Method for preparing cooperative flame retardant nylon 6

A synergistic flame retardant and nylon technology, applied in the field of flame retardant composite material preparation, can solve the problem of no substitutes, and achieve the effect of small impact, small mechanical properties and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

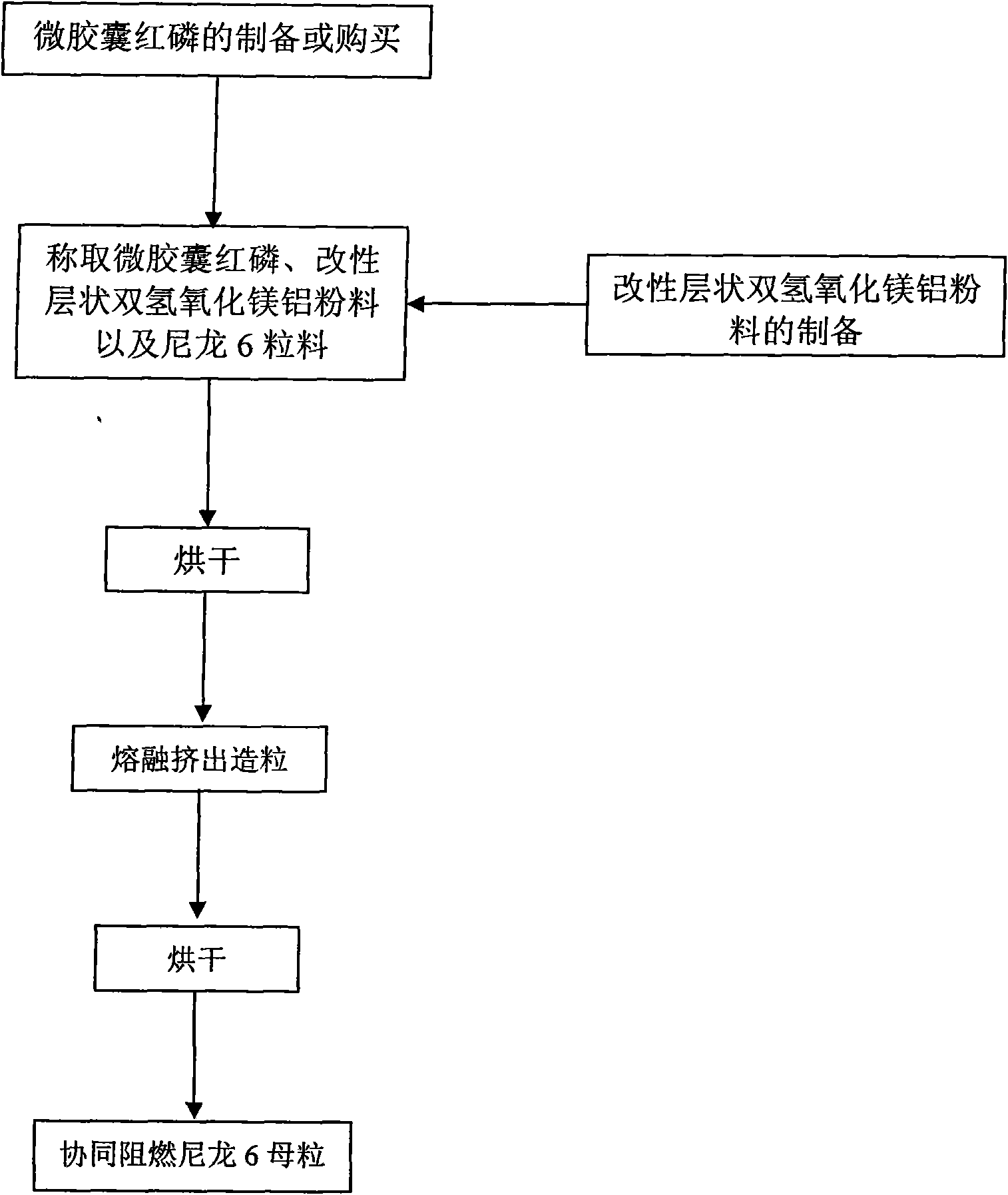

[0013] In conjunction with accompanying drawing, the preparation method of synergistic flame-retardant nylon 6 of the present invention, its steps are as follows:

[0014] The first step is to add sodium hydroxide aqueous solution to aluminum nitrate and magnesium nitrate aqueous solution to react at room temperature, and the reaction time is 1.5 to 3 hours; then add dissolved sodium stearate aqueous solution to the aforementioned reaction system to continue the reaction , the reaction time is 1.5 to 3 hours; the product is filtered, washed and dried to obtain the modified layered magnesium aluminum hydroxide powder. Wherein, the molar ratio of sodium stearate, aluminum nitrate and magnesium nitrate is 0.8~1.2:1:3.

[0015] The second step is to weigh microcapsule red phosphorus, modified layered magnesium aluminum hydroxide powder and nylon 6 pellets respectively, and dry them; wherein microcapsule red phosphorus, layered magnesium aluminum hydroxide powder and nylon 6 pellet...

Embodiment 1

[0018] The preparation method of synergistic flame-retardant nylon 6 of the present invention, its steps are as follows:

[0019] Step 1: Mix 60g of melamine and 119.05g of formaldehyde solution (36%), react at pH=9, 80°C for 25 minutes to prepare a prepolymer; add 5.5g of ammonium persulfate and the prepolymer to 300g of red In 1.2L aqueous solution of phosphorus (about 5000 mesh), the pH value is adjusted to 5, the temperature is controlled at 55°C, and the reaction is carried out for 1.5h; the product is filtered, washed, and dried to obtain microencapsulated red phosphorus;

[0020] Step 2: At room temperature, add 3L of 1.5M sodium hydroxide aqueous solution to 3L of 2M aluminum nitrate and 6M magnesium nitrate aqueous solution, and react for 1.5h; Sodium fatty acid aqueous solution, reacted for 1.5h; the product was filtered, washed, and dried to obtain the modified layered magnesium aluminum hydroxide powder;

[0021] Step 3: Weigh 30g of microcapsule red phosphorus, 3...

Embodiment 2

[0025] The preparation method of synergistic flame-retardant nylon 6 of the present invention, its steps are as follows:

[0026] The first step: mix 60g of melamine and 119.05g of formaldehyde solution (36%), react at pH=9, 95°C for 45min to prepare a prepolymer; add 5.5g of potassium persulfate and the prepolymer to 360g of red In 1.2L aqueous solution of phosphorus (about 5000 mesh), adjust the pH value to 6, control the temperature at 75°C, and react for 1.5h; filter, wash and dry the product to obtain microencapsulated red phosphorus;

[0027] Step 2: At room temperature, add 3L of 1.5M sodium hydroxide aqueous solution to 3L of 2M aluminum nitrate and 6M magnesium nitrate aqueous solution, and react for 1.5h; Sodium fatty acid aqueous solution, reacted for 1.5h; the product was filtered, washed, and dried to obtain the modified layered magnesium aluminum hydroxide powder;

[0028] Step 3: Weigh 36g of microcapsule red phosphorus, 30g of modified layered magnesium alumin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ignition point | aaaaa | aaaaa |

| Ignition point | aaaaa | aaaaa |

| Ignition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com