Method for manufacturing sintered Nd-Fe-B magnet on basis of vapor deposition heat treatment for fine powder

A production method and technology of sintered magnets, which are applied in the field of magnet manufacturing, can solve the problems of long time for diffusion, bad scratches of magnet materials, high cost of fixture consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

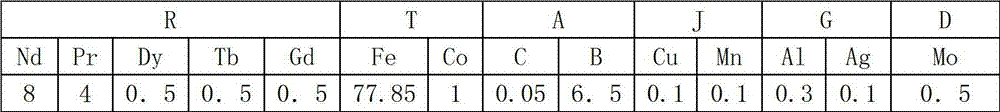

[0064] In the raw material preparation process: prepare Nd, Pr, Dy, Tb, Gd with a purity of 99.5%, Fe-B for industrial use, pure Fe for industrial use, Co with a purity of 99.99%, Cu, Mn, Al, Ag, Mo with a purity of 99.5% , C.

[0065] In terms of atomic percentage at%, according to the composition is R e T f A g J h G i D. k to prepare.

[0066] The content of each element is shown in the table below:

[0067]

[0068] In order to complete the above preparation composition, a total of 500kg of raw materials were weighed and prepared.

[0069] In the smelting process: take 500kg of the prepared raw material and put it into a crucible made of alumina, and carry out vacuum melting at a temperature below 1500°C in a vacuum below 10Pa in a high-frequency vacuum induction melting furnace.

[0070] In the casting process: Ar gas is introduced into the smelting furnace after vacuum smelting to make the air pressure reach 30,000 Pa, and then cast into slabs with an average ...

Embodiment 2

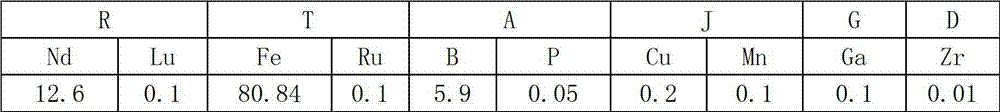

[0099] In the raw material preparation process: prepare Nd and Lu with a purity of 99.9%, Fe-B, Fe-P, Fe-Cr for industrial use, pure Fe for industrial use, Ru, Cu, Mn, Ga with a purity of 99.9%, Zr with a purity of 99.5% .

[0100] In terms of atomic percentage at%, according to the composition is R e T f A g J h G i D. k to prepare.

[0101] The content of each element is shown in the table below:

[0102]

[0103] In order to complete the above preparation composition, a total of 100kg of raw materials were weighed and prepared.

[0104] In the smelting process: take 100kg of prepared raw materials and put them into a crucible made of magnesium oxide, and put them in a high-frequency vacuum induction melting furnace at 10 -2 Vacuum melting is performed at a temperature below 1650°C in a vacuum below Pa.

[0105] In the casting process: Ar gas is introduced into the smelting furnace after vacuum smelting to make the air pressure reach 20,000 Pa, and then cast into...

Embodiment 3

[0134] In the raw material preparation process: La, Ce, Nd, Ho, Er with a purity of 99.5%, Fe-B for industrial use, pure Fe for industrial use, Ru with a purity of 99.99%, P, Si, Cr, Bi, Sn with a purity of 99.5% , Ta.

[0135] In terms of atomic percentage at%, according to the composition is R e T f A g J h G i D. k to prepare;

[0136] The content of each element is as follows:

[0137] In the R component, La is 0.1, Ce is 0.1, Nd is 12.5, Ho is 0.2, and Er is 0.2;

[0138] In the T component, Fe is 78.79, and Ru is 1;

[0139] In component A, P is 0.05, and B is 6.5;

[0140] In J component, Si is 0.01, Cr is 0.15;

[0141] In the G component, Bi is 0.1 and Sn is 0.1;

[0142] In component D, Ta is 0.5.

[0143] In order to complete the above preparation composition, a total of 500kg of raw materials were weighed and prepared.

[0144] In the smelting process: take 500kg of the prepared raw material and put it into an alumina crucible, and carry out vacuum mel...

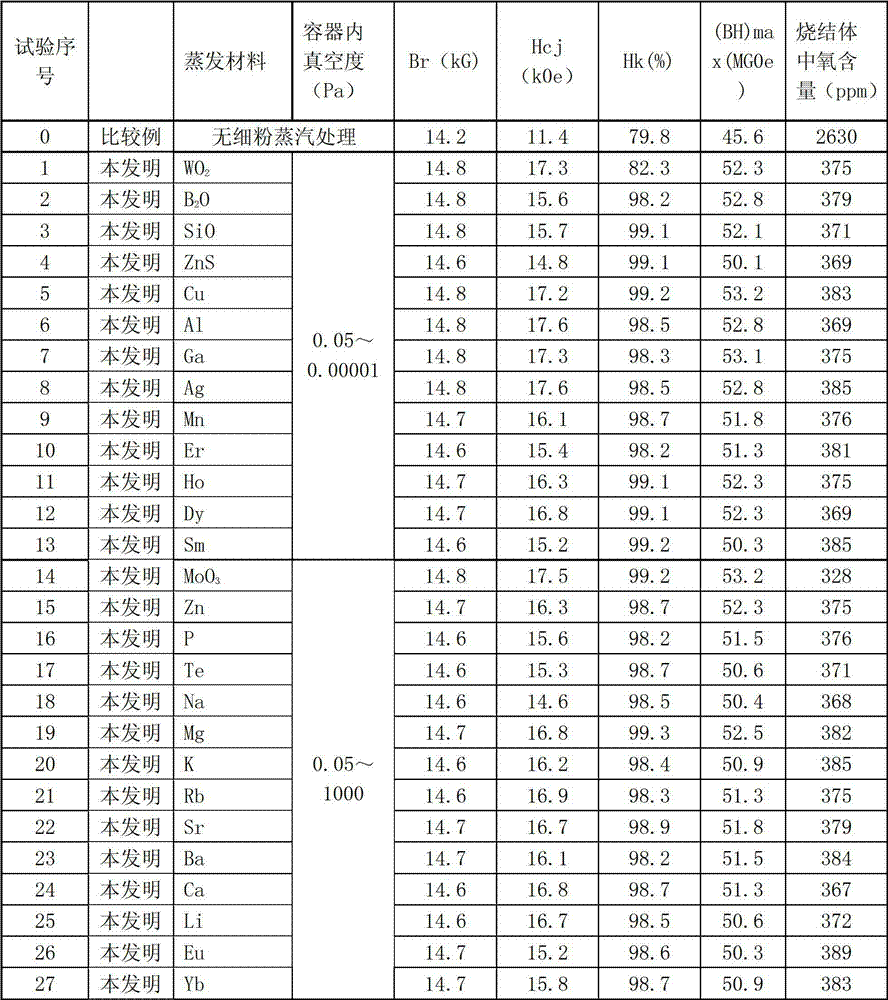

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com