 1 to 2 hours at the temperature of 1,200 + / - 20 DEG C under the vacuum condition during sintering the pressed blank, and then performing low-pressure liquid phase sintering at the temperature of between 1,250 and 1,550 DEG C to obtain the hard alloy using the FeAl or the Fe3Al as the bonding phase, wherein the FeAl or the Fe3Al is 10 to 40 volume percent. The preparation method has simple process and is low in manufacturing cost; holes are difficult to form in the liquid phase sintering process or are small; and the obtained hard alloy has high strength, good abrasion resistance and excellent high-temperature oxidation resistance and sulfur corrosion resistance.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

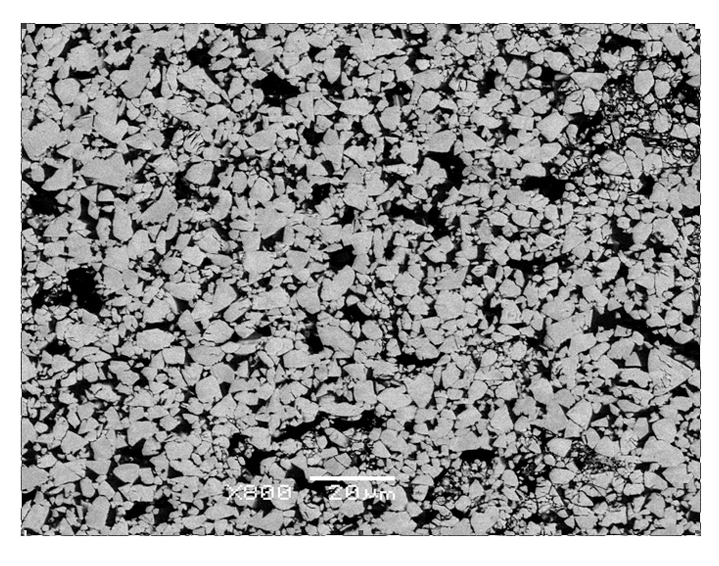

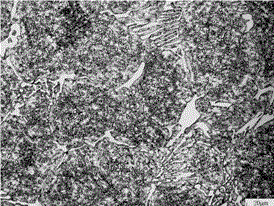

High-wear-resistance alloy tool steel roll and manufacturing method thereof

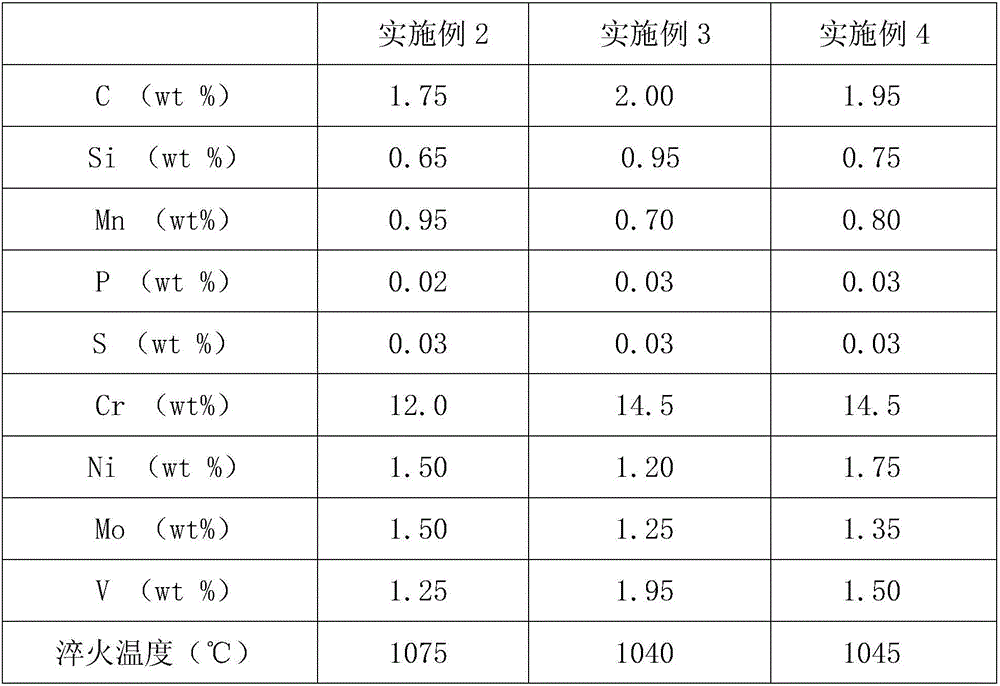

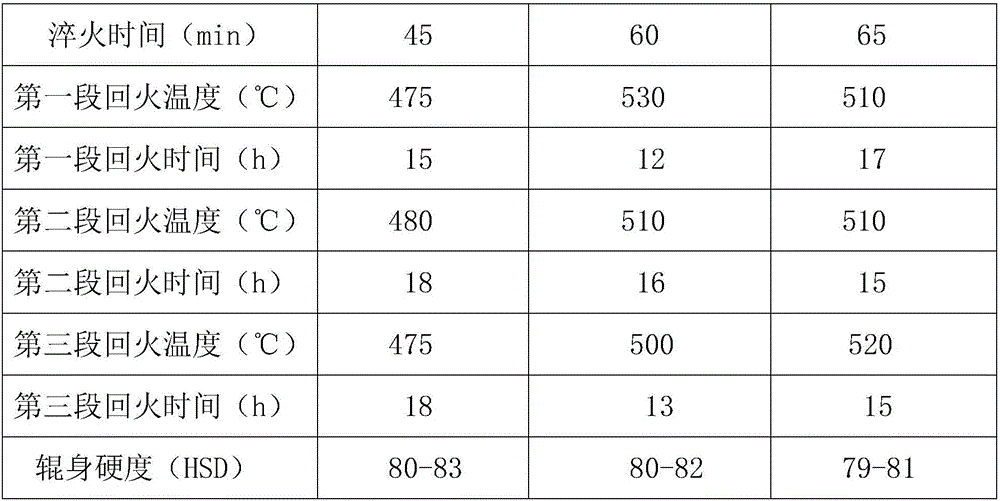

The invention discloses a high-wear-resistance alloy tool steel roll and a manufacturing method thereof, applied to the finish rolling front segment of a hot strip continuous mill and a medium width and thickness plate mill; a working layer is made from, by weight, 1.50-2.00% of C, 0.30-1.00% of Si, 0.50-1.20% of Mn, < / =0.10% of P, < / =0.05% of S, 10.0-15.0% of Cr, 0.50-2.00% of Ni, 0.20-1.50% of Mo, 0.20-2.00% of V, and the balance of Fe and unavoidable impurities; the high-wear-resistance alloy tool steel roll is made by means of centrifugal composite casting technique, quenching thermal treatment process of spray cooling at 1020-1100 DEG C for 40-80 min, and three-stage tempering at 450-550 DEG C for 10-20 h, and is a high-wear-resistance roll with low oxide film growth rate and excellent hot cracking resistance.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

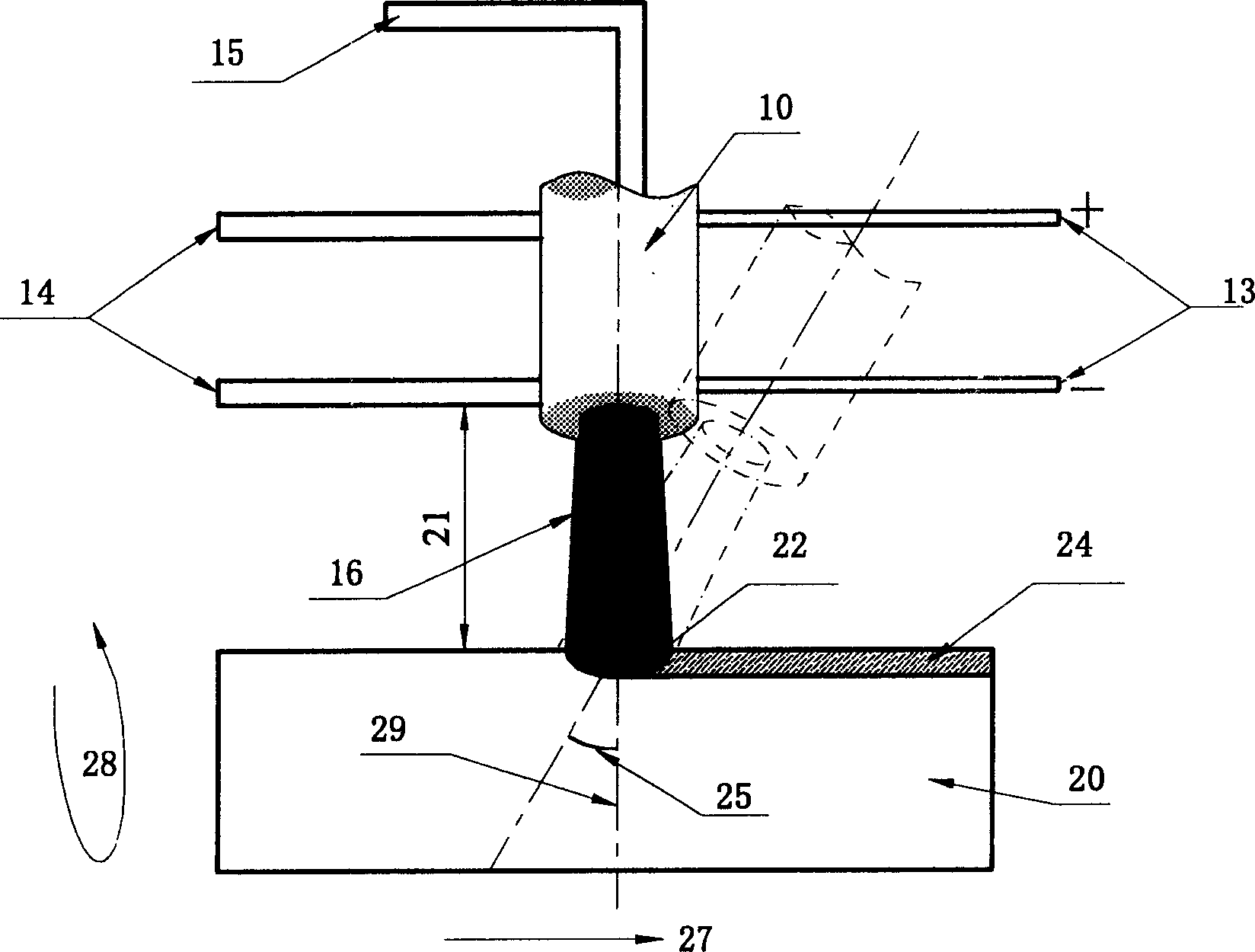

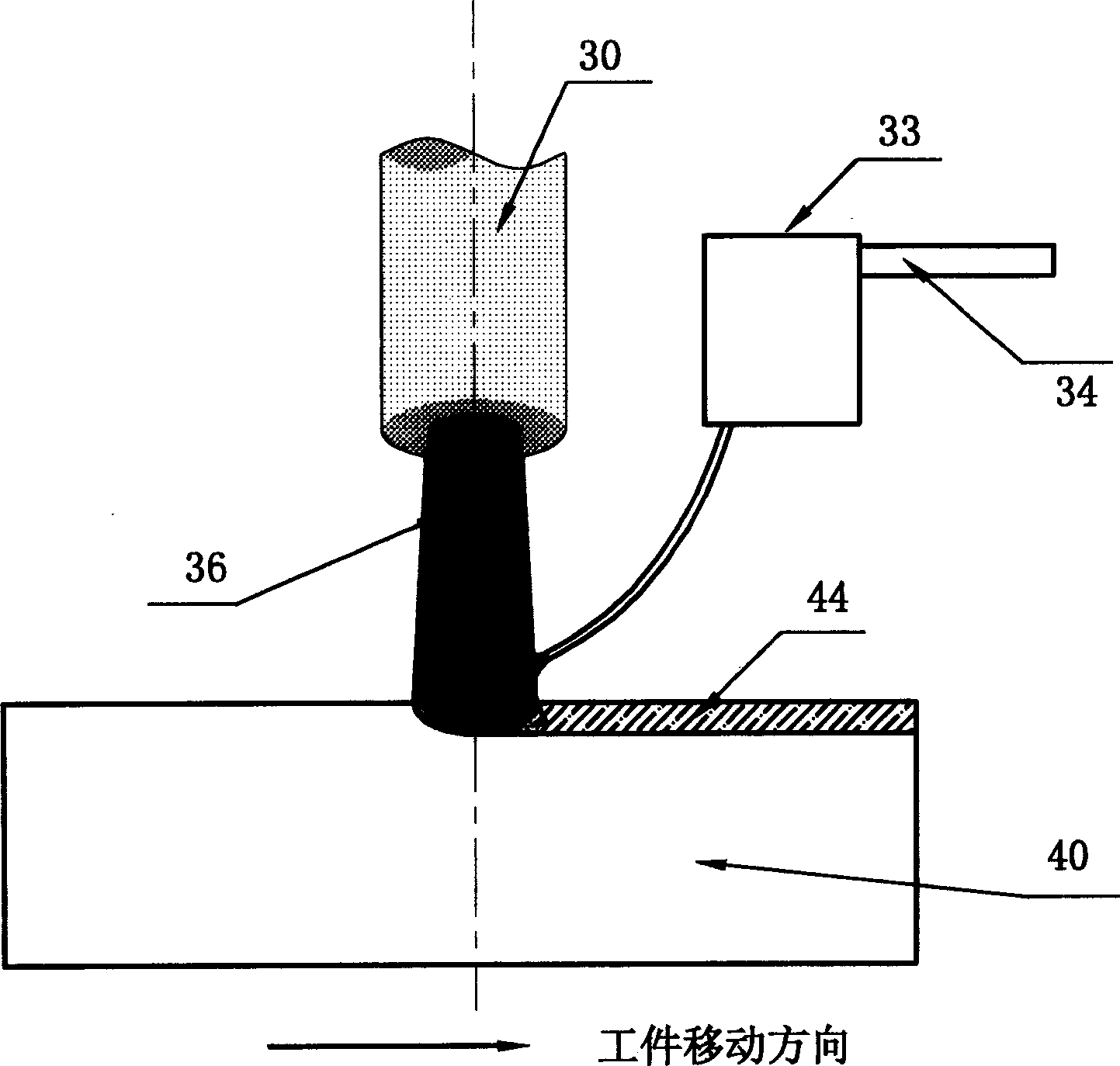

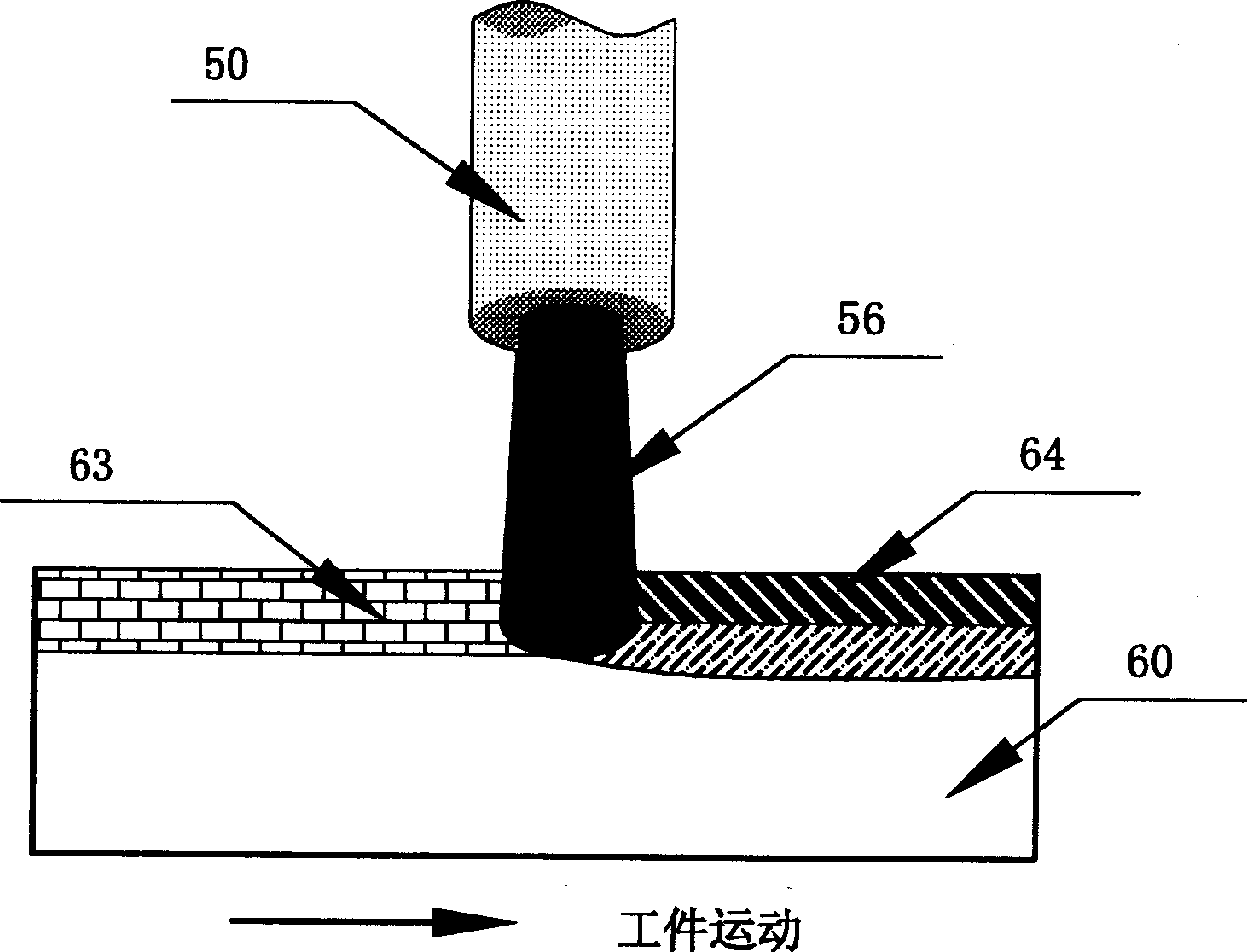

Laminar flow arc plasma jet material surface processing method

InactiveCN1501761AMeet anti-fatigueMeet wear resistanceMolten spray coatingPlasma techniqueJet flowMoving speed

The invention relates to a process for treating the surface of laminar current electrical arc plasm jet flow material, wherein the DC non-transforming type laminar current electrical arc plasma jet flow generator is used as heat source, The generator is connected to the work piece wirelessly, bby changing the laminar flow plasma jet energy, the distance between the generator exit and the work piece, the spacing included angle and relative movement speed between the generator and the work piece, the work piece surface of various types of conducting materials can be treated. The method by the invention has good stability and repeatability.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

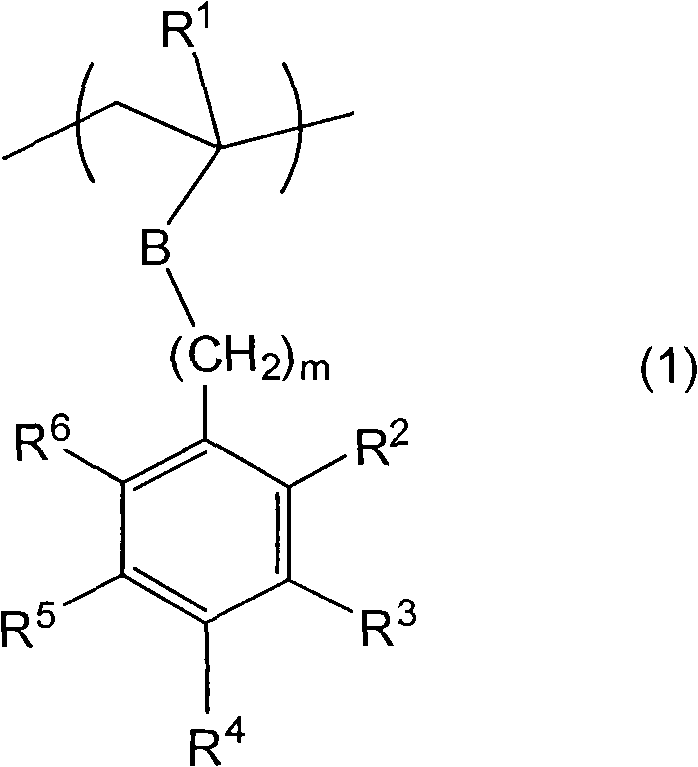

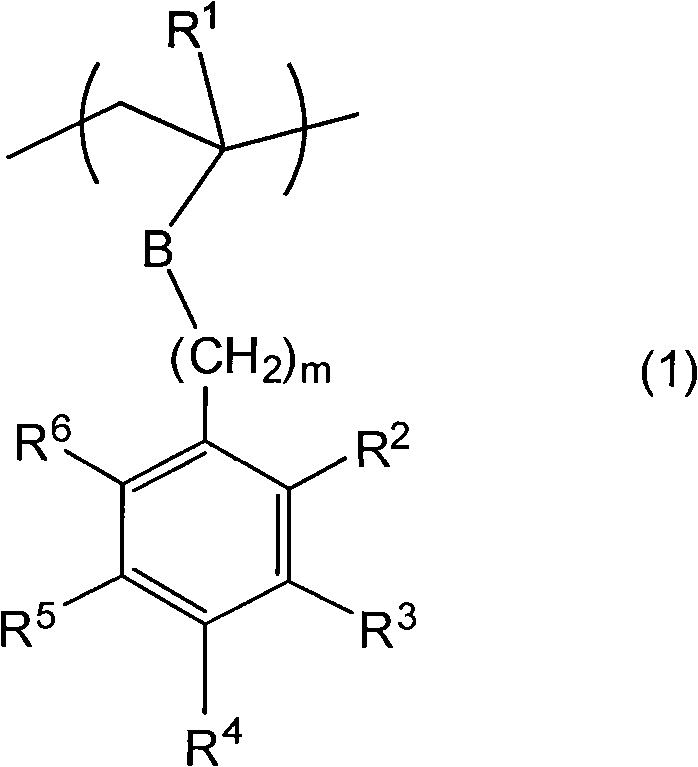

Radiation-sensitive composition, protective film and inter layer insulating film, and method for forming the same

ActiveCN102053493AExcellent adhesionImprove crack resistancePhotosensitive materials for photomechanical apparatusCarbon numberTectorial membrane

The invention relates to a radiation-sensitive composition, a protective film, an interlayer insulating film and a method for forming those. The radiation-sensitive composition is suitable for forming the protective film and the interlayer insulating film which satisfy such generally required properties as transparency, heat-resistant transparency and surface hardness and have high cracking resistance and high adhesion to an ITO transparent conductive film and metal wiring of molybdenum or the like even under severe conditions of high temperature and high humidity. The radiation-sensitive composition comprises [A] a siloxane polymer, [B] a polymer comprising a repeating unit represented by a general formula (1) (wherein R1 is an alkyl group with a hydrogen or carbon number 1-4; R2-R6 are respectively an alkyl group with a hydrogen, hydroxy or carbon number 1- 4; B is a single bond, -Coo-* or -CONH-* ; m is an integer of 0 to 3; at least one of R2-R6 is a hydroxy group, -COO-* or each connection bond of the * in the -CONH-* and carbon connection with (CH2)m, and [C] a radiation-sensitive acid generator or a radiation-sensitive base generator.

Owner:JSR CORPORATIOON

Prepolymer method used for preparing modified nano carbon black water-based color paste

InactiveCN104893429AGood dispersionImprove wear resistanceFibre treatmentPigment pastesWater basedPolyethylene glycol

The invention relates to a prepolymer method used for preparing modified nano carbon black water-based color paste. Carbon black possesses excellent stainability and stability, and is widely applied to the industrial fields such as rubber, paint, and plastic. Particle size of carbon black is small; specific surface area is large; surface function group content is low; particle clustering is easily caused, and is difficult to eliminate; so that further application of carbon black is limited to a great extent. The prepolymer method comprises following steps: (1) a polyurethane prepolymer is synthesized from polyethylene glycol and diisocyanate; (2) a carbon black aqueous dispersion is prepared with a hyperdispersant; (3) the polyurethane prepolymer is subjected to chain extension and dispersion in the carbon black aqueous dispersion so that the surfaces of carbon black particles are coated with polyurethane layers, and the steadily dispersed modified nano carbon black water-based color paste is obtained. The odified nano carbon black water-based color paste can be used for coloring of coating of leather, plastic, and woodenware, and especially can be used for leather coating as a novel black pigment paste; obtained coating layers are high in black brightness, and possesses dry and wet rubbing resistance, wear resistance, excellent flexicity, and high warping strength.

Owner:SICHUAN UNIV

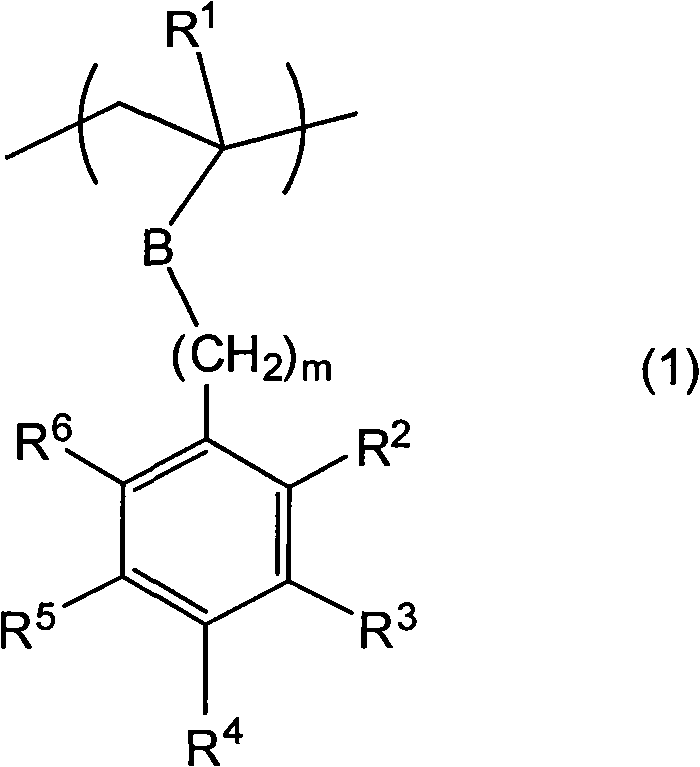

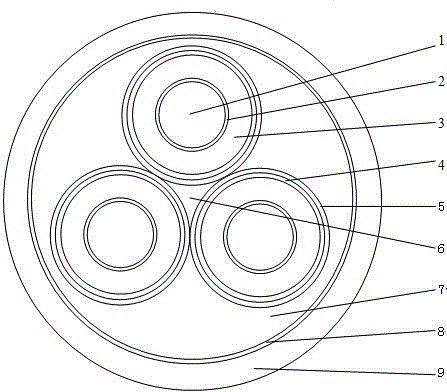

Flexible rubber jacketed cable for shield tunneling machine

ActiveCN104361927AGood electrical performanceGuaranteed service lifePower cables with screens/conductive layersFlexible cablesShield machineVoltage

The invention discloses a flexible rubber jacketed cable for a shield tunneling machine, and belongs to the technical field of wires and cables. The flexible rubber jacketed cable for the shield tunneling machine comprises a cable core, an inner protective jacket extruded outside the cable core, a reinforcing layer knitted on the inner protective jacket and an outer protective jacket extruded outside the reinforcing layer. The cable core is formed by three insulating wire cores and a center reinforcing core in a cabling mode. Each insulating wire core is sequentially formed by a conductor, a conductor shielding layer, an insulating layer, an insulation shielding layer and a weaving layer from inside to outside, wherein each weaving layer is formed by mixing metal wires and fibers. According to the flexible rubber jacketed cable for the shield tunneling machine, the mainly supplied nominal voltage is 18 / 30 kV, and the requirements of the shield tunneling machine for the wires and cables in the using process can be met; the cable has the advantages of being small in bending radius, capable of being moved and twisted frequently, resistant to abrasion and oil, flexible, tensile, resistant to tear, resistant to low temperatures and the like; the service life of the cable is greatly prolonged.

Owner:SICHUAN MINGXING CABLE

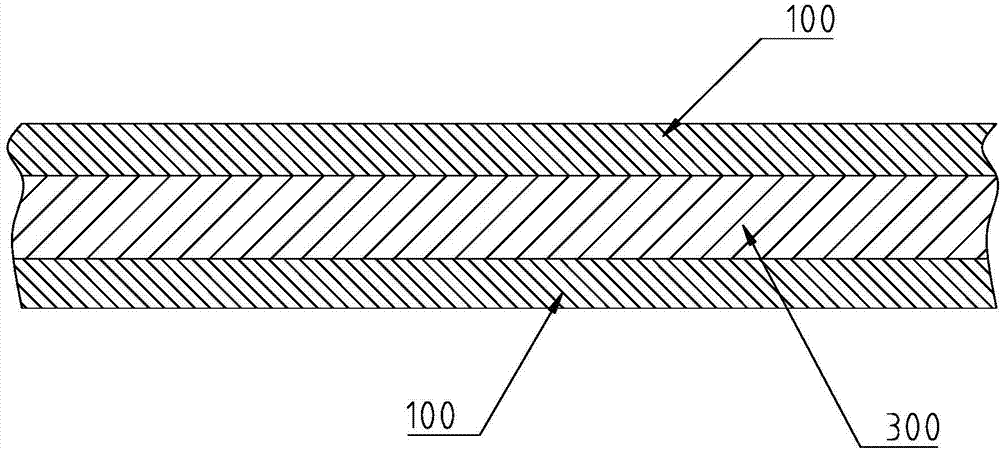

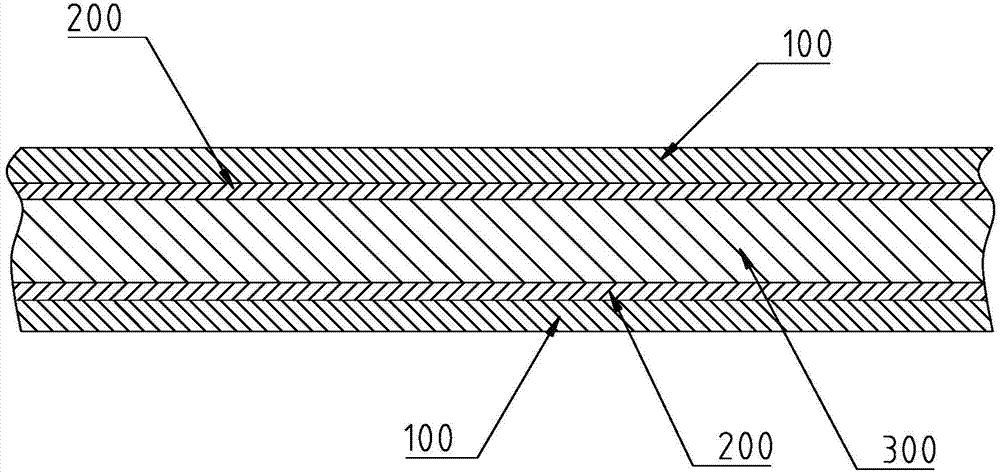

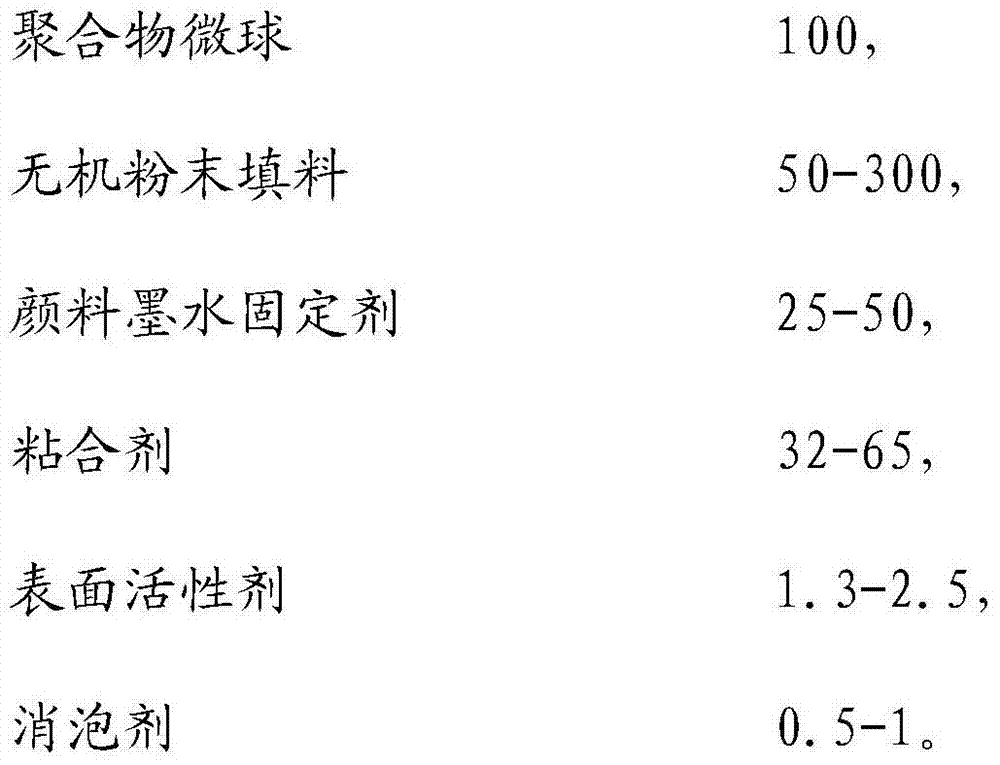

Coated paper suitable for high-speed ink-jet printer and production method thereof

InactiveCN103757989AImprove clarityMeet wear resistanceSurface covering paperNon-fibrous pulp additionEngineeringHigh definition

The invention discloses coated paper suitable for a high-speed ink-jet printer and a production method thereof. The coated paper suitable for a high-speed ink-jet printer comprises a base material, wherein one side or both sides of the base material is / are coated with an ink absorption coating, and the ink absorption coating comprises polymer microspheres, inorganic powder filler and pigment ink fixing agent and adhesive for pigment ink. The production method of coated paper comprises the following steps of preparing coating liquid of the ink absorption coating, wherein the coating liquid comprises polymer microspheres, inorganic powder filler and pigment ink fixing agent and adhesive for pigment ink; coating one side or both sides of the base material with the ink absorption coating, wherein the coating weight of the ink absorption coating is 10-30gsm. The coated paper disclosed by the invention is suitable for being directly printed with high-speed ink-jet printing equipment using pigment type ink, high-definition images and texts can be provided, and the printed product has excellent scraping resistance.

Owner:胡勇

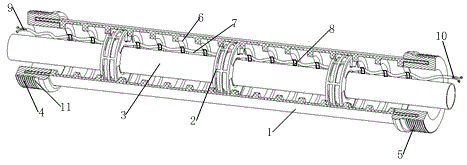

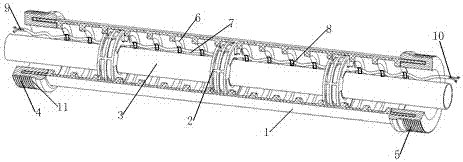

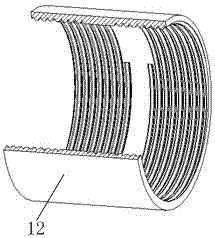

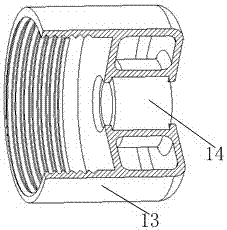

Blockage preventing device for shotcrete pumping pipe

ActiveCN105605366AGuaranteed normal transmissionMeet spray mixing requirementsPipe elementsShotcretePolybutylene

The invention discloses a blockage preventing device for a shotcrete pumping pipe. The blockage preventing device comprises an inner pipe, an outer pipe and self-oscillating rings, wherein the outer pipe is formed by connecting at least two unit pipes by connecting components, and a splicing length is free and flexible; one self-oscillating ring is arranged inside each unit pipe, so that the dominant function of oscillating blockage prevention is realized; the self-oscillating rings are arranged on the outer wall of the inner pipe in a sleeving way and the number of the self-oscillating rings is at least two, so that the oscillating efficiency is guaranteed; a pipe body of the outer pipe is made of polyurethane rubber (PUR), so that various outside contact conditions and oscillating reduction requirements are met; the inner pipe and the connecting components are made of polybutylene (PB), so that concrete is efficiently conveyed; by using all the functions of three parts, the concrete is efficiently conveyed, the problem of pipe blockage in the shooting process is better solved, and the working efficiency of the shotcreting is improved; meanwhile, the occurrence of pipe explosion accidents is avoided, and the safety of working is guaranteed.

Owner:XIAN UNIV OF SCI & TECH

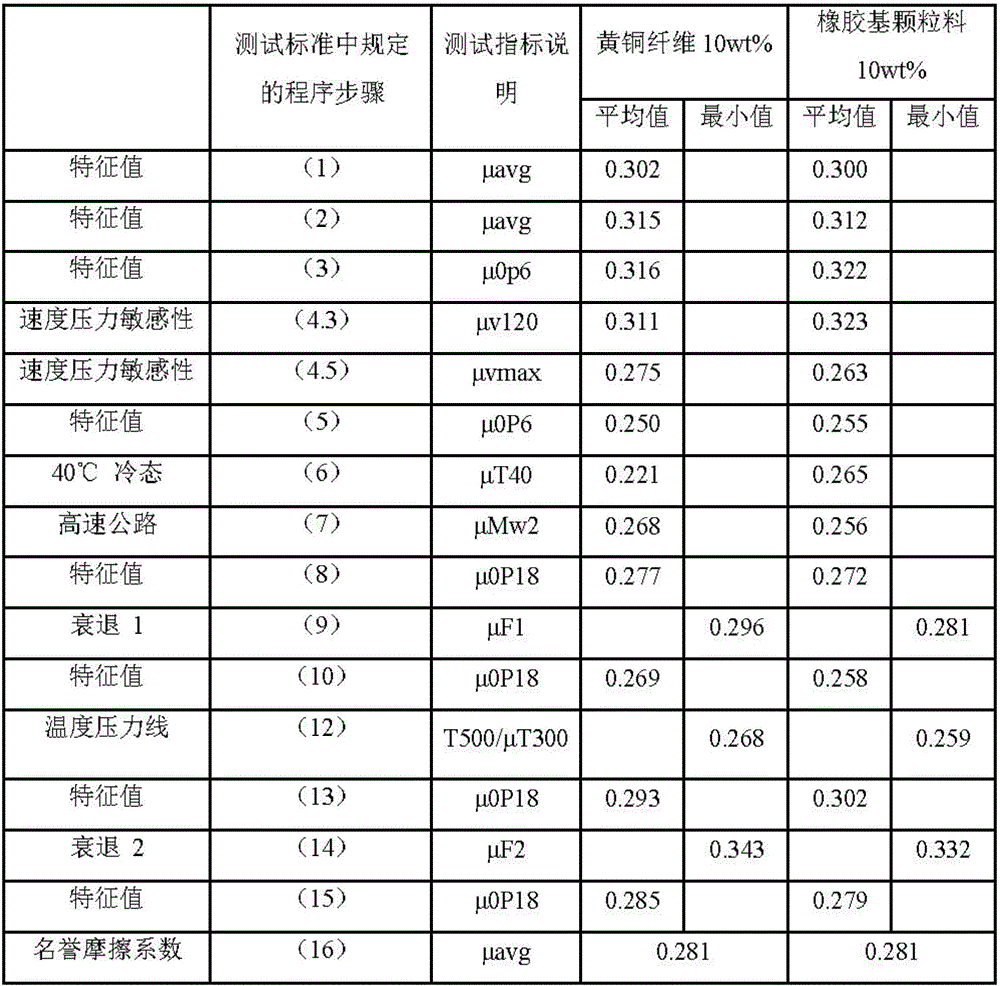

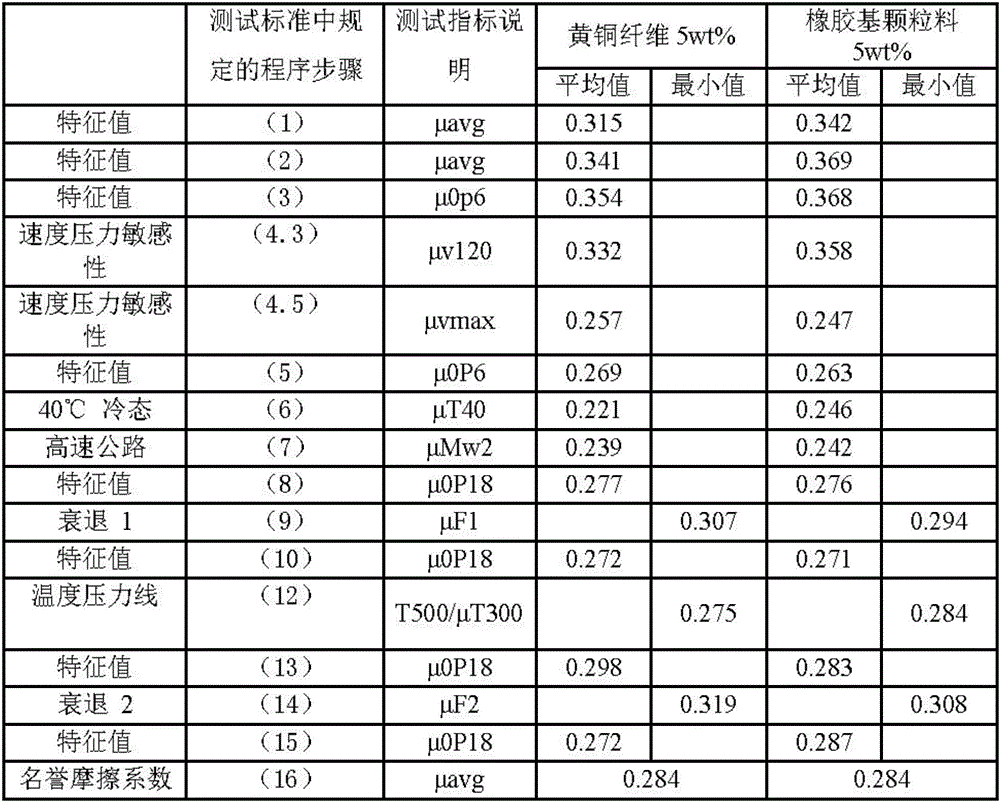

Rubber based granular material and preparation method thereof

ActiveCN106397878ASpeed up heat dissipationAccelerate the lossHeat-exchange elementsFriction liningFiberPolymer science

The invention provides a rubber based granular material and a preparation method thereof, and more specifically relates to the technical field of automobile components. The total mass of raw material components of the rubber based granular material is used as a reference for calculation, and the rubber based granular material comprises the following raw material components in percentages by mass: 7-12% of butyronitrile rubber, 2-5% of styrene butadiene rubber, 3-7% of carbon black, 1-4% of sulphur, 1-3% of a vulcanization accelerator, and 70-85% of a multielement heat-conducting composite powder. The rubber based granular material can replace brass fiber in a friction material in equal proportion, and friction performance and abrasiveness of the prepared friction material are nearly not changed; at the same time, compared with the brass fiber, the noise reduction performance of the rubber based granular material is better, comfort level of a pedal in a braking process is greatly improved, initial performance is excellent when the addition amount is small, and running-in period is shortened; the rubber based granular material has the advantages of cleaning, and environmental protection without pollution.

Owner:SHANDONG GOLD PHOENIX

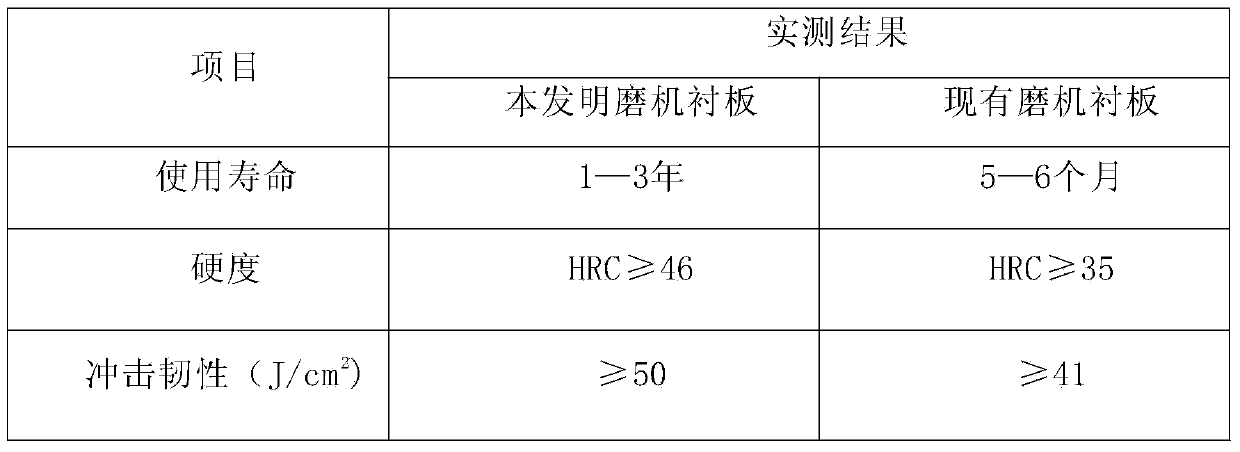

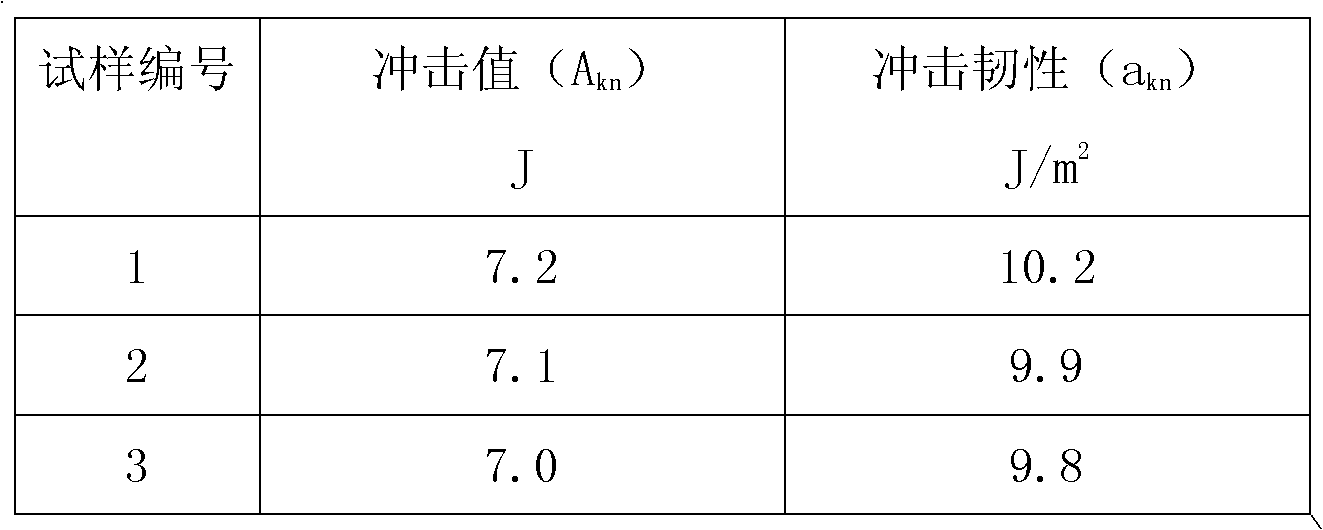

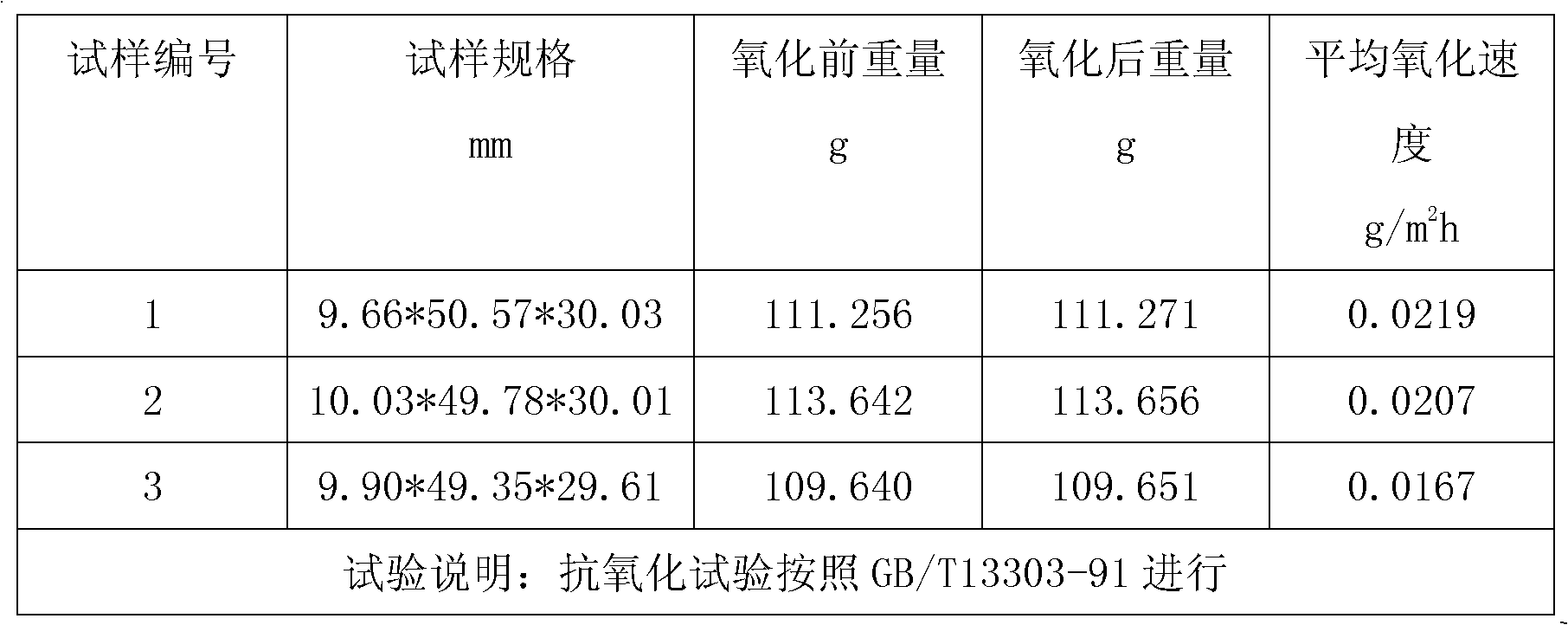

Mine wet mill liner and making method thereof

InactiveCN103993239AMeet wear resistanceCorrosiveProcess efficiency improvementWear resistantMetallic materials

The invention relates to the technical field of wear resistant metal materials, and discloses a mine wet mill liner and a making method thereof. The liner comprises 0.10-0.3wt% of C, 0.2-0.6wt% of Si, 0.3-1wt% of Mn, 7-10wt% of Cr, 0.7-1wt% of Mo, 1.5-2wt% of Ni, 0.1-0.18wt% of Ti, 0.005-0.03wt% of S, 0.005-0.03wt% of P, 0.01-0.025wt% of RE, and the balance Fe. The mine wet mill liner has the advantages of very long service life, improved wear resistance, substantially improved impact toughness, meeting of the impact resistance of a mine wet mill liner, very high strength and hardness, reduction of the liner replacement frequency of a factory, labor intensity reduction, easily available raw materials, simple preparation method and effective energy saving.

Owner:安徽新马铸造科技有限公司

Laser cladding repair method for breast roll

InactiveCN109722662AAchieving wear resistanceMeet wear resistanceMetallic material coating processesOptoelectronicsHigh pressure water

The invention discloses a laser cladding repair method for a breast roll. The laser cladding repair method comprises the following steps of removing a fatigue layer, performing overlaying to restore the size, performing annealing, performing outer diameter turning, performing low carbon overlaying, performing preheating, performing laser cladding, performing slow cooling and performing argon arc welding repair. For re-repairing, it is presented that re-repairing is performed when a laser cladding layer is worn away by 0.8-1.2 mm; and according to the laser cladding repair method, the repair ofthe breast roll is realized, meanwhile, the requirements for impact resistance, wear resistance, oxidation corrosion resistance, high temperature resistance and high-pressure water erosion resistanceof the breast roll are met, and the service life reaches 2 years or more.

Owner:鞍山大陆激光技术有限公司

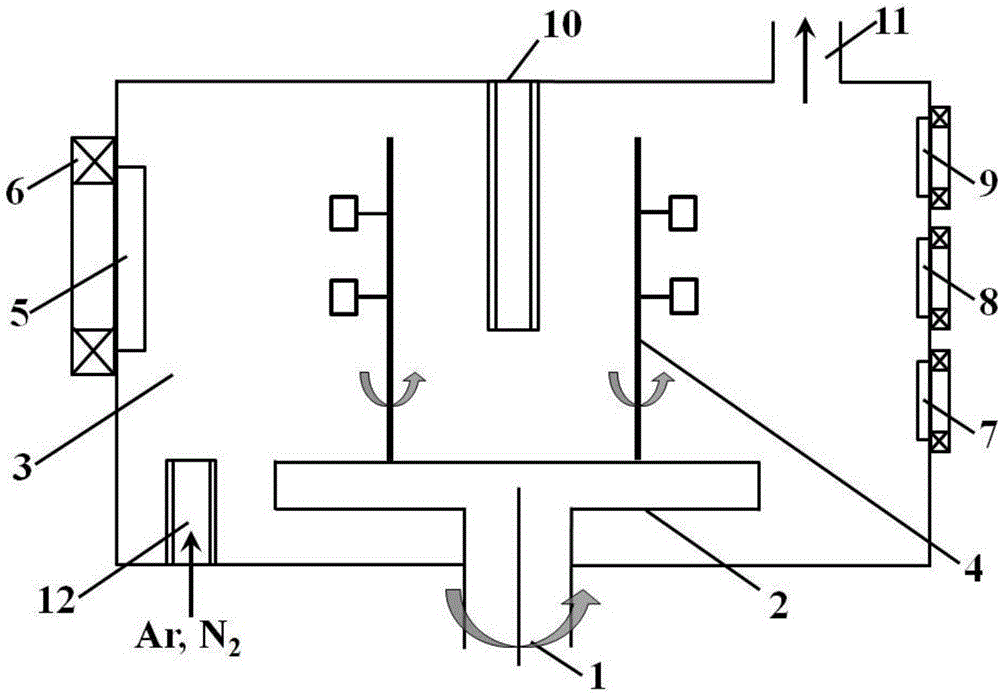

Method for preparing high-temperature alloy cutting tool coating in ion source enhanced arc ion plating mode

InactiveCN106835031ASolve cleaningSolve etchingVacuum evaporation coatingSputtering coatingOxidation resistantSuperalloy

The invention discloses a method for preparing a high-temperature alloy cutting tool coating in an ion source enhanced arc ion plating mode. The method comprises the steps that a high-temperature alloy cutting tool is pretreated and then placed to a rotating stand rod in a vacuum chamber of ion source enhanced arc ion plating equipment, a rectangular arc Ti target serves as a bottom Ti source, and the sputtering rate of the arc Ti target is controlled by adjusting the current of the arc Ti target; a round arc CrAl target serves as a Cr and Al element source for preparing aCrAlN coating, and the sputtering rate of the arc CrAl target is controlled by adjusting the current of the arc CrAl target; high-purity Al and high-purity N2 enter the vacuum chamber through the ion sources, wherein the Ar serves as the ionizing gas, and an effective glow discharging process is guaranteed; and the N2 serves as the reaction gas and is ionized to be combined with Cr and Al elements, and the CrAlN coating is formed on the surface of the high-temperature alloy cutting tool in a deposition mode. According to the prepared CrAlN coating, the anti-oxidization temperature of the coating is 1000 DEG C, the microhardness is Hv3500, and requirements of the high-temperature alloy cutting tool for the abrasion resistance, the thermal fatigue resistance and the anti-oxidization performance can be well met.

Owner:XI AN JIAOTONG UNIV

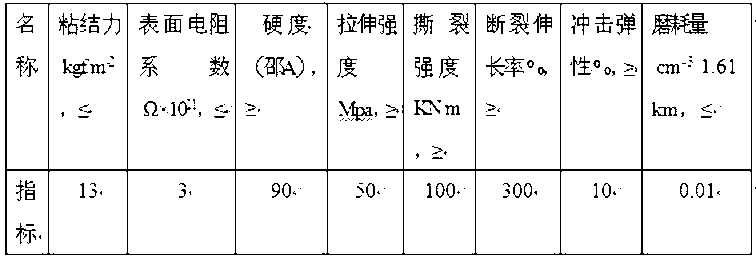

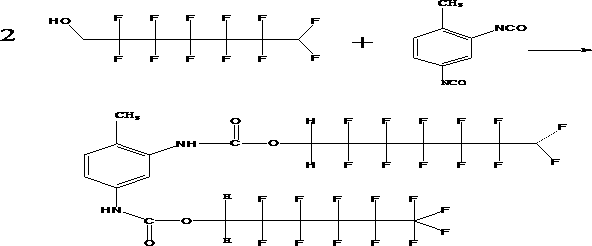

Making method of anti-sticking polyurethane elastomer lining plate

A making method of an anti-sticking polyurethane elastomer lining plate comprises the following steps: putting polyester polyol in a sand mill, adding molybdenum disulfide micropowder and colloidal graphite micropowder, dispersing, placing the obtained mixture in a reaction kettle, heating, carrying out vacuum pumping stirring dehydration, cooling, adding toluene diisocyanate and methyl diphenylene diisocyanate, heating, carrying out a polymerization reaction, and defoaming to prepare a polyurethane prepolymer; adding 1H,1H,7H-dodecafluoro-1-heptanol, a TDI-100 compound, triethyl silane and polytrifluoropropylmethylsiloxane, stirring, and carrying out heating reacting and defoaming to obtain a polyurethane prepolymer mixture containing fluorine and silicon; and heating 3,3'-dichloro-4,4'-diaminodibenzyl methane for melting, mixing with the polyurethane prepolymer mixture containing fluorine and silicon, carrying out cast molding by a casting machine, and carrying out release vulcanizing to make the anti-sticking polyurethane elastomer lining plate. The lining plate has the advantages of seismic resistance, low noise, sticking resistance, wear resistance and the like, and can satisfy the requirements of the lining plate in the material transportation process of all industries.

Owner:太原英可奥笔墨科技有限公司

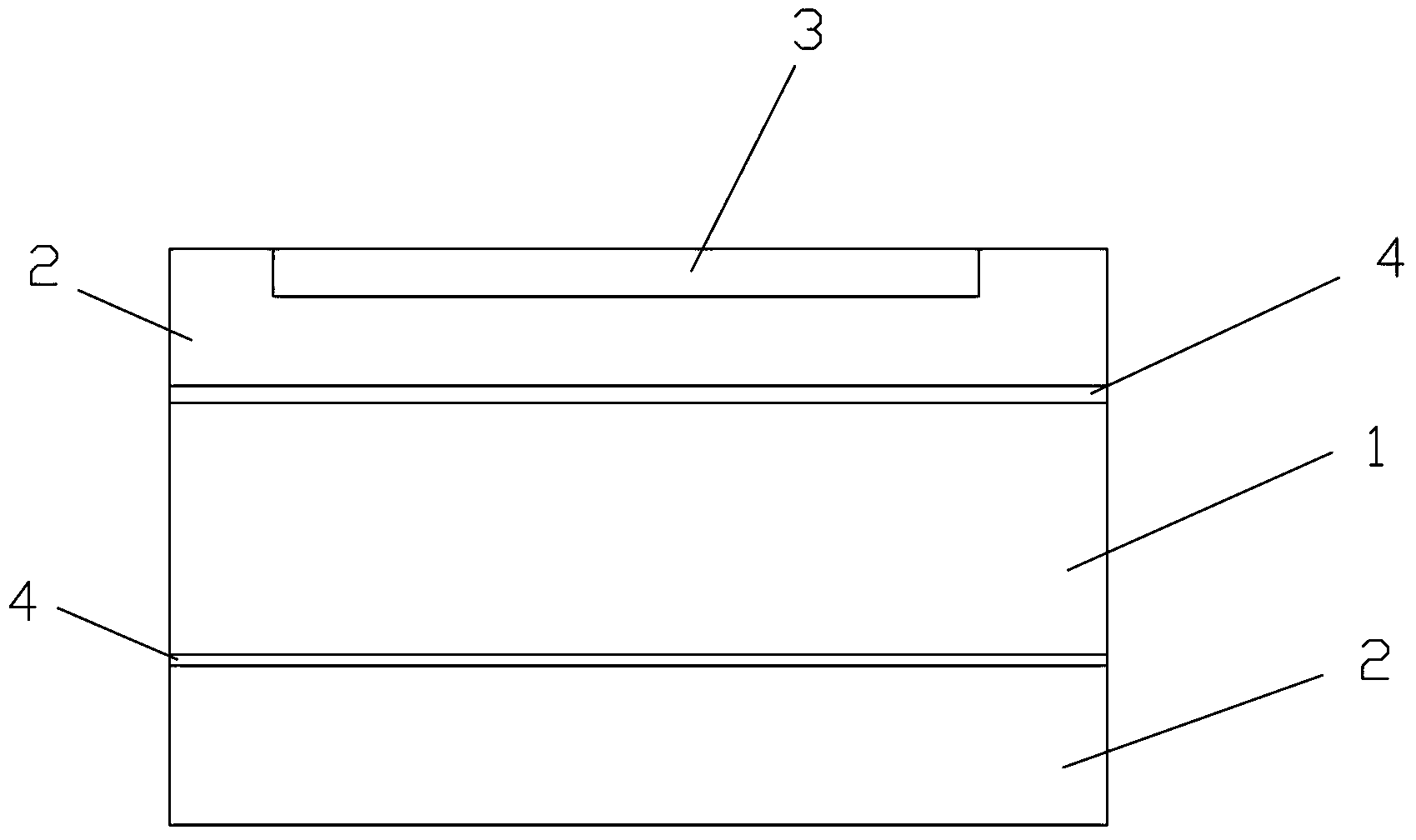

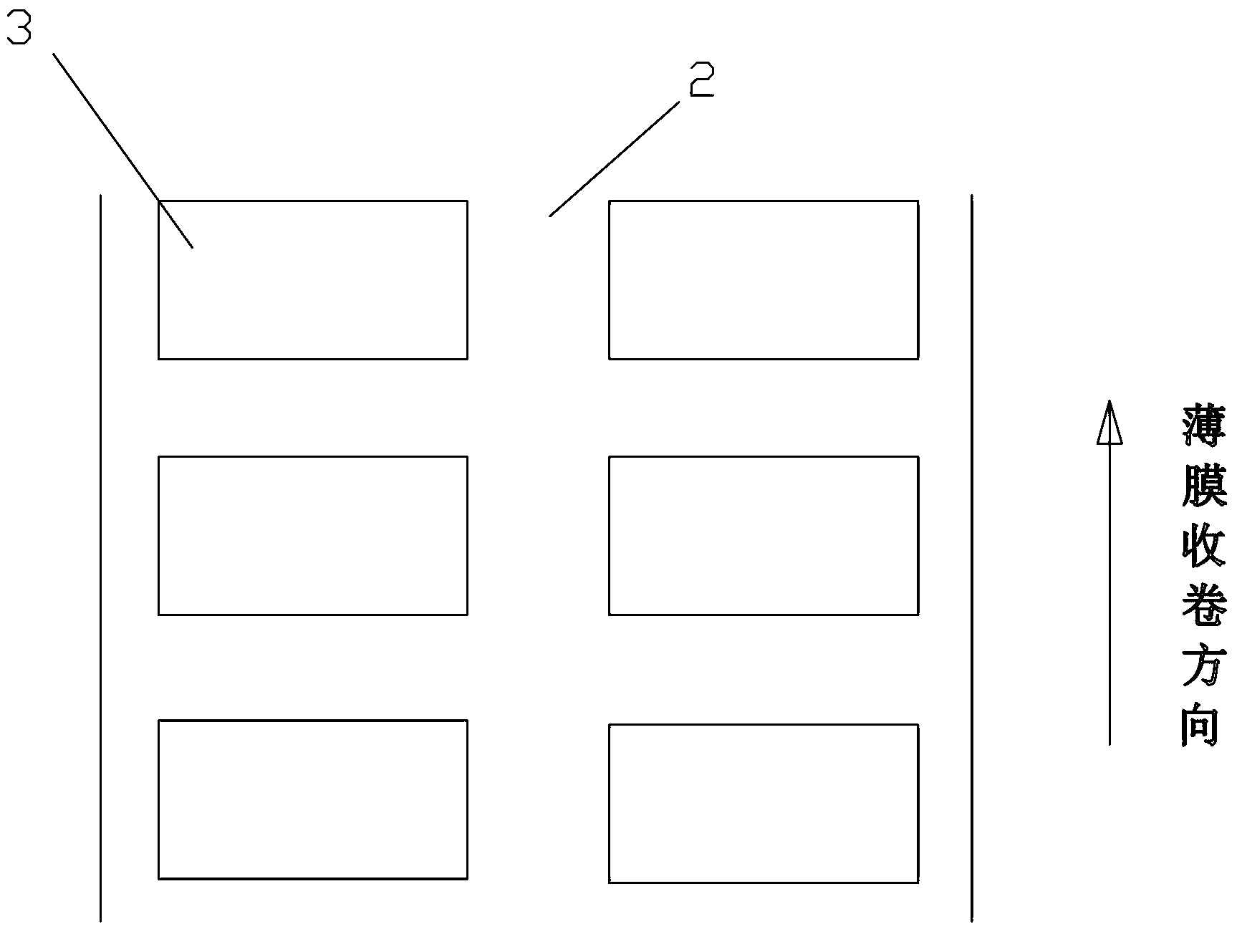

Wear-resisting cigarette packaging thin film and production method thereof

ActiveCN103252960AGood heat sealingGuaranteed bondingSynthetic resin layered productsHardnessEngineering

The invention utilizes a coating and printing method to respectively print a polyacrylic ester layer and a UV (Ultraviolet) curing coating on different positions of a cigarette packaging thin film aiming at the disadvantages of a three-layer structure of an existing cigarette film that the crystallization degree of a random PP (Propene Polymer) heat sealing layer is low, the hardness is small and the existing cigarette film is easy to wear. A heat sealing layer of an existing three-layer co-extruded cigarette film is copolymerized PP and is obtained by a method comprising the steps of extruding by a screw rod, casting a piece, stretching and carrying out heat setting; the method disclosed by the invention adopts a polyacrylic ester solution to coat on a BOPP (Biaxially-oriented Polypropylene) heat shrinkage thin film layer and then the coating is dried to obtain the heat sealing layer; and the BOPP heat shrinkage thin film layer and the polyacrylic ester layer are spliced by adopting transparent glue, so as to guarantee the binding force between the polyacrylic ester layer and the BOPP heat shrinkage thin film layer.

Owner:佛山市百事和运通科技有限公司

Guide roller and preparation technique thereof

The invention discloses a guide roller and a preparation technique thereof. The guide roller comprises the raw material components by weight percent: 3.1-3.45% of C, 0.1-0.9% of Si, 0.1-0.4% of Mn, 0.01-0.03% of P, 0.01-0.03% of S, 24-25% of Cr, 0.4-0.6% of Mo, 0.9-1% of V, 2-3% of W, 0.05-0.1% of rare earth and the balance of Fe. The preparation technique of the guide roller comprises the steps of: firstly, making the guide roller by precision casting, treating by the guide roller by annealing, rough machining, quenching, tempering and finish machining, and obtaining the finished product. The prepared guide roller is low in cost, long in service life and good in high-temperature oxidation resistance, and has the advantages of high-temperature strength, shock resistance, high-temperature toughness and high-temperature frictional wear resistance.

Owner:HEFEI ORIENT METALLURGICAL EQUIP

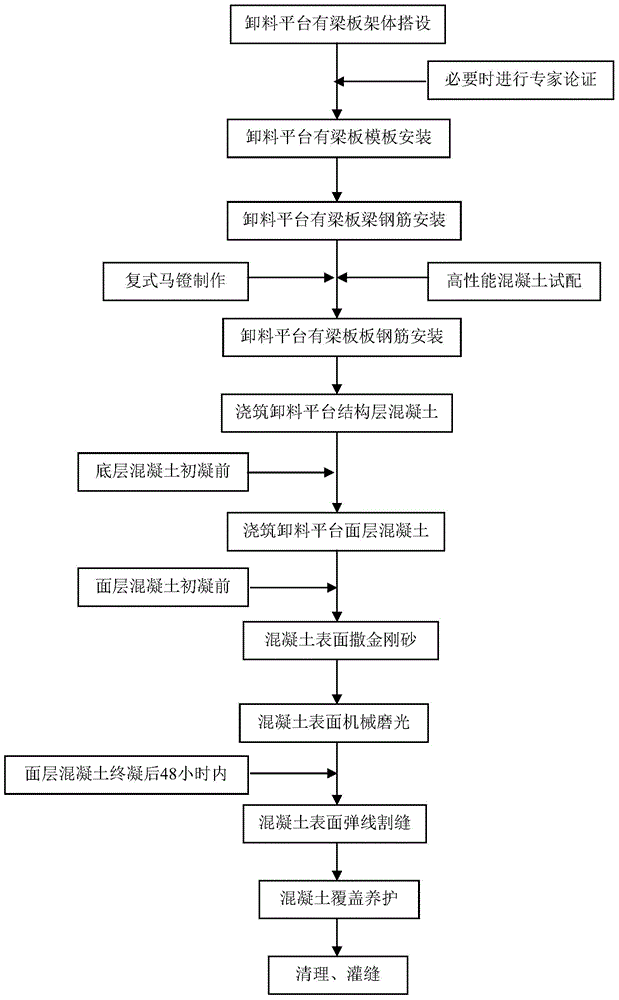

Composite surface construction technology for garbage discharging platform of garbage incineration power plant

ActiveCN104929365ASolve the performance of compression resistance and bending resistanceImprove wear resistanceBuilding material handlingPower stationArchitectural engineering

The invention particularly relates to a composite surface construction technology for a garbage discharging platform of a garbage incineration power plant. The composite surface construction technology for the garbage discharging platform of the garbage incineration power plant is characterized by comprising the steps that 1, concrete is prepared; 2, a formwork support and steel bars are erected; 3, composite horse stools are prepared and welded; 4, double-deck double-way steel bars are arranged; 5, inspection is conducted before the concrete is poured; 6, concrete pouring is conducted; 7, carborundum is sprinkled when strengthened surfaces are poured; 8, concrete surface elevation is controlled, and screeding and leveling are conducted; 9, concrete curing is conducted. Compared with a construction technology of the prior art, the composite surface construction technology for the garbage discharging platform of the garbage incineration power plant has the advantages that the construction technology is detailed, the innovativeness is strong, the scientificity is strong and the operability is strong; integrality construction is achieved, the construction technology is not compressing and stacking of the construction steps, the function of a whole structure layer is changed, and the comprehensive effects of being resistant to pressure, abrasion, corrosion, seepage, fracture and the like are achieved; construction is simultaneously conducted on the structure layer and the surface effectively, and the construction period is shortened; 4, the safety and the reliability are achieved, and the economic benefits are significant.

Owner:SHANDONG ZIJIAN GRP

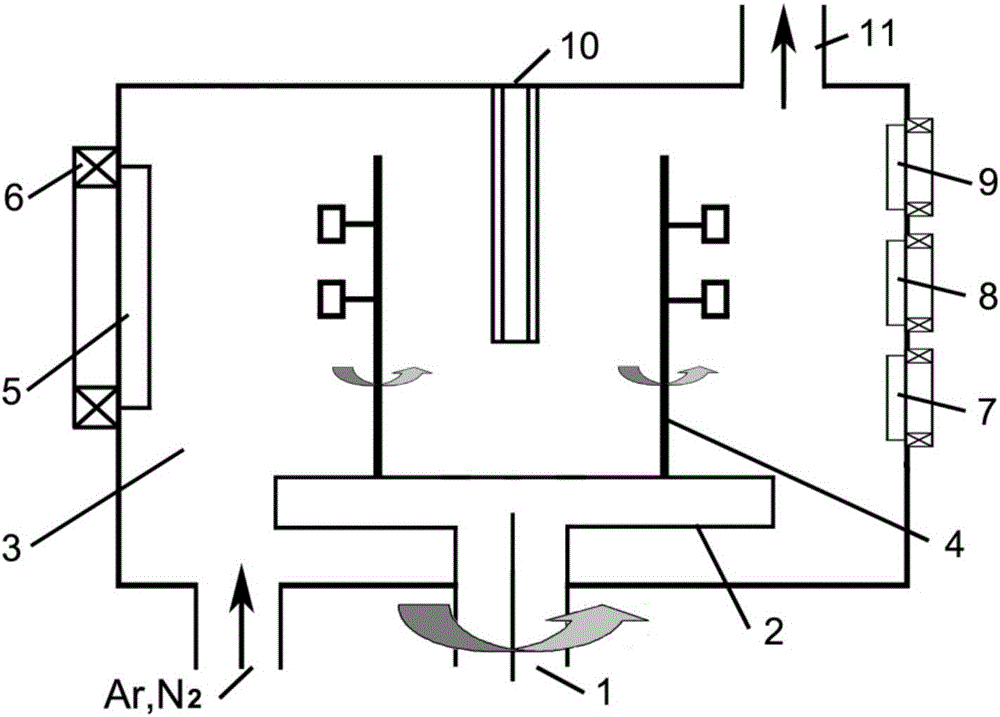

Preparation method of hot die-casting die surface coating

ActiveCN106399952AIncrease working temperatureMeet wear resistanceVacuum evaporation coatingSputtering coatingAbrasive blastingOxidation resistant

The invention relates to a preparation method of a hot die-casting die surface coating. The preparation method of the hot die-casting die surface coating comprises the following steps: blasting sand on the surface of a hot die-casting die, washing the surface of the hot die-casting die, then putting the hot die-casting die into an electric arc ion plating device, taking a rectangular Ti target as a Ti source of a bottom layer, mounting the rectangular Ti target on the left inner wall of a furnace body, controlling the evaporation rate of the rectangular Ti target through current of a rectangular Ti target electric arc power supply and preparing a Ti bottom layer on the surface of the hot die-casting die; then taking a circular CrAl target as Cr and Al element sources for preparing a CrAlN coating, wherein the atomic component ratio of the Cr to Al is expressed as Cr / Al and is 70 to 30, and controlling the evaporation rate of the CrAl target through current of a circular CrAl target electric arc power supply; taking high-purity N2 as reaction gas, ionizing the N2 and combining N2 with Cr and Al elements, and depositing N2 and the Cr and Al elements on the Ti bottom layer to form the CrAlN coating. The oxidation resistance temperature of the prepared CrAlN coating reaches 1100 DEG C; the hardness of the CrAlN coating reaches Hv3000; the requirements of abrasion resistance, fatigue resistance and oxidation resistance of the hot die-casting die can be well met; the CrAlN coating is suitable for strengthening the surface of the hot die-casting die under severe service conditions such as high temperature, high speed and heavy load and the like.

Owner:XIAN HAOYUAN COATING TECH

Novel aluminum alloy material and production process thereof

The invention relates to the technical field of aluminum alloy production, in particular to a novel aluminum alloy material and a production process thereof. The novel aluminum alloy material comprises, by mass percentage, 0.05-0.22 wt% of nickel, 0.8-1.6 wt% of chromium, 0.024-0.032 wt% of manganese, 0.78-1.5 wt% of magnesium, 0.66-1.65 wt% of silicon, 0.45-1.2 wt% of iron, 3.5-5.8 wt% of copper, 4.8-6.5 wt% of zinc, and the balance aluminum and other inevitable impurities. The mechanical property and mechanics property of the novel aluminum alloy material are excellent, and the surface of an aluminum alloy profile can be effectively protected against scratches; and in addition, the process is simple and reasonable, and the production efficiency is high.

Owner:ANHUI HENGXING DECORATION ENG CO LTD

Preparation method of aluminum-based composite material applied to light brake disc

The invention discloses a preparation method of an aluminum-based composite material applied to a light brake disc. The preparation method comprises the following steps: preparing Al2O3 foamed ceramic by adopting an organic foam dipping method, subsequently adding SiC particles into molten aluminum alloy and uniformly stirring to obtain a SiC particle reinforced aluminum-based composite material prefabricated body, and then allowing the molten prefabricated body to permeate into pores of the Al2O3 foamed ceramic by adopting a high-temperature pressure casting process to obtain an Al2O3 foamed ceramic reinforced aluminum-based composite material containing SiC particles. The surface of the brake disc is prepared from the Al2O3 foamed ceramic reinforced aluminum-based composite material containing the SiC particles. The aluminum-based composite material has unique wear resistance and high-temperature resistance as well as light weight and can preferably meet the requirements on the safety and wear resistance of the brake disc than a cast iron material.

Owner:SHANGHAI UNIV

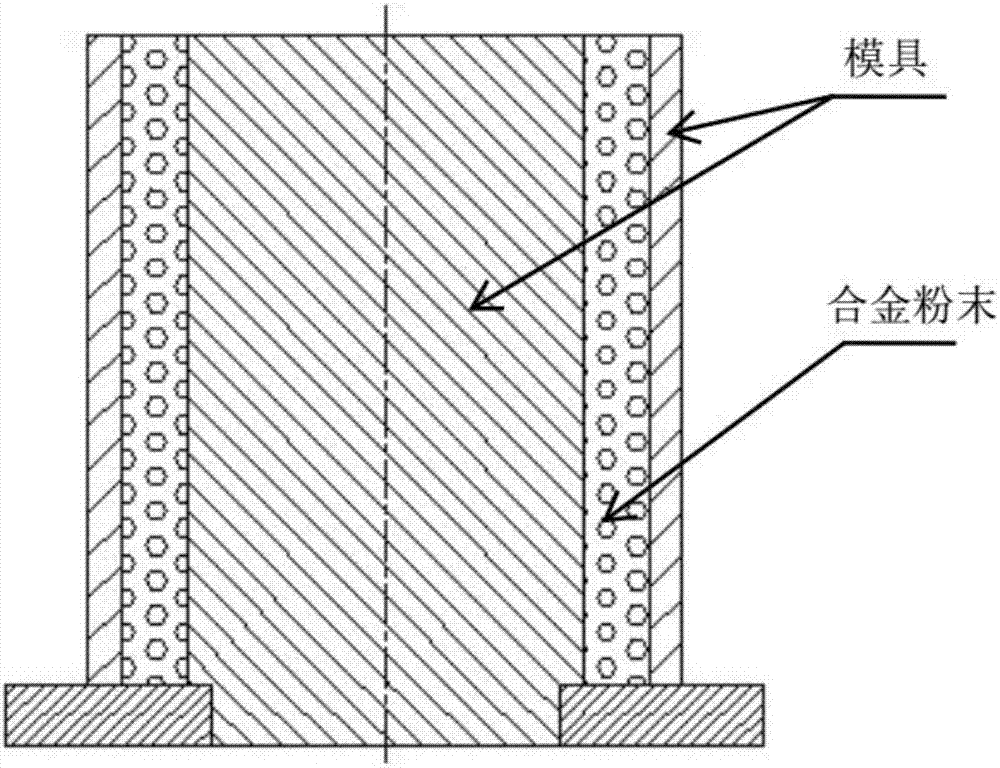

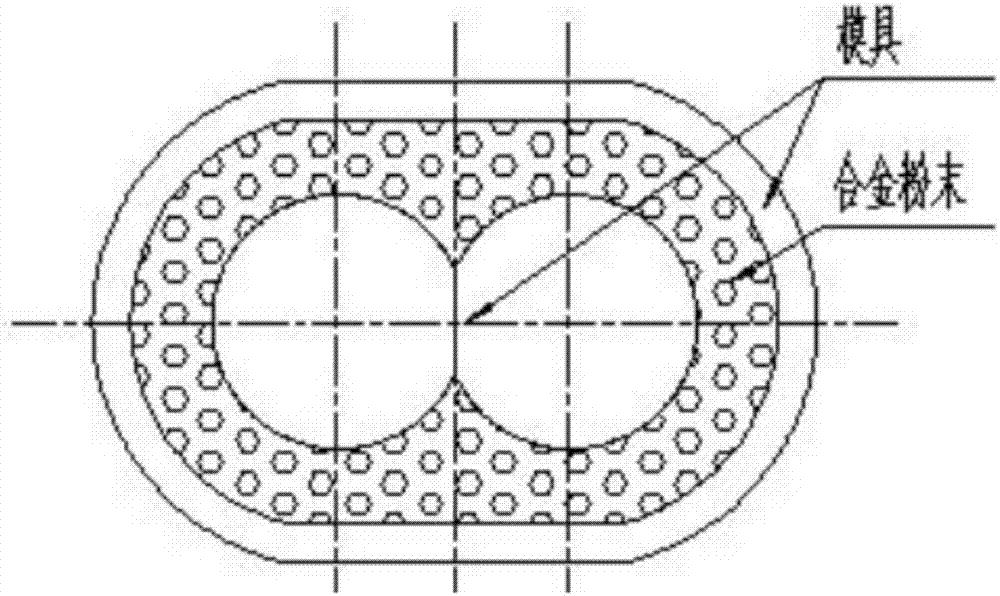

Iron-base alloy double-screw integral alloy lining and preparing method thereof

The invention discloses an iron-base alloy double-screw integral alloy lining and a preparing method thereof. The iron-base alloy double-screw integral alloy lining is formed through integral sintering of cobalt-base alloy powder. The nickel-base alloy powder comprises, by weight percent, 1.50%-3.00% of B, 0.80%-1.60% of C, 6.00%-12.00% of Cr, 8.00%-16.00% of Ni, 2.00%-3.50% of Si, 0.00%-3.00% of W and the balance Fe. The unique machining technology process is adopted in the method, the traditional technology manner of the lining and machine barrel combination is innovated, the hardness of a sintered iron-base alloy lining is HRC58-65, the abrasion resisting performance is 4-7 times of the abrasion resisting performance of 6542 materials, the service life of the lining is effectively prolonged, the production cost is reduced, and the active demand of the market on constant product quality increasing is met.

Owner:苏州艾盾合金材料有限公司

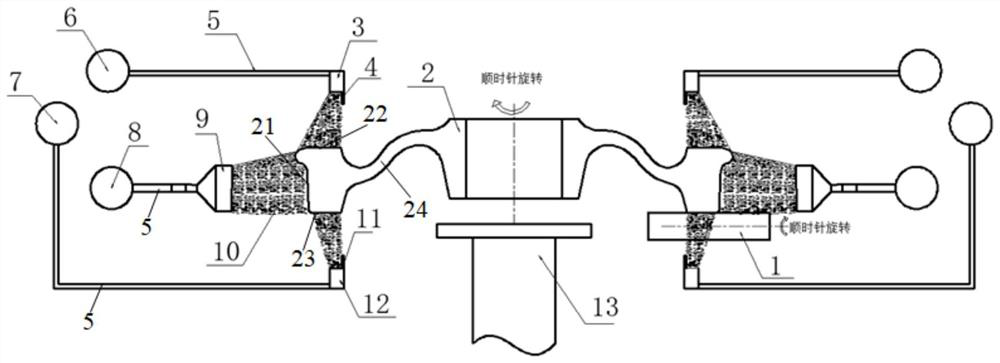

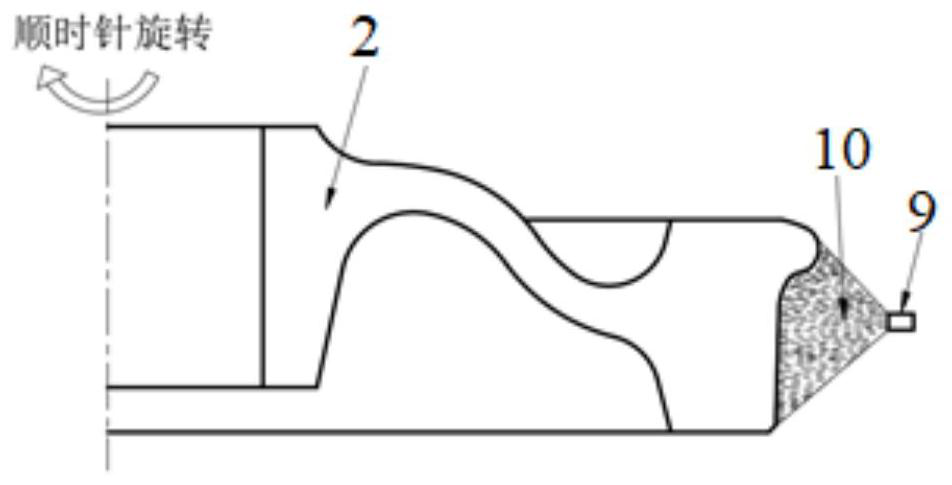

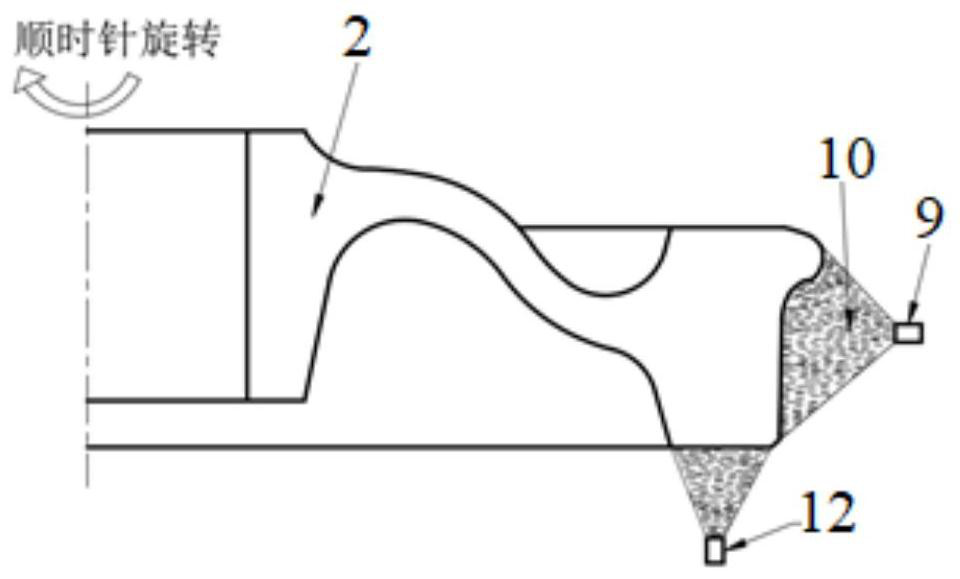

Heat treatment process for wheel

ActiveCN113046540AHigh hardnessImprove toughnessFurnace typesHeat treatment process controlTemperingPearlite

The invention discloses a heat treatment process for a heavy-load wheel. The heat treatment process comprises the steps of: a, heating a rolled wheel; b, quenching the wheel; and c, tempering and cooling the wheel. In the heat treatment process for the heavy-load wheel, a quench cooling device used for quench cooling of the wheel is included, the quench cooling device comprises a carrier roller platform for supporting the wheel, nozzles for carrying out quench cooling on a wheel tread and a wheel rim surface, and a cooling mechanism for quench cooling of the nozzles; the wheel is placed on the carrier roller platform; the nozzles are evenly distributed in the circumferential direction of the carrier roller platform and connected with the cooling mechanism; carrier rollers rotate to drive the wheel to rotate; and quench cooling liquid is evenly sprayed on the wheel tread and the wheel rim surface. According to the quench cooling mode and the heat treatment process for the wheel, on the premise that the microstructure of conventional high-carbon steel AAR-C is still kept to be fine pearlite and a small amount of ferrite, the wheel has high hardness, high toughness and high plasticity at the same time, and the wear resistance and safety of the heavy-load wheel with the axle load of 40 tons are met.

Owner:MAANSHAN MAGANG JINXI RAIL TRANSPORT EQUIP

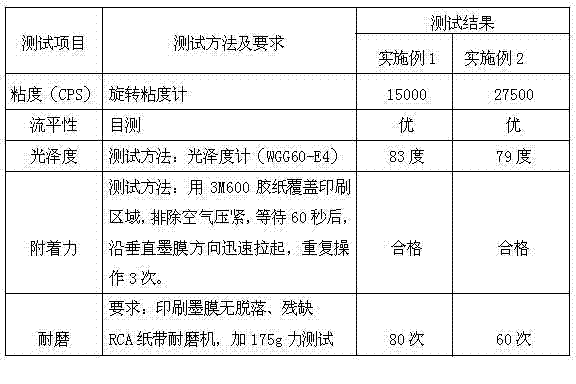

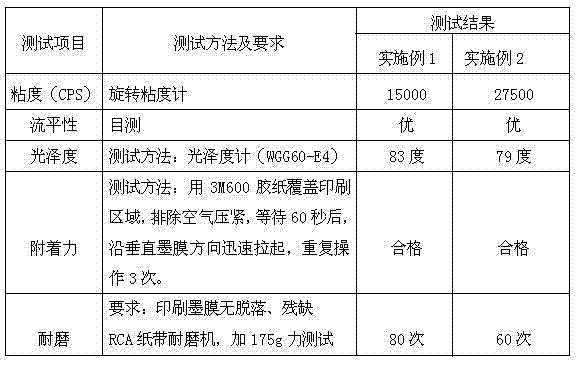

Curing-agent-free treatment-free silk-screen printing ink for thermoplastic polyurethane material

The invention discloses curing-agent-free treatment-free silk-screen printing ink for a thermoplastic polyurethane (TPU) material. The ink comprises the following components in percentage by weight: 40-50% of PU resin, 30-45% of ketone solvent, 20-25% of ester solvent and 1-2 parts of additive. The ink disclosed by the invention is environmentally-friendly silk-screen printing ink free of surfacetreatment and a curing agent, has good printing property and strong adhesion force on the printed material, and can reach the functional requirements of wear resistance, striking resistance, impact resistance and the like.

Owner:深圳市美丽华科技股份有限公司

High-strength impact-resistance type steel used for shelf beam and welding technology thereof

InactiveCN104762558ALow wear resistanceGuaranteed flexibilitySuperimposed coating processElectroplatingImpurity

The invention discloses a high-strength impact-resistance type steel used for shelf beam, which comprises the following chemical components by weight percentage: 0.13-0.28% of C, 0.20-0.30% of Si, 0.20-0.46% of Mn, 0.85-0.95% of Cr, 0.28-0.32% of Ti, 0.16-0.22% of Mo, 0.24-0.36% of Nb, 0.05-0.07% of Cu, 0.18-0.36% of V, 0.59-0.79% of Al, 0.25-0.32% of rare earth trace element and the balance of Fe and impurity; the rare earth trace element comprises the following chemical components by mass percentage: 2-4% of Nd, 4-8% of Ce, 3-5% of Er, 2-6% of Pr, 1-4% of Pm, 0-5% of Dy, and the balance of La; the total content of impurity is less than or equal to 0.2, wherein, P is less than or equal to 0.005%, S is less than or equal to 0.007%, H is less than or equal to 0.004%, N is less than or equal to 0.006%, and O is less than or equal to 45ppm. The steel processing technology comprises the following steps: feeding, electroplating, drawing, annealing, insulating, pickling, drying and warehousing. The invention also designs a processing technology of the high-strength impact-resistance type steel used for shelf beam. The high-strength impact-resistance type steel used for shelf beam can obviously increase the wear-resistant compact-resistant capability of the steel, and has the advantages of simple operation technology, energy saving and environmental protection.

Owner:SUZHOU KESHENG STORAGE & LOGISTICS EQUIP

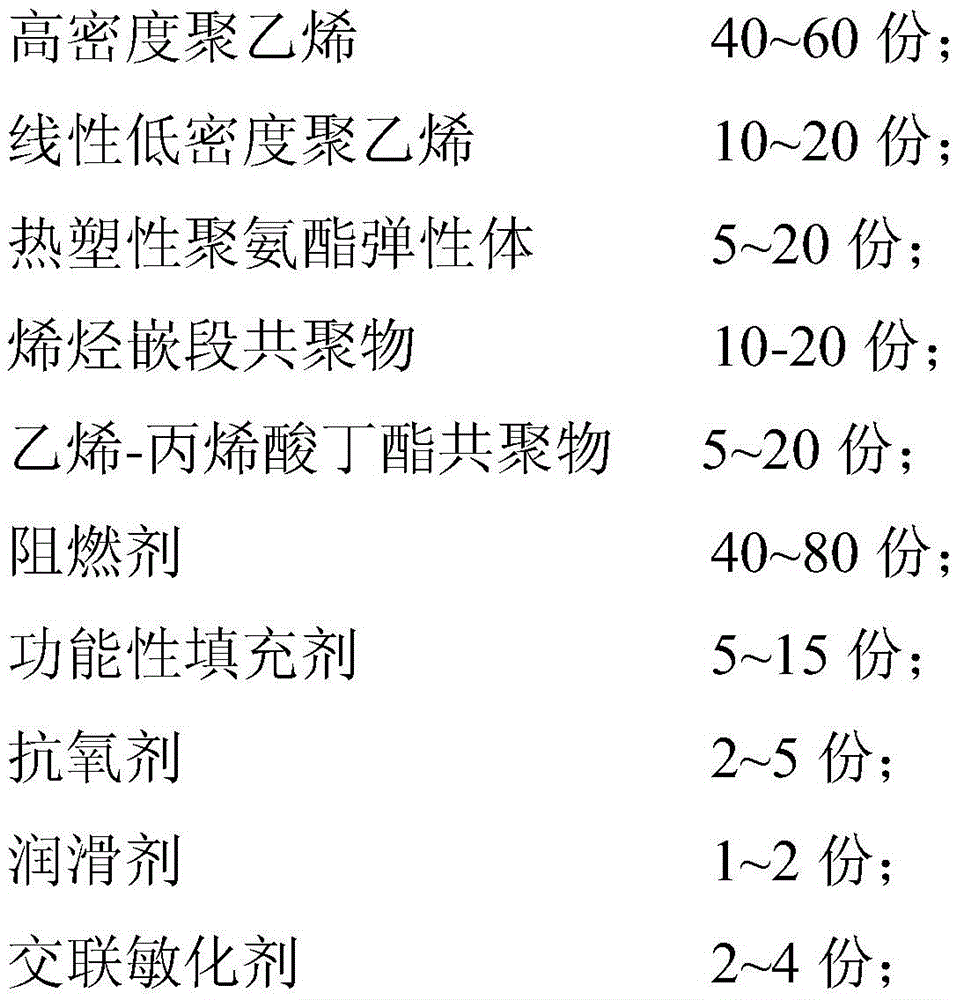

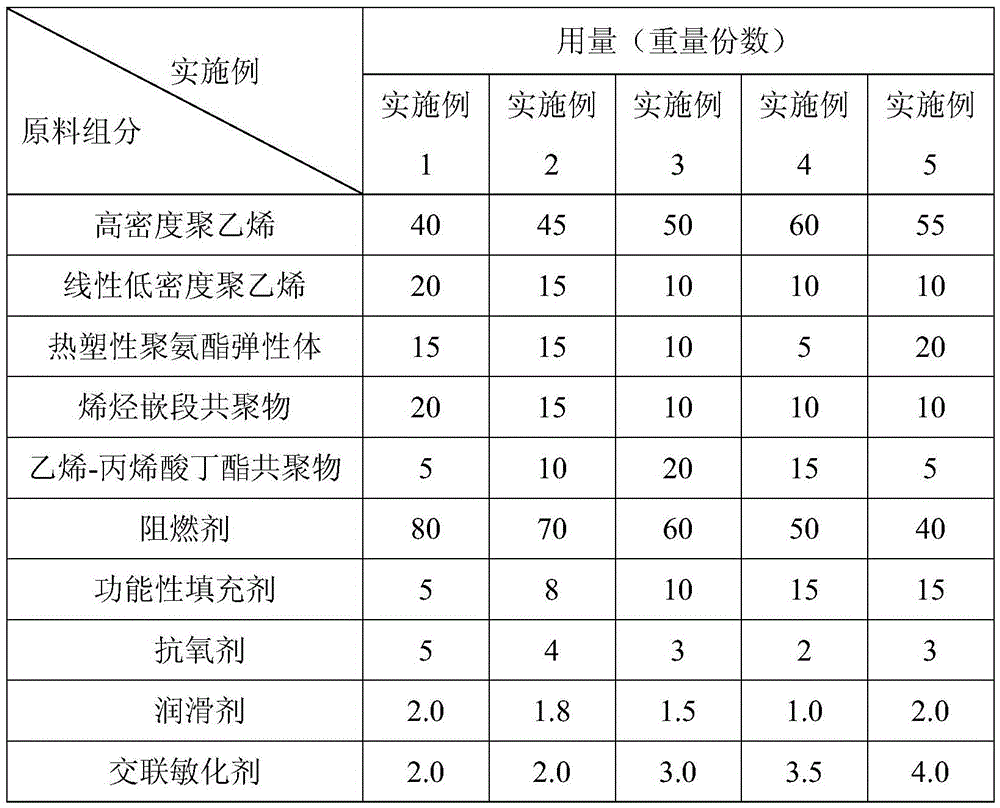

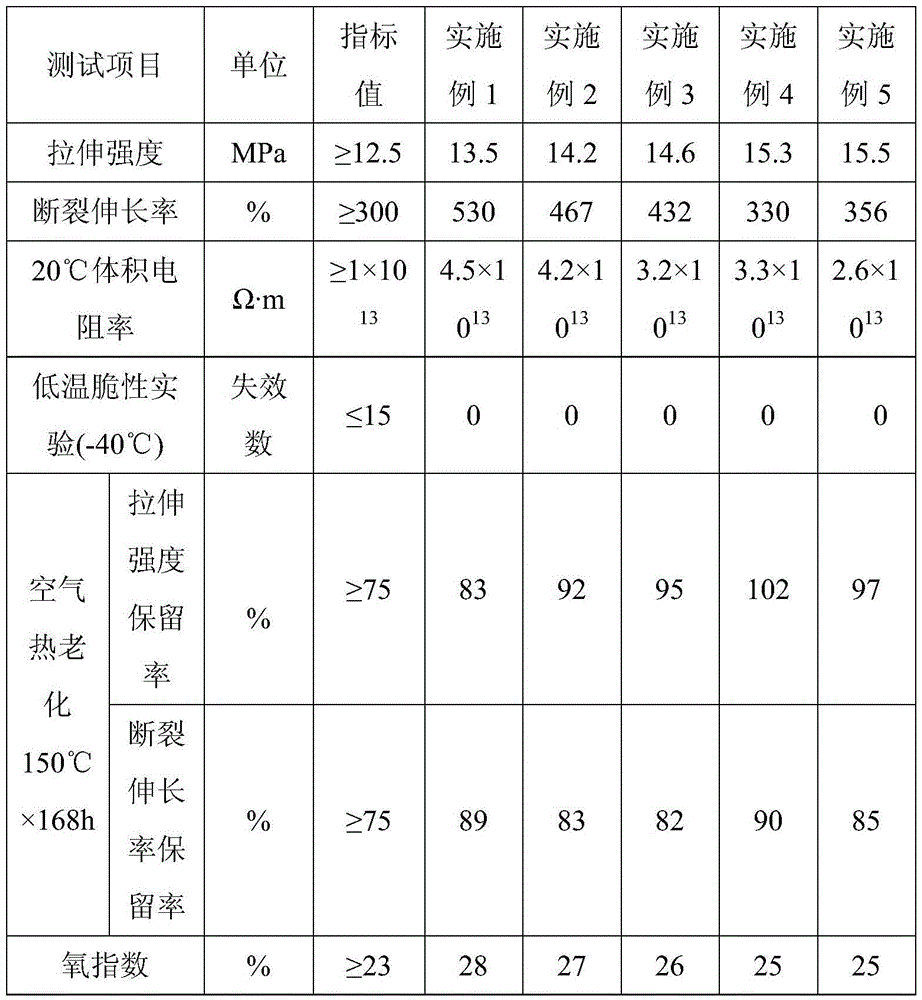

High-temperature-irradiation-resistant halogen-free flame-retardant automobile wire material and preparation method thereof

ActiveCN105602071AImprove flame retardant performanceLow costPlastic/resin/waxes insulatorsAntioxidantResin matrix

The invention discloses a high-temperature-irradiation-resistant halogen-free flame-retardant automobile wire material and a preparation method thereof. The high-temperature-irradiation-resistant halogen-free flame-retardant automobile wire material adopts high-density polyethylene, linear low-density ethylene, a thermoplastic polyurethane elastomer, an olefin block copolymer and an ethylene-butyl acrylate copolymer with different melt indexes as resin matrixes; a halogen-free flame retardant composed of an intumescent flame retardant, magnesium hydroxide and zinc borate is added into the resin matrixes, and a functional filler, an antioxidant, a lubricant and a crosslinking sensitizer are combined; and thus, the obtained automobile wire material can satisfy the required softness and wear resistance and also ensure the thermal overload property of the product. Besides, the wire material has the advantages of favorable flame retardancy, low smoke and no halogen, and conforms to the requirements for environmental protection. The preparation method of the product has the advantages of simple technique and low cost, and is easy to operate and suitable for popularization and application.

Owner:JIANGSU DEWEI ADVANCED MATERIALS

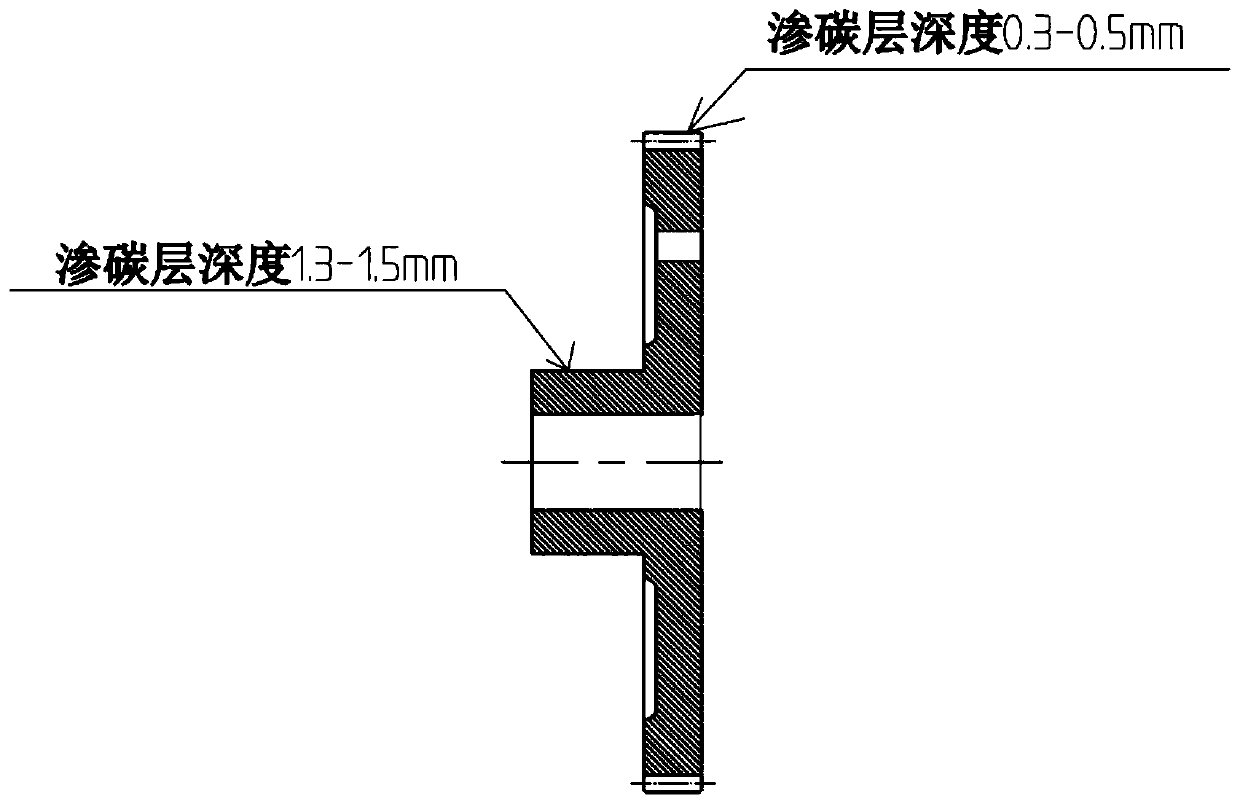

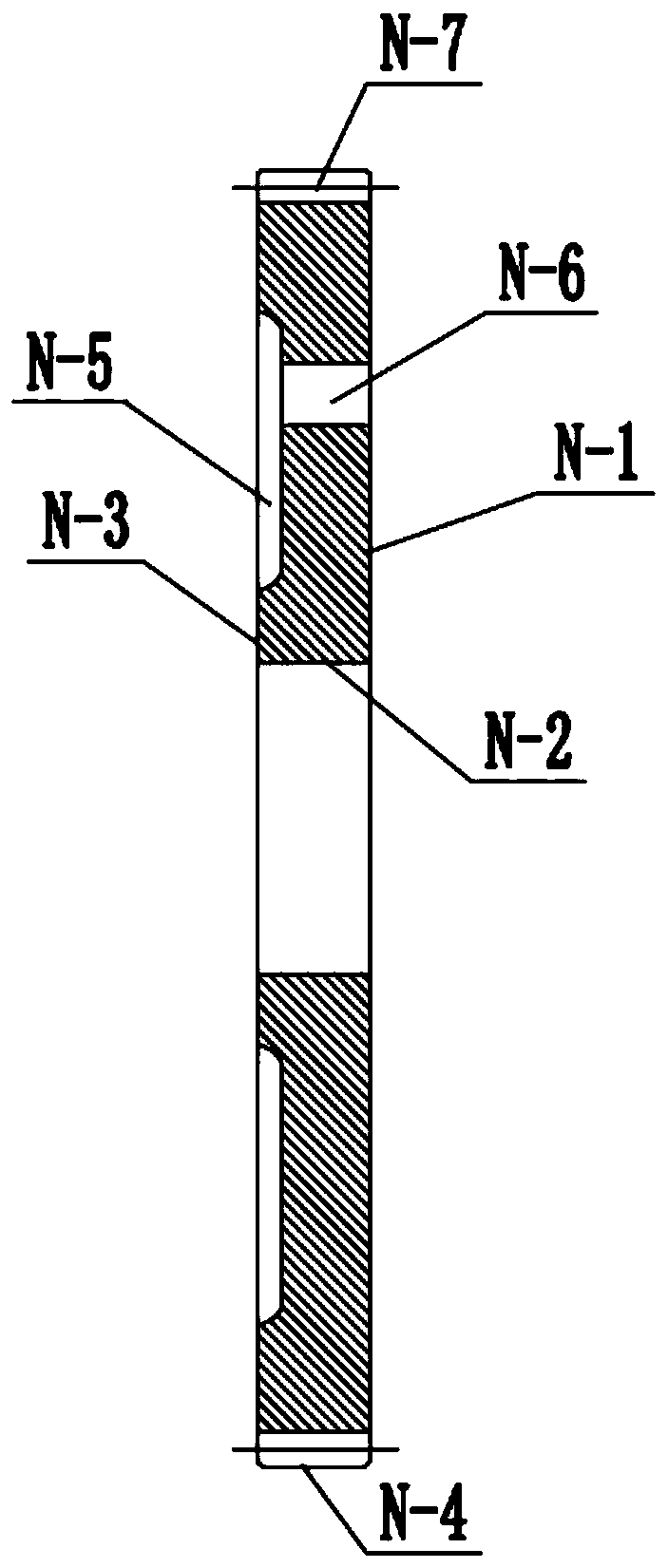

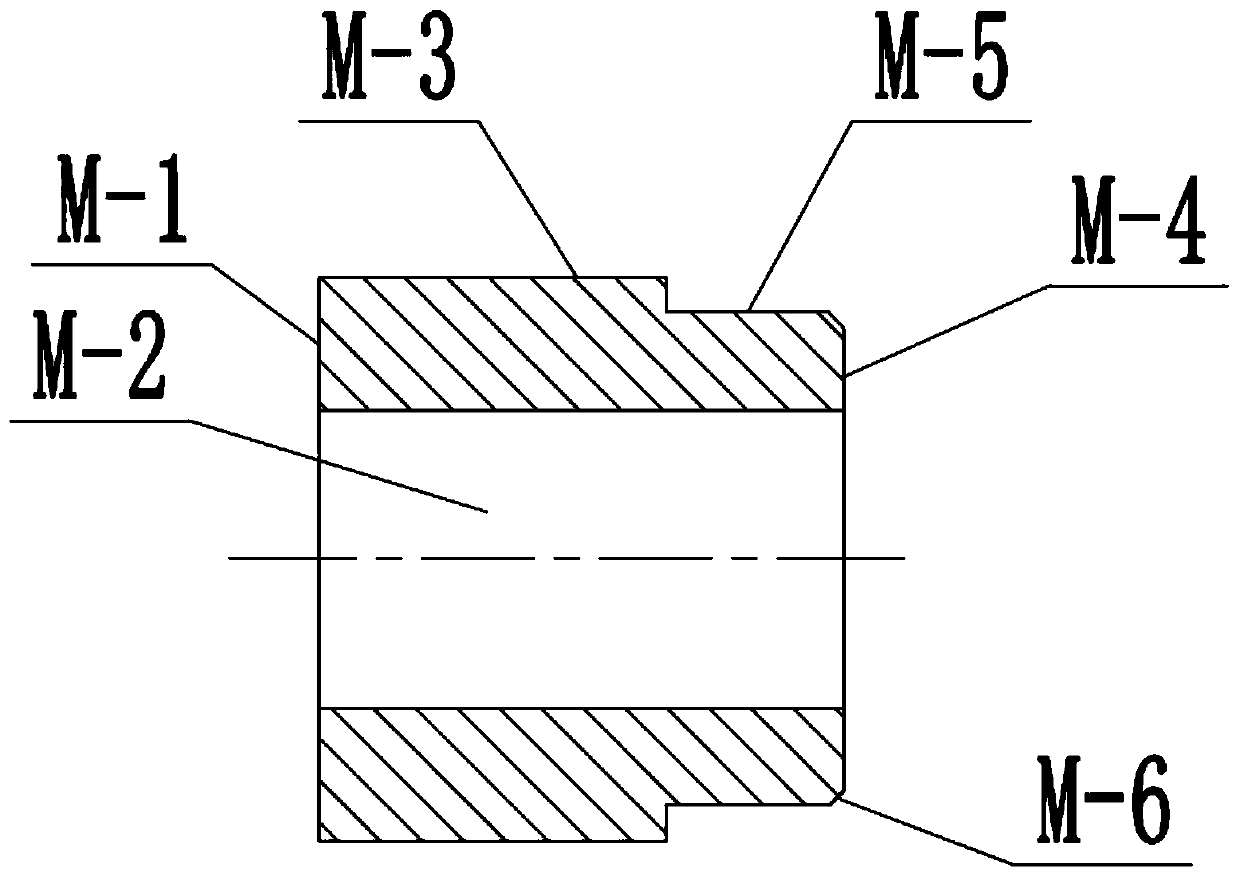

Processing technology of starting transmission gear

InactiveCN110421326ASolve technical problems with different depth requirementsImprove the difficulty of processingPunchingHobbing

The invention discloses a processing technology of a starting transmission gear. The processing technology is characterized in that a gear disc and a gear sleeve are machined separately, and then thegear disc and the gear sleeve are combined to machine; the individual processing steps of the gear disc comprise comprises the following steps of forging, finish turning a first end face and a first inner hole, finish turning second end surface, a first outer circle and a sedimentation table, drilling or punching, gear hobbing, deburring, and inspection; the individual processing steps of the gearsleeve comprises the following steps of forging, finish turning a third end face, a second inner hole and a second outer circle, finish turning a fourth end face and a stepped outer circle, carryingout carburizing heat treatment, and turning a welding groove and turning to remove a carburized layer on the fourth end face; and the combination machining of the gear disc and the gear sleeve comprises the following steps of assembling the gear disc and the gear sleeve in a press fitting manner, welding the gear disc and the gear sleeve into a whole, carrying out heat treatment, and fine turninga second inner hole and a second outer circle of the gear sleeve. According to the processing technology, manufacturing and processing of the starting transmission gear can be realized, and the technical problem that the depth requirements of the carburized layer at different parts of the starting transmission gear are different can be solved.

Owner:重庆申耀机械工业有限责任公司

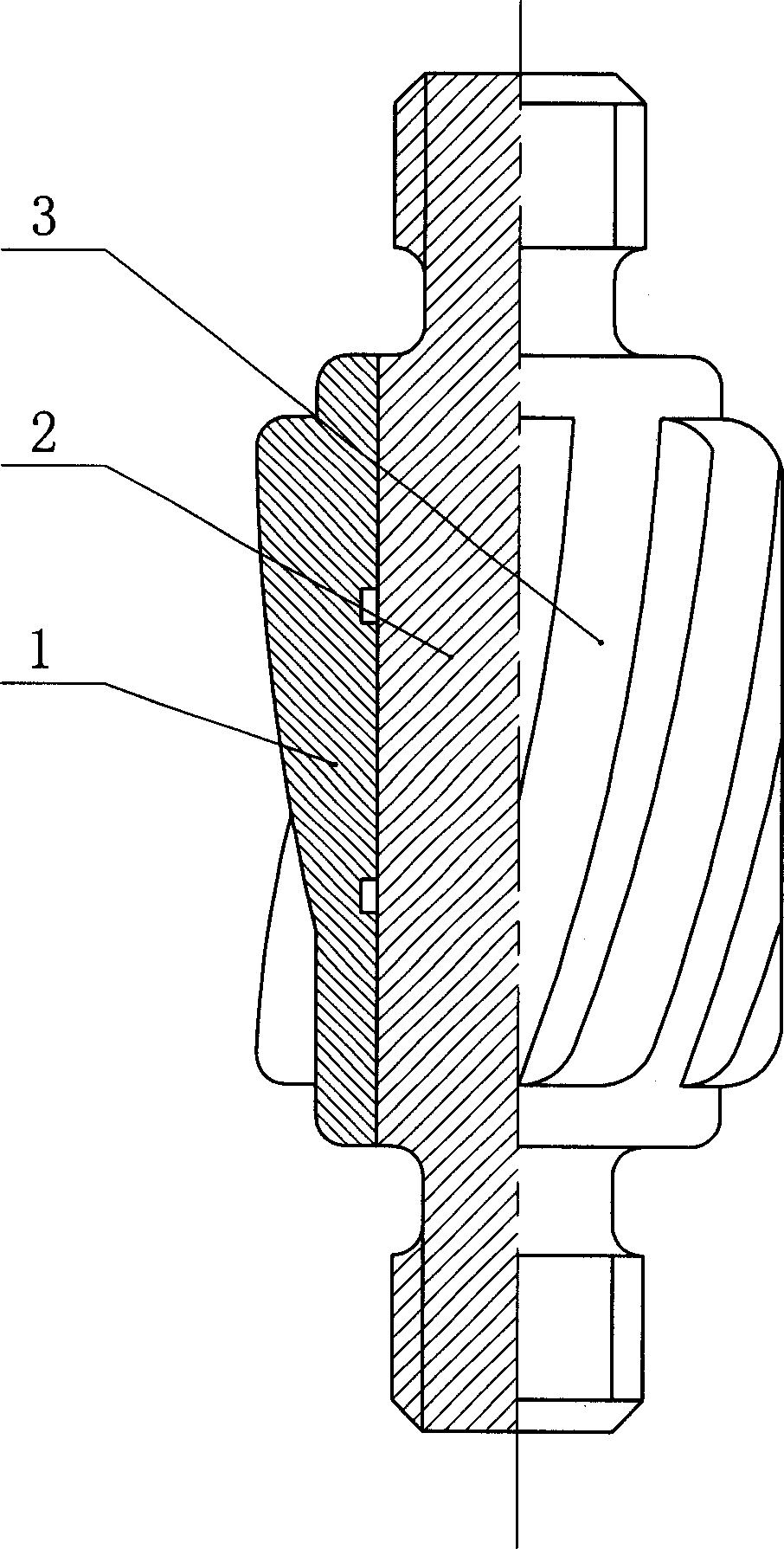

Centralizer and its manufacturing method

InactiveCN1755062AGood processing performanceUnique wear-resistantDrilling rodsCeramic shaping apparatusCeramicSilicon nitride

The invention discloses a stabilizer and making method for supplying an uneasy abrasive, long lifespan, long replacing period, high product efficient stabilizer, which comprises the following parts: stable block (1), short rob (2) and diagonal pilot channel (3), wherein the stable block (1) is encased around the peripheral short rob (2); several diagonal pilot channels (3) are set around the stable block (1) and each channel forms a certain critical angle to the stable block (1); the stable block (1) is made of silicon nitride ceramics material which comprises the following peculiar advantages: abrasion-proof, corrosion-resisting, high temperature-resistant and light quality. The making method of the stabilizer comprises the following steps: loading the silicon nitride ceramics power in the preparing stabilizer mould; compressing the mould by 1800kg / cm2 pressure to form a pattern; finishing the stabilizer by agglomeration in 1100-1300 Deg.C. The making method contains simple process and low cost, which can be applied in the domain of oil exploitation.

Owner:王敬东

Anti-clogging device for sprayed concrete pumping pipe

ActiveCN105605366BGuaranteed normal transmissionMeet spray mixing requirementsPipe elementsShotcretePolybutylene

The invention discloses a blockage preventing device for a shotcrete pumping pipe. The blockage preventing device comprises an inner pipe, an outer pipe and self-oscillating rings, wherein the outer pipe is formed by connecting at least two unit pipes by connecting components, and a splicing length is free and flexible; one self-oscillating ring is arranged inside each unit pipe, so that the dominant function of oscillating blockage prevention is realized; the self-oscillating rings are arranged on the outer wall of the inner pipe in a sleeving way and the number of the self-oscillating rings is at least two, so that the oscillating efficiency is guaranteed; a pipe body of the outer pipe is made of polyurethane rubber (PUR), so that various outside contact conditions and oscillating reduction requirements are met; the inner pipe and the connecting components are made of polybutylene (PB), so that concrete is efficiently conveyed; by using all the functions of three parts, the concrete is efficiently conveyed, the problem of pipe blockage in the shooting process is better solved, and the working efficiency of the shotcreting is improved; meanwhile, the occurrence of pipe explosion accidents is avoided, and the safety of working is guaranteed.

Owner:XIAN UNIV OF SCI & TECH

Refractory metal or stainless steel with electroplating layer on surface and refractory metal or stainless steel surface electroplating process

The invention provides a kind of refractory metal or stainless steel with an electroplating layer on the surface. The refractory metal or the stainless steel comprises a base material and the electroplating layer formed on the surface of the base material. The base material comprises a refractory metal base material or a stainless steel base material, wherein the refractory metal base material ismade of titanium, or tantalum, or niobium, or other alloy; the electroplating layer comprises a rhodium-ruthenium alloy layer. The electroplating layer has good adhesive force, corrosion resistance and weldability, the welding capability of a refractory metal product is improved, and the refractory metal or the stainless steel is beneficial to industrial application. The invention further providesa refractory metal or stainless steel surface electroplating process.

Owner:RAMBO TECH SHENZHEN LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com