Centralizer and its manufacturing method

A manufacturing method and a technology of centralizers, which are applied in the manufacture of tools, earth square drilling, ceramic molding machines, etc., can solve the problems of affecting crude oil output, short replacement cycle, and lower production efficiency, so as to prolong the repair and maintenance cycle and reduce maintenance costs , the effect of increasing crude oil production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

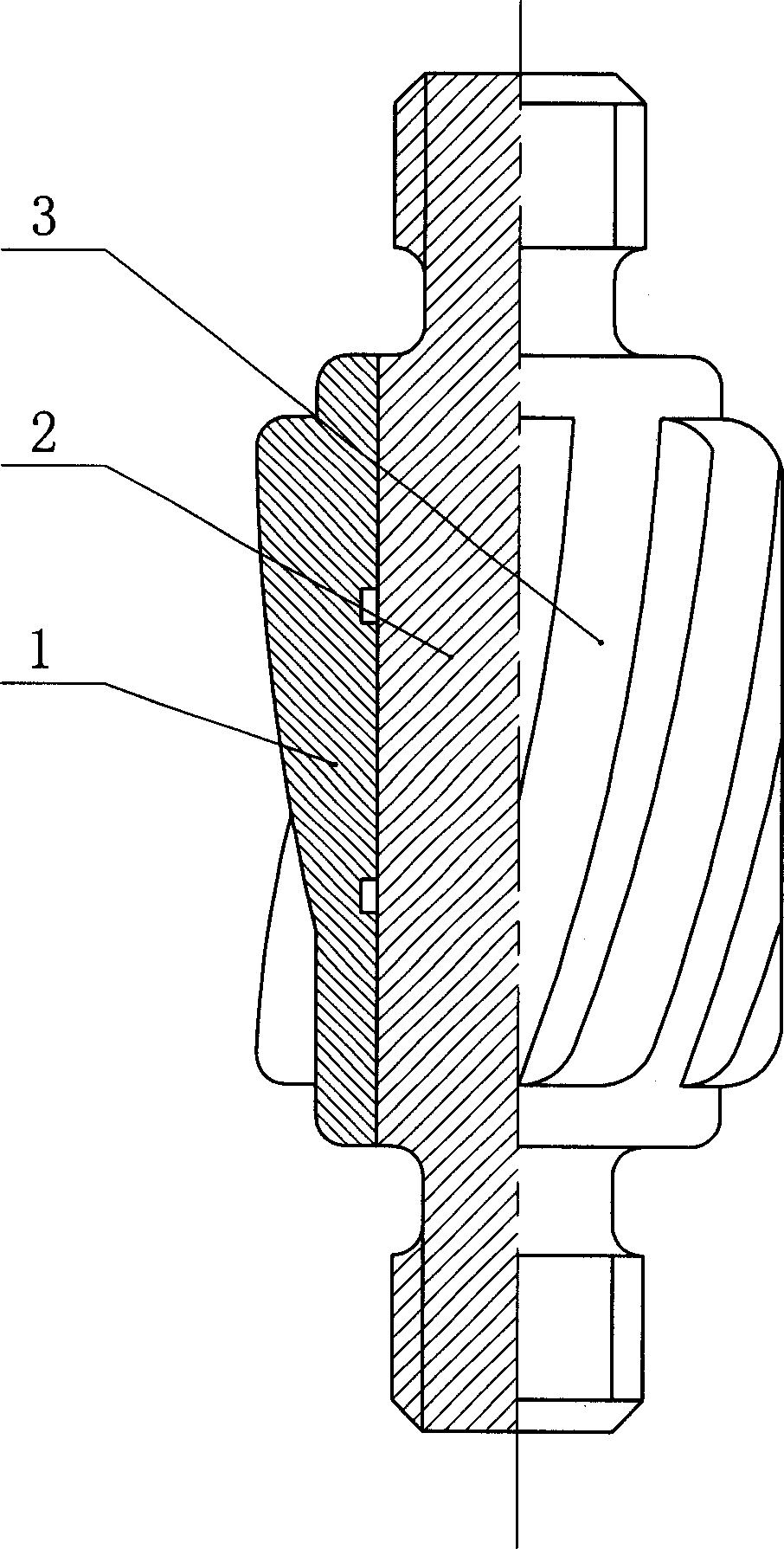

[0021] Such as figure 1 As shown, the present invention includes a centralizing block 1 and a short rod 2. The centralizing block 1 is sleeved on the outer periphery of the short rod 2 of the sucker rod. To the oblique flow guide groove 3 with a critical angle of 18 degrees. The centralizing block 1 is made of silicon nitride ceramic material.

[0022] Since the silicon nitride ceramic material has the unique properties of wear resistance, corrosion resistance, high temperature resistance and light weight, the centralizer has the advantages of not easy to wear, long life, long replacement cycle, and can improve production efficiency.

[0023] The manufacture method of above-mentioned centralizer comprises the following steps:

[0024] 1. make a mold according to the technical requirements of said righting block 1;

[0025] ② Grinding silicon nitride ceramic powder into fine powder through rough grinding and fine grinding process;

[0026] ③Put the silicon nitride ceramic f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com