Plasticized polyvinyl chloride material and its preparation

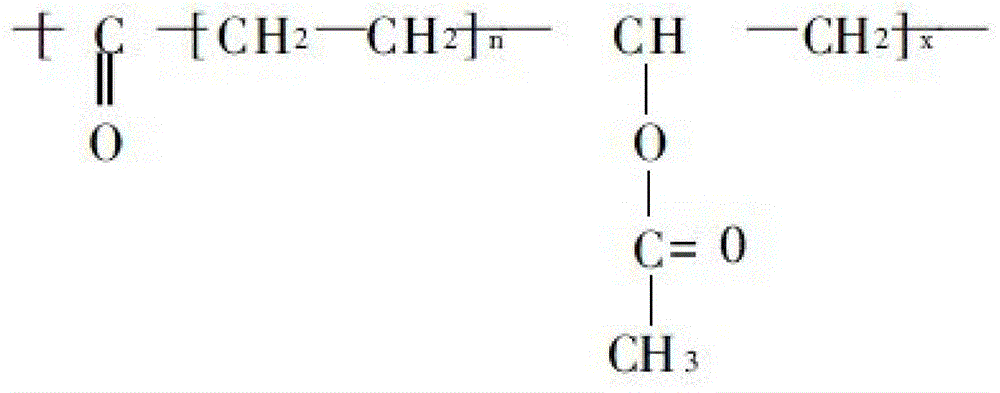

A technology of polyvinyl chloride and ethylene, which is applied to the preparation method and application field of the material, and can solve the problems of low plasticization efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] 25 parts of average degree of polymerization is 1050 low degree of polymerization PVC resin, 75 parts of high degree of polymerization PVC resin of 2400 degree of polymerization and 1.2 parts of calcium-zinc composite stabilizer (106-8 type from Shanghai Yongyan Chemical Technology Co., Ltd. ) into the high-speed mixer first, start stirring, the paddle speed is 950rpm, the temperature rises to 90°C, maintain the speed and temperature, and then add 45 parts of DEHCH plasticizer, 5 parts of epoxy soybean oil, and 0.4 parts of phosphorous acid Tris(nonylphenyl ester) and 0.3 parts of benzyl silicone oil were stirred and mixed for 15 minutes, and then transferred to a two-roller mixer to be mixed with 10 parts of Elvaloy741. The spacing is 2 minutes, the rotating speed of the roller is 55 rpm, and the mixing time is 15 minutes, and then the blend obtained by mixing is extruded, granulated, and injected to make samples for testing.

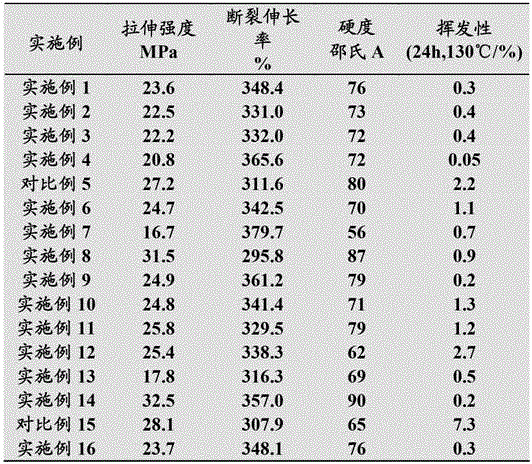

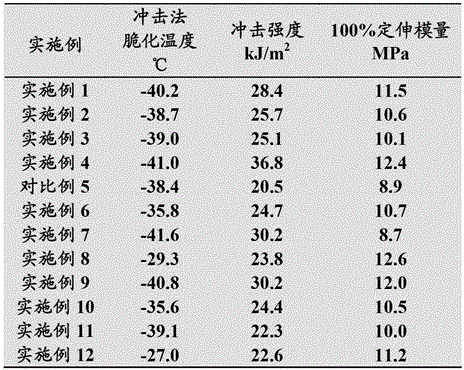

[0086] The test results are shown in Tabl...

Embodiment 2

[0088] Repeat Example 1, the difference is: the average degree of polymerization is 1050 low polymerization degree of PVC resin into 37 parts, the average degree of polymerization of 2400 high degree of polymerization PVC resin into 63 parts.

[0089] The test results are shown in Table 1 and Table 2.

Embodiment 3

[0091]Repeat Example 1, the difference is: PVC with a high degree of polymerization is replaced by PVC with an average degree of polymerization of 2100.

[0092] The test results are shown in Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com